Abstract

Cross-linked poly(ε-caprolactone) (PCL) is a smart biocompatible polymer exhibiting two-way shape memory effect. PCL samples with different cross-link density were synthesized by heating the polymer with various amounts of radical initiator benzoyl peroxide (BPO). Non-isothermal crystallization kinetics was characterized by means of conventional differential scanning calorimetry (DSC) and fast scanning calorimetry (FSC). The latter technique was used to obtain the dependence of the degree of crystallinity on the preceding cooling rate by following the enthalpies of melting for each sample. It is shown that the cooling rate required to keep the cooled sample amorphous decreases with increasing cross-link density, i.e., crystallization process slows down monotonically. Covalent bonds between polymer chains impede the crystallization process. Consequently, FSC can be used as a rather quick and low sample consuming method to estimate the degree of cross-linking of PCL samples.

Keywords: poly(ε-caprolactone), cross-linking, crystallization kinetics, fast scanning calorimetry, differential scanning calorimetry

1. Introduction

Poly(ε-caprolactone) (PCL) is a biocompatible and biodegradable polymer with good mechanical properties. It is produced by the polymerization of ε-caprolactone with an annual global production of tens of thousands of tons [1]. The low melting point (around 60 °C) of PCL makes it a convenient material for 3D printing and rapid prototyping. Prospective biomedical applications of PCL include the manufacturing of implants, especially scaffolds for tissue, bone, and cartilage engineering, surgical sutures, and other medical devices [2]. It is also possible to use PCL for the encapsulation of pharmaceuticals in micro- and nanospheres, which can be administered through ingestion or injection [3,4]. The rate of biodegradation of PCL in the human organism is lower than that of some other biocompatible polyesters, such as polylactic and polyglycolic acids [2,5], making it more applicable for long-term drug delivery systems.

The properties of PCL can be tailored by fabrication of PCL-based blends and composites, either by copolymerization of caprolactone, with different amounts of polyhydric alcohols or hydroxy acids. In addition, PCL is capable of cross-linking when treated with radical initiators. Cross-linked PCL has a greater mechanical strength, does not flow, even at temperatures above its melting point, and has a slower biodegradation rate [6], which may be useful to reduce the rate of drug release from encapsulated forms. A very interesting property of cross-linked PCL is its two-way shape memory effect [7]. The polymer can remember one shape at a low temperature and another shape at a high temperature and recover them after deformation for both heating and cooling, which is considered a step towards the development of programmable matter.

PCL has a low glass transition temperature (around −60 °C) and stays in a semi-crystalline rubbery state at room temperature. The degree of crystallinity of the polymer also affects its mechanical and other physical properties, as well as the rate of biodegradation [8,9]. In order to control crystallinity, an understanding of crystallization kinetics is important. The kinetics of crystallization of PCL and some of its blends [10,11,12,13] have been studied previously using differential scanning calorimetry (DSC), employing samples with masses of a few milligrams. However, during the processing of polymers, they are cooled at high rates and their crystallization occurs at a high supercooling. Conventional DSC is limited to hundreds K·min−1 cooling rates, which makes it impossible to study fast crystallization processes at low temperatures. In the last decades, fast scanning calorimetry (FSC) using chip sensors was developed, allowing heating and cooling of the polymer samples with rates up to millions K·min−1 [14,15,16,17,18,19,20]. Such controlled high cooling rates became available due to a dramatic reduction of the calorimeter and the sample size. Chip sensors use free standing silicon nitride membranes with addenda heat capacities down to 100 pJ∙K−1 at room temperature and comparable small sample heat capacities [14,18,21]. FSC is able to determine the rate of crystallization, as well as nucleation process, over a broad temperature range even for rapidly crystallizing polymers [22,23,24,25]. It was previously applied to study crystallization of pure PCL with various molecular masses [26,27] and some of its composites [28]. However, no FSC data on crystallization kinetics of cross-linked PCL have been reported up to now. Moreover, applications of FSC to study cross-linked polymers have yet to be done.

Studies of the influence of the degree of cross-linking on the parameters of polymer phase transitions can be useful for technological purposes as well as for the development of theoretical descriptions of phase transitions. There is also an interest in quick, robust, and low sample consuming methods to determine the cross-link density of polymer samples [29]. Thus, any physical property of the polymer that shows a dependence on its cross-link density is of potential use. In the present work, we study the crystallization behavior of PCL samples cross-linked using different amounts of benzoyl peroxide (BPO) by means of both conventional DSC and FSC. Our goal was to analyze the influence of the spatial density of cross-links between linear PCL chains on the characteristic features of the crystallization process.

2. Materials and Methods

2.1. Synthesis of Cross-Linked PCL

In order to prepare the samples of cross-linked PCL, commercial PCL (Aldrich, St. Louis, MO, USA, average Mn = 45,000 g·mol−1, density ρp = 1.142 g·cm−3) and benzoyl peroxide (BPO, Aldrich, 75%, remainder is water as a stabilizer) were taken in different proportions and dissolved in dichloromethane (Komponent-Reaktiv, Moscow, Russia, 99.85%). The solvent was evaporated, and the mixture was heated up to 150 °C and kept for 60 min at this temperature to cross-link the sample.

