Abstract

Extrusion cooking is a high temperature short time process where food materials are cooked in a barrel with a combination of pressure, moisture and temperature. In this study a finger millet based snack product fortified with banana powder is extruded with a combination of rice flour, corn flour and cheese and its properties are studied. In addition to that the parameter for extrusion cooking of the snack product is also optimized. Response surface methodology was used to optimize the process parameters like barrel temperature (118–122 °C), extruder rpm (345–355) and banana powder concentration (1–4 g) on physical and functional properties of extruded snack food based on finger millet. Central composite design with three levels, three factors is used for optimization. Analysis of variance was used to study the effects of process parameters. Regression analysis is also done for variability and it is fitted to a second order quadratic model with coded value for each response. Based on Analysis of Variance model confirmed the fitness for dependent variables.

Keywords: Banana powder, Optimization, Response surface methodology, Extrusion, Finger millet

Introduction

Extrusion cooking is a high-temperature, short-time process in which moistened, starchy food materials are plasticized and cooked in a barrel by a combination of moisture, pressure, temperature and mechanical shear, ensuing in chemical reactions and molecular conversion (Castells et al. 2005). In the food industry extrusion issued for the making of expanded snack foods, pet foods and ready to eat snacks. Extrusion technology has many different advantages like flexibility, low cost, improved product quality and zero process effluents (Camire et al. 1990).

Finger millet grain has high nutritive value and therapeutic value so it can be used for the production of expanded foods. Corn grits are the main constituent for extruded foods, for example, ready-to-eat snacks and cereals (Gujral et al. 2001), at present it is required to advance the nutritional value of this category of food because cereal-based snack foods are frequently consumed by children (Pastor-Cavada et al. 2011). The effect of value addition using certain grains and ingredients to corn grits and characteristics of the extrudate are studied widely (Semasaka et al. 2010). Rice flour is used as a most accepted component in the production of gluten-free products (Neumann and Bruemmer 1997). Extruded snack made out of multigrain like finger millet, corn and rice become a nutritious product especially for children.

Banana is one of the greatly used fruits in Southeast Asia mainly in tropical and subtropical regions. It belongs to the family Musaceae and class Liliopsida and bananas contain noticeably higher amount of potassium, a trace amount of sodium and iron (Chauhan and Jethva 2016). Extruded products enriched with banana powder are also a functional product because it is rich in carbohydrate, dietary fiber, and minerals that can improve the nutritional properties of snacks.

The advantages of extrusion process are starch gelatinization, increased soluble dietary fibers, removal of anti-nutritional factors. Extrusion retains natural colors and flavors of foods and result in a decrease of lipid oxidation and low occurrence of microbial contamination (Singh et al. 2007).

Response surface methodology (RSM) is a tool that can be used for the improvement of product and process. RSM helps experimenter to determine the effect of process parameters on responses by designing and optimizing the experiment (Myers et al. 2004).

Rice flour, corn flour combined with ragi flour for the production of carbohydrate-rich extruded snack food when it is fortified with raw banana powder it becomes rich in mineral content. Physical and chemical properties of extruded products have an important role in the acceptability of the final product. Cheese addition helps in better puffing, flavor and nutritional enhancement which helps in consumer acceptability. Flavouring substance can be added before or after extrusion which dominates unwanted flavour with desirable one during extrusion (Mega and Kim 1989). The objective of this study is to optimize process parameters like barrel temperature, extruder rpm, and banana powder concentration on some physical, functional and chemical properties of extruded snack based on finger millet in combination with rice flour, corn flour, and cheese which is fortified with banana powder.

Materials and methods

Raw materials

Ragi flour, rice flour, and corn flour are obtained from the local market of Chennai. The raw banana powder was obtained from local market of Kerala (India). Cheese (processed cheddar cheese blocks from Amul dairy limited) is purchased from the local store and is kept in refrigerated condition.

Blend preparation

Flour blend is prepared with the combination of ragi flour, rice flour, and corn flour in the ratio 40:30:30. Banana flour is added to the blend according to experimental design. 3% cheese is added to each sample. Proper mixing of the raw materials is done manually without the addition of water. Then the blend is sieved through a 4 mm sieve and kept as such for 10 min.

Extrusion processing

Extrusion was done on Laboratory Model High Shear Twin-Screw Extruder with nominal rated capacity of 5–15 kg/hour. Model BTPL, Basic Technology Private Limited, Kolkata, India. Die diameter is 4.95 mm and feeding rate is also kept constant.

