Abstract

The objective of this study was to evaluate the effect of operating parameters including milling weight (MW; 10, 95, 220, 345, 430 g), filling ratio (FR; 1, 1.4, 2, 2.6, 3) and milling duration (MD; 6, 30, 65, 100, 124 s) on head rice yield (HRY), whiteness index (WI) and specific energy consumption (Es). The experiments were conducted based on a vertical circulation mill employing a 5 level, 3 parameters CCD design and operating parameters were optimized using response surface methodology. During the processing, MW and MD had significant negative effects on HRY. On the contrary, they both had significant positive effects on WI. All the three parameters had a significant effect on Es Taking HRY, WI, Es as the evaluative index and degree of milling, temperature rise of milled rice as the restrictive index, the best combination of operating parameters was obtained, namely MW of 345 g, FR of 2.6 and MD of 30 s. The Pearson correlation coefficients between all the milling qualities were analyzed. Results showed that the temperature rise as an easy measurement index was highly correlated with the other qualities. The regression models between temperature rise and the other milling quality indices can assist in evaluating the quality of milled rice quickly and quantifiably.

Keywords: Brown rice, Correlation analysis, Milling quality, Optimization, Response surface methodology

Introduction

Rice as the stable food is normally consumed in the form of milled rice kernel. Milling is a key procedure to remove the bran and yield the white rice during the processing of grain. The milling can be commonly classified into two types: (1) abrasion milling, in which the rub between the surface of an abrasive surface and rice kernels plays a dominant role; (2) friction milling, in which the rub between the brown rice kernels under pressure plays the leading role (Takai and Barredo 1981). While according to the structure, the mill can be divided into vertical mill and horizontal mill. Compared with horizontal mill, the internal pressure in milling chamber of the vertical mill is more uniform. Therefore, vertical mill is widely used in the milling industry. Based on the difference of the feeding form, the flow of brown rice in the vertical mill is either along with the gravity or opposite with the gravity. No matter what kind of feeding form it is, adjusting the operating parameters can alter the pressure in the milling chamber, for obtaining the different quality of milled rice (Mir et al. 2015). The high quality of milled rice is of complete shape and glossy surface (Yadav and Jindal 2008). Although a well-milled rice has a superior optical quality attribute which is more acceptable to consumers, the process of milling results in an increase of broken content and a reduction in the nutritional value (Yoon and Kim 2004; Kim and Lee 2012). Meanwhile, over-milling leads to higher energy consumption (Monks et al. 2013; Ahmad et al. 2017). Corresponding to that, under-milled rice has an inferior eating and optical quality because of the existence of bran layer (Roberts 1979; Park et al. 2007). Therefore, in order to maximize the proportion of head rice yield with desired degree of kernel whiteness meanwhile minimize specific energy consumption, it is necessary to investigate the effect of operating parameters on milling qualities.

The effect of several operating parameters on the milled rice quality was studied. Roberts and Wasserman (1977) found that the increase in width of the feed gate opening had a positive effect on head rice yield and reduced the energy consumption when milling the same weight of brown rice. Meanwhile, the decrease of clearance between rotor and milling bar leads to the improvement of milling efficiency but coincides with the reduction of head rice yield. Andrews et al. (1992) also reported that the milling time and milling weight were critical to determine head rice yield for the McGill No. 2. The increase of milling pressure or milling time both decreased the head rice yield. Gujral et al. (2002) found that the degree of milling was inversely proportional to the weight of sample being milled and directly proportional to the weight applied on the mill chamber during milling. All those research findings were based on the McGill type mill, as it was the official laboratory mill in America. Different structures certainly bring the difference in milling quality. However, there is limited information about the effect of operating parameters on the milled rice quality for the vertical rice mill. Yan et al. (2005) investigated the effect of moisture content, shaft speed, emery size and outlet resistance on broken rice ratio and whiteness index to optimize the milling performance for a vertical rice mill. In our previous study, it was found that the outlet opening size had more influence on particle flow than roller shaft rotational speed (Han et al. 2016). For the vertical friction circulation mill, the effect of milling weight (MW), filling ratio (FR) and milling duration (MD) on milling qualities has not been identified.

With the aim to improve the milling quality, a few researchers mainly focused on the changing of the head rice yield, optical value, energy consumption, physicochemical and nutritional properties with degree of milling (Yoon and Kim 2004; Mohapatra and Bal 2007; Copper and Siebenmorgen 2007; Roy et al. 2008; Srikham and Noomhorm 2015). It was found that the milling yield, head rice yield, color intensity and nutritional properties decreased while whiteness index and energy consumption increased with an increase in the degree of milling. However, it is worthy to point out that these findings usually modified one operating parameter, like milling time to obtain the different degree of milling with the other operating parameters fixed. But the change of milling qualities must be different under different combination of operating parameters. However, there is limited information available on how the different combinations of operating parameters affected the milling qualities.

