Abstract

Ether based electrolytes have surfaced as alternatives to conventional carbonates allowing for enhanced electrochemical performance of sodium-ion batteries; however, the primary source of the improvement remains poorly understood. Here we show that coupling titanium dioxide and other anode materials with diglyme does enable higher efficiency and reversible capacity than those for the combination involving ester electrolytes. Importantly, the electrolyte dependent performance is revealed to be the result of the different structural evolution induced by a varied sodiation depth. A suit of characterizations show that the energy barrier to charge transfer at the interface between electrolyte and electrode is the factor that dominates the interfacial electrochemical characteristics and therefore the energy storage properties. Our study proposes a reliable parameter to assess the intricate sodiation dynamics in sodium-ion batteries and could guide the design of aprotic electrolytes for next generation rechargeable batteries.

Sodium ion batteries are known to benefit from the use of ether electrolytes. Here the authors reveal the origin showing that the energy barrier of charge transfer at the electrolyte/electrode interface dominates the interfacial electrochemical characteristics and is favorably small.

Introduction

Sodium-ion batteries (SIBs) have attracted more attention in recent years particularly for large-scale energy storage due to the natural abundance of sodium compared to lithium1,2. However, their performance including specific capacity, rate capability, and cycle life are severely hindered by the larger diameter of sodium ions than lithium ions3,4, and as a result there have been extensive efforts in searching for suitable electrode materials, in particular on the anode side5,6. In order to improve the electrochemical performance of the present anode materials, modifying the electrolyte is an important and effective approach. Most commonly used non-aqueous electrolytes inevitably decompose forming a solid electrolyte interphase (SEI) on the anode materials because the operating voltage is lower than their stable voltage range. Conventional electrolytes in SIBs are formulated using ester-based solvents similar to those used in lithium-ion batteries (LIBs)7,8, and these produce SEIs that are often reported to be not sufficiently stable and likely to cause severe polarization9. In this context, ether-based electrolytes are believed to be less useful in LIBs owing to inferior passivation on both anodes and cathodes, but they have recently been revived in SIBs because of their ability to trigger the highly reversible co-intercalation of sodium ions with an ether solvent into graphite10–14. The improved sodium storage performance has been observed on different anode materials like CuS nanosheets3, ZnS nanospheres11, bismuth15, and reduced graphene oxide (rGO)9 when ester-based electrolytes are replaced with ether analogs. It is proposed that this improvement is due to the suppression of dissolved polysulfide intermediates3, faster Na+ transport, good electrode wettability11,15, and the formation of a thinner SEI9. Su et al.11 proved that Na ions can be easily absorbed on an ether-based solvent and there is a low energy barrier for Na ion diffusion in it, and Seh et al.16 proved that a glyme-based electrolyte (a typical type of ether-based electrolyte) is superior to an EC/DEC-based electrolyte (a typical ester-based electrolyte; here ethylene carbonate is denoted as EC and diethyl carbonate is denoted as DEC) for a Na metal anode due to the formation of low resistivity SEI, making a large advance on the research of ether-based electrolytes for SIBs. However, the interfacial electrochemical characteristics, especially charge transfer in different types of electrolyte has not yet been systematically investigated. A deeper understanding of the issue is urgently needed so as to clarify the intrinsic origin of the improvement produced by ether-based electrolytes in SIBs. This is a key point in the revival of this technology using an ether-based electrolyte17,18.

Selecting a typical and ideal anode material is crucial to address this issue and TiO2 is preferably chosen in this study considering the following points. Firstly, the sodiation of TiO2 results in the formation of an amorphous sodium titanate phase so that the structural evolution during sodiation can be easily detected19–22. Secondly, the intercalation mechanism and the small volume change produced by pseudocapacitive sodium storage in amorphous sodium titanate23,24 also guarantee the formation of a mechanically stable interface between electrolyte and electrode, which is difficult to achieve in other anodes that involve large volume changes or conversion reactions upon sodiation. Thirdly, unlike the long flat plateau at ~ 1.75 V vs Li/Li+ in lithium-ion batteries (LIBs), the operating potential of TiO2 in SIBs decreases to 0.005 V, which inevitably results in the formation of SEI layer on the electrode25. Lastly, optimizing electrolyte is also promising to address the bottleneck of practical application of TiO2 anodes including low initial coulombic efficiency (ICE) and fast capacity decay18,26–28, although current efforts have mostly targeted the improvement of the electronic conductivity in TiO229–33,34–36,37. Further extending the knowledge and experience of above TiO2-based research to other metal and carbon-based anodes can better illustrate the generality and origin of ether-enhanced interfacial electrochemical characteristics.

In the present work, we investigate ether-induced interfacial electrochemical characteristics for SIBs by coupling anatase TiO2 with a diglyme-based electrolyte. Such a TiO2 anode shows excellent capacity retention and rate capability, compared to those coupled with an EC/DEC-based electrolyte. Insights into the structural evolution and sodiation dynamics obtained by in operando Raman, X-ray diffraction (XRD), and electrochemical kinetic studies reveal that the charge transfer characteristics of the electrolyte/electrode interface play a vital role in determining the performance, which is also confirmed for Sn, rGO, and CMK-3 anodes. Comprehensive X-ray photoelectron spectroscopy (XPS) analyses show that the SEI formed in different electrolytes is composed of different organic species and exhibits distinct composition changes along the SEI depth with more inorganic species in the inner region when formed in an ether-based electrolyte. This is the origin of the electrolyte-dependent sodiation dynamics and battery performance. Our results indicate a general and fundamental explanation of the improved electrochemical performance of different anodes for SIBs induced using an ether-based electrolyte. This study might suggest an avenue for the design of efficient electrolyte/electrode interfaces for improved performance of non-aqueous rechargeable batteries.

