Abstract

Self-assembled peptide and protein amyloid nanostructures have traditionally been considered only as pathological aggregates implicated in human neurodegenerative diseases. In more recent times, these nanostructures have found interesting applications as advanced materials in biomedicine, tissue engineering, renewable energy, environmental science, nanotechnology and material science, to name only a few fields. In all these applications, the final function depends on: (i) the specific mechanisms of protein aggregation, (ii) the hierarchical structure of the protein and peptide amyloids from the atomistic to mesoscopic length scales and (iii) the physical properties of the amyloids in the context of their surrounding environment (biological or artificial). In this review, we will discuss recent progress made in the field of functional and artificial amyloids and highlight connections between protein/peptide folding, unfolding and aggregation mechanisms, with the resulting amyloid structure and functionality. We also highlight current advances in the design and synthesis of amyloid-based biological and functional materials and identify new potential fields in which amyloid-based structures promise new breakthroughs.

1. Introduction

The self-assembly and aggregation of peptides and proteins play crucial roles in many of the human’s body functions.1 For instance, networks of collagen fibrils provide a biochemical scaffold with many functions governing the morphology and mechanical properties of biological tissue.2,3 Self-assembled actin fibrils are essential elements for many key functions in eukaryotic cells, such as motility, morphology, maintenance of cell polarity and the regulation of transcription.4 In blood coagulation, wound healing proceeds through the aggregation of fibrin into sealing clots, allowing tissue repair. In addition, there are a number of diseases associated with errant protein aggregation. The misfolding of proteins and their subsequent assembly into amyloid fibrils are pathological hallmarks of a number of devastating degenerative diseases, including Parkinson’s, Alzheimer’s, Type II diabetes and others.5

Historically, due to the discovery of their association with disease states, the study of amyloid fibrils has been largely centred on those associated with neurodegenerative disorders. A great deal of research has been performed to elucidate the formation mechanisms and to understand the mechanisms of toxicity arising from various amyloid species ranging from oligomers to mature amyloid nanofibrils.6 Consequently, a large number of biomedical studies have been devoted to uncovering how to inhibit amyloid formation, and a multitude of biomedical, biochemical, biophysical and nanotechnological processes have been investigated in an attempt to design therapies that can slow down the progress of amyloid-related diseases.7–10

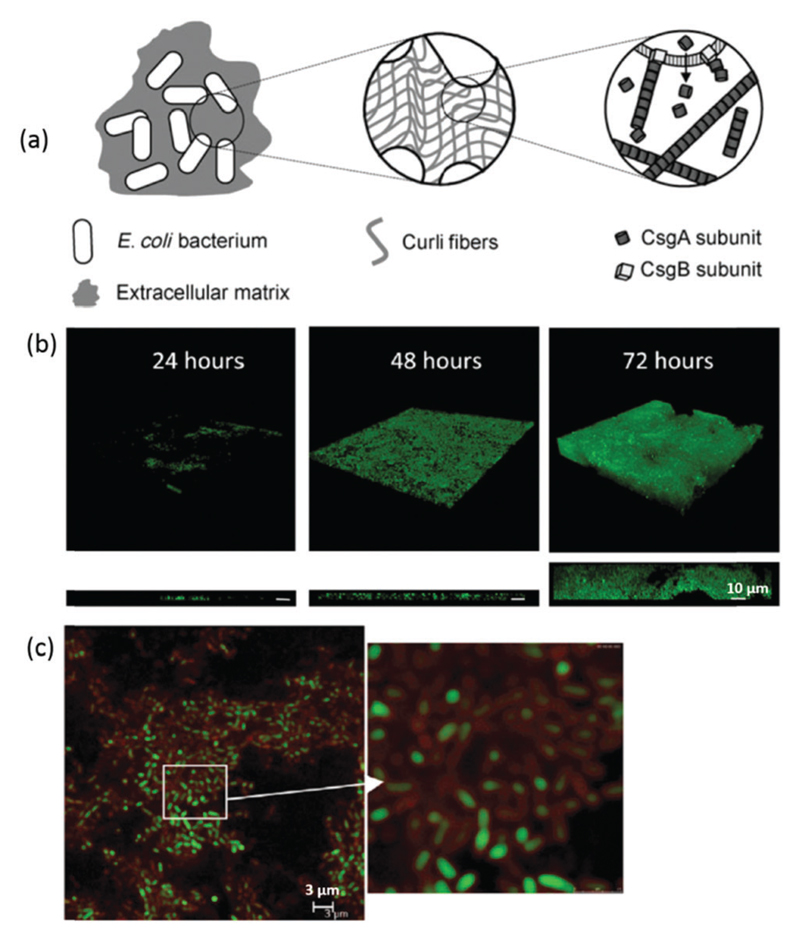

The discovery that functional amyloid fibrils in living organisms also play vital physiological roles within and on the surface of living cells has introduced a new paradigm for the study of amyloid fibrils. Examples of the physiological roles of functional amyloids include, curli fibrils,11 which are associated with the adhesive properties of E. coli biofilms, catalysis of melanin synthesis in mammalian melanosomes12 and human peptide hormone storage.13

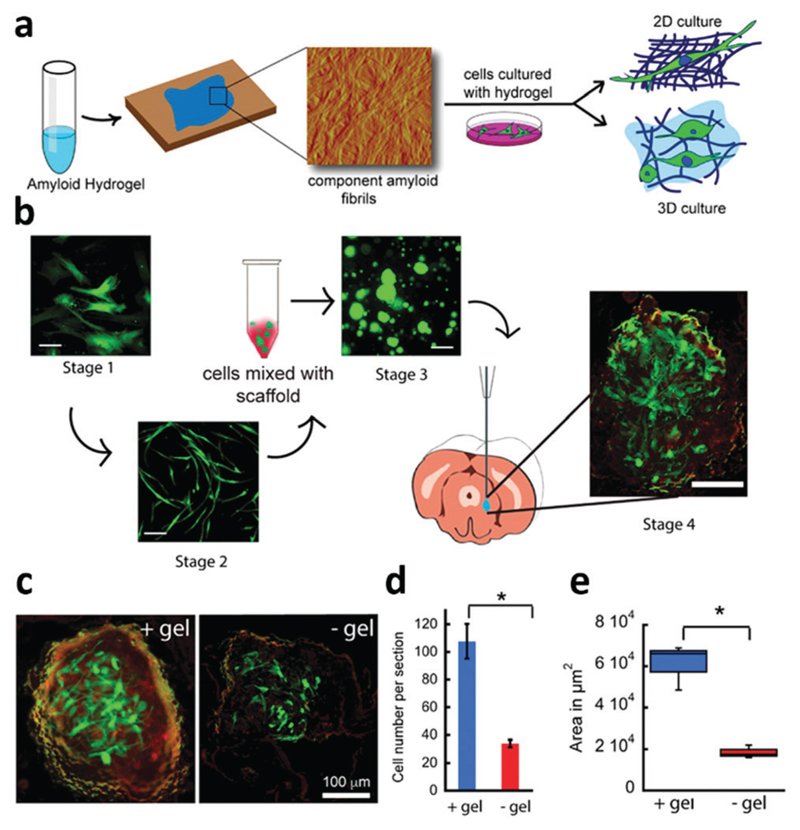

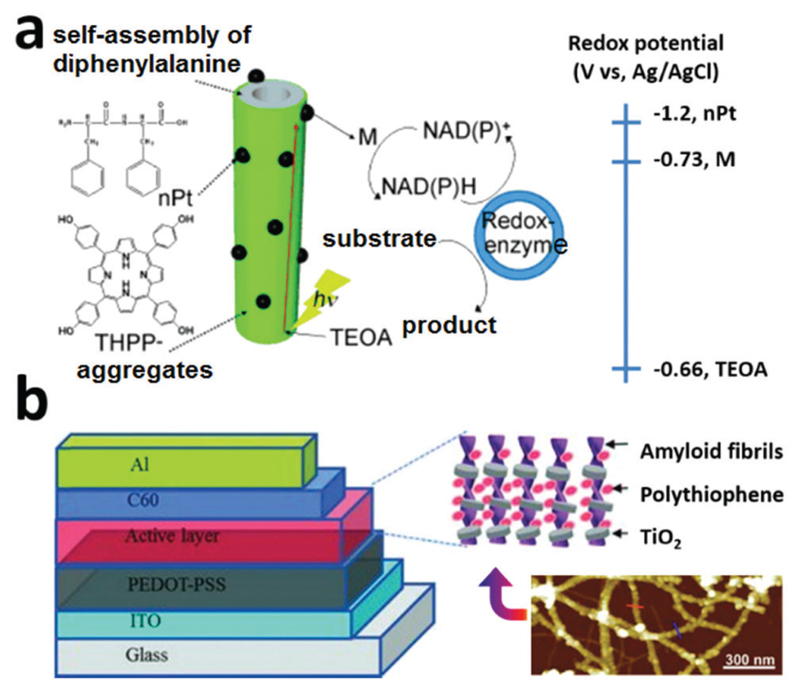

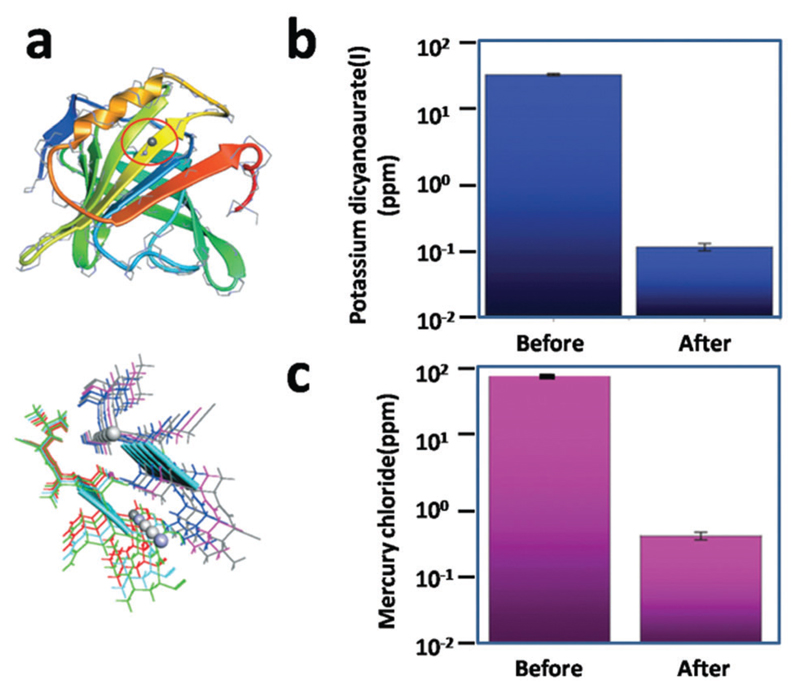

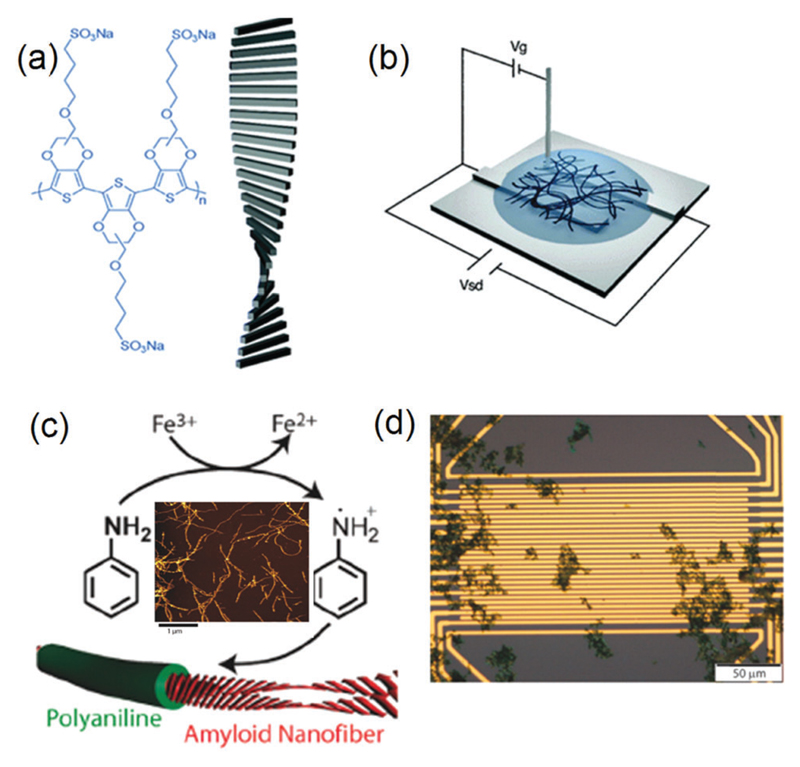

In addition to toxic and functional amyloids, in recent years there has been a growing interest in the applications of amyloid fibrils as templates or building blocks in ordered nanomaterials for biomedical, biomaterial and nanotechnological applications.14 Amyloid nanofibrils have been successfully employed as a fundamental component in biomembranes,15 functional nanodevices,16,17 hydrogels for cell culture and drug delivery,18,19 biosensors,20 functional materials with high biocompatibility and unique bio-recognition ability21,22 and as energy conversion materials.23 All the above functions and applications of amyloid fibrils arise due to their unique structural features, enabling them to serve in an extremely vast context of fundamental and applied sciences, spanning from biology to materials science and nanotechnology.

At the atomistic length-scale, the structural features of amyloid fibrils are remarkably similar,24,25 with amino acids arranged into β-strands (separated by ~4 Å) running orthogonal to the fibril axis and closely packed into β-sheets running parallel to the fibril axis (typical intersheet distance ~10–12 Å). In sharp contrast, the mesoscopic structure of amyloid fibrils shows a remarkable diversity, with a multitude of shapes and topologies, depending on the specific aggregation pathways followed.26,27 To date, nanoparticles, nanofibrils, nanotubes, ribbons, nanosheets and 3D scaffolds or multilayers represent just some of the amyloid morphologies observed.28–31 A wide spectrum of available morphologies and free energies, high surface-to-volume ratio, high density of hydrogen bonds and the presence of biocompatible amino acids on their surfaces gives amyloid fibrils a remarkable range of nanomechanical properties and applications across many scientific fields.32,33

In this review, we comprehensively analyse the relationship between the molecular mechanisms of assembly into amyloid fibrils, the resulting amyloid structure and polymorphism, and the ensuing physical properties. We then discuss how the structure and the physical properties of amyloids can be harnessed to provide applications as advanced materials in nanotechnology. In Section 2, we discuss the self-assembly and aggregation mechanisms of amyloids from unfolded proteins (e.g. α-synuclein), folded globular proteins (e.g. β-lactoglobulin) and peptides (e.g. Amyloid β, Aβ). In Section 3, we review the main structural traits of amyloids from the atomic to the mesoscopic length scale. In Sections 4 and 5, we discuss the functionality of natural and artificial amyloid materials and present the current biomedical, material and nanotechnological applications of amyloid-based hybrid materials. We conclude by highlighting the current challenges and future perspectives of amyloid-based materials and discuss the emerging fields in which amyloid fibrils are ideal candidates to contribute to their development. It is expected that this comprehensive review will forge new directions for the design, synthesis and wider applications of protein and peptide amyloid-based biological and functional materials.