In addition, to comprehensively evaluate the milling quality, researchers normally need to measure multiple indices. It is a complicated process which takes a lot of time. While the establishment of relationship between each milling quality can assist in building quick and quantifiable evaluation system. Although as mentioned above, the relationship between degree of milling and other milling qualities like head rice yield or optical quality had been widely investigated (Sun and Siebenmorgen 1993; Monks et al. 2013). It is still necessary to discuss the correlation between other milling qualities.

The objectives of this study were to (1) investigate the effects of operating parameters like milling weight, filling ratio and milling duration on the milling qualities including head rice yield (HRY), whiteness index (WI) and specific energy consumption (Es) in a vertical circulation mill. (2) optimize operating parameters for the vertical circulation mill (SY95-PC + PAE5, Ssangyong Machinery Co., Korea) to maximize head rice yield and whiteness index and minimize specific energy consumption under the given degree of milling (DOM) and temperature rise (TR). (3) analyze the Pearson correlation coefficients between five milling indices, namely HRY, WI, Es, DOM and TR, aiming at establishing the regression models to assist in developing a quick and precise evaluation system for milled rice.

Materials and method

Materials

Short grain of the Japonica type (Dongnong No. 429) provided by the rice processing laboratory of the Northeast Agricultural University (Harbin, China) was dehusked using a Satake rice dehusker (THU-35B type, Satake, Tokyo, Japan). The initial moisture content of brown rice was 14.1 ± 0.1% (w.b.), which was determined using standard air oven method by keeping 5 g of brown rice in oven (DGH-9053A type, Yiheng, Shanghai, China) at 105 °C for 24 h and then noting the weight and was expressed in percent wet basis. The optimal moisture content of brown rice for milling is recommended to be between 15 and 16% (w.b.) (Jia et al. 2006). Therefore, in this study, brown rice samples were conditioned to a moisture content level of 15.5 ± 0.1% (w.b.), by adding a measured amount of distilled water, followed by thorough mixing, and sealing the samples in double polythene bags. The conditioned samples were kept at 5 ± 1 °C in a refrigerator for 7 d to allow uniform distribution of moisture throughout the sample (Vishwakarma et al. 2012).

Milling

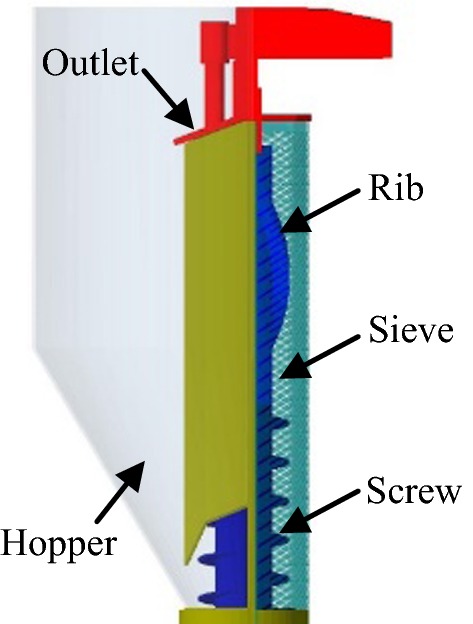

Desired quantity of brown rice was milled in a frictional type laboratory vertical circulation mill (SY95-PC + PAE5, Ssangyong Machinery Co., Korea) according to the requirement of experimental design. The vertical circulation mill used in this paper (Fig. 1), essentially consists of four parts: a feed hopper, a roller shaft with a screw and two convex ribs, an outlet and a milling chamber surrounded by octagon rice sieve. MW, FR and MD are three controlled operating parameters which can determine the milling quality. MW is the weight loaded on the top cover of the chamber to generate the milling pressure (Pan et al. 2007). FR is the weight of brown rice placed in the feed hopper divided by 100 g. It should be noted that 100 g was the least weight of rice sample that should be put in the milling chamber to conduct milling. If the weight of the sample was lower than 100 g, the bran layer could not be removed. MD is the time that rice was milled in the milling chamber. All experiments were repeated three times and average data of the triplicate samples was used for analysis.

Fig. 1.

Geometry of the vertical circulation mill

Milling quality indices

HRY and WI are the most important parameters used to define the quality of milled rice in their transactions (Yadav and Jindal 2008). Es is of vital importance for the benefit of the factory. Therefore, these three indices were chosen to evaluate the milling quality. Meanwhile, as mentioned above, an inappropriate DOM leads to a terribly nutritional and cooking quality (Sandhu et al. 2018). In addition, a higher TR during milling means a poor milling quality (Mohapatra and Bal 2004b; Pan et al. 2005, 2013). In order to make sure the rice after milled by different combination of operating parameters were in an acceptable quality. The DOM and TR should be restricted in a reasonable range in the optimization part in this paper. Rahaman et al. (1996) reported that milling should be restricted to 7–8% for maximum recovery, which is a common practice in most developing countries. Besides, once the temperature rise of milled rice was over 25 °C, the broken content increased obviously based on the preliminary experiments. Therefore, in the optimization part, DOM and TR were restricted to a given range of 7–10% and 0–25 °C, respectively.

