Abstract

This study examined the effects of using different fiber sources [apple pomace powder (APP), carrot pomace powder (CPP) and orange pomace powder (OPP)] on batter rheology and quality characteristics of rice flour-based gluten-free cakes. Gluten-free cake batters were formulated by replacing different amounts of rice flour (0, 5, 10, and 15%) with APP, CPP, and OPP. As a control cake, batters containing no pomace powder were used. The flow behaviors and viscoelastic characteristics of dietary fiber-enriched cake batters were investigated. All cake batters showed shear thinning behavior and the Power Law model was found to explain the flow behavior of all batter formulations. Apparent viscosity, elastic modulus (G′), and viscous modulus (G″) of the batter increased with increasing pomace powder content. Furthermore, addition of pomace powder increased batter specific gravity and crumb hardness, and decreased specific volume of cakes. Cakes containing 5% OPP had similar volume index and hardness values to the control sample. The sensory properties of the cake samples were investigated concerning color, texture, appearance, flavor and overall acceptability, and those with 5% OPP received the highest acceptance scores from the panelists.

Keywords: Gluten-free cake, Batter, Rheology, Dietary fiber, Pomace, Fruits and vegetable by-products

Introduction

The demand for gluten-free products is increasing since approximately one percent of the world population is suffering from gluten intolerance. Celiac patients also have to consume gluten-free products (excluding wheat, rye oat, triticale, and barley) all their lives to prevent symptoms of the disease (Shevkani et al. 2015). However, gluten is a major component of bakery products, and removing gluten from these products causes inferior quality considering the important role it plays in providing the desirable texture, sensory attributes, and overall quality. Thus, production of gluten-free products with high quality is challenging, and many gluten-free products on the market have low quality and nutritional value, demonstrating poor flavor and mouth-feel (Gularte et al. 2012). To improve the quality characteristics of gluten-free products, incorporation of hydrocolloids; e.g., gums, proteins and fibers has been suggested (Singh et al. 2016).

Most gluten-free products are generally made from purified starches or flours deficient in dietary fiber. Consumption of dietary fiber is recommended due to its protective effects against chronic diseases, such as certain type of cancers, cardiovascular diseases, diabetes, and gastrointestinal disorders (Figuerola et al. 2005). A 25–30 g/day increase in dietary fiber in daily diet has been recommended. Thus, consumption of high-fiber food products has received increasing attention. Fiber incorporation could help to overcome fiber deficiency (Fernández-Ginés et al. 2003). For fiber enrichment, the best products are breakfast cereals and bakery products (Gularte et al. 2012). In the past, dietary fibers from cereals were widely used in bakery products; however, today by-products from the juice production industry are receiving increasing attention from health-conscious consumers (Ayala-Zavala et al. 2011). Due to their higher content of bioactive compounds and soluble and total fibers, better water and oil holding capacities, and lower phytic acid content and caloric value, vegetable fibers have better nutritional quality than those found in cereals (Singh et al. 2016; Larrauri 1999). In addition to health benefits, dietary fibers also have functional properties, such as a high capacity of water binding and holding. Their viscoelastic response and high yield stress at low solid concentrations make them an ideal constituent to increase gel formation and viscosity (Salehi et al. 2016).

Fruit and vegetable by-products have been successfully used in the production of bakery products as economical sources of functional ingredients including vitamins, antioxidants, and high levels of dietary fiber. Although use of fruit and vegetable by-products in gluten-free bakery products is relatively new, studies investigated orange juice pomace (O’Shea et al. 2015), black carrot pomace (Singh et al. 2016), and carrot pomace powder (Majzoobi et al. 2016) for this purpose.

Apple, carrot, and orange have been used for juice production, and large amounts of pomace have been produced during juice processing. These by-products are generally utilized in animal feeding. Pomace is the main by-product of juice processing industries and constitutes approximately 45–60% of orange (O’Shea et al. 2015), 25% of apple (Kodagoda and Marapana 2017), and 30–50% of carrot (Yu et al. 2018). Citrus, apple and carrot pomaces have abundant availability and better quality due to their high bioactive compound content and more balanced compositions. Considering the limited number of studies on the use of fruit and vegetable by-products in gluten-free formulations, this study aimed to examine the effects of incorporating apple, carrot and orange pomace powders (APP, CPP and OPP, respectively) at different concentrations on the rheological properties of batters and quality characteristics of gluten-free cakes, and develop new fiber-enriched cake formulations for celiac patients.

Materials and methods

Materials

Rice flour (10.55 ± 0.29% moisture, 6.87 ± 0.10% protein, 1.41 ± 0.03% oil, and 0.47 ± 0.08% ash), sugar, egg, milk, sunflower oil, and baking powder were supplied locally. Fresh apples (cv. Red Delicious), carrots (Daucus carota L.), and oranges (Washington Navel variety) with a similar degree of ripeness were purchased locally at the same time and used to produce pomace powder.

Pomace powders production

Apple pomace was obtained by washing, coring, chopping, and separating the juice from pomace using a Santos No: 50 juice extractor (Santos SA, Lyon, France). Then, the pomace from the extractor was washed twice with warm water (30 °C) and dried at 60–70 °C until the pomace powder reached 2–3% moisture content in a tray dryer (Armfield Ltd., Ringwood Hampshire, England). The dried pomace was ground to a fine powder by passing it through a 355 µm sieve. CPP and OPP were obtained after washing, cutting, extracting the juice, washing the pomace with warm water, drying it under the same conditions as APP, and grinding it to the same particle size. All powders were packed under vacuum and stored in a household refrigerator at + 4 °C for less than a week until use in formulations.

Batter and cake preparation

Table 1A illustrates the basic recipe and amount of pomace powder replaced with 5, 10, and 15 g/100 g rice flour. First, eggs were whisked using a stand mixer with a wire whip (KitchenAid, St. Joseph, MI, USA) for 4 min at speed 6. Sugar was added and the mixing process continued for 3 min at speed 6. Then, sunflower oil and milk were added and mixed for 2 min at speed 4. Lastly, all the remaining dry ingredients (rice flour and/or pomace powder, and baking powder) were added to the mixture and mixed for 1 min at speed 2. A cake batter of 300 g was placed into disposable, aluminum, oil-coated cylindrical pans of 14 cm diameter and 5 cm height and were baked in duplicate in a conventional oven (Vestel, Turkey) for 40 min at 170 °C. After baking, the cakes were removed from the pans and cooled at room temperature for 1 h; then, they were covered with stretch film to prevent drying. For each cake recipe, two sets of experiments were conducted on different days. Physical measurements were performed on four cakes obtained from the same batter, and texture measurements on two cakes 1 day after baking.

Table 1.

