Summary

The purpose of this review was to assess the available literature regarding bonding between current adhesive systems and computer-aided design/computer-aided manufacturing (CAD/CAM) indirect resin materials, to provide clinicians with a comparative overview of the relevant bonding procedures. An electronic search was performed through PubMed based on the keywords CAD/CAM and dental bonding. Additional relevant literature was obtained from the citations in the articles. A total of 313 papers were identified, of which 281 were excluded as being unsuitable, and an additional 3 papers were identified, giving a total of 32 articles that are included in this review. Based on this survey, it is recommended that microretentive surfaces should be generated by either blasting or hydrofluoric acid etching. This initial process should be followed by silanization to ensure chemical adhesion prior to bonding to CAD/CAM indirect resin composite materials (including Lava Ultimet, KATANA AVENCIA block, Gradia Block, Cerasmart, Paradigm, and Block HC) and CAD/CAM polymer-infiltrated ceramics (such as Vita Enamic). The use of materials containing methyl methacrylate (MMA) also appears to improve the bonding of CAD/CAM poly(methyl methacrylate) (PMMA) resin materials (including XHIPC-CAD/CAM, artBloc Temp, and Telio).

Keywords: Adhesive dentistry, Esthetic materials, Dental bonding, Bonding effectiveness, Computer-aided design, Computer-aided manufacturing

1. Introduction

Since the 1980s, computer-aided designing/computer-aided manufacturing (CAD/CAM) technology has been employed to lower production costs, ensure uniform quality of materials, and develop standardized manufacturing processes via the implementation of automation. In recent years, CAD/CAM processes have also been applied to restorative dentistry, resulting in significant advances [1]. These improvements have allowed CAD/CAM technology to be applied to various manufacturing requirements in dentistry, including the fabrication of indirect dental restorations. For this reason, there is presently much interest in the research and development of substances that can be employed in conjunction with the application of CAD/CAM to dentistry.

Both ceramics and indirect resins are used in association with CAD/CAM-based restorations for the purpose of tooth coloring [2], [3]. Resins are highly advantageous because they are readily machinable, although glass-ceramics/ceramics have better esthetic appearance and mechanical properties. A number of CAD/CAM indirect resin materials are commercially available at present, and are typically classified as either composite- or PMMA-based. A new class of CAD/CAM materials based on polymer-infiltrated ceramic-network materials has also been introduced. These substances, often referred to as hybrid ceramics, offer the advantages of both ceramics and composites and thus exhibit superior mechanical properties [4].

So-called “composite” resin premolar crowns fabricated using CAD/CAM technology were approved by the Japanese social insurance system in 2014, along with polymer-infiltrated ceramics. As a result, these crowns are now being introduced in ever-increasing numbers in Japan. The majority of polymeric CAD/CAM blocks have a single coloration and so, to improve the esthetics of these materials, different colors of veneering composite are added to a framework. Thus, the framework is fabricated by CAD/CAM milling, after which a layered veneer is bonded to the frame. The importance of bonding between the crown/inlay/onlay and the resin cement is well known. However, the procedures used to bond these new materials have not yet been clearly elucidated. The purpose of the present review is therefore to survey the available literature regarding bonding between current adhesive systems and CAD/CAM indirect resin materials to provide clinicians with a comparative overview of the techniques available to bond.

2. Subjects and methods

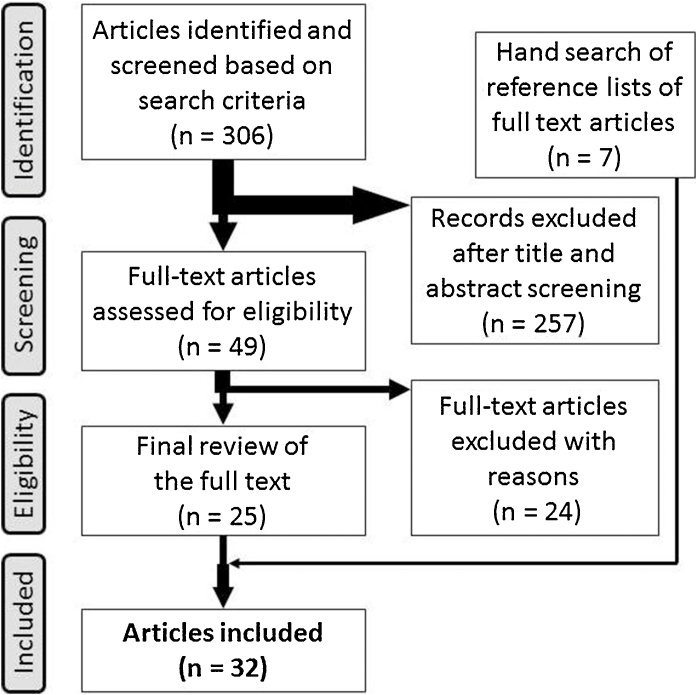

An electronic search of the literature was performed via the PubMed database, using the keywords CAD/CAM and dental bonding as MeSH terms. Articles eligible for inclusion in the present review were published in English, peer-reviewed, and dated from January 1947 to March 2, 2018. Additional relevant literature was obtained by following the reference citations in the papers retrieved from the initial literature search to provide more supporting information (Fig. 1). The titles and abstracts of all papers were carefully appraised to remove articles that were outside the scope of this review. Papers were excluded if their main focus was ceramics (such as glass-matrix and polycrystalline ceramics, e.g., zirconia), implants, or digital impressions, or if they did not include bonding tests. In the event that the focus of the paper could not be determined accurately from the title or abstract, the full-text article was examined.

Fig. 1.

Flow diagram outlining the review identification and screening process adapted.

Additionally, a search was performed using the Institute for Scientific Information (ISI) Web of Science, examining the number of citations of all articles from 1945 through March 20, 2018.

3. Results and discussion

3.1. Overview

A total of 313 titles were identified, with 281 excluded during the initial review. Three papers were also included based on a non-electronic search, to give a total of 32 articles included in the present review [5], [6], [7], [8], [9], [10], [11], [12], [13], [14], [15], [16], [17], [18], [19], [20], [21], [22], [23], [24], [25], [26], [27], [28], [29], [30], [31], [32], [33], [34], [35], [36] (Fig. 1, Table 1). An analysis of these papers demonstrates that the field of study targeted in this review has clearly increased in importance over the last five years. It was also apparent that Vita ENAMIC (a polymer-infiltrated ceramic), Lava Ultimate (an indirect resin composite), and artBloc-Temp [a poly(methyl methacrylate) (PMMA) resin] were often used as CAD/CAM blocks during research trials. The majority of studies incorporated aging procedures (such as water storage and/or thermal cycling) and its importance was confirmed. A total of 17 studies used micro tensile bond strength tests and tensile bond strength tests of crowns were also reported in four papers. It has been claimed that the micro tensile test is superior to the traditional macro shear test [37].