Head rice yield (HRY)

Head rice is defined as milled kernels that are at least three-quarters of the original kernel length (USDA 1990). The head and broken kernels were separated by means of grading sieves (AnpingWeiming mesh product Co., Ltd, China) and then weighed separately after milling. HRY was calculated using the following formula (Bello et al. 2015):

| 1 |

Whiteness index (WI)

WI of milled rice was measured using a colorimeter (DC-P3, Beijing Xingguang colorimeter Co., Ltd, China). Measurement was based on the Hunter system with color values of L*, a* and b*, where L* represents the light–dark spectrum with a range of 0 (black) to 100 (white), a* represents the green–red spectrum with a range of − 60 (green) to 60 (red) while b* represents the blue–yellow spectrum with a range of − 60 (blue) to 60 (yellow). WI was calculated as follows (Prasert and Suwannaporn 2009):

| 2 |

Before the measurement, the colorimeter was calibrated with the white and black ceramic plate. Each milled rice sample was immediately put into a closed case (3 cm diameter and 2 cm height) after milling, of which the center of bottom is a circular glass to avoid the rice exposing to the air for a long time causing the irrelevant effects on the experiment. Then the case was put on the instrument to measure the color value.

Specific energy consumption (Es)

Energy consumption of milling was measured using a power meter (PM001, Ningbo Huading Electric & Tech Co., Ltd, China). The power meter was connected to a power source and the mill was connected to the power meter. The energy required for operating the machine without load was first noted and it was subtracted from the energy data collected when machine was running under load. The real-time power and milling duration were recorded during the running periods. Es can be calculated using:

| 3 |

where Pt is the real time power during the milling process; P0 is the operating power without brown rice in the milling hopper; t is the milling duration.

Degree of milling (DOM)

DOM was determined using gravimetric methods, by the equation (Mohapatra and Bal 2007)

| 4 |

Temperature rise (TR)

Before each running, the temperature of brown rice was measured using an infrared thermometer (1326S, TES, Taiwan, China) as the initial temperature. The temperature of milled rice was measured immediately after the milled rice was discharged into a container from the milling hopper. TR was equal to the difference between the initial temperature and the temperature after milled.

Experimental design and statistical analysis

A central composite design (CCD) of three variables (MW, FR, MD) with five levels was adopted, employing Design Expert software program (V8.0.6, Stat-Ease Co., Minneapolis, MN, USA). The range of values for the independent factors was selected based on preliminary experiments and previous researches (Gujral et al. 2002; Mohapatra and Bal 2010). The variables and their levels were given in Table 1. A multiple regression analysis was carried out to obtain empirical model for each response variable, namely HRY, WI and Es. The second-order polynomial of the following form was fitted to the data of the response.

| 5 |

Table 1.