2. Self-assembly and aggregation mechanisms of amyloids

The formation of amyloids can be achieved with either native folded proteins, which often have to undergo activation reactions, such as unfolding and hydrolysis before aggregating, or unfolded proteins and peptides, which under a broad range of conditions exhibit 1D growth after a fast nucleation step. In this part, we would like to introduce key information on the self-assembly and aggregation mechanisms of peptides and proteins, which include a series of microscopic events, such as protein unfolding, hydrolysis and aggregation. We describe the application of chemical kinetic studies to identify different microscopic mechanisms and we discuss the connections between aggregation mechanisms and the length distribution of the aggregate population, which are key properties defining the function of the final amyloid product.

2.1. Amyloidogenic proteins and peptides

2.1.1. Protein folding and unfolding

The formation of well-folded protein structures is central to the function of every living cell.34 Based on the information coded by DNA molecules and transcribed into messenger RNA, the ribosome synthesizes polypeptide chains of a specific amino acid sequence, which undergo internal organization to form distinct conformational arrangements. The spontaneous arrangement of the amino acid chain based on the physicochemical properties of its constituents is denoted as “protein folding”.35 The correct organization of the polypeptide chain into well-folded three-dimensional (3D) arrangements allows the proper activity of proteins, including enzymatic activity, storage, transport, sensing, signalling and structural functions. The folding of proteins into the distinct thermodynamically favourable conformations is achieved through folding pathways that hierarchically direct the protein into the lowest energy thermodynamic state. Several canonical secondary structures, such as alpha-helix and beta-sheet, constitute the tertiary folding, which is a much more complex energy-minimized molecular organization. As will be further discussed, this dogma is currently challenged as the amyloid state of proteins and polypeptides may actually represent the true energetic minimum of protein assemblies.

Even though correct protein folding is required for their biological function, under certain conditions, proteins can undergo an unfolding process, losing their tertiary as well as secondary structure.36 The unfolding can be induced physically, especially by temperature changes (mostly heating and in some cases cooling), as well as by hydrostatic pressure or chemically, by the addition of chaotropic agents (such as urea, guanidinium chloride, magnesium chloride, alcohols and detergents) that are able to disrupt the hydrogen bonding network between water molecules.

Protein unfolding can be either reversible or irreversible, depending on potential irregular interactions of the unfolded protein either within the same polypeptide chain (intramolecular interactions) or with neighbouring molecules (intermolecular interactions). The association of exposed hydrophobic surfaces is the main driving force of intermolecular interactions. Instead of a normal folding process in which the hydrophobic parts of a protein are buried in its core, many of these parts are held together by non-covalent interactions. In the case of intermolecular interactions, the molecular assemblies can form ordered assemblies, such as crystals or amyloid fibrils.37

2.1.2. Unfolded proteins

Unlike the more common case of folded proteins, many intrinsically unfolded proteins exist in a natively unfolded state, either for the entire molecule or at specific regions of the peptide chain.38–40 In such a case, the hydrophobic parts of the proteins are exposed without any external unfolding reaction. Solution-based analytical methods, including nuclear magnetic resonance (NMR) and circular dichroism (CD), have allowed the determination of the unfolded state of proteins. The use of temperature-controlled experiments allows the melting temperature to be determined. Indeed, in some cases, proteins were found to be unfolded at physiological temperature (37 °C) but completely folded at a lower temperatures (e.g. 4 °C).41,42

The basis for the existence of proteins in an unfolded state might have a clear physiological significance. For instance, one of the roles of protein unfolding is to control the physiological stability of such proteins. The fact that unfolded proteins expose hydrophobic patches, which are otherwise buried within the core of the protein, results in their identification as damaged proteins, leading to their degradation by the protein quality control machinery.43 The existence of proteins in this state allows the modulation of their half-life. In extreme cases, some protein molecules could be degraded in a few minutes. This property is useful for two-component systems, such as bacterial toxin–antitoxin systems, in which the instability of one component is critical for the physiological control of the system.44

Protein unfolding plays a critical role in at least three biological processes, such as protein translocation, protein degradation and the passive elasticity of striated muscle,45 in which the unfolding is thought to be induced by the cellular machinery pulling the polypeptide chain to better disentangle the native domains. For the amyloid fibrils formed by globular proteins, the unfolding is a necessary step to change the conformation of the protein from one minimum to another in the protein folding energy landscape.46

2.1.3. Misfolded proteins

As mentioned above, proteins can exist in an aggregated amyloid organization which was first associated with human diseases, including Alzheimer’s disease (AD), Parkinson’s disease and Type II diabetes.47 The intermolecular interaction between unfolded or partially unfolded proteins can lead to the formation of supramolecular β-sheet structures consisting of more than one protein molecule. This could be considered an abnormal organization in which a handful of proteins or polypeptide molecules join together to form ordered assemblies.

Amyloids were first identified more than a century ago in association with disease. In 1901, Dr Eugene L. Opie, an American physician, identified the formation of deposits in the pancreas of Type II diabetes patients.48 A few years later, in 1906, the deposition of biomaterial in the brain of a demented patient post mortem was found by Aloysius “Alois” Alzheimer in Germany.49 The deposits were denoted as “amyloids” (starch-like) due to their positive staining by iodine as carbohydrate deposits. Only decades later were these aggregative forms found to be made of proteins. With the advancement of electron microscopy in the 1950s, it was discovered that these protein assemblies have a typical nanoscale order. This regularity at the nanoscale underlies some of the properties that were later utilized for various technological applications, as described in this review.

The structure of amyloids, regardless of their source, is a very typical one comprising elongated supramolecular filaments with a diameter of 7–10 nm. Amyloids have a predominantly β-sheet secondary structure as determined by X-ray fibre diffraction (XRFD) and infrared or CD spectroscopy. Interestingly, both parallel and antiparallel β-sheet structures have been observed within amyloid fibrils of different sources in spite of the very uniform ultrastructure. Amyloid fibrils were also found to bind to specific dyes. Beyond their ability to be stained with iodine, later on, other amyloid-specific dyes were identified, including Thioflavin T (ThT) and Congo red.50,51 The use of Congo red is especially interesting due to the typical birefringence that is observed upon the staining of the amyloid fibrils when placed between cross-polarizers. It was suggested that proteins of unrelated origin could form remarkably similar structures in the disease state. The hypothesis was that the formation of such structures plays a role in the damage caused to various organs and tissues observed in these diseases. Indeed this “amyloid hypothesis” was supported by the observation of notable toxicity of the amyloids or their earlier soluble intermediates.

A very important extension of the “amyloid hypothesis” was provided by Dobson and co-workers who realized that non-disease-related proteins could also form typical amyloid fibrils with all the common structural and biophysical characteristics of disease-associated amyloid assemblies.52 It was thus suggested that the amyloid structure may actually reflect a generic minimal energy organization of polypeptide chains and that the structure of folded proteins is essentially a meta-stable kinetically trapped state, suggesting that most or all proteins would reach the favourable amyloidal organization at infinite time.53 This hypothetical notion was later supported empirically as it was found that most cellular proteins are at the verge of aggregation (the “life at the edge” phenomenon) and that the proteostasis of the biological system requires an advanced cellular machinery that can keep the proteins and polypeptides in a soluble state.54

2.1.4. Peptide-based amyloids

The formation of amyloid fibrils has also been identified in various functional peptides, including the islet amyloid polypeptide (37 amino acids), Amyloid β (40–42 amino acids) and human calcitonin (31 amino acids), all associated with human diseases. The aggregated form of the islet amyloid peptide is found in the pancreas of Type II diabetes patients,55 whilst aggregated forms of Aβ are found in the brain of Alzheimer’s disease patients and similar structures made of calcitonin are found in the thyroid of patients with thyroid carcinoma, all identified using electron microscopy (EM). Furthermore, the peptide amyloids were found to share all other biophysical properties of protein amyloids, including the spectroscopic features, XRFD patterns and the staining with specific dyes.

As noted above, the formation of amyloid fibrils was initially identified in naturally occurring proteins and polypeptides. A reductionist approach has since been applied to identify the minimal peptide fragments that can form amyloid fibrils. Tenidis and co-workers were able to identify hexapeptide fragments of the islet amyloid polypeptide that form amyloid fibrils.56 Later studies identified the ability of a pentapeptide fragment of calcitonin, as well as heptapeptide fragments of Aβ, to form such ordered assemblies.57

2.1.5. Peptide nanostructures and non-protein amyloids

Further reductionist approaches were used in order to identify even shorter amyloid-forming peptide motifs. It was found that the dipeptides diphenylalanine (FF) can form amyloid-related assemblies. The diphenylalanine motif is at the centre of the Aβ polypeptide associated with Alzheimer’s disease. As noted above, it was demonstrated that a heptapeptide fragment of Aβ, specifically KLVFFAE (Lys-Leu-Val-Phe-Phe-Ala-Glu), could form fibrillar assemblies, and two pentapeptide fragments, specifically KLVFF and LVFFA, are inhibitors of amyloid formation by the full-length protein.58 It was found that the nanostructures made by FF shares many functional properties with amyloid assemblies,59,60 including the intrinsic luminescence properties, the binding of amyloid-specific dyes, mechanical rigidity and the production of reactive oxygen species. This suggests that the FF nanostructures indeed represent a highly simplified model that reflects the structural, biophysical and biochemical properties of amyloid structures.28,61

Later studies identified the ability of various short peptides to form ordered assemblies. Frederix and co-workers screened over 8000 naturally occurring tripeptides for the formation of supramolecular entities using molecular dynamics simulations.62 The most aggregation-prone peptide screened was PFF (Pro-Phe-Phe), whilst many other highly aggregating peptides contained the FF motif, and to a lower extent other diaromatic motifs (including FW, WF, FY and WW). This comprehensive non-biased analysis of all peptides is consistent with the observation of the high occurrence of aromatic amino acids in short peptides that can form typical amyloid fibrils.

In order to identify the minimal requirement for amyloid formation, amino acids were also tested for their ability to self-associate. Very surprisingly, it was found that phenylalanine could form amyloid fibrils with all the characteristics of protein fibrils, including nanoscale fibrillar morphology, the binding of ThT and Congo red and notable cytotoxicity.63 X-ray crystallography suggested the formation of β-sheet like structures by this amino acid. Similar to protein amyloids, the phenylalanine amyloids were also found to bind to phospholipid membranes. Later on, it was found that other amino acids (including Trp, Tyr and Cys), as well as nucleotides and other metabolites, could also form typical amyloid-like structures.64,65 The formed assemblies reveal many ultrastructural similarities among themselves and to protein and peptide amyloids. It was therefore suggested that the amyloid hypothesis could be even further extended to include nonproteinaceous building blocks.

The simple synthesis, chemical diversity, small size and low cost make very short motifs, including tripeptides, dipeptides and single amino acids, ideal building blocks for various applications in nanoscience and nanotechnology.66,67 Moreover, the mechanical, optical, electric and piezoelectric properties of some self-assembled structures should allow their use as alternatives to inorganic components in electronic, electrooptic and electromechanical systems. The bottom-up assembly of complex nanostructures from these simple building blocks allows the utilization of fabrication techniques that were previously used in surface modification applications, including physical vapour deposition, printing using inkjet technology and unidirectional axial growth by the controlled evaporation of volatile solvents.

2.2. Factors controlling amyloid growth and kinetics

2.2.1. Solution property-mediated amyloid formation

2.2.1.1. pH-Mediated amyloids

The growth of amyloid fibrils is highly sensitive to solution conditions, including pH and the presence of salts or denaturing agents. Very careful preparation protocols have to be followed in studying the fibrillization of Aβ42, for example starting from a well-defined state of the unaggregated peptide (achieved by initial dissolution in a hydrophobic solvent) and then carefully by controlling the addition of water or buffer to a dried film.68

Typically, amyloid fibril formation by proteins is induced by reducing the pH. The aggregation of short peptides depends on the pI of the peptide or the pKa of its constituent residues and its relationship to the solution pH. It has been suggested that fibril formation is favoured when the net charge of the peptide is not too large (in the range of −1 to +1).69

A study of amylin peptide fibrillization indicates the presence of two ionizable residues: the α-amino group at the N-terminus and His18.70 The pKa values of the former unit in the amylin peptide were found to be similar to the random coil value (pKa = 8); however, the His18 residue had a pKa = 5.0, significantly lower than the random coil value pKa = 6.5. This was ascribed to the local influence of hydrophobic residues. His18 was found to act as an electrostatic switch hindering fibrillization in its charged state. An apparent pKa = 4.0 for an amylin fragment peptide, NAc-SNNFGAILSS-NH2, which contains no titratable groups, was instead ascribed to the pH-induced ionization of the amyloid-sensitive dye, ThT.

