INTRODUCTION

In 2013, the National Research Council (NRC) issued the consensus study report, Improving Self-Escape from Underground Coal Mines (National Research Council, 2013; available at https://www.nap.edu/download/18300). The NRC report (p. 2) defined self-escape in the event of a mine emergency as “the ability of an individual or group of miners to remove themselves from the mine using available resources,” and called for detailed task analysis of self-escape to describe self-escape behaviors and required capabilities, knowledge, and skills.

In response to this report’s recommendation, the Centers for Disease Control (CDC) and The National Institute for Occupational Safety and Health (NIOSH) funded work to accomplish a detailed task analysis. The scope of this project was bounded between (a) miners making the decision on their own or based on notification by coworkers or mine management of the need to evacuate due to a hazardous situation, and (b) completed self-escape at exit from the underground mine. The goals of this effort were two-fold: (1) to produce a set of specific recommendations to facilitate self-escape that would reduce task demands to operate within individual cognitive capabilities; (2) to facilitate and optimize human performance in meeting task demands, and increase the likelihood of success through eliminating tasks, redesigning tasks to reduce differences between task demands and individual capability, or improving human performance through better training and/or assistive tools and technology.

The project consisted of four phases, and the current paper focuses on the cognitive task analysis (CTA) work done in Phase 4. During Phase 1, we developed data collection protocol and materials and secured NIOSH Institutional Review Board approval and clearance from the U.S. Office of Management and Budget (OMB), which is required to collect data from persons outside the government. In Phase 2, we identified self-escape tasks, organized them into categories, and identified which tasks are critical to successful escape. In Phase 3, we performed hierarchical task analysis recommendations development. Finally, in Phase 4, we performed a CTA to describe thought-based components of escape, particularly information sharing, goal setting, planning, and decision-making, and developed results-based recommendations.

BACKGROUND ON UNDERGROUND COAL MINING

Bise (2013) provides an excellent source for background information on coal mining. Coal beds exist throughout the world and are the result of topological conditions that compressed ancient plant life into layers of carbon. This coal exists in layers that vary in thickness and depth below the surface. Coal is extracted by either (a) removing earth and rock from the surface to expose and extract the coal seam (surface mining, which was not included in this research); or (b) accessing the coal seam underground by shaft, slope, or drift and then removing the coal from between layers of rock.

Underground mines are complex and continuously-changing industrial operations that often extend in a lattice-like maze of tunnels expanding across miles underground. Underground mining machines extract coal by cutting it free from the surrounding rock, leaving an open space, known as entries, which are thereafter used to transport workers and equipment, mined coal, and ventilating air. In the continuous mining method, also known as room and pillar mining, machines cut and load coal into shuttle cars that carry the mined coal to a system of long rubber conveyor belts, powered by underground electric motors, which continuously move coal from the working face area to the surface and outside the mine. Mine ventilation systems maintain continuously controlled air flow, with each mine having a unique ventilation plan that routes clean outside air (intake air) into the mine and across working face areas. At the face, the ventilating air dilutes and entrains contaminants (dust and methane gas) and then is exhausted (as return air) through entries that are separate from those designated for routine transport. After coal is extracted at the working face, miners install bolts into the roof to prevent roof material from falling into the entry. Longwall mining is another underground mining method, in which continuous mining machines cut entries that outline a single large block of coal of up to 480 meters wide by 6,100 meters long. To extract the coal from this block, a shearer moves back-and-forth across the width of the face while cutting away 1 meter of coal with each pass. The mined coal is loaded onto an armored face conveyor and then transferred to a rubber conveyor belt for transport out of the mine. Movable shields support the roof above the immediate face area and are moved forward as coal is sheared from the block, after which the unsupported roof behind the shields falls into the remaining void.

Each mine has rail or rubber-tired mantrip systems to transport miners and equipment between the entry portal and work locations within the mine, as well as systems to provide water and electrical power. Each mine also has designated escapeway routes, which miners would use to exit the mine during an emergency. Escapeways are marked with reflective signs, and ropes having tactile-coded markers that are mounted along the walls (ribs) and roof to enable miners to find their way to the exit even in complete darkness.

To enable miners to breathe should the mine become filled with smoke, dust, or toxic gasses, each miner carries a self-contained self-rescuer (SCSR) device, one type of which is shown in Figure 1, which provides 10 minutes of breathable air. Donning the 10-minute SCSR provides time for the miner to locate and don a larger, one-hour capacity breathing device. These are stored in caches located throughout designated areas of the mine in numbers sufficient for each miner to don his or her own device plus have some as spares and replacements. One-hour devices provide breathable air to each miner during escape or while awaiting rescue. The Appendix provides supplementary information on SCSRs.

FIGURE 1.

(TOP) A 10-MINUTE DURATION SCSR UNIT (LEFT) AND CARRYING CASE (RIGHT); (BOTTOM) SCSR SIMULATOR EXPECTANCY TRAINING DEVICE. A 12-INCH RULER IS PROVIDED FOR SCALE

Work to Prepare for the CTA

During Phase 1 of this research, we used a variety of information sources to gain a broader general understanding of underground mine operations. We sought to understand: (a) the conditions and context of emergency event scenarios that can induce the need for self-escape; (b) the complexities and coordination required of the escape and recovery system after an emergency; and (c) mining terminology to facilitate later communication with miners. We produced documentation for submission to the NIOSH Institutional Review Board and for Office of Management and Budget approval. Almost one year was required to secure these two approvals before further research could begin.

In Phase 2, the research team confirmed the predetermined NIOSH-specified self-escape roles (described in the Methods section), developed our understanding of current self-escape training, captured miner ideas about improving self-escape, and identified and categorized primary self-escape tasks. Researchers interviewed mine managers, met with focus groups made up of miners, and observed mining operations activities at each of the participating mines (described further in the Methods section). Each researcher completed the required training to enter underground portions of the mines, which included learning to use SCSRs and to follow designated escape procedures. Underground tours provided by the host mine sites allowed us to experience the mine environment, view systems that transport miners and coal, and view continuous and longwall mining operations. Interviews with mine managers confirmed the designated self-escape roles and actions required of each role during underground mine emergencies.

Existing literature suggests that communication and coordination are two team processes critical to positive outcomes during an emergency (Dunn, Lewandowsky, & Kirsner, 2002; Risser et al., 1999), and this was further supported by our work. We confirmed that individuals and crews need to coordinate with each other, and identified an initial list of communication and coordination behaviors, along with potential risk points and challenges during self-escape. Using focus groups, we developed a list of 146 tasks required by any of the four self-escape roles during escape, then (along with our Mining subject matter expert, or SME) identified tasks critically important to self-escape. Examples of these tasks include “Decide on best strategy to care for or transfer injured miners,” “Diagnose mine conditions extent of damage caused by disaster,” “Recognize and interpret alarms/alerts,” and “Conduct headcount to account for personnel.” A critical task was defined as one substantially lowering the probability of self-escape if not performed successfully. While criticality is subjective, researchers worked with miners, our SME, and drew upon our own task analysis experience to derive criticality decisions. The safety director of one mine performed the final review of these judgments. About half the tasks (70 of 146) were judged to be critically important for self-escape and became stimuli for Phase 3 and Phase 4 focus groups.

