Abstract

The aim of the study was to evaluate the physical and mechanical properties of the nut and kernel of the Mexican pink pinion (Pinus pinea L.), as well as the physicochemical and functional properties of whole pink pinion meal (WPPM) as well defatted pink pinion meal (DPPM). The length, width, thickness, geometric diameter, arithmetic diameter, sphericity, aspect ratio, surface area, volume, density and hardness of the nut were higher than those of the kernels. The kernel had the highest coefficient of friction, while the nut had the highest angle of repose. WPPM had high fat and protein contents, at 40.5 g/100 g and 41.1 g/100 g, respectively. The major component of DPPM was protein (64.85 g/100 g). The DPPM had higher water absorption, oil absorption, emulsifying and lower gelation capacities (4%), indicating that the meal is a potential source of protein isolates or additives for functional foods and WPPM in food formulations.

Keywords: Angle of repose, Coefficient of friction, Defatted meals, Gravimetric properties

Introduction

Pinion nuts (Pinus pinea L.) are edible seeds that are highly appreciated all over the Mediterranean area. There are four important types of nuts with different nutritional contents, namely, Pinus gerardiana, P. koraiensis, P. sibirica and P. pinea (Henríquez et al. 2018). Pinion nuts are consumed raw or roasted and used as an ingredient in various traditional dishes such as breads, sweets, sauces and cakes. The nuts of P. pinea have a composition of 5.6% moisture, 31.1% protein, 47.4% lipids, 10.7% carbohydrates and 4.3% ash, which make them a source of nutrients (Nergiz and Dönmez 2004). However, no published data is available on the physical, mechanical, functional properties and chemical composition of pinion of the pink variety. Although Nergiz and Dönmez (2004) studied the chemical composition of the white pine nut cultivated in Spain, there has been no report on the pink variety cultivated in Mexico, which is examined in this study. Information on the shape, size, volume, surface area, grain weights, density, porosity and angle of repose, is necessary for the design of separation, handling, storage and drying systems for the product. The physical properties are also important for designing and optimizing equipment required in the processing stages of an agricultural product (Hernández-Santos et al. 2015). The frictional properties (angles of repose and coefficients of friction) are important for designing equipment and machines for the harvesting, conveying, dehulling, separating, sorting, handling, processing and storage of the nuts (Razavi and Edalatian 2012). The static coefficient of friction is used to determine the angle at which chutes must be positioned to achieve a consistent flow of material through the chute. In addition, it is important to design the conveyors with the necessary friction to hold the nuts and kernels to the conveying surface without slipping or sliding backward (Razavi and Edalatian 2012). The shape of the product is important for analytical prediction of its behaviour during drying (Işik and Ünal 2007). The functional properties of possible food additives are studied to obtain an overall view of their possible applications in food formulation (Hernández-Santos et al. 2015), which specifically affect the appearance and behaviour of such foods. The functional properties include hydration, foaming, emulsification, gelation and other characteristics, which have generally been associated with proteins and other components of food (Rodríguez-Miranda et al. 2012). Functionality is associated with the type of processing, storage and the physicochemical and structural properties of the raw materials (Juárez-Barrientos et al. 2017). Therefore, this study aims to evaluate the physical and mechanical properties of the nut and kernel of the Mexican pink pinion (Pinus pinea L.), as well as the physicochemical and functional properties of whole pink pinion meal (WPPM) and defatted pink pinion meal (DPPM).

Materials and methods

Pink pinion (Pinus pinea L.) variety cembroides (Fig. 1) was purchased (5 kg) from the local market in the city of Durango, Durango, Mexico (Location: 24°56′05″N 104°54′43″O, to 1966 m a.s.l., average temperature of 16 °C cold and very dry). The nuts were dehulled manually, and 150 nuts that did not present observable physical damage were selected.

Fig. 1.

Pink pinion nuts in shell (left) and kernels (right)

Physical properties

The method described by Mpotokwane et al. (2008) was used to determine the linear dimensions of the pinion seeds. The length (L), width (W) and thickness (T) were determined for 100 nuts (PN) and kernels (PK). The geometric diameter (Dg), arithmetic diameter (Da) and sphericity (φ) were calculated using the equations proposed by Mohsenin (1986) as well as volume (V) and surface area (SA).

| 1 |

| 2 |

| 3 |

The volume (V) and surface area (SA) of PN and PK were calculated by analogy to a spherical surface (SA = mm2) for the samples using the equations given by McCabe et al. (1986).

| 4 |

| 5 |

| 5.1 |

The aspect ratio (AR) was determined by the following relationship (Hernández-Santos et al. 2015).

| 6 |

The method described by Mpotokwane et al. (2008) was used to determine the weight of 100 seeds.

Bulk density (BD)

Briefly, 0.1 kg of sample was placed in 100-mL graduated cylinders, and the cylinders were tapped 5 times against the palm of the hand.

| 7 |

where M is the mass of the sample (kg); and V is the volume of the filled sample (m3).

Hardness (H)

The PN and PK hardness was measured for the compression axes Z using a texture analyser (TAXT2, Stable Microsystems, Ltd., Goldalming, UK) equipped with a 25-k load cell. The return-to-start method was employed. In this method, force was measured under compression with a 2-mm cylindrical probe, and the maximum force peak was recorded. The crosshead speed was set at 1 mm/s, and the maximum force required for shearing (maximum peak) was recorded as degree-of-hardness. Samples were measured fifteen times and results were expressed in Newtons (N) (Rodríguez-Miranda et al. 2016).

Coefficient of friction (μ0)

The coefficient of friction of the nut (PN) and kernel (PK) was determined according to a procedure described by Barahona and Torres (2011). A texture analyser (TAXT2 Plus, Stable Microsystems, Ltd., Goldalming, UK) in the stress test option, with the help of a pulley, allowed exertion of a horizontal force on a bottomless box and allowed for a displacement of 50 mm at a constant speed of 10 mm/s. Samples were placed in a wooden box (90 × 90 × 90 mm) (Fig. 2). The coefficient of friction of the PN and PK was evaluated for six surfaces made of different materials: plywood, stainless steel, glass, polyvinyl chloride (PVC), rubber and galvanized steel. The coefficients of friction were calculated using the following equation:

| 8 |

where μ0 is the coefficient of friction; F is the maximum force required to move the sample; and W is the sample weight.

Fig. 2.