Cake formulations, pomace powder and cake compositions. A: formulations of cakes (g/100 g rice flour) and PP is apple, carrot or orange pomace powder which was used in gluten free cake formulation, B: Moisture, ash and dietary fiber (TDF, SDF and IDF) contents of rice flour and pomace powders, C: composition of the cakes with different formulations

| Formulation | Control | 5% PP | 10% PP | 15% PP |

|---|---|---|---|---|

| A | ||||

| Rice flour | 100 | 95 | 90 | 85 |

| Pomace powder | 0 | 5 | 10 | 15 |

| Egg | 55 | 55 | 55 | 55 |

| Sugar | 70 | 70 | 70 | 70 |

| Sunflower oil | 45 | 45 | 45 | 45 |

| Milk | 27.5 | 27.5 | 27.5 | 27.5 |

| Baking powder | 2.5 | 2.5 | 2.5 | 2.5 |

| Total (g) | 300 | 300 | 300 | 300 |

| Moisture (%) | Proteina | Asha | TDFa | SDFa | IDFa | |

|---|---|---|---|---|---|---|

| B | ||||||

| RF | 10.55 ± 0.29 | 7.96 ± 0.10 | 0.47 ± 0.08 | 7.91 ± 1.50 | 2.43 ± 0.01 | 5.53 ± 0.01 |

| APP | 1.91 ± 0.06 | 3.57 ± 0.08 | 4.29 ± 0.06 | 64.84 ± 1.78 | 20.27 ± 0.09 | 44.57 ± 0.24 |

| CPP | 2.97 ± 0.16 | 8.23 ± 0.06 | 6.32 ± 0.35 | 83.91 ± 0.68 | 22.73 ± 0.08 | 61.18 ± 0.26 |

| OPP | 2.31 ± 0.01 | 9.81 ± 0.05 | 8.48 ± 0.11 | 82.22 ± 2.01 | 13.42 ± 0.02 | 68.80 ± 0.31 |

| PP type | PP (%) | Moisture (%) | Proteina | Fata | Asha | Carbohydratea |

|---|---|---|---|---|---|---|

| C | ||||||

| – | 0 | 21.21 ± 3.16d | 7.27 ± 0.06c | 24.60 ± 0.53a | 1.13 ± 0.02a | 58.12a |

| APP | 5 | 16.71 ± 0.86b | 6.30 ± 0.08bc | 22.96 ± 0.19a | 1.04 ± 0.01a | 63.62c |

| 10 | 16.23 ± 2.49b | 5.94 ± 0.09b | 23.31 ± 0.65a | 1.05 ± 0.02a | 63.83c | |

| 15 | 17.60 ± 1.38b | 5.96 ± 0.64b | 23.65 ± 0.08a | 1.09 ± 0.00a | 62.74b | |

| CPP | 5 | 15.54 ± 0.29a | 6.75 ± 0.20c | 23.48 ± 0.37a | 1.13 ± 0.01a | 62.87bc |

| 10 | 16.78 ± 0.37a | 6.66 ± 0.07bc | 23.76 ± 0.20a | 1.18 ± 0.01b | 62.03b | |

| 15 | 16.51 ± 1.25a | 6.30 ± 0.21b | 23.17 ± 0.14a | 1.23 ± 0.01c | 63.23c | |

| OPP | 5 | 18.36 ± 0.58c | 5.39 ± 0.06a | 24.25 ± 0.33a | 0.96 ± 0.01a | 62.52b |

| 10 | 17.80 ± 0.99c | 5.29 ± 0.12a | 23.53 ± 0.12a | 1.20 ± 0.01b | 63.48c | |

| 15 | 16.88 ± 1.42c | 5.09 ± 0.13a | 23.10 ± 0.07a | 1.25 ± 0.03c | 64.58c | |

Mean ± standard deviation values, followed by different letters within a column denote significant differences (p < 0.05)

aDry basis

Pomace powder measurements

The total (TDF), soluble (SDF) and insoluble (IDF) dietary fiber contents of rice flour, APP, OPP and CPP samples were determined according to the AOAC Method No:991.43, Furthermore, moisture (method 925.09), protein (method 920.39) and ash (method 923.03) contents of the pomace powders were specified according to AOAC (2000).

Batter properties

Specific gravity

The density of batter was measured in duplicate using a pycnometer (Elcometer, Manchester, UK), a cup consisting of a 100 ml cylindrical container and a cover with a hole for removing excess liquid. The specific gravity was calculated as the ratio between the density of the batter and water density at the same temperature.

Rheological measurements

Rheological measurements were carried out using a controlled stress rheometer (DHR-3, TA Instruments, New Castle, DE, USA) with a parallel-plate geometry probe (40 mm diameter and 1 mm gap) at 25 °C. The samples were prepared immediately before the experiments and rested for 5 min to allow relaxation. Shear stress and viscosity were recorded as a function of shear rate over the range of 0.01–100 s−1. The results were fitted to the Power Law (Eq. 1) and Casson models (Eq. 2).

| 1 |

| 2 |

where τ is shear stress (Pa), shear rate (1/s), K consistency index (Pa sn), n flow behavior index, Koc Casson’s yield stress (Pa)1/2, and Kc Casson’s plastic viscosity (Pa s)1/2. The Casson yield stress (τoc) in Pa was determined as the square of the intercept Koc and Kc was obtained from the linear regression of the square roots of –τ data.

In addition, the frequency sweep tests ranging from 0.1 to 10 Hz were performed, and storage modulus (G′) and loss modulus (G″) were obtained. Frequency sweep tests were conducted at constant strain within the linear viscoelastic range. Frequency sweep data were fitted to the Power Law model (Ronda et al. 2011):

| 3 |

| 4 |

| 5 |

The coefficients , and represent the elastic and viscous moduli and the loss tangent at the frequency of 1 Hz, respectively. Exponents a, b, and c quantify the dependence degree of these moduli and the loss tangent with the oscillation frequency.

Physical characteristics of the cakes

After the cake samples were baked and cooled down for 1 h, their specific volumes and volume indexes were measured by the rape seed displacement method (AACC 2000) and the AACC template method 10-91 (AACC 2000), respectively. The crust and crumb color of the cakes were determined using a Minolta CR-400 chroma-meter (Konica Minolta Sensing, Inc., Osaka, Japan). For each sample, L*, a*, and b* color values were measured in triplicate at three different points to determine the differences that occurred in the cake samples as a result of the addition of APP, CPP, and OPP. Crumb texture evaluation was performed 24 h after baking using a TA-XT2i Texture Analyzer (Stable Micro Systems Ltd., Surrey, UK) equipped with Texture Expert software. An aluminum 36 mm-diameter cylindrical compression platen probe was used in a double compression test for texture profile analysis. The center of the cake samples was cut into rectangular shapes with the dimensions of 20 × 40 × 40 mm and compressed to 50% of their original thickness (20 mm) at 2 mm/s with a 30-s delay between the first and second compressions. Hardness (N), springiness (cm), cohesiveness, resilience, and adhesiveness (g s) were obtained from the software. The mean results of eight measurements belonging to the gluten-free cake samples (four rectangular slices from the central part of the cakes on two different cakes of each set) were presented.

Proximate composition

The nutritional composition of the cake samples was examined as explained below: Moisture (Method 44-19) and ash (Method 08-01) contents were determined using AACC (2000) methods. Crude fat contents were obtained according to the Soxhlet extraction method, and crude protein contents using a Leco N Analyzer (FP-538, Leco Corporation) with a factor of N×6.25. The carbohydrate content of the samples was determined based on the differences.

Scanning electron microscopy (SEM) analysis

SEM was performed to determine the microstructure of rice flour, APP, CPP, OPP, and the obtained cake samples. The baked cake samples were cut into cubes of 1 cm3 and freeze-dried (Armfield, 158 FT 33, England) at − 18 °C prior to SEM analysis. The samples were coated with gold (Emitech K550X, France) and analyzed using a Quanto 250 FEG Scanning Electron Microscope (FEI, Czech Republic).

Sensory evaluation

Sensory analysis was performed with a group of 25 volunteers, recruited from the staff and undergraduate and graduate students of Ege University Food Engineering Department, Turkey. None of the volunteers had celiac disease. All the participants underwent a 1-h training session, in which the session, color, texture, appearance, flavor attributes and description of the gluten-free products were explained. The cake samples were cooled to room temperature, and then cut, coded and served to the panelists. The panelists evaluated the arbitrarily presented gluten-free cakes identified with random three-digit numbers for texture, color, taste, appearance, and overall acceptability using a 5-point hedonic scale (1 = dislike extremely, 5 = like extremely) in a testing area under fluorescent lighting. Consumer evaluation of the cakes in different sessions was separately analyzed to avoid any influence of consumer conditions. Sensory analysis was conducted in duplicate.