Design and results of the experiment

| Run | Factors | Response | ||||||

|---|---|---|---|---|---|---|---|---|

| x1(g) | x 2 | x3(s) | HRY/% | WI | Es/kJ/kg | DOM % | TR/°C | |

| 1 | 95(− 1) | 1.4(− 1) | 30(− 1) | 79.35 | 48.73 | 54.29 | 6.30 | 17.50 |

| 2 | 345(+ 1) | 1.4(− 1) | 30(− 1) | 75.55 | 52.29 | 57.14 | 9.13 | 22.90 |

| 3 | 95(− 1) | 2.6(+ 1) | 30(− 1) | 80.05 | 46.66 | 30.15 | 5.19 | 16.10 |

| 4 | 345(+ 1) | 2.6(+ 1) | 30(− 1) | 78.99 | 50.86 | 43.69 | 8.61 | 17.60 |

| 5 | 95(− 1) | 1.4(− 1) | 100(+ 1) | 65.42 | 52.78 | 108.29 | 8.92 | 29.40 |

| 6 | 345(+ 1) | 1.4(− 1) | 100(+ 1) | 60.74 | 53.57 | 116.79 | 11.00 | 30.20 |

| 7 | 95(− 1) | 2.6(+ 1) | 100(+ 1) | 70.96 | 52.16 | 75.88 | 9.04 | 27.80 |

| 8 | 345(+ 1) | 2.6(+ 1) | 100(+ 1) | 58.51 | 53.95 | 97.19 | 11.88 | 32.20 |

| 9 | 10(− 1.682) | 2(0) | 65(0) | 75.96 | 50.88 | 59.00 | 7.65 | 21.80 |

| 10 | 430(+ 1.682) | 2(0) | 65(0) | 67.31 | 52.39 | 64.50 | 10.30 | 22.60 |

| 11 | 220(0) | 1(− 1.682) | 65(0) | 69.34 | 53.25 | 94.10 | 9.40 | 20.30 |

| 12 | 220(0) | 3(+ 1.682) | 65(0) | 70.12 | 52.64 | 57.43 | 10.60 | 23.50 |

| 13 | 220(0) | 2(0) | 6(− 1.682) | 84.12 | 45.07 | 12.40 | 2.95 | 8.50 |

| 14 | 220(0) | 2(0) | 124(+ 1.682) | 58.67 | 53.82 | 114.15 | 11.10 | 34.50 |

| 15 | 220(0) | 2(0) | 65(0) | 71.37 | 52.71 | 71.00 | 9.80 | 25.40 |

| 16 | 220(0) | 2(0) | 65(0) | 69.79 | 53.04 | 73.85 | 10.00 | 25.20 |

| 17 | 220(0) | 2(0) | 65(0) | 72.61 | 51.81 | 81.75 | 10.45 | 23.60 |

| 18 | 220(0) | 2(0) | 65(0) | 70.51 | 53.11 | 77.40 | 10.65 | 25.30 |

| 19 | 220(0) | 2(0) | 65(0) | 68.56 | 52.84 | 72.85 | 10.40 | 26.20 |

| 20 | 220(0) | 2(0) | 65(0) | 72.12 | 51.24 | 83.05 | 9.95 | 26.50 |

| 21 | 220(0) | 2(0) | 65(0) | 68.61 | 53.10 | 73.60 | 9.75 | 26.40 |

| 22 | 220(0) | 2(0) | 65(0) | 68.63 | 52.81 | 76.65 | 8.90 | 24.20 |

| 23 | 220(0) | 2(0) | 65(0) | 72.31 | 52.30 | 78.75 | 9.55 | 26.10 |

x1 milling weight, x2 filling ratio, x3 milling duration, HRY head rice yield, WI whiteness index, Es specific energy consumption, DOM degree of milling, TR temperature rise

Where Y are the dependent responses; βi, βii and βij represent the regression coefficients of the process variables. xi and xj are coded independent variables. The analysis of variances (ANOVA) was used to test the adequacy of acquired model. The validity of the model was confirmed by equation analysis, lack of fit (p = 0.05) tests and R2 (the ratio of explained variation to the total variation) analysis. The variable level combinations and responses of the experiment were shown in Table 1. A numerical optimization module in the software was used to obtain optimal operating parameters. Correlation coefficients and regression coefficients between all the milling quality indices were obtained using SPSS software, version 18 (Inc., Chicago, IL, USA).

Results and discussion

Effect of variables on HRY

The measured values of HRY are presented in Table 1. It varied between 58 and 84% within the combination of the variables studied. According to the ANOVA results shown in Table 2, a second order polynomial equation was highly conspicuous (p < 0.01) for the response. No significant lack of fit and the high R2 (0.9582) values showed that most of the variability can be explained by the variables tested. After calculating the contribution ratio of factors affecting HRY, it was found that MW was the most important factor, followed by MD and FR was the least important. Their contribution ratio were 1.517, 1.417 and 0.507, respectively. Results in Table 2 indicated that, in this case, linear terms of MW and MD were significantly different (p < 0.01). The interaction terms of MW and MD were significantly different (p < 0.05). The predicted model for the HRY can be described by the following equation in terms of actual factors under the tested conditions.

| 6 |

Table 2.

Analysis of the regression coefficients to the polynomial equation for milling qualities

| Coefficients | Head rice yield | Whiteness index | Specific energy consumption |

|---|---|---|---|

| 70.50** | 52.55** | 76.40** | |

| − 2.68** | 0.94** | 4.06* | |

| 0.64 | − 0.35 | − 11.08** | |

| − 7.40** | 2.1** | 28.12** | |

| 0.45 | − 0.30 | − 3.87* | |

| − 0.22 | 0.16 | 1.09 | |

| 0.37 | − 1.08** | − 3.33* | |

| − 0.63 | 0.21 | 2.94 | |

| − 1.53* | − 0.65* | 1.68 | |

| − 0.10 | 0.41 | − 1.80 | |

| R 2 | 0.9582 | 0.9210 | 0.9724 |

| SigLack-of-fit | 0.4130 | 0.1249 | 0.0918 |

**Extremely significant at p < 0.01; *Significant at p < 0.05

It can be seen from Table 2, the effect of FR (p > 0.05) was not significant on HRY. Andrews et al. (1992) also found that the sample size was the least significant variable affecting the HRY. Therefore, only the other two variables were analyzed in this paper.

