Abstract

Minimizing flavor variation in cheeses without perceived flavor defects in order to produce a consistent product is a challenge in the Swiss cheese industry. This study evaluated flavor variability based on correlations of volatile flavor compounds and sensory attributes. The headspace concentrations of volatile compounds were analyzed using selected ion flow tube-mass spectrometry (SIFT-MS), while the sensory attributes were evaluated using descriptive sensory analysis and consumer testing. The important discriminating volatile compounds were classified into five functional groups: sulfur-containing compounds (methyl mercaptan, hydrogen sulfide, dimethyl disulfide, dimethyl trisulfide, and methional), organic acids (propanoic acid, acetic acid, 3-methylbutanoic acid), aldehydes (3-methylbutanal, butanal, and 2-methylpropanal), a ketone (2,3-butanedione), and an ester (ethyl hexanoate). Correlations were identified among volatile compounds and between volatile compounds and sensory attributes. Only a small number of volatile compounds strongly correlated positively or negatively to a specific sensory attribute. Nutty malty, milkfat lactone, salty, umami, and sweet positively correlated to overall liking and nutty flavor liking of Swiss cheese. Evaluation of cheese flavor using correlations between volatile compounds and sensory attributes provided further understanding of the complexity of flavor and flavor variability among Swiss cheeses manufactured from different factories that can be used to improve flavor consistency of Swiss cheeses.

Keywords: Swiss cheese flavor, selected ion flow tube-mass spectrometry (SIFT-MS), descriptive sensory analysis, odor activity values (OAVs)

1. Introduction

Flavor consistency is a challenging task for the Swiss cheese industry. Flavor, a fundamental basis for sensory assessment, is an important characteristic that determines consumer choice and acceptance [1,2,3]. The biochemical events occurring during cheese ripening involve complex microbiological and physicochemical changes to the curd that give the characteristic flavor and aroma of a particular cheese variety [4,5,6]. The characteristic nutty, mild, and slightly sweet flavor of Swiss cheese after 60 days or more of curing and ripening becomes more aromatic as the cheese ages with its characteristic eyes formed by CO2(g) [6,7,8].

Previously, high impact key volatile compounds were determined to discriminate Swiss cheese samples from different manufacturers using odor activity values (OAVs) [9]. OAV is defined as the concentration of a compound divided by its odor or sensory threshold value. Compounds with concentrations greater than their odor or sensory threshold value are considered to be key, high impact volatiles that significantly contribute to flavor [9,10]. To further understand the differentiation and flavor variability in Swiss cheese, it is important to study the compounds affecting the behavior (i.e., intensity) of a particular flavor compound. In reference to the component balance theory, the flavor of cheese results from a balanced concentration and mixture of a wide variety of volatile and non-volatile flavor compounds [11,12,13]. Because of this mixture of compounds, it is useful to study the correlation of compounds especially to key flavor volatiles and understand the physicochemical effect they have on each other. An increase or suppression of volatile intensity or even generation of new aroma qualities of odorants may change by interaction, causing changes in the overall flavor profile [14,15,16,17].

One of the ultimate goals in flavor chemistry research is to identify the relevance and association of flavor compounds with sensory perceptions and attributes. However, finding and interpreting these associations and interactions are difficult and challenging because the basis of their methodologies is fundamentally different. Nonetheless, there is a much-improved understanding and better appreciation of flavor when a specific correlation between volatile compounds and sensory attributes is established, which is especially useful for resolving flavor issues [18,19,20,21].

The objective of this study was to further understand flavor variability in Swiss cheese samples without perceived flavor defects, in relation to volatile flavor compounds and sensory attributes. The concentrations of Swiss cheese volatile flavor compounds and the intensities of sensory attributes were measured. The correlations among the volatile flavor compounds and sensory attributes were then evaluated. Descriptive analysis and consumer testing were performed to understand flavor characteristics and attributes that affect consumer liking and the overall consumer preferences that determine flavor variation in Swiss cheese.

2. Materials and Methods

2.1. Swiss Cheese Volatile Flavor Compound and Odor Activity Value (OAV) Analyses

Swiss cheese blocks (8–10 lb (3.6–4.5 kg) cheese block) were obtained from five different factories (148, 207, 374, 465, and 528) and were vacuum-packed and stored at −40 °C if not immediately utilized. Table 1 lists the ages of the Swiss cheese samples and the different starter and adjunct cultures used by each factory.

Table 1.

Swiss cheese samples age, starter microorganism, and adjunct culture used by the different factories in Swiss cheese making.

| Factory | Cheese Age (Days) at the Time of Packaging (Post-Curing and Ripening) | Streptococcus (S.) a | Propionibacterium (P.) a | Primary Lactobacillus (L.) a | Adjunct Lactobacillus (L.) a |

|---|---|---|---|---|---|

| 148 | 30 | S. thermophilus | P. freudenreichii | L. delbrueckii | L. casei |

| 207 | 54 | S. thermophilus | P. freudenreichii | L. helveticus | Lactobacillus |

| 374 | 35–36 | S. thermophilus | P. freudenreichii | L. helveticus | L. rhamnosus |

| 465 | 32 | S. thermophilus | P. freudenreichii | L. helveticus | None |

| 528 | 31 | S. thermophilus | P. freudenreichii | L. delbrueckii var lactis | L. casei |

a Each factory uses different and undisclosed strains for each of their starters and adjunct cultures.

For headspace volatile compound analysis, shredded Swiss cheese samples (5 g) were placed into a 500-mL Schott bottle and capped with a polytetrafluoroethylene (PTFE)-lined silicone septum. The samples were warmed for 1 h at 40 °C to allow headspace equilibration prior to volatile analysis using selected ion flow tube-mass spectrometry (SIFT-MS, V200 Syft Technologies, Christchurch, New Zealand). Immediately after heating, the headspace sampling was carried out by inserting a passivated sampling needle (~3.5 cm) through the bottle’s septum. The sample inlet flow rate was 0.28 ± 0.01 Torr•L s−1 (21 ± 1 cm3 min−1) under standard ambient temperature (298 K). A selected ion monitoring (SIM) scan method was used to measure the headspace concentration of volatile flavor compounds for a total scan duration of 120 s. Table 2 lists the volatile compounds and their corresponding kinetic information used within the SIM scan method for volatile compound analysis [22].