In another example, the aggregation of the amyloid β peptide Aβ1–42 was studied as a function of pH.71 This was investigated experimentally and the analysis was facilitated by molecular mechanics modelling of the fragment peptide Aβ17–42, which revealed favourable electrostatic interactions between Asp23 and Lys28 (i.e. salt bridge formation) above the pI of the peptide. The aggregation of the Aβ1–42 peptide itself was analyzed at lower pH. At pH > 9.5, aggregation was not observed because Lys28 was uncharged.71

The self-assembly of another type of amyloid-forming building block, so-called peptide amiphiphiles (PAs), can also be mediated by the solution property. PAs are designed amyloidogenic peptides modified by the attachment of hydrophobic lipid tails,72 which then show combined surfactant-like properties and a self-assembly ability.73 The pH value has a pronounced effect on the self-assembly of PAs. For example, Stupp’s group demonstrated that PAs containing acidic amino acids could be triggered to self-assemble into nanofibrils at acidic pH74 or with the use of divalent cations.75

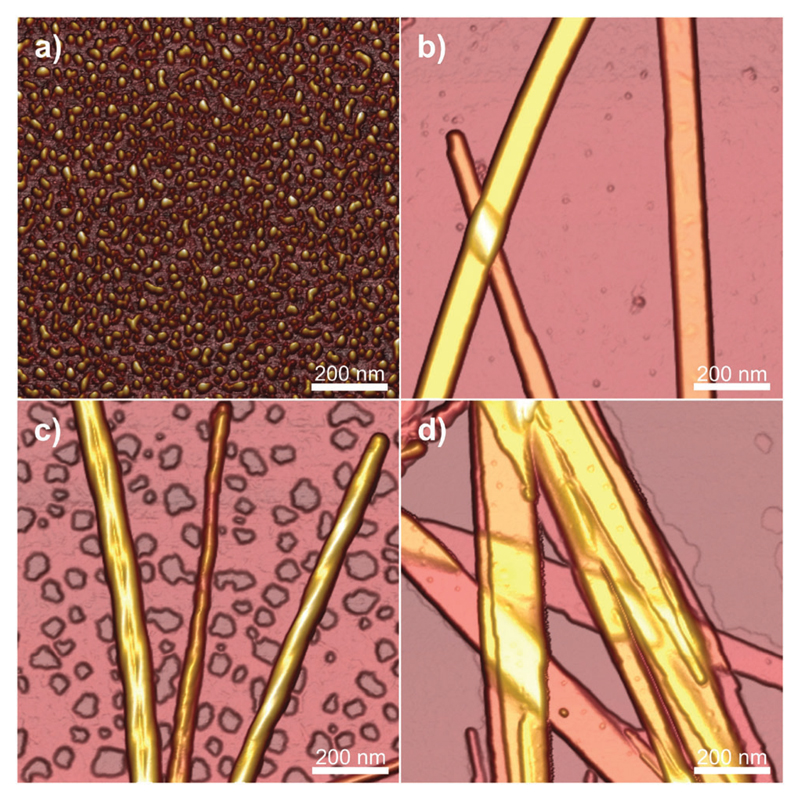

In another case, Dehsorkhi et al. found that PAs containing the pentapeptide KTTKS sequence, i.e. containing two cationic lysine residues, could be assisted to form adjustable nanostructures ranging from spherical micelles to tape-like and twisted structures by simply adjusting the pH of the solution to 2, 3, 4 and 7, respectively.76 Atomic force microscopy (AFM) was used to image the morphology at the selected pH values. It can be seen from Fig. 1 that fibrils, tapes or spherical micelles form depending on the pH (the net charge is approximately +1 at pH 7 and +2 at low pH). Small-angle X-ray scattering (SAXS) confirmed these morphology transitions and CD indicated a transition from a β-sheet conformation in fibrils and tapes to a disordered conformation at pH 2 for the spherical micelles.

Fig. 1.

Tapping mode AFM height images showing the morphology of C16-KTTKS at pH values of (a) pH 2, (b) pH 3, (c) pH 4, (d) pH 7. Reprinted with permission from ref. 76. Copyright 2013, Royal Society of Chemistry.

2.2.1.2. Ionic strength-mediated amyloids

Along with the pH dependence of amyloid formation, we also highlight a few pertinent examples in which the ionic strength of the solution also shows close effects on the formation of amyloids.

Hoyer et al. investigated, together with the effects of pH, the role of salt concentration on the in vitro aggregation of α-synuclein, and observed aggregates of varying morphologies depending on both the pH and salt concentration (NaCl and MgCl2).77 Their results indicated that the morphology of α-synuclein aggregates is highly sensitive to the solution conditions (both pH value and ionic strength). In another case, Raman et al. investigated the effect of salts such as NaCl, NaI, NaClO4 and Na2SO4 on the formation of β2-microglobulin amyloid.78 The presence of salts increased the hydrophobicity of proteins, whilst increasing the anion concentration affected the interplay between the electrostatic and hydrophobic interactions during amyloid formation. In particular SO42− ions were identified as having strong effects on amyloid formation, and this was suggested to be important in terms of the role of glycosaminoglycans and proteoglycans in amyloidogenesis. The critical aggregation concentration of β-lactoglobulin also depends on the ionic strength, and below this concentration mainly “dead-end” species are formed that consist of irreversibly denatured proteins.79 The morphology of the fibrils also changes and shorter and more flexible fibrils are formed at higher ionic strength.

The formation of peptide amyloids is also be affected by varying the ionic strength. For example, Marek et al. investigated the ionic strength effects on the formation of islet amyloid polypeptide (IAPP) fibrils.80 They suggested that the kinetics of IAPP amyloid formation is strongly dependent on the ionic strength in the range of 20–600 mM at pH 8.0. Recently, Abelein and co-workers characterized the explicit effect of ionic strength on the microscopic aggregation rates of Aβ40,81 and found that physiological ionic strength could accelerate the aggregation kinetics of Aβ40 by promoting the surface-catalyzed secondary nucleation reactions. Their results indicated that the salts could decrease the free-energy barrier for Aβ40 folding to a mature stable state, thereby favouring the formation of mature fibrils.

A recent model, based on DLVO-type colloid theory, accounts for the stability of amyloid fibril dispersions and allows for the influence of ionic strength and salt concentration (as well as the presence of organic reagents).82 The theory was used to calculate certain quantities (fibril hydrodynamic radius and Fuchs stability ratio, which describes the energy barrier between two interacting fibrils) that were then compared to experimental data for a model amphiphilic peptide (RADA 16-I).82

2.2.2. Temperature-mediated fibrillation

Heating (with or without pH adjustment to acidic conditions) is another common method of inducing amyloid formation with proteins and peptides.25 Again, there are too many studies involving heat treatment to review them all and space permits only selected examples to be discussed herein. At sufficiently high concentration, the fibrillization of peptides is accompanied by gelation. For example, β-lactoglobulin forms fibrillar gels on heating at low pH values. Particulate gels are formed at higher pH values, close to the isoelectric point where the protein has a low net charge.83,84 Cold denaturation is generally a milder form than hot denaturation and leads only to a partial unfolding of proteins85 and so, rarely, amyloid formation is reported under these conditions. However, cold denaturation can be used to dissociate amyloid fibrils, as discussed below.

PAs can show thermal transitions mediated by lipid chain melting behaviour as well as changes in the hydrogen bonding of amino acid residues, and temperature-dependent changes in solubility. In one example, conjugates of C23 or C25 alkyl chains (both containing one diacetylene unit) and the bio-derived GANPNAAG peptide sequence were shown to have very different disassembly transition temperatures on heating, as well as distinct thermosreversibility properties.86 The longer chain PA reassembled on cooling, the shorter one did not.86 The same PA C16-KTTKS discussed in the previous section also exhibited interesting temperature-mediated fibrillization below 30 °C (depending on concentration), which may be associated with the palmitoyl chain melting temperature.87 At low temperature, this compound (Tradename: Matrixyl) forms extended tape-like fibrils, but at high temperature, small spherical micelles are observed.87 The thermoresponsiveness of other lipopeptides and peptides, for example, elastin-like peptides, which undergo LCST (lower critical solution temperature) behaviour, has been reviewed elsewhere.88

The formation of amyloid fibrils by the egg-white protein ovalbumin occurs at high temperature (90 °C) and low pH, and the fibril morphology has been examined with or without NaCl.89 Two types of aggregate were observed: thin flexible worm-like fibrils or thicker periodically twisted ribbons. Differences in β-sheet content between the two were studied by CD, WAXS and Fourier transform infrared spectroscopy (FTIR) (the latter aggregate lacks amyloid characteristics). The stiffness of the two types of fibril also differs, as quantified by peak force-quantitative nanomechanical AFM.89

In another example, the fibrillization and defibrillization (‘depolymerization’) of β2-microglobulin was followed by detailed ThT fluorescence measurements.90 Incubation at 99 °C for 10 min was found to lead to complete dissociation of the fibrils into monomers. This occurred via both fibril breakage and dissociation of monomers from the fibril ends. Repolymerization experiments revealed that the number of extendable fibril ends increased significantly upon incubation at elevated temperatures. Stabilization of the fibrils using a number of additives (salts or surfactant) was examined and it was found that the anionic surfactant SDS (sodium dodecyl sulfate) could prevent fibril dissociation up to 99 °C.90

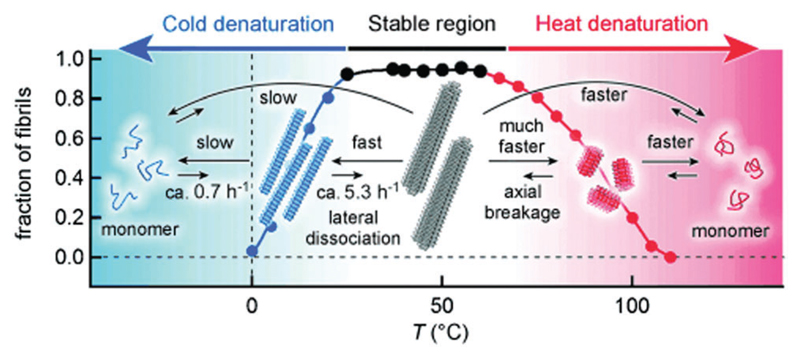

Whilst the amyloid fibrils of many peptides, such as β2-microglobulin and Aβ1–40 or Aβ1–42, undergo heat-induced breakup, cold denaturation (dissociation into monomers) was additionally observed for α-synuclein (Fig. 2).91 CD spectroscopy was used to monitor the loss of the β-sheet structure on cooling (to 0 °C), and the temperature dependence was analyzed, together with additional isothermal titration calorimetric (ITC) measurements, to provide thermodynamic information. The results suggested that cold denaturation results from the burial of charged residues in the core of α-synuclein fibrils, opposite to the case of protein folding.91 The dissociation of amyloid fibrils under cold conditions is exemplified by a study on α-synuclein in supercooled water at –15 °C.86

Fig. 2.

Schematic of the defibrillization of α-synuclein upon either cold or hot denaturing. Reprinted with permission from ref. 91. Copyright 2014, Wiley-VCH Verlag GmbH & Co.

The denaturation of insulin under extreme temperature conditions up to 140 °C was probed via CD and ThT fluorescence experiments.92 The amyloid structure was gradually replaced with a random coil structure above 80 °C until no amyloid structure was detected at 140 °C. Fibrillization was observed when the sample was cooled down to 100 °C and incubated, showing that even exposure to very high temperature, which favours full unfolding, does not lead to a completely irreversible denaturing.92

2.2.3. Organic reagent-induced fibrillation

Protein denaturing agents, such urea, salts, guanidinium hydrochloride, or surfactants (e.g. SDS) can cause amyloid fibril formation. For example, many studies on amyloid fibril formation by the prion protein PrP have involved chemical denaturants that promote non-native conformational states.93 Alcohol co-solvents generally lead to an increase in the β-sheet structure associated with the fibril formation of peptides and proteins. On the other hand, high concentrations of hexafluoroisopropanol (HFIP) or 2,2,2-trifluoroethanol (TFE) inhibit aggregation (and are widely used to disperse peptides and proteins in an unaggregated form). Acetonitrile is also reported to have an effect in inhibiting fibrillization.7

In a further example, the formation of fibrils (so-called protein nanofibres) by the extracellular matrix (ECM) adhesion protein fibronectin was observed after incubation at 37 °C in water/ethanol mixtures.94 The fibrils were used as scaffolds to deposit N-hydroxysulfosuccinimide (NHS)-modified CdSe–ZnS core–shell quantum dots (QDs), which had potential applications as biophotonic nanohybrid materials. Fibrinogen also forms fibrils by incubation at pH 2, and these were used as templates for biomineralization.95

2.2.4. Metal ion-induced fibrillation

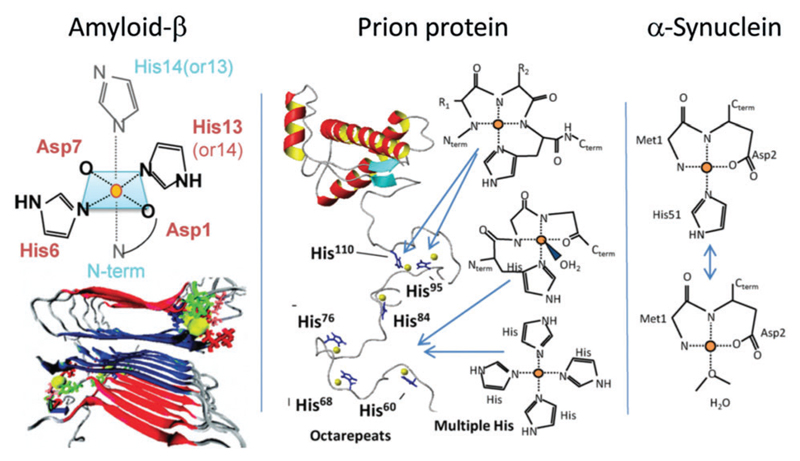

Metal ions are associated with amyloid deposits in several neurodegenerative disorders, including Alzheimer’s, Parkinsons and prion diseases. Metal ion coordination (through residues such as histidine) may cause inter-peptide cross-linking (Fig. 3 shows some possible structures), which in turn influences oligomerization and fibrillization. In Parkinson’s disease, elevated levels of copper and iron ions are found in the cerebrospinal fluid and Lewy bodies (which are intracellular inclusion bodies containing β-sheet-rich aggregates of α-synuclein).96 An early characteristic of prion disease is a metal imbalance. Here, Cu2+ has been found in scrapie isolates and confers the prion strain type.96 Furthermore, copper ions, found in trace quantities in the bloodstream, are known to bind to PrP in vivo and in vitro and to influence PrP levels in the brain. The aggregation of Aβ in Alzheimer’s disease may also be promoted by metal ions.97–101 Metal ions (e.g. Cu2+, Fe3+, Zn2+, Al3+) were found to be co-localized at abnormally high concentrations with senile plaques in AD brains.102–106 Furthermore, Aβ rapidly aggregates in the presence of physiological concentrations of Zn2+ at pH 7.4.107–109 In addition, metal ion-mediated amyloid formation is thought to be associated with inflammation in AD patients. For example, Cu2+-induced aggregation was enhanced at mildly acidic pH values associated with inflammation.109 The apparent interdependence of metal ions and amyloid assembly in AD opens up potential therapeutic targets. For instance, treatment with metal ion chelators can reduce the deposition of Aβ in brains.110–113 The majority of studies to date have focused on metal ions ability to enhance Aβ fibrillation (e.g. Cu2+, Zn2+ Al3+ and Fe3+);114 however, some studies have proposed that under certain conditions copper111,115,116 and zinc111,115 (but not iron111) ions are non-fibrillogenic. It should be noted, however, that amorphous and/or oligomeric aggregates may still be promoted through increased intramolecular bridging. This was exemplified by a study of different fragments of Aβ peptides, some of which promote fibrillization, whilst others reduce fibril formation.116 Apart from Aβ, di- and tri-valent metal ions have been shown to cause significant increases in the rate of fibril formation of α-synuclein and there appears to be a correlation to the ion charge density.117 The binding between protein and metal ions occurs via metal–ligand supramolecular interactions, which has been studied in detail for model metal ions by Bolisetty et al., both by molecular dynamic simulations and binding isotherms.118

Fig. 3.