Results

Sodium ion storage performance

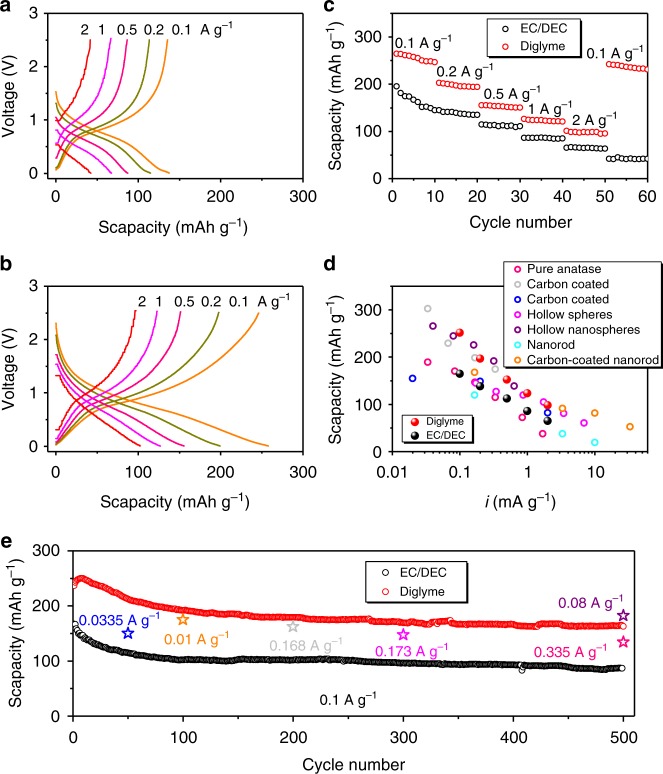

Rhombic anatase TiO2 nanocrystals were synthesized using a solvothermal technique similar to that reported elsewhere38. The average size of the nanocrystals was around 16 nm as shown in Supplementary Figures 1 and 2. Supplementary Figure 2b is a HRTEM image of an individual TiO2 nanocrystal, clearly showing the TiO2 anatase crystal lattice with (101) planes and a d-spacing of 0.35 nm. The XRD pattern and Raman spectrum (Supplementary Figure 2c and d) confirm that the anatase TiO2 nanocrystals are monophasic (JCPDS 21-1272) with a high crystallinity. The SIB anode was prepared using these TiO2 nanocrystals (70 wt%) as the active material, carbon black (15 wt%) as the conductive agent, and polyvinylidene fluoride (PVDF) (15 wt%) as the binder. Coin cells were then assembled using two different solvent-based electrolytes, i.e., NaCF3SO3 dissolved in EC/DEC and NaCF3SO3 in diglyme. Figure 1a shows the discharge/charge voltage profiles of SIBs prepared with this TiO2 anode and the EC/DEC electrolyte, measured at current densities ranging from 0.1 to 2 A g−1. The voltage profiles are linear with no obvious plateau regions, which is different from the flat and prolonged voltage plateau observed in LIBs39. This indicates that the sodiation of TiO2 proceeds by a different mechanism from lithiation, which might indicate a single-phase Na-intercalation process40. As clearly demonstrated by others, the sodiation of anatase TiO2 is a solid-solution-like reaction21,41. The operation potential of these anatase nanocrystals as the SIB anode is averaged to be ~0.8 V, which is significantly lower than that for Li intercalation (~1.75 V vs. Li/Li+)39, making TiO2 more promising for practical applications. When EC/DEC is replaced by diglyme, a significant improvement is observed in the anode performance, as shown in Fig. 1b. For instance, the specific capacity at 0.2 A g−1 is improved from 114.8 to 199.4 mAh g−1. Increasing the current rate from 0.1 to 2 A g−1 causes a capacity loss in both cases, but it is more severe in the EC/DEC case (decreasing from 137.5 to 42.2 mAh g−1) than in diglyme (decreasing from 257.9 to 102.1 mAh g−1). It is also worth noting that using the diglyme-based electrolyte obviously improves the ICE of TiO2 as an SIBs anode, which is one of the critical issues for TiO2 SIB anodes. As shown in Supplementary Figure 3, the ICE is as high as 69% in a diglyme-based electrolyte, much higher than the 33% in an EC/DEC-based electrolyte, although a further increase is still needed for the real applications.

Fig. 1.

Battery performance. a Voltage profiles of the TiO2 anode at different rates using the EC/DEC-based electrolyte (scapacity: specific capacity). b Voltage profiles of the TiO2 anode at different rates using the diglyme-based electrolyte. Note that the profiles at 0.1 A g−1 in a and b are for the third cycle while the others are for the first cycle at corresponding rates. c Rate performance. d Performance compared with anatase TiO2-based SIB anodes reported in the literature, i.e., pure anatase TiO256, carbon-coated anatase57,58, hollow spheres23 and hollow nanospheres59, anatase nanorods60, and coated anatase nanorods60. e Cyclic performance at 0.1 A g−1, and comparison with cyclic performance reported in the literature

Figure 1c, d shows the rate capabilities of the TiO2 anode using two different electrolytes. The cells using the diglyme-based electrolyte show an exceptional high rate capability, much higher than that for the EC/DEC system. Remarkable reversible capacities of ~252, 197, 153, 124, and 99 mAh g−1 were recorded for the diglyme case at current rates of 0.1, 0.2, 0.5, 1, and 2 A g−1, respectively. The corresponding values for EC/DEC are only ~165, 139, 113, 86, and 66 mAh g−1. When the current rate is decreased to 0.1 A g−1, the cell with diglyme retains its high capacity while the cell based on EC/DEC does not, indicating better reversibility when the diglyme-based electrolyte is used. Compared to the anatase TiO2 SIB anodes reported in the literature, the performance of the present TiO2 anode coupled with diglyme is among the best available. It is worth noting that the present TiO2 active materials are not carbon-modified or doped with other elements, implying a potential for further optimization by compositing with carbons or other elements. Both cells using diglyme and EC/DEC electrolytes have a quite stable long-life cyclic performance at 0.1 A g−1 as shown in Fig. 1e. But the absolute capacities of the cells using EC/DEC are much lower than those with the diglyme counterpart. After 500 cycles at 0.1 A g−1, a reversible capacity of 165 mAh g−1 was maintained for the cell based on the diglyme electrolyte, while the value was only 87 mAh g−1 for the case with EC/DEC. Our previous work9 demonstrated that carbon anodes such as rGO and CMK-3 showed much better efficiency and reversible capacity in the diglyme-based electrolyte than in EC/DEC system. Here, we further studied an Sn anode and found that the efficiency and reversible capacity in a diglyme-based electrolyte were superior to what was observed for EC/DEC (Supplementary Figure 4).

Structural analysis

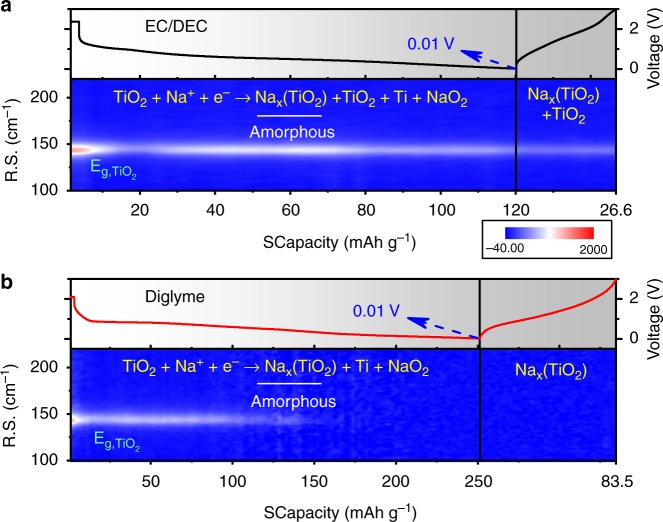

To gain an insight into the excellent performance from the diglyme-based electrolyte and particularly into the Na-ion diffusion dynamics during sodiation/de-sodiation, we conducted in operando Raman spectroscopy (Supplementary Figure 5) and XRD (Supplementary Figure 8), and ex situ XRD to reveal the structural evolution, and scanned rate-dependent cyclic voltammetry (CV) as well as temperature-dependent electrochemical impedance spectroscopy (EIS). The sodiation of anatase TiO2 is an intercalation reaction described as follows: the sodium is intercalated into the TiO2 lattice, distorts the lattice, and partially reduces the TiO2 to form metallic titanium, sodium oxide, and amorphous sodium titanate21, which acts as the host for the Na ion storage in the following cycles. Taking the above mechanism into consideration, complete sodiation of TiO2 results in the disappearance of the Raman bands of crystalline TiO2, which will not reappear after de-sodiation. As shown in Fig. 2b, the Raman spectra evolution characteristics of the TiO2 anode coupled with a diglyme-based electrolyte during the first cycle conform to this mechanism. In sharp contrast, when using the EC/DEC-based electrolyte, the TiO2 cannot be fully sodiated even when the voltage is 0.01 V in the first cycle, as shown in Fig. 2a where the Raman signal of TiO2 can still be observed, indicating a lower accessible capacity than when using diglyme in the first cycle, and only after ~4 cycles is the TiO2 completely transformed to the amorphous phase (Supplementary Figure 6). This incomplete sodiation of anatase TiO2 has also been observed in an EC/PC (propylene carbonate)-based electrolyte42. The ex situ XRD results (Supplementary Figure 7) further prove the amorphization of the TiO2 during the first discharge in the diglyme-based electrolyte and the incomplete sodiation in the EC/DEC-based electrolyte. Ex situ XRD results of the Sn anode (Supplementary Figure 10) show the formation of the NaxSn phase when discharged to 0.1 V in the diglyme-based electrolyte, which is not observed for the EC/DEC case. The in operando Raman spectroscopy and XRD (Supplementary Figure 9) along with the ex situ XRD results show that the sodiation of TiO2 and Sn is much easier in the diglyme-based electrolyte than in the EC/DEC-based electrolyte. In our previous work9, we showed that carbon materials like rGO and CMK-3 can be sodiated to a higher extent in the diglyme-based electrolyte than in the EC/DEC-based electrolyte.