Table 2.

Selected ion mode method. List of volatile compounds and kinetic information (i.e., reagent ion, rate coefficients, and product ions) used in volatile compound analysis using selected ion flow tube-mass spectrometry (SIFT-MS).

| Compound | Reagent | Reaction Rate, k (cm3/s) | Branching Ratio (%) | Mass-to-Charge Ratio (m/z) | Product |

|---|---|---|---|---|---|

| (E)-2-nonenal | H3O+ | 4.8 × 10−9 | 100 | 141 | C9H17O+ |

| H3O+ | 159 | C9H17O+•H2O | |||

| NO+ | 3.8 × 10−9 | 80 | 139 | C9H15O+ | |

| NO+ | 20 | 169 | C9H15O+•NO+ | ||

| O2+ | 3.7 × 10−9 | 18 | 83 | C5H7O+ | |

| 84 | C5H8O+ | ||||

| 96 | C7H12+ | ||||

| 2,3-butanedione | H3O+ | 1.7 × 10−9 | 100 | 87 | C4H7O2+ |

| NO+ | 1.3 × 10−9 | 35 | 43 | C2H3O+ | |

| NO+ | 65 | 86 | C4H6O2+ | ||

| 2-methylpropanal | O2+ | 3.0 × 10−9 | 70 | 72 | C4H8O+ |

| 3-methylbutanal | NO+ | 3.0 × 10−9 | 100 | 85 | C5H9O+ |

| H3O+ | 3.6 × 10−9 | 30 | 65 | C5H6+ | |

| 3-methylbutanoic acid | H3O+ | 3.0 × 10−9 | 95 | 103 | C5H11O2+ |

| NO+ | 2.5 × 10−9 | 70 | 132 | C5H10O2+•NO+ | |

| 3-methylindole | H3O+ | 3.3 × 10−9 | 100 | 132 | C9H10N+ |

| NO+ | 2.5 × 10−9 | 100 | 131 | C9H10N+ | |

| O2+ | 2.4 × 10−9 | 20 | 130 | C9H10N+ | |

| 75 | 131 | C9H10N+ | |||

| acetic acid | H3O+ | 2.6 × 10−9 | 100 | 61 | CH3COOH2+ |

| 79 | CH3COOH2+•H2O | ||||

| 97 | CH3COOH2+•2H2O | ||||

| ammonia | H3O+ | 2.6 × 10−9 | 100 | 18 | NH4+ |

| 2.6 × 10−9 | 36 | NH4+•H2O | |||

| O2+ | 2.6 × 10−9 | 100 | 17 | NH3+ | |

| butanal | NO+ | 3.5 × 10−9 | 100 | 71 | C4H7O+ |

| butanoic acid | H3O+ | 2.9 × 10−9 | 90 | 89 | C3H7COOH2+ |

| 107 | C3H7COOH2+•2H2O | ||||

| NO+ | 1.9 × 10−9 | 50 | 118 | NO+•C3H7COOH | |

| diethyl sulfide | O2+ | 2.5 × 10−9 | 30 | 75 | C3H7S+ |

| 2.5 × 10−9 | 35 | 90 | C4H10S+ | ||

| dimethyl disulfide | NO+ | 2.4 × 10−9 | 100 | 94 | (CH3)2S2+ |

| O2+ | 2.3 × 10−9 | 80 | 94 | (CH3)2S2+ | |

| dimethyl sulfide | H3O+ | 2.5 × 10−9 | 100 | 63 | (CH3)2S.H+ |

| NO+ | 2.2 × 10−9 | 100 | 62 | (CH3)2S+ | |

| O2+ | 2.2 × 10−9 | 25 | 47 | CH3S+ | |

| dimethyl trisulfide | H3O+ | 2.8 × 10−9 | 100 | 127 | C2H6S3H+ |

| NO+ | 1.9 × 10−9 | 100 | 126 | C2H6S3+ | |

| O2+ | 2.2 × 10−9 | 15 | 111 | CH3S3+ | |

| O2+ | 2.2 × 10−9 | 45 | 126 | C2H6S3+ | |

| ethanol | H3O+ | 2.7 × 10−9 | 100 | 47 | C2H7O+ |

| 2.7 × 10−9 | 65 | C2H7O+•H2O | |||

| 2.7 × 10−9 | 83 | C2H7O+•(H2O)2 | |||

| NO+ | 1.2 × 10−9 | 100 | 45 | C2H5O+ | |

| 1.2 × 10−9 | 63 | C2H5O+•H2O | |||

| 1.2 × 10−9 | 81 | C2H5O+•(H2O)2 | |||

| O2+ | 2.3 × 10−9 | 75 | 45 | C2H5O+ | |

| 2.3 × 10−9 | 63 | C2H5O+•H2O | |||

| 2.3 × 10−9 | 81 | C2H5O+•2H2O | |||

| ethyl butanoate | H3O+ | 3.0 × 10−9 | 80 | 117 | C6H12O2•H+ |

| 135 | C6H13O2+•H2O | ||||

| NO+ | 2.4 × 10−9 | 30 | 146 | C6H12O2+•NO+ | |

| ethyl hexanoate | H3O+ | 3.0 × 10−9 | 100 | 145 | C8H16O2•H+ |

| H3O+ | 3.0 × 10−9 | 163 | C8H16O2•H+•H2O | ||

| NO+ | 2.5 × 10−9 | 95 | 174 | C8H16O2+•NO+ | |

| ethyl methyl sulfide | H3O+ | 2.4 × 10−9 | 100 | 77 | CH3SHC2H5+ |

| furaneol | H3O+ | 4.0 × 10−9 | 100 | 129 | C6H8O3•H+ |

| 4.0 × 10−9 | 147 | C6H8O3•H3O+ | |||

| NO+ | 2.5 × 10−9 | 95 | 128 | C6H8O3+ | |

| O2+ | 3.0 × 10−9 | 100 | 128 | C6H8O3+ | |

| γ-decalactone | H3O+ | 3.0 × 10−9 | 100 | 171 | C10H18O2•H+ |

| NO+ | 2.5 × 10−9 | 100 | 200 | C10H18O2•NO+ | |

| homofuraneol | H3O+ | 3.0 × 10−9 | 100 | 143 | C7H10O3•H+ |

| H3O+ | 3.0 × 10−9 | 161 | C7H10O3•H+•H2O | ||

| NO+ | 2.5 × 10−9 | 100 | 142 | C7H10O3+ | |

| O2+ | 2.5 × 10−9 | 100 | 142 | C7H10O3+ | |

| hydrogen sulfide | H3O+ | 1.6 × 10−9 | 100 | 35 | H3S+ |

| 1.6 × 10−9 | 53 | H3S+•H2O | |||

| O2+ | 1.4 × 10−9 | 100 | 34 | H2S+ | |

| methional | O2+ | 2.5 × 10−9 | 75 | 104 | C4H8OS+ |

| methionol | NO+ | 2.5 × 10−9 | 100 | 106 | C4H10OS+ |

| O2+ | 2.5 × 10−9 | 30 | 89 | C4H9S+ | |

| 2.5 × 10−9 | 40 | 106 | C4H10OS+ | ||

| methyl mercaptan (methanethiol) | H3O+ | 1.8 × 10−9 | 100 | 49 | CH4S.H+ |

| 1.8 × 10−9 | 67 | CH4S.H+•H2O | |||

| phenylacetaldehyde | H3O+ | 3.0 × 10−9 | 100 | 121 | C8H8O•H+ |

| H3O+ | 3.0 × 10−9 | 157 | C8H8O•H+•2H2O+ | ||

| NO+ | 2.5 × 10−9 | 15 | 91 | C7H7+ | |

| NO+ | 2.5 × 10−9 | 60 | 120 | C8H8O+ | |