2.2. Equilibrium Swelling Experiments

The degree of cross-linking of the obtained samples was measured using an equilibrium swelling method. About 0.2 g of each sample were first swollen in boiling toluene (Komponent-Reaktiv, 99.85%) using a Soxhlet extractor (Medsteklo, Klin, Russia) for 8 h and then left to equilibrate with toluene at 25 °C for 48 h. The mass m of the swollen PCL was determined, then the specimen was dried in vacuum and weighed again to record the mass of the dry polymer mp. For each BPO:PCL ratio, the experiment was repeated four times with new cross-linked samples averaging the volume swelling ratio:

| (1) |

where ρs = 0.862 g·cm−3 and ρp = 1.142 g·cm−3 are the densities of toluene and the polymer, respectively. Repetitive swelling experiments with the same sample do not significantly change the values of Q. The spatial density of cross-links was calculated according to the Flory-Rehner equation [30]:

| (2) |

where vp = 1/Q is the volume fraction of PCL in swollen state, = 1.06 × 10–4 m3·mol−1 is the molar volume of the solvent (toluene), and χ is the Flory-Huggins interaction parameter. The value of χ can be estimated according to the equation:

| (3) |

Using the literature values of Hildebrand solubility parameters for PCL at 25 °C δp = 19.7 MPa1/2 [31] and toluene δs = 18.2 MPa1/2 [32] yields χ = 0.10.

2.3. Conventional DSC Experiments

The DSC curves of PCL and the cross-linked samples were recorded with a Mettler Toledo DSC823 (Mettler Toledo, Greifensee, Switzerland) and a Perkin Elmer Pyris 1 DSC instruments (PerkinElmer, Waltham, MA, USA) at 5–200 K·min−1 scanning rates. Using these curves, the temperatures and enthalpies of phase transitions were determined, and the kinetics of the non-isothermal crystallization process were characterized.

2.4. FSC Experiments

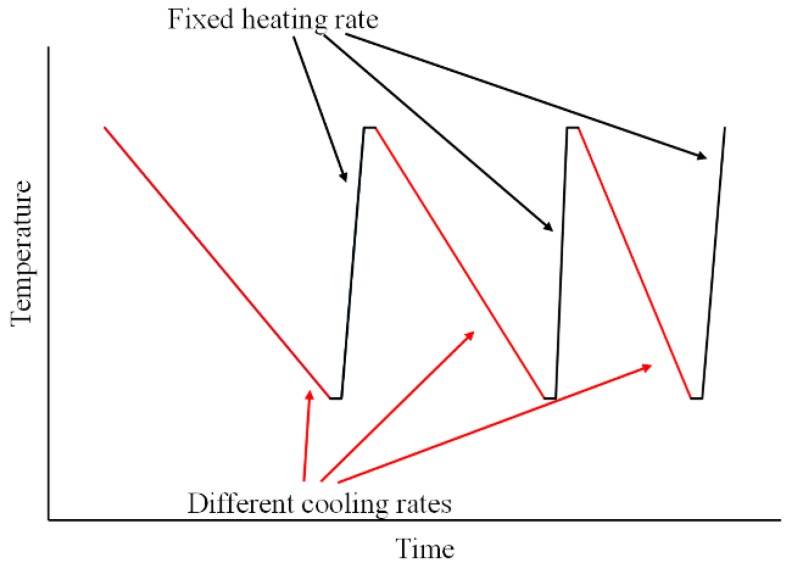

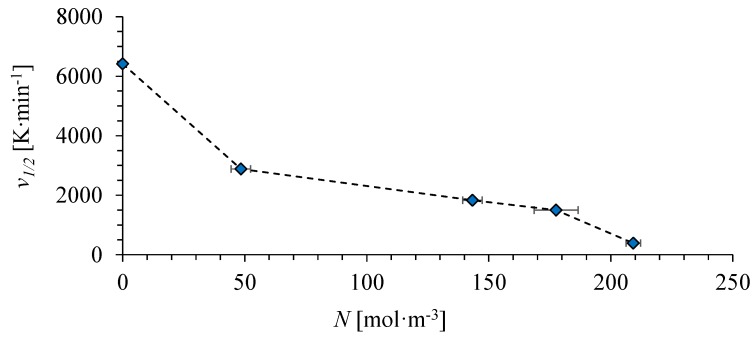

Fast scanning calorimetry experiments were performed using a Mettler Toledo Flash DSC 1 instrument (Mettler Toledo, Greifensee, Switzerland) with the UFS1 sensor allowing up to 300,000 K·min−1 (5000 K·s−1) heating and cooling rates. In a typical experiment, 10–50 ng of the specimen was put onto the chip sensor as shown in Figure 1, heated up to 150 °C and cooled down to −80 °C several times in order to erase the thermal memory and achieve better thermal contact with the chip sensor. After that, the specimen was repeatedly heated with the same fixed rate 300,000 K·min−1 and cooled with successively increasing rate from 30 to 300,000 K·min−1 (0.5 to 5000 K·s−1, see Figure 2 for a schematic representation of the thermal program).