During Phase 3 work, we developed a model of important variables relating to self-escape interventions (training, task design, and tools, technology, and/or equipment) and human characteristics (motivation to learn and/or attitudes; knowledge and skill; job experience and/or tenure; age; abilities). We performed a hierarchical task analysis (HTA) on critical Phase 2 tasks, producing a hierarchy of 21 task clusters, 36 critical general tasks, and 118 sub-tasks. To obtain SME feedback and validation, as well as additional information on the self-escape tasks and knowledge, skills, abilities, and other attributes (KSAOs), we facilitated focus groups with experienced miners at each of the mines. Participants reviewed the tasks for accuracy, completeness, and relative difficulty. We used the same method for the KSAO analysis to generate self-escape task demands and knowledge/skills. The O*NET ability taxonomy (52 abilities clustered under the categories cognitive, psychomotor, physical, and sensory) specified task demands in the HTA. The mean number of ability demands per task was 10.9, and the median was 9.5. Recommendations based on the Phase 3 work were structured using the variables identified in the Self-Escape Model, with the human characteristics variables (motivation to learn and/or attitudes; knowledge, skills, abilities; task demands; job experience or tenure; and age) nested under the three interventions (self-escape training; task design; and tools, technology, and equipment).

Phase 4 (Conduct Cognitive Task Analysis)

In Phase 4, we conducted a cognitive task analysis (CTA) targeting tasks that included a significant cognitive component involving judgment and decision-making. The CTA would offer recommendations regarding the training of and preparation for decision-making, problem solving, and other cognitive aspects of self-escape.

As part of the CTA, we specifically addressed tasks that appear to involve substantial mental processes of perception, sense making, setting goals, deciding how to achieve these goals, and communicating. We defined perception as becoming aware of something through the senses. Sense making involved selecting and attending to signals indicating conditions that would be meaningful and relevant to emergency situations and escape from the noise and clutter of all available sensory information, and focusing attention to maintain awareness as the situation evolves. Setting goals was to use attended-to sensory information, interpret the situation, and determine appropriate outcomes. Deciding how to achieve goals involved weighing appropriate outcomes, situational information, and relevant knowledge and skill information to determine how to achieve the desired outcomes. Communicating involved determining information to share and provide to coworkers, with a focus on the content and timing of the communication itself rather than selecting or operating communications technologies.

METHODS

Based on the information gained from Phase 2 work, the research team proposed an approach to perform a detailed CTA for all of the critical tasks identified in Phase 2 that include a significant cognitive component. A NIOSH panel reviewed the proposed approach and provided recommendations to ensure that results could be combined with other related NIOSH research efforts.

Two underground coal mines, both located in West Virginia, agreed to host this research. The larger mine employed a unionized non-management workforce of 250 to 300 miners working three shifts, and has an average seam height of 2.1 meters (7 feet), meaning that miners can generally walk upright throughout the mine. The smaller mine had approximately 45 non-unionized miners working three shifts. The average seam height is 1.2 meters (4 feet), requiring miners typically to stoop or crawl in working spaces.

To frame the task analysis process and results, NIOSH asked us to consider self-escape of workers in four roles and four emergency event scenarios. The first role was Mining Crew Member at the mine working face (the point at which coal is actively mined), who would be operating mining machines or directly supporting mining operations, such as the roof bolter, who installs roof supports as coal is extracted. The second was Escape Group Leader, who may be a formal line manager or an informal leader who emerges from a group of miners to plan, organize, and direct the escape. The Responsible Person is a formally assigned role—normally a dispatcher or foreman who, pursuant to federal regulations, is designated to direct evacuation efforts in the early phases of a mine emergency. The final role, Outby1 Worker, can be performing support or maintenance tasks underground and away from the working face. In most cases, outby workers work alone or in pairs, and can be anywhere within the mine, including parts that are in deep areas of the mine that have been closed to further mining, or between the working face and the mine entrance (and egress point).

NIOSH had previously identified four potential emergency event scenarios as the focal points for this study. Scenario 1, considered the most likely, was a fire occurring outby the working sections in a conveyor belt drive unit. Scenario 2 was an explosion that occurred within the mine due to accumulation of methane gas. Scenario 3 was a failure of the mine wall or roof structure that allowed liquid and/or non-breathable gas to flow into and fill the mine. Scenario 4 was a roof fall that blocked all but one route into or out of the mine.

Researchers visited the mines to conduct individual interviews. At each location, managers provided access to their people for a total of approximately eight hours (16 hours across the two mines), and each interview lasted two hours. We conducted interviews using two researchers, one of whom took handwritten notes while the other facilitated the discussions.

At each mine, researchers met with miners nominated by their employer and at a facility provided by mine management. Both mines provided privacy for the researchers to meet with participants.

Participants

The fourteen participants had held a number of positions in mining and mining qualifications during their careers, in addition to their current position. At each mine, at least one of the participants possessed state-issued foreman “papers” (certification). Examples of qualifications included:

State-certified as Mine Foreman.

Experienced working face crew member with papers (that is, a state certification) to be a supervisor

Senior miner with experience in multiple roles and having belt examiner papers.

Senior miners (Section Boss, Crewman), including one miner who was a rescuer at the Upper Big Branch Mine mishap.

Safety manager (from each mine).

Mining company owner.

Mine senior manager.

Session Procedures

At each mine, the interviews lasted approximately two hours. Two researchers provided each miner with the IRB consent form, gave each participant a paper handout providing background on the study, including its goals and sponsor, and reviewed and explained the project and form to the miners. At each session, every miner consented to participate. The project briefing described why self-escape was being studied, research issues of interest, demographic information sought, the work already accomplished, and the four emergency scenarios we wanted to discuss with them.

At both mines, one researcher reviewed each of the emergency scenarios with the participant or participants. The researchers used probes from the interview guide to help participants to recount their experiences and identify the key decisions that were made. The researchers probed further to uncover the cues, factors, rules of thumb, and equipment that participants used to assess the situation and make each decision. Whenever possible, researchers asked miners to draw pictures and use work artifacts (mine maps, SCSRs, air sensors) to illustrate why a particular decision was made, whether it was difficult and why, where expertise played a role, or how a miner’s equipment could help or hinder a safe and expeditious self-escape. If participants had not experienced any of the four emergency scenarios while working, researchers queried them about training experiences they thought were particularly difficult, valuable, or provided a useful lesson for other miners.

The second researcher took handwritten notes, capturing the scenario timeline, significant events, important concerns, decision points, actions considered and taken, and asked probing “what if” questions after the participant fully recounted the event. For example, after a participant described his list of concerns and the actions he would take in a scenario involving a fire near the working face, the second researcher read the list back to confirm that key details were captured. Upon receiving confirmation, the researcher asked the miner what he would have done differently if the fire had been in the intake instead of near the working face, for example. Asking hypothetical questions such as this allowed the researchers to identify the critical KSAOs for a variety of self-escape situations. Further, it allowed researchers to explore why certain self-escape strategies were feasible for some situations but not others, providing insight into how the location of an emergency and the environmental conditions of the mine influence miner decision-making. The researchers ended each session by asking participants what they believe are the biggest challenges in training for self-escape and why, and if they had suggestions for how to improve training.

Analysis Methods

Analysis converts raw content into coherent, meaningful findings, decomposing data gathered into discrete elements to code, categorize, synthesize, and summarize to develop explanations and extract meaning. Decomposing the data makes it possible to identify requirements, central themes, and organizational issues. We based analysis on the general CTA process offered by Rosen, Salas, Lazzara, and Lyons (2012) and the CTA methodology presented by Crandall, Klein, and Hoffman (2006). The method we used for analysis was adapted from part of the process we apply for Mission Essential Competencies (MECs; Alliger, Beard, Bennett, & Colgrove, 2012).

We performed three sets of analyses. The first set distilled the verbatim CTA field notes into an organized set of categories for use in developing recommendations and suggestions. The second set identified, from the set of knowledge and skills identified in Phase 3, which of these contain substantial cognitive components. The final set developed a concept map that outlined decisions required in recognizing the need to perform self-escape and to plan, select, and execute a method to do so successfully.

After we had transcribed the first set of interview notes (those from the smaller mine), we read them separately to identify trends and gaps that we could target in later interviews. We did the same for the second set of interviews (those from the larger mine). The second set of interviews expanded and clarified the earlier content as well as provided new information. After the second set of independent analyses, we met to discuss and resolve any differences and develop the set of categories for recommendations and suggestions.

