Abstract

Background/purpose

This study evaluated the torsional resistances of nickel-titanium rotary instruments by two methods: i) dynamic resistance: repetitive torsional loading (RTL) and ii) static resistance: single torsional loading (STL) based on the International Organization for Standardization.

Materials and methods

In RTL method, a pre-set rotational loading (0.5 N cm) was applied after fixing the 3-mm tip of the file, and this clockwise loading to the pre-set torque and counter-clockwise unloading to original position was repeated at 50 rpm until the file fractured. The number of repetition cycles until fracture was counted. In STL method, the torsional strength was determined by continuous clockwise rotation (2 rpm) until fracture. Results from both methods were compared after testing the torsional resistances of four instrument systems (n = 15): Hyflex CM, HyFlex EDM, V-Taper2, and V-Taper2H. A scanning electron microscope (SEM) was used to examine the topographic features of the fractured surfaces and longitudinal aspects (n = 5) from both methods.

Results

The RTL and STL methods had similar results: V-Taper2 had the highest resistance and the Hyflex CM had the lowest (P < 0.05). Spearman correlation test showed the results from two methods were strongly correlated (coefficient = 1). Under the SEM, specimens from the RTL showed ruptured aspects on cross-sections with multiple areas of crack propagation, while the STL showed the typical features of torsional failure such as circular abrasion marks and fatigue dimples.

Conclusions

This study suggests the clinically relevant torsional test (RTL) method yield similar results with the STL method, but they have different topographic findings.

Keywords: Fracture, Nickel-titanium rotary instrument, Torsional resistance, Dynamic repetitive load, Static rotation

Introduction

Root canal preparation with nickel-titanium (NiTi) rotary files is not only easier and faster than preparation with hand instruments, but also causes fewer iatrogenic alterations to the shape of the root canal.1 Notwithstanding the enhanced flexibility and strength compared with other endodontic files, NiTi rotary instruments are still subject to separation in the clinical use.2, 3, 4

It has been previously reported in the literature that NiTi endodontic instruments have two basic mechanisms of fracture.3, 4, 5, 6 Flexural or cyclic fatigue fractures occur when an instrument rotates in a curved canal, and are caused by repeated compressive and tensile stresses.3,4,6 On the other hand, torsional failure correlates with the continuous rotation of the engine when the tip of the instrument binds in the canal.4

Cyclic fatigue resistance of NiTi rotary instruments has been assessed extensively, but there is little information available on torsional fracture resistance tests. The only method of testing for static rotational fracture is the comparing the torsional resistances of the instruments. This method was mainly based on the International Organization for Standardization (ISO) 3630-1.7 However, its original purpose was for testing stainless steel manual endodontic instruments. According to this specification, the 3 mm file tip was fixed with the brass and 2 rpm of rotational speed was applied to create a torsional load. However, the test conditions with a rotational speed of 2 rpm to create torsional stress and the static rotation until a fracture are not sufficient for testing the rotary instruments that rotate at speeds much higher than 2 rpm or for the specific motors with “auto-reverse” mode.

During the clinical use of rotary NiTi instruments, the file undergoes repetitive locking and unlocking by the auto-reverse movements at a pre-fixed level of torsional stress. Fatigue may be defined as the failure of a material after repetitive stress at levels below its yield point.8 Clinically, no one file will be fractured by static rotation until fracture by a continuous loading as the ISO test method. On the other hand, rotary instruments will be loaded by repeated locking (and release) by using the torque-control motor.9 Especially, in narrow canals, rotary instruments are subject to higher torsional stresses than in the wider canals,10 hence the chance of experiencing such repetitive torsional loads are increased.

Thus, in this study, the torsional resistances of various NiTi instruments were compared using the method with dynamic and repetitive torsional loads that incorporates the clinically relevant auto-reverse motion. The method was compared with the ISO based method.

