Abstract

In 2016, the Mine Safety and Health Administration required the use of continuous monitors to measure respirable dust in mines and better protect miner health. The Personal Dust Monitor, PDM3700, has met stringent performance criteria for this purpose. In a laboratory study, respirable mass concentrations measured with the PDM3700 and a photometer (personal DataRam, pDR-1500) were compared to those measured gravimetrically for five aerosols of varying refractive index and density (diesel exhaust fume, welding fume, coal dust, Arizona road dust (ARD), and salt [NaCl] aerosol) at target concentrations of 0.38, 0.75, and 1.5 mg m−3. For all aerosols except coal dust, strong, near-one-to-one, linear relationships were observed between mass concentrations measured with the PDM3700 and gravimetrically (diesel fume, slope = 0.99, R2 = 0.99; ARD, slope = 0.98, R2 = 0.99; and NaCl, slope = 0.95, R2 = 0.99). The slope deviated substantially from unity for coal dust (slope = 0.55; R2 = 0.99). Linear relationships were also observed between mass concentrations measured with the pDR-1500 and gravimetrically, but one-to-one behavior was not exhibited (diesel fume, slope = 0.23, R2 = 0.76; coal dust, slope = 0.54, R2 = 0.99; ARD, slope = 0.61, R2 = 0.99; NaCl, slope = 1.14, R2 = 0.98). Unlike the pDR-1500, mass concentrations measured with the PDM3700 appear independent of refractive index and density, suggesting that it could have applications in a variety of occupational settings.

Keywords: density, gravimetric methods, occupational aerosols, PDM3600, PDM3700, pDR-1500, personal DataRAM, Personal Dust Monitor, refractive index

Introduction

Respirable particles that can reach the alveolar region of the lung (ACGIH, 2017) represent an inhalation hazard for a wide array of occupations from welding to mining. In underground mines, the respirable particles emitted as byproducts of combustion from blasting, welding, and operating diesel engines (Cantrell and Rubow, 1990) are implicated in a variety of adverse health effects (Donoghue, 2004). They are also emitted by mechanical processes in mines, such as the operation of mining machine picks, drills, and crushers (Cantrell and Rubow, 1990), which are associated with silicosis, coal worker’s pneumoconiosis, and other chronic respiratory illnesses (Donoghue, 2004). The Mine Safety and Health Administration (MSHA) mandates permissible exposure limits for respirable dust to prevent adverse health effects among miners.

From 1980 until 2016, the permissible exposure limit for coal mines was 2.0 mg m−3 for an 8-hour, time-weighted average as measured with a specific gravimetric sampler, the ‘coal mine dust personal sampler unit’ (CMDPSU) (MSHA, 2014). During CMDPSU operation, a belt-mounted personal sampling pump draws air through a 10-mm nylon Dorr Oliver cyclone and pre-weighed filter positioned within the miner’s breathing zone. Respirable mass concentration as defined by the Mining Research Establishment (MRE) is then calculated as the mass collected on the filter divided by the volume of air sampled multiplied by a factor of 1.38. Although highly accurate and precise, gravimetric measurements are often unavailable for days or weeks (Volkwein et al., 2004).

With the promulgation of 79 United States Federal Register 24813, MSHA enacted key changes to further protect miners from developing coal worker’s pneumoconiosis (MSHA, 2016). MSHA lowered the permissible exposure limit for respirable dust to 1.5 mg m−3 as measured over a full work shift. MSHA also required measurement of respirable dust by an ‘approved’ continuous personal dust monitor (CPDM) for those underground coal miners at high potential of elevated exposure to respirable particles. The Code of Federal Regulations, 30 CFR Part 74, provides performance requirements for approval of CPDMs. Worn by a miner, a CPDM continuously measures respirable dust concentrations, providing output on a 30-minute, rolling basis and at the end of the work shift. The mine operator is required to take immediate corrective actions, if dust concentrations reported by the CPDM are above the permissible exposure limit (MSHA, 2016). Only one commercially available instrument, the Personal Dust Monitor (PDM 3700, Thermo Fisher Scientific, Franklin, MA, USA) is approved for use as a CPDM (Thermo, 2016). The PDM3700 uses a tapered element oscillating microbalance (TEOM) to continuously measure the mass of collected particles (Table 1 provides specifications). Particle-laden air is drawn at 2.2 l min−1 into an inlet positioned in the miner’s breathing zone and through a transport tube to an instrument worn at the miner’s waist (Volkwein et al., 2006). Within the PDM3700, the air is passed through a respirable cyclone (Higgens-Dewell), heated, and directed through a filter mounted on the top of a specially shaped, hollow tube, the tapered element. A series of magnets oscillate the tapered element. The frequency of oscillation decreases as particles deposit on the filter, thereby providing a way to infer mass concentration continuously. The design of the PDM3700 was based on Thermo Scientific’s TEOM 1400, a large, freestanding monitor approved by the US Environmental Protection Agency as an alternative to measuring ambient mass concentrations gravimetrically (Volkwein et al., 2006).