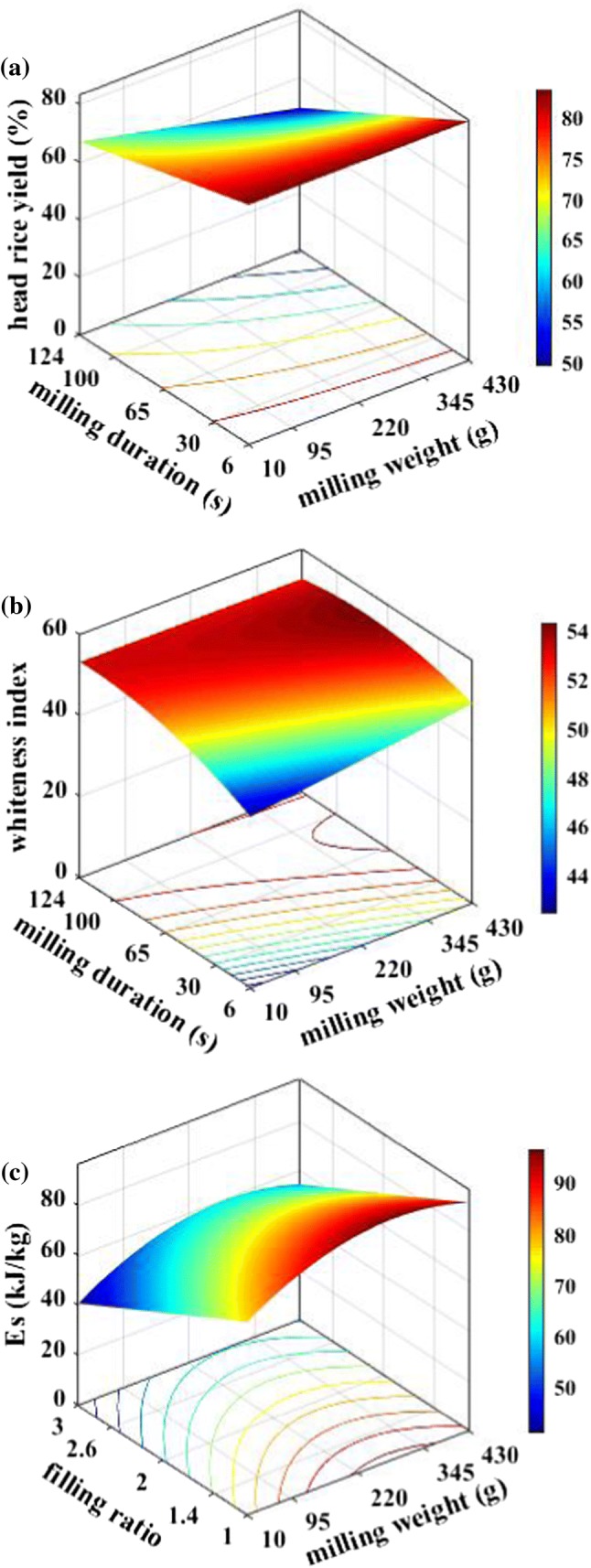

HRY decreased linearly with the increase of either MD or MW (Fig. 2a). It was because the longer MD was, the more times rice cycled in the milling chamber, resulting in an increase of broken content. From the microcosmic point of view, the collision and collision power were accumulated between rice kernels (Han et al. 2016). Once reached the destructive force, ultimately, the rice was broken. Therefore, the increase of MD would lead to the decrease of the HRY. This was consistent with results of Yadav and Jindal (2008). With the variation of MW, the pressure in the milling chamber increased, leading to the strengthening of rubs among kernels. The extensive rubbing generated much heat which further caused the deformation of rice unable to relief. Ultimately, it resulted in the occurrence of breakage. Mohapatra and Bal (2004a, b) also pointed out that milled rice temperature has a negative effect on HRY using a lab scale abrasive mill. In addition, the increase of MW increased the resistance of outlet, showing as the shortening of outlet opening size, macroscopically. In our previous study (Han et al. 2016), it was found that the decrease of opening size of outlet on the one hand led to the increase of velocity and total force of rice kernel in the milling area, further causing more collision among particles. On the other hand, shortening the movement space weakened the random distribution of particle orientation angle. Most of the rice particles were in the horizontal direction in the milling chamber which means they were more easily subjected to the combined action of blending and torsion, resulting in the occurrence of breakage.

Fig. 2.

a Effect of milling weight and milling duration on head rice yield; b effect of milling weight and milling duration on whiteness index; c effect of milling weight and filling ratio on specific energy consumption

The interactive effect of MW and MD can be seen from Fig. 2a. It can be seen that when the weight applied on the outlet was in a low level, HRY decreased slowly with the increase in MD. Compared with that, when MW was higher, HRY reduced to a low value rapidly with the increase in MD. It can be explained that the increase of MW lowered the opening size of outlet which significantly improved the density of rice kernels in the milling chamber, further strengthened the milling pressure, finally resulted in the increase of rice breakage. The lower MW leads to the bran layer gradually removed with MD. But when MW was in a higher level, the violent rubs among brown rice kernels caused immediately broken. Therefore, using lower MW for longer MD could increase HRY compared with higher MW in the vertical circulation mill. The results coincided well with Pan, Amaratunga and Thompson (2007).

Effect of variables on WI

WI varied from 45 to 53 within the combination of the variables (Table 1). According to the ANOVA results showed in Table 2, the model was highly conspicuous (p < 0.01) for the response. Both the high R2 of 0.9210 and no significant lack of fit confirming the validity of the polynomial fit. The sequence of factors affecting WI was MD, MW and FR of which the contribution ratio was respectively 2.610, 1.897, 0.861. Results in Table 2 indicated that, in this case, linear terms of MW and MD were extremely significantly different (p < 0.01). The quadratic term of MD was extremely significantly different. The interaction terms of MW and MD were significantly different (p < 0.05.) The predicted model for WI can be described by the following equation in terms of actual factors.

| 7 |

Figure 2b shows that with the increase of MW, WI had an upward trend. As mentioned above, MW actually controlled the opening size of the outlet. The heavier the weight applied on the outlet was, the smaller the opening size became. When the opening size was small, the strength of wear increased significantly, leading to amount of bran and outer endosperm removed and more inner endosperm exposed. In addition, the inner endosperm contains less red and yellow pigments than the bran and outer endosperm according to Lamberts et al. (2007). Therefore, WI increased with increasing MW. WI gradually increased to a maximum value and then declined slightly with the increase of MD. It could be explained that the increasing of MD leads to the increase of degree of milling which means more bran and outer endosperm was removed (Singh et al. 2000), reflecting that WI increased gradually (Rodríguezarzuaga, Cho, Billiris, Siebenmorgen and Seo, 2016). But with further increase of MD, both the milled rice and milling chamber were in a high temperature which may cause the oxidation of starch, which is concentrated more in the endosperm than in branny layers (Sandhu et al. 2018).