Materials and methods

Two torsional test methods were conducted with four NiTi instrument systems: Hyflex CM (HCM; Coltene, Altstätten, Switzerland) made of CM-wire, HyFlex EDM (HDM; Coltene) produced via electro-discharge machining (EDM) using CM-wire, V-Taper2 (VT2; SS White, Lakewood, CA, USA) made of conventional NiTi alloy, and heat treated V-Taper2H (VTH; SS White). The files used in this study had the same ISO tip size of #25, a similar taper (0.06 taper for HCM and VTH, 0.08 taper for VT2 and variable taper for HDM), and 25-mm length. No defects or deformities were detected on any instrument upon inspection under a dental operating microscope (Zeiss Pico; Carl Zeiss MediTec, Jena, Germany) prior to the experiment.

Test I: determination of torsional resistance by repetitive torsional load (RTL)

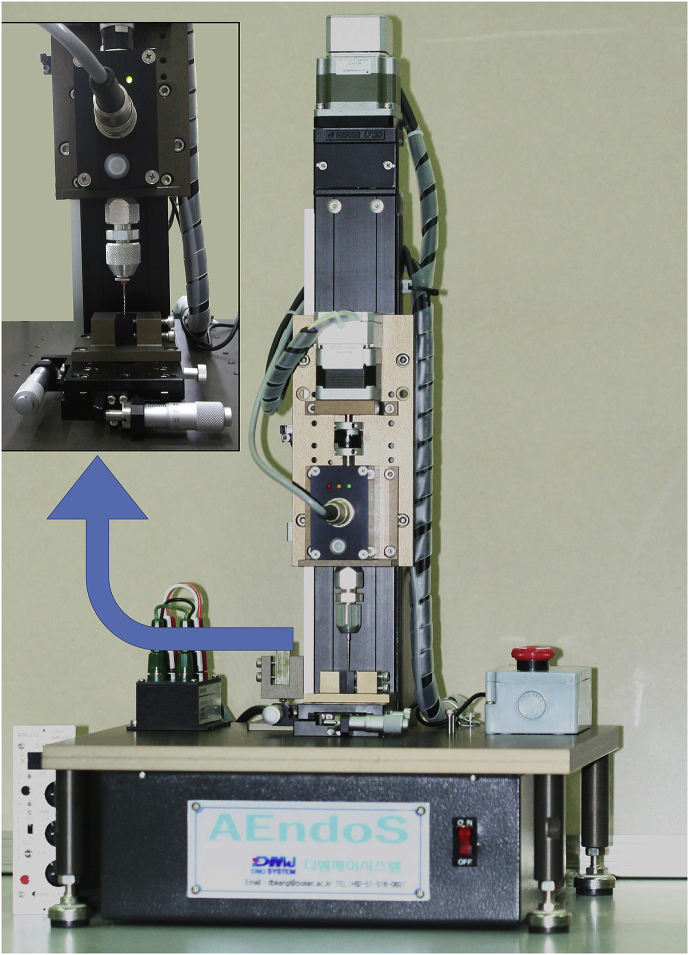

The apical 3 mm portion each instrument (n = 15 per brand) was secured between brass plates. The file was driven at 50 rpm clockwise until it achieved the pre-set torque of 0.5 N cm, then it was returned to its original position using a custom-made device (AEndoS; DMJ system, Busan, Korea) (Fig. 1). This was considered one torsional loading cycle. Dwell time was set as 50 ms. The loading was repeated automatically until the file broke. The custom-made device automatically recorded the number of repetitive load cycles until fracture (NRCF) of each instrument.

Figure 1.

The test device (AEndoS; DMJ, Busan, Korea) used in this study to make dynamic torsional loading on RTL method and single continuous torsional loading in STL method.

Test II: determination of the torsional resistance by static rotational torsional load (STL)

The ultimate torsional strength (N·cm) until fracture was determined for each instrument (n = 15 per brand) using the same device. The apical 3 mm portion of the instrument was secured between brass plates. They were then rotated at a constant rate of 2 rpm in a clockwise direction until fracture, while keeping the files straight. The torsional loading during rotation including the maximum strength (N·cm) and distortion angle (degree) were recorded during the rotation of the files at the rate of 20 Hz (20 data of torque values were collected per 1 s). The toughness until the point of fracture was computed from the area under the plot by using Origin v 6.0 Professional (Microcal Software Inc., Northampton, MA, USA).