Determination of product responses

Expansion ratio is calculated by dividing the average diameter with the diameter of the die orifice and for calculating mean diameter ten extrudates diameter was measured and average is taken. Bulk density (BD) was calculated according to the method of (Alvarez Martinez et al. 1988). Water absorption index (WAI) and water solubility index (WSI) were determined according to (Anderson et al. 1969). Water holding capacity (WHC) was determined. The color of the samples was measured with a Hunter colorimeter (Hunter associates Laboratory, USA). The results were expressed as L*, a* and b* values. The L* value ranged from black 0 to white 100, the a* value ranged from greenness − a* to redness + a* and the b* value ranged from blueness − b* to yellowness + b*. Measurements were made in triplicate. Hardness and flexural strength of the extrudates were determined using texture analyzer (TA XT plus texture analyzer). The extrudates were subjected to 75% compression with a probe (P/75). Triplicate reading was taken.

Compositional analysis

Moisture, ash, protein and fat analysis of extrudates was carried out using standard procedures of AOAC (1990). All the experiments were replicated so that the data in the paper are expressed as the mean (± SD) of triplicate analysis. The water activity of the extruded samples is measured using water activity meter (LabSwift-aw, Novatron scientific ltd, UK) (Singh et al. 2014).

Sensory analysis

Sensory analysis of the optimized and control extruded sample is done by 20-panel members. The evaluation is based on the highest scores of sensory liking (appearance, color, flavor, texture and overall acceptability). Nine point hedonic scale ranging from 1 (extremely dislike) to 9 (extremely like) was used to determine the acceptability of (Kong et al. 2008). Statistical analysis of sensory evaluation is done using SPSS software (version 20).

Scanning electron microscopy

Microstructural analysis of optimized extruded sample and extruded control samples were examined using field emission scanning electron microscope (FEI Quanta 200 FEG, FEICompany, USA).

Experimental design

Response surface methodology was used in the design of experimental combinations. The central composite design for three independent variables like barrel temperature, extruder rpm, and banana powder concentration was selected. The independent variables and variation levels were (barrel temperature 118–122 °C, extruder rpm 345–355, banana powder concentration 1–4 g). Each independent variable was used according to preliminary trials and literature. Composite flour (finger millet flour, rice flour, and corn flour in the ratio 40:30:30) as a base material was used according to the preparatory trials and literature details for suitable extrusion cooking. Dependent variables are hardness, fracturability, color, expansion ratio, bulk density, water solubility index, water absorption index and water holding capacity. Design expert version 10 was used for experimental designing and optimization of the process.

Statistical analysis

Statistical analysis was done using design expert version 10 software, stat ease. The experimental data’s were analyzed and fitted to a second order quadratic model for each response. The model can be expressed with coded variables A, B and C as follows

where y is estimated response, β0 is equation parameter for constant term, β1 represent linear terms, βij represent interaction term (i = 1 − 3; j = 1 − 3) and βii represent quadratic term for a single variable. Response surface plot is developed as a function of two variables keeping other at a constant value.

Results and discussion

Table 1 shows the experimental design range and values of independent variables. Regression analysis was applied to fit a full response surface model for every response calculated including all linear (A, B, C), interaction (AB, AC, BC), and quadratic terms (A2, B2, C2). The regression coefficients for the response surface model in terms of coded units are shown in Table 2. To develop a fitted response surface model all terms which are insignificant are eliminated (P > 0.05) and the fitted models are shown in Table 3. R2 value is the measurement of the degree of fitness. Model fitness is best when R2 value approaches unity (Sin et al. 2006). Optimum extrusion condition is established by fixing banana flour % at center coded value and changing other two parameters. The estimated response function and effect of independent variables (barrel temperature A, screw speed B, and banana flour % C) on responses are shown in Figs. 1 and 2.

Table 1.

Experimental design range and values of independent variables

| Independent variables | Symbol | Levels code values | ||

|---|---|---|---|---|

| − 1 | 0 | 1 | ||

| Real values | ||||

| Barrel temperature (°C) | A | 118 | 120 | 122 |

| Screw speed (rpm) | B | 345 | 350 | 355 |

| Banana flour (%) | C | 1 | 2.5 | 4 |

Table 2.