| NO+ | 2.5 × 10−9 | 25 | 150 | C8H8O•NO+ | |

| O2+ | 2.5 × 10−9 | 40 | 91 | C7H7+ | |

| O2+ | 2.5 × 10−9 | 40 | 92 | C7H8+ | |

| O2+ | 2.5 × 10−9 | 20 | 120 | C8H8+ | |

| O2+ | 2.5 × 10−9 | 121 | C8H8O•H+ | ||

| propanoic acid | H3O+ | 2.7 × 10−9 | 90 | 75 | C2H5COOH2 + |

| NO+ | 1.5 × 10−9 | 30 | 57 | C2H5CO+ | |

| O2+ | 2.2 × 10−9 | 80 | 74 | C2H5COOH+ | |

| tetramethylpyrazine | H3O+ | 3.0 × 10−9 | 100 | 137 | C8H12N2•H+ |

| NO+ | 2.5 × 10−9 | 100 | 136 | C8H12N2 + | |

| O2+ | 2.5 × 10−9 | 100 | 136 | C8H12N2 + |

In SIFT-MS, volatiles are identified and quantified via known product ions resulting from the soft chemical ionization of the selected compounds with the instrument’s reagent ions (H3O+, NO+, and O2+). The headspace volatile compound concentration is obtained using the reaction-specific rate constant (k), reaction time (tr), and the count rates of the reagent ions ([R+]) and the product ion ([M+]) [23,24,25]. Subsequently, odor activity values were obtained by dividing the measured headspace concentration of a volatile compound by its odor threshold value [7,9,26]. The odor threshold values in air were obtained from the literature [27].

2.2. Descriptive Sensory Analysis

Flavor evaluation using descriptive sensory analysis is a powerful sensory tool for cheese flavor research. It involves effective consumer testing to assess cheese flavor acceptability, preference, and consumer perception [28,29]. Although descriptive sensory analysis cannot provide analytical data on specific flavor compounds and flavor profiles, linking instrumental analysis with descriptive sensory analysis could effectively characterize specific flavors significantly influencing consumer acceptability where important flavor attributes are perceived that directly correlate to consumer preferences [28,29,30]. For descriptive sensory analysis, Swiss cheese cut into cubes (2.5 cm3) were served at room temperature (25 °C) in a 64-mL translucent plastic soufflé cup labeled with a random three-digit factory code (Table 1).

The analysis was conducted at North Carolina State University. Eight panelists (six females, two males, ages 23–44 years) were trained in the SpectrumTM descriptive analysis method [31,32]. Panelists were trained (10 h each) in specific Swiss cheese flavor attributes prior to cheese assessment to carefully identify and scale Swiss cheese flavor descriptors. Each panelist evaluated three Swiss cheese samples per factory using a previously developed cheese flavor sensory language adapted to Swiss cheese flavor that included 21 attributes (Table 3) [30,33]. For assessment, a 0 to 15-point universal intensity scale was used in accordance with the SpectrumTM method for a uniform scoring of intensities across all cheese attributes [31].

Table 3.

| Swiss Cheeses Sensory Descriptor | Definition |

|---|---|

| Bitter | Fundamental taste sensation elicited by various compounds |

| Cooked cabbage | Aromatics associated with cooked cabbage |

| Cooked/milky | Aromatics associated with cooked milk |

| Diacetyl (buttery) | Aromatics associated with diacetyl |

| Dried fruit | Aromatics associated with dried fruits, specifically peaches and apricots |

| Milk fat | Aromatics associated with milk fat |

| Nutty | Nutlike aromatic associated with different nuts |

| Prickle | Chemical feeling factor of which the sensation of carbonation on the tongue is typical |

| Salty | Fundamental taste sensation elicited by salts |

| Sour | Fundamental taste sensation elicited by acids |

| Sweaty | Aromatic associated with human sweat |

| Sweet | Fundamental taste sensation elicited by sugars |

| Umami | Chemical feeling factor elicited by certain peptides and nucleotides |

| Vinegar | Aromatics associated with vinegar |

| Whey | Aromatics associated with Cheddar cheese whey |

Cheeses were evaluated in a randomized order in booths dedicated to sensory analysis and free from external aromas, noise, and distractions. Compusense Five version 5.2 (Compusense, Guelph, ON, Canada) was used for data collection. Panelists were instructed to expectorate samples after evaluation, and spring water was available to each panelist for palate cleansing.