RESULTS

Our initial content analysis identified high-level categories (Alliger et al., 2012) useful to categorize the information. We used these categories to identify differences and redundancies and to identify cognitive requirements and tasks. The categories formed the basis of recommendations we would later offer to optimize miner performance on cognitive tasks to increase the likelihood of successful self-escape. The two principal researchers discussed the draft categories and refined them until both were satisfied that they would be satisfactory. The set of six categories were:

Decisions miners have to make during emergency and self-escape.

Pre-mishap escape planning and preparation.

Sharing situational awareness (SA) through communications practices.

Mental simulation for continuous planning.

Preparation to lead.

Training philosophy and methods.

The goal of having a second set of analyses was to identify tasks that present high cognitive demands in terms of active information processing. We excluded tasks that are primarily physical in nature or likely to depend on automatized mental processing. To identify and categorize within the 146 tasks previously identified during Phase 3 that are likely to have a substantial cognitive component, the research team developed two sets of criteria from descriptions of CTA methodology theory presented in Crandall et al. (2006) and Rosen et al. (2012). Our categorizations differ somewhat from the tasks identified during Phase 3 as cognitive because we considered additional information beyond that used for HTA, specifically the results of our discussions with the miners and a more detailed consideration of the components of the tasks that involve perception, decision-making, and memory. Three analysts, each having substantial familiarity with job analysis methods and at least a basic familiarity with coal mining, separately reviewed the tasks using two criteria. We performed three rounds of analysis, with intervening discussions to refine our shared understanding of the criteria and discuss tasks that were not clearly cognitive or not clearly non-cognitive.

Our first criterion was the degree to which the task appeared in our notes from discussions during the CTA data collection or in the Phase 3 analysis as substantially involving application of knowledge, control of negative emotions, decision-making and mental processing of information, and/or mental activities. Our detailed considerations in applying this criterion were whether the task required mental activities to: (a) perceive and attend to relevant environmental stimuli; (b) make effortful use of strategies and application of knowledge and reasoning to generate goals; (c) plan behaviors to achieve these goals; and (d) communicate goals and plans to other miners.

In communicating, we considered determining the need to communicate and what information should be included, but not the relatively simple act required to make the actual communication (for example, deciding what to say and who needs the information, but not pressing a press-to-talk key and speaking into a microphone). We instead considered the effortful part—in which the miner applies effortful, active, and conscious thought—to be essential in that the human capacity to perform effortful processing is limited (Miller, 1956; Nugent, 2013a; 2013b). In contrast, automatized processing develops with repeated practice, and can be carried out rapidly and without conscious effort or intent (Mohr, Wolfensteller, Betzel, Mišić, Sporns, Richiardi, & Ruge, 2016). Task performance that depends on effortful processes is more likely to deteriorate in the face of the stressors that miners will encounter during an emergency event. In contrast, largely subconscious automatized mental processes can be performed completely and accurately despite stress.

Our second criterion was whether the task appears useful for miners to include in mental simulations or mental rehearsals in response to emergencies, and involves any of six mental functions listed below:

-

8.

Build mental models (or schema) of the mine’s physical layout, equipment, functioning, emergency planning, and mine procedures, and practice to recall and apply this knowledge for decision-making.

-

9.

Gain, maintain, or share SA to enable accurate and timely decision-making.

-

10.

Recognize the need to share information by determining who needs what information, creating, the message, confirming receipt and understanding, and following up if anything changes or is misunderstood. As before, this does not reflect operating any technology (such as a phone or radio) to distribute the information.

-

11.

Plan methods to achieve goals and then direct oneself or others to achieve the goals, then communicate knowledge of the plan and the participation expected of individual miners. Track progress toward achieving goals, and adjust as needed.

-

12.

Eliminate barriers to cooperative work among the miners by controlling counterproductive emotions, especially panic; motivate and inspire members to work together toward goals; resolve conflicts. We defined panic as sudden, uncontrollable sensations of fear or anxiety that would dominate or prevent reasoning and logical thought, replacing it with overwhelming feelings of anxiety and frantic agitation consistent with an animalistic fight-or-flight reaction.

-

13.

Apply knowledge of technical capabilities and procedures to manage workload and creatively exploit available resources to accomplish goals.

A senior researcher with expertise in developing concept maps drafted the initial version of the concept map, and then the two senior researchers reviewed the draft map and made several revisions. Applying methods described in Crandall et al., (2006) and in Moon, Hoffman, Novak, and Cañas (2011), we based our design on what we had learned in total through the various phases of this research, and on the results of our interviews.

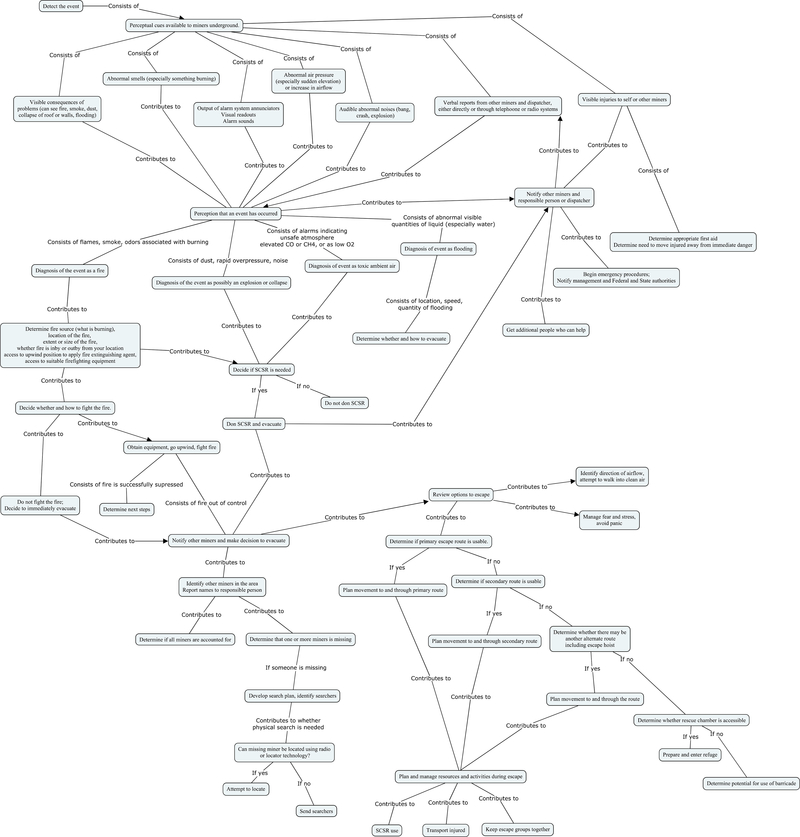

Figure 2 depicts the research team’s analysis of one possible view of the cognitions associated with performing self-escape. The cognitions begin with the perceptions that an event outside normal operations has occurred. These perceptions include visible components of the emergency (such as seeing flames or smoke, or visibly injured coworkers), hearing and seeing alarms and verbal reports from other miners, and abnormal smells. If the miner interprets these sensory inputs as indicative that an event has occurred, diagnosis of the event as an emergency that could potentially require evacuation from the mine begins, along with warning other miners, supervisors, and the responsible person or mine dispatcher. The miner makes an assessment as to the nature of the emergency and how to personally respond. This response includes whether or not to fight a fire, what equipment might be needed to proceed with plans, whether to don a SCSR, whether all miners are accounted for, and whether to search for missing miners. If the miner makes the determination that escape is appropriate, decisions involve selecting an optimal route, planning and managing resources needed to escape (such as having an adequate access to SCSRs for the time they may be needed), and consideration for the need to instead take refuge in a rescue chamber and await rescue.

FIGURE 2.