Figure 1.

Sample of polymer on fast scanning calorimetry chip sensor.

Figure 2.

Schematic representation of the thermal program for the crystallization study of cross-linked PCL.

3. Results

3.1. Equilibrium Swelling Experiments

Results of the swelling experiments for cross-linked PCL obtained from the mixtures with different percentage of BPO are given in Table 1. As expected, the cross-link density increases with increasing fraction of the radical initiator. The sample with 1% BPO has broken into small pieces during swelling, and accurate weighing necessary to determine N became impossible. However, these pieces could not be completely dissolved in toluene, which means that the sample is also cross-linked.

Table 1.

Swelling ratios, cross-link densities, and enthalpies of fusion and crystallization at 10 K·min−1 cooling rate for the samples of PCL and cross-linked PCL obtained using various amounts of BPO.

| Weight % of BPO | Q | N/mol·m−3 | ΔfusH/J·g−1 | ΔcrystH/J·g−1 |

|---|---|---|---|---|

| 0 | 0 | 0 | 73.5 ± 2.1 | −67.6 ± 1.9 |

| 1 | 72.9 ± 2.6 | −64.3 ± 2.4 | ||

| 3 | 14.9 ± 0.5 | 48.4 ± 4 | 71.7 ± 1.8 | −65.2 ± 2.1 |

| 5 | 8.2 ± 0.1 | 143.3 ± 4 | 68.7 ± 2.4 | −65.2 ± 1.0 |

| 7 | 7.4 ± 0.2 | 177.6 ± 9 | 67.5 ± 2.0 | −60.6 ± 1.7 |

| 10 | 6.7 ± 0.04 | 209.2 ± 3 | 57.3 ± 1.2 | −49.2 ± 1.8 |

3.2. Conventional DSC Experiments

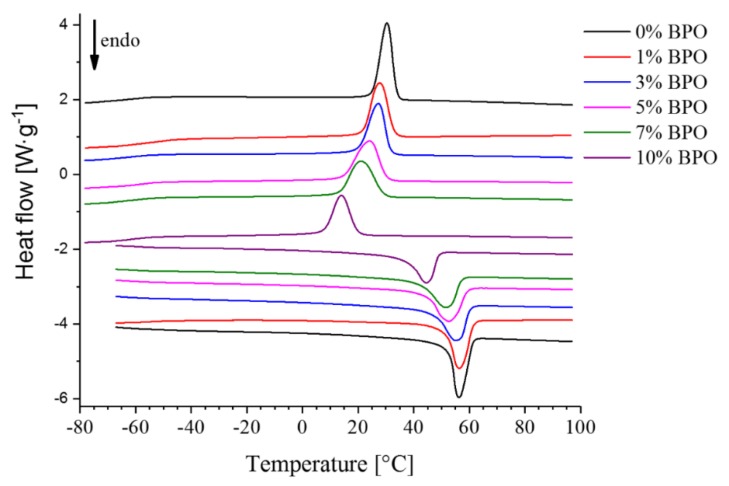

DSC curves recorded at 10 K·min−1 heating rate after cooling at 10 K·min−1 are shown in Figure 3. The enthalpies of fusion and crystallization of the studied samples determined from these curves are also given in Table 1. They show little dependence on the cross-link density. The difference between the enthalpies of fusion and crystallization is caused by the difference in melting and crystallization temperatures and in the heat capacities of crystalline and molten states, which are about 25 K and 0.22 J·g−1·K−1 [33] for pure PCL, respectively. With these values Kirchhoff’s law provides a correction term of about 5.5 J g−1, explaining the value differences in Table 1. The values of the enthalpies of fusion were used to calculate the masses of the samples in FSC experiments, which cannot be done by direct weighing. According to different literature sources, 100% crystalline PCL has a melting enthalpy from 135.4 to 156.8 J g−1 [34], which corresponds to 47%–54% crystallinity of the unmodified PCL used for cross-linking. With increasing cross-linking density crystallinity decreases to 37%–42% for N = 209 mol·m−3. All the studied samples undergo a glass transition in the temperature range −65 to −60 °C.

Figure 3.

DSC cooling and subsequent heating curves recorded at 10 K·min−1 scanning rate.