2.3. Consumer Testing

While descriptive sensory analysis provides information about the sensory aspects of products, effective consumer tests provide information on consumer liking and could give further understanding of the cheese flavor variation from a consumer perspective [31]. For consumer testing, 100 untrained consumers (76 females and 24 males, 18–50 years old) were pre-recruited from the Food Industry Center database at The Ohio State University. Demographics indicated that over 75% of the panelists consumed Swiss cheese regularly or at least twice every two weeks. A cheese sample from each factory was served at room temperature in a 64-mL translucent plastic soufflé cup labeled with the same three-digit codes. All samples were presented in randomized order to reduce potential first order bias. Panelists evaluated samples individually in separate booths and entered their own responses directly into a computer using Compusense Five data collection and analysis software (Compusense® Five, version 5.2, Compusense Inc., Guelph, ON, Canada). Panelists assessed visual characteristics before tasting and rated each sample independently for overall liking and nutty flavor liking on a 9-point vertical hedonic category scale. Panelists were allowed to swallow or expectorate samples, as desired. Sample re-tasting was allowed, and each panelist proceeded at his or her own pace. Room temperature spring water was provided for rinsing between samples.

2.4. Statistical Analysis

Multidimensional datasets from volatiles and sensory evaluation were analyzed using principal component analysis (PCA, XLSTAT, Addinsoft, New York, NY, USA) with varimax rotation (clockwise rotation of 15° or cosine of 0.97) [34,35]. Squared cosine (cos2) and factor loading values were evaluated to determine the most significant discriminating volatile compounds (i.e., compounds mostly correlated to the principal components (PCs)) and assess volatile correlation between a volatile compound, sensory attribute, or cheese factory (i.e., observation or variable) and a PC axis. A large value of cos2 (i.e., cos2→1) for an observation or a variable indicates that a PC contributes a relatively large portion of the total distance projected by an observation or variable to the PC. This suggests that a particular observation or variable correlates significantly to the PC and is therefore considered an important observation or variable for discrimination. The factor loading values, on the other hand, determine the variables that account for the differences among observations and thus the correlation (positive or negative) between a component and a variable [35,36].

The statistical relationship or association among volatile compounds or sensory attributes, and principal component space was evaluated based on the dimensionless Pearson’s correlation coefficient test statistic (r), a method of assessing a possible two-way linear association between two continuous variables and squared cosines [37]. The magnitude and direction of the relationship (−1.00 ≤ r ≥ +1.00) indicate the strength and linear association of variables. Correlation between attributes and volatile compounds is described as either strong direct or a strong inverse relationship as r approaches (+1) or (−1), respectively. An r = 0 indicates negligible correlation between continuous variables. In this study, we adopted a simple rule of thumb for interpreting the size of r as follows: 0.90 ≤ r ≤ 1.00 or −0.90 ≥ r ≥ −1.00 (very high positive or negative correlation, respectively); 0.70 ≤ r ≤ 0.89 or −0.70 ≥ r ≥ −0.89 (high positive or negative correlation, respectively); 0.50 ≤ r ≤ 0.69 or −0.50 ≥ r ≥ −0.69 (moderate positive or negative correlation, respectively); 0.30 ≤ r ≤ 0.49 or −0.30 ≥ r ≥ −0.49 (low positive or negative correlation, respectively); and 0.29 ≥ r ≥ −0.29 (negligible correlation) [37,38,39].

Correlations between volatile compounds or sensory attributes were evaluated via correlation circle plots using statistical integrative approaches (i.e., partial least squares regression). The correlation between a volatile or a sensory variable and a component are the coordinates (centered and standardized) projected on the PC axes. The angle between two vectors defines the nature of the correlation between two variables. A sharp, acute angle (cos(α) > 0) signifies a positive correlation, while an obtuse or straight angle (cos(β) < 0) indicates a negative correlation, and a right angle (cos(θ) ≈ 0) suggests a null correlation between two volatile compounds or sensory attributes [40,41]. For a more conservative approach, and to further simplify our analyses, the following conditions were applied as thresholds: strong positive correlation (cos(0 ± 8°)): cos(8) > cos(α) > cos(352); strong negative correlation (cos(180 ± 8°)): cos(172) < cos(β) < cos(188); and strong null correlation (cos(90 ± 1°)): cos(89) < cos(θ) < cos(91). A positive correlation indicates that a compound or attribute is well-linked to another compound or attribute, respectively (i.e., parallel increase or decrease in the concentrations of two volatile compounds or intensities of two sensory attributes). A negative correlation suggests that an increase in a volatile concentration or intensity of a sensory attribute causes a decrease in the concentration of another compound or intensity of a sensory attribute, respectively. A null or orthogonal correlation indicates no correlation between two variables, such that an increase or decrease in the volatile concentration of a compound or intensity of a sensory attribute does not affect another volatile compound or sensory attribute.

3. Results and Discussion

3.1. Variability and Correlation of Swiss Cheese Volatile Compounds

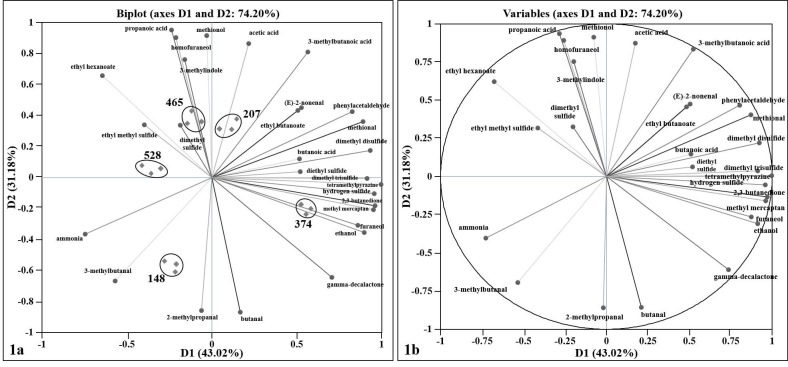

The biplot in Figure 1a shows a simultaneous representation of volatile compounds and Swiss cheese samples from different factories in principal component (PC) space. The figure shows clear differentiation of Swiss cheeses by production factory. The differentiation is primarily described by the first two components, which accounted for 74% of the total data variability. The first component (D1) separates factories 465, 528, and 148 from factories 207 and 374. The second component (D2) separates factories 528, 465, and 207 from factories 148 and 374. The significant discriminating volatile compounds are methyl mercaptan, hydrogen sulfide, dimethyl disulfide, dimethyl trisulfide, methional, 2,3-butanedione, ethyl hexanoate, propanoic acid, acetic acid, 3-methylbutanoic acid, 3-methylbutanal, butanal, and 2-methylpropanal. Because the Swiss cheese samples used in this study did not have perceived flavor defects, these volatile compounds are important to distinguish flavor variability between good cheese samples (i.e., cheeses without flavor defects), as companies work to produce a consistent product.