COGNITIONS IN PERFORMING SELF-ESCAPE BEGIN WITH PERCEIVING THAT AN EVENT OUTSIDE NORMAL OPERATIONS HAS OCCURRED, DIAGNOSING THE EVENT AS AN EMERGENCY THAT COULD POTENTIALLY REQUIRE EVACUATION FROM THE MINE, AND THEN DETERMINING THAT EVACUATION AND SELF-ESCAPE WILL BE APPROPRIATE. ONCE THE MINER OR MINERS DECIDE UPON THE NEED TO ESCAPE, DECISION-MAKING TURNS TO HOW BEST TO DO THIS.

Table 1 presents a cross-tabulated summary of the allocation of tasks as cognitive or non-cognitive. This table shows that, overall, we categorized about 54% of the tasks (n = 79) as involving substantial elements of perception, decision-making, or mentally stimulating information.

TABLE 1.

CROSS-TABULATED COUNTS OF NUMBER OF ROLES FOR WHICH THE TASK IS COGNITIVE VERSUS NOT COGNITIVE

| Cognitive | ||||

|---|---|---|---|---|

| No | Yes | Total | ||

| Count of roles for which the task is critical to escape | 0 | 37 | 34 | 71 |

| 1 | 2 | 13 | 15 | |

| 2 | 4 | 8 | 12 | |

| 3 | 20 | 18 | 38 | |

| 4 | 4 | 6 | 10 | |

| Total | 67 | 79 | 146 | |

Table 2 displays the results of a simple analysis of variance (ANOVA) to examine whether there are significant differences between the cognitive and non-cognitive tasks in terms of number of roles for which each task is critical. As the results show (p = .77, ns; is greater than 0.05), the categorizations we made were not significantly different in terms of whether the task is critical for one or more roles.

TABLE 2.

ANOVA RESULTS FOR COUNT VERSUS WHETHER OR NOT THE ROLE WAS IDENTIFIED AS COGNITIVE

| df | Mean Square | F | p | |

|---|---|---|---|---|

| Between Groups | 1 | .18 | .09 | .77 |

| Within Groups | 144 | 2.15 | ||

| Total | 145 |

PHASE 4 CONCLUSIONS AND RECOMMENDATIONS

In offering recommendations, our options were to eliminate tasks; change tasks to meet human abilities; augment human abilities through tools, technology, or other equipment; or change human capabilities through training. We found no data to support a recommendation to eliminate or change a task. Most of our recommendations fall into the last category by suggesting changes and enhancements to training practices and content, especially to better enable miners to acquire and practice cognitive skills needed during mine escape. We also offer two technology recommendations—one that would help miners to better recall, manage, and communicate information, and a second to practice an escape alternative for which a simulation does not appear to currently exist. Our recommendations to revise training requirements or alternatives to training included:

-

1

Help mine managers balance production and protection.

-

2

Enhance training philosophy and methods.

-

3

Provide leadership training.

-

4

Teach miners mental simulation techniques.

-

5

Teach miners how to build cognitive maps.

-

6

Teach miners the value of standardized communication.

-

7

Teach miners to avoid functional fixedness when using equipment.

Our two recommendations to provide tools, technology, or other equipment to reduce the discrepancy between demand and individual capability are:

-

8

Investigate message-based communications technology.

-

9

Develop an escape hoist simulation.

Help Mine Managers Balance Production and Protection

Our first recommendation is to develop training for mine managers to help them better understand and balance production and protection requirements (Reason, 1997, 2016). Production is essential, because it ensures timely supply of raw materials to the market and provides financial rewards to the workers. To meet public demand, the mining industry places stringent requirements on production. Unlike many other industries, however, mining is fraught with risks and hazards, many of which are life-threatening. These include working in confined underground spaces, working in close proximity to operating heavy machinery, being surrounded by flammable, explosive, and toxic materials, and being exposed throughout the work day to loud noise. Miners recognize and accept these risks and hazards as part of their work (Bise, 2001).

Unlike production, protection often remains below both public and management awareness, and mining accidents can occur when managers focus greater emphasis on production rather than on protection. Managers may go through cycles in which they focus on production rather than protection, and unless an accident is severe enough to be covered by the media, it is often dealt with locally and quietly. Overemphasizing protection may help to avert mishaps, but hyper vigilant organizations may fail to meet production requirements. In contrast, overemphasizing production should increase output, but stringent production requirements can lead to forced errors, which are situations in which workers use unsafe shortcuts to increase or maintain performance (Perrow, 1999, pp. 247–248). Forced errors can lead to mishaps that cause injury and interrupt production. Optimal functioning results from an appropriate balance of emphasis on both productivity and safety. Specific to mining, Gowrisankaran, He, Lutz, and Burgess (2018), found that in the second year following a mining disaster (defined as an accident with five or more fatalities) there were reductions in both productivity (11%) and the probability of fatalities (80%) for mines located in the state in which the accident occurred. It is beneficial to both worker safety and the bottom line for mine operators to remain aware of this tradeoff and to train mine managers and safety professionals about the enormous human and economic costs of injuries and fatalities.

Enhance Training Philosophy and Methods

Our interviews revealed that current legal requirements for training might not always ensure that miners are adequately prepared to face a self-escape situation, even when miners complete all legally mandated training. However, we do not recommend simply adding training requirements. Rather, we recommend revisions to the current training philosophy that would enable mine operators to adopt local solutions that integrate equipment, situation, and techniques, create engagement, and stimulate innovation. Further, we are not advocating expensive additions. Rather, we recommend enhancing training fidelity and cognitive load, which can be implemented locally and without adding to the current training burden.

Our estimate of the shortfall in training is that training requirements are largely specified in hours of training for specific designated tasks or equipment. While this approach is widely used, training tends to be stovepiped into tasks or equipment operation and discussed in isolation. The result is that miners may not have opportunities to practice with all the parts that may have to operate in concert during an actual escape. A simple example of this is the challenge of speaking on a phone or radio while using an SCSR. Either task can readily be performed alone, but during an escape, miners must perform them together. Ideally, they should never face a situation during escape for which they have had no opportunity to practice during integrated training.

Integrate Training

In our observations of training and in interviews with miners, we noticed that the majority of the training involves learning different parts of the escape task in a piecemeal fashion. For example, miners learn to don and operate SCSRs during one classroom training event, learn about lifelines in a second classroom training event, and then practice walking escape routes in a third event—often underground to exit the mine at the end of a working shift. We agree that it is essential to master the building blocks of successful escape. However, we also recognize the importance of subsequently integrating these separate exercises into a master exercise that would allow miners practice multiple skills concurrently from start to finish. We further recommend conducting these master exercises whenever it is safe and feasible to do so, using realistic combinations of equipment, planned procedures, and in as realistic an environment as possible.

Enhance Training Fidelity

The interviews with miners support the literature review in Phase 3 with regard to the argument that the current training needs to become more realistic. Specifically, the interviewees expressed a concern that all miners do not take emergency planning and training seriously. This is partly because that the current training seems to lack the fidelity necessary for miners to practice making the kinds of decisions they would have to make during an actual escape. Miners mentioned there is often a lack of “real” risk during training. To achieve more realistic training, miners should be required to practice walking the escapeways while using, wearing, and carrying all the equipment that would be used in real life. This will provide realistic expectations of what it might be like to escape during a real emergency event. Trainers can also inject challenging events and other stressors into the scenario to enhance realism or fidelity, such as requiring miners to move equipment, obstacles, or role-playing injured miners while wearing full gear, walk the entire escapeways while wearing breathing apparatus, or escape with low visibility due to soot or smoke. During training events, miners should be taught to ask specific questions to gain SA about what is going on elsewhere in the mine. For example, at each section, there should be a map annotated with primary and secondary airshafts. Miners should also be taught to anticipate and use effects that would result from the emergency scenario on mine features such as SCSR caches, lifelines, signage, and air direction walls, or stoppings (which can indicate where an explosion has occurred as well as the direction and intensity of the blast) to make escape decisions.