Statistical analysis

All experiments were performed at least in duplicate, and the mean values and standard deviations were reported. The experimental data were statistically analyzed using one-way analysis of variance (ANOVA) to determine the significant differences between different formulations at 95% confidence level. Duncan’s multiple range test (p < 0.05) was used to determine significant differences between the means. All statistical analyses were conducted using SPSS v. 20.0 (IBM, NY, USA).

Results and Discussion

Pomace powder properties

Table 1B shows the moisture, protein, ash, and dietary fiber (TDF, SDF, IDF and IDF/SDF) contents of rice flour and pomace powders. The ash and total dietary fiber contents of pomace powders were found to be much higher than that of rice flour. All pomace powders had a moisture content lower than 3%, and the ash content in pomace powders varied between 4.29 ± 0.06 and 8.48 ± 0.11 g/100 g (DM). The protein contents were 7.96, 3.57, 8.21 and 9.81 g/100 g (DM) in rice flour, APP, CPP and OPP, respectively. OPP had a higher protein content than the other pomace powders and rice flour. The protein contents of pomace powders are in agreement with those reported by Figuerola et al. (2005) for apple and orange fruit residues, and those found by Chau et al. (2004) for CPP. According to Larrauri (1999), products with a fiber content greater than 50% TDF are a rich source of dietary fiber. CPP and OPP had a higher TDF content compared to APP while rice flour had 7.91 g/100 g (dry basis) TDF. It is clear that replacement of rice flour by pomace powder enriched gluten-free cakes in terms of dietary fiber. The TDF content of APP was 64.84 ± 1.78, which is approximately 25% higher than the values reported by Sudha et al. (2007) and in accordance with the value (61.9%) given in the study by Chen et al. (1988). The TDF of OPP mass fraction was approximately 82.2 g/100 g, which was higher than that reported by de Moraes et al. (2013) for orange fiber (63.6 g/100 g) and by Figuerola et al. (2005) for orange waste fiber (64.3 g/100 g). The TDF content of CPP (83.91 g/100 g) obtained in this study was higher than the values reported previously by Turksoy and Ozkaya (2011) and Chantaro et al. (2008). The differences in these values could be related to the use of different cultivars and varieties, the maturation stage of the harvest, and processing steps. IDF is the largest fraction of all pomace powders; however, we also found a high amount of SDF. Insoluble fibers have also been reported as the predominant fiber fraction in many other vegetable by-products (Turksoy and Ozkaya 2011; de Moraes et al. 2013; Figuerola et al. 2005). In this study, SDF accounted for 31.3, 21.4 and 16.3% of the TDF found in APP, CPP, and OPP, respectively. The high content of both fractions indicates that consumption of fibers from fruits and vegetables may result in positive physiological effects. The IDF/SDF ratio is important for both dietary and functional properties, but it varies in different pomace powders, ranging from 2.20 in APP to 5.12 in OPP. Among our samples, the lowest IDF/SDF ratio was obtained from APP, which also had a high SDF. de Moraes et al. (2013) indicated that dietary fiber generally had an IDF/SDF of approximately 2:1 and could be used as a food ingredient. In this respect, APP, CPP and CPP appear to have a good balance and excellent nutritional quality.

Batter properties

The batter specific gravity was significantly affected by the source and amount of pomace powder (p < 0.05). The specific gravity of the control batter was 0.71 and significantly smaller than that of the batters containing pomace powders (Table 2A); i.e., less air was incorporated with the addition of pomace powders (p < 0.05). Increasing the amount of pomace powders increased the specific gravity of the cake batters (p < 0.05). The highest specific gravity was 1.04 obtained from the batter prepared with 15% CPP. Similar results were reported by CPP addition to the gluten-free cake batter (Majzoobi et al. 2016) and insoluble fibers to wheat-based batters (Gomez et al. 2010). The chemical composition of the batter greatly affected batter properties. By replacing rice flour with pomace powders, the fiber, protein (except for APP), ash, and sugar content of the batter increased. Increasing fibers, proteins and sugars can increase batter density as these components can impair the aeration process of the batter by disrupting its structure and releasing the trapped air or CO2 from the baking powder (Majzoobi et al. 2016).

Table 2.

Statistical results of rheological studies. A: specific gravity and Power law and Casson model constants explaining flow behavior of the cake batters with different formulations, B: Power Law model constants explaining viscoelastic behavior of the cake batters with different formulations

| PP type | PP (%) | Specific gravity | Power Law model | Casson model | ||||

|---|---|---|---|---|---|---|---|---|

| K (Pa sn) | n | r2 | σ0c (Pa) | Kc (Pa s)1/2 | r2 | |||

| A | ||||||||

| – | 0 | 0.71 ± 0.01 | 53.14 | 0.47 | 0.9942 | 58.34 | 1.328 | 0.9772 |

| APP | 5 | 0.75 ± 0.01 | 65.56 | 0.41 | 0.9715 | 72.68 | 1.375 | 0.9192 |

| 10 | 0.85 ± 0.00 | 88.77 | 0.46 | 0.9917 | 95.55 | 1.905 | 0.9659 | |

| 15 | 0.87 ± 0.00 | 176.10 | 0.40 | 0.9735 | 175.2 | 2.302 | 0.9184 | |

| CPP | 5 | 0.74 ± 0.00 | 97.31 | 0.48 | 0.9980 | 142.5 | 1.793 | 0.9775 |

| 10 | 0.88 ± 0.02 | 214.55 | 0.36 | 0.9872 | 244.9 | 2.008 | 0.9420 | |

| 15 | 1.04 ± 0.02 | 436.35 | 0.38 | 0.9348 | 498.7 | 2.798 | 0.7224 | |

| OPP | 5 | 0.72 ± 0.00 | 81.53 | 0.49 | 0.9974 | 118.9 | 1.801 | 0.9778 |

| 10 | 0.80 ± 0.01 | 121.05 | 0.45 | 0.9980 | 190.7 | 1.803 | 0.9762 | |

| 15 | 0.85 ± 0.01 | 222.25 | 0.37 | 0.9732 | 256.3 | 2.036 | 0.9169 | |

| PP type | PP (%) | G′ω1 | a | r 2 | G″ω1 | b | r 2 | tan (δ)ω1 | c | r 2 |

|---|---|---|---|---|---|---|---|---|---|---|

| B | ||||||||||

| – | 0 | 287.80 | 0.21 | 0.9857 | 137.15 | 0.34 | 0.9715 | 0.45 | 0.16 | 0.9986 |

| APP | 5 | 240.35 | 0.28 | 0.9893 | 149.55 | 0.37 | 0.9831 | 0.61 | 0.10 | 0.9935 |

| 10 | 353.60 | 0.30 | 0.9921 | 237.90 | 0.37 | 0.9865 | 0.67 | 0.08 | 0.9803 | |

| 15 | 1100.25 | 0.24 | 0.9939 | 658.25 | 0.31 | 0.9771 | 0.57 | 0.10 | 0.9970 | |

| CPP | 5 | 1074.25 | 0.37 | 0.9856 | 555.01 | 0.47 | 0.9965 | 0.51 | 0.12 | 0.9869 |

| 10 | 6125.00 | 0.29 | 0.9991 | 2861.50 | 0.36 | 0.9995 | 0.47 | 0.06 | 0.9797 | |

| 15 | 21705.00 | 0.25 | 0.9990 | 7789.00 | 0.32 | 0.9982 | 0.36 | 0.07 | 0.9883 | |

| OPP | 5 | 1053.00 | 0.34 | 0.9970 | 508.10 | 0.46 | 0.9966 | 0.49 | 0.11 | 0.9917 |

| 10 | 2033.50 | 0.34 | 0.9975 | 1050.60 | 0.45 | 0.9923 | 0.41 | 0.11 | 0.9873 | |

| 15 | 10720.50 | 0.34 | 0.9980 | 4663.50 | 0.40 | 0.9976 | 0.48 | 0.06 | 0.9899 | |