Table 1.

Specifications of direct-reading Instruments.

| PDM3700a | pDR-1500b | |

|---|---|---|

| Cost | $17000 | $6000 |

| Size (L × W × H) | 8.3 cm × 24.3 cm × 17.2 cm | 8.4 cm × 14.3 cm × 18.1 cm |

| Weight | 2.0 kg | 1.2 kg |

| Sampling flow | 2.2 Lpm | 1.0–3.5 Lpm |

| Concentration range | 0–200 mg m−3 | 0.001–400 mg m−3 |

| Cut-point diameter | 4.0 µm | 1.0–10 µm |

| Cyclone | Higgins-Dewellc | SCC 1.062 or GK 2.05 |

| Resolution | 0.01 mg m−3 | 0.1% of reading or 0.001 mg m−3, whichever is larger |

aThermo, 2016.

bThermo, 2014.

cVolkwein et al., 2006.

We are unaware of literature on the performance of the PDM3700, although researchers have evaluated an earlier model, the PDM3600. The PDM3600 is identical to the PDM3700, except for changes in the display of data and the positioning of the air inlet on a lamp on a miner’s helmet. Mass concentrations measured with the PDM3600 compared favorably to those measured gravimetrically for coal dust, dust in mines (Volkwein et al., 2004, 2006; Page et al., 2008), and diesel exhaust fume (Noll et al., 2013). Thorpe and Walsh (2013) found that mass concentrations measured with a PDM3600 with the respirable cyclone removed compared well to those measured with an inhalable sampler for wood dust, aluminum oxide powder, flour dust, and grain dust. These data suggest that the PDM3700 may have application to industry in general, rather than in mining exclusively.

The ability of the PDM3700 to monitor respirable mass concentrations continuously makes it a competitor of other direct-reading instruments, including photometers. Personal photometers, such as the personal DataRAM™ (Table 1, pDR-1500, Thermo Fisher Scientific), are commonly used in environmental or occupational settings. They rely on the principle that the light scattered by an assembly of particles scales with the mass concentration of aerosol (Baron, 1998). Unlike the TEOM technology employed in the PDM3700, light scattering is sensitive to particle refractive index, size, and shape (Baron, 1998). Consequently, experimental calibration of the photometer response to a gravimetric measurement is recommended before deployment in a new environment. Moreover, the accuracy of mass concentrations measured with a photometer are affected by high relative humidity, which occurs in mines from the water spray used in dust control systems (Volkwein et al., 2004).

Our objective was to compare respirable mass concentrations measured with the PDM3700 and pDR-1500 to gravimetric measurements for a variety of aerosols with differing size, refractive index, and shape. We conducted laboratory tests over a range of concentrations typical of occupational settings to evaluate these instruments for diesel exhaust fumes, welding fumes, coal dust, Arizona road dust (ARD), and sodium chloride (NaCl) aerosol. This work allowed us to contrast mass concentrations measured by instruments relying on two different direct-reading technologies.

Methods

Experimental set up

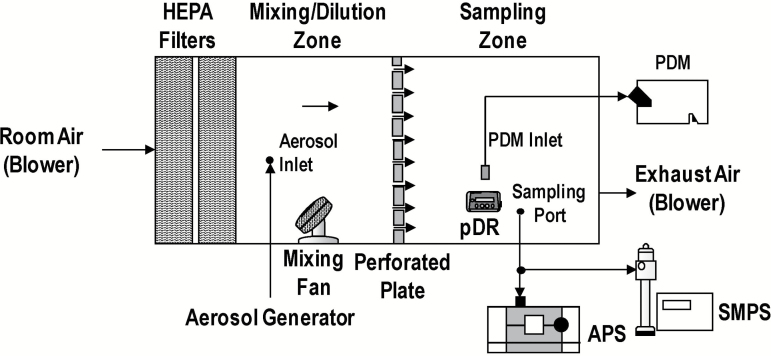

Experiments were conducted in a two-zone test chamber (Fig. 1). Aerosol was injected to the mixing/dilution zone (0.64 × 0.64 × 0.66 m) of the chamber along with air cleaned by passing through two consecutive HEPA filters. We used a small fan in the mixing/dilution zone to mix the aerosol with the clean air. The diluted aerosol was then passed through a perforated plate to promote uniformity in the sampling zone (0.53 × 0.64 × 0.66 m). The airflow rate through the chamber was maintained from 0.019 m3 min−1 to 0.62 m3 min−1 to achieve desired aerosol concentrations within the sampling zone. Sousan et al. (2016a) showed that the concentrations within the sampling zone of this chamber are homogeneous with a coefficient of variation of <10%.

Figure 1.

Experimental setup of test chamber.