Figure 1.

Principal component analysis showing (1a) PCA biplot differentiation of Swiss cheeses from different factories (148, 528, 465, 207, and 374) based on volatile compounds and (1b) a correlation circle projection of volatile compounds.

The discriminating volatile compounds can be classified according to their functional group. The major groups include the sulfur-containing compounds (methyl mercaptan, hydrogen sulfide, dimethyl disulfide, dimethyl trisulfide, and methional), organic acids (propanoic acid, acetic acid, 3-methylbutanoic acid), aldehydes (3-methylbutanal, butanal, and 2-methylpropanal), a ketone (2,3-butanedione), and an ester (ethyl hexanoate). Many of the compounds with the same functional group originate from the same biochemical pathway of production in cheese [8,42,43,44,45]. Inherently, this implies that although the main biochemical pathways during the manufacture and ripening of Swiss cheese remain the same, the activity of some pathways producing volatile compounds could be characteristically more or less dynamic in each factory, causing flavor variation among Swiss cheeses.

Correlation analysis between volatile compounds (Figure 1b) provided additional insights into the variability of Swiss cheeses from different factories. The discriminating compounds with significantly positive correlations with other compounds (both discriminating and non-discriminating) include 2,3-butanedione with methyl mercaptan and hydrogen sulfide; dimethyl disulfide with butanoic acid and diethyl sulfide; dimethyl trisulfide with tetramethylpyrazine, diethyl sulfide, and hydrogen sulfide; ethyl hexanoate with ethyl methyl sulfide; hydrogen sulfide with methyl mercaptan; methional with phenylacetaldehyde; methyl mercaptan with furaneol; and propanoic acid with 3-methyl indole and homofuraneol. On the other hand, the discriminating compounds with significantly negative correlations with other compounds (both discriminating and non-discriminating) include 2-methylpropanal with 3-methylbutanoic acid, ethyl butanoate, and (E)-2-nonenal; 3-methylbutanal with acetic acid and methionol; butanal with 3-methylindole, propanoic acid, homofuraneol, and methionol; ethyl hexanoate with gamma-decalactone; and methional with ammonia.

The discriminating volatile compounds that do not significantly (positive or negative) correlate (i.e., strong null correlation) were 2-methylpropanal and ethyl hexanoate; 3-methylbutanal and hydrogen sulfide; acetic acid and 2,3-butanedione; acetic acid and methyl mercaptan; and between butanal and dimethyl disulfide. Moreover, among the non-discriminating compounds, no significant correlation was observed between butanoic acid and homofuraneol; and diethyl sulfide and methionol.

Some observations can be inferred from these correlations. For instance, the strong negative correlation between 3-methylbutanoic acid and 3-methylbutanal (both are differentiating compounds) indicates an inverse relationship between these compounds. This is to be expected since 3-methylbutanoic acid is produced from the oxidation of 3-methylbutanal [29,46,47]. Thus, the greater the oxidation of 3-methylbutanal, the more 3-methylbutanoic acid is produced. This relationship could be useful in detecting excessive oxidation in Swiss cheese during ripening. Cheese has a low oxidation/reduction potential, which contributes to the ripening and development of characteristic cheese flavor and ensures limited oxidative degradation [5,48,49]. Excessive oxidation may result in extensive degradation of lipids, primarily polyunsaturated fatty acids. Oxidative degradation of lipids produces various strongly flavored unsaturated aldehydes, resulting in the flavor defect oxidative rancidity [49,50]. One cause of oxidation in cheese is light-induced oxidation due to light exposure during cheese storage and retail distribution [51,52,53,54].

A strong negative correlation was also observed between ethyl hexanoate (a discriminating compound) and gamma-decalactone (a non-discriminating compound). Both the ester and lactone are produced from the metabolism of fatty acids during cheese ripening, and these free fatty acid-derived compounds directly affect cheese flavor [44,49]. Esters impart a fruity flavor note (i.e., apple-, banana-, pear-, pineapple-, and strawberry-like) while lactones contribute to a buttery character in cheese [44,49,55]. It is notable that these compounds require different types of glyceride substrate early in their biochemical pathways of production, which are acted upon by different catalytic enzymes from various strains of starter and non-starter lactic acid and propionic acid bacteria [5,43,44]. Triacylglycerides esterified with hydroxylated fatty acid precursor undergo direct lactonization to form lactones, such as gamma-decalactone [43,49,56]. On the other hand, monoglycerides and diglycerides are acted on by lactic acid bacteria esterases to produce esters such as ethyl hexanoate [44,57,58]. Thus, the extent of milk fat hydrolysis to produce mono-, di-, or triacylglycerides, which is in turn influenced by the different lipolytic and esterolytic enzymes, affects the relative formation of these two compounds, which impacts the fruity versus buttery flavor in Swiss cheese [49,59,60]. High levels of ethyl esters cause a fruity flavor defect, while elevated lactone concentration results in high buttery notes in cheese [44,49,58].

A strong positive correlation between the two sulfur compounds, dimethyl disulfide (a discriminating compound) and diethyl sulfide (a non-discriminating compound), and butanoic acid (a non-discriminating compound) was observed. The biochemical pathways for these compounds are different, and not obviously connected. The two low molecular weight sulfur compounds are formed predominantly from the elimination reaction-initiated catabolism of the amino acid methionine, so the positive correlation between dimethyl disulfide and diethyl sulfide is expected [61,62,63]. Butanoic acid, on the other hand, is a free fatty acid (FFA) generally produced from the lipolysis of milk fat [5,46]. This positive correlation suggests an implicit association between proteolysis (catabolism of methionine) and lipolysis (generation of FFA) during the ripening of Swiss cheese. This relationship should be further explored to determine whether it is causational or accidental.

A strong positive correlation was also observed between 2,3-butanedione, methyl mercaptan, and hydrogen sulfide (all discriminating compounds). A similarity in the variation of the levels of hydrogen sulfide and methyl mercaptan with the age of cheese has been previously observed [64]. However, there is no clear relationship between the two biochemical pathways, which generate the sulfur-containing compounds from proteolysis, and 2,3-butanedione from citrate metabolism [61,62,65,66]. Thus, this relationship should also be further explored to determine whether it is causational or accidental.