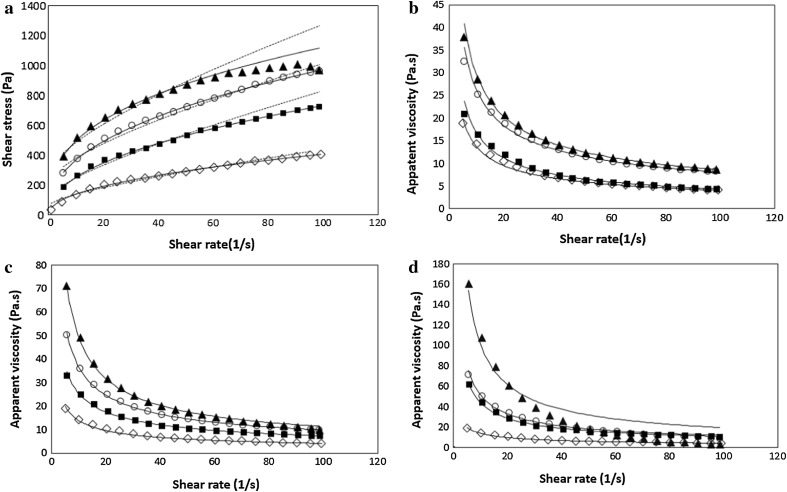

The flow curves of the cake batters are shown in Fig. 1. The average values of shear stress vs. shear rate referring to the control and batter containing 10% pomace powder are given in Fig. 1a as an example. This figure also illustrates the fitting curves of the Power Law and Casson models. Similar curves were obtained for all pomace concentrations. The changes in apparent viscosity with respect to the shear rate are illustrated in Fig. 1b–d for all batters. All the formulations containing different pomace powders with different amounts showed shear thinning (pseudoplastic) behavior; i.e., apparent viscosity decreased as the shear rate increased (Fig. 1b–d). The same behavior was observed by Turabi et al. (2008) in rice cake batters. The shear stress versus shear rate data of the cake batters were fitted well to the Power Law model (r2 = 0.935–0.994). The constants obtained by fitting the shear stress versus shear rate data to the Power Law and Casson models as influences of pomace powder concentration and pomace type are shown in Table 2A. The flow index (n) may vary from n = 1 (leading to the Newtonian law) to n < 1 or n > 1 to describe shear-thinning or shear-thickening flow behavior (Fischer et al. 2009), and the consistency index is an indicator of the viscous nature of the system (Koocheki et al. 2009). The n values of the cake batters ranged from 0.36 to 0.49, while the K values were between 53.14 and 436.35. The n values were less than 1 for all samples indicating pseudoplastic behavior. The low n values indicate the great departure of flow from the Newtonian behavior, and they also had high viscosity at low shear rates, decreasing dramatically as the shear increased. It was previously reported that when the n value was less than 0.6, non-Newtonian behavior became more prominent (Koocheki et al. 2009). In the current study, addition of 5% of each pomace powder had no significant (p > 0.05) effect on the flow behavior and consistency indexes of the cake batters. However, except for 10% APP, inclusion of more than 5% of pomace powders decreased the flow behavior index (p < 0.05). This indicates that the apparent viscosity of the cake batter decreased more noticeably when the shear rate increased. It is also clear the from Table 2A that the K values increased with pomace powder concentration due to the expected development of a stronger structure, and CPP produced the highest consistency index. Because of the higher water binding capacity of pomace powder, water absorption increases, thus reducing the free water in batters and increasing the consistency index. The Casson model was also found suitable to explain the rheological behavior of the cake batters, except for the sample containing 15% CPP (r2 = 0.722). This is considered to be due to the high apparent viscosity value of this formulation and the broken gel structure of the batter during analysis. The control cake batter had the lowest Casson yield stress (σ0c) and plastic viscosity (Kc).

Fig. 1.

The flow behavior of the cake batters. a Shear stress versus shear rate values for the gluten-free cake batters containing different pomace powders at 10%; b, c and d: apparent viscosity versus shear rate values for the gluten-free cake batters containing different pomace powders at 5%, 10%, and 15%, respectively. Open diamond control, filled square APP, filled triangle CPP, open circle OPP, straight line Power Law model, dashed line Casson model

Viscosity increased with the increasing pomace content (Fig. 1b–d). Dietary fibers have a high water holding capacity. When the water holding capacity of ingredients used in cake batters increases, the free water content facilitating the movement of particles decreases and the apparent viscosity increases (Ronda et al. 2011). One-way ANOVA applied for apparent viscosity revealed that addition of pomace powders, except 5% APP and OPP, affected apparent viscosity (p < 0.05). Increased batter viscosity and specific gravity may be attributed to the high fiber and sugar content of pomace powders. The highest apparent viscosity values were observed in CPP added cake batters for all concentrations.

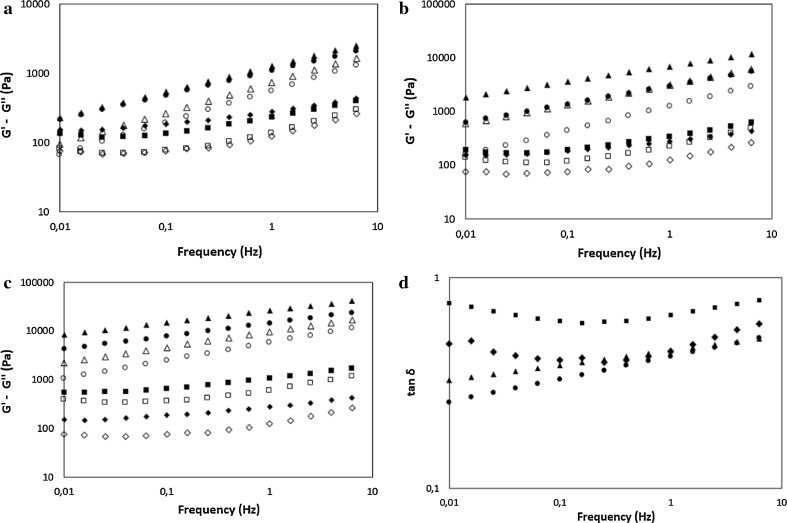

The viscoelastic properties of rice based gluten-free cake batters containing different pomace powders were examined using the dynamic oscillatory test. The mechanical spectra of all batter formulations exhibited the typical behavior of soft gels; storage modulus () resulted in higher values compared to loss modulus (), both demonstrating a slight dependence on frequency (Fig. 2a–c). Thus, the loss tangent () values were lower than 1 and slightly dependent on frequency (Fig. 2d). This indicated that the behavior of soft gel was more solid-like. Similar results were reported by Matos et al. (2014), Shevkani et al. (2015), and Singh et al. (2016) for rice batters.

Fig. 2.