The regression coefficients for the response surface model in terms of coded units

| Parameter | Term | Regression coefficient | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| L | A | Hardness | Fracturability | Bulk density | Expansion ratio | WAI | WSI | WHC | ||

| β 0 | Intercept | 60.4 | 3.69 | 8479.97 | 7743.06 | 0.0616 | 1.82 | 11.47 | 21.88 | 3.37 |

| β 1 | Barrel temperature, A | 1.24 | 0.039 | − 2.594 | 65.682 | − 0.0012 | 0.16 | 0.20 | 0.36 | 0.35 |

| β 2 | Screw speed, B | 1.09 | − 0.24 | 1266.74 | 703.895 | − 0.00069 | − 0.017 | 0.13 | 0.21 | 0.12 |

| β 3 | Banana flour %, C | 2.79 | 0.024 | 1553.11 | 1206.23 | − 0.0097 | 0.30 | 1.70 | 3.11 | 0.076 |

| β 12 | A*B | 0.3525 | 0.061 | − 0.15 | − 0.12 | − 0.17 | ||||

| β 13 | A*C | 0.115 | 0.030 | − 0.13 | − 0.25 | − 0.026 | ||||

| β 23 | B*C | − 0.0825 | − 0.028 | − 0.051 | 4.87e−015 | 0.00875 | ||||

| β 11 | A2 | 0.021 | − 1.43 | − 2.91 | 0.70 | |||||

| β 22 | B2 | − 0.0078 | − 1.31 | − 2.50 | 0.50 | |||||

| β 33 | C2 | 0.11 | − 1.22 | − 2.07 | 0.39 | |||||

Table 3.

Response surface model for all responses

| Response | Quadratic polynomial model | R2 | P |

|---|---|---|---|

| L | 0.6977 | 0.0002 | |

| A | 0.7266 | 0.0051 | |

| Hardness | 0.4528 | 0.0192 | |

| Fracturability | 0.5275 | 0.0063 | |

| Bulk density | 0.6732 | 0.0004 | |

| Expansion ratio | 0.9675 | 0.0023 | |

| WAI | 0.9818 | < 0.0001 | |

| WSI | 0.9725 | < 0.0001 | |

| WHC | 0.9314 | < 0.0001 |

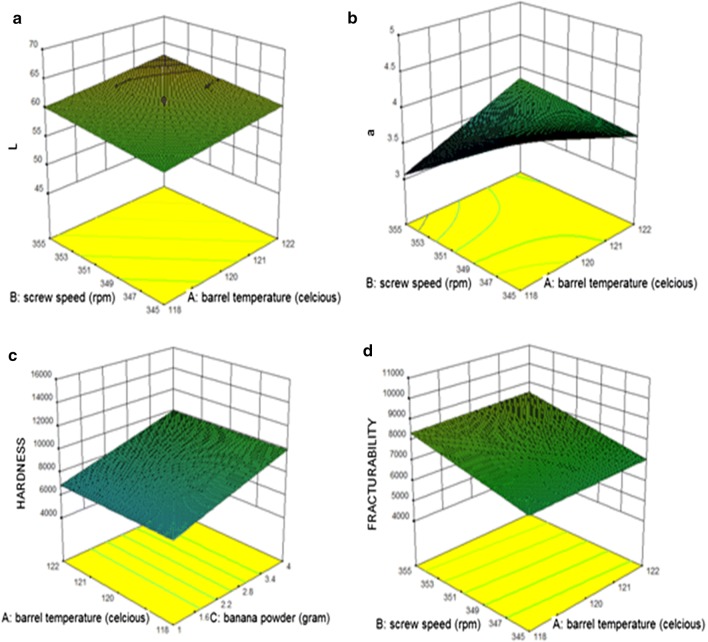

Fig. 1.

Response surface plot showing the effect of screw speed and barrel temperature on a L value of extrudate b a value of extrudate c effect of barrel temperature and banana powder % on hardness of extrudate d effect of screw speed and barrel temperature on fracturability of extrudate

Fig. 2.

Response surface plot showing the effect of a screw speed and barrel temperature on bulk density of the extrudate b effect of banana powder % and barrel temperature on expansion ratio of extrudate c effect of screw speed and barrel temperature on water absorptive index (WAI) of extrudate d effect of screw speed and barrel temperature on water holding capacity of extrudate (WHC)

Products color analysis

The color is an important characteristic of the extrudate. Color changes give data about the level of browning reactions such as Maillard reaction, caramelization, the degree of cooking and pigment deterioration during the extrusion process (Altan et al. 2009). The regression equation for L*values are significant as revealed by R2 value and p value (Table 3). The concentration of banana flour has a highly significant effect on L* value of the extrudate followed by barrel temperature. A similar effect on L* value of banana flour and temperature was shown by Kaur et al. (2015). From the regression analysis, it is revealed that A and coefficient is significant whereas C coefficient is not significant (P > 0.05). There is no interaction effect of A, B, and C on L* value of the extrudate. Linear model best fits for L* values of the extrudates. The model F-value of 12.31 implies the model is significant. The increase in L* with an increase in screw speed may be due to lesser residence result in less pigment reduction (Yu et al. 2012). For a* value of the extrudate coefficient of B has significant negative effect on it but the coefficient of A and C are not significant (P > 0.05). There is interaction effect of A and B on a value of the extrudates. The model F-value of 5.76 implies the model is significant. Interaction model best fits for a value of the extrudates.