The data were first examined using the Kolmogorov–Smirnov test for normality of distribution. The results were statistically analysed using a one-way analysis of variance (ANOVA) and Duncan post-hoc comparison for the STL test and Kruskal–Wallis and Mann–Whitney test for the RTL test to identify differences between the groups. Wilcoxon rank-sum test was done together to make an order for the groups. The results from the two test methods were also statistically compared for any differences between methods using the Spearman correlation test (SPSS v. 23.0 for Mac; IBM Corp, Somers, NY, USA). All statistical analyses were completed at a significance level of 95%.

Scanning electron microscope examination

Five fractured fragments from each instrument system of each method were randomly selected and ultrasonically cleaned with absolute alcohol for approximately 120 s. The fractured surfaces and longitudinal aspects of the fractured instruments were examined under a scanning electron microscope (SEM) (SU8220; Hitachi High Technologies, Tokyo, Japan) for the topographic features.

Results

Test I: determination of torsional resistance using repetitive torsional load (RTL)

The repetitive torsional test showed that the VT2 group had the highest NRCF among the test groups, while the HCM group had the least (P < 0.05). The order of the NRCF according to the Wilcoxon rank-sum test was as follows from highest to lowest: VT2, EDM, VTH, and HCM.

Test II: determination of the torsional resistance by static rotational torsional load (STL)

The results of STL test using the ISO method of static rotational torsional loading showed that among all the test groups, the VT2 group also had the highest ultimate torsional strength, while the HCM group had the least (P < 0.05). Based on the results of the Wilcoxon rank-sum test, the order of the ultimate strength was same with the RTL method: VT2, EDM, VTH, and HCM.

Meanwhile, STL method presented the distortion angles of the tested groups: VTH is the biggest and HCM was the least.

Relationship between the two torsional resistance test methods

The results of the RTL method at 50 rpm were the same (correlation coefficient = 1) as those from the torsional resistance test using the STL method according to the ISO 3630-1.

When the same instrument underwent testing by these 2 tests, the results between the two tests were strongly correlated. The RTL method yielded the same order of resistances as the STL method (Table 1).

Table 1.

Comparison of torsional resistance (Mean ± SD) by the two methods.

| Test method |

RTL method |

STL method |

|

|---|---|---|---|

| File | NRCF | Ultimate strength (N·cm) | Distortion angle (°) |

| Hyflex CM | 52 ± 23d | 0.64 ± 0.06d | 458 ± 35c |

| HyFlex EDM | 2373 ± 820b | 1.35 ± 0.16b | 598 ± 62b |

| V-Taper 2 | 5454 ± 1790a | 1.70 ± 0.19a | 609 ± 72b |

| V-Taper 2H | 1865 ± 827c | 1.16 ± 0.22c | 678 ± 96a |

a,b,c,d: Different superscript letters indicate significant differences between groups in vertical column (P < 0.05).

RTL: repetitive torsional loading, STL: static torsional loading.

NRCF: number of repetitive load cycles until fracture.