Photograph of the device used to measure the coefficient of friction

Angle of repose (θ)

The angle of repose (θ) of PN and PK. Determination involves the use of a bottomless cylinder with a diameter of 75 mm and height of 200 mm. The cylinder was placed on each of six different surfaces (plywood, stainless steel, glass, PVC, rubber and galvanized steel) and raised gradually until the filled cylinder just began to slide down. The diameter (D) and height (H) of the heap were recorded and the angle of repose was calculated from the following equation (Gharibzahedi et al. 2010):

| 9 |

Preparation of meal

Whole pink pinion meal (WPPM) was obtained by drying the kernels (Binder Stove, mod ED 115, Germany) at 60 ± 2 °C for 24 h. The kernels were then milled and sieved through a 30-mesh sieve (0.59 mm). Defatted pink pinion meal (DPPM) was prepared using the method described in Rodríguez-Miranda et al. (2014). Hexane was added to 25 g of sample at a 1:20 (w/v) ratio and kept under agitation for 10 min at 60 °C. The solution was filtered, the defatted meal dried at 25 °C for 2 h and then at 50 °C for 2 h (ED 115 Binder Oven). It was screened through No. 30 (0.59 mm) mesh.

Chemical composition of the meals

The moisture, ash, protein, fat, crude fibre and available nitrogen-free extract (NFE) contents were determined according to the methods of AOAC (2012).

Colour and pH of meals

The colour was determined using a Hunter Lab colorimeter (MiniScan Hunter Lab, Model 45/0 L, Hunter Associates Lab., Ind., Reston, Virginia USA). The values of L*, a* and b* obtained were used to calculate the chromaticity (C*), hue angle (h°) and total colour difference (ΔE). The pH was measured by dispersing 1 g of meal in 10 mL of distilled water at 25 °C.

Functional properties

Water Absorption Capacity (WAC) and Water Solubility Capacity (WSC) were determined as described by Rodríguez-Miranda et al. (2012). The results are expressed as grams of water retained per gram of sample for WAC and WSC in percent.

Oil Absorption Capacity (OAC) was determined as described by Hernández-Santos et al. (2015). The results are expressed as grams of oil retained per gram of sample.

Emulsifying capacity (EC) was determined as described by Rodríguez-Miranda et al. (2016). The emulsion is expressed in percentage as the height of the emulsified layer with respect to the total height of the liquid column.

Apparent density (AD) was determined as described by Hernández-Santos et al. (2015). The AD was divided by the volume of meal (cm3) and reported in g/cm3.

Least gelation concentration (LGC) was determined using the method described by Rodríguez-Miranda et al. (2016). The lowest concentration at which all triplicates formed a gel that did not collapse or slip from the inverted test tube was reported as the LGC.

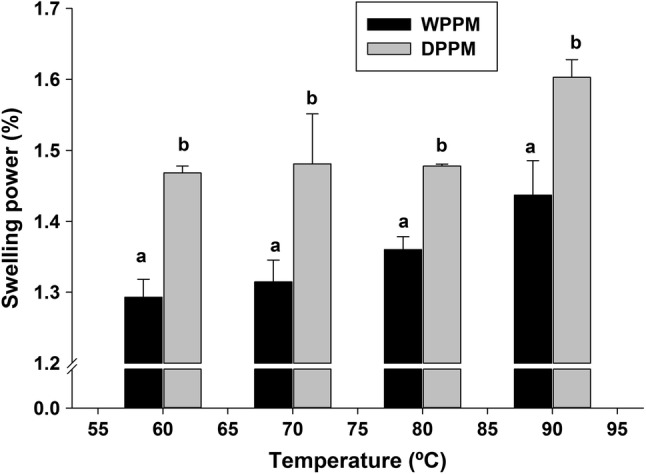

Swelling power (SP) was determined as described by Rodríguez-Miranda et al. (2012). The results are expressed as percentage of water retained per gram of sample.

Statistical analysis

The results were analysed using one-way ANOVA, and the differences among the means were determined using the least-significant-difference (LSD) test with a confidence level of 95% using the statistical program Statistica Version 8.0 (StatSoft, Inc. 1984–2008, USA), as well as the Pearson correlation in the ratios (L/W, L/T, L/M, L/Da, T/M and W/M).

Results and discussion

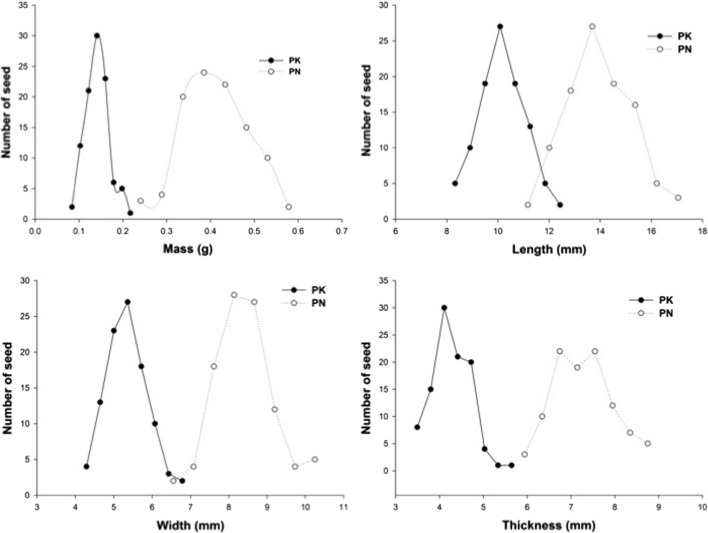

Linear properties

The frequency distribution curves (Fig. 3) for the dimensions (M, L, W and T) with a moisture content of 7.58% of PN and PK show a trend towards a normal distribution. It was observed that 92% of PK had an M of 0.08–0.16 g and approximately 91% of PN had an M of 0.29–0.53 g. Approximately 88% of PK had an L of between 8.32 and 11.26 mm, while in PN 90% had an L of between 11.17 and 15.37 mm. The 91% of PK had a W of between 4.29 and 6.07 mm and 85% of PN had a W of between 7.08 and 9.19 mm. Finally, approximately 94% of PK had a T between 3.18 and 4.72 and 92% of PN had a T between 5.53 and 8.55 mm (Fig. 3). Table 1 shows the results for the physical properties evaluated in PN and PK. Significant differences (P < 0.05) were found in all determinations evaluated, with the exception of Da. The L, W and T of the PN were significantly (P < 0.05) higher compared to PK, due to the presence of the PN cover (Table 1). The results show that the Mexican pink pinion is smaller than the white variety. Nergiz and Dönmez (2004) reported values of L = 18.34 mm and W = 8.83 mm in pinion harvested in Turkey. However, Özgüven and Vursavuş (2005) found values in the intervals of L = 15.21–22.21 mm, W = 6.98–11.54 mm and T = 5.82–9.58 mm for pinion harvested in Turkey. Gharibzahedi et al. (2010) observed values for L = 15. 21–22.21 mm, W = 6.98–11.54 mm and T = 5.82–9.58 mm for pinion harvested in Iran. Pinion harvested in Spain had dimensions with values of L = 17. 22–17.84 mm, W = 8.46–8.98 mm and T = 7.27–7.58 mm (Cárcel et al. 2012).