Provide Leadership Training

We recommend that all miners receive some degree of general leadership training, and particularly first-line supervisors and potential escape group leaders. Our justification for this recommendation is that emergencies are likely to change the group dynamic, render designated leaders unable (for example, due to injury) to fulfill their duties, and add stressors that current training and normal work situations do not prepare miners to face (Kowalski, Mallett, & Brnich, 1996). Our conversations with miners suggest that the individual who might normally be considered as unlikely to be a leader may need to assume a leadership role. The new leader will need to be able to perform a number of essential skills, including thinking clearly under pressure, assuming control over the situation, and gaining the cooperation of fellow miners to preserve life and minimize risks. The sudden leader may need to quickly develop and brief an escape plan, including assigning roles and responsibilities to each crew member. They also need to know where to physically position themselves to lead (at front or in back), and how to delegate authority to others to perform specific actions.

Interviewees proposed a number of skills to embed in the leadership training. Among the most frequently mentioned were conflict resolution skills, skills to build and maintain trust, skills to build confidence in oneself and others, teambuilding skills, and escape planning skills.

Teach Miners Mental Simulation Techniques

A well-researched cognitive technique for mustering emotional responses to stressful situations and for aiding creative problem solving is known as mental simulation (MS). MS allows an individual to envision future possibilities and rehearse strategies for dealing with them (Taylor & Schneider, 1989). Literature recommends constructing hypothetical yet realistic events in the form of stories or narratives and ascribing them with realistic features (such as social roles, social settings, and what people may say or do—see Taylor, Pham, Rivkin, & Armor, 1998). By envisioning a realistic situation, people may discover new characteristics about the situation that might not have been previously apparent.

Research has also shown that MS can lead to positive changes in attitudes and behaviors if the simulation is self-relevant and repeated (Escalas, 2004). This can subsequently enhance people’s readiness for unexpected events and mentally prepare them for fast and innovative problem solving. MS skills would provide a tool for individual miners to practice personal pre-mishap escape planning and preparation.

It is recommended to practice MS on a regular basis (daily, during breaks/spare time, pre-shift, etc.) using mental rehearsal and verbalization (Adams, 1976; Schmidt, 1975). Mental rehearsal, a technique for visualizing a motor task, is widely recognized as being beneficial for maintaining motor memory (Malouin, Jackson, & Richards, 2013). The probability of engaging in a desired behavior increases with mental rehearsal, which is especially true for cognitively loaded tasks (Ryan & Simons, 1981). Verbalization, or verbal planning, involves discussing the verbal part of the cognitive component of the MS (Decety & Ingvar, 1990). For example, miners could envision a fire within their section. They may ask questions like: What is burning (oil, coal, rubber hose)? When should I don a breathing apparatus? Can I fight the fire or should I avoid it? What items do I need to take with me? As literature suggests, it is useful to talk through an action before executing it (Decety & Ingvar, 1990). Together, mental rehearsal and verbalization may enhance the miners’ self-efficacy with regard to mine escapes and may ultimately help them to securely evacuate the mine.

Two of the most oft-researched MS types are process simulation and outcome simulation. Whereas the latter involves vividly envisioning oneself in the desired end state, the former involves simulating the process required to achieve a certain goal (Taylor et al., 1998). In other words, it is recommended to simulate the steps needed to reach the desired outcome, rather than the outcome itself. For example, miners may envision that there has been an explosion in their section and they quickly need to escape. Assuming escape is the desired outcome (rather than shelter within the mine, for example), miners may mentally rehearse the process needed to reach an envisioned end state, which may force them to identify and organize the steps involved in the activities needed to get there, which, in turn, yields a plan (Taylor et al., 1998). At the same time as one is mentally walking through these activities, the emotions that will be involved may be evoked, at least in a modest state, such that one can anticipate what these emotional states will be and develop some degree of control over them (Taylor et al., 1998). Although there are benefits to each MS type, the process simulation type may prove to be more helpful for miners.

The immediate benefits of MS include an increased realism of the imaged scenario, a developed framework for organizing experience, and an improved coping mechanism (Taylor & Schneider, 1989). In other words, MS can help people work through an imagined problem as if it were real, rehearse a number of possible solutions, and examine both physiological and psychological reactions they may experience. This exercise may help with translating thoughts into actions, which is especially important in emergencies such as fires, explosions, and gas or water inundations when people tend to fall back on the cognitively available solutions.

Teach Miners How to Build Cognitive Maps

The interviewees indicated that the current escapeway training is insufficient and they offered several ideas for suggested enhancements. First, they emphasized the importance of knowing the layout of the mine, teaching new workers how to get in and out of the mine, and training all miners on escape routes and mine ventilation plans. Miners need to know both primary and secondary escapeways by heart, and actually walk them. If miners relax and become oblivious to their surroundings (“zone out”) between the entry portal and the work area during the mantrip ride, they will not know how to get from the work area to the portal. Initial and ongoing mine-specific training should include an extensive overview of the mine and include alternate and other lesser-known potential escape routes. For instance, miners should be aware of tunnels that are not officially approved for use as escape routes that could take them back to an approved route. They should also be taught to walk into clean air whenever possible — that is, air should be in their face when walking out the primary route because the primary route should contain only clean air isolated from toxic contaminants.

Although it is important for miners to be able to read and interpret a mine’s physical maps in an emergency situation, it is equally important for them to rely on mental representations of the locations of objects and places, known as cognitive maps (Anderson, 2015). Research suggests that people tend to create cognitive maps of their environments by simply interacting with or navigating through them, even without ever seeing a physical map. Cognitive maps are constructed with the aid of spatial ability, which relates to the intake and organization of the knowledge of objects and their features in a three-dimensional space (Rumelhart & Norman, 1988; Wagner, 2006).

Cognitive maps are valuable for choosing and following an escape path that could enhance the possibility of a successful escape. When choosing an escape path, miners must maintain SA regarding the escape routes near their location. They must also interpret airflow as they are escaping, and choose an alternate route if the first escape path proves to be unworkable. In some situations, they may need to move away from the ultimate goal in order to continue making progress. Our SMEs recommended that, as the crew walks the escapeway during training, section leaders should quiz the crew about key features in the escapeway, such as what they would do if the escapeway were blocked at a certain point, and how they would handle various challenges that may occur.

Humans use cognitive maps by exploiting three types of knowledge: landmarks, route map, and survey map (Thorndyke, 1981; Thorndyke & Hayes-Roth, 1982). Research also draws a distinction between route cognitive maps and survey cognitive maps (Muffato, Meneghetti, & De Beni, 2018). Route maps contain directions for how to get from point A to point B without spatial information. So, if the route between A and B were blocked, one would not be able to detour (Hart & Moore, 1973). Surveys maps, on the other hand, contain spatial features of the environment (Anderson, 2015). While route maps may be useful in daily activities such as getting from the mine portal to the work station, survey maps may be more instrumental in helping miners escape. The distinction between the two mental representations is evidenced by fMRI studies which show that route following and wayfinding activate different parts of the brain (Shelton & Gabrieli, 2002). Since mine escapeway maps are often developed from actual survey maps upon which routes and other mine emergency features are overlaid, this distinction becomes less important to mine escape. Although useful, cognitive maps are not completely immune to errors. For example, as research shows, people tend to estimate shorter distances when traveling to a landmark than when traveling away from it (Tversky, 2005; Wagner, 2006). Despite potential distortions, cognitive maps may be the only resource available to miners in an emergency. For example, a wall-mounted physical map may be destroyed after a fire or explosion, and miners may need to rely on their mental knowledge of the escapeways, estimate the time it would take them to walk versus taking a mantrip, and predict if there would be any barriers and obstacles on their way to the escapeway. Mine workers with varying spatial abilities might benefit from virtual reality exercises, such as NIOSH’s Underground Coal Mine Map Reading Training; (https://www.cdc.gov/niosh/mining/works/coversheet1825.html) and Mine Emergency Escape Training (https://blogs.cdc.gov/niosh-science-blog/2016/05/12/mine-escape-simulation/).