Products texture analysis

The textural property of extrudate was determined by measuring the force required to break the extrudate (Singh et al. 1994). The regression equation of hardness is significant as per R2 value and P-value (Table 3). concentration of banana flour has a highly significant effect on hardness value followed by screw speed. A similar effect of banana flour on the texture of the extrudate is shown in (Kaur et al. 2015). From the regression analysis, it is revealed that B and C coefficient is significant whereas A is not significant (P > 0.05). Linear model F factor value is 4.41 implies it is significant. For the fracturability analysis concentration of banana flour shows a significant effect on process parameters. From the regression analysis, it is revealed that coefficient of C is significant. The linear model F factor value is 5.95 with P-value 0.0063. The texture of extruded product depends primarily on the processing parameters, but ingredients composition is also a factor (Stanley 1986).

Bulk density

Bulk density is related to the expansion ratio in explaining the degree of puffing in extrudates (Asare et al. 2004). From the regression analysis, it is revealed that coefficient of barrel temperature, screw speed, and banana flour has significant negative effect on the bulk density of the extrudate. Bulk density values decrease with increase in extrusion temperature due to gelatinization of starch. This result agrees with the earlier results (Hernandez-Nava et al. 2011; Case et al. 1992). They reported that volume of extruded product increases as gelatinization increases and bulk density decreases. Interaction effect of process parameters also has a significant effect on process parameters. The coefficient of determination of bulk density is 0.6732. ANOVA shows the quadratic model with F factor 10.99 implies model fitness with P-value 0.0004.

Expansion ratio

The degree of expansion in food depends on the difference between the vapor pressure of water and the atmospheric pressure, as well as the ability of the product to sustain expansion (Singh et al. 2007). Regression analysis shows the coefficient of A and C has significant positive effect on expansion ratio of the extrudate. The coefficient of B shows the significant positive effect on expansion ratio of the extrudate. Expansion ratio increased with increase in barrel temperature. At high temperatures, gelatinization increases and starch expands result in an increase in expansion ratio. Similar results were reported earlier (Singh et al. 1998; Altan et al. 2009; Chinnaswamy and Hanna 1988; Ali et al. 1996; Hagenimana et al. 2006). Expansion ratio increased with increase in banana flour concentration. A similar result was reported earlier (Kaur et al. 2015; Li et al. 2005). The increase in banana flour will decrease the protein content which in turn increase expansion ratio as reported by Kaur et al. (2015). ANOVA shows the quadratic model with F factor 33.10 shows model is significant with P-value 0.0023 and R2 value 0.9675.

Water absorptive index, water solubility index and water holding capacity

The water absorption index (WAI) is the measure of starch volume when it swells in excess water which indicates its integrity in aqueous dispersion. Water solubility index (WSI), measures the degree of starch conversion to soluble polysaccharides during extrusion (Yang et al. 2008). Regression model for water absorptive index was significant with an R2 value of 0.9818. The coefficient of A, B, and C shows the significant positive effect on water absorptive index of the extrudate. Interactive effect of banana flour and screw speed on WAI is also significant, the similar effect shown by Kaur et al. (2015). Quadratic model with F factor value of 59.96 fit best for this response. There is the significant interactive effect of process parameters on water absorptive index. Regression model for water solubility index was significant with an R2 value of 0.9725. ANOVA shows the quadratic model with F factor value of 39.35 fit best for water solubility index of extrudates. The coefficient of A, B, and C shows the significant positive effect on water solubility index of the extrudate. WSI increased with extrusion temperature and similar effect was reported earlier for corn extrudates (Singh et al. 1998; Thakur et al. 2017; Kaur et al. 2015; Gujral et al. 2001). Process parameters have a significant interactive effect on the WSI. Regression model for water holding capacity (WHC) was significant with an R2 value of 0.9314. Quadratic model with F factor value of 15.08 implies best fit for this response. The coefficient of A, B, and C shows the significant positive effect on water holding capacity of the extrudates. The model also shows the significant interactive effect of process parameters on the extrudates.