Proposed modes of metal ion binding involved in the aggregation of the three proteins or peptides indicated. Reprinted with permission from ref. 96. Copyright 2012, Elsevier Ltd.

The subject of peptide self-assembly triggered by metal ions has been reviewed in depth.119 Many artificial ligands for metal ions have been incorporated into peptide-based molecules, and in addition the influence of metal ions on peptides incorporating natural ion-binding residues (histidine, cysteine, tryptophan or glutamic acid) has been examined. Self-assembly into different structures, including α-helix-based structures, β-turns, has been reviewed,119 but this is outside the scope of the current review.

2.2.5. Biopolymer-induced formation

Proteoglycans are an essential component of the ECM and they have important effects on amyloid aggregation in vivo, and have also been investigated in vitro. Glycosaminoglycans (GAGs) or proteoglycans are thought to be associated with AD since sulfated GAGs, such as heparin or chondroitin sulfate, are present in neuritic plaques, neurofibrillary tangles and vascular amyloid deposits.113,120–122 The binding of some sulfated GAGs can prevent the proteolytic degradation of fibrillar Aβ. Sulfated GAGs can interact with histidine residues on peptides, such as Aβ. Interestingly, sulfated GAGs can promote fibril formation due to a charge templating effect.123 It has been reported that the sulfate spacing in heparin and several other GAGs is ideal for β-sheet formation (with an associated 4.8 Å strand spacing), but this is not the case for some other polysaccharides.123 In parallel studies, it has been reported that heparin or heparin sulfate can accelerate the fibrillization of Aβ in vitro,121 probably due to electrostatic binding to a specific domain in the Aβ11–28 region.124 The influence of uncharged polysaccharides on fibril formation has been less studied, although one study suggests that glycogen can promote β-sheet formation of the prion protein.125

In a few cases, the inhibition of amyloid fibrillization by polysaccharides has been reported; for instance, κ-carrageenan forms a complex with positively charged β-lactoglobulin that partly hindered high temperature fibril formation.126 Uncomplexed β-lactoglobulin still formed fibrils, but protein–carrageenan complexes did not. Chitosan and poly(vinylsulfate) have been reported to have an inhibitory effect on Aβ1–42 fibrillization.123 The influence of proteoglycans on amyloid fibrillization is reviewed elsewhere.7,114

Linse’s group investigated the effects of polyamino acids and polyelectrolytes on Aβ fibrillization.127 They investigated the kinetics of Aβ1–42 aggregation using ThT fluorescence measurements and observed a concentration-dependent accelerating effect on the aggregation process from all the positively charged polymers examined (polyglutamic acid and polyacrylic acid). In contrast, no effect was seen for the negative polymers polylysine or poly(ethylenimine) or poly(diallyldimethyl ammonium chloride) or the neutral polymers polythreonine.127

The interaction between nucleic acids and amyloid fibrils has been investigated by several groups. DNA is known to be a powerful promotor of fibrillization due to electrostatic interactions with negatively charged residues on the DNA. The complexation of DNA with two arginine-containing molecules – one bola-amphiphile and one PA – has been examined.128 Both of these peptide-based compounds self-assemble into layered β-sheet structures with incorporated DNA, with the structural integrity of the DNA maintained.

In another example, it was shown that DNA origami nanotubes can sheathe transthyretin fragment amyloid fibrils formed within them.129 A DNA origami construct was used to form 20-helix DNA nanotubes with sufficient space for the fibrils inside.

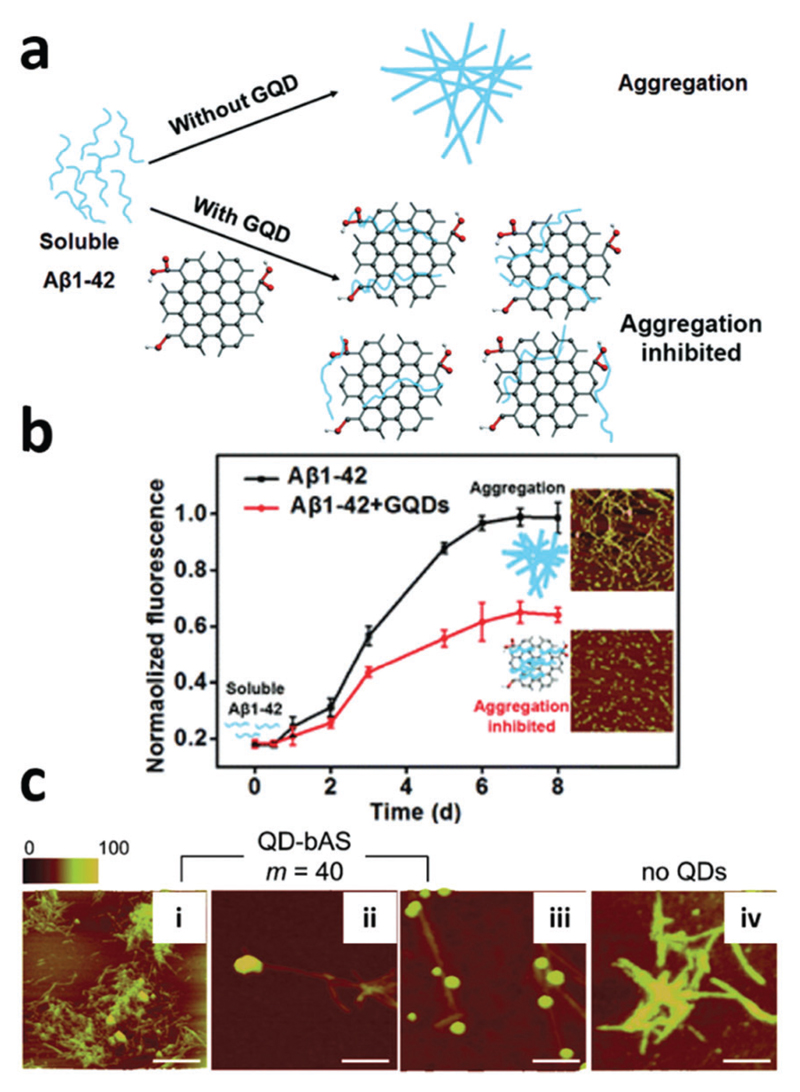

2.2.6. Nanoparticle-induced/inhibited amyloid fibrillation

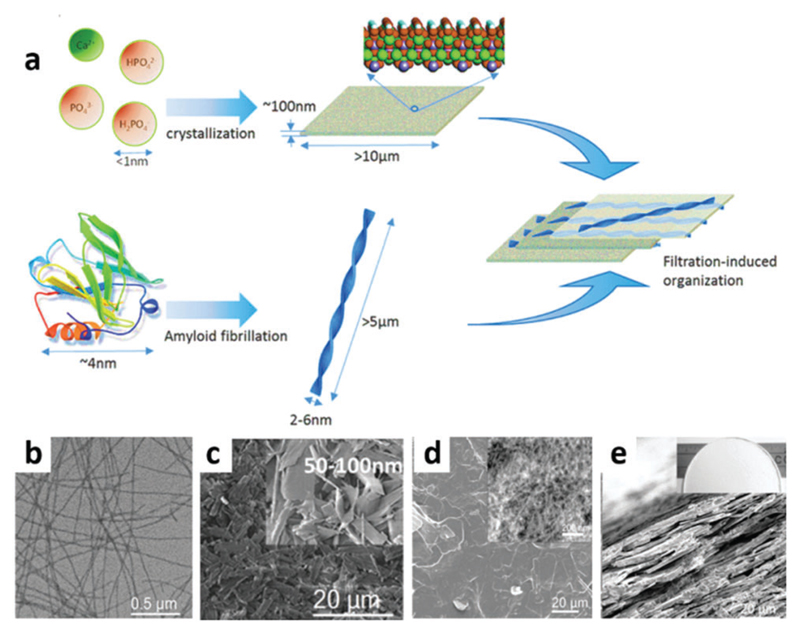

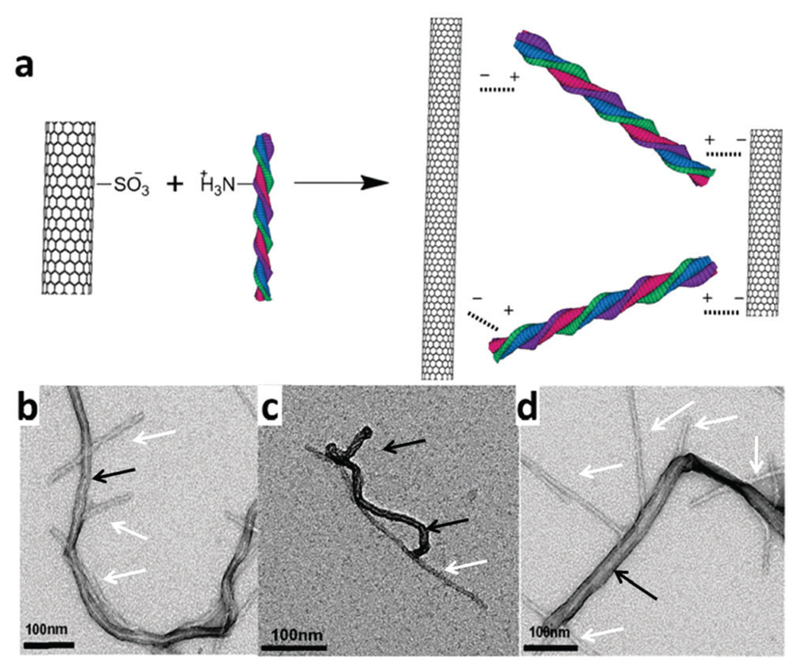

Nanoparticles can significantly influence amyloid formation as they may catalyze fibril formation due to increased local protein concentration or may inhibit aggregation when there is strong binding or a large particle/protein interaction surface area.130 In the context of a high local amyloid concentration, nanoparticle/amyloid hybrids have been proposed as model systems to understand amyloid formation under crowded conditions relevant to those observed in vivo.131 The effects of nanoparticles on amyloid formation may also be related to aspects of protein adsorption on nanoparticles in the blood stream, with relevance to nanoparticle toxicity.132 The ability of a nanoparticle to influence amyloid aggregation is dependent on the stability of the protein and its intrinsic aggregation rate.130 Amyloid fibrillization in the presence of nanoparticles with varying hydrophobicity and other surface chemistries has been examined. Polymeric nanoparticles can either increase or decrease the fibrillization of amyloid proteins, depending on the nanoparticle hydrophobicity and the unfolding behaviour of the protein and the hydrogen bonding capacity of the subunits within it.133

Polymeric nanoparticles (uncharged acrylamide-based copolymers) inhibit the fibrillization of Aβ1–40, an observation ascribed to the binding of Aβ (in monomeric or oligomeric form) to the nanoparticles.134 The binding mainly affects nucleation, and the lag time was found to be strongly influenced by the copolymer composition. The binding is due to a combination of hydrophobicity (controlled via copolymer composition) and hydrogen bonding between polar groups on the polymer and in Aβ.134 In the case of cationically (amide)-functionalized polystyrene nanoparticles, the inhibition of fibrillization is observed for high particle surface areas, whereas fibrillization is accelerated for low particle surface areas due to reduction of the lag phase.135

Inorganic nanoparticles can function as Aβ fibrillization inhibitors, although this was demonstrated with cytotoxic CdTe nanoparticles.136 On the other hand, it seems that TiO2 nanoparticles can promote Aβ fibril formation by reducing the nucleation period;137 however, the precise mechanism of this is unclear. Polyoxometalates that comprise inorganic early transition metal clusters also inhibit the aggregation of Aβ.138 Surprisingly, inorganic nanoparticles based on porous silica have been shown to penetrate the brains of fruit flies (D. melanogaster), without exhibiting neurotoxic effects, thus potentially enabling delivery across the blood–brain barrier (BBB).139 BBB permeability can be modelled using the parallel artificial membrane permeability assay, which measures the passive diffusion of small molecule through an artificial lipid membrane.140,141

There is growing evidence that metal nanoparticles may act as seeds for amyloid nucleation and growth,142 an observation which could be relevant for amyloid-related neurodegenerative diseases in the light of the fact that nanoparticles may be able to pass through the BBB. For instance, the nucleation of amyloid oligomers has been reported on gold nanorods143 for a model synthetic bacterial protein that was functionalized with a hexa-histidine tag for binding to the gold surface. Conformational changes in the bound protein were probed using surface-enhanced Raman spectroscopy (SERS), and the nucleation was ascribed to the formation of immobilized pre-amyloidogenic monomers.143 Gold and silver nanoparticles have been shown to accelerate fibril growth of the NNFGAIL peptide from human islet amyloid polypeptide and the prion protein Sup35 peptide GNNQQNY in physiological aqueous solutions.144 Large-scale molecular dynamics simulations highlighted the role of the structural reorganization of the peptide corona around the gold nanoparticles as being the rate-limiting step in the aggregation process.145

Both metal ions and metal nanoparticles could promote the formation of amyloid fibrils, but the nature of their binding with proteins is different. Metal nanoparticles adhere with amyloids predominantly through electrostatic interactions and surface tension reduction, whereas metal ions bind to amyloids via supramolecular metal–ligand interactions.

2.2.7. Interface- and mechanical-force-mediated amyloid formation

It has been suggested that fibrillization kinetics can be influenced during mixing by mass transfer effects. In addition, mixing leads to shear forces, which can then influence the growth of fibrils by perturbing the equilibrium between soluble protein molecules and proteins incorporated into fibrils, since fibrils can fragment and create new nuclei.146 The possibility to fragment fibrils by mechanical forces has been commonly exploited to produce monodispersed short amyloid fibrils by the sonication of long filaments. For instance, Chatani et al. studied this process for β2-microglobulin.147 However, (ultra)sonication is not always required to produce low dispersity (in width) amyloid fibrils, as exemplified by the protocol used by the Mezzenga group to prepare well-defined β-lactoglobulin fibrils, which does not involve sonication.148

The influence of shear on the structure and mechanical properties of amyloid fibrils of this protein has been investigated using both controlled (steady shear in a Couette cell) or uncontrolled (stirring) shear flows. It has been observed that distinct morphologies (with different mechanical behaviour) can be obtained depending on the shear conditions.149 Couette shear induces amyloid fibril formation in β-lactoglobulin starting from a spheroidal seed-like species.150 In contrast, bovine serum albumin undergoes irreversible unfolding (without amyloid formation) in Couette flow.151 The influence of mechanical stress (linear shaking) on the fibrillization kinetics and on the morphology of glucagon has been examined.152 Studies of this type highlight the need for great care in the interpretation and comparison of amyloid formation kinetic data.