Kinetics of crystallization was studied by conventional DSC experiments. Non-isothermal crystallization at constant cooling rate can be described by a modification of the Avrami model made by Jeziorny [35]. The Avrami equation

| (4) |

or its linearized form

| (5) |

are commonly used for quantitative description of isothermal crystallization kinetics. Here Xc is the degree of crystallinity changing in time during the crystallization process, n is the Avrami exponent dependent on the mechanism of nucleation, and Zt is the crystallization rate constant. For non-isothermal crystallization, the quantity

| (6) |

where v is the scanning rate, is supposed to be constant for fast crystallizing polymers at least at moderate scanning rates (5–20 K·min−1) typical for conventional DSC experiments. is considered to be a measure of the crystallization rate of a polymer. Another quantity that allows rapid estimation of crystallization rate is crystallization half-time t1/2. It is the interval of time in which the sample cools from crystallization onset temperature to the temperature at which half of the possible crystallinity is achieved. Crystallization t1/2 decreases with increasing scanning rate. Thus, it should be compared at the same cooling rate for different polymers. In Table 2, a comparison of the values of n and obtained from Avrami plots (see supplementary material for the plots), and t1/2 at 10 and 20 K·min−1 cooling rates is given. In all cases, the values of n equal 2 or slightly above. has similar values for both cooling rates for pure PCL and two samples with the lowest cross-link densities. At 10 K·min−1, decreases and t1/2 increases with increasing cross-link density N for all the samples except one with the largest N. At 20 K·min−1, two samples with the largest cross-link density obtained using 7% and 10% BPO crystallize faster than the one obtained using 5% BPO. Such behavior means that the crystallization process slows down with increasing cross-link density if we consider it at the same temperature. However, the drop in crystallization temperature for 7% and 10% BPO sample at 20 K·min−1 cooling rate is so large (possibly because of a different nucleation mechanism) that non-isothermal crystallization takes place at much lower temperature and is likely to proceed faster due to this reason.

Table 2.

Crystallization onset temperatures, half-times, and kinetic parameters of non-isothermal crystallization determined using the modified Avrami method.

| Weight % of BPO | Cooling Rate/K·min−1 | Tonset/K | t1/2/s | n | Zc/min−n·K−1 |

|---|---|---|---|---|---|

| 0 | 10 | 307.2 | 27 | 2.05 | 1.13 |

| 0 | 20 | 303.6 | 13 | 1.96 | 1.14 |

| 1 | 10 | 306.1 | 33 | 2.04 | 1.09 |

| 1 | 20 | 302.3 | 22 | 1.96 | 1.08 |

| 3 | 10 | 304.9 | 33 | 2.01 | 1.09 |

| 3 | 20 | 301.3 | 22 | 1.96 | 1.08 |

| 5 | 10 | 303.6 | 45 | 2.12 | 1.02 |

| 5 | 20 | 299.9 | 29 | 2.01 | 1.06 |

| 7 | 10 | 302.5 | 50 | 2.39 | 1.01 |

| 7 | 20 | 298.6 | 29 | 2.33 | 1.07 |

| 10 | 10 | 293.0 | 37 | 2.24 | 1.07 |

| 10 | 20 | 289.2 | 23 | 2.21 | 1.09 |

3.3. FSC Experiments

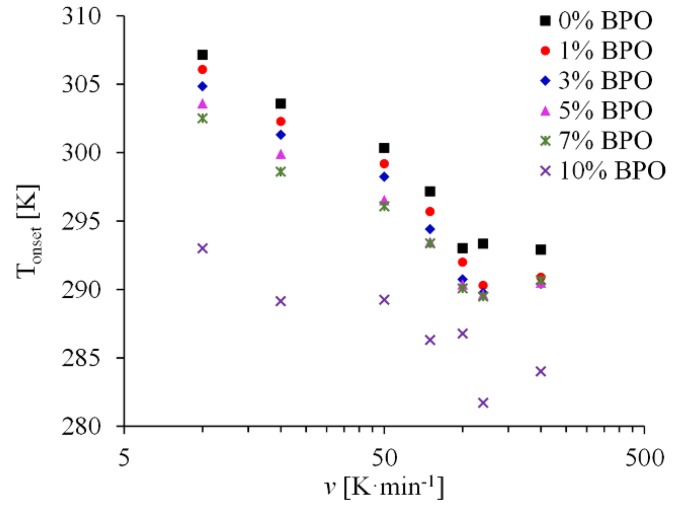

DSC curves show that the process of crystallization of samples with higher density of cross-links starts at lower temperature (see Table 2). With increasing cooling rate, the crystallization peak position moves to lower temperatures and at some point its area starts to decrease due to incomplete crystallization during rapid cooling. The temperature corresponding to the crystallization onset changes almost linearly with the logarithm of the cooling rate (Figure 4) until it reaches certain value when the sample has not enough time to crystallize and the peak disappears. This critical cooling rate, vc, is another characteristic of crystallization kinetics. It is about 18,000 K·min−1 (300 K·s−1) [26] for unmodified PCL, which is higher than the maximum possible rate for conventional DSC instruments. FSC experiments allow to reach this and even higher cooling rates. However, it is difficult to determine the critical rate precisely from the FSC cooling curves because the crystallization peak is very small and the signal is noisy.

Figure 4.