3.2. Correlation of Volatile Compounds with Sensory Attributes

Correlations between flavor volatile compounds and sensory attributes were evaluated using Pearson correlation from PCA (Table 4). Not all volatile compounds have strong significant correlations with sensory attributes and vice versa, because volatile compounds may or may not play crucial roles in flavor or contribute to the overall cheese flavor [19,20,48,49,50]. In this study, significant correlations (positive and negative) between volatile compounds (discriminating or non-discriminating) and sensory attributes were observed. These correlations agree with the premise of component balance theory that was first proposed by Kosikowski and Mocquot, which states that a mixture of compounds is responsible for each cheese flavor [12]. Among the discriminating volatile compounds, strongly significant correlations with different sensory attributes (positive attribute, (negative attribute); indicated with these fonts) were observed. This includes: 2,3-butanedione with diacetyl and (sweet, sour, and umami); 2-methylpropanal with milkfat lactone, nutty malty, salty; 3-methylbutanal with milkfat lactone; 3-methylbutanoic acid with (salty); acetic acid with (milkfat lactone); ethyl hexanoate with bitter, cooked cabbage, dried fruit, prickle, sour, sweaty, sweet, umami, vinegar/sour aromatic, and (cooked milky and whey); and methyl mercaptan with diacetyl and (umami). On the other hand, no correlations (i.e., strong null correlation) were observed between 2,3-butanedione with milkfat lactone; 3-methybutanoic acid with dried fruit; and methyl mercaptan with milkfat lactone.

Table 4.

Pearson correlation between sensory attributes and volatile compounds.

| Sensory Attribute | Compounds with Positive Correlation | Compounds with Negative Correlation | Sensory Attribute | Compounds with Positive Correlation | Compounds with Negative Correlation | ||||

|---|---|---|---|---|---|---|---|---|---|

| Compound | Score, r | Compound | Score, r | Compound | Score, r | Compound | Score, r | ||

| bitter | ethyl hexanoate | 0.87 | furaneol | −0.90 | sweaty | ethyl hexanoate | 0.78 | ethanol | −0.94 |

| dimethyl sulfide | 0.65 | diethyl sulfide | −0.82 | homofuraneol | 0.78 | gamma-decalactone | −0.93 | ||

| butanoic acid | −0.79 | propanoic acid | 0.74 | 2,3-butanedione | −0.89 | ||||

| butanal | −0.73 | methyl mercaptan | −0.89 | ||||||

| gamma-decalactone | −0.71 | hydrogen sulfide | −0.83 | ||||||

| cooked cabbage | ethyl hexanoate | 0.96 | gamma-decalactone | −0.98 | tetramethylpyrazine | −0.78 | |||

| propanoic acid | 0.80 | furaneol | −0.87 | furaneol | −0.74 | ||||

| homofuraneol | 0.78 | ethanol | −0.85 | dimethyl disulfide | −0.71 | ||||

| methyl mercaptan | −0.79 | sweet | ethyl methyl sulfide | 0.79 | ethanol | −0.93 | |||

| 2,3-butanedione | −0.79 | 3-methylindole | 0.73 | methyl mercaptan | −0.90 | ||||

| butanal | −0.77 | ethyl hexanoate | 0.71 | hydrogen sulfide | −0.88 | ||||

| tetramethylpyrazine | −0.75 | propanoic acid | 0.71 | 2,3-butanedione | −0.87 | ||||

| hydrogen sulfide | −0.71 | dimethyl trisulfide | −0.79 | ||||||

| cooked milky | gamma-decalactone | 0.98 | ethyl hexanoate | −0.96 | tetramethylpyrazine | −0.77 | |||

| furaneol | 0.85 | homofuraneol | −0.76 | gamma-decalactone | −0.75 | ||||

| butanal | 0.81 | propanoic acid | −0.69 | furaneol | −0.72 | ||||

| 2-methylpropanal | 0.71 | umami | ethyl hexanoate | 0.70 | 2,3-butanedione | −0.99 | |||

| diacetyl | 2,3-butanedione | 0.93 | ethyl hexanoate | −0.68 | homofuraneol | 0.50 | methyl mercaptan | −0.98 | |

| ethanol | 0.91 | homofuraneol | −0.59 | ethanol | −0.97 | ||||

| methyl mercaptan | 0.91 | hydrogen sulfide | −0.96 | ||||||

| hydrogen sulfide | 0.87 | tetramethylpyrazine | −0.94 | ||||||

| tetramethylpyrazine | 0.87 | dimethyl disulfide | −0.91 | ||||||

| gamma-decalactone | 0.86 | gamma-decalactone | −0.84 | ||||||

| dimethyl disulfide | 0.85 | furaneol | −0.81 | ||||||

| furaneol | 0.74 | methional | −0.75 | ||||||

| dried fruit | ethyl hexanoate | 0.77 | gamma-decalactone | −0.93 | dimethyl trisulfide | −0.75 | |||

| homofuraneol | 0.76 | ethanol | −0.83 | vinegar/sour aromatic | propanoic acid | 0.93 | gamma-decalactone | −0.91 | |

| propanoic acid | 0.63 | 2,3-butanedione | −0.81 | ethyl hexanoate | 0.90 | butanal | −0.85 | ||

| methyl mercaptan | −0.79 | homofuraneol | 0.87 | ethanol | −0.75 | ||||

| tetramethylpyrazine | −0.74 | methionol | 0.79 | 2-methylpropanal | −0.72 | ||||

| hydrogen sulfide | −0.72 | 3-methylindole | 0.72 | furaneol | −0.72 | ||||

| furaneol | −0.72 | whey | gamma-decalactone | 0.99 | ethyl hexanoate | −0.95 | |||

| milkfat lactone | 2-methylpropanal | 0.93 | (E)-2-nonenal | −0.85 | butanal | 0.82 | homofuraneol | −0.85 | |

| 3-methylbutanal | 0.84 | 3-methylbutanoic acid | −0.69 | furaneol | 0.80 | propanoic acid | −0.81 | ||

| butanal | 0.84 | ethyl butanoate | −0.66 | ethanol | 0.75 | methionol | −0.62 | ||