Fig. 2.

In operando Raman spectroscopy. Raman spectra of the TiO2 anode during the first cycle of electrochemical sodiation/de-sodiation at a rate of 100 mA g−1 (R.S.: Raman shifts), a using the EC/DEC-based electrolyte and b using the diglyme-based electrolyte21

Dynamic analysis

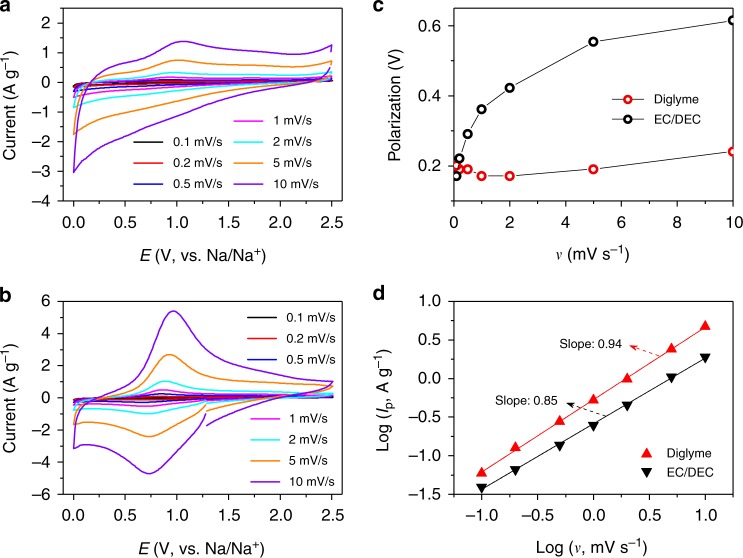

To reveal the true nature of the polarization at the TiO2 working electrode, we designed a coin cell-type 3-electrode setup (Supplementary Figure 12) and performed scan rate-dependent CV measurements, by which the effect at the Na counter electrode was eliminated. The CV results obtained from these tests are quite similar to those observed in the 2-electrode measurements (Supplementary Figure 11), as shown in Fig. 3, except for the smaller polarizations. It can be seen from Fig. 3c that the TiO2 working electrode coupled with the EC/DEC-based electrolyte has a much higher polarization than when coupled with the diglyme-based electrolyte, and the polarization becomes more severe as the scan rate increases. The potential polarization with an increased scan rate is extremely small in the case of diglyme, indicating quite favorable sodiation dynamics of the TiO2 electrode. Additionally, CV shows that the sodium storage of TiO2 is controlled by both capacitance and diffusion, and using the diglyme-based electrolyte increases the contribution from capacitance and facilitates the rapid (de)intercalation of sodium ions. This is very similar to that observed in graphene-modified TiO2 where the polarization decreases43 and the Na ion intercalation pseudocapacitive process increases24.

Fig. 3.

Scan rate-dependent cyclic voltammetry (CV) from the 3-electrode tests (see the experimental setup in Supplementary Figure 12). a, b CV curves of the TiO2 anode at different scan rates with the EC/DEC-based electrolyte (a) and the diglyme-based electrolyte (b). c Separation (potential polarization) between the cathodic and anodic peaks in the CV curves as a function of scan rate. d b-values (slopes) obtained from the current peaks, Ip = avb, of the CV curves

The total charge stored in a CV scan can be separated into faradaic contributions from Na-ion intercalation and pseudo-capacitance, and a non-faradaic contribution from the double layer effect that depends on the surface area44. These capacitive effects (pseudo-capacitance and double layer charging) can be distinguished from Na-ion intercalation by analyzing the CV data at different sweep rates according to the relationship between the measured current (I) and the scan rate (v)45:

and the b-value is determined by the slope of the log(v)–log(I) plot. In particular, a b-value of 0.5 indicates total diffusion-controlled behavior, whereas 1.0 indicates a capacitive process. The log(v)–log(Ip) plots and corresponding b-values are shown in Fig. 3d (note that here we use the peak current Ip rather than the current I at a given potential because of the large polarization), showing that in both cases the (de)sodiation is a combination of capacitance and diffusion. However, the b-values in the EC/DEC case are smaller than in the case of diglyme, meaning that for the EC/DEC the (de)sodiation is more diffusion-controlled and has slower diffusion kinetics than with diglyme. When using diglyme, a higher contribution of capacitive charge causes an increased intercalation pseudocapacitive behavior of Na+ in the electrode (considering the double layer charging is sensitive to the surface area and thus is the same no matter the electrolyte), which contributes to the excellent rate capability and high capacity24.

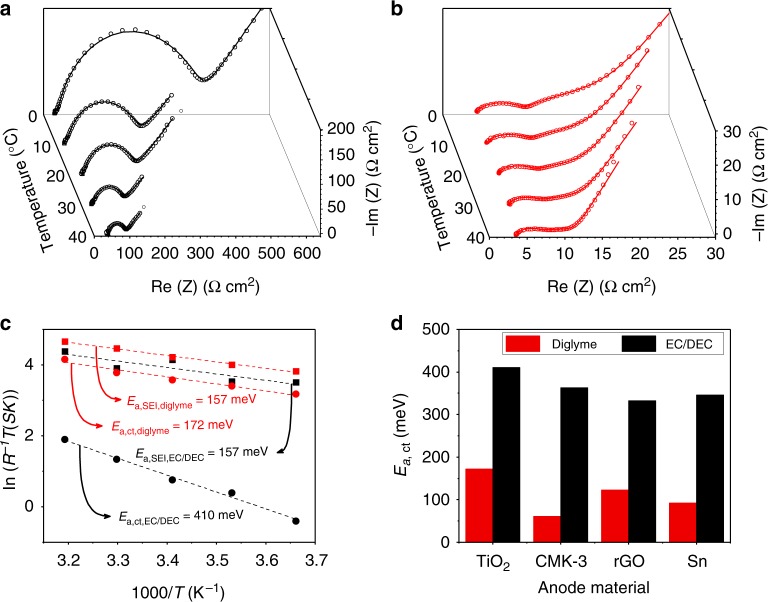

The increased intercalation pseudo-capacitance triggered by the diglyme-based electrolyte indicates faster sodium ion diffusion and electron transport across the whole cell. To gain more fundamental insight into the faster dynamics, we conducted temperature-dependent EIS to examine the dynamic properties (the resistance and activation energy Ea) of individual components in the cell system. According to Barsoukov’s model46, the sodium ions diffuse across the liquid electrolyte (LE) and SEI layer, followed by a charge transfer process at the SEI/electrode interface and diffusion inside the electrode material. Here, we assume an SEI/electrode interface extending from the SEI layer to the electrode (as illustrated in Supplementary Figure 14). Different resistances and activation energies are involved. The resistances can be determined by fitting the EIS spectra, and the activation energies can be determined by fitting the temperature-dependent resistances. Figure 4a, b, respectively, shows the temperature-dependent EIS spectra of 2-electrode cells assembled using EC/DEC-based and diglyme-based electrolytes after 10 discharge–charge cycles at a rate of 100 mA g−1. Two semicircles and a straight line are identified in all these spectra, and in order to assign them, we compared the EIS spectra measured using both 2-electrode and 3-electrode setups (Supplementary Figure 13). It was found that the small semicircle at higher frequencies observed in the 2-electrode study almost disappears in the 3-electrode study, which implies that the first semicircle at higher frequencies in the 2-electrode study includes the information of the SEI at the Na counter electrode. The second semicircle at lower frequencies in the 2-electrode study is very similar to the semicircle observed in the 3-electrode study. The DC-bias current-dependent EIS study using the 3-electrode setup confirms that this semicircle may be assigned to the charge-transfer process (Supplementary Figure 13a). Therefore, in the following discussion, we use the 2-electrode EIS study. The Arrhenius plots in Fig. 4c and data in Supplementary Table 2 represent the individual contributions of the solid electrolyte interphase RSEI and the charge transfer resistance Rct, obtained from data fitting the temperature-dependent impedance spectra based on the equivalent circuit given in Supplementary Figure 14. For both the SEI and the SEI/electrode interface, an Arrhenius equation is used to determine the activation energies47:

Here, A is the pre-exponential factor, Ea is the apparent activation energy for ion transport, kB is the Boltzmann constant, σ is the ionic conductivity, and T is the absolute temperature. As expected, transport across the SEI/electrode interface has higher activation energy (Ea, ct) than that across the SEI layer (Ea, SEI) for both cases. When the EC/DEC-based electrolyte is used, the activation energy across the interface (Ea,ct, EC/DEC) is the highest with a value of ~410 meV (which is very close to the value of ~400 meV from the 3-electrode EIS study, as shown in Supplementary Figure 13b, c and Supplementary Table 1, further verifying the effectiveness of the analysis in the 2-electrode study), and is higher by a factor of 2.4 than the corresponding value for the diglyme-based electrolyte. This means that at any temperature, transport of Na ions is faster across the SEI/electrode interface formed in diglyme than that formed in EC/DEC. The activation energy of Na+ diffusion in the SEI layer Ea, SEI is almost the same for the two cases. This is probably due to the fact that Na+ diffuses in the SEI layer by hopping migration and the activation energy for this is not significantly different in different SEI compositions48,49. It is also worth noting that the interfacial ionic conductivity in the diglyme-based system is much higher than that in the EC/DEC-based system, which implies a major effect of the use of different solvent-based electrolytes in SIBs. If transport through the SEI/electrode interface is sluggish, this interfacial resistance will have a detrimental effect on the rate capability47. This finding provides crucial insight into the improved interfacial characteristics induced by ether-based electrolytes, which is also demonstrated for other electrode materials, as shown in Fig. 4d. We also examined the temperature-dependent EIS of a CMK-3 anode (Supplementary Figure 15 and Table 3), an rGO anode (Supplementary Figure 16 and Table 4), and an Sn anode (Supplementary Figure 17 and Table 5) after cycling. In all cases, the charge transfer energy barrier (Ea, ct) across the interface in the EC/DEC-based electrolyte is much higher than that in the diglyme-based electrolyte, by a factor of around 6 for a CMK-3 anode, 2.7 for an rGO anode, and 4 for an Sn anode.

Fig. 4.

Electrochemical impedance spectroscopy analysis after ten discharge–charge cycles. a, b Temperature-dependent Nyquist plots of the TiO2 anode for the EC/DEC-based electrolyte (a) and the diglyme-based electrolyte (b). c Arrhenius plot of the resistance contributions of the solid electrolyte interphase RSEI and the charge transfer resistance Rct, with the derived activation energies Ea,SEI and Ea,ct for the TiO2 anode in the two electrolytes. d Comparison of the charge transfer energy barriers in the diglyme-based electrolyte and EC/DEC-based electrolytes for various electrode materials

SEI analysis

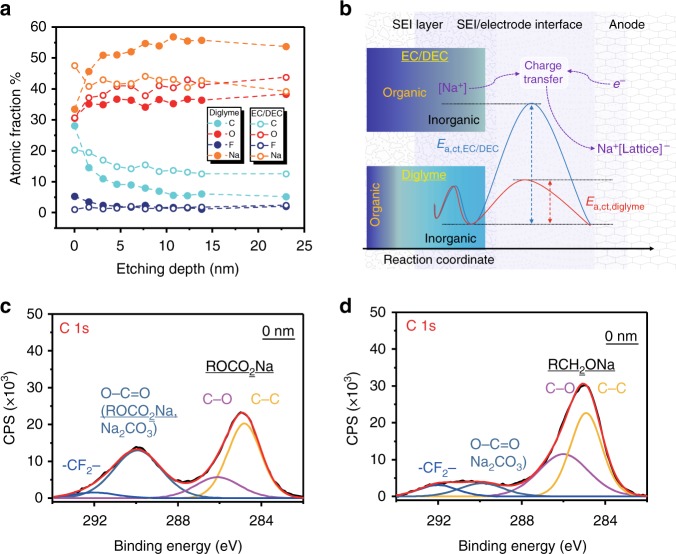

SEM examination of the electrode surface showed that an SEI had formed after cycling (Supplementary Figure 18). It seems that the formation of the SEI in a diglyme-based electrolyte is more uniform than that formed in an EC/DEC-based electrolyte. We therefore carried out XPS to examine the SEIs formed in the two electrolytes, as shown in Fig. 5a–d. XPS depth profiling was done using Ar ion sputtering. As shown in Supplementary Figure 19, C, O, F, and Na signals were detected on the electrode surface in both cases and also at different etching depths. Figure 5a shows the elemental compositions of the SEI layer at different depths obtained by quantitative analysis of the XPS spectra. The most significant feature is that in the SEI formed in the diglyme-based electrolyte, the atomic fraction of C decreases distinctly with increasing etching depth (~28% at the surface and ~5% at 23 nm depth), while the atomic fraction of Na shows a completely opposite trend, and the atomic fraction of O increases slightly with etching depth. This means that the organic species are mainly distributed near the surface while the interior of the SEI is mainly composed of inorganic species. Although a slight decrease in the atomic fraction of C in the SEI formed in the EC/DEC-based electrolyte with etching depth is also observed, its value is much higher than with the diglyme counterpart. This indicates that there are more organic species in the SEI formed in the EC/DEC-based electrolyte and they are spread over the whole thickness of the SEI. Analyses of the Na Auger Parameter confirms these conclusions (Supplementary Figure 21 and Supplementary Table 6)50. The inorganic species are generally localized and remain in a stable thin layer during cycling, leading to a low charge transfer resistance and energy barrier16,49. The presence of organic products, which are usually porous, makes the SEI much thicker16, leading to a much higher charge transfer resistance and energy barrier.

Fig. 5.