Teach Miners the Value of Standardized Communication

Communication skills are essential in organizing a mine escape because relaying accurate information is essential to establishing and maintaining the shared SA that enables miners to coordinate their activities and act appropriately. Because of the cognitive focus of our part of the study, we sought greater detail on message content and decisions about what to send rather than the specific actions to operate communications methodology and technology, which were targeted in earlier work.

Importantly, extreme circumstances add challenges to communicating. In this study, we were particularly concerned with communications underground during situations in which miners had to use SCSRs. Regardless of the specific communications technology being used, verbal communication depends upon speech and hearing. Current SCSRs use a mouthpiece that is held between the teeth, severely limiting the user’s ability to speak. To maintain a breathable air supply, miners cannot remove their mouthpieces to communicate once they have donned their SCSRs. We considered the challenge of verbal communications with current voice technology and current SCSRs and asked miners about this specifically. The consensus among our participants (and the opposite of what the researchers expected) was that while the current SCSR mouthpiece arrangement clearly makes it difficult to understand the user’s muffled speech, it would still be possible to communicate accurately to some degree in an emergency. While recommendations for structured communication, radio discipline, and nonverbal communication have been developed (Kingsley-Westerman, Brnich, & Kosmoski, 2011; Kosmoski, Margolis, Kingsley-Westerman, & Mallet, 2012; Mallett, Vaught, & Brnich, 1999), we suggest efforts to encourage the adoption of standardized radio messaging practices that reduce the dependence on speech as the transmittal mode.

Investigate Message-based Communications Technology

In addition to developing better communication skills that could be implemented quickly at low cost, we recommend a longer-term investigation into a communications technology that would allow creation and transmission of customized, structured checklists on handheld computers. Electronic, text-based communications could minimize the challenges presented by voice communications for persons wearing breathing apparatus; reduce the cognitive load of recalling plans, required actions, and procedural steps; and increase the speed and effectiveness of communications. Despite a number of unique challenges in underground coal mines, this technology offers several benefits, including making prepared checklists of emergency actions available at all times and easily sharing this recorded information with others, both of which can reduce the cognitive burden on miners during emergency response and self-escape.

Teach Miners to Avoid Functional Fixedness when Using Equipment

Miners are typically equipped with various tools and technologies, including radios, phones, cap lamps and flashlights, maps, lifelines, taglines, gas meters, escapeway reflectors, tracking systems, alarm systems, SCSRs, vehicles, medical equipment, and refuge chambers (portable structures that provide a temporary refuge space with emergency air, food, and water in underground mine emergencies). In emergencies, miners also rely on additional equipment, such as dry chemical extinguishers or handheld extinguishers, or patient-handling equipment such as Reeves Sleeve, Stokes litter, or WauK® board. There may also be additional items that could prove to be valuable in an emergency for application to solving problems that are very different from their intended uses. One example that arose in our discussions was the potential use of oxygen tanks from welding sets to provide additional breathing oxygen. A quick internet search and telephone conversation with a major provider of industrial oxygen suggests that this could be feasible, as oxygen intended for human life support is packaged and transported using methods that ensure the high-pressure bottles remain clean, but is otherwise the oxygen content is same element, from the same sources, as oxygen bottled for use in welding. It could also be feasible to use these tanks to provide additional oxygen only as a last resort, life-saving measure while taking refuge or barricading within the mine. Of course, this would assume a safe means to access the oxygen and that users follow correct oxygen-taking procedures and safety precautions associated with using pure oxygen. Controlled release is essential to avoid creating concentrations of pure oxygen, which present health risks, and if sources of ignition are also present, potential for rapid combustion and explosion of otherwise noncombustible materials.

The above is just one example of how “out of the box” thinking could provide opportunities to better manage and exploit available equipment during survival and escape in an emergency. These decisions include whether to: (a) abandon tools and materials used for normal work that may no longer have value for escape; (b) retrieve useful equipment from miners who have been evacuated or died; and (c) innovatively adapt and exploit available equipment in a new way for which it was not originally intended. Proficiency in thinking “outside the box” would enable miners to repurpose what they have available to solve problems they are facing.

Develop an Escape Hoist Simulation

Mine escape hoists come in a wide variety of temporary and permanently installed configurations, and are essentially improvised elevators intended only for emergency use. Based on our research, appropriate training in the use of escape hoists appears to be essential to avoid issues and controversies during an emergency; however, mine operators are unable to provide realistic and complete training with escape hoists because miners are prohibited by law from riding the escape hoists except in an emergency (due to safety features to prevent free fall). A simulator appears to provide an ideal solution to this problem. In our mine visits, we did not observe any type of simulator that could replicate the ride on an escape hoist, but conversations with simulator manufacturers suggest that creating such a tool would not be an overly difficult technical challenge. This simulator should be able to replicate operational hoist communications methods and controls, as well as the ride conditions of the actual hoist.

DISCUSSION

Our goal was to offer recommendations to optimize miners’ cognitive performance during emergencies to increase their likelihood of success in self-escape. Overall, the results of Phase 4 reaffirmed outcomes of the preceding phases and further highlighted the importance of preventative training. The benefits of preventative training often outweigh the costs associated with post-accident recovery, because preventative training focuses on enhancing individual- and team-level readiness in miners. Well-designed training should equip miners with physical and mental skills necessary for self-escape by providing opportunity for miners to (a) sharpen their leadership skills, (b) build their trust in equipment and technologies, (c) learn about common cognitive biases, such as functional fixedness, that emerge under stress and how to counter them, (d) learn how to build and navigate cognitive maps, (e) engage in mental rehearsal.

Emergencies often happen unexpectedly and present unique sets of challenges, but providing miners with more opportunities to practice making decisions in environments that produce, as much as possible, the environment in which escape will occur increases their odds of successful self-escape. When the context is familiar or has familiar features, individuals are more likely to recall to memory the courses of action they practiced during practice. When miners trained on eliciting certain behaviors during practice, they will be more likely to use these behaviors as a framework when facing a similar situation in real life. In sum, practicing decision-making, problem solving, leadership, and other cognitive tasks in low-risk, high-fidelity environments is likely to help miners develop cognitive capabilities to manage workload and creatively exploit available resources to accomplish goals under stress.

Suggestions for Future Research

Concerns about panic and the resulting effects arose throughout our discussions with miners. Our participants noted that in an emergency, miners may make decisions based on panic, emotion, or fear, rather than thoughtfully considering all available options. Miners must learn to avert panic when facing restrictions of movement, breathing, and vision. Providing miners with ample opportunity to practice in these conditions during training could help to minimize panic during a real emergency.

In our interviews, miners recommended training that includes restriction of vision and breathing, how to get out of a maze, and how to control panic by being aware of your own breathing. Unfortunately, current research literature provides few investigations into panic or empirical tests of how to limit its effects, probably because research that would involve generating realistic degrees of actual panic in typical research settings would be difficult, risky, and potentially unethical. Further, anecdotal evidence from historical reports of individuals in stressful situations (such as after disasters and during military operations) suggests that it is difficult to predict who will panic, as well as the degree and length of panic. We found no feasible training method that would provide assurance of preventing panic, and consequently, panic remains an issue we were unable to address.

One of our reviewers noted an interesting question for future research concerning the impact of differences in height within the coal seams might affect the speed at which miners could egress from the mine. It appears that mines generally provide difficult environments in which to walk, with varying height, floors that range from loose gravel and soft sand to smooth hard bare rock, intermittent darkness, and equipment or other objects that can protrude into the space a person walking would occupy. These factors make simply walking in a mine is a physically demanding activity, but one that can be performed in a mine with a wider (and thus higher space) coal seam. In mines with thinner coal seams, miners could have to crawl substantial distances on their hands and knees, which is likely to take more time and physical effort, however, at least miners who had worked in these mines for some time would have substantial conditioning form daily work involving this activity. Future research could explore the potential interaction between physical conditioning and egress training practices in conditions specific to the mine to time required to egress.