Crystallization onset temperature Tonset against the logarithm of the cooling rate for PCL and cross-linked PCL

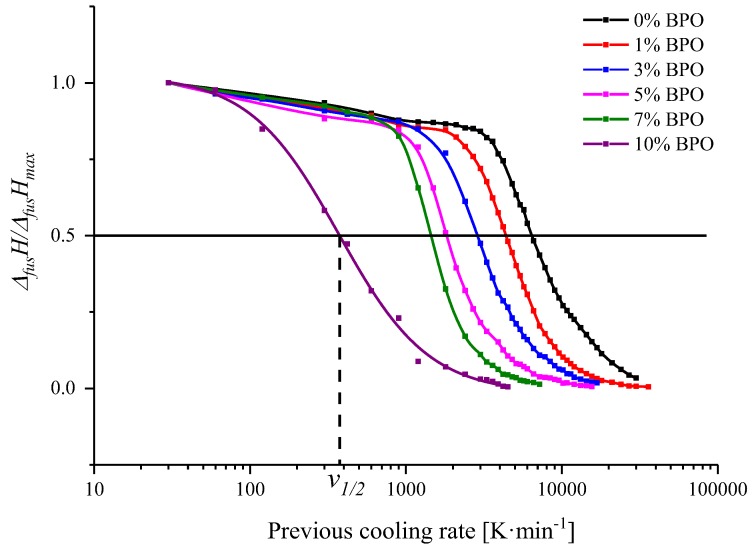

Therefore we made a number of scans with different cooling rates ranging from 30 to 300,000 K·min−1 immediately followed by reheating scans with a constant scanning rate of 300,000 K·min−1. Heating with this rate results in curves without the peak of cold crystallization. Thus, the melting enthalpy characterizes the total amount of crystalline phase in the polymer after cooling. The values of the melting enthalpies decrease with increasing preceding cooling rate and approach zero when the crystallization peak disappears in the cooling curves (Figure 5). Nevertheless, it is more precise and convenient to determine the cooling rate v1/2 at which the melting enthalpy reaches half of its maximum value measured at the slowest preceding cooling rate.

Figure 5.

Dependence of the normalized enthalpy of melting at 300,000 K·min−1 (5000 K·s−1) heating rate on the previous cooling rate for PCL with different cross-link densities. Solid and dashed lines show the way to determine v1/2.

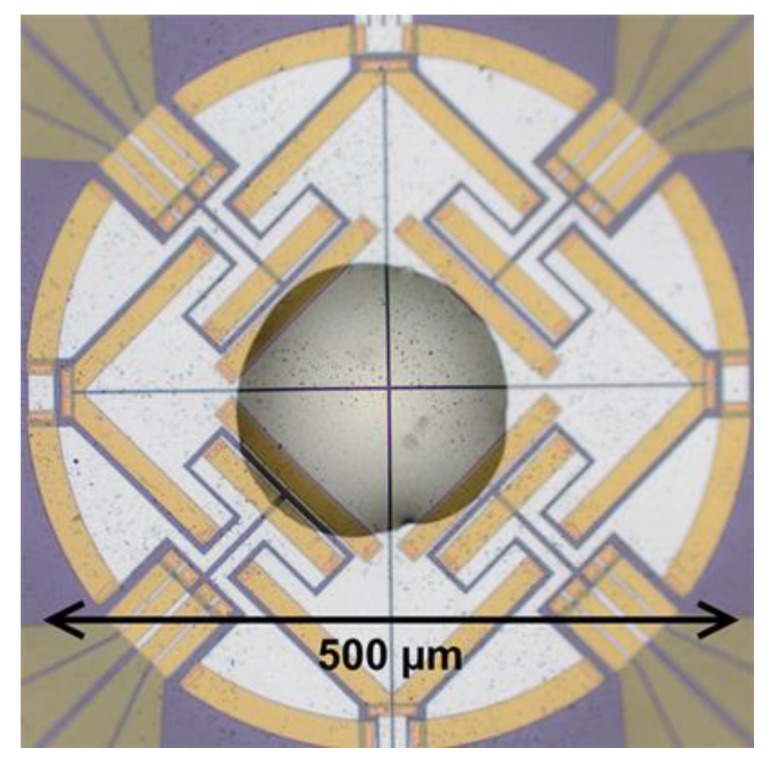

The values of v1/2 are found to decrease monotonically with increasing cross-link density (Figure 6). The results were reproduced with several samples for each cross-link density. Covalent bonds between PCL chains seem to impede the crystallization process. This is similar to a conclusion made for some other cross-linked polymers from theoretical [36] and experimental [37,38,39] considerations. Such monotonic dependence makes measuring v1/2 by FSC a prospective way to characterize the degree of cross-linking of PCL with minimum sample consumption. Crystallization onset temperatures from conventional DSC requiring somewhat larger amounts of sample may also be suitable for this purpose.

Figure 6.

Dependence of the half-crystallization cooling rate v1/2 on the cross-link density of PCL.