The effect of interaction between MW and MD on WI can be seen from Fig. 2b. When MD was at a low level, WI increased gradually with the increase of MW. While WI kept in a relatively stable and high value when MD was in a high level whether MW was light or heavy. It can be explained that due to the low level of milling duration, the bran layer and outer endosperm were constantly removed. Meanwhile increasing MW strengthened rubs among rice kernels, resulting in the successive increase of WI.

However, the brown rice had already milled sufficiently when MD was in a high level. In this situation, the increase of MW could merely strengthen the removal of core endosperm. While the interior was tough and hard, it could offer more resistance to abrasion compared to the outer bran layer (Mohapatra and Bal 2004a, b). Meanwhile, the pigments diffusion of core endosperm is steady which contains less red and yellow pigments. Therefore, WI only changed slightly with the increase of MW under the longer MD. In order to maximize WI for increasing the consumer acceptability, it is better to milling brown rice in a longer MD under lower MW.

Effect of variables on Es

The values of Es varied from 12.4 to 116.79 kJ/kg was shown in Table 1. A high correlation coefficient (R2 = 0.9724) and no significant lack of fit for the response were shown in Table 2, indicating that the polynomial fitted well for predicting the Es. By calculating contribution ratio of factors affecting Es, MW was the most important factor, followed by MD and FR was the least important. Their contribution ratios were 2.04, 1.83 and 1.27, respectively. Results in Table 2 indicated that, in this case, linear terms of FR and MD were extremely significantly different at p < 0.01 and MW was significantly different at p < 0.05. The quadratic terms of MW and MD were significantly different at p < 0.05. In addition, none of the interaction terms was significantly different at p < 0.05. The polynomial equation generated after removing insignificant terms of the models were as follows:

| 8 |

Figure 2c depicts the response of Es with respect to MW and FR. Due to the increase in FR, the rubs among the brown rice kernels were strengthened, leading to the decrease of Es. It was also observed that with increase in MW, the Es increased to a maximum value and decreased slightly thereafter. This phenomenon can be explained as follows. Due to the reinforcement of grinding strength with increase in MW, more bran layers and endosperm were prone to be removed. The hard starchy endosperm was much resistant to abrasion than the bran layer which was made up of oil bodies, cellulose, hemicelluloses and fiber (Laokuldilok et al. 2013). Therefore, more energy was taken. But with further increase of MW, Es declined slightly. It may be due to the fact that MW was heavy enough to make the rice surface smooth in a relatively short time. Further milling can not increase the amount of removal. As a result, the Es may slightly decrease compared with lighter MW.

Determination and validation of the optimal parameters

With the target to get the maximum of HRY, WI and the minimum Es, each parameter was optimised by the response surface methodology using Design Expert software. Meanwhile, DOM and TR as mentioned above were restricted to the given range. The optimal conditions were generated by running the solutions menu of the numerical optimization program built into the Design Expert software. Under the experimental condition ranges, the optimum parameters for response were as follows: MW was 345 g, FR was 2.6, MD was 30 s. And the optimum results were the HRY of 77.11%, WI of 50.88 and Es of 34.72 kJ/kg. Meanwhile DOM and TR were of 8.09% and 16.86 °C, respectively.

Validation experiments were performed based on the optimum parameters. The measured values of HRY, WI and Es were 76.21%, 50.57 and 33.69 kJ/kg, respectively, which were found close to the predicted values within the acceptable limits of error percentage (0.61–2.97%). It demonstrated that the regression equations could predict the experimental results from the response surface.

Correlation and regression analysis between milling qualities

Table 3 shows Pearson correlation analysis between each milling qualities. Results showed that all the milling qualities were significantly positively correlated with each other except for HRY which was significantly negatively correlated with all the other parameters (p < 0.01). Among all the indices, the correlation coefficient between WI and DOM was the highest, reaching 0.940. Srikham and Noomhorm (2015) also found the same relationship between DOM and WI. Followed by the coefficient (0.900) between HRY and TR which means the increase of TR can significantly cause the breakage of rice. It agrees well with results of Mir, Bosco, Shah, Mir, and Ganai (2015). Pan, Thompson, Amaratunga, Anderson, and Zheng (2005) also once pointed out that every 10 °C reduction in the milled rice temperature corresponded to an increase of 1.7% in HRY. The third highest coefficient (0.888) was between HRY and ES. Since TR was not only highly correlated with the other indices but also had the advantage of easy measurement, it was chosen to evaluate milling quality directly. The other milling qualities can be determined based on the regression equation between TR and them, shown in Table 4. The R2 values indicated that the relationship between TR and other milling qualities can be described by the fitting model. It provided a simple and quick method which could be used to evaluate and control milling quality.