Many amyloid-forming proteins and peptides have surfactant-like properties and are active at the air–water interface. This leads to the possibility of using amyloid fibrils as emulsifying agents.153,154 For example, a designed β-sheet-forming peptide containing alternating phenylalanine and charged residues was able to act as a water–oil emulsifier.153 The fibrillization of α-synuclein is enhanced at the air–water interface compared to that at a solid–liquid interface because fibrils are selectively adsorbed at the air–water interface.155 Fibril nucleation is observed even without the presence of seeds, although fibril elongation is faster in bulk when seeds are added at a sufficient concentration.155 A designed coiled-coil peptide forms α-helices at the air–water interface, which can then transform into β-sheets, either with intrinsic slow kinetics or stimulated by the addition of metal ions, such as Zn2+.156 At the interface, increasing peptide conformation or parallel alignment (by compression) of the α-helical intermediates (which tends to pre-align the β-strands) has the greatest effect on β-sheet aggregation. The metal ions actually hinder aggregation of this peptide in bulk but not at the interface.156

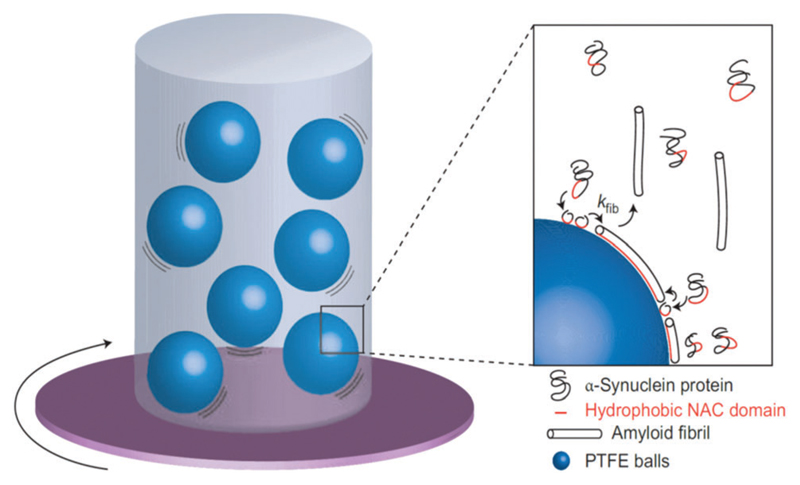

The presence of hydrophobic interfaces can influence the fibrillization of amyloid-forming proteins. Pronchik et al. studied the fibrillization of α-synuclein using a standard fluorescence dye technique used to assay amyloid formation.157 The kinetics of fibrillization in dilute aqueous solutions of the protein were monitored as a function of incubation time, the samples being subjected to agitation in the presence of different types of particles 1–2 mm in diameter (Fig. 4).158 The particles were made of borosilicate glass, which is largely inert, polymethyl-methacrylate (PMMA), which is slightly hydrophilic, or polytetrafluoroethylene (PTFE), which is hydrophobic. Some samples were also agitated in the presence of controlled volumes of air (which is hydrophobic). The fibrillization kinetics were found to depend strongly on the number of PTFE particles, i.e. to the hydrophobic surface area. The inverse lag time also increased in a non-linear fashion with the number of PTFE particles. Further nucleation and growth of fibrils was induced by the addition of PTFE particles to a sample containing fibrils that had already developed upon agitation in the presence of PTFE particles. An increase in dye fluorescence was observed in the presence of air, although fibrils were not observed using AFM. In the case of glass particles, no fibril formation was observed. Fibrillization was observed using PMMA particles, but to a much lower extent than with PTFE particles. As a further control, quiescent samples were examined and these showed no increase in ThT fluorescence in the absence of agitation. The fibrillization kinetics were proportional to the PTFE surface area, but not to the surface area of glass or PMMA. The contact angle of PTFE decreases dramatically in the presence of protein, showing that the protein coats the PTFE surface, progressively reducing the amount of available catalytically active interface. Moreover, the fact that the addition of more PTFE particles leads to the re-initiation of growth indicates that saturation of adsorption had not occurred since fibril-capable protein was still present in solution. Accelerated fibrillization was also observed in the presence of air, although the morphology of fibrils was different (globular aggregates were observed). These results clearly show the importance of hydrophobic interfaces in accelerating the fibrillization of the amyloid-forming protein α-synuclein. These findings provide an important insight to understanding the issues of sample-to-sample reproducibility that plague in vitro studies of amyloid fibrillization. The variability in morphology resulting from mixing in the presence of hydrophobic interfaces may also be important since fibril polymorphism, resulting, for instance, from sonication, has a profound effect on toxicity.159

Fig. 4.

Formation of amyloid fibrils by α-synuclein. A solution was agitated in the presence of particles of hydrophobic PTFE, slightly hydrophilic PMMA or chemically inert glass; experiments with air injected at the top of the cuvette were also performed. Inset: Proposed mechanism of the fibrillization. The aggregation of proteins into fibrils (at the rate constant kfib), caused by association of the protein hydrophobic NAC domains, is enhanced in the presence of the hydrophobic PTFE interface. Reprinted with permission from ref. 158. Copyright 2010, Nature Publishing Group.

The effect of lipid membranes on amyloid aggregation has been examined for several peptides including Aβ and α-synuclein.160,161 The importance of lipid interactions with Aβ is highlighted by the fact that apolipoprotein E (ApoE), (especially the ε4 allele) a key genetic risk factor for AD, is involved in lipid metabolism.162,163 Lipid membranes have a number of important roles in modulating amyloid fibrillization. These include: (partially) unfolding the peptide, increasing the local concentration of peptide bound to the membrane, orienting the bound protein in an aggregation-prone manner and by variation of the penetration depth into the membrane thus affecting the nucleation propensity.164 Lipid rafts are implicated in Aβ dimer and oligomer formation,165–167 and may provide platforms for the selective deposition of different Aβ aggregates (this also depends on the ordering of the lipids within the membranes, which may be different in the rafts168).169 Further information on the interaction of Aβ with membranes is available elsewhere.114

Lipid membranes are influenced by amyloid peptides and vice versa. Advanced fluorescence imaging techniques enabled membrane disruption caused by native and mutant forms of α-synuclein to be examined.170 It was shown that171 α-synuclein partially inserts into the outer leaflet of the lipid bilayer,172 and it was thought that this was due to the interaction with anionic lipid membranes.171,173 However, it was demonstrated that the protein was able to remodel lipid membranes from vesicles to tubules, even when the lipid membrane had no net charge.171

The cross-interaction of IAPP and Aβ peptides at lipid membranes has also been investigated.174 Mixed fibrils are formed at the anionic lipid raft membranes.174

2.3. Aggregation mechanisms and kinetics of proteins and peptides

2.3.1. Aggregation mechanisms of unfolded and folded proteins

In the previous sections we discussed the effect of several physicochemical parameters on the conversion of soluble monomeric peptides and proteins into insoluble amyloid fibrils. In most of these systems, the formation of amyloids is the consequence of an aggregation process under kinetic control. In this perspective, amyloid formation differs from other types of protein aggregation phenomena that are under thermodynamic control, such as protein oligomerization, precipitation and liquid–liquid phase separation. In light of this observation, the kinetics and the mechanisms of amyloid formation play a key role in determining the properties and functions of the final fibrillar products. Therefore, in order to design amyloid products with tailored functions, an understanding of the microscopic mechanisms underlying the aggregation process represents a crucial component.154

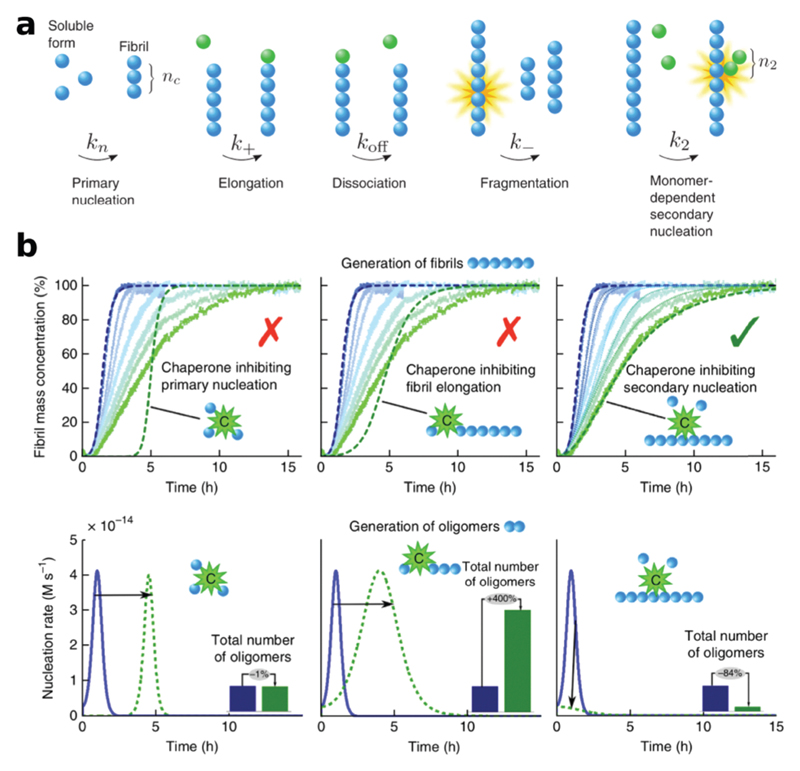

This task exhibits several challenges, since the formation of amyloids is the consequence of a complex aggregation network represented by several elementary reactions of nucleation and growth (Fig. 5a).175,176 The formation of amyloids is triggered initially by primary nucleation processes, which generate the first nuclei from soluble monomers. These nuclei can be represented by a variety of different small soluble species, which can be defined with different terminologies depending on their size, structure and reactivity. In the context of this section, we define generically this broad class of small assemblies as oligomers. Some of these species are non-reactive and off-pathway with respect to the transition into amyloids and accumulate in the system, whilst other oligomers are on-pathway and can further grow into protofibrils and eventually into mature filaments.177–179

Fig. 5.

(a) Individual microscopic events underlying the aggregation mechanisms of amyloids. (b) The identification of the aggregation mechanisms and the specific intervention on targeted microscopic reactions are fundamental for the rational design of tailored functions. This concept is illustrated here with the example of the peptide Aβ1–42, for which the generation of particularly active species can be modulated by inhibiting different microscopic steps. Reprinted with permission from ref. 225. Copyright 2015 Nature Publishing Group.

In the vast majority of amyloid systems, fibril growth occurs via elongation reactions, where a monomeric unit is incorporated at the end of an existing fibril via a diffusion motion over an energetic barrier.180 This process can in principle be reversible. However, the dissociation of monomers from fibrils is typically negligible, given the high thermodynamic stability of the fibrillar structure. In a very few cases, fibril growth can occur via fibril–fibril aggregation, as observed for amphiphilic peptides exhibiting complementary defects at the fibril ends.181

In addition to primary nucleation reactions, secondary nucleation processes have been increasingly identified in the aggregation of several amyloidogenic peptides. Such secondary nucleation processes involve typically the fragmentation of fibrils induced by either thermal energy or mechanical forces.146,182 These breakage events multiply the number of fibrils and increase the concentration of reactive fibril ends that can recruit monomers and elongate. Another common secondary nucleation process, originally identified in seminal studies on sickle haemoglobin,183 involves the generation of new oligomers catalyzed by the presence of the surfaces of existing fibrils.184–187 Such a surface-induced secondary process has been demonstrated to account for most of the production of toxic species during the aggregation of the peptide Aβ185 and, under certain conditions, also of α-synuclein.188 Importantly, these mechanisms of aggregation, commonly identified in vitro, are recently starting to find correlations also in in vivo studies performed using worms189 and mice models.190

The generic aggregation mechanism described above applies to both unfolded and globular proteins forming amyloids. A key difference between these two classes of proteins, however, is related to the monomeric form responsible for initiating and propagating aggregation. Indeed, short peptides and largely unstructured proteins are typically prone to form amyloid fibrils without the requirement of major conformational changes.54,191 In contrast, the formation of amyloids from proteins that are largely folded follows typically a pre-aggregation event that triggers the conversion of the native form into an aberrant conformation that is more aggregation-prone.

One of the most common events is protein misfolding, i.e. the conformational change of the initially folded state into an unfolded or partially folded intermediate.192–194 This is the case, for instance, for insulin,195–198 lysozyme,199,200 β2-microglobulin,201,202 enzyme superoxide dismutase (SOD1)203 and light chain immunoglobulin,204 which have been observed to form fibrils under conditions that promote the formation of partially folded species.

Other reactions that can trigger the formation of amyloids from globular proteins involve truncation of the protein205 or hydrolysis of the original polypeptide sequence into smaller fragments. For instance, lysozyme206,207 and β-lactoglobulin206,208,209 have been shown to form amyloid fibrils under acidic conditions after hydrolysis of the full-length protein into smaller peptides. In particular, two classes of peptides can be identified based on their reactivity: a series of peptides that convert over time into amyloids and a second sub-class that does not aggregate and remains soluble.208,209 An analogous system is represented by the amyloidogenic peptides Aβ1–40 and Aβ1–42, which are generated from the enzymatic cleavage of the amyloid precursor protein (APP).114 The higher aggregation propensity of short peptides with respect to the precursor globular protein is not surprising, since steric constraints disfavour the thermodynamic stability of amyloid fibrils with respect to the soluble state for polypeptide sequences longer than 100 residues.54 Indeed, for large globular proteins, such as immunoglobulins, the formation of amorphous fractal-like aggregates rather than fibrils is typically more favoured.210–212

The formation of individual amyloid filaments can be followed by additional supramolecular events, leading to the generation of 2D and 3D amyloids. These additional processes include lateral fibril–fibril association206 as well as the formation of nematic phases213,214 and gels.154,215 This rich phase behaviour opens a route to finely tuning the morphology and the mechanical properties of supramolecular fibrillar hydrogels and other soft materials by carefully controlling the individual events underlying the aggregation process. This observation highlights once more the importance of identifying the aggregation mechanisms to allow rational design in structure–function studies of amyloid materials.