Scanning electron microscope (SEM) examination

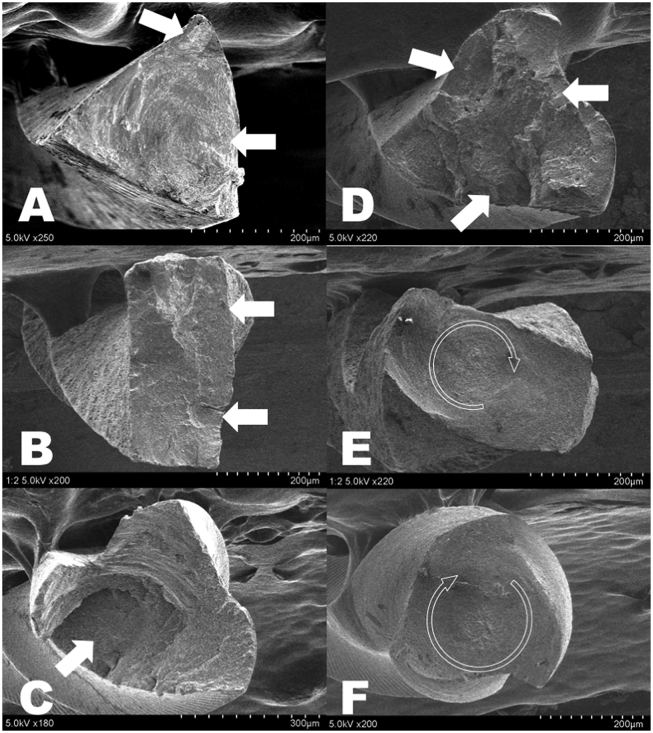

The SEM examination of the fractured specimens from the RTL and STL methods showed significantly different features. Examination of the cross-sections of the specimens using the RTL method showed ruptured aspects with multiple areas of initiated and propagating cracks, while the STL method showed typical features of torsional failure, such as circular abrasion marks and fatigue dimples at the centre of rotation (Fig. 2).

Figure 2.

Representative cross-sectional aspects of the fracture fragments from the RTL method (A to D) and STL method (E and F) (A; Hyflex CM, B and E; HyFlex EDM, C and F; V-Taper2, D; V-Taper2H). Specimens from the RTL method show ruptured aspects (white arrows) on the cross-section with multiple areas of initiated and propagated cracks, while the specimens from STL method show typical features of torsional failure, such as a circular abrasion mark (circle arrow) and fatigue dimple at the centre of rotation.

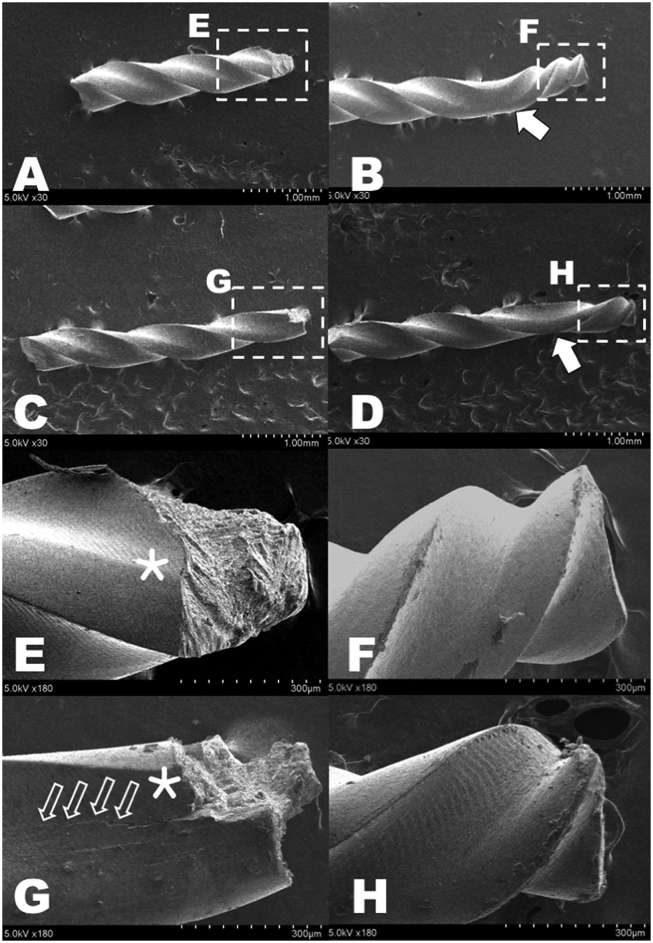

On the longitudinal and lateral aspects of the fractured fragments, specimens from the RTL method showed rare unwinding near the fracture area, while the specimens from STL method had typical features of unwinding area. The specimens from the RTL method showed irregular fracture aspects with some cracks and without unwinding (Fig. 3).