We positioned the sampling inlet of a new PDM3700 inside the sampling zone with the instrument portion, typically worn on a worker’s belt, placed outside the chamber. The PDM3700 was operated with default settings, which includes output of mass concentration as MRE equivalent concentration. A sampling line of the PDM3700 supplied by the manufacturer connected the inlet to the instrument portion. All components of the PDM3700 were oriented in the same position throughout all tests. A factory-calibrated photometer (pDR-1500, Thermo Fisher Scientific) was placed inside the sampling zone with the inlet positioned within 10 cm of the inlet of the PDM3700. The pDR-1500 was equipped with a GK 2.05 cyclone on the inlet and operated at a flow rate of 2.39 l min−1 to achieve a 50% cut-off diameter of 4.5 µm. This cut-off diameter was selected to match that of the cyclone within the PDM3700 as incorrectly reported to us by the manufacturer. This cut-off diameter is larger than that of the respirable criterion of 4.0 µm used by the ISO and the American Conference of Governmental Industrial Hygienists. We operated the pDR-1500 with a 37-mm glass microfiber filter (934-AH, GE Whatman, Pittsburgh, PA, USA) downstream of the optics to serve as a gravimetric sampler. A scanning mobility particle sizer (SMPS) and an aerodynamic particle sizer (APS) were used to measure the size distribution of the aerosol in the sampling zone. The SMPS (3082; TSI Inc, Shoreview, MN, USA) was used in conjunction with a condensation particle counter (3788; TSI Inc) to classify particles between 10 nm and 1000 nm. The APS (3321, TSI Inc) was used to classify particles between 0.5 and 20 µm.

We selected five aerosols for testing: diesel exhaust fume, welding fume, coal dust, ARD, and sodium chloride (NaCl) aerosol. Diesel exhaust and welding fume were included as combustion aerosols due to their prevalence in occupational settings, especially mines. The refractive indices of diesel exhaust fume and welding fume are 1.465 and 1.800, respectively (Glinsmann et al., 1985; Arik et al., 2014). A portion of the diesel exhaust fume from a diesel electric generator (DG6LE, Red Hawk Equipment LLC, Akron, NY, USA) was diverted into the chamber. Welding fume was produced with a metal inert gas (MIG) welding system (0.76-mm Flux-Corded MIG Wire, Campbell Hausfeld, USA) operated inside a sandblast cabinet (Item 62454, Central Pneumatic, Calabasas, CA, USA). A variable-speed fan equipped with a HEPA filter was used to push the fume into the chamber. We selected coal dust and ARD to represent mechanically generated dusts. Coal dust was selected because the primary intended use of the PDM3700 is in coal mines and because the refractive index of coal dust has a large absorptive component (1.540-0.5i) (Willeke and Liu, 1976). ARD (refractive index = 1.510) was included to simulate irritant dust that workers may experience outdoors or in occupational settings (Sousan et al., 2016b). Coal dust (Pittsburgh seam coal; <5% SiO2; Hosokawa Micron Powder Systems; Summit, NJ, USA) and ARD (Fine Grade, Part No.1543094, Powder Technology Inc, Arden Hills, MN, USA) aerosols were generated using a fluidized bed aerosol generator (3400A, TSI Inc).

NaCl aerosol was also included as a common laboratory test aerosol and environmental aerosol with a refractive index similar to ARD (1.544). To generate solid NaCl aerosol, we used a vibrating mesh nebulizer (Aeroneb Solo System, Aerogen, Ireland) that was turned on and off at 1 Hz to produce a cloud of droplets consisting of NaCl solution (0.9% w/v, #7210, Fisher Scientific, Pittsburgh, PA, USA). These droplets were dried to form an aerosol composed of dry NaCl particles.

Testing procedure

For each aerosol, we targeted gravimetric mass concentrations in the chamber of 0.38, 0.75, and 1.5 mg m−3, or ¼, ½, and 1 times MSHA’s permissible exposure limit for respirable dust (1.5 mg m−3). The sampling time was set to collect at least 0.1 mg on the filter to be substantially above the limit of detection for fiberglass filters in our laboratory (3 × SD of 10 blank filters = 3 × 0.011 mg = 0.033 mg). For welding fume, we conducted tests only for the highest concentration due to difficulties in maintaining steady-state concentration over extended times.

For each aerosol and target concentration, the mass concentration was measured in triplicate with the PDM3700 and the pDR-1500 with the filter (n = 4 aerosols × 3 concentrations × 3 replications + 1 welding fume × 1 concentration × 3 replications = 39 tests), while the size distribution was measured once with the SMPS and APS. The pDR-1500 data was corrupted for a single test (high concentration of coal dust) so there were only 38 tests for that instrument. A new gravimetric filter was used for each test. Filters were weighed before and after sampling on a microbalance (Mettler MT5 MT-5 analytical Microbalance, Mettler-Toledo, Columbus, OH, USA) after equilibrating in a cleanroom for at least 24 h.