Sensory analysis

The sensory evaluation of both control and optimized extrudate sample was carried out using 9 point hedonic scale. The parameters such as appearance, color, texture, taste, and overall acceptability were used to understand the effect of process parameters on organoleptic properties of the extrudate. The above parameters were evaluated by 20-panel members. The result from the ANOVA showed there was a considerable variation in (P > 0.05) in the sensory characteristics between the control and optimized extrudate sample. Overall acceptability was comparatively more for optimized sample (9 ± 0.19) than control sample (8 ± 0.07).

Scanning electron micrograph

Microstructural analysis of the optimized extrudate is studied using SEM analyzer and it is compared with control samples. As a result of extrusion a number of visible changes in the structure of starch, related to loss of granule shapes, such as gelatinization, plasticization, and rupture of intermolecular bonds. The extruded sample produced using optimum processing conditions contained no intact starch granules, probably because these either melted or plasticized due to the heat of extrusion (Fig. 3). Control samples without banana powder and without cheese also show visible changes in the starch structure.

Fig. 3.

Scanning electron micrograph of selected extrudates, a optimized sample, b control sample without banana powder, c control sample without cheese

Conclusion

Change of extrusion conditions like barrel temperature, screw speed, and banana flour are observed to have a significant effect on the physical properties of extruded finger millet based ready-to-eat snacks in the present experiment. Physical characteristics of the extrudate play an important role in the development of high quality extruded product. The experiment is optimized with desirability 1. Desirable process parameters are barrel temperature 119 °C, screw speed 346 and banana flour concentration 3.67 g. The model developed could be used for designing of extrusion conditions for getting extrudates with desirable physical characteristics.

Contributor Information

Aryasree Sukumar, Phone: 8075925336, Email: aryasree10010@gmail.com.

K. A. Athmaselvi, Phone: 960000782, Email: athmaphd@gmail.com

References

- Ali Y, Hanna MA, Chinnaswamy R. Expansion characteristics of extruded corn grits. LWT-Food Sci Technol. 1996;29(8):702–707. [Google Scholar]

- Altan A, McCarthy KL, Maskan M. Effect of extrusion process on antioxidant activity, total phenolics and β-glucan content of extrudates developed from barley-fruit and vegetable by-products. Int J Food Sci Technol. 2009;44(6):1263–1271. [Google Scholar]

- Alvarez Martinez L, Kondury KP, Harper JM. A general model for expansion of extruded products. J Food Sci. 1988;53(2):609–615. [Google Scholar]

- Anderson RA, Conway HF, Pfeifer VF, Griffin EL. Gelatinization of corn grits by roll-and extrusion-cooking. Cereal Sci Today. 1969;14(1):4. [Google Scholar]

- AOAC . Official methods of analysis. 15. Washington: Association of Official Analytical Chemists; 1990. [Google Scholar]

- Asare EK, Sefa-Dedeh S, Sakyi-Dawson E, Afoakwa EO. Application of response surface methodology for studying the product characteristics of extruded rice–cowpea–groundnut blends. Int J Food Sci Nutr. 2004;55(5):431–439. doi: 10.1080/09637480400003238. [DOI] [PubMed] [Google Scholar]

- Camire ME, Camire A, Krumhar K. Chemical and nutritional changes in foods during extrusion. Crit Rev Food Sci Nutr. 1990;29(1):35–57. doi: 10.1080/10408399009527513. [DOI] [PubMed] [Google Scholar]

- Case SE, Hamann DD, Schwartz SJ. Effect of starch gelatinization on physical properties of extruded wheat and corn based products. Cereal Chem. 1992;69(4):401–404. [Google Scholar]

- Castells M, Marin S, Sanchis V, Ramos AJ. Fate of mycotoxins in cereals during extrusion cooking: a review. Food Addit Contam. 2005;22(2):150–157. doi: 10.1080/02652030500037969. [DOI] [PubMed] [Google Scholar]

- Chauhan N, Jethva KR. Drying characteristics of banana powder. Indian J Sci. 2016;23(77):75–88. [Google Scholar]

- Chinnaswamy R, Hanna MA. Optimum extrusion-cooking conditions for maximum expansion of corn starch. J Food Sci. 1988;53(3):834–836. [Google Scholar]

- Gujral HS, Singh N, Singh B. Extrusion behaviour of grits from flint and sweet corn. Food Chem. 2001;74(3):303–308. [Google Scholar]