SEI chemistry and the charge transfer process. a The atomic fractions of C, O, F, and Na as a function of SEI depth, calculated from the XPS spectra depth profiling (Supplementary Figure 19). b Schematic of the SEI compositions formed in different electrolytes and a comparison of the charge transfer energy barriers. [Na+] means that the Na+ may be solvated. There is a smaller amount of organic species in the SEI formed in the diglyme-based electrolyte and the inner part of the SEI is mainly composed of inorganic species. c XPS C 1s spectrum before etching in the EC/DEC-based electrolyte. d XPS C 1s spectrum before etching in the diglyme-based electrolyte

The SEI composition was also analyzed by high-resolution XPS using a Mg X-ray source. First, we analyzed the composition of the SEI formed in the diglyme-based electrolyte (Fig. 5d, Supplementary Figures 22–26 and Supplementary Table 7). The C 1s spectrum was fitted using four peaks with binding energies of ~284.9 eV (C–C), ~286.0 eV (C–O), ~289.9 eV (O–C=O), and ~292.0 eV (–CF2–), which are consistent with sodium alkoxides (RCH2ONa) being the main reduction products of diglyme and Na2CO3 and PVDF9,16,50. The O 1s spectrum contained three peaks at ~532.6 eV (R–O–Na), ~531.1 eV, and ~530.0 eV (Na–O–Ti), belonging to RCH2ONa, Na2CO3, and NaxTiO2, respectively. The O 1s spectrum change with etching depth also proves that the organic species decrease in the inner region of the SEI (Supplementary Figure 24a–c). The F 1s spectrum showed a peak at ~684.9 eV (Na–F) and the Na 1s spectrum showed a peak at ~1072.2 eV (Na–F, Na–O), indicating the existence of NaF and other sodium compounds (RCH2ONa, Na2CO3). Overall, we concluded that the SEI formed in the diglyme-based electrolyte contains both organic (RCH2ONa) and inorganic (Na2CO3, NaF) components. In the case of the EC/DEC-based electrolyte, we saw distinct XPS peaks corresponding to sodium alkyl carbonate (ROCO2Na) and inorganic products (Na2CO3, NaF), as shown in Fig. 5c, Supplementary Figures 22–26, and Supplementary Table 8 (refs. 9,16,50–54). Therefore, in addition to the distinct composition change along the SEI depth, there is also a difference between the SEIs formed in the two electrolytes because of the organic components formed by the decomposition of the different solvents, which is consistent with what is found in SIB Bi electrodes15. It has been reported that sodium alkoxides (RCH2ONa) ensure fast Na+ transport and are essential for the interfacial stability of the Bi electrode15. First-principles calculations conducted by Su et al. demonstrated that an ether-based solvent reduces the energy barrier for sodium-ion diffusion and thus improves the electrochemical performances11. It is reasonable to deduce that the RCH2ONa also reduces the energy barrier for sodium-ion diffusion. The inorganic species in the SEI generally have low Na+ diffusion activation energies (e.g., the activation energy for NaF is ~100–150 meV49). Combined with the above dynamic analysis, we conclude that the different SEI chemistries lead to the huge difference in the electrochemical performance of the two different solvent-based electrolytes by modifying the resistance of the SEI/electrode interfaces and the transport of Na+ and electrons in them.

Discussion

The dynamic properties of the SEI/electrode interface play a vital role in the sodium storage. Modification of this interface can be achieved by changing the SEI chemistry, which depends on whether an ether-based or an ester-based electrolyte is used. But how the SEI chemistry works behind-the-scenes has not yet been fully determined, and undoubtedly needs further in situ experimental investigation and theoretical analysis. To support the governing role of the SEI/electrode interface, we measured the electrochemical performance and analyzed the sodiation dynamics of an anatase TiO2 anode composed of 84 nm nanocrystals (Supplementary Figure 26). First, as shown in Supplementary Figure 27, this anode shows similar voltage profiles to those of the 16 nm TiO2 nanocrystal anode but has relatively lower specific capacities in both the EC/DEC-based and diglyme-based electrolytes, with the capacity in the latter being higher than in the former, similar to what is observed for the 16 nm nanocrystal anode. We hypothesize that the reasons for the inferior capacity of 84 nm nanocrystal material are the high sodium diffusion energy barrier and relatively small crystal surface area. Interestingly, dynamic analysis shows that in the diglyme-based electrolyte, as shown in Supplementary Figure 28, 29 and Table 9, the activation energies of sodium diffusion through the SEI layer as well as the SEI/electrode interface are quite close for the two materials, meaning almost the same energy barriers for sodium transport and charge transfer. On the one hand, this indicates that the activation energy for charge transfer at the electrolyte/electrode interface is inherent to the nature of the interface and is almost independent of particle size. On the other hand, the large surface area is one of the reasons accounting for the better performance of the 16 nm than the 84 nm material, because a larger surface area results in a correspondingly larger interface area and higher electrochemical reactivity.

Apart from the electrolyte/electrode interfacial properties, solvent wettability is another parameter that may influence the sodium ion surface diffusion kinetics. Better solvent wettability is beneficial for improving the rate performance because of better ion availability as a result of the easier penetration of the electrolyte, since the surface ion availability may play an essential role in providing sufficient Na ions for intercalation into the TiO255. The solvent wettability is measured by the contact angle. As shown in Supplementary Figure 30, both the EC/DEC-based and diglyme-based electrolytes effectively spread over the electrode surface composed of 16 nm TiO2 nanocrystals, super P and PVDF within 5 s, suggesting that the electrolyte wettability is not a decisive factor that influences the battery performance of the 16 nm TiO2 anode. While for the electrode consisting 84 nm nanocrystals, the wettability is distinctly different for the two electrolytes (Supplementary Figure 30) with that of the diglyme-based electrolyte being better than that of the EC/DEC-based electrolyte. Except for the larger electrochemical active surface area, the better electrolyte wettability should also contribute to the superior electrochemical performance of the 16 nm TiO2 compared to the 84 nm TiO2.

In summary, as a superior model anode, the 16 nm nanocrystal anatase TiO2 coupled with the diglyme-based electrolyte shows a reversible capacity of 257.9 mAh g−1 at 100 mA g−1 and more than 100 mAh g−1 at 2000 mA g−1, both of which are much better than in the EC/DEC-based electrolyte and are among the best values ever reported for anatase-based anodes for SIBs. The Sn, rGO, and CMK-3 anodes also show superior Na+ storage performance in the diglyme-based electrolyte than in the EC/DEC-based electrolyte. In operando Raman spectra and XRD show that the ether-based electrolyte facilitates the sodiation-induced structural transitions of the TiO2 and Sn anodes. We have also shown that charge transfer dynamics at the SEI/electrode interface play a crucial role in the rate-cycling performance and are nearly size-independent. Charge transfer has an energy barrier of 172 meV for the interface formed in the diglyme-based electrolyte (1.4 times lower than for the interface in the EC/DEC-based electrolyte) for the TiO2 anode, providing faster charge transfer across the electrolyte/electrode interface. Significant reductions in the charge transfer energy barrier are also demonstrated in Sn, CMK-3, and rGO electrodes when the EC/DEC-based electrolyte is replaced by the diglyme-based electrolyte. The faster dynamics increase the Na+ intercalation pseudocapacitive behavior, which is highly beneficial to fast charge storage and long-term stability. The chemistry and composition distribution in the SEI layer are of great relevance for the charge transfer, with the organic species formed in the ether-based electrolyte together with the inorganic species favoring the sodiation dynamics. The information obtained in this work provides a general framework for understanding the origin of the extraordinary performance and improved interfacial characteristics of an ether-based electrolyte for SIB anodes, and can guide the future design and matching between non-aqueous electrolytes and novel electrode materials for rechargeable batteries.

Methods

Synthesis of anatase TiO2 nanocrystals

Titanium(IV) butoxide (TB, 97%), oleic acid (OA, 90%), oleylamine (OM, 70%), and absolute ethanol were purchased form Aldrich. All chemicals were used as received. The synthesis of the TiO2 nanocrystals was accomplished using a solvothermal method. Typically, 5 mmol TB was added to a mixture of 25 mmol OA, 25 mmol OM, and 100 mmol absolute ethanol. The mixture was stirred in a 40-mL Teflon cup for 10 min before being transferred into a 100-mL Teflon-lined stainless-steel autoclave containing 20 mL of a mixture of ethanol and water (96% ethanol, v/v). The system was then heated at 180 °C for 18 h. The white TiO2 nanocrystal precipitates obtained were washed several times with ethanol and then dried at room temperature before being heated at 350 °C for 5 h in air.