Calculations

For each test, we calculated the mean mass concentration measured by the PDM3700 and the pDR-1500, and the ratios of these means to that measured gravimetrically. A t-test was used to investigate the hypothesis that each ratio was statistically equal to one at a significance level of 0.05. For each aerosol type, except welding fume, we performed linear regression to investigate the relationships between the mass concentrations measured with the PDM3700 and pDR-1500, and those obtained gravimetrically. We tested the hypothesis that the slope was equal to one and the intercept was equal to zero at a significance level of 0.05. All statistical tests were carried out in Minitab (version 17, State College, PA, USA).

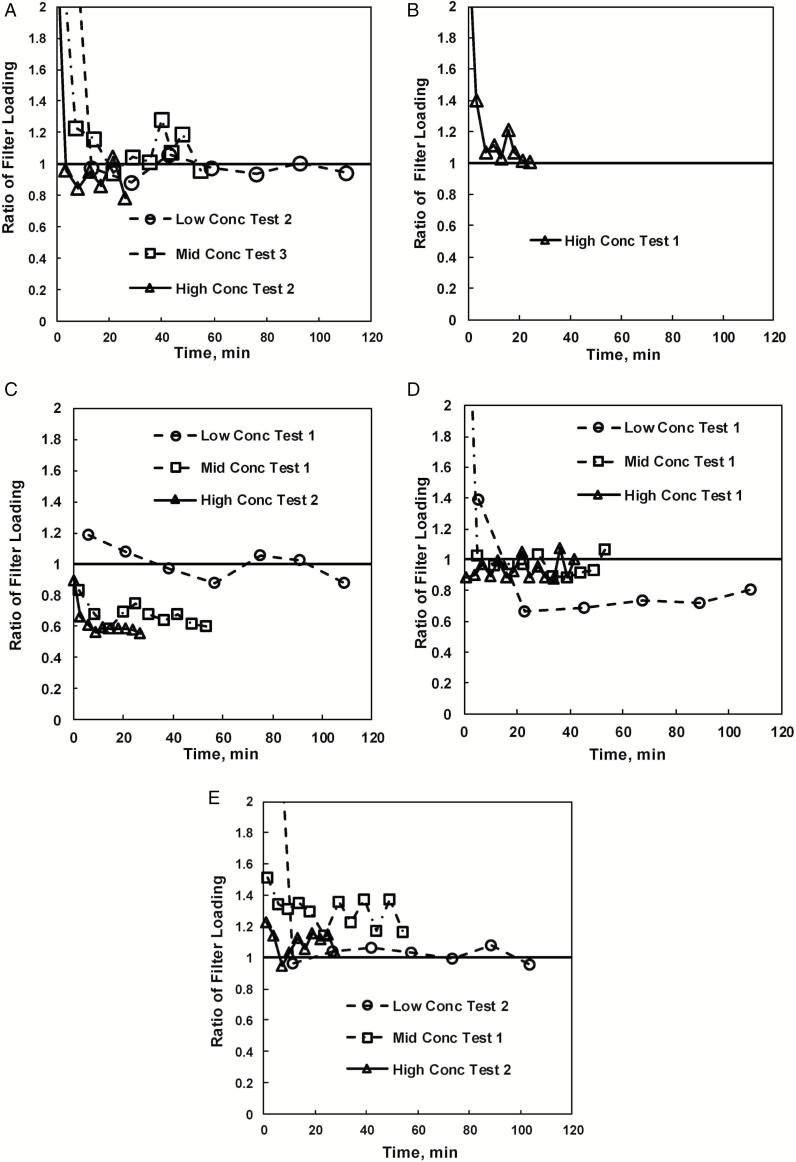

For each experiment, we calculated the ratio of 1-min mass concentrations from the PDM3700 to gravimetric estimates to investigate the progression of mass loading on the TEOM filter over time. For the PDM3700, 1-min mass concentrations were estimated by dividing the mass collected on the PDM3700 filter (output from PDM software) by the volume of air sampled. These mass concentrations were divided by corresponding, 1-min, gravimetrically adjusted mass concentrations measured with the pDR-1500. Gravimetric adjustments were made by multiplying the 1-min pDR-1500 data by the ratio of the mass concentration measured gravimetrically to the mean concentration measured with the pDR-1500.