Fig. 3.

Frequency distribution of pink pinion nuts (PN) and kernel (PK) dimensions

Table 1.

Some physical properties, coefficient of friction, angle of repose, ratios and coefficient of correlation (r) values of pink pinion nuts (PN) and kernel (PK) at 7.58% moisture content

| Physical properties | PN | PK |

|---|---|---|

| Length = L (mm) | 13.51 ± 1.29a | 9.91 ± 0.92b |

| Width = W (mm) | 8.15 ± 0.75a | 5.16 ± 0.51b |

| Thickness = T (mm) | 7.10 ± 0.68a | 4.10 ± 0.41b |

| Geometric diameter = Dg (mm) | 9.20 ± 0.71a | 5.93 ± 0.40b |

| Arithmetic diameter = Da (mm) | 9.59 ± 0.71a | 6.39 ± 0.44a |

| Sphericity = Ø (%) | 68.31 ± 3.71a | 60.08 ± 4.35b |

| Aspect rations = AR (%) | 60.58 ± 5.28a | 52.37 ± 6.12b |

| Surface area = SA (mm2) | 267.57 ± 41.64a | 110.89 ± 15.13b |

| Volume = V (mm3) | 289.68 ± 68.27a | 23.12 ± 3.58b |

| Mass = M (g) | 0.39 ± 0.08a | 0.13 ± 0.03b |

| Bulk density = BD (kg/m3) | 632.49 ± 13.87a | 556.26 ± 1.91b |

| Hardness = H (N) | 235.25 ± 36.15a | 3.21 ± 0.31b |

| Coefficient of friction | ||

| Plywood | 0.35 ± 0.02a | 0.58 ± 0.04b |

| Stainless Steel | 0.63 ± 0.05a | 0.67 ± 0.06a |

| Glass | 0.45 ± 0.04a | 0.78 ± 0.05b |

| Polyvinyl chloride (PVC) | 0.35 ± 0.05a | 0.75 ± 0.05b |

| Rubber | 0.88 ± 0.15a | 0.90 ± 0.07a |

| Galvanized steel | 0.62 ± 0.04a | 0.72 ± 0.07b |

| Angle of repose (°) | ||

| Plywood | 27.97 ± 0.40a | 26.96 ± 1.36b |

| Stainless Steel | 27.41 ± 0.97a | 27.76 ± 0.38a |

| Glass | 27.02 ± 0.86a | 26.28 ± 0.28b |

| Polyvinyl chloride (PVC) | 20.45 ± 1.90a | 25.66 ± 0.45b |

| Rubber | 28.80 ± 0.83a | 27.49 ± 1.44b |

| Galvanized steel | 27.73 ± 0.53a | 26.88 ± 0.39b |

| Ratios | ||

| L/W | 1.66 ± 0.14 (0.58**) | 1.94 ± 0.23 (0.27**) |

| L/T | 1.91 ± 0.19 (0.47**) | 2.44 ± 0.31 (0.11) |

| L/M | 36.53 ± 9.14 (− 0.13) | 77.51 ± 15.92 (0.26**) |

| L/Da | 1.41 ± 0.06 (0.89**) | 1.55 ± 0.08 (0.84**) |

| T/M | 19.16 ± 4.43 (− 0.06) | 32.34 ± 8.11 (− 0.14) |

| W/M | 22.01 ± 5.33 (− 0.08) | 40.42 ± 8.87 (0.14) |

Values represent the average of 100 measurements ± standard deviation (coefficient of correlation). Means in rows with different letters are significantly different (P < 0.05)

**Correlations significant at P < 0.01

The results show that the seeds and nut of the pink pinion are bigger than other grains and seeds such as: sesame (Sesamum indicum L.) (L = 2.80 mm, W = 1.69 mm, and T = 0.82 mm) (Tunde-Akintunde and Akintunde 2004), melon (Cucumis melo L.) seeds and kernels (L = 6.40–8.61 mm, W = 3.10–4.21 mm and T = 0.65–1.00 mm) (Mansouri et al. 2017), pea (Pisum sativum) (L = 7.80 mm, W = 6.41 mm, and T = 5.55 mm) (Yalçın et al. 2007), and smaller than seeds such as: kindney bean (Phaseolus vulgaris L.) (L = 13.95 mm, W = 7.11 mm, and T = 5.95 mm) (Wani et al. 2017), castor (Ricinus communis) seed (L = 10.06–15.01 mm, W = 11.39–14.26 mm, and T = 10.36–14.89 mm) (Lorestani et al. 2012) and faba bean (Vicia faba L.) grains (L = 18.40–19.77 mm, W = 12.54–13.66 mm, and T = 7.00–8.02 mm) (Altuntaş and Yıldız, 2007). From Table 1, the following general expressions can be used to describe the relationship between the PN and PK dimensions at 7.58% moisture content:

For PN:

| 10 |

T = 19.16 M, W = 22.01 M.

For PK:

| 11 |

T = 32.34 M, W = 40.42 M

The results in (Table 1) show that the L/W, L/T and L/Da correlations for PN are statistically significant (P < 0.01). Correlations for L/W, L/M and L/Da ratios of PK were also significant. This indicates that thickness and arithmetic diameter are closely related to the length of the pink pinion. These results are similar to those published by Özgüven and Vursavuş (2005) for pine nuts, as well as other seeds such as fava bean (Vicia faba L.), Tylosemia esculentum, and carob bean (Ceratonia siliqua L.) (Altuntaş and Yıldız 2007; Jideani et al. 2009; Karababa and Coşkuner 2013). The relationship between Da and Dg for PN and PK, the following equations were obtained:

For PN:

| 12 |

For PK:

| 13 |

Geometric properties

Dg, AR and Ø values of PN were higher than corresponding values for PK (P < 0.05) (Table 1). The Dg found of PK (Table 1) was lower than 8.64–23.49 mm reported in other investigations on white pinion (Özgüven and Vursavuş 2005; Cárcel et al. 2012), as well as for other grains (Canavalia cathartica (Dg = 10.20–11.64 mm) (Niveditha et al. 2013), carob bean (Dg = 4.92–6.54 mm) (Karababa and Coşkuner 2013), ebony seed (Dg = 10.76 mm) (Hernández-Santos et al. 2015), pumpkin seed (Dg = 6.40–8.64 mm) (Rodríguez-Miranda et al., 2016)) and higher than reported in sesame seed (Dg = 1.56 mm) (Tunde-Akintunde and Akintunde 2004).