Materials characterization

Transmission electron microscope (TEM) images and selected area electron diffraction (SAED) patterns of the TiO2 nanocrystals were obtained using a JEOL 2010F transmission electron microscope operated at 200 kV. Raman spectra were collected using a Raman spectrometer (LabRAM HR spectrometer, Horiba) with a 532.05-nm Ar-ion laser. XRD patterns were recorded over the range 20–80° on a Rigaku diffractometer equipped with a Cu Kα radiation source operated at 40 kV and 120 mA.

Cell assembly and testing

The active materials (70 wt%) were homogeneously mixed with conductive carbon black (15 wt%) and PVDF (15 wt%) in NMP to form a slurry, which was stirred for 6 h and coated onto a Cu foil. After vacuum-drying at 110 °C for 10 h, the electrodes were cut into circular pieces with a diameter of 12 mm, which were used as anodes for the assembled cell. The mass loading of the electrodes was 1.5 mg cm−2. The electrolytes for comparison were 1 M NaCF3SO3 dissolved in a mixture of EC and DEC (volume ratio = 1:1), and 1 M NaCF3SO3 dissolved in diglyme. Using these electrodes and electrolytes with pure sodium foils as counter electrodes and Whatman GF/D glass fibers as separators, 2032-type coin cells were assembled in an argon-filled glove box with oxygen and moisture contents below 0.1 ppm. Galvanostatic charge–discharge tests were conducted on a LAND CT2001 battery program controlling system at different current densities with a voltage window of 0.005–2.5 V vs. Na/Na+.

Cyclic voltammetry

CV measurements were conducted using an electrochemical workstation (VMP3, Bio Logic, France) at scanning rates from 0.1 mV s−1 to 10 mV s−1 in the voltage range of 0.005–2.5 V vs. Na/Na+ at room temperature.

Electrochemical Impedance Spectroscopy

All EIS measurements were carried out using a PARSTAT 4000 electrochemical workstation, using a frequency range of 105 Hz to 100 mHz and an AC voltage amplitude of 10 mV. The cell temperature was controlled in a temperature-controlled chamber (Linkam Scientific) and was varied between 0 and 40 °C (±0.1 °C) in steps of 10 °C using a nitrogen-gas flow and electronic heaters (Linkam Scientific) for the temperature-dependent experiments.

In operando Raman spectroscopy and in situ XRD

Raman spectra acquisition during cell operation has been described in detail elsewhere and is schematically shown in Supplementary Figure 5 (ref. 39). For the measurements, a special electrode was used which was prepared by mixing the active materials with super P and 5 wt% PTFE in water to obtain a homogenous slurry. The final content of the active materials was 80 wt%. The slurry was rolled into a thin film, which was then pressed onto a stainless-steel mesh. A delicate battery cell with a quartz window on the top was used (Supplementary Figure 5). The Raman spectra were recorded on a MicroRaman system (LabRAM HR spectrometer, Horiba) with an Olympus BX microscope and an argon ion laser (532.05 nm). Each spectrum was acquired for 20 s. The galvanostatic discharge of the cell was controlled by an electrochemical workstation (PARSTAT 4000). A similar battery cell to that used for the in operando Raman spectroscopy was designed, replacing the quartz window with a Kapton film window to perform the in situ XRD measurements (Supplementary Figure 8).

Surface characterization

XPS survey scan analyses were conducted on a PHI 5000 VersaProbe II spectrometer using a monochromatic Al Kα X-ray (1486.6 eV) source. High-resolution XPS analyses were carried out using an ESCALAB 250Xi spectrometer with a Mg Kα X-rays source, in order to eliminate the interferences of the Na Auger peak with the oxygen 1s photoelectron line and the Ti Auger peak with the Na 1s peak. The batteries were disassembled in a glove box after 10 discharge–charge cycles at a rate of 100 mA g−1, and the anodes were washed several times with the related solvent, i.e., dimethyl carbonate (DMC) for EC/DEC and dimethoxyethane (DME) for diglyme. After drying, the anodes were transferred to a vacuum box and then transferred into the XPS chamber. Samples were ion-etched using 2 kV Ar ions over 2 × 3 mm2 with an etching rate of approximately 4.3 nm min−1. Spectra were charge corrected to the main line of the carbon 1s spectrum (adventitious carbon) and set to a BE of 284.8 eV (Supplementary Figure 21).

Supplementary information

Acknowledgements

This work was supported by the National Science Fund for Distinguished Young Scholars, China (No. 51525204), the National Natural Science Foundation of China (Nos. U1601206, 51772164, and U1710256), Local Innovative and Research Teams Project of Guangdong Pearl River Talents Program (2017BT01N111), the Shenzhen Technical Plan Project (Nos. JCYJ20170412171630020 and JCYJ20170412171359175), the 111 project (No. D16002) from the State Administration of Foreign Experts Affairs and the Ministry of Education, PRC, and the General Research Fund (No. 15210718) from Hong Kong Research Grants Council. The authors thank Mr. Kun Qian for his assistance in the in situ XRD measurements.

Author contributions

Q.H.Y., T.Y.Z., and L.M.Z. managed the project and guided the research; K.K.L. and J.Z. contributed equally to the paper; D.M.L., B.H.L., Y.B.H., and F.Y.K. participated in the experiments; W.L., D.W.W., and S.S. were involved in the discussions; K.K.L. and J.Z. wrote the manuscript with the supervision of Q.H.Y., T.Y.Z., and L.M.Z., and all authors have approved the final manuscript.

Data availability

The data that support the findings of this study are available within the article and its Supplementary Information files. All other relevant data supporting the findings of this study are available from the corresponding authors upon reasonable request.

Competing interests

The authors declare no competing interests.

Footnotes

Journal peer review information: Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work.

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

These authors contributed equally: Kaikai Li, Jun Zhang.

Change history

3/13/2019

The original version of this Article incorrectly omitted an affiliation of Kaikai Li: ‘Shenzhen Environmental Science and New Energy Technology Engineering Laboratory, Tsinghua-Berkeley Shenzhen Institute (TBSI), Tsinghua University, Shenzhen 518055, China’. This has been corrected in both the PDF and HTML versions of the Article.

Contributor Information

Quan-Hong Yang, Email: qhyangcn@tju.edu.cn.

Limin Zhou, Email: mmlmzhou@polyu.edu.hk.

Tong-Yi Zhang, Email: mezhangt@ust.hk.

Electronic supplementary material

Supplementary Information accompanies this paper at 10.1038/s41467-019-08506-5.

References

- 1.Van Noorden R. The rechargeable revolution: a better battery. Nature. 2014;507:26–28. doi: 10.1038/507026a. [DOI] [PubMed] [Google Scholar]

- 2.Vaalma C, Buchholz D, Weil M, Passerini S. A cost and resource analysis of sodium-ion batteries. Nat. Rev. Mater. 2018;3:18013. doi: 10.1038/natrevmats.2018.13. [DOI] [Google Scholar]

- 3.Li J, et al. Significantly improved sodium-ion storage performance of CuS nanosheets anchored into reduced graphene oxide with ether-based electrolyte. ACS Appl. Mater. Interfaces. 2017;9:2309–2316. doi: 10.1021/acsami.6b12529. [DOI] [PubMed] [Google Scholar]

- 4.Huang H, Wu HH, Wang X, Huang B, Zhang TY. Enhancing sodium ionic conductivity in tetragonal-Na3PS4 by halogen doping: a first principles investigation. Phys. Chem. Chem. Phys. 2018;20:20525–20533. doi: 10.1039/C8CP02383B. [DOI] [PubMed] [Google Scholar]

- 5.Li YM, et al. Recent advances of electrode materials for low-cost sodium-ion batteries towards practical application for grid energy storage. Energy Storage Mater. 2017;7:130–151. doi: 10.1016/j.ensm.2017.01.002. [DOI] [Google Scholar]