- Hagenimana A, Ding X, Fang T. Evaluation of rice flour modified by extrusion cooking. J Cereal Sci. 2006;43(1):38–46. [Google Scholar]

- Hernandez-Nava RG, Bello-Perez LA, San Martín-Martínez E, Hernandez-Sanchez H, Mora-Escobedo R. Effect of extrusion cooking on the functional properties and starch components of lentil/banana blends: response surface analysis. Revista Mexicana de Ingeniería Química. 2011;10(3):409–419. [Google Scholar]

- Kaur A, Kaur S, Singh M, Singh N, Shevkani K, Singh B. Effect of banana flour, screw speed and temperature on extrusion behaviour of corn extrudates. J Food Sci Technol. 2015;52(7):4276–4285. doi: 10.1007/s13197-014-1524-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kong J, Dougherty MP, Perkins LB, Camire ME. Composition and consumer acceptability of a novel extrusion-cooked salmon snack. J Food Sci. 2008;73(3):118–123. doi: 10.1111/j.1750-3841.2007.00651.x. [DOI] [PubMed] [Google Scholar]

- Li SQ, Zhang HQ, Tony Jin Z, Hsieh FH. Textural modification of soya bean/corn extrudates as affected by moisture content, screw speed and soya bean concentration. Int J Food Sci Technol. 2005;40(7):731–741. [Google Scholar]

- Mega JA, Kim CH. Co-extrusion of rice flour with dried fruits and fruit juice concentrations. Lebensmittel-Wissenschaft & Technologie. 1989;22:182–187. [Google Scholar]

- Myers RH, Montgomery DC, Vining GG, Borror CM, Kowalski SM. Response surface methodology: a retrospective and literature survey. J Qual Technol. 2004;36(1):53. [Google Scholar]

- Neumann H, Bruemmer JM. Investigations with the production of gluten free bread and roll specialties. Getreide Mehl Brot. 1997;51:50–55. [Google Scholar]

- Pastor-Cavada E, Drago SR, González RJ, Juan R, Pastor JE, Alaiz M, Vioque J. Effects of the addition of wild legumes (Lathyrusannuus and Lathyrusclymenum) on the physical and nutritional properties of extruded products based on whole corn and brown rice. Food Chem. 2011;128(4):961–967. [Google Scholar]

- Semasaka C, Kong XZ, Hua Y. Optimization of extrusion on blend flour composed of corn, millet and soybean. Pakistan J Nutr. 2010;9(3):291–297. [Google Scholar]

- Sin HN, Yusor S, Hamid NSA, Rahman RA. Optimixation of enzymatic clarification of sapodilla juice using response surface methodology. J Food Eng. 2006;73:313–319. [Google Scholar]

- Singh J, Hoseney RC, Faubion JM. Effect of dough properties on extrusion-formed and baked snacks. Cereal Chem. 1994;71:417–422. [Google Scholar]

- Singh N, Smith AC, Frame ND. Effect of process variables and monoglycerides on extrusion of maize grits from two sizes of extruder. J Food Eng. 1998;35:91–109. [Google Scholar]

- Singh S, Gamlath S, Wakeling L. Nutritional aspects of food extrusion: a review. Int J Food Sci Technol. 2007;42:916–929. [Google Scholar]

- Singh RR, Majumdar RK, Venkateshwarlu G. Optimum extrusion-cooking conditions for improving physical properties of fish-cereal based snacks by response surface methodology. J Food Sci Technol. 2014;51(9):1827–1836. doi: 10.1007/s13197-012-0725-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stanley DW. Chemical and structural determinants of texture of fabricated foods. Food Tech. 1986;40(3):65. [Google Scholar]

- Thakur S, Singh N, Kaur A, Singh B. Effect of extrusion on physicochemical properties, digestibility, and phenolic profiles of grit fractions obtained from dry milling of normal and waxy corn. J Food Sci. 2017;82(5):1101–1109. doi: 10.1111/1750-3841.13692. [DOI] [PubMed] [Google Scholar]

- Yang SH, Peng J, Lui WB, Lin J. Effects of adlay species and rice flour ratio on the physicochemical properties and texture characteristic of adlay-based extrudates. J Food Eng. 2008;84(3):489–494. [Google Scholar]

- Yu L, Ramaswamy HS, Boye J. Twin-screw extrusion of corn flour and soy protein isolate (SPI) blends: a response surface analysis. Food Bioprocess Technol. 2012;5(2):485–497. [Google Scholar]