The Da was 6.39 mm for PK and 9.59 mm for PN, with no significant differences (P > 0.05), whereas AR = 52.37 and 60.58%, for PK and PN, respectively.

However, the observed values of Da were within the range reported for other sources (melon seed (3.47–4.42 mm), pumpkin seed (7.66–11.54 mm), Canavalia seed (11.04–12.07 mm), castor seed (11.41–14.32 mm) (Mansouri et al. 2017; Rodríguez-Miranda et al. 2016; Niveditha et al. 2013; Lorestani et al. 2012). AR value reported to other grains such as: kidney bean 40–51% (Wani et al. 2017); sponge gourd (Luffa aegyptiaca) Seeds 62–64% (Ogunsina et al. 2014); ebony seed 68.24% (Hernández-Santos et al. 2015); Parkia speciosa seeds 74% (Abdullah et al. 2011); and carob bean 71–77% (Karababa and Coşkuner, 2013) and castor seed 99.31% (Lorestani et al. 2012) were lower.

The higher Ø value for PN (68.31%) indicates that it has a more spherical shape than PK (Table 1). Eke et al. (2007) reported that sphericities above 70% indicate that the seed or grain is spherical. The value of Ø for PK (60.08%) was higher than that reported by Cárcel et al. (2012) 59.39–59.85%, Gharibzahedi et al. (2010) 45.49–45.69% and within the range reported by Özgüven and Vursavuş (2005) of 54.46–60.74% for white pine nuts, indicating that the pink pinion tends to be spherical, unlike other varieties of pinion. This property is important in the development of the hopper and design of bark for this seed. The Ø of PN and PK was higher than that reported for pepper 51–57% (Alibas and Koksal 2015), pumpkin 45.36% (Rodríguez-Miranda et al. 2016), melon 36.85% (Mansouri et al. 2017), peanut 51.6% (Aydin, 2007), kidney bean 62.12% (Wani et al. 2017) and faba bean 63.47% (Altuntaş and Yıldız, 2007), being more spherical than these.

There were higher values of V (289.68 mm3) and SA (367.57 mm2) for PN compared to corresponding values for PK (Table 1). The values of V (23.12 mm3) and SA (110.89 mm2) for PK indicate that there is a space between the shell and the kernel in the interior of the nuts. However, these results are lower than those reported by Özgüven and Vursavuş (2005) and Gharibzahedi et al. (2010) in white pine nuts, whose values were SA = 307.46–364.44 mm2 and V = 301.75–417.87 mm3. V and SA are important during bulk handling and processing operations, such as heat and mass transfer. Irregular seed surfaces play an important role in determining the projected area of seeds that move in turbulent air currents and are therefore useful in the design of seed cleaners, separators and conveyors (Niveditha et al. 2013).

The V and SA found in PN was superior to other seeds as basil (Ocimum basilicum) (V = 7.55 mm3, SA = 12.79 mm2) (Razavi et al. 2010), melon (V = 10.06–12.17 mm3, SA = 22.44–25.49 mm2) (Mansouri et al. 2017), carob bean (V = 39.79–141.0 mm3, SA = 63.99–131.1 mm2) (Karababa and Coşkuner 2013) and kidney bean (V = 173 mm3, SA = 185.94 mm2) (Wani et al. 2017), and lower than seeds as Canavalia cathartica SA = 333–428 mm2 (Niveditha et al. 2013) and parkia speciosa (V = 2084.37 mm3, SA = 786.86 mm2) (Abdullah et al. 2011).

Gravimetric properties

The mass of PN was 0.39 g, of which 0.13 g (Table 1) corresponds to the weight of PK, which represents 33.33% of the PN and the edible part of the nut. The weight of PK was lower than reported by Nergiz and Dönmez (2004), 0.18 g for white pine nuts. However, the percentage of the edible part (33.33%) was higher than 27.25% reported earlier (Nergiz and Dönmez (2004). The PN mass was lower than that reported in white pine nuts, by Nergiz and Dönmez (2004) 0.68 g, Özgüven and Vursavuş (2005) 0.74–1.01 g, Gharibzahedi et al. (2010) 0.85–0.93 g and Cárcel et al. (2012) 0.631–0.812 g.

The BD (Table 1) was lower for PK, as influenced by the shape and size. This can be attributed to the presence of the cover in PN, which considerably reduces the total mass per unit volume occupied by the nut. The results found in PN are within the range of 593.6–640.80 kg/m3 reported for white pine nut (Gharibzahedi et al. 2010; Özgüven and Vursavuş 2005). The results of BD show that the pink pinion was denser than seeds of sesame 580 kg/m3 (Tunde-Akintunde and Akintunde 2004), peanut 243–184 kg/m3 (Aydin 2007) and basil 340.24 kg/m3 (Razavi et al. 2010) and lower than that reported in seeds of pea 712.1–647.5 kg/m3 (Yalçın et al. 2007). Niveditha et al. (2013) mentioned that densities < 1000 kg/m3 indicate that seeds are lighter than water and therefore float. These data are useful for designing seed cleaning and separation machines.

Mechanical properties

Hardness (H)

H was significantly higher (P < 0.05) for PN than PK (Table 1) because the shell and thickness of the nuts was hard compared to the soft texture of the kernel. The results found for PN were lower (373.23–505.71 N) than reported for pinion nut by Özgüven and Vursavuş (2005) and Cárcel et al. (2012) and higher values were reported for other seeds such as: lentils (Lens culinaris) (red = 127.62 N and green = 143.48 N); castor (Ricinus communis) (198.11 N) and maunaloa (Canavalia cathartica) (147.1 N). (Niveditha et al. 2013; Lorestani et al. 2012; Gharibzahedi et al. 2014). However, the values of H for PK (3.21 N) were lower (6.23 N) than those reported for pumpkin seeds without shells (Rodríguez-Miranda et al. 2016). H is a key factor in the process of pressing and dehulling before oil extraction (Rodríguez-Miranda et al. 2016).

Coefficient of friction

The static coefficients of friction of PN and PK for the six test surfaces (plywood, stainless steel, glass, PVC, rubber and galvanized steel) are shown in Table 1. Significant differences (P < 0.05) were found between the coefficients of friction of PN and PK in most of the studied surfaces, except for the values reported in rubber and stainless steel. The highest values of the coefficient of friction were found for PK, with a maximum value in rubber (0.90), followed by glass (0.78), PVC (0.75), galvanized steel (0.72), stainless steel (0.67) and plywood (0.58). These differences between PN and PK were due to differences in the surface structures of the shell and nuts. PN has a smooth surface, with minimum values of friction in all studied surfaces, whereas PK presented a rough surface with greater adhesion and resistance to slip. The rubber materials exerted a greater tangential force on both PN and PK, which may require more effort by transport systems of this material, resulting a process that was less efficient and requires more energy.