- 6.Masse RC, Uchaker E, Cao GZ. Beyond Li-ion: electrode materials for sodium- and magnesium-ion batteries. Sci. China Mater. 2015;58:715–766. doi: 10.1007/s40843-015-0084-8. [DOI] [Google Scholar]

- 7.Slater MD, Kim D, Lee E, Johnson CS. Sodium-ion batteries. Adv. Funct. Mater. 2013;23:947–958. doi: 10.1002/adfm.201200691. [DOI] [Google Scholar]

- 8.Kundu D, Talaie E, Duffort V, Nazar LF. The emerging chemistry of sodium ion batteries for electrochemical energy storage. Angew. Chem. Int. Ed. Engl. 2015;54:3431–3448. doi: 10.1002/anie.201410376. [DOI] [PubMed] [Google Scholar]

- 9.Zhang J, et al. Achieving superb sodium storage performance on carbon anodes through an ether-derived solid electrolyte interphase. Energy Environ. Sci. 2017;10:370–376. doi: 10.1039/C6EE03367A. [DOI] [Google Scholar]

- 10.Hu Z, et al. Pyrite FeS2 for high-rate and long-life rechargeable sodium batteries. Energy Environ. Sci. 2015;8:1309–1316. doi: 10.1039/C4EE03759F. [DOI] [Google Scholar]

- 11.Su DW, Kretschmer K, Wang GX. Improved electrochemical performance of Na-ion batteries in ether-based electrolytes: a case study of ZnS nanospheres. Adv. Energy Mater. 2016;6:1501785. doi: 10.1002/aenm.201501785. [DOI] [Google Scholar]

- 12.Cohn AP, Share K, Carter R, Oakes L, Pint CL. Ultrafast solvent-assisted sodium ion intercalation into highly crystalline few-layered graphene. Nano. Lett. 2016;16:543–548. doi: 10.1021/acs.nanolett.5b04187. [DOI] [PubMed] [Google Scholar]

- 13.Kim H, et al. Sodium storage behavior in natural graphite using ether-based electrolyte systems. Adv. Funct. Mater. 2015;25:534–541. doi: 10.1002/adfm.201402984. [DOI] [Google Scholar]

- 14.Zhang, J., et al. Ethers illume sodium-based battery chemistry: uniqueness, surprise, and challenges. Adv. Energy Mater. 8, 1801361 (2018).

- 15.Wang CC, Wang LB, Li FJ, Cheng FY, Chen J. Bulk bismuth as a high-capacity and ultralong cycle-life anode for sodium-ion batteries by coupling with glyme-based electrolytes. Adv. Mater. 2017;29:1702212. doi: 10.1002/adma.201702212. [DOI] [PubMed] [Google Scholar]

- 16.Seh, Z. W., Sun, J., Sun, Y. M., & Cui, Y. A highly reversible room-temperature sodium metal anode. ACS Cent. Sci.1, 449–455 (2015). [DOI] [PMC free article] [PubMed]

- 17.Larcher D, Tarascon JM. Towards greener and more sustainable batteries for electrical energy storage. Nat. Chem. 2015;7:19–29. doi: 10.1038/nchem.2085. [DOI] [PubMed] [Google Scholar]

- 18.Munoz-Marquez MA, et al. Na-ion batteries for large scale applications: a review on anode materials and solid electrolyte interphase formation. Adv. Energy Mater. 2017;7:1700463. doi: 10.1002/aenm.201700463. [DOI] [Google Scholar]

- 19.Xu Y, et al. Nanocrystalline anatase TiO2: a new anode material for rechargeable sodium ion batteries. Chem. Commun. 2013;49:8973–8975. doi: 10.1039/c3cc45254a. [DOI] [PubMed] [Google Scholar]

- 20.Lunell S, Stashans A, Ojamae L, Lindstrom H, Hagfeldt A. Li and Na diffusion in TiO2 from quantum chemical theory versus electrochemical experiment. J. Am. Chem. Soc. 1997;119:7374–7380. doi: 10.1021/ja9708629. [DOI] [Google Scholar]

- 21.Wu LM, et al. Unfolding the mechanism of sodium insertion in anatase TiO2 nanoparticles. Adv. Energy Mater. 2015;5:1401142. doi: 10.1002/aenm.201401142. [DOI] [Google Scholar]

- 22.Li W, et al. A reversible phase transition for sodium insertion in anatase TiO2. Chem. Mater. 2017;29:1836–1844. doi: 10.1021/acs.chemmater.7b00098. [DOI] [Google Scholar]

- 23.Zhang GQ, Wu HB, Song T, Paik U, Lou XW. TiO2 hollow spheres composed of highly crystalline nanocrystals exhibit superior lithium storage properties. Angew. Chem. Int. Ed. Engl. 2014;53:12590–12593. doi: 10.1002/anie.201406476. [DOI] [PubMed] [Google Scholar]

- 24.Chen C, et al. Na(+) intercalation pseudocapacitance in graphene-coupled titanium oxide enabling ultra-fast sodium storage and long-term cycling. Nat. Commun. 2015;6:6929. doi: 10.1038/ncomms7929. [DOI] [PubMed] [Google Scholar]

- 25.Aravindan V, Lee YS, Yazami R, Madhavi S. TiO2 polymorphs in ‘rocking-chair’ Li-ion batteries. Mater. Today. 2015;18:345–351. doi: 10.1016/j.mattod.2015.02.015. [DOI] [Google Scholar]

- 26.Longoni G, et al. Shape-controlled TiO2 nanocrystals for Na-ion battery electrodes: the role of different exposed crystal facets on the electrochemical properties. Nano Lett. 2017;17:992–1000. doi: 10.1021/acs.nanolett.6b04347. [DOI] [PubMed] [Google Scholar]

- 27.Wu LM, Buchholz D, Bresser D, Chagas LG, Passerini S. Anatase TiO2 nanoparticles for high power sodium-ion anodes. J. Power Sources. 2014;251:379–385. doi: 10.1016/j.jpowsour.2013.11.083. [DOI] [Google Scholar]

- 28.Dahbi M, Yabuuchi N, Kubota K, Tokiwa K, Komaba S. Negative electrodes for Na-ion batteries. Phys. Chem. Chem. Phys. 2014;16:15007–15028. doi: 10.1039/c4cp00826j. [DOI] [PubMed] [Google Scholar]

- 29.Tahir MN, et al. Extraordinary performance of carbon-coated anatase TiO2 as sodium-ion anode. Adv. Energy Mater. 2016;6:1501489. doi: 10.1002/aenm.201501489. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Xiong Y, Qian J, Cao Y, Ai X, Yang H. Electrospun TiO2/C nanofibers as a high-capacity and cycle-stable anode for sodium-ion batteries. ACS Appl. Mater. Interfaces. 2016;8:16684–16689. doi: 10.1021/acsami.6b03757. [DOI] [PubMed] [Google Scholar]

- 31.Qiu S, Xiao L, Ai X, Yang H, Cao Y. Yolk-shell TiO2@C nanocomposite as high-performance anode material for sodium-ion batteries. ACS Appl. Mater. Interfaces. 2017;9:345–353. doi: 10.1021/acsami.6b12001. [DOI] [PubMed] [Google Scholar]

- 32.Shi XD, et al. Anatase TiO2@C composites with porous structure as an advanced anode material for Na ion batteries. J. Power Sources. 2016;330:1–6. doi: 10.1016/j.jpowsour.2016.08.132. [DOI] [Google Scholar]

- 33.Chen J, et al. Pinecone-like hierarchical anatase TiO2 bonded with carbon enabling ultrahigh cycling rates for sodium storage. J. Mater. Chem. A. 2016;4:12591–12601. doi: 10.1039/C6TA03505A. [DOI] [Google Scholar]