An attractive strategy to modulate the aggregation mechanisms in a tailored way consists of introducing into the system suitable reactive species. For instance, aggregation reactions can be seeded by adding preformed fibrils or other non-native species, which can trigger the aggregation of physiological monomers following prion-like mechanisms. As discussed previously, other important heterogeneous nucleation events involve the presence of air–water interfaces,155 hydrophobic surfaces157,216 and vesicles,160 which are particularly prone to trigger the formation of amyloid fibrils, although the exact mechanisms underlying these effects are only starting to be elucidated.

We conclude this paragraph by highlighting two emerging directions in amyloid mechanistic studies: a first activity is aimed at increasing our understanding of the microscopic steps underlying the generation of the oligomers.217 This topic is clearly relevant to understand the toxicity associated with the aggregation process in biological systems, and is also crucial to clarify the safety issues associated with the use of amyloid biomaterials for healthcare applications. A second important direction is the description of the behaviour of proteins at high concentrations, which underlies several biotechnological and biological applications. Indeed, under these conditions, the quaternary state of proteins is governed by complex physics, since an increase in protein concentration can both change the phase diagrams and accelerate the rate of nucleation and growth reactions by increasing the activities of the reagents. There is therefore a need to correlate the thermodynamic phase behaviour with the kinetic aspects of the aggregation processes.

2.3.2. Identifying aggregation mechanisms from kinetic studies

In order to identify the microscopic aggregation mechanisms in a particular system, it would be convenient to fully characterize the large class of intermediate species populated during the aggregation process. However, several of these intermediate species are transient and present at low concentrations, and therefore are challenging to characterize experimentally. Indeed, biophysical assays for structural studies are typically well suited to characterize only the initially soluble monomeric state and the final insoluble fibrillar aggregates.

To address this limitation, in analogy with other branches of chemistry and protein biophysics, chemical kinetics is emerging as a powerful tool to investigate amyloid aggregation mechanisms at the molecular level from the measurements of macroscopic rate laws.146,193,218 By recording the global aggregation profiles at different protein concentrations, the reaction orders can be extracted, and compared with integrated laws based on mathematical models describing different microscopic mechanisms.219 One of the greatest advantages of this method is the possibility to extract information on multiple microscopic events of nucleation and growth from a limited number of experimental macroscopic read-outs, which typically include the monomer conversion or the total amount of aggregates formed over time.

For instance, high-throughput assays have been well established to monitor the formation over time of the total fibril content. A conventional method is based on a ThT fluorescent assay,220,221 which relies on an increase in the fluorescence yield of the dye upon binding to the characteristic β-sheet structure of the fibrils. The time evolution of the total fibril content typically exhibits a sigmoidal profile, where a lag phase is followed by an exponential growth regime and eventually by a plateau related to consumption of the soluble monomer. It is important to note that the microscopic reactions described in the previous section are present during all the stages of the aggregation process, even at the early beginning of the reaction. Indeed, although it may be tempting to consider the lag phase as a waiting time, this period represents the time required by the fibrils to reach a critical concentration that is detectable by the experimental assay.222,223

The application of chemical kinetics in amyloids has been hampered for a long time by the complexity of the non-linear aggregation scheme described in the previous paragraph, which has challenged the derivation of analytical rate laws. Moreover, the high sensitivity of amyloids to several physicochemical factors complicates the establishment of robust kinetic assays, which often suffer from irreproducibility issues. Advances in theoretical analysis,146 and the development of optimized experimental protocols,224 however, have recently opened the possibility to apply the kinetic platform to several amyloidogenic systems, leading to the identification of the aggregation mechanisms under a broad range of conditions.

An attractive advantage of kinetic studies is the high sensitivity in detecting, also with high resolution, changes in the aggregation mechanisms derived from modulation of the reagent composition or of intrinsic and extrinsic factors.160,185,188,189,225–227

Of particular interest is the analysis of the changes in the aggregation mechanisms in the presence of inhibitors of amyloid formation. This information is particularly important in the biomedical context of the search for drugs to fight against amyloid-related disorders, where a kinetic inhibition of the aggregation process can represent an effective strategy to avoid the onset and development of the associated disorders over a characteristic lifespan.114 It is becoming apparent, however, that this approach cannot be achieved simply by a generic inhibition of the aggregation process but requires a specific intervention aimed at targeting specific microscopic events that are most responsible for the formation of toxic species, in particular oligomers.228 In this context, the application of chemical kinetics is fundamental to identifying the specific processes that are affected by the presence of different modulators.228,229

A recent example of the importance of this activity has been demonstrated with the peptide Aβ1–42, whereby the application of chemical kinetics and the understanding of the microscopic mechanisms underlying the aggregation process has opened the possibility to tune in a controlled way the generation of specific intermediates characterized by a particularly high level of toxicity, as shown in Fig. 5b.225 This platform allowed the identification of a biological molecule that can selectively suppress the secondary nucleation reaction and therefore the generation of the oligomers. By contrast, the specific targeting of primary nucleation and the elongation rate, although equally efficient in delaying the formation of the fibril amount (top panels), cannot deplete the oligomer formation (bottom panels). This outcome would have not been achievable by means of experimental characterization alone, and thus highlights the importance of theoretical mechanistic frameworks in the structure–activity studies of amyloids.

It is envisioned that in the near future improvements in experimental assays to detect oligomers217,230,231 will enable researchers to perform kinetic studies specific to these species, thereby improving the understanding of the microscopic steps responsible for the formation of these important intermediates.

2.3.3. Aggregation mechanisms and fibril length distribution

In the previous paragraphs, we discussed the importance of identifying aggregation mechanisms in amyloids and we described the use of chemical kinetics as one of the major tools to perform this operation. A particularly important aspect of these activities that deserves special attention in material sciences is the characterization of the time evolution of the fibril length distribution. Indeed, fibrils with different lengths are associated with drastically different mechanical properties and activities, including different toxicity in biological systems.232

From an experimental point of view, different techniques have been successfully applied to characterize the fibril length of amyloids. Single-molecule imaging techniques, including AFM,209,233–237 EM225 and super resolution fluorescence microscopy,238,239 provide a high level of resolution by analysis of a large number of individual filaments. Alternative bulk methods have also been recently developed based on the indirect evaluation of the fibril length from measurements of the physicochemical properties, such as the rotational240 or translational diffusion coefficient241,242 or the sedimentation coefficient.243–247

In addition to the improvements in the experimental characterization, recent progress in the analytical treatment of kinetic models has allowed the derivation of compact expressions describing the dependence of the fibril length distribution on key kinetic parameters.248,249 Experimental information on the full-length distribution provides a large number of constraints for comparisons to be made between model simulations and experimental data. Thereby, the robustness and the refinement of the derived aggregation mechanisms are significantly increased with respect to kinetic analysis that relies only on the comparison with a limited number of average quantities of the fibril population. These more refined models lead to a better understanding of the relationship between aggregation mechanisms, the fibril length distribution and product functions.

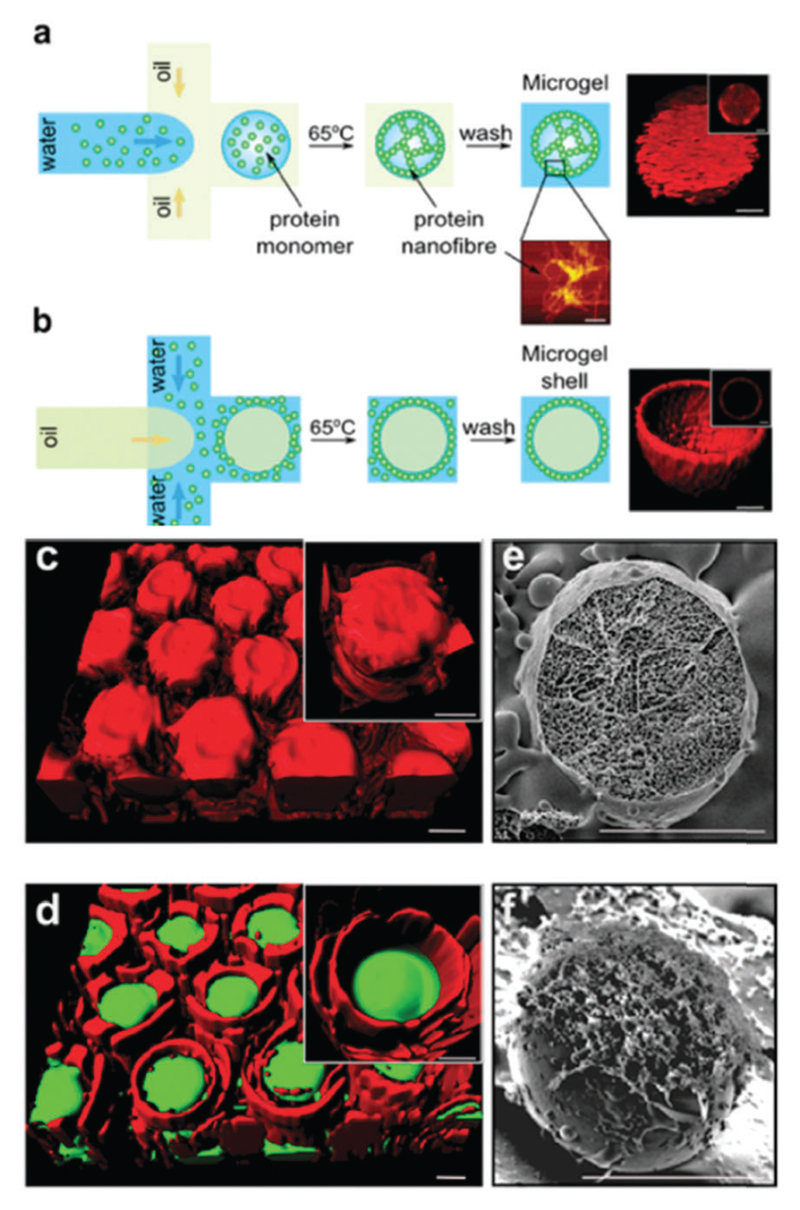

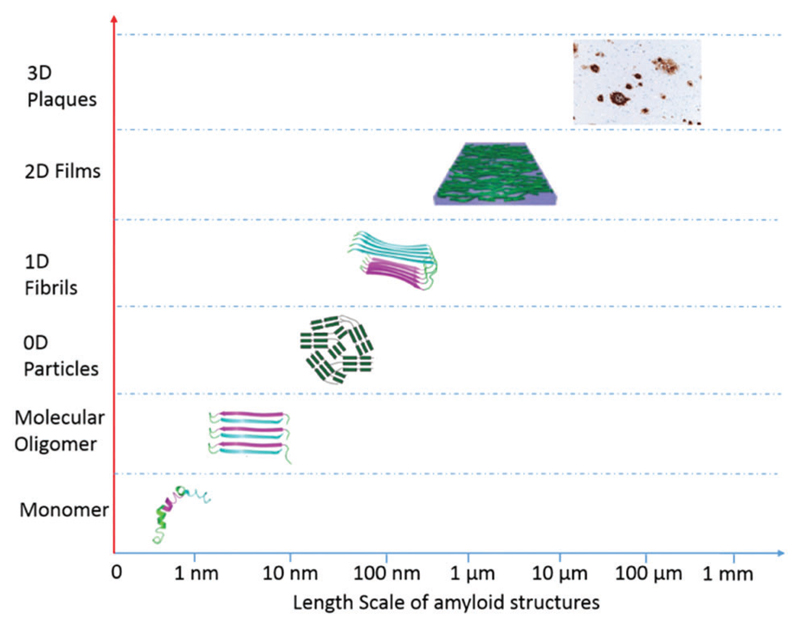

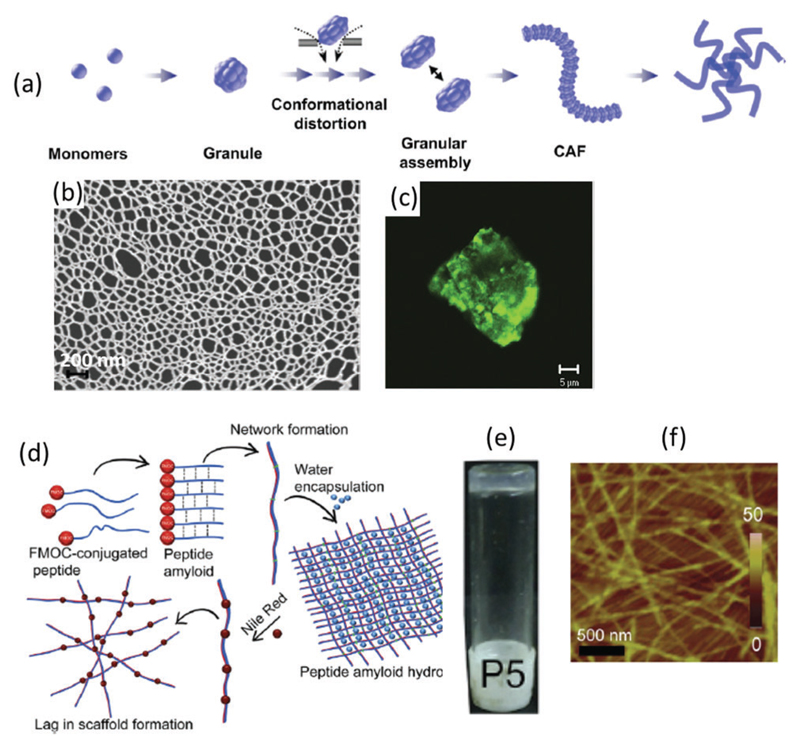

3. Atomic to mesoscopic structure of protein and peptide amyloids

In the above part, we demonstrated and discussed the various self-assembly and aggregation mechanisms of amyloid-forming proteins and peptides. It is clear that small differences in molecular aggregation and self-assembly are responsible for the formation of a wide variety of amyloid nanostructures. Recently, Luo and co-workers reviewed recent advances in the protein assembly for the fabrication of various nanostructures by biotechnological and chemical strategies.250 Although that review did not focus specifically on amyloid fibrils, it reviewed the state of the art on the use of protein assemblies as versatile platforms for designing attractive functional nanostructures. In this section, we focus on the atomistic to mesoscopic structures of a number of amyloid assemblies, including molecular oligomers, 0D aggregates (nanoclusters, nanoparticles, nanotriangles, squares and loops), 1D aggregates (protofibrils, nanofibrils, nanoribbons and nanotubes), 2D aggregates (sheets, films and membranes) and 3D amyloid plaques and scaffolds.