Table 1.

General summary of the papers included in the review.

| No. | Authors | Year | Journal | Number of citations | Bonding test | Aging | Additional tests | Block | Compo/PMMA/Hybrid | Additional information | Notes (test conditions, tested groups, goals, etc.) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| #1 | Kawaguchi-Uemura et al. | Epub ahead of print | J Prosthodont Res | N/A | μTBS | Water storage (6 months) | SEM surface observation, 3D laser analysis, surface roughness, contact angle | KATANA AVENCIA block | Compo | Table 2 | Saliva contamination |

| #2 | El-Damanhoury et al. | 2018 | J Prosthodont Res | 0 | SBS | Thermocycling (5000) | Surface roughness/topography, elemental analysis | Vita ENAMIC | Hybrid | Table 3 | Effect of pretreatment using a self-etching primer in comparison to pretreatment with hydrofluoric acid and silane |

| #3 | Shinohara et al. | 2017 | Odontology | 0 | SBS | Thermocycling (10,000) | FTIR analysis | Gradia Block | Compo | Table 2 | Effects of an experimental adhesive agent and two adhesive agents containing silane on the bond strength between a CAD/CAM resin composite and a light-curing resin composite veneering material |

| #4 | Ishii et al. | 2017 | Dent Mater J | 0 | μTBS | Cyclic loading in water (157 N × 300,000) | Weibull modulus | Lava Ultimate, VITA ENAMIC | Compo/Hybrid | *1 | With and without immediate dentin sealing (IDS). Standardized mesial-distal-occlusalbuccal (MODB) cavities |

| #5 | Lise et al. | 2017 | Oper Dent | 1 | μTBS | Water storage (6 months) | SEM surface observation | Vita Enamic, Cerasmart | Compo/Hybrid | Tables 2, 3 | Effect of different surface treatments |

| #6 | Flury et al. | 2016 | Dent Mater J | 1 | SBS | Water storage (6 months) | – | Lava Ultimate, VITA ENAMIC | Compo/Hybrid | *2 | Cemented to mid-coronal dentin of 300 extracted human molars with RelyX Ultimate, PANAVIA F2.0, Variolink II, els cem, or Ketac Cem Plus |

| #7 | Peumans et al. | 2016 | J Adhes Dent | 5 | μTBS | – | Effect of different surface treatments | Lava Ultimate, VITA ENAMIC | Compo/Hybrid | Tables 2, 3 | The influence of different surface treatments of six novel CAD/CAM materials on the bonding effectiveness of two luting composites |

| #8 | Roperto et al. | 2016 | Dent Res J (Isfahan) | N/A | μTBS | – | – | Paradigm | Compo | *3 | 30 crowns of sound freshly extracted human molars, Group 1: conventional resin cement + total-etch adhesive system, Group 2: conventional resin cement + self-etch adhesive system, and Group 3: self-adhesive resin cement with no adhesive |

| #9 | Kawaguchi et al. | 2016 | Dent Mater J | 1 | μTBS | Water storage (6 months) | SEM surface observation | KATANA AVENCIA block | Compo | Table 2 | Effects of ultrasonic and acid cleaning |

| #10 | Higashi et al. | 2016 | Dent Mater J | 1 | μTBS | Water storage (6 months) | SEM surface observation | KATANA AVENCIA block | Compo | Table 2 | Effects of blasting and silanization. |

| #11 | Duzyol et al. | 2016 | J Prosthodont | 4 | μTBS | – | SEM surface observation | Lava Ultimate | Compo | Table 2 | Evaluate blocks repaired with composite resin using three surface treatment techniques |

| #12 | Gilbert et al. | 2016 | Clin Oral Investig | 2 | SBS,TBS | Thermocycling (5000) | The work of adhesion, surface free energy | XHIPC-CAD/CAM | PMMA | Table 4 | Three resin composite cements combined with different bonding agents |

| #13 | Campos et al. | 2016 | Oper Dent. | 4 | μTBS | Thermocycling (6000) + water storage (2 month) | SEM/3D surface analysis, contact angle | Vita Enamic | Hybrid | Table 3 | Effects of different surface treatments |

| #14 | Elsaka SE | 2016 | Odontology | 5 | SBS (bracket) | Thermocycling (1000) | SEM surface observation, Weibull modulus | Vita Enamic | Hybrid | Table 3 | Effect of four different surface treatments methods |

| #15 | Arao et al. | 2015 | J Appl Oral Sci | 1 | SBS | Thermocycling (10,000) | SEM surface observation, surface roughness | Cerasmart, Block HC | Compo | Table 2 | Effects of air abrasion with alumina or glass beads |

| #16 | Kassotakis et al. | 2015 | J Adhes Dent | 1 | μTBS | Thermocycling (3000) | SEM surface observation | Lava Ultimate | Compo | Table 2 | Effects of different surface treatments |

| #17 | Stawarczyk et al. | 2015 | Materials (Basel) | 0 | TBS (crown) | Thermocycling (5000) | – | XHIPC-CAD/CAM | PMMA | Table 4 | 120 human caries-free molars were prepared, and polymeric crowns were milled and pretreated |

| #18 | Frankenberger et al. | 2015 | Int J Comput Dent | 23 | μTBS | Thermocycling (10,000) | SEM/CLSM surface observation | Lava Ultimate, VITA ENAMIC | Compo/Hybrid | Tables 2, 3 | Evaluate the adhesive bonding performance after different pretreatment protocols and using different luting materials |

| #19 | Elsaka | 2015 | Dent Mater J | 4 | μTBS | – | SEM surface observation | Vita Enamic | Hybrid | Table 3 | Evaluated the repair bond strength of a nanohybrid resin composite to a novel CAD/CAM hybrid ceramic based on four intraoral ceramic repair systems |

| #20 | Stawarczyk et al. | 2015 | Clin Oral Investig | 17 | μTBS | Thermocycling (10,000) only for resin blocks, then thermocycling (10,000) after bonding procedure | – | LAVA Ultimate | Compo | Table 2 | Assess the pretreatment method, the conditioning method, the repair resin composite, the contamination of CoJet air-abraded surfaces with water, and the effect of phosphoric acid |