4. Conclusions

Crystallization of cross-linked PCL was studied by means of conventional and fast scanning calorimetry. FSC clearly shows that crystallization rate decreases with increasing spatial density of cross-links. This result is in general agreement with the analysis of conventional DSC curves. However, at high crystallization temperatures the difference in crystallization rates of the samples of PCL with different cross-link densities is small, while FSC method shows quite a large change in the rates of crystallization with varying cross-link density at high supercooling. In the further studies, this difference can be a subject of more detailed analysis in isothermal crystallization experiments using FSC.

The magnitude of the cross-link density is difficult to obtain experimentally. Equilibrium swelling remains the most common method to determine it, despite its results depending on the value of the Flory parameter, which is unavailable for many polymer–solvent systems, and the Flory-Huggins theory of polymer solutions being quite a rough approximation itself. Furthermore, swelling studies require precise determination of the mass or volume of the swollen sample, which can be very imprecise and require large polymer samples. Thus, the search for alternative methods to estimate the cross-link densities remains an actual problem. A few methods based on the mechanical properties of the polymer, Raman, and NMR spectroscopy were previously suggested [29,40,41,42]. Our study shows that it is possible to use FSC for this purpose by determining the cooling rate at which half of the possible crystallinity is achieved. FSC requires a very small amount of sample that can be cut even from the final product.

Acknowledgments

Authors thank Igor Kolesov for his helpful suggestions regarding the synthesis of cross-linked PCL and Marat Ziganshin for the help in the experiments.

Supplementary Materials

The supplementary material containing the Avrami model plots is available online at http://www.mdpi.com/2073-4360/10/8/902/s1.

Author Contributions

I.S. conceived and designed the experiments and wrote the paper. C.S. developed the experimental methodology and edited the paper. T.Ma. prepared the samples and analyzed experimental data. A.A., E.Y., T.Mu. and A.K. performed the experiments.

Funding

Igor Sedov acknowledges the Russian Federation President Grant MK-6547.2018.3. The work was supported by the Ministry of Education and Science of the Russian Federation, grant 14.Y26.31.0019.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- 1.Global Polycaprolactone Market to Reach US$ 214.2 Mn by an End of 2021, Persistence Market Research (PMR) Report 2016. [(accessed on 1 August 2018)]; Available online: https://www.persistencemarketresearch.com/mediarelease/polycaprolactone-market.asp.

- 2.Jenkins M., editor. Biomedical Polymers. Woodhead Publ.; Cambridge, UK: 2007. Woodhead Publishing in Materials. [Google Scholar]

- 3.Merkli A., Tabatabay C., Gurny R., Heller J. Biodegradable polymers for the controlled release of ocular drugs. Prog. Polym. Sci. 1998;23:563–580. doi: 10.1016/S0079-6700(97)00048-8. [DOI] [Google Scholar]

- 4.Sinha V.R., Bansal K., Kaushik R., Kumria R., Trehan A. Poly-ϵ-caprolactone microspheres and nanospheres: An overview. Int. J. Pharm. 2004;278:1–23. doi: 10.1016/j.ijpharm.2004.01.044. [DOI] [PubMed] [Google Scholar]

- 5.Vieira A.C., Vieira J.C., Guedes R.M., Marques A.T. Degradation and Viscoelastic Properties of PLA-PCL, PGA-PCL, PDO and PGA Fibres. Mater. Sci. Forum. 2010;636–637:825–832. doi: 10.4028/www.scientific.net/MSF.636-637.825. [DOI] [Google Scholar]

- 6.Yang L., Li J., Jin Y., Li M., Gu Z. In vitro enzymatic degradation of the cross-linked poly(ε-caprolactone) implants. Polym. Degrad. STable. 2015;112:10–19. doi: 10.1016/j.polymdegradstab.2014.12.008. [DOI] [Google Scholar]

- 7.Pandini S., Passera S., Messori M., Paderni K., Toselli M., Gianoncelli A., Bontempi E., Riccò T. Two-way reversible shape memory behaviour of crosslinked poly(ε-caprolactone) Polymer. 2012;53:1915–1924. doi: 10.1016/j.polymer.2012.02.053. [DOI] [Google Scholar]

- 8.Pitt C.G., Chasalow F.I., Hibionada Y.M., Klimas D.M., Schindler A. Aliphatic polyesters. I. The degradation of poly(ϵ-caprolactone) in vivo. J. Appl. Polym. Sci. 1981;26:3779–3787. doi: 10.1002/app.1981.070261124. [DOI] [Google Scholar]

- 9.Jenkins M.J., Harrison K.L. The effect of crystalline morphology on the degradation of polycaprolactone in a solution of phosphate buffer and lipase. Polym. Adv. Technol. 2008;19:1901–1906. doi: 10.1002/pat.1227. [DOI] [Google Scholar]

- 10.Wang Z., Jiang B. Crystallization Kinetics in Mixtures of Poly(ε-caprolactone) and Poly(styrene-co-acrylonitrile) Macromolecules. 1997;30:6223–6229. doi: 10.1021/ma961458h. [DOI] [Google Scholar]