PVC, plywood and glass would be suitable materials for transport systems for PN because they present smaller tangential forces, giving better efficiency of mass flow. For PK, the most suitable materials would be plywood, stainless steel and galvanized steel. These results are comparable to those reported for pine nuts by Özgüven and Vursavuş (2005) and Gharibzahedi et al. (2010). These results were in accordance with those reported by Mansouri et al. (2017) in galvanized iron had a lower coefficient of friction in melon seeds, Tunde-Akintunde and Akintunde (2004) reported a lower friction for sesame seed glass, as did Razavi et al. (2010) in basil seeds.

Angle of repose

The angle of repose indicates cohesion between individual seed and grain units (Niveditha et al. 2013). Significant differences (P < 0.05) were found between the angles of repose of PS and PK in all evaluated surfaces, except for stainless steel. The highest values of angle of repose were found for PN, while the lowest value was obtained for PVC (20.45°) (Table 1). For PK, the lowest values were found in PVC (25.66°), glass (26.76°) and plywood (26.96°). These results were below the (35°–39°) reported by Gharibzahedi et al. (2010) and within the interval (15.25°–26.18°) reported by Özgüven and Vursavuş (2005) for white pinion.

The results indicated that the resting angle of PN and PK of the pink pinion will have good fluidity in hoppers and gravity transport systems. Barbosa-Casanovas et al. (2005) mentioned that an angle of repose near 35° indicates free flow, 35°–45°, somewhat cohesive flow, 45°–55°, cohesive flow (free flow loss), and greater than 55°, limited low. The results generated in this study of friction properties will be useful for hopper design with gravity flow, since the inclination angle of the hopper walls must be greater than the angle of rest to ensure continuous flow of material (Sologubik et al. 2013). The angle of repose found in both samples was lower than that reported in melon seeds (Mansouri et al. 2017), sesame (Tunde-Akintunde and Akintunde, 2004) and within the range reported in seeds of Canavalia cathartica (Niveditha et al. 2013) as well as higher than that reported in basil seeds (Razavi et al. 2010).

Chemical composition

The proximate composition shows significant differences (P < 0.05) in all analysed components of WPPM and DPPM (Table 2). DPPM has higher protein content due to removal of fat. This defatting effect was also observed earlier (Rodríguez-Miranda et al. 2012, 2016; Hernández-Santos et al. 2015).

Table 2.

Chemical composition (dry basis), pH values, Hunter color values and functional properties of whole pink pinion nut meal (WPPM) and defatted pinion nut meal (DPPN)

| Property | WPPM | DPPN |

|---|---|---|

| Chemical composition (g/100 g) | ||

| Protein (N × 6.25) | 41.10 ± 0.03a | 64.85 ± 0.04b |

| Fat | 40.54 ± 0.06a | 6.71 ± 0.02b |

| Crude fiber | 2.04 ± 0.08a | 2.67 ± 0.49b |

| Ash | 2.43 ± 0.05a | 8.23 ± 0.01b |

| Carbohydrates1 | 13.90 ± 0.01a | 17.54 ± 0.01b |

| Physicochemical | ||

| pH | 7.23 ± 0.01a | 6.12 ± 0.01b |

| L* | 51.59 ± 0.17a | 72.39 ± 0.04b |

| a* | 7.85 ± 0.04a | 7.37 ± 0.01b |

| b* | 16.62 ± 0.30a | 27.52 ± 0.03b |

| C* | 18.38 ± 0.29a | 28.49 ± 0.03b |

| ºh | 64.70 ± 0.60a | 75.01 ± 0.01b |

| ΔE | 23.48 ± 0.07 | |

| Functional properties | ||

| WAC (g H2O/g sample) | 1.07 ± 0.04a | 1.19 ± 0.03b |

| WSC (%) | 42.19 ± 0.76a | 45.23 ± 0.07b |

| OAC (g oil/g sample) | 1.62 ± 0.03a | 2.54 ± 0.02b |

| EC (%) | 6.33 ± 0.52a | 41.67 ± 0.00b |

| AD (g/cm3) | 1.03 ± 0.02a | 0.44 ± 0.00b |

| LGC (%) | 0.00 ± 0.00a | 4.00 ± 0.00b |

Values represent the average of 3 replicates ± standard deviation. Different letter superscripts in the same row indicate significant difference (P < 0.05)

WAC = water absorption capacity, WSC = water solubility capacity, OAC = oil absorption capacity, EC = emulsification capacity, AD = Apparent density, LGC = Least gelation concentration

1Obtained by difference

The protein content for WPPM was higher than reported values for other varieties of pinion (29.0–35.93 g/100 g) (Escalona-Bustos, 2005; Nergiz and Dönmez, 2004; González et al. 2012; Lutz et al. 2017) and other seeds: ebony: 38.51 g/100 g (Hernández-Santos et al. 2015); Cucurbita pepo: 35.45 g/100 g (Rodríguez-Miranda et al. 2012); Cucurbita ficifolia: 35.25 g/100 g (Rodríguez-Miranda et al. 2016), Jack Bean (Canavalia ensiformis): 29.8–32.2 g/100 g (Doss et al. 2011) and kidney bean (Phaseolus vulgaris): 20.01–29.24 g/100 g (Parmar et al. 2014, 2017).

DPPM had a higher protein content than other defatted seeds: ebony: 44.72 g/100 g (Hernández-Santos et al. 2015); and Cucurbita pepo: 64.13 g/100 g (Rodríguez-Miranda et al. 2012).

WPPM had lower lipid content (Table 2) than other pinion varieties (46.02–51.87 g/100 g) (Escalona-Bustos 2005; Nasri et al. 2005; Nergiz and Dönmez 2004; González et al. 2012; Lutz et al. 2017) and other seeds: Cucurbita pepo: 49.14 g/100 g (Rodríguez-Miranda et al. 2012); pistachio: 46.10 g/100 g; macadamia: 67.63 g/100 g; and hazelnut: 63.96 g/100 g, as reported by Joschi et al. (2015).

WPPM had higher raw fibre content than other pinion varieties (1.09–1.8 g/100 g) (González et al. 2012; Escalona-Bustos, 2005) but a significantly lower fibre content than other seeds: jackfruit: 3.90 g/100 g (Juárez-Barrientos et al. 2017); and cowpea: 5.32 g/100 g (Appiah et al. 2011).