Results

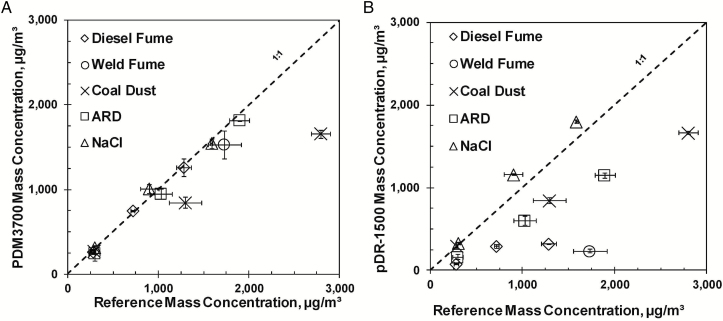

Except for coal dust, all mass concentrations measured with the PDM3700 agreed well with those measured gravimetrically (Fig. 2A), having mass ratios statistically equal to or close to unity (Table 2). For all aerosols, a strong linear relationship was observed between mass concentrations measured with the PDM3700 and gravimetrically (Table 3; R2 ≥ 0.98). For diesel fume, ARD, and NaCl aerosols, slopes (range: 0.94 to 0.99) were statistically equal to one, and intercepts (range: −49 µg m−3 to 55 µg m−3) were statistically equal to zero. In contrast, medium and high concentrations for coal dust deviated substantially from the one-to-one line (Table 3; slope = 0.55, statistically not equal to one; intercept = 120 µg m−3, statistically not equal to zero) and yielded mass ratios statistically different than and substantially <1 (Table 2; medium concentration, ratio = 0.65; high concentration, ratio = 0.59).

Figure 2.

Mass concentrations measured with the direct-reading instrument compared to those measured gravimetrically for: (A) the PDM3700; and (B) the pDR-1500. Each point represents the average of three independent trials. Error bars indicate one standard deviation.

Table 2.

Mean ratio of the mass concentrations measured by the PDM3700 or pDR-1500 to those measured gravimetrically.

| Aerosol | PDM3700 | pDR-1500 | ||||

|---|---|---|---|---|---|---|

| Concentration level | Concentration level | |||||

| Low | Medium | High | Low | Medium | High | |

| Diesel fume | 0.91 (0.02) | 1.03 (0.04) | 0.98 (0.03) | 0.26 (0.01) | 0.40 (0.03) | 0.25 (0.02) |

| Welding fume | — | — | 0.89 (0.19) | — | — | 0.14 (0.02) |

| Coal dust | 0.93 (0.07) | 0.65 (0.04) | 0.59 (0.03) | 1.00 (0.05) | 0.66 (0.07) | 0.59 (0.02) |

| Arizona road dust | 0.79 (0.15) | 0.92 (0.05) | 0.95 (0.05) | 0.54 (0.04) | 0.58 (0.04) | 0.61 (0.03) |

| NaCl | 1.02 (0.02) | 1.07 (0.16) | 0.97 (0.03) | 1.07 (0.03) | 1.23 (0.15) | 1.13 (0.02) |

Standard deviation of the ratio shown in parentheses. Bold indicates that the mean ratio is statistically equal to 1 at a significance level of 0.05.

Table 3.

Results of linear regression for the PDM3700 and the pDR-1500 by aerosol.

| Aerosol | PDM3700 | pDR-1500 | ||||

|---|---|---|---|---|---|---|

| Slope | Intercept µg m−3 | R 2 | Slope | Intercept µg m−3 | R 2 | |

| Diesel fume | 0.99 (0.03) | −5.0 (26) | 0.99 | 0.23 (0.05) | 52 (42) | 0.76 |

| Coal dust | 0.55 (0.02) | 120 (30) | 0.99 | 0.54 (0.02) | 140 (25) | 0.99 |

| Arizona road dust | 0.97 (0.03) | −49 (42) | 0.99 | 0.61 (0.02) | −22 (23) | 0.99 |

| NaCl | 0.94 (0.06) | 55 (62) | 0.98 | 1.14 (0.05) | 16 (59) | 0.98 |

Standard error of the parameter estimate shown in parentheses. Bold indicates parameter estimate statistically equal to 1 for slope or 0 for intercept at a significance level of 0.05.

In contrast, the pDR-1500 underestimated gravimetric mass concentrations for all aerosol types, except NaCl (Fig. 2B). The largest underestimation was observed for welding fume (Table 2; mean ratio = 0.14). Only three mass concentration ratios for the pDR-1500 were statistically equal to one (Table 2; low concentration for NaCl and coal dust, and medium concentration for NaCl). The relationships between the pDR-1500 and gravimetric measurements were highly linear for coal dust, ARD, and NaCl (Table 3, R2 ≥ 0.98), but less so for diesel fume (R2 = 0.76). The slopes ranged from 0.23 for diesel fume to 1.14 for NaCl, none of which was statistically equal to one. The intercepts for aerosols other than coal dust ranged from −22 µg m−3 for ARD to 52 µg m−3 for diesel fume and were statistically equal to zero. For coal dust, the intercept was substantially and significantly different than zero (intercept = 140 µg m−3).

The 1-min ratios of PDM3700 to gravimetric estimates are shown in Fig. 3. Most ratios were above one at the beginning of the test, dropped rapidly, and then reached steady-state values near or slightly above one, except for a single ARD test at low concentration and for coal dust tests at medium and high concentrations. For ARD at low concentration, the ratio started near two and then declined to a fairly steady-state ratios of ~0.65. For coal dust at medium and high concentrations, ratios declined slightly throughout the test rather than reaching steady state.