- 11.L’Abee R., Van Duin M., Goossens H. Crystallization kinetics and crystalline morphology of poly(ε-caprolactone) in blends with grafted rubber particles. J. Polym. Sci. Part B Polym. Phys. 2010;48:1438–1448. doi: 10.1002/polb.22025. [DOI] [Google Scholar]

- 12.Madbouly S.A. Isothermal crystallization kinetics in binary miscible blend of poly(ε-caprolactone)/tetramethyl polycarbonate. J. Appl. Polym. Sci. 2007;103:3307–3315. doi: 10.1002/app.25834. [DOI] [Google Scholar]

- 13.Madbouly S.A. Nonisothermal Crystallization Kinetics of Miscible Blends of Polycaprolactone and Crosslinked Carboxylated Polyester Resin. J. Macromol. Sci. Part B. 2011;50:427–443. doi: 10.1080/00222341003648987. [DOI] [Google Scholar]

- 14.Lai S.L., Ramanath G., Allen L.H., Infante P., Ma Z. High-speed (104 °C/s) scanning microcalorimetry with monolayer sensitivity (J/m 2) Appl. Phys. Lett. 1995;67:1229–1231. doi: 10.1063/1.115016. [DOI] [Google Scholar]

- 15.Schick C., Mathot V., editors. Fast Scanning Calorimetry. Springer International Publishing; Cham, Switzerland: 2016. [Google Scholar]

- 16.Schick C., Androsch R. Handbook of Thermal Analysis and Calorimetry. Volume 6. Elsevier; New York, NY, USA: 2018. Fast Scanning Chip Calorimetry; pp. 47–102. [Google Scholar]

- 17.McCluskey P.J., Vlassak J.J. Parallel nano-Differential Scanning Calorimetry: A New Device for Combinatorial Analysis of Complex nano-Scale Material Systems. MRS Proc. 2006;924 doi: 10.1557/PROC-0924-Z08-14. [DOI] [Google Scholar]

- 18.Lopeandía A.F., Cerdó L. l., Clavaguera-Mora M.T., Arana L.R., Jensen K.F., Muñoz F.J., Rodríguez-Viejo J. Sensitive power compensated scanning calorimeter for analysis of phase transformations in small samples. Rev. Sci. Instrum. 2005;76:065104. doi: 10.1063/1.1921567. [DOI] [Google Scholar]

- 19.Mathot V., Pyda M., Pijpers T., Vanden Poel G., van de Kerkhof E., van Herwaarden S., van Herwaarden F., Leenaers A. The Flash DSC 1, a power compensation twin-type, chip-based fast scanning calorimeter (FSC): First findings on polymers. Thermochim. Acta. 2011;522:36–45. doi: 10.1016/j.tca.2011.02.031. [DOI] [Google Scholar]

- 20.Minakov A.A., Schick C. Ultrafast thermal processing and nanocalorimetry at heating and cooling rates up to 1MK/s. Rev. Sci. Instrum. 2007;78:073902. doi: 10.1063/1.2751411. [DOI] [PubMed] [Google Scholar]

- 21.Denlinger D.W., Abarra E.N., Allen K., Rooney P.W., Messer M.T., Watson S.K., Hellman F. Thin film microcalorimeter for heat capacity measurements from 1.5 to 800 K. Rev. Sci. Instrum. 1994;65:946–959. doi: 10.1063/1.1144925. [DOI] [Google Scholar]

- 22.Androsch R., Schick C. Interplay between the Relaxation of the Glass of Random l/d-Lactide Copolymers and Homogeneous Crystal Nucleation: Evidence for Segregation of Chain Defects. J. Phys. Chem. B. 2016;120:4522–4528. doi: 10.1021/acs.jpcb.6b03022. [DOI] [PubMed] [Google Scholar]

- 23.Schawe J.E.K. Cooling rate dependence of the crystallinity at nonisothermal crystallization of polymers: A phenomenological model. J. Appl. Polym. Sci. 2016;133 doi: 10.1002/app.42977. [DOI] [Google Scholar]

- 24.Toda A., Androsch R., Schick C. Insights into polymer crystallization and melting from fast scanning chip calorimetry. Polymer. 2016;91:239–263. doi: 10.1016/j.polymer.2016.03.038. [DOI] [Google Scholar]

- 25.Zhuravlev E., Madhavi V., Lustiger A., Androsch R., Schick C. Crystallization of Polyethylene at Large Undercooling. ACS Macro Lett. 2016;5:365–370. doi: 10.1021/acsmacrolett.5b00889. [DOI] [PubMed] [Google Scholar]

- 26.Wurm A., Zhuravlev E., Eckstein K., Jehnichen D., Pospiech D., Androsch R., Wunderlich B., Schick C. Crystallization and Homogeneous Nucleation Kinetics of Poly(ε-caprolactone) (PCL) with Different Molar Masses. Macromolecules. 2012;45:3816–3828. doi: 10.1021/ma300363b. [DOI] [Google Scholar]