| #21 | Keul et al. | 2015 | Clin Oral Investig | 4 | TBS (crown) | Thermocycling (5000) | – | artBloc Temp | PMMA | Table 4 | Effect of different pretreatments |

| #22 | Zaghloul et al. | 2014 | Eur J Dent | N/A | μTBS | – | SEM surface observation | Paradigm MZ100, (Paradigm C) | Compo | Table 2 | Repair potential of CAD/CAM composite blocks using a silane-containing bonding agent with different repair protocols |

| #23 | Keul et al. | 2014 | J Dent | 7 | The work of adhesion | – | – | artBloc Temp, Telio CAD,exp. CAD/CAM nanohybrid composite, Nano Composite CFI-C, LAVA Ultimate | Compo/PMMA | *4 | To derermine the impact of pre-treatment of adhesive systems on the work of adhesion (WA) between CAD/CAM polymers and resin composite cements and compare with conventional tests of previous studies |

| #24 | Elsaka SE | 2014 | J Adhes Dent | 25 | μTBS | 30 day water storage | SEM surface observation | Vita Enamic, LAVA Ultimate | Compo/Hybrid | Tables 2, 3 | The effect of different surface treatments |

| #25 | Lührs et al. | 2014 | Dent Mater | 22 | μTBS | – | Degree of conversion | Lava Ultimate | Compo | Table 2 | The effect of curing mode and restoration-surface pre-treatment |

| #26 | Stawarczyk et al. | 2014 | Dent Mater | 3 | TBS (crown) | Thermocycling (5000) | – | Experimental nano-composite CAD/CAM blocks | Compo | Table 2 | To test the tensile bond strength of luted composite CAD/CAM crowns after use of different adhesive systems combined with different resin composite cements on dentin abutments |

| #27 | Liebermann et al. | 2013 | Dent Mater | 9 | TBS | Thermocycling (5000) | Surface energy, surface roughness | ArtBloc Temp | PMMA | Table 4 | Plasma treatment combined with different conditioning methods |

| #28 | Bähr N et al. | 2013 | Dent Mater J | 29 | SBS | Thermocycling (5000) | – | ArtBloc Temp | PMMA | Table 4 | The impact of different adhesives and resin composite cements |

| #29 | Stawarczyk et al. | 2013 | Acta Odontol Scand | 12 | SBS | – | – | CAD-Temp, artBloc Temp,TelioCAD | PMMA | Table 4 | Whether the bond strength of a hybrid composite and a PMMA-based veneer to CAD/CAM polymers would improve after pre-treatment |

| #30 | Stawarczyk et al. | 2012 | J Prosthet Dent | 28 | TBS (crown) | Mechanical load (1,200,000) + thermocycling (6000) | – | ArtBloc Temp | PMMA | Table 4 | Assess the tensile strength of polymeric crowns after conditioning with 2 different protocols: luted with self-adhesive or with conventional resin cements to dental abutments |

| #31 | El Zohairy et al. | 2003 | Dent Mater | 73 | μTBS | – | SEM surface observation | Paradigm MZ100 | Compo | Table 2 | Resin cements bonded to composite CAD/CAM blocks following various surface treatments |

| #32 | Yoshida et al. | 2001 | J Prosthet Dent | 24 | SBS | Thermocycling (50,000) | – | GN-I | Compo | Table 2 | The effect of silane coupling agent |

TBS: tensile bond strength, SBS: shear bond strength, PMMA: poly(methyl methacrylate) block, Compo: resin composite block, Hybrid: Hybrid ceramic.

*1: IDS improves not only the internal bond strength, but also the bond reliability of metal-free CAD/CAM onlay restorations. The resin composite block seems to be more effective than a typical glass-ceramic block for achieving both high bond strength and excellent bond reliability. *2: After six months, SBS was highest when Lava Ultimate was cemented with RelyX Ultimate and when VITA ENAMIC was cemented with RelyX Ultimate or with Variolink II. Lava Ultimate was somewhat more sensitive to storage than was VITA ENAMIC. *3: Cementation of CAD/CAM restorations, either composite or ceramic, can be significantly affected by using different adhesive strategies. *4: The sole determination of WA is insufficient to draw conclusions regarding the bond between different materials. Additional pretreatment of the dental CAD/CAM resin restoration by bonding systems can be recommended for clinical use.

Surface treatments (including blasting, acid treatment, and silanization) of CAD/CAM indirect resin materials (including indirect resin composites, polymer-infiltrated ceramics, and PMMA resins) are discussed in the following sections. The specific types of cement/resin composites and adhesives are not included for two reasons. Firstly, there is an insufficient body of data to allow an in-depth discussion, and secondly, the type of cement has been shown not to determine the effectiveness of bonding [38].

3.2. Bonding to CAD/CAM indirect resin composite materials (Table 2)

Table 2.

CAD/CAM indirect resin composite materials bonding.

| No. | Author (year) | Cement/resin composite | Adhesive (primer) | Surface treatment |

Comments from the authors |

||

|---|---|---|---|---|---|---|---|

| Blasting | Acid | Silanization | |||||

| #1 | Kawaguchi-Uemura et al. (Epub) | PANAVIA V5 (CC) | – | Al2O3 (50 μm)↑ | H3PO4↑ | Clearfil Ceramic Primer Plus | The long-term durability of bonds between CAD/CAM resin blocks and luting agent cement was significantly reduced by artificial saliva contamination. However, blasting or phosphoric acid cleaning can recover bonding effectiveness by 75–85%. |

| #3 | Shinohara et al. (2017) | Gradia Direct (RC) | MMA-TBB liquid, Scotchbond Universal |