| homofuraneol | −0.63 | 2-methylpropanal | 0.71 | ||||||

| nutty malty | 3-methylbutanal | 0.94 | dimethyl disulfide | −0.94 | 2,3-butanedione | 0.69 | |||

| 2-methylpropanal | 0.83 | ethyl butanoate | −0.93 | methyl mercaptan | 0.68 | ||||

| 3-methylbutanoic acid | −0.83 | tetramethylpyrazine | 0.64 | ||||||

| hydrogen sulfide | −0.82 | ||||||||

| 2,3-butanedione | −0.77 | ||||||||

| methyl mercaptan | −0.76 | ||||||||

| methional | −0.74 | ||||||||

| tetramethylpyrazine | −0.72 | ||||||||

| prickle | ethyl hexanoate | 0.77 | gamma-decalactone | −0.85 | |||||

| homofuraneol | 0.58 | diethyl sulfide | −0.83 | ||||||

| butanoic acid | −0.79 | ||||||||

| furaneol | −0.73 | ||||||||

| salty | 3-methylbutanal | 0.94 | ethyl butanoate | −0.98 | |||||

| 2-methylpropanal | 0.82 | 3-methylbutanoic acid | −0.76 | ||||||

| butanal | 0.70 | dimethyl disulfide | −0.74 | ||||||

| sour | homofuraneol | 0.68 | ethanol | −0.94 | |||||

| ethyl hexanoate | 0.65 | 2,3-butanedione | −0.92 | ||||||

| propanoic acid | 0.61 | methyl mercaptan | −0.91 | ||||||

| hydrogen sulfide | −0.88 | ||||||||

| gamma-decalactone | −0.84 | ||||||||

| dimethyl disulfide | −0.81 | ||||||||

| tetramethylpyrazine | −0.80 | ||||||||

Some notable observations include the significant positive correlation between 2,3-butanedione (a discriminating compound) and the diacetyl sensory attribute, which is expected. Many studies have identified the correlation between 2,3-butanedione and the flavor attribute diacetyl, which is highly associated with a buttery flavor note. Moreover, historically these two terms have been used interchangeably [28,29,67].

On the other hand, 2,3-butanedione has a strong negative correlation with the sweet sensory attribute. According to the sensory lexicon in Table 3 and descriptive language of sensory attributes developed by Drake and co-workers [33], this indicates that the fresh butter aroma of 2,3-butanedione is inversely associated with the basic taste sensation elicited by sugars (sweet). It was previously observed that high levels of 2,3-butanedione result in an unbalanced buttery flavor that lacks the sweetness, delicate, and smooth sensation and flavor of fresh milk fat in high-quality butter [68,69]. Thus, based on previous studies, 2,3-butanedione could cause a lower sweetness to be perceived.

Ethyl hexanoate (a discriminating compound) positively correlated with the sensory attributes dried fruit, sweet, and bitter. The positive correlation of ethyl hexanoate with dried fruit and sweet flavor is expected because ester compounds, such as ethyl hexanoate, are known to produce sweet, fruity flavor and are responsible for the aroma of fruits [70,71,72]. Ester compounds were also previously correlated with the sweet odor in Appenzeller, Gruyѐre, Swiss, Italian, and blue cheeses [73]. Similarly, Lawlor and co-workers detected the positive correlation of ester compounds with sweet flavor [67]. The positive correlation between ethyl hexanoate and bitter attribute was unexpected. At low concentration, ethyl hexanoate carries a fruity flavor note in Swiss cheese, however, increased concentrations of ethyl hexanoate and other ethyl esters were strongly associated with fruity flavor defects in Cheddar cheese [7,20,71,74]. It could be that high levels of the fruity flavor of ethyl hexanoate are eliciting the bitter sensory attribute in Swiss cheese.

Gamma-decalactone positively correlated with cooked milky and diacetyl flavor attributes. Lactones are generally characterized by very pronounced fruity notes, although they have been found to contribute to a buttery character in cheese [49,55]. Thus, it must be the buttery flavor characteristic of gamma-decalactone that was associated with cooked milky and diacetyl flavor notes detected in Swiss cheese.

The alkyl aldehydes 2-methylpropanal and 3-methylbutanal (both are discriminating compounds) have a strong positive correlation with the flavor attributes nutty malty and salty. The correlation of 2-methylpropanal and 3-methylbutanal with nutty malty flavor agrees with previous sensory studies, which reported that the Strecker aldehydes 2-methylpropanal, 2-methylbutanal, and 3-methylbutanal contribute nutty flavors in aged Cheddar cheese [75,76]. Parmesan and Swiss cheese, which are characterized by their intense nutty flavor, have Strecker aldehydes as predominant compounds [77,78,79,80,81,82]. The positive correlation between 3-methylbutanal and salty flavor also agrees with previous sensory studies, particularly in cured ham [83,84,85].