3.1. Amyloid oligomers

Due to their ubiquitous presence in the brains of patients suffering from many neurodegenerative diseases and their apparent cytotoxicity in vitro, insoluble peptide and protein amyloid aggregates were assumed to be the cytotoxic culprit in these diseases.251 However, new evidence suggests that prefibrillar soluble amyloid oligomers with low molecular weight could be the primary toxic species responsible for neuron death in both Alzheimer’s and Parkinson’s disease.114,252,253 Although there is no universal consensus on what constitutes an amyloid oligomer, they can typically be considered to possess some or all of the following biochemical and biophysical characteristics:254 they are molecular aggregates with β-sheet-rich structures composed of between 2 and 30 assembled monomers; they possess various sizes and morphologies, are soluble in aqueous solutions; their morphology is polymorphic and time-dependent and they can aggregate into long, stable mature amyloid fibrils. Previously, a number of excellent review articles on the structure, formation mechanism and toxicity of natural and artificial amyloid oligomers have been reported.114,255,256

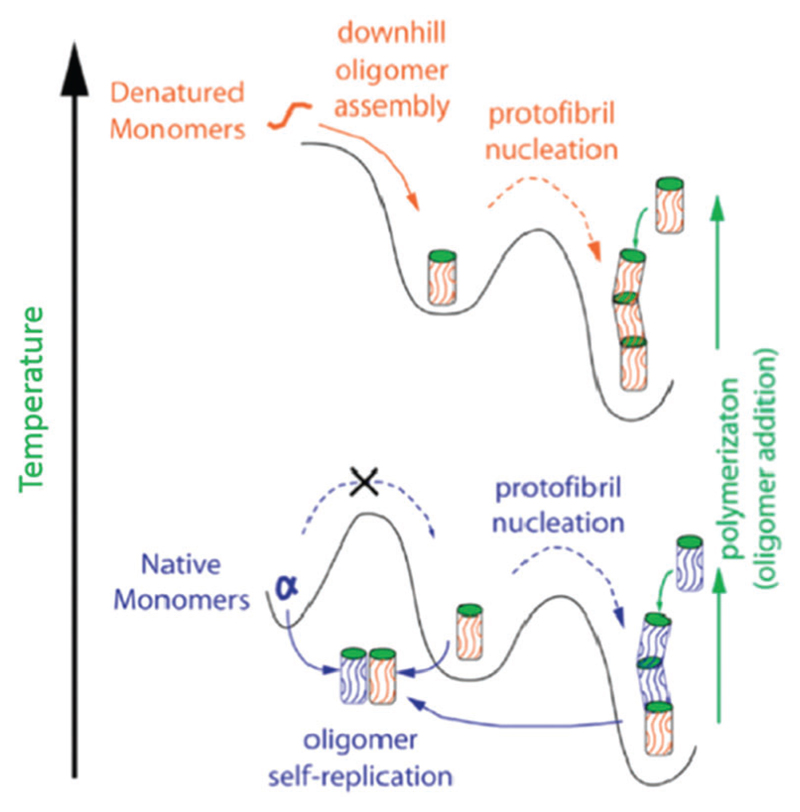

A range of techniques, including AFM,257 EM,258 attenuated total reflection (ATR)-FTIR,259 NMR260 and single particle confocal microscopy,261 have been used to investigate oligomeric structures and the conformational transition between oligomers and mature fibrils. Mulaj et al. combined ThT fluorescence assays, static and dynamic light scattering (S/DLS), AFM and ATR-FTIR to assess the stability, kinetics and structure of hen egg-white lysozyme during its transition from oligomeric species to protofibrils and nanofibrils.257 They found that the amyloid oligomers and protofibrils but not latter stage filaments were responsible for the amyloid growth at both physiological and denaturing temperatures, as shown in Fig. 6. Their results led them to suggest that at physiological temperatures amyloid seeds cannot form spontaneously from native lysozyme monomers. Oligomer self-replication from native monomers at physiological temperature is required to promote protofibril nucleation and the further assembly into mature nanofibrils (bottom part of Fig. 6), which can also be created by using the denatured monomers and thus elevated temperatures (upper part of Fig. 6). This study outlined the self-replication ability of amyloid oligomers and protofibrils as distinct assembly pathways, and is important for understanding the molecular mechanisms and aggregation behaviour of both pathological and functional amyloid materials.

Fig. 6.

Schematic assembly pathways of lysozyme oligomers at both denaturing and native temperatures. Reprinted with permission from ref. 257. Copyright 2014, American Chemical Society.

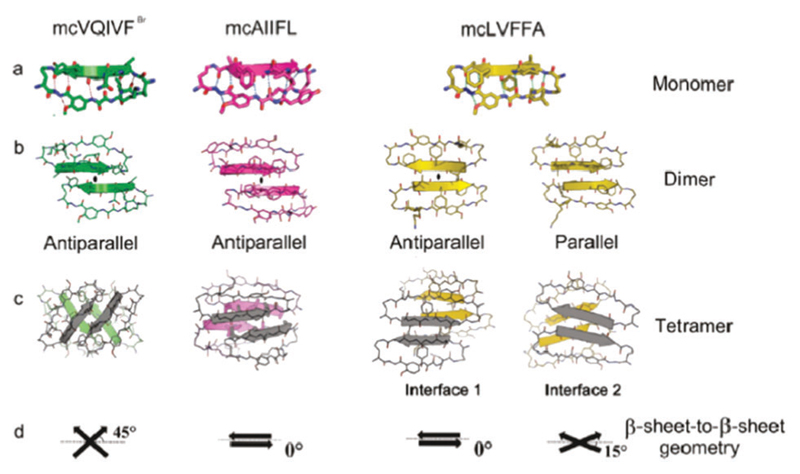

X-ray crystallography and computer simulations have been widely utilized to investigate the atomic structure of amyloid oligomers that can assemble into crystalline morphologies.254,262,263 Liu and co-workers designed a series of macrocyclic peptides based on Aβ and Tau proteins (associated with AD) that formed amyloid oligomers with a crystalline morphology.254 Fig. 7 shows the atomistic structures of three macrocyclic peptides: mcVQIVFBr, mcAIIFL and mcLVFFA, as monomers (Fig. 7a), dimers (Fig. 7b) and tetramers (Fig. 7c) as determined by X-ray crystallography and atomistic simulations. In the monomers, the interactions between the neighbouring strands are limited to the backbone hydrogen bonding (a typical β-sheet structure). For the dimers, the formed intermolecular β-sheets could be aligned in either parallel or antiparallel orientations via hydrogen bonding interactions. In addition, tetramers could be formed by the complementary side-chain interactions of dimers with different molecular packing geometries, as shown in Fig. 7c and d. These findings are helpful for understanding the assembly of amyloidogenic oligomers at the atomic level and offer clues for the design of structure-based therapeutics against amyloid diseases. More recently, the same authors solved the crystal structure of a toxic amyloid oligomer of an 11-residue segment (KVKVLGDVIEV) from the Aβ protein.262 Separately, Domanska et al. demonstrated the utility of nanobodies to trap and characterize the crystalline intermediates of β2-microglobulin amyloids by X-ray crystallography.263

Fig. 7.

(a–c) Crystal structure of macrocyclic peptides with (a) monomer, (b) dimer, and (c) tetramer. (d) Several interaction modes of dimers to form a tetramer. Reprinted with permission from ref. 254. Copyright 2011 American Chemical Society.

Amyloid oligomers with distinct molecular structure and morphology can be created by altering the assembly environment (e.g. temperature, pH) and changing the pathways of monomer aggregation. Alternatively, aggregation can be modified by promoting interactions between protein/peptide monomers with additional biomolecules (e.g. non-amyloid proteins or macromolecular sugars).264 Elucidating the structure of these oligomeric species at the atomic level will promote an understanding of the formation mechanisms and toxicity of amyloid structures.

3.2. 0D amyloid aggregates

By 0D objects we refer to aggregates/clusters, in which there is not a dominant dimensional feature, as in 1D or 2D objects, but for which self-limiting size is observed, differently from 3D aggregates. Numerous 0D amyloid aggregates have been generated in vitro. Observed morphologies include nanoparticles,265–268 nanospheres,269,270 loops, triangles, squares and rings.271–273 In this section, we review the main preparation strategies for these nanostructures and their corresponding formation mechanisms.

3.2.1. Nanoparticles and nanospheres

Prefibrillar amyloid structures, such as spheroidal aggregates (nanoparticles and nanospheres), similar to the molecular oligomers introduced previously, have been frequently proposed to be a highly cytotoxic species in many neurodegenerative diseases.265,274 Silveira and co-workers degraded large prion protein (PrP) aggregates into smaller PrP nanoparticles with sizes ranging from 17 to 27 nm,265 and then characterized the PrP nanoparticles with DLS, non-denaturing gel electrophoresis and transmission electron microscopy (TEM). Their findings suggested that the PrP nanoparticles with masses equivalent to 14–28 PrP molecules are the most infectious initiators for prion diseases. In another study, EI Moustaine et al. formed amyloid nanofibrils and nanoparticles from recombinant PrP at high pressure.266 This study provided insights into the initial molecular processes that lead to misfolding and eventually self-assembly into higher order structures.

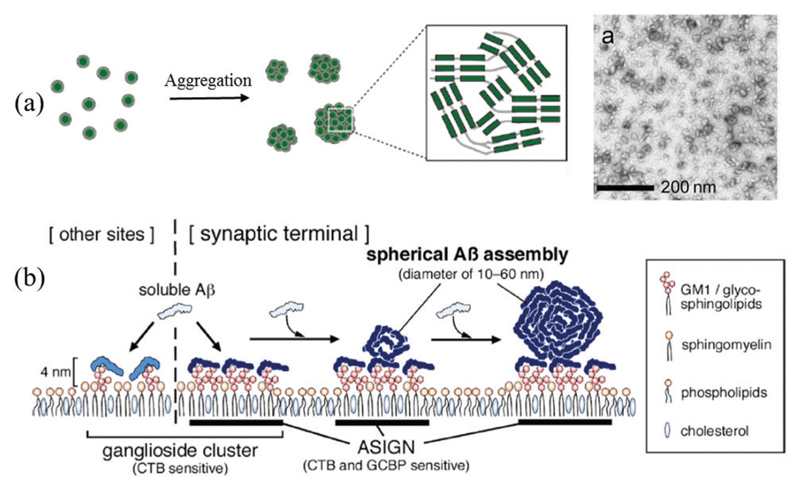

Other strategies besides elevated pressure and the degradation of larger aggregates have been investigated for amyloid–nanoparticle fabrication. Fändrich et al. reported the creation of Aβ1–40 amyloid peptide nanoparticles by a simple self-aggregation method (Fig. 8a).267,268 Typically, Aβ1–40 with a concentration of 2.5 mg mL−1 was first dissolved in 100% HFIP, and the solution was diluted 10-fold with ultrapure water after 10 min incubation. Amyloid nanoparticles with sizes ranging from 15 to 30 nm were formed after a further 15 min incubation, as shown in the TEM image in Fig. 8a. In another study, Guo and co-workers reported that it is theoretically possible for triphenylalanine (FFF)-based peptides to self-assemble into nanospheres using large-scale coarse-grained molecular dynamics simulations.269 The simulations showed that the FFF nanospheres were formed and stabilized by peptide–peptide electrostatic interactions, vdW interactions and strong peptide–solvent interactions.

Fig. 8.

Typical strategies for creating 0D amyloid (a) nanoparticles and (b) nanoclusters: (a) Aβ oligomer self-aggregation, (b) lipid bilayer membrane-induced Aβ assembly. CTB is cholera toxin B subunit. ASIGN is Aβ-sensitive ganglioside nanocluster. Images (a and b) are reproduced with permission from (a) ref. 268, Copyright 2014, American Chemical Society, and (b) ref. 270, Copyright 2013, American Chemical Society.

Matsubara and co-workers demonstrated that Aβ1–40 peptides can be induced to self-assemble into nanospheres on synapsemimicking lipid membranes (Fig. 8b).270 They showed that Aβ binding and assembly was promoted on GM1 lipid domains. This was found to be due to the presence of an Aβ-sensitive ganglioside nanocluster (ASIGN) within the glycosphingolipids (GM1) domain. The corresponding AFM images indicated that a thin Aβ layer and Aβ nanospheres were formed simultaneously. This study outlines a possible lipid-mediated assembly mechanism of Aβ proteins that may occur in the AD brain.