Figure 3.

Rate of filter mass collection measured with the PDM3700 compared to rate measured gravimetrically for: (A) diesel exhaust fume; (B) welding fume; (C) coal dust; (D) Arizona road dust; and (E) NaCl aerosol. Each point represents one independent trial.

Discussion

Mass concentrations measured with the PDM3700 appear independent of aerosol refractive index, size, and density. Except for coal dust, PDM3700 mass concentrations were similar to those measured gravimetrically, PDM ratios were statistically equal to or close to one, and linear relationships were strong and near one-to-one with slopes statistically equal to one and intercepts statistically equal to zero. Excluding coal dust, mean concentrations measured with the PDM3700 were within 21% of gravimetric results. We observed this favorable response for a wide range of aerosol sizes [ultrafine- and fine-dominated aerosols (diesel fume, welding fume, and NaCl) and coarse aerosol (ARD)] and refractive indices [those with (diesel and welding fume) and without absorptive components (NaCl and ARD)].

Our results are similar to those observed by other researchers who studied the PDM3600, a precursor instrument to the PDM3700. Noll et al. (2013) reported that PDM3600 measurements fell within 16% of TEOM 1400 results (slope = 0.98 ± 0.16; intercept = 1.79 ± 10.15 mg m−3; R2 = 0.97) for diesel fume, which is similar to our observations (slope = 0.99; intercept = −5.0 mg m−3; R2 = 0.99). Additionally, Thorpe and Walsh (2013) compared the performance of a PDM3600 (modified to remove the respirable cyclone) against an IOM gravimetric sampler for inhalable dust particles. For laboratory experiments conducted with barley grain dust, wood dust, flour dust, and aluminum oxide powder, PDM results were similar to our own (slope = 0.73, R2 = 0.965, intercept = 1.41).

The deviation from the one-to-one line for coal dust was unexpected as the intended use of the PDM3700 is to protect workers from developing pneumoconiosis specifically from inhalation of coal dust. In our work, the PDM substantially underestimated mass concentrations of coal dust for medium (Table 2, ratio = 0.65) and high (0.59) concentrations. Although the linear relationship for coal dust was strong (R2 = 0.99), the slope was substantially lower than one (0.55) and the intercept substantially greater than zero (120 µg m−3).

Our results conflict with observations made in underground coal mines. Page et al. (2008) reported a strong one-to-one linear relationship between the mass concentrations measured with a PDM3600 and a respirable sampler (CMDPSU) in 129 underground coal mines scattered around the USA featuring different coal districts and mining methods (slope = 0.95; 95% CI = 0.93 to 0.97). Volkwein et al. (2004) observed that mass concentrations measured by PDM3600 were similar (slope = 0.92; intercept = 0.03; R2 = 0.86) to those from a respirable sampler (BGI-4CP, BGI, Inc., Waltham, MA, USA) in four coal mines with varying mining methods (including longwall and continuous), ventilation systems, and equipment types (diesel-powered or electrical). Volkwein et al. (2006) found that the respirable concentrations from the PDM3600 were within ±25% of those measured gravimetrically in underground coal mines. The fact that mines contain mixtures of aerosols and the possibility that coal dust may be at concentrations where we observed ratios near unity may help explain the difference in slopes observed in field tests by Volkwein et al. and Paige et al.

Similar to our findings, Volkwein et al. (2004) observed a strong linear relationship between mass concentrations measured with the PDM3600 and gravimetrically (R2 = 0.93), a slope <1 (0.84) and an intercept greater than zero (0.13) in the laboratory for coal dust. They also observed underestimation of the PDM measurements compared to the gravimetric measurements at higher mass loading on the TEOM filter. The authors attributed this underestimation in mass to particle losses in a transition and the heater before collection on the TEOM filter. This explanation, however, is inconsistent with our observation of near one-to-one correspondence for other aerosols, including ARD. ARD and coal dust are both coarse-mode dominated aerosols so they should experience similar particle losses. Particle losses should be independent of aerosol concentration, unless particle size distribution changes. The size distribution of coal dust in our experiments was similar for low and high concentrations (see Supplementary Figure 1, available at Annals of Work Exposures and Health online).

We considered transport losses and particle blow-off from the TEOM filter as possibilities to explain underestimation of coal dust concentrations by the PDM3700. Coal dust may have been lost to the interior walls of the transport tube or belt-mounted components more than other aerosols. Such loss was unlikely due to electrical forces as all tests were conducted at similar humidity conditions of 63% (±4% standard deviation) and the dielectric constant of coal dust (εr = 2.0 to 4.0) is similar to ARD (2.5 to 3.5) (Clipper, 2017). The fact that the coal dust was visually flaky in nature may have contributed to more losses due to interception than for other aerosols. We also considered the possibility that the flaky coal dust could be re-entrained (i.e., blown off the filter) into the airflow after collection on the TEOM filter. The finding that the ratio of PDM3700 mass to gravimetric mass decreased instead of becoming steady state for coal dust only (Figure 3C) provides some evidence to support blow-off. For other aerosols, the ratio became steady state. Thorpe and Walsh (2013) also concluded that the PDM underestimation of mass compared to gravimetric measurements was due to particle losses from the filter surface. However, they studied inhalable particles, which may be more susceptible to loss from the filter surface than the respirable particles studied in the current work.