– | H3PO4 | Scotchbond Universal↑, GC Ceramic Primer II↑ |

The combined use of the MMA-TBB liquid and the silane agent significantly improved the bond strength. Appropriate adhesive agents should, thus, be applied to CAD/CAM resin composite restorations when veneering with light-curing resin composites. |

| #5 | Lise et al. (2017) | G-CEM LinkAce (SA), G-ænial Universal Flo (RC) | – | Al2O3 (27 μm)↑ | HF↑ | GC Ceramic Primer II↑ | Creating a microretentive surface by either blasting or hydrofluoric acid etching, followed by silanization for chemical adhesion, is mandatory to maintain the bond strength upon water storage for six months. |

| #7 | Peumans et al. (2016) | Clearfil Esthetic Cement (CC), Panavia SA Cement (SA) | Heliobond | Al2O3 (27 μm)↑↑, CoJet (30 μm)↑↑ | HF↑↑ | Monobond plus↑ | For Panavia SA Cement, the highest bond strengths were obtained after Al2O3 pre-treatment with or without subsequent chemical surface treatment. For Clearfil Esthetic Cement, HF and HF+S resulted in the highest bond strength out of all mechanical surface treatments. |

| #9 | Kawaguchi et al. (2016) | PANAVIA V5 (CC), Panavia SA Cement (SA) | – | Al2O3 (50 μm) | H3PO4↓,→ | Clearfil Ceramic Primer Plus | The PANAVIA V5 exhibited higher μTBS values than the Panavia SA Cement. There is no need for ultrasonic and acid cleaning after blasting with regard to improving micro-tensile bond strength. |

| #10 | Higashi et al. (2016) | PANAVIA V5 (CC), Panavia SA Cement (SA) | – | Al2O3 (50 μm)↑ | – | Clearfil Ceramic Primer Plus↑ | The PANAVIA V5 showed higher μTBS values compared to the Panavia SA Cement. Longer maintenance of bond strength was observed when CAD/CAM resin block surfaces were pretreated with a combination of both blasting and silanization. |

| #11 | Duzyol et al. (2016) | Filtek Z 550 (RC) | Single Bond Universal | Al2O3 (50 μm)↓, CoJet↓↓ | HF↓↓ | RelyX Ceramic Primer | All surface treatments reduced the bond strength for resin nano ceramic and should be avoided. |

| #15 | Arao et al. (2015) | ResiCem (CC), G-CEM Cerasmart (SA) | – | Glass beads (75 μm)↑↑, ↑,Al2O3 (50 μm)↑,↑ | H3PO4 | Ceramic Primer II↑,→, Porcelain Primer→,↑ | Air abrasion with glass beads was more effective in increasing bond durability between the resin cements and CAD/CAM composite materials than was using an alumina powder and a ceramic primer (for Cerasmart). |

| #16 | Kassotakis et al. (2015) | Filtek Ultimate Universal Restoration System | Single Bond Universal |

Sodium bicarbonate→, glycine→, Al2O3↑↑, Cojet↑↑, SilJet↑↑ | – | (Single Bond Universal) |

No surface treatment, sodium bicarbonate (60–70 μm), and glycine (65 μm) surface treatment resulted in complete debonding after thermocycling. Alminum oxide (50 μm), CoJet (30 μm), and SilJet (30 μm) showed similarly high μTBS values after thermocycling. The silicated powders of the CoJet, and SilJet tribochemical system showed no significant advantage in term of μTBS compared to pure alumium oxide. |

| #18 | Frankenberger et al. (2015) | Calibra (CC) + Prime&Bond XP (self-cure activator), Rely X Unicem (SA) | Al2O3 (50 μm)↑↑,↑ | HF ↑,→ | Monobond plus (MP)→ | Calibra MP: No treatment = Silane < HF = HF+Silane < blasting = blasting + Silane | |

| Rely X Unicem: No treatment = Silane = HF = HF+silane < blasting = blasting + Silane | |||||||

| Blasting is recommended only for the resin nano ceramic Lava Ultimate. | |||||||

| #20 | Stawarczyk et al. (2015) | Arabesk Top (RC), GrandioSo (RC) | Futurabond U, Scotchbond Universal, One Coat Bond, Visio.link | CoJet↑ | H3PO4→ | (Scotchbond Universal)↑ | CoJet produced superior TBS compared to grinding of the surface prior to repair. Phosphoric acid or water contamination does not affect the repair bond strength. The tested universal adhesives proved to be effective intermediate agents for repairing aged CAD/CAM block, while visio.link and Scotchbond Universal performed slightly better than Futurabond U. |

| #22 | Zaghloul et al. (2014) | Filtek Z350XT (RC) | Single Bond Universal | CoJet↓,→ | HF →,↓ | Rely X Ceramic Primer↓,→ | No treatment = Cojet+Silane > silane = HF = HF+silane = Cojet |

| Silica coating + silanization is the most acceptable repair protocol. | |||||||

| #24 | Elsaka (2014) | Biflx SE (SA), (Filtek Z250) | – | Al2O3 (110 μm)↑ | HF↑ | Ultradent silane→ | No treatment < blasting = blasting + Silane = HF = HF + silane |

| There was no significant difference in the bond strength values between different surface treatment. | |||||||

| #25 | Lührs et al. (2014) | Nexus 3 (CC, Optibond XTR), RelyX Ultimate (CC, Scotchbond Universal) | XTR Adhesive, Scotchbond Universal | Al2O3 (50 μm) | – | Kerr Silane Primer, RelyX Ceramic Primer | The curing mode is decisive for bonding effectiveness of adhesively luted composite CAD/CAM restorations to dentin. Solely auto-cure of adhesive and/or composite cement is not recommended for adhesive cementation of indirect restorations. |

| #26 | Stawarczyk et al. (2014) | Variolink II (CC), Clearfil SA Cement (SA) | Heliobond, Ambarino P60, Visio.link, VP-Connect | (Al2O3) (50 μm) | H3PO4 | Monobond Plus↑,→ | No higher or durable tensile bond strength could be obtained despite the use of different adhesive liquids for pre-treatment. No resin composite cement remained completely attached to the CAD/CAM crown for all the tested groups. |

| #31 | El Zohairy et al. (2003) | Tetric flow (Syntav single component), Nexus (CC, Optibond solo plus), Rely X ARC (CC, Scotchbond 1) | – | HF↑ | Monobond S↑ | HF is used to teat composite surfaces prior to bonding, and additional silane treatment would further enhance the bond strength. Adhesive application to a processed composite substrate improved the bond strength. | |

| #32 | Yoshida et al. (2001) | Link Max (CC), Vita Cerec Duo cement (CC) | Repair Bond II | – | – | G-Cera Cosmotech II↑, Porcelain Bond↑ | The application of a silane coupling agent to the CAD/CAM composite surface provided the highest bond strength. After 50,000 thermocycles, all specimens treated with silane cupling agent showed cohesive failures within the composite material. |

RC: resin composite, SA: self-adhesive resin cement, CC: conventional resin cement, Al2O3: Alumina, CoJet: 3 M, Silicatized sand, Corundum (aluminum trioxide) particles, modified by silica, with a mean particle size of 30 μm, SilJet: Danville Materials, 30 μm silica nano-coated alumina 85-95%, SiO2 5–15%. ↑: significantly improves the bond strength, ↑↑: much improves the bond strength, →: no significant difference in the bond strength, ↓: significantly reduces the bond strength.