The viscoelastic behavior of the cake batters. a, b and c: G′–G″ versus frequency values for the gluten-free cake batters containing different pomace powders at 5%, 10%, and 15%, respectively; d: tan δ versus frequency values for the gluten-free cake batters containing different pomace powders at 10%, respectively. Filled diamond control, filled square APP, filled triangle CPP, filled circle OPP. For a, b and c; closed symbols refer to storage modulus (G′) and open symbols indicate loss modulus (G″)

The mechanical spectra of all batter formulations provided a good fit for the Power Law model. Table 2B presents the viscoelastic data at a frequency of 1 Hz,, , coefficients and exponents a, b, and c obtained by adjusting the variation curves of the moduli and the loss tangent with frequency. The high r2 values indicated a satisfactory fit of the experimental data to the Power Law model. Similar results were obtained by Ronda et al. (2011) for the viscoelastic properties of gluten-free cake batters prepared with different starch sources and protein isolates.

According to the ANOVA results, the addition of pomace powders at 5% and 10% did not affect and (p > 0.05); however, using 15% pomace powder had a statistically significant effect (p < 0.05). While CPP provided the highest and values, the other fiber sources did not significantly differ at all concentrations. The a and b exponents increased significantly by a small amount of pomace powder addition, but higher amounts of pomace powders caused a decrease in these values. The loss tangent () of gluten-free batter formulations ranged from 0.36 to 0.67. As all batters showed , the loss tangent was lower than 1. The loss tangent of the batters did not significantly change due to the presence of pomace powders (p > 0.05). However, the loss tangent of the cake batters containing 5% and 10% APP increased (p < 0.05); i.e., these concentrations of APP significantly increased the batter viscoelasticity (values of closer to 1), and the viscous component naturally decreased the elastic component of the cake batter.

Physical properties of the cakes

Air bubbles entrapped within the cake batter expand due to increased temperature and chemical leavening during baking. In addition to starch gelatinization and protein denaturation, in some cases, coalescence is observed, all of which contribute to the formation of the cake structure (Yang and Foegeding 2010). Table 3A–C illustrate the physical properties of the cakes prepared by replacing rice flour with different pomace powders at 5%, 10%, and 15% concentration.

Table 3.

Physical and sensory properties of gluten-free cakes. A: specific volume and volume index values, B: crust and crumb color parameters, C: texture profile analysis, D: sensory evaluation of gluten-free cakes

| PP type | PP (%) | Specific volume (cm3/g) | Volume index |

|---|---|---|---|

| A | |||

| – | 0 | 2.32 ± 0.16d | 129.50 ± 2.12d |

| APP | 5 | 1.92 ± 0.03b | 110.75 ± 2.89c |

| 10 | 1.87 ± 0.15ab | 105.50 ± 0.71c | |

| 15 | 1.75 ± 0.05a | 98.50 ± 2.12b | |

| CPP | 5 | 2.11 ± 0.06c | 110.50 ± 0.71c |

| 10 | 1.62 ± 0.12a | 103.00 ± 0.00bc | |

| 15 | 1.56 ± 0.05a | 88.00 ± 0.71a | |

| OPP | 5 | 2.18 ± 0.13 cd | 124.00 ± 4.24d |

| 10 | 1.86 ± 0.19ab | 111.50 ± 4.95c | |

| 15 | 1.72 ± 0.29a | 105.50 ± 0.71c | |

| PP type | PP (%) | Crust color | Crumb color | ||||

|---|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | ||

| B | |||||||

| – | 0 | 58.23 ± 2.05e | 13.15 ± 0.38a | 22.82 ± 0.89d | 69.90 ± 0.88d | − 0.02 ± 0.37b | 21.55 ± 0.86bc |

| APP | 5 | 52.82 ± 1.63c | 14.64 ± 0.24c | 22.40 ± 1.01c | 66.83 ± 1.59c | 3.30 ± 0.25d | 18.35 ± 0.44a |

| 10 | 50.78 ± 2.13b | 14.67 ± 0.49c | 21.10 ± 1.95b | 64.26 ± 1.12b | 5.13 ± 0.38e | 19.25 ± 0.19ab | |

| 15 | 49.19 ± 1.10a | 15.02 ± 0.33d | 20.34 ± 1.23a | 62.29 ± 0.99a | 6.84 ± 0.30f | 21.85 ± 0.41c | |

| CPP | 5 | 55.43 ± 2.33d | 13.45 ± 0.30b | 22.27 ± 1.63d | 71.01 ± 0.79e | 0.62 ± 0.40c | 23.35 ± 0.92d |

| 10 | 55.63 ± 3.71d | 16.39 ± 0.44d | 27.79 ± 3.29f | 71.29 ± 0.52e | 2.52 ± 0.85d | 28.48 ± 0.25e | |

| 15 | 56.81 ± 2.01de | 16.84 ± 0.32e | 29.88 ± 1.68 h | 73.07 ± 0.54 g | 2.88 ± 0.37e | 28.34 ± 0.88e | |

| OPP | 5 | 55.93 ± 13.30d | 13.30 ± 0.18b | 26.13 ± 1.37e | 70.06 ± 1.52d | − 0.28 ± 0.15a | 27.73 ± 1.14e |

| 10 | 55.11 ± 2.47d | 14.65 ± 0.40c | 27.14 ± 1.61f | 70.96 ± 1.67e | 0.50 ± 0.10c | 35.09 ± 1.22f | |

| 15 | 55.14 ± 2.52d | 14.62 ± 0.32c | 28.45 ± 1.94 g | 71.90 ± 0.79f | 1.75 ± 0.41d | 39.76 ± 0.99g | |

| PP type | PP (%) | Hardness (N) | Springiness (cm) | Cohesiveness | Resilience | Adhesiveness (g s) |

|---|---|---|---|---|---|---|

| C | ||||||

| – | 0 | 9.46 ± 0.29a | 0.91 ± 0.01b | 0.62 ± 0.01d | 0.28 ± 0.01d | − 2.62 ± 1.28ab |

| APP | 5 | 15.80 ± 1.88b | 0.86 ± 0.01ab | 0.52 ± 0.02c | 0.23 ± 0.01c | − 2.61 ± 1.39ab |

| 10 | 17.48 ± 1.47bc | 0.85 ± 0.02ab | 0.46 ± 0.02ab | 0.19 ± 0.01b | − 1.95 ± 0.72a | |

| 15 | 19.88 ± 3.31c | 0.80 ± 0.12a | 0.51 ± 0.06b | 0.21 ± 0.03bc | − 1.64 ± 1.22a | |

| CPP | 5 | 10.49 ± 0.29a | 0.83 ± 0.02a | 0.49 ± 0.01b | 0.19 ± 0.01b | − 2.12 ± 1.08ab |

| 10 | 20.18 ± 1.60c | 0.80 ± 0.06a | 0.45 ± 0.02a | 0.18 ± 0.01b | − 2.19 ± 1.73ab | |

| 15 | 43.79 ± 3.24d | 0.83 ± 0.03a | 0.46 ± 0.01a | 0.19 ± 0.01b | − 2.48 ± 1.67ab | |

| OPP | 5 | 10.16 ± 1.49a | 0.86 ± 0.02a | 0.53 ± 0.01c | 0.24 ± 0.01c | − 2.24 ± 1.61ab |

| 10 | 15.66 ± 1.58b | 0.84 ± 0.02a | 0.45 ± 0.03a | 0.20 ± 0.01b | − 1.46 ± 0.85a | |

| 15 | 21.82 ± 0.68c | 0.83 ± 0.02a | 0.42 ± 0.01a | 0.17 ± 0.00a | − 3.35 ± 2.13b | |