While the PDM3700 is capable of measuring diesel exhaust fumes with high accuracy, prolonged sampling at high concentrations may not be appropriate. During diesel exhaust tests, PDM3700 filter loads above 0.4 mg or 0.5 mg (concentration × time = 95 mg m−3 × min) triggered ‘high filter load’ warnings. According to the instrument manual, the PDM3700 should function correctly for filter loads below 4 mg and the ‘high filter load’ warning should only trigger for a high pressure drop across the PDM3700 filter (Thermo, 2016). By visual inspection of PDM3700 filters, diesel fume particulate collected in thick, irregular layers while other aerosols collected in fine, flat layers. The irregular morphology and ‘sticky’ nature of diesel fume may increase pressure differentials across the PDM3700 filter more rapidly than other aerosols.

As expected, the relationship between pDR-1500 and gravimetric measurements was highly linear but exhibited substantially different slopes for each aerosol type. Few pDR-1500 to gravimetric ratios were statistically equal to one, as the pDR-1500 generally underestimated mass concentrations. Variation between slopes was expected, given that the pDR-1500 detects particles optically and each aerosol type had a different refractive index. Linear behavior was observed between all pDR-1500 and gravimetric measurements, although it was strongest for aerosols with higher refractive indices (NaCl, ARD, and coal dust; refractive index = 1.51 to 1.544; R2 = 0.99). It was surprising that the pDR-1500 measurements for ARD were not near the one-to-one line, as the pDR is factory calibrated with a SAE Fine Test Dust (Thermo, 2014), which is similar to the ARD we used. We hypothesize that the test dust used to calibrate the pDR-1500 may have a larger size distribution than the ARD we were using. We were also surprised by the similarity between the pDR-1500 measurements for coal dust (slope = 0.54; intercept = 140 µg m−3; R2 = 0.99) and the PDM3700 (slope = 0.55; intercept = 120 µg m−3; R2 = 0.99). The pDR-1500’s underestimation of diesel fume and welding fume, however, was anticipated because a large fraction of these are associated with particles smaller than the wavelength used in the photometer. The response of photometers progressively diminishes with decreasing particle size less than ~300 nm (Baron, 1998).

For many aerosols, the TEOM technology used in the PDM3700 provides superior performance in measuring mass concentrations compared to photometer technology used in the pDR-1500. Unlike the pDR-1500, the PDM3700 directly provided mass concentrations that compared favorably to gravimetric measurements for a wide range of aerosol types (diesel fume, welding fume, ARD, and NaCl). More robust estimates of gravimetric mass concentration are obtained with photometers like the pDR-1500 with the use of aerosols-specific correction factors (Wang et al., 2016). However, the development of a correction factor requires weighing of filters to obtain gravimetric results, and the calibration factor changes with aerosol type, which may be unknown to the user. Photometers do offer the advantage of more rapid response (~1 sec resolution) than the PDM3700 (30-min resolution), which may be important when identifying specific tasks that increase aerosol concentrations. Moreover, photometers are less costly (~$5000 to $9000) than the PDM3700 (~$17000).There were limitations to this study. Only one PDM3700 was tested due to budget constraints so we were unable to measure instrument precision. We only tested welding fume at a single concentration due to difficulties with generation, although the ratio near one is suggestive that the PDM3700 may be applicable for a welding environment. Finally, the PDM was only operated from a stationary position. Further tests are needed to confirm the PDM’s potential to measure exposure when on a mobile worker.

Conclusion

Respirable mass concentrations measured with a PDM3700 were similar to those measured gravimetrically for a range of aerosols with varying size, composition, refractive index, and density. In contrast, as expected, the photometer (pDR-1500) was highly sensitive to aerosol physical characteristics. Further studies with the PDM3700 are recommended to diagnose underestimates of mass concentrations of coal dust, to better understand causes of rapid loading for diesel exhaust, to measure the precision of multiple instruments, and to evaluate the instrument under field conditions. Our results suggest that the PDM3700 has broad applicability to occupational settings beyond coal mines.

Supplementary Data

Supplementary data are available at Annals of Work Exposures and Health online.

Supplementary Material

Acknowledgements

This work was funded partially by a research grant from NIOSH (R01OH010533) and a private contract from a manufacturer of heavy vehicles. The work was made possible with equipment borrowed from the Heartland Center for Occupational Health and Safety Research (CDC/NIOSH - 2 T42 OH008491) and the Environmental Health Science Research Center (P30 ES05605).