Direct and indirect composite resins restorations do not have the same formulations, and CAD/CAM indirect composite resin blocks are associated with greater degrees of polymerization. As has been previously reported in the case of various indirect resin composite materials [4], the majority of manufacturers recommend the blasting of composite CAD/CAM indirect resin composite materials before silanization. The most highly cited article in the present review makes this same recommendation [35].

The majority of studies confirmed the effects of blasting, such as with Al2O3 and CoJet/SilJet (silica-coated Al2O3), based on comparisons with untreated resin composites [9], [11], [14], [20], [22], [24], [28], with only one paper offering a contrary opinion [15]. Duzyol et al. claimed that all surface treatments [including blasting with CoJet or etching with hydrofluoric acid (HF)] should be avoided, while Yoshihara et al. reported that low-pressure blasting was desirable, as this reduces the formation of subsurface cracks [39]. Along the same lines, the use of glass beads for blasting resin composites has been recommended, because glass beads are softer than alumina [19].

Other studies showed that composite blocks can be bonded more effectively as a result of HF etching [9], [11], [22], [28], [35]. Frankenberger recommended blasting rather than HF etching for the surface treatment of Lava Ultimate [22]. Interestingly, the positive effects of treating uncontaminated specimens with phosphoric acid (H3PO4) have not yet been explained [13], [24]. H3PO4 is not reactive enough to induce visible surface roughening, but apparently has a cleaning effect [40]. Kawaguchi-Uemura et al. [5] determined that blasting or H3PO4 cleaning can recover bonding effectiveness by 75–85%. In contrast, Kawaguchi et al. [13] found that, as long as restorations are sandblasted after the try-in procedure in the clinical setting, there is no need for ultrasonic and H3PO4 cleaning after blasting to improve bond strength.

Silane coupling agents are commonly used to bond resin to porcelain and are also employed as filler particles in resin composites because they offer potential sites for silanization. It is widely believed that silanization is effective in promoting CAD/CAM indirect composite resin bonding, and ten of the papers reviewed demonstrated this effectiveness [7], [9], [11], [14], [19], [24], [26], [30], [35], [36]. However, some groups found no effect of silanization [19], [22], [28], [30], and so the effectiveness of this process when applied to either bonding agents or blocks is evidently variable. With regard to chemical surface treatments, Shinohara et al. [7] examined the effects of an experimental adhesive agent [a methyl methacrylate-tributylborane liquid (MT)] and two silane-based adhesive agents on the bonding between CAD/CAM indirect composite resin materials. They concluded that the use of MT in conjunction with a silane agent significantly improved the bond strength.

3.3. Bonding to CAD/CAM polymer-infiltrated ceramics (Table 3)

Table 3.

CAD/CAM polymer-infiltrated ceramics bonding.

| No. | Author (year) | Cement/resin composite | Adhesive |

Surface treatment |

Data and/or Comments from the authors | ||

|---|---|---|---|---|---|---|---|

| Blasting | Acid | Silanization | |||||

| #2 | El-Damanhoury and Gaintantzopoulou (2018) | Multilink-N Automix (RC) | – | – | HF↑ | Monobond plus (MP)↑, Monobond etch & prime (MEP)↑↑ | No treatment < only MP < HF and MP = only MEP |

| Monobond Etch & Prime is a newly introduced one-bottle system combining ammonium polyfluoride and silane without hydrofluoric acid. Although it is termed a self-etching ceramic primer, the applied primer should be rinsed with water. | |||||||

| #5 | Lise et al. (2017) | G-CEM LinkAce (SA), G-ænial Universal Flo (RC) | – | Al2O3 (27 μm)↑ | HF↑ | GC Ceramic Primer II↑ | Creating a microretentive surface by either blasting or hydrofluoric acid etching, followed by silanization for chemical adhesion, is mandatory to maintain the bond strength upon water storage for six months. |

| #7 | Peumans et al. (2016) | Clearfil Esthetic Cement (CC), Panavia Self-adhesive Cement (SA) | Heliobond | Al2O3 (27 μm)↑, CoJet↑ | HF↑ | Monobond plus↑↑ | HF acid etching with silanization or only silanization can be considered as the preferred surface treatment for either luting cement. |

| #13 | Campos et al. (2016) | Panavia F2.0 (CC) | – | CoJet→ | HF↑, H3PO4→ | Clearfil Bond SE Primer and Clearfil Porcelain Bond Activator→ | After being aged, only those in the hydrofluoric acid etching group remained with the highest bond strength values. In conclusion, hydrofluoric acid etching should be used for surface conditioning of the studied hybrid ceramic. |

| #14 | Elsaka (2016) | Transbond XT (light cure adhesive paste) | CoJet↑ | HF↑, H3PO4↓ | (Transbond XT) | CoJet > HF >(=) Bur > H3PO4 | |

| Surface treatment of silica coating enhanced the adhesion. | |||||||

| #18 | Frankenberger et al. (2015) | Calibra (CC) + Prime&Bond XP (self-cure activator), Rely X Unicem (SA) | Al2O3 (50 μm)↑ | HF↑↑ | Monobond plus↑,→ | Both Calibra and Rely X Unicem: No treatment = Silane < blasting = blasting + Silane < HF < HF + silane | |

| Among the hybrid materials, Enamic exhibited higher bond strengths than Lava Ultimate. | |||||||

| #19 | Elsaka (2015) | GrandioSO (RC) | Zircon-adhesive, Peak Universal Bond, Clearfil SE Bond Primer, Visio-Bond | (CoJet) | (HF, H3PO4) | Zircon-primer (CZ), Ultradent silane (PR), Clearfil Porcelain bond activator (CR), ESPE-Sil (CS) | No treatment = Clearfil Repeair (CR) < CoJet system (CS < Porcelain Repair (PR) = Cimara Zircon (CZ) Porcelain Repair (Ultradent) and Cimara Zircon (VOCO) repair systems significantly enhanced the bond strength. |

| #24 | Elsaka (2014) | Biflx SE (SA), (Filtek Z250) | – | Al2O3 (110 μm)↑ | HF↑ | Ultradent silane↑ | No treatment < blasting = HF = (<) blasting + Silane < (=) HF + silane HF + silane showed a higher bond strength value compared to blasting and HF surface treatments. The Vita Enamic provided higher bond strength values compared with the Lava Ultimate. |

RC: resin composite, SA: self-adhesive resin cement, CC: conventional resin cement, Al2O3: Alumina, CoJet: 3 M, Silicatized sand, Corundum (aluminum trioxide) particles, modified by silica, with a mean particle size of 30 μm. ↑: significantly improves the bond strength, ↑↑: much improves the bond strength, →: no significant difference in the bond strength, ↓: significantly reduces the bond strength.