| PP type | PP (%) | Color | Texture | Appearance | Taste | Overall acceptance |

|---|---|---|---|---|---|---|

| D | ||||||

| – | 0 | 4.25 ± 0.75b | 4.00 ± 0.60b | 4.17 ± 0.72bc | 4.25 ± 0.75b | 4.25 ± 0.75 cd |

| APP | 5 | 4.00 ± 0.74b | 4.08 ± 0.51b | 4.33 ± 0.49c | 4.17 ± 0.72b | 4.17 ± 0.58 cd |

| 10 | 3.92 ± 0.79b | 3.92 ± 0.79b | 4.08 ± 0.51bc | 3.83 ± 0.72b | 3.92 ± 0.51bc | |

| 15 | 3.67 ± 0.78ab | 3.17 ± 0.58a | 3.67 ± 0.78b | 3.67 ± 0.78b | 3.58 ± 0.51b | |

| CPP | 5 | 4.08 ± 0.99b | 3.17 ± 0.58a | 4.00 ± 0.60bc | 2.92 ± 0.79a | 3.50 ± 0.52b |

| 10 | 4.08 ± 0.67b | 3.33 ± 0.78ab | 4.00 ± 0.60bc | 2.67 ± 0.98a | 3.17 ± 0.72ab | |

| 15 | 3.33 ± 0.65a | 3.17 ± 0.72a | 3.58 ± 0.79a | 2.58 ± 0.79a | 2.83 ± 0.83a | |

| OPP | 5 | 4.50 ± 0.67bc | 4.17 ± 0.58b | 4.67 ± 0.49c | 4.50 ± 0.52b | 4.67 ± 0.49d |

| 10 | 4.58 ± 0.51c | 3.67 ± 0.65ab | 4.33 ± 0.65c | 4.25 ± 0.62b | 4.33 ± 0.65 cd | |

| 15 | 4.58 ± 0.51c | 3.42 ± 0.90a | 4.50 ± 0.52c | 3.83 ± 0.58b | 4.17 ± 0.58 cd | |

Mean ± standard deviation values, followed by different letters within a column denote significant differences (p < 0.05)

The volume of bakery products is an important parameter affecting consumer preferences. In this study, addition of pomace powder decreased the volume of the cake (p < 0.05) (Table 3A). The cake with the highest specific volume was the control sample. However, no difference was obtained when 5% OPP was used in the formulation (p > 0.05). Using increasing amounts of fiber sources decreased the specific volume and volume index of the cakes except for 5% OPP. As shown in Table 3A, the lowest specific volume and volume index values were obtained from the cake prepared with 15% CPP. At this point, it is important to note that the 15% CPP-added cake had the highest specific gravity and apparent viscosity values, and there was a negative correlation between volume and apparent viscosity and specific gravity. This happens when apparent viscosity increases to such a level that air bubbles can no longer expand sufficiently during baking. The amount of air incorporated into batter, which can be determined by measuring the batter density, has a direct relation to volume, tenderness, and texture in finished cakes (Eggleston et al. 1992). Appropriate batter density and viscosity provide good aeration of batter during mixing. Batters with low consistency cannot preserve the air during mixing and baking, and produce low-volume cakes whereas higher consistency might limit batter expansion. The air captured in the batter must be considered as it is related to the final volume and texture of the cakes (Gomez et al. 2007). Turabi et al. (2008) found that the specific volume of the rice cake formulated with different gums and emulsifiers ranged from 1.08 to 1.66. Different gums and dietary fibers, such as oat fiber improved the cake quality in terms of volume (Turabi et al. 2008; Gomez et al. 2010). However, some authors reported a decrease in cake volume when fibers obtained from different fruit sources were added (Grigelmo-Miguel et al. 1999). Sudha et al. (2007) determined that the volume of the cake decreased as the concentration of apple pomace increased due to the strong water binding properties of this fiber. These differences show that the fiber source is an important parameter for cake enrichment.

The crust and crumb color values of the cake samples were separately analyzed (Table 3). The L*, a*, and b* values for crust and crumb color showed differences between the fiber-enriched cakes (p < 0.05). The lightness of the cake crust decreased with fiber addition irrespective of fiber source (p < 0.05). On the other hand, the lightness of the cake crumb increased with the addition of fiber sources (p < 0.05), except for APP. The color of bakery products is affected by ingredients, process, and ingredient-process interactions, such as Maillard or caramelization reactions (Gularte et al. 2012). The lowest L* values were measured for APP-containing cakes for all concentrations because of the darker color of APP obtained from red apple. The a* value was positive (red hue) for all samples evaluated except for the crumbs of the control and 5% OPP-containing cakes. The a* value for crust and crumb color increased with the increased amount of pomace powders (p < 005). The highest a* values were obtained from the APP-added cakes due to the redness of APP. As for the b* values, all the samples showed positive b* values, indicating hue on the yellow axis. The results showed that the addition of increased amounts of CPP and OPP significantly increased the b* value of crust and crumb, while APP decreased these values (p < 005). This can be attributed to the original yellowish color pigments of CPP and OPP. Similarly, Matos et al. (2014) reported that the differences between crumb color parameters of muffin were due to the original pigmentation of ingredients used for protein enrichment.

Table 3C illustrates the effect of fiber sources on the textural properties of rice flour-based gluten-free cakes. According to the results, the hardness of the cake increased significantly when the amount of fiber increased. However, no difference was obtained between the control cake and the 5% CPP- and 5% OPP-added cakes (p > 0.05). Generally, the crumb hardness followed an opposite trend to the specific volume (Gomez et al. 2010). The hardest cake was the one containing 15% CPP, which had the lowest specific volume. Ingredients rich in dietary fiber are known to increase hardness (Ktenioudaki and Gallagher 2012). Sudha et al. (2007) reported that dietary fibers found in fruit also increased the crumb hardness. In the current study, the presence of fiber decreased the crumb springiness; however, the source and rate of fiber did not affect this value (p > 0.05). Gularte et al. (2012) observed a significant decrease in the springiness of the cakes when rice flour was substituted with inulin. Grigelmo-Miguel et al. (2001) stated that no significant differences were observed in the springiness value of muffins as a result of addition of peach fiber. In the present study, cohesiveness and resilience values of cake crumbs decreased significantly (p < 0.05) upon adding increased amounts of fiber, except for the resilient CPP-added samples that showed no difference (p > 0.05) after the addition of pomace powder. For adhesiveness, numbers of greater negative values represent more adhesive structure. The sample containing 15% OPP displayed the greatest adhesiveness among the samples but no significant difference was observed with pomace powder addition.

Table 1C illustrates the nutritional composition of rice flour-based gluten-free cakes. The presence of fiber decreased the moisture content of the cakes (p < 0.05). However, no difference was observed in the moisture content of the cakes prepared with different amounts of the same pomace powder (p > 0.05). The moisture content of the cakes was affected by the fiber source (p < 0.05). Due to the differences between the moisture content of rice flour and pomace powders (Table 1C), the moisture content was reduced. Another reason for this may be the higher water holding capacities of dietary fibers. The replacement of rice flour by pomace powders reduced the protein content of the cakes (p < 0.05). Gularte et al. (2012) reported that replacement of rice flour by dietary fibers reduced the protein content from 6.02% to 5.40%. In the current study, the presence of fiber sources did not significantly affect the fat content, as expected. The ash content of the cakes increased when CPP and OPP were used at a concentration of more than 10%. Similarly, Kim et al. (2012) reported that addition of dietary fiber increased the mineral content of the cake samples.