- 34.Ni J, et al. Self-supported nanotube arrays of sulfur-doped TiO2 enabling ultrastable and robust sodium storage. Adv. Mater. 2016;28:2259–2265. doi: 10.1002/adma.201504412. [DOI] [PubMed] [Google Scholar]

- 35.Wang B, et al. Boron-doped anatase TiO2 as a high-performance anode material for sodium-ion batteries. ACS Appl. Mater. Interfaces. 2016;8:16009–16015. doi: 10.1021/acsami.6b03270. [DOI] [PubMed] [Google Scholar]

- 36.Liu SA, Cai ZY, Zhou J, Pan AQ, Liang SQ. Nitrogen-doped TiO2 nanospheres for advanced sodium-ion battery and sodium-ion capacitor applications. J. Mater. Chem. A. 2016;4:18278–18283. doi: 10.1039/C6TA08472A. [DOI] [Google Scholar]

- 37.Zhang J, et al. The interplay of oxygen functional groups and folded texture in densified graphene electrodes for compact sodium-ion capacitors. Adv. Energy Mater. 2018;8:1702395. doi: 10.1002/aenm.201702395. [DOI] [Google Scholar]

- 38.Dinh CT, Nguyen TD, Kleitz F, Do TO. Shape-controlled synthesis of highly crystalline titania nanocrystals. ACS Nano. 2009;3:3737–3743. doi: 10.1021/nn900940p. [DOI] [PubMed] [Google Scholar]

- 39.Li K, et al. Ultrafast-charging and long-life li-ion battery anodes of TiO2-B and anatase dual-phase nanowires. ACS Appl. Mater. Interfaces. 2017;9:35917–35926. doi: 10.1021/acsami.7b11652. [DOI] [PubMed] [Google Scholar]

- 40.Li K, et al. Discovering a first-order phase transition in the Li-CeO2 system. Nano Lett. 2017;17:1282–1288. doi: 10.1021/acs.nanolett.6b05126. [DOI] [PubMed] [Google Scholar]

- 41.Bella F, et al. Unveiling the controversial mechanism of reversible Na storage in TiO2 nanotube arrays: amorphous versus anatase TiO2. Nano Res. 2017;10:2891–2903. doi: 10.1007/s12274-017-1656-6. [DOI] [Google Scholar]

- 42.Yan D, et al. Improved sodium-ion storage performance of TiO2 nanotubes by Ni2+ doping. J. Mater. Chem. A. 2016;4:11077–11085. doi: 10.1039/C6TA04906K. [DOI] [Google Scholar]

- 43.Das SK, et al. Graphene mediated improved sodium storage in nanocrystalline anatase TiO2 for sodium ion batteries with ether electrolyte. Chem. Commun. 2016;52:1428–1431. doi: 10.1039/C5CC09656A. [DOI] [PubMed] [Google Scholar]

- 44.Wang J, Polleux J, Lim J, Dunn B. Pseudocapacitive contributions to electrochemical energy storage in TiO2 (anatase) nanoparticles. J. Phys. Chem. C. 2007;111:14925–14931. doi: 10.1021/jp074464w. [DOI] [Google Scholar]

- 45.Li SM, et al. Alternating voltage induced ordered anatase TiO2 nanopores: an electrochemical investigation of sodium storage. J. Power Sources. 2016;336:196–202. doi: 10.1016/j.jpowsour.2016.10.072. [DOI] [Google Scholar]

- 46.Barsoukov E, et al. Comparison of kinetic properties of LiCoO2 and LiTi0.05Mg0.05Ni0.7Co0.2O2 by impedance spectroscopy. Solid State Ion. 2003;161:19–29. doi: 10.1016/S0167-2738(03)00150-4. [DOI] [Google Scholar]

- 47.Busche MR, et al. Dynamic formation of a solid-liquid electrolyte interphase and its consequences for hybrid-battery concepts. Nat. Chem. 2016;8:426–434. doi: 10.1038/nchem.2470. [DOI] [PubMed] [Google Scholar]

- 48.Soto FA, Marzouk A, El-Mellouhi F, Balbuena PB. Understanding ionic diffusion through SEI components for lithium-ion and sodium-ion batteries: insights from first-principles calculations. Chem. Mater. 2018;30:3315–3322. doi: 10.1021/acs.chemmater.8b00635. [DOI] [Google Scholar]

- 49.Choudhury S, et al. Designing solid-liquid interphases for sodium batteries. Nat. Commun. 2017;8:898. doi: 10.1038/s41467-017-00742-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 50.Munoz-Marquez MA, et al. Composition and evolution of the solid-electrolyte interphase in Na2Ti3O7 electrodes for Na-ion batteries: XPS and Auger parameter analysis. ACS Appl. Mater. Interfaces. 2015;7:7801–7808. doi: 10.1021/acsami.5b01375. [DOI] [PubMed] [Google Scholar]

- 51.Pan Y, et al. Investigation of the solid electrolyte interphase on hard carbon electrode for sodium ion batteries. J. Electroanal. Chem. 2017;799:181–186. doi: 10.1016/j.jelechem.2017.06.002. [DOI] [Google Scholar]

- 52.Bi XX, et al. Investigating dendrites and side reactions in sodium-oxygen batteries for improved cycle lives. Chem. Commun. 2015;51:7665–7668. doi: 10.1039/C5CC00825E. [DOI] [PubMed] [Google Scholar]

- 53.Dahbi M, et al. Black phosphorus as a high-capacity, high-capability negative electrode for sodium-ion batteries: investigation of the electrode/interface. Chem. Mater. 2016;28:1625–1635. doi: 10.1021/acs.chemmater.5b03524. [DOI] [Google Scholar]

- 54.Eshetu GG, et al. Impact of the electrolyte salt anion on the solid electrolyte interphase formation in sodium ion batteries. Nano Energy. 2019;55:327–340. doi: 10.1016/j.nanoen.2018.10.040. [DOI] [Google Scholar]

- 55.Zhou M, et al. Amorphous TiO2 inverse opal anode for high-rate sodium ion batteries. Nano Energy. 2017;31:514–524. doi: 10.1016/j.nanoen.2016.12.005. [DOI] [Google Scholar]

- 56.Chen J, et al. Black anatase titania with ultrafast sodium-storage performances stimulated by oxygen vacancies. ACS Appl. Mater. Interfaces. 2016;8:9142–9151. doi: 10.1021/acsami.6b01183. [DOI] [PubMed] [Google Scholar]

- 57.Li Y, et al. Excellent sodium storage performance of carbon-coated TiO2: assisted with electrostatic interaction of surfactants. J. Power Sources. 2017;361:326–333. doi: 10.1016/j.jpowsour.2017.06.076. [DOI] [Google Scholar]

- 58.Oh SM, et al. High electrochemical performances of microsphere C-TiO(2) anode for sodium-ion battery. ACS Appl. Mater. Interfaces. 2014;6:11295–11301. doi: 10.1021/am501772a. [DOI] [PubMed] [Google Scholar]

- 59.Su DW, Dou SX, Wang GX. Anatase TiO2: better anode material than amorphous and rutile phases of TiO2 for Na-ion batteries. Chem. Mater. 2015;27:6022–6029. doi: 10.1021/acs.chemmater.5b02348. [DOI] [Google Scholar]

- 60.Kim KT, et al. Anatase titania nanorods as an intercalation anode material for rechargeable sodium batteries. Nano Lett. 2014;14:416–422. doi: 10.1021/nl402747x. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The data that support the findings of this study are available within the article and its Supplementary Information files. All other relevant data supporting the findings of this study are available from the corresponding authors upon reasonable request.