The Academy for Adhesive Dentistry reported that HF etching in combination with silane is a superior pretreatment for CAD/CAM polymer-infiltrated ceramics [41]. This recommendation cites Elsaka [28] and Frankenberger et al. [22], who found that HF processing followed by silanization is the best treatment for CAD/CAM polymer-infiltrated ceramics Lise et al. [9] demonstrated that the formation of a microretentive surface by either blasting or HF etching, followed by silanization to promote chemical adhesion, is required to obtain the same bond strength as that exhibited by CAD/CAM indirect resin composite materials. Elsaka [18] reported improvements in shear bond strength values in the following order: CoJet system > HF > control > H3PO4. Therefore, blasting is a reasonable option for mechanical surface treatment.

3.4. Bonding to CAD/CAM PMMA resin materials (Table 4)

Table 4.

CAD/CAM PMMA resin material bonding.

| No. | Author (year) | Cement/resin composite | Adhesive | Surface treatment |

Comments from the authors | ||

|---|---|---|---|---|---|---|---|

| Blasting | Acid | Silanization | |||||

| #12 | Gilbert et al. (2016) | Clearfil SA Cement (SA),RelyX ARC (CC), Variolink II (CC) | VP connect, Visio.link | Al2O3 (50 μm) | – | Clearfil Ceramic Primer Plus | Measured TBS values were higher than SBS ones. In general, SBS and TBS showed similar trends for the ranges of the values for the groups. WA results were not comparable with SBS/TBS results and therefore no conclusions can be drawn. |

| For a clinical use of XHIPC-CAD/CAM resin, the bond surface should be additionally pretreated with Visio.link as the bonding agent. | |||||||

| #17 | Stawarczyk et al. (2015) | Variolink II (CC), Rely X Ultimate (CC) | Visio.link, Scotchbond Universal, Monobond Plus/Heliobond, Margin Bond, Margin Bond mixed with acetone (1:1) | Al2O3 (50 μm) | – | (Scotchbond Universal, Monobond Plus/Heliobond) | The tested universal coupling agents showed no impact on the retention strength results. Crowns cemented using RelyX Ultimate showed higher retention strength than those polymerized with Variolink II. For Variolink II, Monobond Plus/Heliobond had the poorest survival, as the estimated cumulative failure function of the debonded crown increased very quickly with increasing TBS. With the RelyX Ultimat, no significant differences were determined. |

| #21 | Keul et al. (2015) | Clearfil SA Cement (SA), Variolink II (CC) | Heliobond, Ambarino P60, Visio.link, VP Connect | Al2O3 (50 μm) | (H3PO4) | Monobond Plus | None of the tested pretreatments showed higher and durable TBS values compared with the non-treated control group. |

| #27 | Liebermann et al. (2013) | RelyX Unicem Automix (SA), Clearfil SA Cement (SA) | Visio.Link↑,↑, VP connect↓,↑ | Al2O3 (50 μm) | Plasma treatment (low-density cold active inert argon gas) | Plasma treatment of PMMA did not increase the adhesion to self-adhesive resin composite cements. | |

| #28 | Bähr et al. (2013) | Clearfil SA Cement (SA), Variolink II (CC) | Heliobond, Visio.Iink, Ambarino P60, exp VP Connect, | Al2O3 (50 μm) | – | Monobond Plus↑ | This study tested polymeric CAD/CAM materials, and the use of additional adhesives for conditioning was found to be necessary. |

| #29 | Stawarczyk et al. (2013) | Gradia (RC), Integral esthetic press (RC) | StickResin | Al2O3 (50 μm), CoJet | – | Air abrasion increased the bond strength in all tested groups. Additional silane application did not increase the bond strength of hybrid composites. | |

| #30 | Stawarczyk et al. (2012) | RelyX Unicem (SA), G-CEM (SA), artCem GI (SA),Variolink II (CC) | – | Al2O3 (50 μm, 110 μm) | – | Air abrasion increased the tensile strength of polymeric CAD/CAM crowns with the resin cements tested, except for Variolink II. | |

RC: resin composite, SA: self-adhesive resin cement, CC: conventional resin cement, Al2O3: Alumina, CoJet: 3 M, Silicatized sand, Corundum (aluminum trioxide) particles, modified by silica, with a mean particle size of 30 μm. ↑: significantly improves the bond strength, ↓: significantly reduces the bond strength.

The Stawarczyk research group has studied several cement/resin composites, adhesives, and PMMA resin materials using a number of test methods, including shear bond strength, tensile bond strength, and tensile bond strength of crowns. Many papers from this group have a relatively high number of citations. The latest research from this group concludes that, when using an XHIPC-CAD/CAM resin in a clinical setting, the bonding surface should receive an additional pretreatment with Visio.link as the bonding agent. Other studies also support the use of this technique [25], [31], [32]. Visio.link is a proprietary product containing methyl methacrylate (MMA), dimethacrylate, pentaerythritol acrylate (PETIA), and a photoinitiator. Since both indirect resin composite materials and polymer-infiltrated ceramics also have matrix resins, MMA-containing materials could have applications to those resin materials, as reported by Shinohara et al. (see also Section 3.2).

4. Conclusion

Based on a comprehensive literature review, creating a microretentive surface by either blasting or HF etching followed by silanization to promote chemical adhesion should be recommended when bonding to CAD/CAM indirect resin composite materials (such as Lava Ultimet, KATANA AVENCIA block, Gradia Block, Cerasmart, Paradigm, and Block HC) and CAD/CAM polymer-infiltrated ceramics (such as Vita Enamic). In addition, the use of materials containing MMA is recommended as a means of improving bonding to CAD/CAM PMMA resin materials (such as XHIPC-CAD/CAM, artBloc Temp, and Telio).

Conflict of interest

The authors declare that no conflicts of interest are associated with this review.

Acknowledgment

This work was supported by JSPS KAKENHI grant number 17H04389.