Figure 3.

Representative longitudinal and lateral aspects of the fracture fragments from the RTL method (left column; A, C, E, and G) and STL method (right column; B,D,F and H) (A, B, E and F; HyFlex EDM, C, D, G and H; V-Taper2). Specimens from the RTL method show rare unwinding near the fracture area (A and C; dotted box), while the specimens from STL method show typical features of unwinding (B and D; closed white arrows). The magnified aspects (E and G from A and C respectively) from the specimens of RTL method show irregular and catastrophic aspects (*) with some cracks without unwinding, while the magnified aspects (F and H from B and D respectively) had clear cut end. Especially, the specimen (G) from VT2 show the longitudinal microcracks (open white arrows).

Discussion

Due to the super-elasticity of a NiTi instrument, clinicians can predictably shape curved, well-centred root canals, with a decreased risk of transportation, ledging, and perforation compared to stainless steel files.11 Nevertheless, there still remains the risk of instrument failure with NiTi rotary instruments. Fractures of NiTi files are known result from torsional failure, cyclic fatigue, or a combination of both.4 The literature is replete with studies that compare the difference between various NiTi systems by evaluating two fracture modes separately.

While cyclic fatigue resistance is usually compared using the NCF value measured under various conditions of the radius of the canal curvature and arc length using simulated canals,4 the torsional strength of NiTi instruments has been compared mainly by the method described in the ISO 3630-1, ADA/ANSI specifications number 28,12 or their modifications.5, 6, 7 As a torsional moment is gradually applied while the tip of the instrument is clamped rigidly, the parameters, such as the maximum torque and/or the angular deflection at breakage, are recorded.12,13 However, torsional loading under such “monotonic” conditions rarely occur clinically.14 In clinic, a torsional load is typically not applied to the instrument until it fractures, but is frankly limited by the torque-controlled endodontic motor. The auto-reverse movement by the endodontic motor may create repetitive loading and unloading due to a certain condition from the root canal or operator.

Furthermore, the test condition of rotational speed (2 rpm) is imperfect because the ISO and ADA/ANSI specifications are for stainless-steel instruments used in hand or finger manipulation, even though the NiTi instruments are used at a motor driven speed, which is typically much higher than 2 rpm. Therefore, for the RTL method in the present study, the increased speed of 50 rpm and repetitive torsional loading, based on the auto-reverse mode (repetitive loading and unloading), were applied to improve the clinical relevance.

Interestingly, both methods yielded same results when the instruments were compared. The instruments with a relatively higher torsional resistance during the repetitive loading method also had higher resistance with the static rotational loading method. It may implicate that the more clinically relevant method with the repetitive torsional loading is the more appropriate method for the NiTi engine-driven instruments.

In the present study, both test methods resulted in the same order of resistances among the 4 tested groups. VT2 showed the highest torsional resistance from both methods. It seemed due to the stiffer properties of conventional NiTi alloy of VT2 file, while other files were made of heat treated NiTi alloy. Of course the bigger taper of VT2 (8%) would be the major reason of higher torsional strength. Basically the geometries of the instruments may affect on their torsional resistances; i.e., the instrument with bigger cross-sectional area has the higher resistances.15

The characteristics of the instruments made of CM-wire are a higher flexibility and lower stiffness, which contributed to the lower torsional resistance and strength than conventional NiTi alloy.16,17 Although the EDM and HCM were made of same CM-wire, the higher resistance of EDM made of the same CM-wire may result from their geometric differences, including the cross-sectional area and the special manufacturing method.17, 18, 19 The electric discharge machining for the manufacturing of EDM would be another reason for the relatively higher torsional resistance with their cross sectional differences.20, 21, 22, 23, 24 The HCM had the least distortion angle and the VTH had the biggest angle than others in the STL method and it might be resulted from the differences of stiffness and geometric and/or volumetric size among them.