Table 3.

Pearson correlation analysis between milling indices

| HRY | WI | Es | DOM | TR | |

|---|---|---|---|---|---|

| HRY | 1 | ||||

| WI | − 0.829** | 1 | |||

| Es | − 0.888** | 0.814** | 1** | ||

| DOM | − 0.818** | 0.940** | 0.769** | 1 | |

| TR | − 0.900** | 0.849** | 0.885** | 0.846** | 1 |

HRY head rice yield, WI whiteness index, Es specific energy consumption, DOM degree of milling, TR temperature rise. **Extremely significant at p < 0.01

Table 4.

Regression equation between TR and milling qualities

| Regression equation | R2 |

|---|---|

| Head rice yield = − 0.019x2 − 0.19x + 87.1 | 0.83 |

| Whiteness index = − 0.014 x2 + 0.94x + 37.57 | 0.81 |

| Specific energy consumption = 0.0102 x2 + 3.47x − 16.999 | 0.78 |

| Degree of milling = − 0.012 x2 + 0.82x − 3.4 | 0.80 |

x = temperature rise (°C)

In this study, the effect of operating parameters of rice mill on the milling quality was investigated based on the short grain Japonica type rice. While physical, chemical and milling properties show significant differences amongst different rice varieties (Sandhu et al. 2018). In future work, there is a need to carry out research work on the effect of varietal differences on the milling qualities under different operating parameters.

Conclusion

MW, FR and MD all had a significant effect on Es, while only FR had a nonsignificant effect on HRY and WI. The obtained regression equation can be used to quantitatively predict the milling quality under different operating parameters. Taking all the indices into a comprehensive consideration, the optimum operating parameters were MW of 345 g, FR of 2.6 and MD of 30 s under the tested conditions. Correlation coefficients and regression coefficients were analyzed between milling qualities. All the indices were extremely significant correlated with each other. And the correlation coefficient between WI and DOM was the highest. The establishment of regression equations between TR and the other milling qualities can provide a quick and convenient method to evaluate and control milling quality.

Acknowledgements

The authors express their acknowledgment to the Chinese Natural Science Foundation (51575098) for financial support and all of the persons who assisted in this writing.

References

- Ahmad U, Alfaro L, Yeboah-Awudzi M, Kyereh E, Dzandu B, Bonilla F, et al. Influence of milling intensity and storage temperature on the quality of catahoula rice (oryza sativa, L.) LWT - Food Sci Technol. 2017;75:386–392. [Google Scholar]

- Andrews SB, Siebenmorgen TJ, Mauromoustakos A. Evaluation of the mcgill No. 2 rice miller. Cereal Chem. 1992;69(1):35–43. [Google Scholar]

- Bello MO, Loubes MA, Aguerre RJ, Tolaba MP. Hydrothermal treatment of rough rice: effect of processing conditions on product attributes. J Food Sci Technol. 2015;52(8):5156–5163. doi: 10.1007/s13197-014-1534-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Copper C, Siebenmorgen TJ. Correcting head rice yield for surface lipid content (Degree of Milling) variation. Cereal Chem. 2007;84(1):88–91. [Google Scholar]

- Gujral HS, Singh J, Sodhi NS, Singh N. Effect of milling variables on the degree of milling of unparboiled and parboiled rice. Int J Food Prop. 2002;5(1):193–204. [Google Scholar]

- Han YL, Jia FG, Zeng Y, Jiang LW, Zhang YX, Cao B. Effects of rotation speed and outlet opening on particle flow in a vertical rice mill. Powder Technol. 2016;297:153–164. [Google Scholar]

- Jia FG, Nan JF, Bai SG. Study on the relationship between the moisture content of rice and milling characteristics. J Northeast Agric Univ. 2006;37(5):665–668. [Google Scholar]

- Kim SY, Lee H. Effects of quality characteristics on milled rice produced under different milling conditions. J Korean Soc Appl Biol Chem. 2012;55(5):643–649. [Google Scholar]

- Lamberts L, Bie ED, Vandeputte GE, et al. Effect of milling on colour and nutritional properties of rice. Food Chem. 2007;100(4):1496–1503. [Google Scholar]

- Laokuldilok T, Surawang S, Klinhom J. Effect of milling on the color, nutritional properties, and antioxidant contents of glutinous black rice. Cereal Chem. 2013;90(6):552–557. [Google Scholar]

- Mir SA, Bosco SJD, Shah MA, Mir MM, Ganai SA. Rice: parboiling and milling properties. Int J Food Eng. 2015;11(6):777–787. [Google Scholar]

- Mohapatra D, Bal S. Wear of rice in an abrasive milling operation, part 1: prediction of degree of milling. Biosyst Eng. 2004;88(3):337–342. [Google Scholar]