The WPPM had a lower ash content than the following varieties of white pinion nuts (4.3–4.5 g/100 g) (González et al. 2012; Escalona-Bustos 2005; Nergiz and Dönmez 2004; Lutz et al. 2017) and other seeds: jackfruit: 3.8 g/100 g (Juárez-Barrientos et al. 2017); ebony: 3.63 g/100 g (Hernández-Santos et al. 2015); and Cucurbita pepo: 5.27 g/100 g (Rodríguez-Miranda et al. 2012).

The nitrogen-free extract content of WPPM was higher than that reported by González et al. (2012) (8.02 g/100 g) and Escalona-Bustos (2005) (12 g/100 g) and similar to that reported by Nergiz and Dönmez (2004) (13.9 g/100 g) for white pinion nuts but was lower than the values obtained for other seeds: jackfruit: 73.44 g/100 g (Juárez-Barrientos et al. 2017); ebony: 29.36 g/100 g (Hernández-Santos et al. 2015); and cowpea: 56.49 g/100 g (Appiah et al. 2011).

The results for WPPM showed that the Mexican pink pinion has high protein and fibre content and lower lipid and ash content than other varieties of pinion. The high protein content of DPPM suggests that the Mexican pink pinion can have broad utility as a raw material in the formulation of new food products to increase their nutritional value.

pH and colour

Table 2 shows the pH and colour parameters for WPPM and DPPM. There was a significant difference between the pH of WPPM and DPPM (P < 0.05); namely, WPPM had a higher pH value (7.23) than DPPM. A pH decrease in defatted meal has been observed by other authors; for example, the pH of defatted ebony meal decreased from 5.96 to 5.86 (Hernández-Santos et al. 2015).

DPPM had a higher luminosity (L*) than WPPM (Table 2). Joshi et al. (2015) mentioned that defatting typically improves the L* value by eliminating lipid-soluble pigments (e.g., carotenoids, xanthophylls and chlorophyll), and this effect was also observed by other authors (Hernández-Santos et al. 2015; Rodríguez-Miranda et al. 2012). The WPPM and DPPM samples had positive values of a* in the red-shaded quadrant. The highest value (7.85) of a* was found in WPPM, which indicates a redder shade than DPPM, because the DPPM sample lost some pigment during the defatting process, in addition to the characteristic colour of the pink pinion variety. The values of b* are located in the yellow-shaded quadrant; the maximum value of b* was found in DPPM (27.52), which indicates a more yellow shade than WPPM. The highest chromaticity (C*) was found in DPPM (28.49). The highest colour saturation was also found in DPPM (h° = 75.01°), with a total difference of colour (ΔE) of 23.48.

Functional properties

The highest WAC was observed for DPPM (1.19 g/g) (P < 0.05) (Table 2), which may have resulted from the dissociation of protein subunits in the meal during the defatting process and an increase in protein content (from 41.10 to 64.85 g/100 g) due to fat removal. WAC is related to the presence of proteins in foods (Rodríguez-Miranda et al. 2012) and other factors such as particle size, starch content and fibre content. Kinsella (1982) reported that WAC increases with fat loss because fat promotes water and protein interactions, which depend on the number and type of hydration sites, physicochemical environment (e.g., pH, solutes, protein arrangement, temperature, solvents, surfactants, carbohydrates, lipids) and thermodynamic properties. DPPM has a higher WAC than ebony seed meal (1.04 g/g, Hernández-Santos et al. (2015)) but a lower WAC than pumpkin seed meal (1.94 g/g, Rodríguez-Miranda et al. (2012)), Cucurbita Ficifolia seed meal (1.40 g/g, Rodríguez-Miranda et al. (2016)), and buckwheat meal (1.39 g/g, Kumari and Raghuvanshi, (2014)).

The highest WSC was found for DPPM (Table 2), likely because DPPM has a higher content of water-soluble proteins. The solubility of proteins is one of the most important functional properties that directly affect foaming ability, emulsification capacity and gel formation (Hye-Jung et al. 2010).

WSC increase is directly related to the change in polarity in the material when lipids are removed using n-hexane, which is associated with most proteins and possibly causes changes in the tertiary or quaternary structure of the sample. The solubility of protein is the thermodynamic manifestation of the balance between protein–protein and solvent-protein interactions, which depends on the hydrophobicity and ionic nature of the sample (Juárez-Barrientos et al. 2017). DPPM had a higher value than other defatted seed meals such as C. pepo (8.75%) (Rodríguez-Miranda et al. 2012), C. Ficifolia (34.08%) (Rodríguez-Miranda et al. 2016) and ebony (26.06%) (Hernández-Santos et al. 2015).

The highest OAC was found DPPM (Table 2), likely due to the large number of non-polar sites of proteins in the defatted sample, which can bind to hydrocarbon units of oil and increase the OAC. Oilseeds with high OAC may provide the most suitable meal for confectionery applications that require oil emulsion (Rodríguez-Miranda et al. 2016). Oil absorption is important in food technology. In pre-cooked frozen products ready for frying, cookies and some cereal-based dishes, OAC can improve the taste and texture of foods (Lorestani et al. 2012).

The highest level of EC was found DPPM (41.67%) (Table 2) because DPPM has a higher protein content, and protein-water interactions occur in the polar regions of the amino acids of protein molecules. Most proteins contain several polar side chains with peptides in the parent chains, which makes them hydrophilic and affects their solubility and emulsion properties. Therefore, the ability of a protein to aid the formation of an emulsion is related to the ability of the protein to form an oil–water interface in an emulsion. Du et al. (2014) mentioned low protein contents in the sample; the EC values were low.

EC for DPPM was higher than that reported for other seed meals such as: C. Ficifolia (24.93%) (Rodríguez-Miranda et al. 2016) and seinat (23.67–38.66%) (Siddeeg et al. 2014) but lower than those in lentil, chickpea, small red bean (61.14–92.20%) (Du et al. 2014), C. pepo (61.71%) (Rodríguez-Miranda et al., 2012) and ebony (53.78%) (Hernández-Santos et al. 2015).

The lowest value of AD was found in DPPM (Table 2). This decrease in AD in the defatted sample was also observed by other researchers in defatted flour (Joshi et al. 2015; Hernández-Santos et al. 2015; Rodríguez-Miranda et al. 2016). AD is affected by particle size and is notably important in the development of a packaging system and material handling. Joshi et al. (2015) mentioned that in the presence of lipids, particles can be packed closer, since triglycerides can act as adhesives in the agglomeration of carbohydrate and protein molecules (alone or together), which increases the AD.