Meanwhile, depending on the alloy and/or geometric differences, the file may have different mechanical properties by the repetitive loading. Ha et al. reported that the NiTi material of conventional instruments is sensitive to not only thermomechanical treatment, but also repetitive mechanical stimulation.6,25, 26, 27 Repeated loading without causing surface defects or micro-cracking, which act as stress raisers and are precursors of material failure, would serve to increase the density of dislocations inside the material.28,29 This situation could result in a higher degree of torsional resistance.26,27 Since repetitive loading during the initial stage of root canal preparation in a clinical situation could change the properties and mechanical resistance of NiTi rotary instrument, the repetitive loading method could have a higher clinical relevance than the static rotational loading test. Considering the possibility of increased strength by the repeated loading, a change in the assessment method would be sensible.

Manufacturers of various brands of NiTi rotary instruments have recommended the use of a certain value of torque that is considered safe, i.e. capable of preventing (shear) fracture of the instrument. That is not completely accurate because in the clinical setting, the handpiece (motor) measures the torsional load from the full length of instrument during movement, while the experimental test measures the torsional load at a specific level (3 mm). Thus, in the present study, since the load was concentrated at the 3 mm level of the instruments, the maximum limit of torque was set to 0.5 N cm.

In fractographic examination, features observed from the specimens of RTL method were significantly different from those of STL method. While the STL method made typical features of torsional failure including circular abrasion marks and fibrous dimples in the centre of this circle, the RTL method made catastrophic aspects with ruptured surfaces of the cross-section as well as the lateral area. Furthermore, while the STL method showed extensive areas of unwinding of the flute near the fracture area, the unwound flutes were rare in the specimens from RTL method. It could be understood that the repetition of a small amount of torsional load at the moment of fracture imposed stress on some of the micro-cracks without unwinding the flute, but the accumulation of micro failures suddenly resulted in ruptured fractures.

Since fracture of an instrument in use can potentially lower the probability of healing, increasing the resistance to fracture has been a focus in the design of NiTi rotary systems.30 Because the fracture resistance is strongly correlated with clinical usage, the fracture test should be conducted under conditions that mimic the clinical setting.

In the current study, constant torsional stress was applied repetitively to simulate repeated locking of the rotary file during canal preparation. A higher number of load application cycles to failure implicated a higher resistance to torsional failure of the instrument. However, torsional stress loaded on multiple levels of the instruments, rather than on the single fixed level of the instrument, needs to be developed to simulate further higher clinical conditions.

Within the limitations of this study, evaluation of torsional resistance using the RTL method yields similar results to those using the STL test method based on ISO specifications. From both test methods, conventional NiTi alloy instrument showed the highest torsional resistance when compared to that of other heat-treated instruments. Clinically accumulated torsional stresses by repetitive torsional load may display different topographic features on the instruments that found usually in the conventional torsional resistant test based on ISO method. Testing the torsional resistance of the instruments using the RTL method would produce results with more clinical relevance.

Conflicts of interest

The authors have no conflicts of interest relevant to this article.

Acknowledgements

This study was supported by grants from the Deanship of Scientific Research, University of Jordan, The University of Jordan.

References

- 1.Cheung G.S., Liu C.S. A retrospective study of endodontic treatment outcome between nickel-titanium rotary and stainless steel hand filing techniques. J Endod. 2009;35:938–943. doi: 10.1016/j.joen.2009.04.016. [DOI] [PubMed] [Google Scholar]

- 2.Sattapan B., Nervo G., Palamara J., Messer H. Defects in rotary nickel-titanium files after clinical use. J Endod. 2000;26:161–165. doi: 10.1097/00004770-200003000-00008. [DOI] [PubMed] [Google Scholar]

- 3.Shen Y., Cheung G.S., Bian Z., Peng B. Comparison of defects in ProFile and ProTaper systems after clinical use. J Endod. 2006;32:61–65. doi: 10.1016/j.joen.2005.10.017. [DOI] [PubMed] [Google Scholar]