- Mohapatra D, Bal S. Wear of rice in an abrasive milling operation, part II: prediction of bulk temperature rise. Biosyst Eng. 2004;89(1):101–108. [Google Scholar]

- Mohapatra D, Bal S. Effect of degree of milling on specific energy consumption, optical measurements and cooking quality of rice. J Food Eng. 2007;80(1):119–125. [Google Scholar]

- Mohapatra D, Bal S. Optimization of polishing conditions for long grain basmati rice in a laboratory abrasive mill. Food Bioprocess Technol. 2010;3(3):466–472. [Google Scholar]

- Monks JLF, Vanier NL, Casaril J, Berto RM, Oliveira MD, Gomes CB, et al. Effects of milling on proximate composition, folic acid, fatty acids and technological properties of rice. J Food Compos Anal. 2013;30(2):73–79. [Google Scholar]

- Pan ZL, Thompson JF, Amaratunga KSP, Anderson T, Zheng XZ. Effect of cooling methods and milling procedures on the appraisal of rice milling quality. Trans ASABE. 2005;48(5):1865–1871. [Google Scholar]

- Pan ZL, Amaratunga KSP, Thompson JF. Relationship between rice sample milling conditions and milling quality. Trans ASABE. 2007;50(4):1307–1313. [Google Scholar]

- Pan ZL, Khir R, Thompson JF. Effect of milling temperature and postmilling cooling procedures on rice milling quality appraisals. Cereal Chem. 2013;90(2):107–113. [Google Scholar]

- Park JK, Kim SS, Kim KO. Effect of milling ratio on sensory properties of cooked rice and on physicochemical properties of milled and cooked rice. Cereal Chem. 2007;78(2):151–156. [Google Scholar]

- Prasert W, Suwannaporn P. Optimization of instant jasmine rice process and its physicochemical properties. J Food Eng. 2009;95(1):54–61. [Google Scholar]

- Rahaman MA, Miah MAK, Ahmed A. Status of rice processing technology in Bangladesh. Ama Agric Mech Asia Afr Latin Am. 1996;27(1):46–50. [Google Scholar]

- Roberts RL. Composition and taste evaluation of rice milled to different degrees. J Food Sci. 1979;44(1):127–129. [Google Scholar]

- Roberts RL, Wasserman T. Effect of milling conditions on yields, milling time and energy requirements in a pilot scale engelberg rice mill. J Food Sci. 1977;42(3):802–803. [Google Scholar]

- Rodríguezarzuaga M, Cho S, Billiris MA, Siebenmorgen T, Seo H. Impacts of degree of milling on the appearance and aroma characteristics of raw rice. J Sci Food Agric. 2016;96(9):3017–3022. doi: 10.1002/jsfa.7471. [DOI] [PubMed] [Google Scholar]

- Roy P, Ijiri T, Okadome H, Nei D, Orikasa T, Nakamura N, et al. Effect of processing conditions on overall energy consumption and quality of rice (oryza sativa, L.) J Food Eng. 2008;89(3):343–348. [Google Scholar]

- Sandhu RS, Singh N, Kaler RSS, Kaur A, Shevkani K. Effect of degree of milling on physicochemical, structural, pasting and cooking properties of short and long grain indica rice cultivars. Food Chem. 2018;260:231–238. doi: 10.1016/j.foodchem.2018.03.092. [DOI] [PubMed] [Google Scholar]

- Singh N, Singh H, Kaur K, Singh MB. Relationship between the degree of milling, ash distribution pattern and conductivity in brown rice. Food Chem. 2000;69:147–151. [Google Scholar]

- Srikham W, Noomhorm A. Milling quality assessment of khao dok mali 105, milled rice by near-infrared reflectance spectroscopy technique. J Food Sci Technol. 2015;52(11):7500–7506. [Google Scholar]

- Sun H, Siebenmorgen TJ. Milling characteristics of various rough rice kernel thickness fractions. Cereal Chem. 1993;70(6):727–733. [Google Scholar]

- Takai H, Barredo IR. Milling characteristics of a friction laboratory rice mill. J Agric Eng Res. 1981;26(5):441–448. [Google Scholar]

- USDA (1990) Inspection handbook for the sampling, inspection, grading, and certification of rice. HB918-11, Agriculture Marketing Service, Washington, DC

- Vishwakarma RK, Shivhare US, Nanda SK. Predicting guar seed splitting by compression between two plates using hertz theory of contact stresses. J Food Sci. 2012;77(9):E231–E239. doi: 10.1111/j.1750-3841.2012.02861.x. [DOI] [PubMed] [Google Scholar]

- Yadav BK, Jindal VK. Changes in head rice yield and whiteness during milling of rough rice (oryza sativa L.) J Food Eng. 2008;86(1):113–121. [Google Scholar]

- Yan TY, Hong JH, Chung JH. An improved method for the production of white rice with embryo in a vertical mill. Biosyst Eng. 2005;92(3):317–323. [Google Scholar]

- Yoon SH, Kim SK. Physicochemical properties of rice differing in milling degrees. Food Sci Biotechnol. 2004;13(1):57–62. [Google Scholar]