Footnotes

Scientific field: Esthetic dentistry, Adhesive dentistry

References

- 1.Witkowski S. (CAD-)/CAM in dental technology. Quintessence Dent Technol. 2005;28:169–184. [Google Scholar]

- 2.Coldea A., Swain M.V., Thiel N. Mechanical properties of polymer-infiltrated-ceramic-network materials. Dent Mater. 2013;29(4):419–426. doi: 10.1016/j.dental.2013.01.002. [DOI] [PubMed] [Google Scholar]

- 3.Ruse N.D., Sadoun M.J. Resin-composite blocks for dental CAD/CAM applications. J Dent Res. 2014;93(12):1232–1234. doi: 10.1177/0022034514553976. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Spitznagel F.A., Horvath S.D., Guess P.C., Blatz M.B. Resin bond to indirect composite and new ceramic/polymer materials: a review of the literature. J Esthet Restor Dent. 2014;26(6):382–393. doi: 10.1111/jerd.12100. [DOI] [PubMed] [Google Scholar]

- 5.Kawaguchi-Uemura A., Mine A., Matsumoto M., Tajiri Y., Higashi M., Kabetani T. Adhesion procedure for CAD/CAM resin crown bonding: reduction of bond strengths due to artificial saliva contamination. J Prosthodont Res. 2018;62(2):177–183. doi: 10.1016/j.jpor.2017.08.006. [DOI] [PubMed] [Google Scholar]

- 6.El-Damanhoury H.M., Gaintantzopoulou M.D. Self-etching ceramic primer versus hydrofluoric acid etching: etching efficacy and bonding performance. J Prosthodont Res. 2018;62(1):75–83. doi: 10.1016/j.jpor.2017.06.002. [DOI] [PubMed] [Google Scholar]

- 7.Shinohara A., Taira Y., Sawase T. Effects of tributylborane-activated adhesive and two silane agents on bonding computer-aided design and manufacturing (CAD/CAM) resin composite. Odontology. 2017;105(4):437–442. doi: 10.1007/s10266-016-0288-8. [DOI] [PubMed] [Google Scholar]

- 8.Ishii N., Maseki T., Nara Y. Bonding state of metal-free CAD/CAM onlay restoration after cyclic loading with and without immediate dentin sealing. Dent Mater J. 2017;36(3):357–367. doi: 10.4012/dmj.2016-289. [DOI] [PubMed] [Google Scholar]

- 9.Lise D.P., Van Ende A., De Munck J., Vieira L., Baratieri L.N., Van Meerbeek B. Microtensile bond strength of composite cement to novel CAD/CAM materials as a function of surface treatment and aging. Oper Dent. 2017;42(1):73–81. doi: 10.2341/15-263-L. [DOI] [PubMed] [Google Scholar]

- 10.Flury S., Schmidt S.Z., Peutzfeldt A., Lussi A. Dentin bond strength of two resin-ceramic computer-aided design/computer-aided manufacturing (CAD/CAM) materials and five cements after six months storage. Dent Mater J. 2016;35(5):728–735. doi: 10.4012/dmj.2016-095. [DOI] [PubMed] [Google Scholar]

- 11.Peumans M., Valjakova E.B., De Munck J., Mishevska C.B., Van Meerbeek B. Bonding effectiveness of luting composites to different CAD/CAM materials. J Adhes Dent. 2016;18(4):289–302. doi: 10.3290/j.jad.a36155. [DOI] [PubMed] [Google Scholar]

- 12.Roperto R., Akkus A., Akkus O., Lang L., Sousa-Neto M.D., Teich S. Effect of different adhesive strategies on microtensile bond strength of computer aided design/computer aided manufacturing blocks bonded to dentin. Dent Res J (Isfahan) 2016;13(2):117–123. doi: 10.4103/1735-3327.178196. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Kawaguchi A., Matsumoto M., Higashi M., Miura J., Minamino T., Kabetani T. Bonding effectiveness of self-adhesive and conventional-type adhesive resin cements to CAD/CAM resin blocks. Part 2: effect of ultrasonic and acid cleaning. Dent Mater J. 2016;35(1):29–36. doi: 10.4012/dmj.2015-235. [DOI] [PubMed] [Google Scholar]

- 14.Higashi M., Matsumoto M., Kawaguchi A., Miura J., Minamino T., Kabetani T., et al Bonding effectiveness of self-adhesive and conventional-type adhesive resin cements to CAD/CAM resin blocks. Part 1: effects of sandblasting and silanization. Dent Mater J. 2016;35(1):21–28. doi: 10.4012/dmj.2015-234. [DOI] [PubMed] [Google Scholar]

- 15.Duzyol M., Sagsoz O., Polat Sagsoz N., Akgul N., Yildiz M. The effect of surface treatments on the bond strength between CAD/CAM blocks and composite resin. J Prosthodont. 2016;25(6):466–471. doi: 10.1111/jopr.12322. [DOI] [PubMed] [Google Scholar]

- 16.Gilbert S., Keul C., Roos M., Edelhoff D., Stawarczyk B. Bonding between CAD/CAM resin and resin composite cements dependent on bonding agents: three different in vitro test methods. Clin Oral Investig. 2016;20(2):227–236. doi: 10.1007/s00784-015-1494-4. [DOI] [PubMed] [Google Scholar]

- 17.Campos F., Almeida C.S., Rippe M.P., de Melo R.M., Valandro L.F., Bottino M.A. Resin bonding to a hybrid ceramic: effects of surface treatments and aging. Oper Dent. 2016;41(2):171–178. doi: 10.2341/15-057-L. [DOI] [PubMed] [Google Scholar]

- 18.Elsaka S.E. Influence of surface treatments on bond strength of metal and ceramic brackets to a novel CAD/CAM hybrid ceramic material. Odontology. 2016;104(1):68–76. doi: 10.1007/s10266-014-0188-8. [DOI] [PubMed] [Google Scholar]

- 19.Arao N., Yoshida K., Sawase T. Effects of air abrasion with alumina or glass beads on surface characteristics of CAD/CAM composite materials and the bond strength of resin cements. J Appl Oral Sci. 2015;23(6):629–636. doi: 10.1590/1678-775720150261. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Kassotakis E.M., Stavridakis M., Bortolotto T., Ardu S., Krejci I. Evaluation of the effect of different surface treatments on luting CAD/CAM Composite resin overlay workpieces. J Adhes Dent. 2015;17(6):521–528. doi: 10.3290/j.jad.a35256. [DOI] [PubMed] [Google Scholar]

- 21.Stawarczyk B., Teuss S., Eichberger M., Roos M., Keul C. Retention strength of PMMA/UDMA-based crowns bonded to dentin: impact of different coupling agents for pretreatment. Materials (Basel) 2015;8(11):7486–7497. doi: 10.3390/ma8115396. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Frankenberger R., Hartmann V.E., Krech M., Krämer N., Reich S., Braun A. Adhesive luting of new CAD/CAM materials. Int J Comput Dent. 2015;18(1):9–20. [PubMed] [Google Scholar]