The sensory evaluation results of the cakes are given in Table 3. ANOVA revealed significant differences in the sensory properties of gluten-free cakes containing different pomace powders (p < 0.05). The color scores decreased for the cake containing 15% CPP (p < 0.05). The cakes prepared with OPP received the highest scores for color. The scores for texture were not affected by fiber addition (p > 0.05), except for the formulations prepared with 15% pomace powder that significantly reduced the texture scores (p < 0.05). Concerning appearance, no significant difference was determined in fiber source (p > 0.05), except for 15% CPP, which reduced the appearance scores. The taste of the cakes containing APP and OPP was similar (p > 0.05); however, the CPP-added cakes received lower scores for taste (p < 0.05). The overall quality scores decreased at all concentrations of CPP and APP over 10% (p < 0.05). The highest overall quality scores were obtained from the OPP-added cakes, indicating high acceptability, especially for the 5% OPP-added cakes. Furthermore, the APP-added cakes were accepted as comparable to the control cake, except for the 15% concentration. Grigelmo-Miguel et al. (2001) reported that using dietary fibers at low levels improved sensory properties or did not modify them; however, using high levels of dietary fibers reduced acceptability.

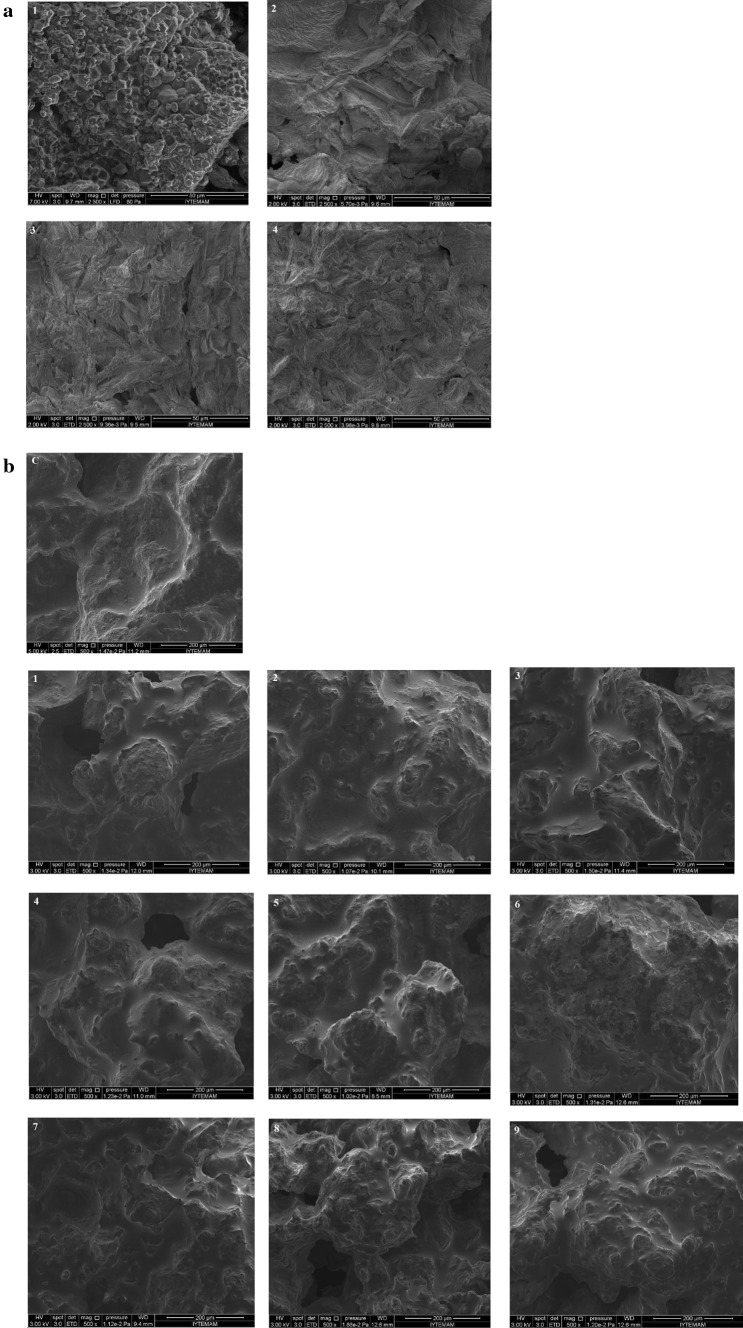

SEM images

SEM provides monitoring macro and micro structures of materials at high resolution. Scanning electron micrographs of rice flour and pomace powders used in cake formulations are shown in Fig. 3a at the same magnification level (2500×). As seen in Fig. 3a, the microstructure of the pomace powders greatly differed from that of rice flour. Therefore, some physical and structural properties of the cakes are expected to change by replacement of rice flour with pomace powders. All pomace powders contain more rough and irregular particles than soft and oval-shaped particles. It was reported that rough materials with an irregular structure have a higher water holding capacity and easily absorb water in formulations (Aguado 2010). Therefore, when the rice flour was replaced with pomace powders in formulations, the viscosity of the batter increased due to the reduced amount of free water. Furthermore, many properties of the cakes; e.g., volume, porosity and texture are affected by structure differences of materials in the formulation.

Fig. 3.

Scanning electron micrographs. a Scanning electron micrographs (×2500) of 1, rice flour; 2, APP; 3, CPP; and 4, OPP. b Scanning electron micrographs (×500) of the cake crumbs, c control cake; Numbers 1, 2 and 3 indicate cakes containing 5% APP, CPP, and OPP, respectively; 4, 5 and 6 are those containing 10% APP, CPP, and OPP, respectively; and 7, 8 and 9 contain 15% APP, CPP, and OPP, respectively

The SEM images of the cake crumbs with different formulations are shown in Fig. 3b. The cake crumbs obtained with 5% pomace powder replacement demonstrated a more homogenous and soft structure than the others, but were similar to the control sample. When the concentration of pomace powder increased, a more irregular structure was observed. Although it is difficult to compare samples containing different types of pomace powders at the same replacement level, it was clear that the 15% CPP-added sample had the highest heterogeneity and roughness. This situation is parallel to the lower quality characteristics of the cakes obtained using the same formulation. Additionally, it was reported that a more open structure can be correlated with increased rise yield and air entrapment; conversely, more dense and closed structures indicate reduced rise yield (Aguado 2010). All 5% pomace powder replacements, control samples, and the 15% OPP-added sample had a more open structure than the remaining cakes containing the same amount of pomace powder.

Conclusion

Gluten-free cake batters formulated with different pomace powders showed shear thinning and typical soft gel behavior. The Power Law model successfully explained the flow and viscoelastic behavior of the batters. Apple, carrot, and orange pomace powders having high amounts of TDF can be valuable sources of dietary fiber. Enriching gluten-free cakes with dietary fibers of acceptable quality had no significant effect on specific volume and other quality characteristics. Since OPP-containing cakes received the highest scores, it is considered that this pomace powder can be used to produce gluten-free cakes with high percentages of dietary fiber. Future studies can be undertaken to determine consumer acceptance among a group of celiac patients. Additionally, the pomace powder percentages can be experimentally determined to obtain the optimal characteristics of batters and cakes.