New developments in work analysis methodology offer ways to better understand decision-making in critical circumstances. For example, contextualized knowledge elicitation (Keeney, Wiggins, Reynolds, Berger, & Hoebbel, 2018; Wiggins, Pagan, Keeney, Bolton, Stacy, & Beaubien, 2014, 2015), a recently developed alternative to traditional self-report job analysis methods, integrates data from multiple sources, including self-reports, sensors, and simulator systems, providing greater insight than either source provides alone to explore perception, recall, and decision-making. Results from multiple sources mutually reinforce each other, balancing strengths and weaknesses. The combination of system-generated data and self-reports provides cues to guide investigations, such as by using self-reports to highlight where to look within voluminous system data, and using system data can show where verbal follow-ups are appropriate. The use of multiple sources also reduces the potential for method bias (method variance, or common method bias; see Conway, 2002; Podsakoff, MacKenzie, Lee, & Podsakoff, 2003).

Current approaches to data collection in job analytic methodology (for example, Fine & Cronshaw, 1999, and those in Wilson, Bennett, Gibson, & Alliger, 2012) all discuss opportunities to introduce error through misunderstanding, memory errors, and mistakes in recording participant responses. Psychometric and methodological issues are documented throughout the research literature (for example, Rogelberg, 2002; Wilson et al., 2012). Work analysis methods rely on incumbent ability and motivation, often in surroundings different from the actual work. Expert performers are desirable as job analysis participants, but expertise inherently involves the development of highly automatized processing occurring outside of conscious awareness. Although incident-based elicitation methods have shown method reliability (Taynor, Crandall, & Wiggins, 1987) and content validity (Rowe & Cooke, 1997), without contextual cues normally present in noisy, stressful, and dangerous environments, even experts may not be able to recall and provide insight into all aspects of task performance.

Contextualized knowledge elicitation (Keeney, et al, 2018; Wiggins, et al., 2014, 2015) uses appropriately instrumented high-fidelity simulations to present research participants with appropriate context for work performance. Simulations enable researchers to present multiple incumbents with knowable, consistent, and controlled stimuli and enable researchers to pause and replay stimuli and participant reactions while exchanging information. This pause and replay helps ensure activation of thought processes most relevant to the task and reinforces the argument that memories are fresh and foremost in the participant’s mind. Further, expanding data collection beyond self-reports by system-based recording of participant actions and unobtrusive instrumentation helps to ensure accuracy and completeness. Data from system-based measures, which are much harder for participants to influence than off-line self-reports, can provide objective corroboration of participants’ descriptions, explanations, and comments. This combination of system-based and highly contextualized self-reports also minimizes the potential for method variance to distort research conclusions and provides insight into task performance not available through observation, self-reports, or system-data alone, such as strategies to adjust work to changing situations and conditions.

ACKNOWLEDGEMENT

The authors thank the management of the two mines who helped us, as well as the instructors at the simulated underground coal mine of the West Virginia University Mining Extension Service and Academy for Mine Training and Energy Technologies. We acknowledge the many contributions during the proposal writing and early tasks of this project by the late Dr. Chris Bise.

This article reflects work performed on a project entitled Mine Escape, under sub-award CDC/APTIMA-2014 between The Group for Organizational Effectiveness, Inc. and Aptima, Inc. An earlier version of this paper was presented at the 2018 Annual Conference of the Society for Industrial and Organizational Psychology.

The consensus study report, Improving Self-Escape from Underground Coal Mines (National Research Council, 2013), recommended detailed task analysis of the tasks that miners must perform to successfully self-escape during an emergency in an underground coal mine. In response, the Centers for Disease Control and Prevention (CDC) and the National Institute for Occupational Safety and Health (NIOSH) funded a study to accomplish this work. This paper focuses on the cognitive task analysis (CTA) portion of this effort. We discuss the methods we used and results-based recommendations to enhance the likelihood that miners can successfully escape from underground emergencies.

Footnotes

DISCLAIMER

The findings and conclusions in this paper are those of the authors and do not necessarily represent the official position of the National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention. Mention of company names or products does not constitute endorsement by NIOSH.

Inby and outby are coal mining terms that refer to opposite directions within the mine from one’s current location. All locations deeper in the mine toward the working face are inby, and all locations toward the mine entrance and thus further from the working face are outby. An emergency outby a location could block escape from that location.

Contributor Information

Michael J. Keeney, Aptima, Inc.

Sterling Wiggins, Aptima, Inc..

Kristy D. Reynolds, Aptima, Inc.

Julia L. Berger, Aptima, Inc.

Cassandra L. Hoebbel, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health Office of Mine Safety and Health Research

REFERENCES

- Adams JA (1976). Issues for a closed-loop theory of motor learning In Selmach GE (Ed.) Motor control: Issues and trends (pp. 87–107). New York: Academic Press. [Google Scholar]

- Alliger GM, Beard R, Bennett W, & Colgrove CM (2012). Understanding mission essential competencies as a job analysis method In Wilson MA, Bennett W, Gibson SG, & Alliger GM (Eds.) The handbook of work analysis: Methods, systems, applications, and science of work measurement in organizations (pp. 603–624). New York: Routledge. [Google Scholar]

- Anderson JR (2015). Cognitive psychology and its implications (8th ed.). New York: Worth. [Google Scholar]

- Bise CJ (2001). Noise. In Karmis M (Ed.) Mine Health and Safety Management (pp. 297–306). Littleton, CO: Society for Mining, Metallurgy, and Exploration, Inc. [Google Scholar]

- Bise CJ (Ed.) (2013). Modern American Coal Mining: Methods and Applications. Englewood CO: Society for Mining, Metallurgy, and Exploration, Inc. [Google Scholar]

- Conway JM (2002). Method variance and method bias in industrial and organizational psychology In Rogelberg SG (Ed.). Handbook of research methods in industrial and organizational psychology (pp. 344–365). Malden: Blackwell. [Google Scholar]

- Crandall B, Klein G, & Hoffman RR (2006). Working minds: A Practioner’s Guide to Cognitive Task Analysis. Cambridge: Bradford. [Google Scholar]

- Decety J, & Ingvar DH (1990). Brain structures participating in mental simulation of motor behavior: A neuropsychological interpretation. Acta psychologica, 73(1), 13–34. [DOI] [PubMed] [Google Scholar]

- Dunn JC, Lewandowsky S, & Kirsner K (2002). Dynamics of communication in emergency management. Applied cognitive psychology, 16(6), 719–737. [Google Scholar]

- Escalas JE (2004). Imagine yourself in the product: Mental simulation, narrative transportation, and persuasion. Journal of advertising, 33(2), 37–48. [Google Scholar]

- Fine SA, & Cronshaw SF (1999). Functional job analysis: A foundation for human resources management. New York: Psychology Press. [Google Scholar]

- Gowrisankaran G, He C, Lutz EA, & Burgess JL (2018) Productivity, Safety, and Regulation in Coal Mining: Evidence from Disasters and Fatalities. National Bureau of Economic Research, Unpublished working paper. Retrieved June 26, 2018, from http://www.nber.org/papers/w21129. [Google Scholar]

- Hart RA, & Moore GT (1973). The Development of Spatial Cognition: A Review In Downs RM & Stea D (Eds.), Image & environment: Cognitive mapping and spatial behavior (pp. 246–288). New Brunswick, NJ: AldineTransaction. [Google Scholar]