LGC was significantly lower (P < 0.05) for DPPM (4%) than WPPM (Table 2). WPPM showed no gelation because, in the degreasing process, lipid concentration decreases while protein concentration increases. Protein concentration is vital for gel formation and firmness, and a higher proportion of globular proteins improve this process (Hernández-Santos et al. 2015). Higher protein concentration improves the gel firmness. However, gelation is related to the protein type and amount, as well as non-protein components (starch) of the flour. The values of LGC for DPPM were lower than reported earlier (Joshi et al. 2015; Hernández-Santos et al. 2015; Rodríguez-Miranda et al. 2012). Gel formation capacity is an important property in the preparation and acceptance of many foods including desserts, jellies, meat products and cheese substitutes. Therefore, DPPM should be used to prepare some of these products.

Significant differences in SP between WPPM and DPPM were observed at all temperatures (P < 0.05) (Fig. 4). The highest SP values were measured in DPPM, and their values increased with increased temperature. This trend was also observed by other researchers (Rodríguez-Miranda et al. 2012). Temperature influences protein denaturation, starch gelatinization and starch interactions with the lipid matrix. When the system warms up, a slow water absorption process begins in the protein corpuscles and amorphous areas of the starch (amylose), which are the least organized and most accessible (Hernández-Santos et al. 2015). With increased temperature, more water is retained, and the granule begins to swell and increases in volume (Rodríguez-Miranda et al. 2012). WPPM has the lowest SP value, likely because the lipids present can inhibit the swelling of starch granules due to the formation of insoluble complexes with the amylose fraction (Joshi et al. 2015).

Fig. 4.

Swelling power of whole pink pinion meal (WPPM) and defatted pink pinion meal (DPPM) at different temperatures. Values represent the average of three replicates ± standard deviation. Different letters in the same temperature indicate significant difference (P < 0.05)

Conclusion

Mexican pink pinion (Pinus pinea L.). Meal showed high protein, fat, and fibre content. It also has a high solubility in water, likely due to the high concentration of proteins. Meanwhile, compared to other defatted meals, defatted pink pinion meal showed higher protein content, water solubility, emulsifying capacity, and lower gelling concentration, which were related to its high protein content. These results suggest that pink pinion meal is a potential source of oil and protein that can be used in food formulations, whereas the defatted meal potential for producing protein isolates or an additive in processing functional foods.

References

- Abdullah MHRO, Ch’ng PE, Lim TH. Some physical properties of Parkia speciosa seeds. Int Conf Food Eng Biotechnol. 2011;9:43–47. [Google Scholar]

- Alibas I, Koksal N. Determination of physical, mechanical, and structural seed properties of pepper cultivars. Int Agrophys. 2015;29(1):107–113. [Google Scholar]

- Altuntaş E, Yıldız M. Effect of moisture content on some physical and mechanical properties of faba bean (Vicia faba L.) grains. J Food Eng. 2007;78(1):174–183. [Google Scholar]

- AOAC . Official methods of analysis. 18. Gaithersburg: AOAC International; 2012. [Google Scholar]

- Appiah F, Asibuo JY, Kumah P. Physicochemical and functional properties of bean flours of three cowpeas (Vigna unguiculata L. Walp) varieties in Ghana. Afr J Food Sci. 2011;5:100–104. [Google Scholar]

- Aydin C. Some engineering properties of peanut and kernel. J Food Eng. 2007;79(3):810–816. [Google Scholar]

- Barahona ÁFR, Torres IDA. Efecto del contenido de humedad sobre propiedades físicas de la semilla de vitabosa (Mucuna deeringiana) Rev Fac Nac Agron Medellín. 2011;64(1):5961–5971. [Google Scholar]

- Barbosa-Casanovas G, Ortega-Rivas E, Juliano P, Yan H. Food powders: physical properties, processing and functionality. New York: Kluwer Academic/Plenum Publisher; 2005. p. 372. [Google Scholar]

- Cárcel LM, Bon J, Acuna L, Nevares I, del Álamo M, Crespo R. Moisture dependence on mechanical properties of pine nuts from Pinus pinea L. J Food Eng. 2012;110(2):294–297. [Google Scholar]

- Doss A, Pugalenthi M, Vadivel V. Nutritional evaluation of wild jack bean (Canavalia ensiformis L. DC) seed in different locations of South India. World Appl Sci J. 2011;13:1606–1612. [Google Scholar]

- Du SK, Jiang H, Yu X, Jane JL. Physicochemical and functional properties of whole legume flour. LWT Food Sci Technol. 2014;55:308–313. [Google Scholar]

- Escalona-Bustos AE (2005) Estudio de componentes presentes en semillas de piñón (Pinus pinea) y michay (Berberis darwinii hook), factibles de utilizar en el desarrollo de alimentos funcionales. Tesis para optar al título de ingeniero en alimentos. Universidad de Chile, Facultad de Ciencias Químicas y Farmacéuticas departamento de Ciencia de los Alimentos y Tecnología Química. P, 21

- Gharibzahedi SMT, Etemad V, Mirarab-Razi J, Fos’hat M. Study on some engineering attributes of pine nut (Pinus pinea) to the design of processing equipment. Res Agric Eng. 2010;56(3):99–106. [Google Scholar]

- Gharibzahedi SMT, Emam-Djomeh Z, Razavi SH, Jafari SM. Mechanical behavior of lentil seeds in relation to their physicochemical and microstructural characteristics. Int J Food Prop. 2014;17(3):545–558. [Google Scholar]

- Henríquez C, Loewe V, Saavedra J, Córdova A, Lutz M. Effect of the type of packaging on the oxidative stability of pine nuts (Pinus pinea L.) grown in Chile. CyTA J Food. 2018;16(1):255–262. [Google Scholar]

- Hernández-Santos B, Santiago-Adame R, Navarro-Cortéz RO, Gómez-Aldapa CA, Castro-Rosas J, Martínez-Sánchez CE, Vivar-Vera MA, Herman-Lara E, Rodríguez-Miranda J. Physical properties of ebony seed (Pithecellobium flexicaule) and functional properties of whole and defatted ebony seed meal. J Food Sci Technol. 2015;52:4483–4490. doi: 10.1007/s13197-014-1482-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hye-Jung Y, Eun-Hye L, Mi-Sun H, Sang-Do H, Dong-Ho B. Production and physicochemical properties of rice bran protein isolates prepared with autoclaving and enzymatic hydrolysis. J Korean Soc Appl Biol Chem. 2010;53:62–70. [Google Scholar]

- Işik E, ÜnaL H. Moisture-dependent physical properties of white speckled red kidney bean grains. J Food Eng. 2007;82(2):209–216. [Google Scholar]