- 4.Cheung G.S. Instrument fracture: mechanisms, removal of fragments, and clinical outcomes. Endod Top. 2009;16:1–26. [Google Scholar]

- 5.Yum J., Cheung G.S., Park J.K., Hur B., Kim H.C. Torsional strength and toughness of nickel-titanium rotary files. J Endod. 2011;37:382–386. doi: 10.1016/j.joen.2010.11.028. [DOI] [PubMed] [Google Scholar]

- 6.Ha J.H., Kim S.K., Cohenca N., Kim H.C. Effect of R-phase heat treatment on torsional resistance and cyclic fatigue fracture. J Endod. 2013;39:389–393. doi: 10.1016/j.joen.2012.11.028. [DOI] [PubMed] [Google Scholar]

- 7.ISO 3630-1 . International Organization for Standardization; Geneve, Switzerland: 1992. Dental Root-Canal Instruments: Files, Reamers, Barbed Broaches, Rasps, Paste Carriers, Explorers and Cotton Broaches. [Google Scholar]

- 8.Askeland D.R., Phulé P.P. 4th ed. Thomson Brooks/Cole; Pacific Grove, CA, USA: 2003. The Science and Engineering of Materials. [Google Scholar]

- 9.Best S., Watson P., Pilliar R., Kulkarni G.G., Yared G. Torsional fatigue and endurance limit of a size 30.06 ProFile rotary instrument. Int Endod J. 2004;37:370–373. doi: 10.1111/j.1365-2591.2004.00814.x. [DOI] [PubMed] [Google Scholar]

- 10.Peters O.A., Peters C.I., Schönenberger K., Barbakow F. ProTaper rotary root canal preparation: assessment of torque and force in relation to canal anatomy. Int Endod J. 2003;36:93–99. doi: 10.1046/j.1365-2591.2003.00628.x. [DOI] [PubMed] [Google Scholar]

- 11.Yamamura B., Cox T.C., Heddaya B., Flake N.M., Johnson J.D., Paranjpe A. Comparing canal transportation and centering ability of endosequence and vortex rotary files by using micro-computed tomography. J Endod. 2012;38:1121–1125. doi: 10.1016/j.joen.2012.04.019. [DOI] [PubMed] [Google Scholar]

- 12.ANSI/ADA Specification No. 28 . American Dental Association; Chicago, USA: 2008. Root Canal Files and Reamers, Type K. [Google Scholar]

- 13.Bahia M.G., Melo M.C., Buono V.T. Influence of simulated clinical use on the torsional behavior of nickel-titanium rotary endodontic instruments. Oral Sur Oral Med Oral Pathol Oral Radiol Endod. 2006;101:675–680. doi: 10.1016/j.tripleo.2005.04.019. [DOI] [PubMed] [Google Scholar]

- 14.Blum J.Y., Machtou P., Micallef J.P. Location of contact areas on rotary Profile instruments in relationship to the forces developed during mechanical preparation on extracted teeth. Int Endod J. 1999;32:108–114. doi: 10.1046/j.1365-2591.1999.00200.x. [DOI] [PubMed] [Google Scholar]

- 15.Baek S.H., Lee C.J., Versluis A., Kim B.M., Lee W., Kim H.C. Comparison of torsional stiffness of nickel-titanium rotary files with different geometric characteristics. J Endod. 2011;37:1283–1286. doi: 10.1016/j.joen.2011.05.032. [DOI] [PubMed] [Google Scholar]

- 16.Elnaghy A.M., Elsaka S.E. Mechanical properties of ProTaper Gold nickel-titanium rotary instruments. Int Endod J. 2016;49:1073–1078. doi: 10.1111/iej.12557. [DOI] [PubMed] [Google Scholar]

- 17.Pedullà E., Lo Savio F., Boninelli S. Torsional and cyclic fatigue resistance of a new nickel-titanium instrument manufactured by electrical discharge machining. J Endod. 2016;42:156–159. doi: 10.1016/j.joen.2015.10.004. [DOI] [PubMed] [Google Scholar]