- 23.Elsaka S.E. Repair bond strength of resin composite to a novel CAD/CAM hybrid ceramic using different repair systems. Dent Mater J. 2015;34(2):161–167. doi: 10.4012/dmj.2014-159. [DOI] [PubMed] [Google Scholar]

- 24.Stawarczyk B., Krawczuk A., Ilie N. Tensile bond strength of resin composite repair in vitro using different surface preparation conditionings to an aged CAD/CAM resin nanoceramic. Clin Oral Investig. 2015;19(2):299–308. doi: 10.1007/s00784-014-1269-3. [DOI] [PubMed] [Google Scholar]

- 25.Keul C., Kohen D., Eichberger M., Roos M., Gernet W., Stawarczyk B. The effect of different pretreatment methods of PMMA-based crowns on the long-term tensile bond strength to dentin abutments. Clin Oral Investig. 2015;19(1):35–43. doi: 10.1007/s00784-014-1215-4. [DOI] [PubMed] [Google Scholar]

- 26.Zaghloul H., Elkassas D.W., Haridy M.F. Effect of incorporation of silane in the bonding agent on the repair potential of machinable esthetic blocks. Eur J Dent. 2014;8(1):44–52. doi: 10.4103/1305-7456.126240. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Keul C., Müller-Hahl M., Eichberger M., Liebermann A., Roos M., Edelhoff D., et al Impact of different adhesives on work of adhesion between CAD/CAM polymers and resin composite cements. J Dent. 2014;42(9):1105–1114. doi: 10.1016/j.jdent.2014.02.020. [DOI] [PubMed] [Google Scholar]

- 28.Elsaka S.E. Bond strength of novel CAD/CAM restorative materials to self-adhesive resin cement: the effect of surface treatments. J Adhes Dent. 2014;16(6):531–540. doi: 10.3290/j.jad.a33198. [DOI] [PubMed] [Google Scholar]

- 29.Lührs A.K., Pongprueksa P., De Munck J., Geurtsen W., Van Meerbeek B. Curing mode affects bond strength of adhesively luted composite CAD/CAM restorations to dentin. Dent Mater. 2014;30(3):281–291. doi: 10.1016/j.dental.2013.11.016. [DOI] [PubMed] [Google Scholar]

- 30.Stawarczyk B., Stich N., Eichberger M., Edelhoff D., Roos M., Gernet W., et al Long-term tensile bond strength of differently cemented nanocomposite CAD/CAM crowns on dentin abutment. Dent Mater. 2014;30(3):334–342. doi: 10.1016/j.dental.2013.12.012. [DOI] [PubMed] [Google Scholar]

- 31.Liebermann A., Keul C., Bähr N., Edelhoff D., Eichberger M., Roos M., et al Impact of plasma treatment of PMMA-based CAD/CAM blanks on surface properties as well as on adhesion to self-adhesive resin composite cements. Dent Mater. 2013;29(9):935–944. doi: 10.1016/j.dental.2013.06.004. [DOI] [PubMed] [Google Scholar]

- 32.Bähr N., Keul C., Edelhoff D., Eichberger M., Roos M., Gernet W., et al Effect of different adhesives combined with two resin composite cements on shear bond strength to polymeric CAD/CAM materials. Dent Mater J. 2013;32(3):492–501. doi: 10.4012/dmj.2012-329. [DOI] [PubMed] [Google Scholar]

- 33.Stawarczyk B., Trottmann A., Hämmerle C.H., Özcan M. Adhesion of veneering resins to polymethylmethacrylate-based CAD/CAM polymers after various surface conditioning methods. Acta Odontol Scand. 2013;71(5):1142–1148. doi: 10.3109/00016357.2012.757354. [DOI] [PubMed] [Google Scholar]

- 34.Stawarczyk B., Basler T., Ender A., Roos M., Ozcan M., Hämmerle C. Effect of surface conditioning with airborne-particle abrasion on the tensile strength of polymeric CAD/CAM crowns luted with self-adhesive and conventional resin cements. J Prosthet Dent. 2012;107(2):94–101. doi: 10.1016/S0022-3913(12)60031-6. [DOI] [PubMed] [Google Scholar]

- 35.El Zohairy A.A., De Gee A.J., Mohsen M.M., Feilzer A.J. Microtensile bond strength testing of luting cements to prefabricated CAD/CAM ceramic and composite blocks. Dent Mater. 2003;19(7):575–583. doi: 10.1016/s0109-5641(02)00107-0. [DOI] [PubMed] [Google Scholar]

- 36.Yoshida K., Kamada K., Atsuta M. Effects of two silane coupling agents, a bonding agent, and thermal cycling on the bond strength of a CAD/CAM composite material cemented with two resin luting agents. J Prosthet Dent. 2001;85(2):184–189. doi: 10.1067/mpr.2001.113628. [DOI] [PubMed] [Google Scholar]

- 37.De Munck J., Mine A., Poitevin A., Van Ende A., Cardoso M.V., Van Landuyt K.L. Meta-analytical review of parameters involved in dentin bonding. J Dent Res. 2012;91(4):351–357. doi: 10.1177/0022034511431251. [DOI] [PubMed] [Google Scholar]

- 38.Inokoshi M., De Munck J., Minakuchi S., Van Meerbeek B. Meta-analysis of bonding effectiveness to zirconia ceramics. J Dent Res. 2014;93(4):329–334. doi: 10.1177/0022034514524228. [DOI] [PubMed] [Google Scholar]

- 39.Yoshihara K., Nagaoka N., Maruo Y., Nishigawa G., Irie M., Yoshida Y., et al Sandblasting may damage the surface of composite CAD-CAM blocks. Dent Mater. 2017;33(3):e124–e135. doi: 10.1016/j.dental.2016.12.003. [DOI] [PubMed] [Google Scholar]

- 40.Loomans B.A., Cardoso M.V., Opdam N.J.M., Roeters F.J.M., De Munck J., Huysmans M.C., et al Surface roughness of etched composite resin in light of composite repair. J Dent. 2011;39(7):499–505. doi: 10.1016/j.jdent.2011.04.007. [DOI] [PubMed] [Google Scholar]

- 41.Özcan M., Volpato C.Â. Surface conditioning and bonding protocol for polymer-infiltrated ceramic: how and why? J Adhes Dent. 2016;18(2):174–175. doi: 10.3290/j.jad.a35979. [DOI] [PubMed] [Google Scholar]