- Jideani VA, Van-Wyk J, Cruywagen MH. Physical properties of Tylosemia esculentum and the effect of roasting on the functional properties of its flour. Afr J Agric Res. 2009;4:1208–1219. [Google Scholar]

- Joshi AU, Liu C, Sathe SK. Functional properties of select seed flours. LWT Food Sci Technol. 2015;60:325–331. [Google Scholar]

- Juárez-Barrientos JM, Hernández-Santos B, Herman-Lara E, Martínez-Sánchez CE, Torruco-Uco JG, Ramírez-Rivera EJ, Pineda-Pineda JM, Rodríguez-Miranda J. Effects of boiling on the functional, thermal and compositional properties of the Mexican jackfruit (Artocarpus heterophyllus) seed. Emir J Food Agric. 2017;29:1–9. [Google Scholar]

- Karababa E, Coşkuner Y. Physical properties of carob bean (Ceratonia siliqua L.): an industrial gum yielding crop. Ind Crops Prod. 2013;42:440–446. [Google Scholar]

- Kinsella JE. Relationships between structure and functional properties of food proteins. In: Fox PF, Condon JJ, editors. Food proteins. New York: Applied Science Publishers; 1982. pp. 51–103. [Google Scholar]

- Kumari N, Raghuvanshi RS. Physico-chemical and functional properties of buckwheat (Fagopyrum esculentum Moench) J Eco Friendly Agric. 2014;10:77–81. [Google Scholar]

- Lorestani AN, Jaliliantabar F, Gholami R. Physical and mechanical properties of castor seed. Qual Assur Saf Crop. 2012;4(5):e29–e32. [Google Scholar]

- Lutz M, Álvarez K, Loewe V. Chemical composition of pine nut (Pinus pinea L.) grown in three geographical macrozones in Chile. CyTA J Food. 2017;15:284–290. [Google Scholar]

- Mansouri A, Mirzabe AH, Ráufi A. Physical properties and mathematical modeling of melon (Cucumis melo L.) seeds and kernels. J Saudi Soc Agric Sci. 2017;16(3):218–226. [Google Scholar]

- McCabe WL, Smith JC, Harriott P. Unit operations of chemical engineering. New York: McGraw-Hill Publisher; 1986. [Google Scholar]

- Mohsenin NN. Physical properties of plant and animal materials, 2nd edition (revised) New York: Gordon and Breach Science Publishers; 1986. [Google Scholar]

- Mpotokwane SM, Gaditlhatlhelwe E, Sebaka A, Jideani VA. Physical properties of bambara groundnuts from Botswana. J Food Eng. 2008;89(1):93–98. [Google Scholar]

- Nasri N, Khaldi A, Fady B, Triki S. Fatty acids from seeds of Pinus pinea L.: composition and population profiling. Phytochemistry. 2005;66:1729–1735. doi: 10.1016/j.phytochem.2005.05.023. [DOI] [PubMed] [Google Scholar]

- Nergiz C, Dönmez I. Chemical composition and nutritive value of Pinus pinea L. seeds. Food Chem. 2004;86(3):365–368. [Google Scholar]

- Niveditha VR, Sridhar KR, Balasubramanian D. Physical and mechanical properties of seeds and kernels of Canavalia of coastal sand dunes. Int Food Res J. 2013;20(4):547–1554. [Google Scholar]

- Özgüven F, Vursavuş K. Some physical, mechanical and aerodynamic properties of pine (Pinus pinea) nuts. J Food Eng. 2005;68(2):191–196. [Google Scholar]

- Parmar N, Virdi AS, Singh N, Kaur A, Bajaj R, Rana JC, Agrawal L, Nautiyal CS. Evaluation of physicochemical, textural, mineral and protein characteristics of kidney bean grown at Himalayan region. Food Res Int. 2014;66:45–57. [Google Scholar]

- Parmar N, Singh N, Kaur A, Thakur S. Comparison of color, anti-nutritional factors, minerals, phenolic profile and protein digestibility between hard-to-cook and easy-to-cook grains from different kidney bean (Phaseolus vulgaris) accessions. J Food Sci Technol. 2017;54(4):1023–1034. doi: 10.1007/s13197-017-2538-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Razavi SMA, Edalatian MR. Effect of moisture contents and compression axes on physical and mechanical properties of pistachio kernel. Int J Food Prop. 2012;15:507–517. [Google Scholar]

- Razavi SM, Bostan A, Rezaie M. Image processing and physico-mechanical properties of basil seed (Ocimum basilicum) J Food Process Eng. 2010;33(1):51–64. [Google Scholar]

- Rodríguez-Miranda J, Hernández-Santos B, Herman-Lara E, Vivar-Vera MA, Carmona-García R, Gómez-Aldapa CA, Martínez-Sánchez CE. Physicochemical and functional properties of whole and defatted meals from Mexican (Cucurbita pepo) pumpkin seeds. Int J Food Sci Technol. 2012;47:2297–2303. [Google Scholar]

- Rodríguez-Miranda J, Hernández-Santos B, Herman-Lara E, Gómez-Aldapa CA, Garcia HS, Martínez-Sánchez CE. Effect of some variables on oil extraction yield from Mexican pumpkin seeds. CyTA J Food. 2014;12:9–15. [Google Scholar]

- Rodríguez-Miranda J, Hernández-Santos B, Castro-Rosas J, Vargas-León EA, Hernandez-Avila J, Rangel-Vargas E, Gómez-Aldapa CA, Falfan-Cortés RN. Physical properties of Cucurbita ficifolia seed and functional properties of whole and defatted meal. Int J Food Proc Technol. 2016;3:27–35. [Google Scholar]

- Siddeeg A, Xu Y, Jiang Q, Xia W. Physicochemical and functional properties of flour and protein isolates extracted from seinat (Cucumis melo var. tibish) seeds. Food Sci Biotechnol. 2014;23:345–353. [Google Scholar]

- Sologubik CA, Campañone LA, Pagano AM, Gely MC. Effect of moisture content on some physical properties of barley. Ind Crops Prod. 2013;43:762–767. [Google Scholar]

- Tunde-Akintunde TY, Akintunde BO. Some physical properties of sesame seed. Biosyst Eng. 2004;88(1):127–129. [Google Scholar]

- Wani IA, Sogi DS, Wani AA, Gill BS. Physical and cooking characteristics of some Indian kidney bean (Phaseolus vulgaris L.) cultivars. J Saudi Soc AgricSci. 2017;16(1):7–15. [Google Scholar]

- Yalçın İ, Özarslan C, Akbaş T. Physical properties of pea (Pisum sativum) seed. J Food Eng. 2007;79(2):731–735. [Google Scholar]