- 18.Shen Y., Qian W., Abtin H., Gao Y., Haapasalo M. Fatigue testing of controlled memory wire nickel-titanium rotary instruments. J Endod. 2011;37:997–1001. doi: 10.1016/j.joen.2011.03.023. [DOI] [PubMed] [Google Scholar]

- 19.Pirani C., Iacono F., Generali L. HyFlex EDM: superficial features, metallurgical analysis and fatigue resistance of innovative electro discharge machined NiTi rotary instruments. Int Endod J. 2016;49:483–493. doi: 10.1111/iej.12470. [DOI] [PubMed] [Google Scholar]

- 20.Chang S.W., Shim K.S., Kim Y.C. Cyclic fatigue resistance, torsional resistance, and metallurgical characteristics of V taper 2 and V taper 2H rotary NiTi files. Scanning. 2016;38:564–570. doi: 10.1002/sca.21301. [DOI] [PubMed] [Google Scholar]

- 21.Young J.M., Van Vliet K.J. Predicting in vivo failure of pseudoelastic NiTi devices under low cycle, high amplitude fatigue. J Biomed Mater Res B Appl Biomater. 2005;72:17–26. doi: 10.1002/jbm.b.30113. [DOI] [PubMed] [Google Scholar]

- 22.Gambarini G., Grande N.M., Plotino G. Fatigue resistance of engine-driven rotary nickel-titanium instruments produced by new manufacturing methods. J Endod. 2008;34:1003–1005. doi: 10.1016/j.joen.2008.05.007. [DOI] [PubMed] [Google Scholar]

- 23.Alapati S.B., Brantley W.A., Iijima M. Metallurgical characterization of a new nickel-titanium wire for rotary endodontic instruments. J Endod. 2009;35:1589–1593. doi: 10.1016/j.joen.2009.08.004. [DOI] [PubMed] [Google Scholar]

- 24.Ye J., Gao Y. Metallurgical characterization of M-Wire nickel-titanium shape memory alloy used for endodontic rotary instruments during low-cycle fatigue. J Endod. 2012;38:105–107. doi: 10.1016/j.joen.2011.09.028. [DOI] [PubMed] [Google Scholar]

- 25.Kim J.Y., Cheung G.S., Park S.H., Ko D.C., Kim J.W., Kim H.C. Effect from cyclic fatigue of nickel-titanium rotary files on torsional resistance. J Endod. 2012;38:527–530. doi: 10.1016/j.joen.2011.12.018. [DOI] [PubMed] [Google Scholar]

- 26.Cheung G.S., Oh S.H., Ha J.H., Kim S.K., Park S.H., Kim H.C. Effect of torsional loading of nickel-titanium instruments on cyclic fatigue resistance. J Endod. 2013;39:1593–1597. doi: 10.1016/j.joen.2013.07.032. [DOI] [PubMed] [Google Scholar]

- 27.Ha J.H., Kim S.K., Cheung G.S., Jeong S.H., Bae Y.C., Kim H.C. Effect of alloy type on the life-time of torsion-preloaded nickel-titanium endodontic instruments. Scanning. 2015;37:172–178. doi: 10.1002/sca.21195. [DOI] [PubMed] [Google Scholar]

- 28.Miyazaki S., Imai T., Igo Y., Otsuka K. Effect of cyclic deformation on the pseudoelasticity characteristics of Ti-Ni alloys. Metallurgical Transactions A. 1986;17:115–120. [Google Scholar]

- 29.Kaplan W.D. The mechanism of crystal deformation. Science. 2015;349:1059–1060. doi: 10.1126/science.aac9623. [DOI] [PubMed] [Google Scholar]

- 30.Thoden van Velzen S.K., Duivenvoorden H.J., Schuurs A.H. Probabilities of success and failure in endodontic treatment: a Bayesian approach. Oral Surg Oral Med Oral Pathol. 1981;52:85–90. doi: 10.1016/0030-4220(81)90178-x. [DOI] [PubMed] [Google Scholar]