The authors would like to thank Mr. Changjie Cai and Dr Jae Hong Park for their assistance during the experimentation process. Thanks also to Dr Emanual Cauda for kindly providing us with coal dust.

References

- ACGIH (2017)Threshold Limit Values and Biological Exposure Indicies. Cincinnati, OH: American Conference of Governmental Industrial Hygienists. [Google Scholar]

- Arik E, Altan H, Esenturk O (2014)Dielectric properties of diesel and gasoline by terahertz spectroscopy. J Infrared Millim Terahertz Waves, 35(9): 759–69. doi:10.1007/s10762-014-0081-0. [Google Scholar]

- Baron P. (1998)Aerosol Photometers for respirable dust measurements. In Eller PM, editor. NIOSH Manual of Analytical Methods, 4th ed Atlanta, GA:National Institute for Occupational Safety and Health; Available at https://www.cdc.gov/niosh/docs/2003–154/pdfs/chapter-g.pdf. Accessed 26 January 2017. [Google Scholar]

- Cantrell BK, Rubow KL (1990)Mineral dust and diesel exhaust aerosol measurements in undergroundmetal and nonmetal mines. NIOSH pub; 90–108: 651–55. [Google Scholar]

- Clipper (2017)Dielectric Constant Values Clipper Controls, Inc; Available at http://www.clippercontrols.com/pages/Dielectric-Constant-Values.html#C. Accessed 26 January 2017. [Google Scholar]

- Donoghue AM. (2004)Occupational health hazards in mining: an overview. Occup Med (Lond); 54: 283–9. [DOI] [PubMed] [Google Scholar]

- Glinsmann PW, Rosenthal FS (1985)Evaluation of an aerosol photometer for monitoring welding fume levels in a shipyard. AIHA J (Fairfax, Va); 46(7): 391–5. [DOI] [PubMed] [Google Scholar]

- MSHA (2014)75 Federal Register 17511. Coal Mine Dust Sampling Devices. Arlington, VA: US Department of Labor. [Google Scholar]

- ——. (2016)Major provisions and effective dates MSHA’s final rule to lower miners’ exposure to respirable coal mine dust Available at http://arlweb.msha.gov/endblacklung/docs/summaryEffectiveDates.pdf. Accessed 26 January 2017.

- Noll J, Volkwein J, Janisko S et al. (2013)Portable instruments for measuring tailpipe diesel particulate in underground mines. Min Eng; 65: 42–9. [PMC free article] [PubMed] [Google Scholar]

- Page SJ, Volkwein JC, Vinson RP et al. (2008)Equivalency of a personal dust monitor to the current United States coal mine respirable dust sampler. J Environ Monit; 10: 96–101. [DOI] [PubMed] [Google Scholar]

- Sousan S, Koehler K, Hallett L, Peters TM (2016a)Evaluation of the Alphasense optical particle counter (OPC-N2) and the Grimm portable aerosol spectrometer (PAS-1.108). Aerosol Sci Tech; 2016: 1352–65. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sousan S, Koehler K, Thomas G, Park JH, Hillman M, Halterman A, Peters TM (2016b)Inter-comparison of low-cost sensors for measuring the mass concentration of occupational aerosols. Aerosol Sci Tech; 50: 462–73. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Thermo (2014)MIE pDR-1500 Instruction Manual Thermo Fisher Scientific; Available at http://tools.thermofisher.com/content/sfs/manuals/EPM-manual-PDR1500.pdf. Accessed 26 January 2017. [Google Scholar]

- ——. (2016)Model PDM3700 Personal Dust Monitor Thermo Fisher Scientific; Available at URL: http://tools.thermofisher.com/content/sfs/manuals/EPM-manual-PDM3700.pdf. Accessed 26 January 2017. [Google Scholar]

- Thorpe A, Walsh PT (2013)Direct-reading inhalable dust monitoring–an assessment of current measurement methods. Ann Occup Hyg; 57: 824–41. [DOI] [PubMed] [Google Scholar]

- Volkwein J, Thimons E, Yanak C et al. (2004)Implementing a new personal dust monitor as an engineering tool. Coal Age; 109: 26–29. [Google Scholar]

- Volkwein JC, Vinson RP, Page SJ et al. (2006)Laboratory and field performance of a continuously measuring personal respirable dust monitor. Report of Investigations 9669. Cincinnatti, OH: National Institute for Occupational Safety and Health.

- Wang Z, Calderón L, Patton AP et al. (2016)Comparison of real-time instruments and gravimetric method when measuring particulate matter in a residential building. J Air Waste Manag Assoc; 66: 1109–20. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Willeke K, Liu B (1976)Single particle optical counter: Principle and application. In BYH, Liu, editors. Fine Particles, Aerosol Generation, Measurement, Sampling and Analysis Academic, Orlando, FL; pp. 698–729. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.