- 27.Zhuravlev E., Schmelzer J.W.P., Wunderlich B., Schick C. Kinetics of nucleation and crystallization in poly(ε-caprolactone) (PCL) Polymer. 2011;52:1983–1997. doi: 10.1016/j.polymer.2011.03.013. [DOI] [Google Scholar]

- 28.Zhuravlev E., Wurm A., Pötschke P., Androsch R., Schmelzer J.W.P., Schick C. Kinetics of nucleation and crystallization of poly(ε-caprolactone)—Multiwalled carbon nanotube composites. Eur. Polym. J. 2014;52:1–11. doi: 10.1016/j.eurpolymj.2013.12.015. [DOI] [Google Scholar]

- 29.Hirschl C., Biebl-Rydlo M., DeBiasio M., Mühleisen W., Neumaier L., Scherf W., Oreski G., Eder G., Chernev B., Schwab W., et al. Determining the degree of crosslinking of ethylene vinyl acetate photovoltaic module encapsulants—A comparative study. Sol. Energy Mater. Sol. Cells. 2013;116:203–218. doi: 10.1016/j.solmat.2013.04.022. [DOI] [Google Scholar]

- 30.Flory P.J., Rehner J. Statistical Mechanics of Cross-Linked Polymer Networks II. Swelling. J. Chem. Phys. 1943;11:521–526. doi: 10.1063/1.1723792. [DOI] [Google Scholar]

- 31.Bordes C., Fréville V., Ruffin E., Marote P., Gauvrit J.Y., Briançon S., Lantéri P. Determination of poly(ε-caprolactone) solubility parameters: Application to solvent substitution in a microencapsulation process. Int. J. Pharm. 2010;383:236–243. doi: 10.1016/j.ijpharm.2009.09.023. [DOI] [PubMed] [Google Scholar]

- 32.Barton A.F.M. CRC Handbook of Solubility Parameters and Other Cohesion Parameters. 2nd ed. CRC Press; Boca Raton, FL, USA: 1991. [Google Scholar]

- 33.Wurm A., Merzlyakov M., Schick C. Reversible Melting During Crystallization of Polymers Studied by Temperature Modulated Techniques (TMDSC, TMDMA) J. Therm. Anal. Calorim. 2000;60:807–820. doi: 10.1023/A:1010195321797. [DOI] [Google Scholar]

- 34.Skoglund P. Fransson, ke Continuous cooling and isothermal crystallization of polycaprolactone. J. Appl. Polym. Sci. 1996;61:2455–2465. doi: 10.1002/(SICI)1097-4628(19960926)61:13<2455::AID-APP25>3.0.CO;2-1. [DOI] [Google Scholar]

- 35.Jeziorny A. Parameters characterizing the kinetics of the non-isothermal crystallization of poly(ethylene terephthalate) determined by d.s.c. Polymer. 1978;19:1142–1144. doi: 10.1016/0032-3861(78)90060-5. [DOI] [Google Scholar]

- 36.Gaylord R.J. A theory of the stress-induced crystallization of crosslinked polymeric networks. J. Polym. Sci. Polym. Phys. Ed. 1976;14:1827–1837. doi: 10.1002/pol.1976.180141008. [DOI] [Google Scholar]

- 37.Tosaka M., Senoo K., Kohjiya S., Ikeda Y. Crystallization of stretched network chains in cross-linked natural rubber. J. Appl. Phys. 2007;101:084909. doi: 10.1063/1.2716382. [DOI] [Google Scholar]

- 38.Jiao C., Wang Z., Liang X., Hu Y. Non-isothermal crystallization kinetics of silane crosslinked polyethylene. Polym. Test. 2005;24:71–80. doi: 10.1016/j.polymertesting.2004.07.007. [DOI] [Google Scholar]

- 39.Mandelkern L. Crystallization of Polymers. 2nd ed. Cambridge University Press; Cambridge, UK: New York, NY, USA: 2002. [Google Scholar]

- 40.Brown P.S., John M., Loadman R., Tinker A.J. Applications of FT-NMR to Crosslink Density Determinations in Natural Rubber Blend Vulcanizates. Rubber Chem. Technol. 1992;65:744–760. doi: 10.5254/1.3538639. [DOI] [Google Scholar]

- 41.Bin Ahmad A., Bin Amu A. Estimation of crosslink density by solid-state NMR spectroscopy. In: Tinker A.J., Jones K.P., editors. Blends of Natural Rubber. Springer Netherlands; Dordrecht, The Netherlands: 1998. pp. 40–52. [Google Scholar]

- 42.Radusch H.-J., Kolesov I., Gohs U., Heinrich G. Multiple Shape-Memory Behavior of Polyethylene/Polycyclooctene Blends Cross-Linked by Electron Irradiation. Macromol. Mater. Eng. 2012;297:1225–1234. doi: 10.1002/mame.201200204. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.