3.2.2. Annular oligomers: loops, triangles, squares and rings

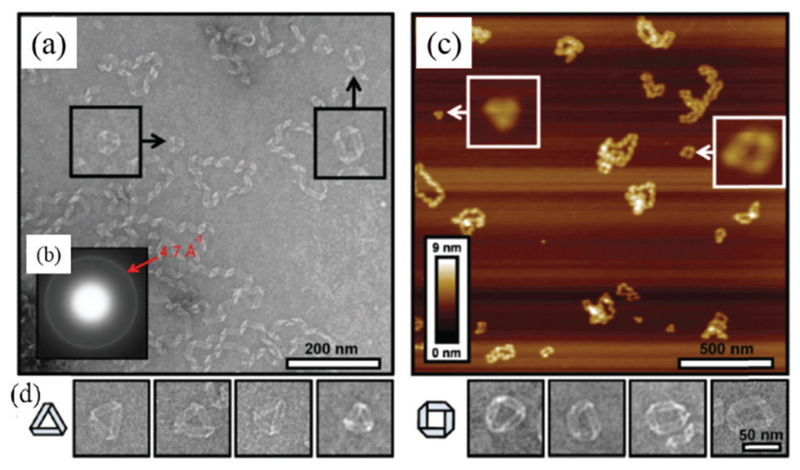

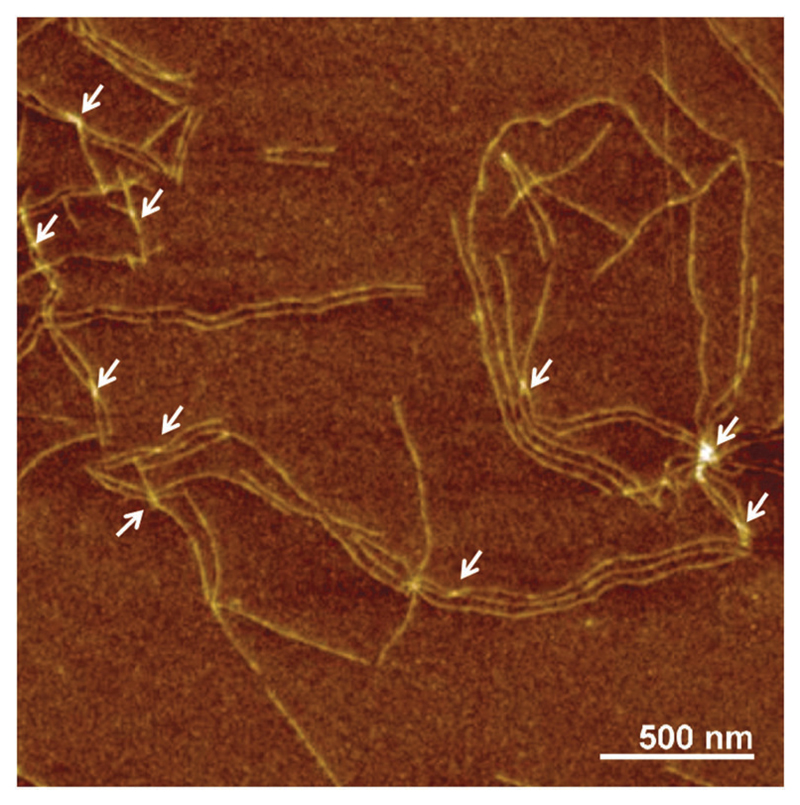

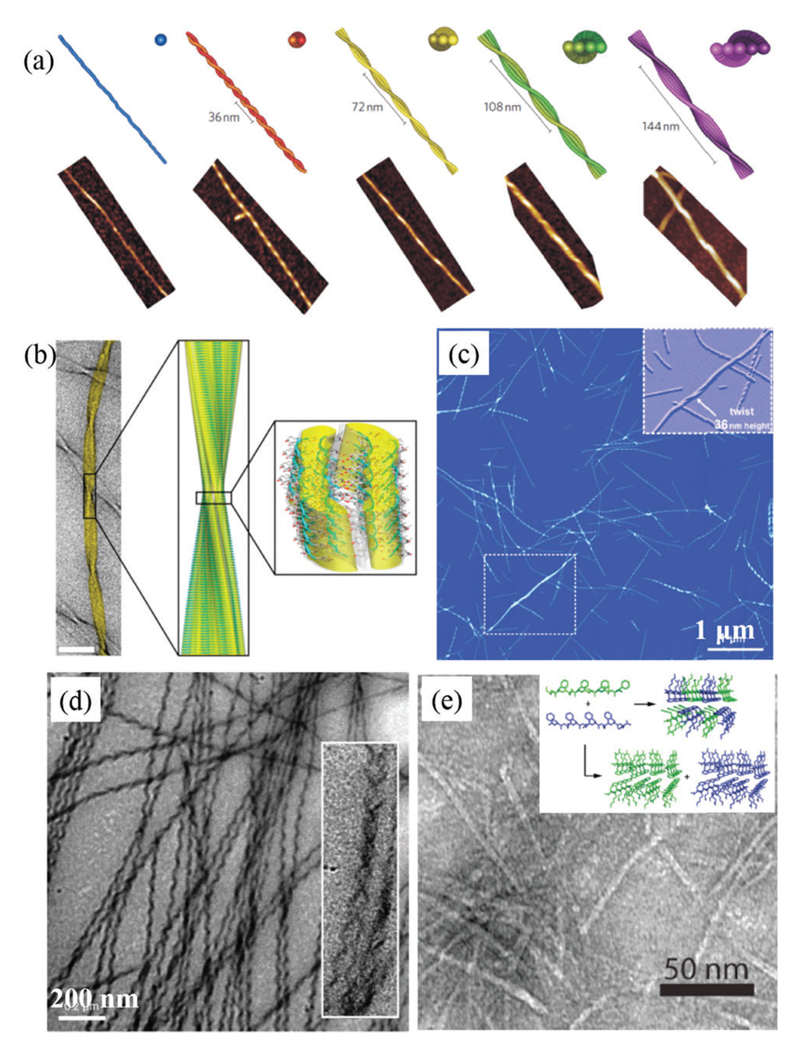

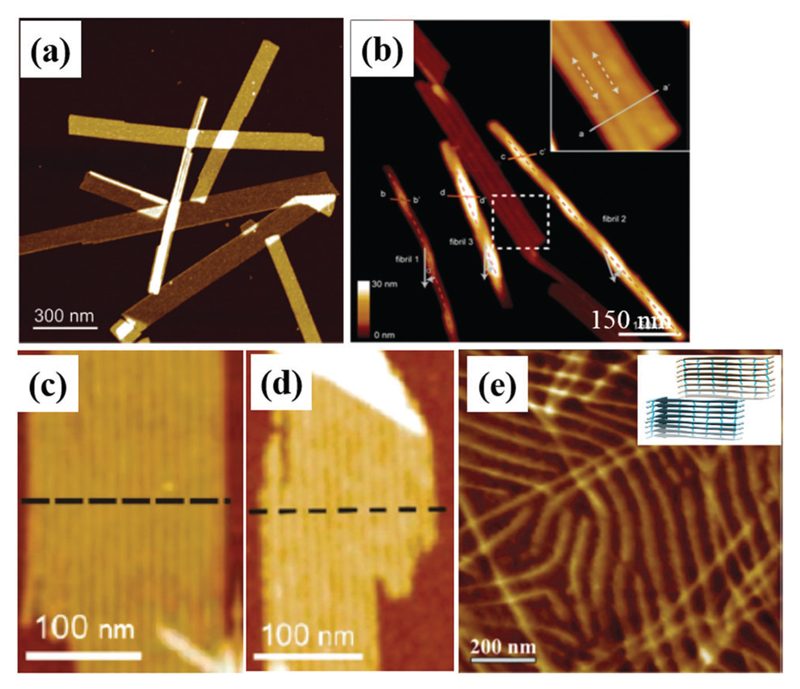

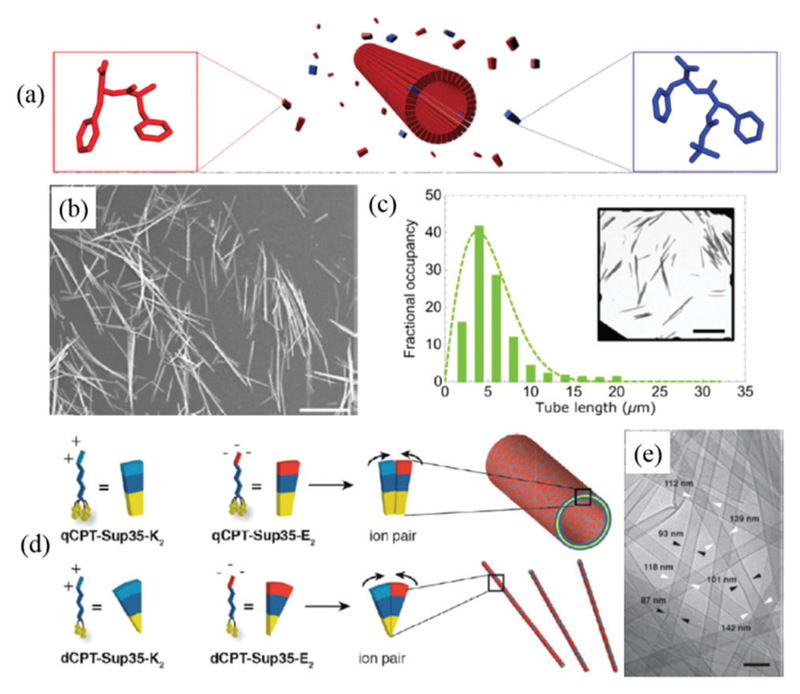

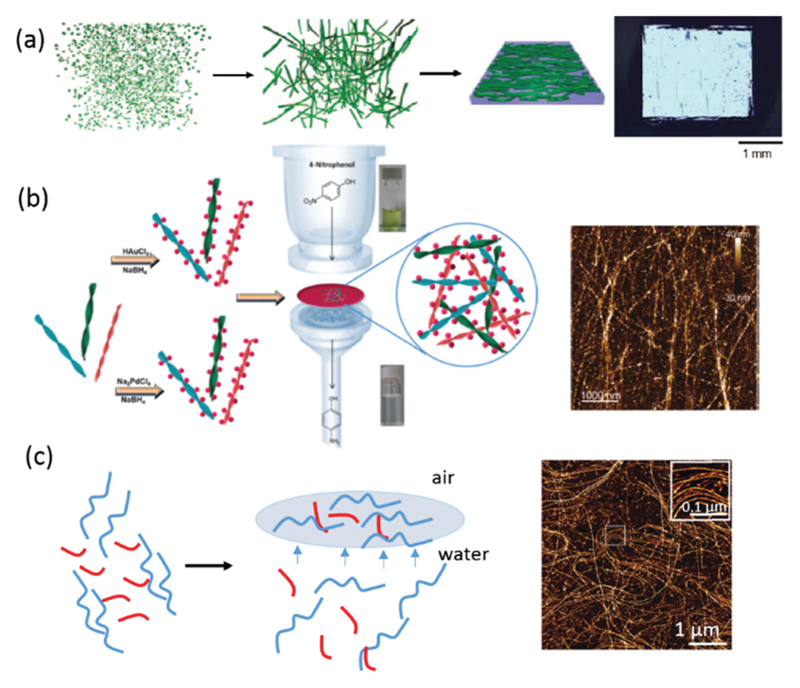

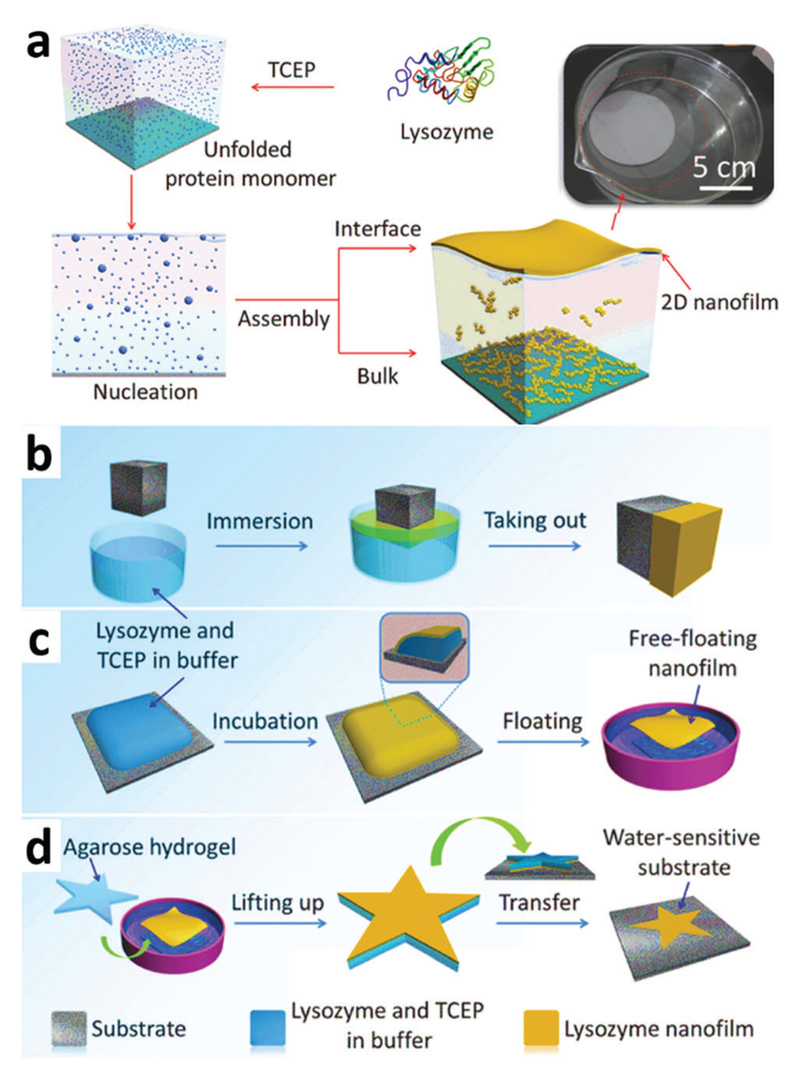

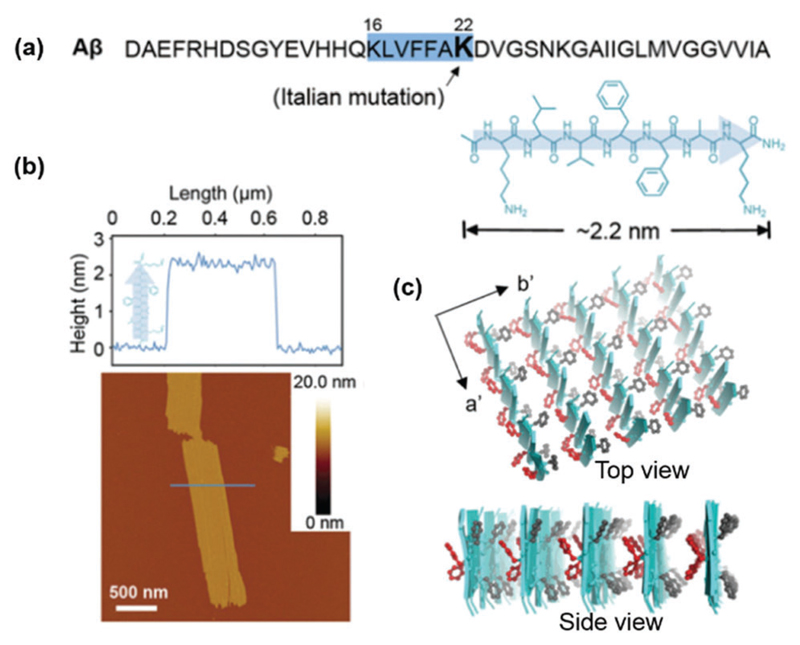

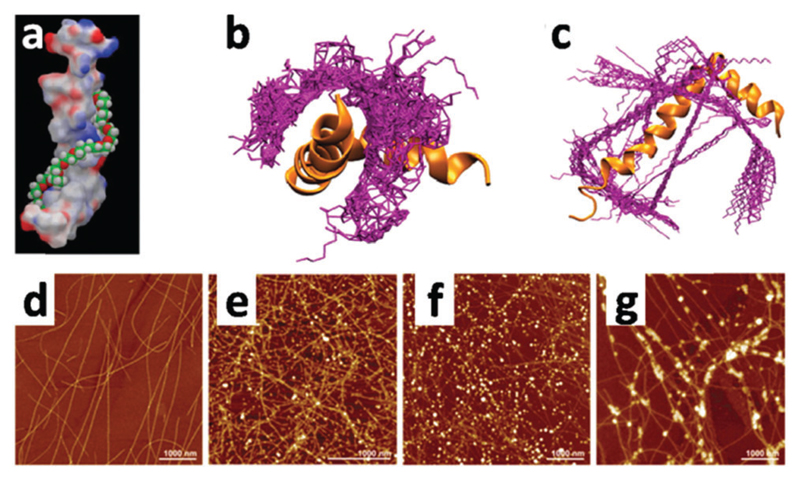

Other more complex 0D amyloid nanostructures have also been observed for a variety of amyloidogenic sequences, including loops, triangles, squares and rings.