- Keeney MJ, Wiggins S, Reynolds KD, Berger J, & Hoebbel C (2018, April). Cognitive Task Analysis of Miner Preparedness to Self-Escape from Mine Emergencies. Top Poster Presentation for 2018 Annual Conference of the Society for Industrial and Organizational Psychology, Chicago, IL. [PMC free article] [PubMed] [Google Scholar]

- Kowalski KM, Mallett LG, & Brnich MJ (1996, May). Leadership Characteristics in Escape from Three Underground Mine Fires. Paper presented at the International Emergency Management and Engineering Conference 1996, Montreal, Canada Available at https://www.cdc.gov/niosh/mining/works/coversheet1177.html [Google Scholar]

- Kingsley-Westerman CY, Brnich MJ, & Kosmoski C (2011). Radio 101: Operating Two-Way Radios Every Day and in Emergencies, DHHS (NIOSH) Publication No. 2012–103, RI 9686. U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health; Retrieved June 26, 2018, from https://www.cdc.gov/niosh/mining/works/coversheet522.html [Google Scholar]

- Kosmoski CL, Margolis KA, Kingsley-Westerman CY, & Mallet L (2012). Instructor’s guide: nonverbal communication for mine emergencies, DHHS (NIOSH) Publication No. 2012–104, RI 9688. U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health; Retrieved June 26, 2018, from https://www.cdc.gov/niosh/mining/works/coversheet461.html [Google Scholar]

- Mallett LG, Vaught C & Brnich MJ (1999). Radio 101: The Emergency Communication Triangle, DHHS (NIOSH) Publication No. 1999–157. U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health; Retrieved June 26, 2018, from https://www.cdc.gov/niosh/mining/works/coversheet838.html. [Google Scholar]

- Malouin F, Jackson PL, & Richards CL (2013). Towards the integration of mental practice in rehabilitation programs. A critical review. Frontiers in human neuroscience, 7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Miller GA (1956). The magical number seven, plus or minus two: Some limits on our capacity for processing information. Psychological Review, 63, 81–97. [PubMed] [Google Scholar]

- Mohr H, Wolfensteller U, Betzel RF, Mišić B Sporns O, Richiardi J, & Ruge H (2016). Integration and segregation of large-scale brain networks during short-term task automatization. Nature Communications, 7, 13217 https://www.ncbi.nlm.nih.gov/pubmed/27808095 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Muffato V, Meneghetti C, & De Beni R (2018). Spatial mental representations: The influence of age on route learning from maps and navigation. Psychological Research. Advance online publication. 10.1007/s00426-018-1033-4 [DOI] [PubMed] [Google Scholar]

- National Research Council (2013). Improving Self-Escape from Underground Coal Mines. Committee on Mine Safety: Essential Components of Self-Escape Board on Human-Systems Integration, Division of Behavioral and Social Sciences and Education. Washington, DC: The National Academies Press. [Google Scholar]

- Nugent P (2013a). “AUTOMATICITY.” In PsychologyDictionary.org, https://psychologydictionary.org/automaticity/, accessed July 21, 2017.

- Nugent P (2013b). “EFFORTFUL PROCESSING.” In PsychologyDictionary.org, https://psychologydictionary.org/effortful-processing/, accessed July 21, 2017.

- Perrow C (1999). Normal accidents: Living with high-risk technologies. Princeton, NJ: Princeton University Press. [Google Scholar]

- Podsakoff PM, MacKenzie SB, Lee JY, & Podsakoff NP (2003). Common method biases in behavioral research: A critical review of the literature and recommended remedies. Journal of Applied Psychology, 88, 879–903. [DOI] [PubMed] [Google Scholar]

- Reason J (1997). Managing the Risks of Organizational Accidents. New York: Taylor and Francis; Kindle Edition. [Google Scholar]

- Reason J (2016). Organizational accidents revisited. Boca Raton FL: CRC. [Google Scholar]

- Risser DT, Rice MM, Salisbury ML, Simon R, Jay GD, Berns SD, & MedTeams Research \Consortium. (1999). The potential for improved teamwork to reduce medical errors in the emergency department. Annals of Emergency Medicine, 34, 373–383. [DOI] [PubMed] [Google Scholar]

- Rogelberg SG (Ed.). Handbook of research methods in industrial and organizational psychology. Malden: Blackwell. [Google Scholar]

- Rosen MA, Salas E, Lazzara EH, & Lyons R (2012). Cognitive Task Analysis In The Handbook of Work Analysis: Methods, Systems, Applications and Science of Work Measurement in Organizations, (pp. 185–200). New York: Routeledge. [Google Scholar]

- Rowe AL, & Cooke NJ (1997). Measuring mental models: Choosing the right tools for the job In Russ-Eft DF, Preskill HS, & Sleezer C (Eds.), Human resource development review: Research and implications (pp. 85–101). Thousand Oaks, CA, US: Sage Publications, Inc. (Reprinted from “Human Resource Development Quarterly,” 6(3), 1995, pp. 243–255). [Google Scholar]

- Rumelhart DE, & Norman DA (1988). Representation in memory In Atkinson RC, Herrnstein RJ, Lindzey G, Luce RD (Eds.), Stevens’ handbook of experimental psychology: Vol. 2. Learning and cognition (2nd ed., pp. 511–587). New York: Wiley. [Google Scholar]

- Ryan ED, & Simons J (1981). Cognitive demand, imagery, and frequency of mental rehearsal as Schmidt, R. A. (1975). A schema theory of discrete motor skill learning. Psychological review, 82(4), 225. [Google Scholar]

- Shelton AL, & Gabrieli JD (2002). Neural correlates of encoding space from route and survey perspectives. Journal of Neuroscience, 22(7), 2711–2717. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Taylor SE, & Schneider SK (1989). Coping and the simulation of events. Social cognition, 7(2), 174–194. [Google Scholar]

- Taylor SE, Pham LB, Rivkin ID, & Armor DA (1998). Harnessing the imagination: Mental simulation, self-regulation, and coping. American Psychologist, 53(4), 429. [DOI] [PubMed] [Google Scholar]

- Taynor J, Crandall B, & Wiggins S (1987). The reliability of the critical decision method. (Tech. Report Contract MDA903–86-C-0170, U.S. Army Research Institute). Fairborn, OH: Klein Associates, Inc. [Google Scholar]

- Thorndyke PW (1981). Distance estimation from cognitive maps. Cognitive psychology, 13(4), 526–550. [Google Scholar]

- Thorndyke PW, & Hayes-Roth B (1982). Differences in spatial knowledge acquired from maps and navigation. Cognitive psychology, 14(4), 560–589. [DOI] [PubMed] [Google Scholar]

- Tversky B (2005). Visuospatial reasoning In Holyoak KJ & Morrison RG (Eds). The Cambridge handbook of thinking and reasoning (pp. 209–240). Cambridge: Cambridge University Press. [Google Scholar]

- Wagner M (2006). The geometries of visual space. Mahwah, NJ: Erlbaum. [Google Scholar]

- Wiggins S, Pagan J, Keeney MJ, Bolton A, Stacy W, & Beaubien JM (2015, April). New Job Analysis Paradigm: Virtuous Circle and Contextualized Knowledge Elicitation. Poster presentation at the 2015 Annual Conference of the Society for Industrial and Organizational Psychology, Philadelphia, PA. [Google Scholar]

- Wiggins S, Pagan J, Keeney MJ, Bolton A, Stacy W, & Beaubien JM (2014, November). The Virtuous Circle and Contextualized Knowledge Elicitation: Application of a New Paradigm for Job Analysis. Presentation at the 2014 Interservice/Industry Training, Simulation, and Education Conference (I/ITSEC), Orlando, FL. [Google Scholar]

- Wilson MA, Bennett W Jr, Gibson SG, & Alliger GM (Eds.). (2013). The handbook of work analysis: Methods, systems, applications and science of work measurement in organizations. New York: Routledge. [Google Scholar]