Acknowledgements

The financial support provided by The Scientific and Technological Research Council of Turkey, TUBITAK (Project Nos: 213O205 and BIDEB-2210 National Scholarship Program) and Ege University Scientific Research Commission (Project No: 2014-BIL-013) is greatly appreciated.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AACC (2000) Approved Methods of the American Association of Cereal Chemists, Methods 10-91, 32-05, 44-19, 10th edn. St. Paul

- Aguado A. Development of okara powder as a gluten free alternative to all purpose flour for value added use in baked goods (Doctoral dissertation) College Park: University of Maryland; 2010. [Google Scholar]

- AOAC (2000) Official methods for analysis, 17th edn, Association of Official Analytical Chemists, Method 923.03, 925.09, Arlington

- Ayala-Zavala JF, Vega-Vega V, Rosas-Domínguez C, Palafox-Carlos H, Villa-Rodriguez JA, Siddiqui MW, González-Aguilar GA. Agro-industrial potential of exotic fruit byproducts as a source of food additives. Food Res Int. 2011;44(7):1866–1874. [Google Scholar]

- Chantaro P, Devahastin S, Chiewchan N. Production of antioxidant high dietary fiber powder from carrot peels. LWT Food Sci Technol. 2008;41(10):1987–1994. [Google Scholar]

- Chau CF, Chen CH, Lee MH. Comparison of the characteristics, functional properties, and in vitro hypoglycemic effects of various carrot insoluble fiber-rich fractions. LWT Food Sci Technol. 2004;37(2):155–160. [Google Scholar]

- Chen H, Rubenthaler GL, Leung HK, Baranowski JD. Chemical, physical, and baking properties of apple fiber compared with wheat and oat bran. Cereal Chem. 1988;65(3):244–247. [Google Scholar]

- de Moraes Crizel T, Jablonski A, de Oliveira Rios A, Rech R, Flôres SH. Dietary fiber from orange byproducts as a potential fat replacer. LWT Food Sci Technol. 2013;53(1):9–14. [Google Scholar]

- Eggleston G, Omoaka PE, Ihedioha DO. Development and evaluation of products from cassava flour as new alternatives to wheaten breads. J Sci Food Agric. 1992;59(3):377–385. [Google Scholar]

- Fernández-Ginés JM, Fernández-López J, Sayas-Barberá E, Sendra E, Pérez-Alvarez JA. Effect of storage conditions on quality characteristics of bologna sausages made with citrus fiber. J Food Sci. 2003;68(2):710–714. [Google Scholar]

- Figuerola F, Hurtado ML, Estevez AM, Chiffelle I, Asenjo F. Fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment. Food Chem. 2005;91(3):395–401. [Google Scholar]

- Fischer P, Pollard M, Erni P, Marti I, Padar S. Rheological approaches to food systems. C R Phys. 2009;10(8):740–750. [Google Scholar]

- Gomez M, Ronda F, Caballero PA, Blanco CA, Rosell CM. Functionality of different hydrocolloids on the quality and shelf-life of yellow layer cakes. Food Hydrocoll. 2007;21(2):167–173. [Google Scholar]

- Gomez M, Manchon L, Oiette B, Ruiz E, Caballero PA. Adequacy of wholegrain non-wheat flours for layer cake elaboration. LWT Food Sci Technol. 2010;43(3):507–513. [Google Scholar]

- Grigelmo-Miguel N, Carreras-Boladeras E, Martin-Belloso O. Development of high fruit-dietary fiber muffins. Eur Food Res Technol. 1999;210(2):123–128. [Google Scholar]

- Grigelmo-Miguel N, Carreras-Boladeras E, Martin-Belloso O. Influence of the addition of peach dietary fiber in composition, physical properties and acceptability of reduced-fat muffins. Food Sci Technol Int. 2001;7(5):425–431. [Google Scholar]

- Gularte MA, Hera E, Gomez M, Rosell CM. Effect of different fibers on batter and gluten-free layer cake properties. LWT Food Sci Technol. 2012;48(2):209–214. [Google Scholar]

- Kim JH, Lee HJ, Lee HS, Lim EJ, Imm JY, Suh HJ. Physical and sensory characteristics of fibre-enriched sponge cakes made with Opuntia humifusa. LWT Food Sci Technol. 2012;47(29):478–484. [Google Scholar]

- Kodagoda K, Marapana R. Utilization of fruit processing by-products for industrial applications: a review. Int J Food Sci Nutr. 2017;2(6):24–30. [Google Scholar]

- Koocheki A, Mortazavia SA, Shahidia F, Razavia SMA, Taherian AR. Rheological properties of mucilage extracted from Alyssum homolocarpum seed as a new source of thickening agent. J Food Eng. 2009;91(3):490–496. [Google Scholar]

- Ktenioudaki A, Gallagher E. Recent advances in the development of high-fiber baked products. Trends Food Sci Technol. 2012;28(1):4–14. [Google Scholar]

- Larrauri JA. New approaches in the preparation of high dietary fibre powders from fruits by-products. Trends Food Sci Technol. 1999;10(1):3–8. [Google Scholar]

- Majzoobi M, Poor ZV, Jamalian J, Farahnaky A. Improvement of the quality of gluten-free sponge cake using different levels and particle sizes of carrot pomace powder. Int J Food Sci Technol. 2016;51(6):1369–1377. [Google Scholar]

- Matos ME, Sanz T, Rosell CM. Establishing the function of proteins on rheological and quality properties of rice based gluten free muffins. Food Hydrocolloid. 2014;35:150–158. [Google Scholar]

- O’Shea N, Rößle C, Arendt E, Gallagher E. Modelling the effects of orange pomace using response surface design for gluten-free bread baking. Food Chem. 2015;166:223–230. doi: 10.1016/j.foodchem.2014.05.157. [DOI] [PubMed] [Google Scholar]

- Ronda F, Oliete B, Gomez M, Caballero PA, Pando V. Rheological study of layer cake batters made with soybean protein isolate and different starch sources. J Food Eng. 2011;102(3):272–277. [Google Scholar]

- Salehi F, Kashaninejad M, Akbari E, Sobhani SM, Asadi F. Potential of sponge cake making using infrared-hot air dried carrot. J Texture Stud. 2016;47:34–39. [Google Scholar]

- Shevkani K, Kaur A, Kumar S, Singh N. Cowpea protein isolates: functional properties and application in gluten-free rice muffins. LWT Food Sci Technol. 2015;63(2):927–933. [Google Scholar]

- Singh JP, Kaur A, Singh N. Development of eggless gluten-free rice muffins utilizing black carrot dietary fibre concentrate and xanthan gum. J Food Sci Technol. 2016;53(2):1269–1278. doi: 10.1007/s13197-015-2103-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sudha ML, Baskaran V, Leelavathi K. Apple pomace as a source of dietary fiber and polyphenols and its effect on the rheological characteristics and cake making. Food Chem. 2007;104(2):686–692. [Google Scholar]

- Turabi E, Sumnu G, Sahin S. Rheological properties and quality of rice cakes formulated with different gums and an emulsifier blend. Food Hydrocolloid. 2008;22(2):305–312. [Google Scholar]

- Turksoy S, Ozkaya B. Pumpkin and carrot pomace powders as a source of dietary fiber and their effects on the mixing properties of wheat flour dough and cookie quality. Food Sci Technol Res. 2011;17(6):545–553. [Google Scholar]

- Yang X, Foegeding EA. Effects of sucrose on egg white protein and whey protein isolate foams: factors determining properties of wet and dry foams (cakes) Food Hydrocolloid. 2010;24(2–3):227–238. [Google Scholar]

- Yu G, Bei J, Zhao J, Li Q, Cheng C. Modification of carrot (Daucus carota Linn. var. Sativa Hoffm.) pomace insoluble dietary fiber with complex enzyme method, ultrafine comminution, and high hydrostatic pressure. Food Chem. 2018;257:333–340. doi: 10.1016/j.foodchem.2018.03.037. [DOI] [PubMed] [Google Scholar]