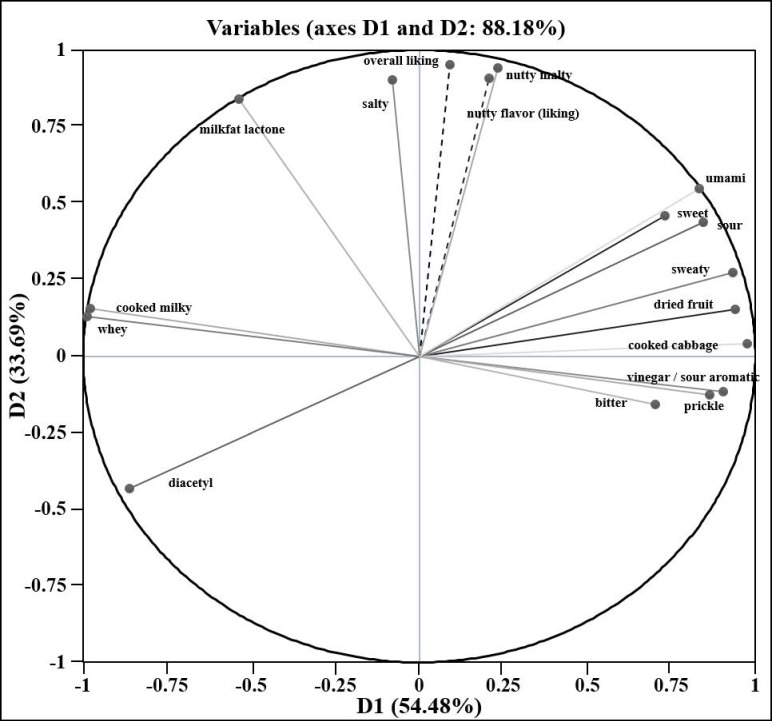

Consumer liking was also measured for these cheeses with an untrained panel. Correlation analysis (Figure 2) between consumer preference and the descriptive panel sensory attributes showed a positive correlation of five attributes (nutty malty, milkfat lactone, salty, umami, and sweet) with consumer preference (overall liking and nutty flavor liking) (Table 5). Thus, these attributes appeared to be the most important to consumer preference. No sensory attribute had a strongly negative correlation with overall liking or nutty flavor liking, which may be due to the Swiss cheese samples tested not having any strong, noticeable flavor defects. Thus, for good quality Swiss cheese, the sensory attributes nutty malty, milkfat lactone, salty, umami, and sweet could be well-associated with overall liking and nutty flavor liking.

Figure 2.

Principal component analysis showing a correlation circle projection of sensory attributes with overall liking and nutty flavor liking.

Table 5.

Pearson correlation between the overall consumer preference (overall liking and nutty flavor liking) with sensory attributes.

| Overall Consumer Preference | Sensory Attributes with Positive Correlation | |

|---|---|---|

| Attribute | Score, r | |

| overall liking | nutty malty | 0.86 |

| milkfat lactone | 0.75 | |

| salty | 0.73 | |

| umami | 0.58 | |

| sweet | 0.56 | |

| nutty flavor (liking) | nutty malty | 0.85 |

| umami | 0.66 | |

| salty | 0.66 | |

| milkfat lactone | 0.64 | |

| sweet | 0.58 | |

4. Conclusions

In this study, flavor variability among Swiss cheeses without perceived flavor defects was evaluated using correlations between volatile compounds and sensory attributes. These correlations brought about further understanding of the complexity of flavor and flavor variability among Swiss cheese samples manufactured from different factories. The important discriminating volatile compounds were classified into five functional groups, namely sulfur-containing compounds (methyl mercaptan, hydrogen sulfide, dimethyl disulfide, dimethyl trisulfide, and methional), organic acids (propanoic acid, acetic acid, 3-methylbutanoic acid), aldehydes (3-methylbutanal, butanal, and 2-methylpropanal), a ketone (2,3-butanedione), and an ester (ethyl hexanoate). The prevailing biochemical activities during the manufacture and ripening of cheese determine the volatile profile of cheese, but the activity of the pathways could be characteristically different for each factory, causing volatile flavor compound variation among Swiss cheeses.

The correlations between descriptive sensory attributes and volatile compounds showed that only a subset of compounds strongly correlates positively or negatively to a specific attribute. These attribute-volatile compound correlations, albeit partial, not only show the flavor complexity of Swiss cheese but also highly suggest, like many other studies have concluded, that the composition of cheese flavor results from the interaction between several volatile compounds and other compositional variables mixed in different and balanced ratios [73,86,87]. For instance, during lipolysis and metabolism of fatty acids, the extent of the hydrolysis of milk fat directly affects the production of different glyceride substrates, which then affects the production of esters (i.e., requires mono- or diglycerides substrate) versus lactones (i.e., requires triacylglyceride substrate). This could then result in either a more fruity (from high levels of esters) or buttery (from elevated level of lactones) flavor of the Swiss cheese. Correspondingly, during citrate metabolism, a more active 2,3-butanedione production and/or its inhibited metabolism could increase 2,3-butanedione concentration in cheese, which could then intensify the buttery flavor of Swiss cheese but could result in lower perceived sweetness of the cheese.

Finally, the overall liking and nutty flavor liking of Swiss cheese were strongly positively correlated with nutty malty, milkfat lactone, salty, umami, and sweet based on consumer preference evaluation. Thus, for cheeses without flavor defects, future sensory analysis on these five sensory attributes could be evaluated based on the overall liking and nutty flavor liking for a more concise flavor quality evaluation of Swiss cheeses.

Author Contributions

H.C. and K.H. performed the experiments and wrote the manuscript. H.C. and S.B. reviewed, edited, and supervised the research and manuscript writing.

Conflicts of Interest

The authors declare no conflict of interest.

References

- 1.Young N., Drake M., Lopetcharat K., McDaniel M. Preference mapping of Cheddar cheeses. J. Dairy Sci. 2004;87:11–19. doi: 10.3168/jds.S0022-0302(04)73136-7. [DOI] [PubMed] [Google Scholar]

- 2.Drake S., Carunchia Whetstine M., Drake M., Courtney P., Fligner K., Jenkins J., Pruitt C. Sources of umami taste in Cheddar and Swiss cheeses. J. Food Sci. 2007;72:360–366. doi: 10.1111/j.1750-3841.2007.00402.x. [DOI] [PubMed] [Google Scholar]

- 3.Kocaoglu-Vurma N., Eliardi A., Drake M., Rodriguez-Saona L., Harper W. Rapid Profiling of Swiss Cheese by Attenuated Total Reflectance (ATR) Infrared Spectroscopy and Descriptive Sensory Analysis. J. Food Sci. 2009;74:232–239. doi: 10.1111/j.1750-3841.2009.01188.x. [DOI] [PubMed] [Google Scholar]

- 4.Langsrud T., Reinbold G.W. Flavor development and microbiology of Swiss cheese—A review. I. Milk quality and treatments. J. Milk Food Technol. 1973;36:487–490. doi: 10.4315/0022-2747-36.9.487. [DOI] [Google Scholar]

- 5.McSweeney P.L. Biochemistry of cheese ripening. Int. Dairy J. 2004;57:127–144. doi: 10.1111/j.1471-0307.2004.00147.x. [DOI] [Google Scholar]

- 6.Castada H.Z., Harper W.J. Variability of volatile organic compounds during the manufacture of Swiss-type cheese using selected ion flow tube mass spectrometry. Bull. Int. Dairy Fed. 2014;473:29–50. [Google Scholar]

- 7.Preininger M., Grosch W. Evaluation of key odorants of the neutral volatiles of Emmentaler cheese by the calculation of odour activity values. Lebensmittel-Wissenschaft Und Technologie. 1994;27:237–244. doi: 10.1006/fstl.1994.1048. [DOI] [Google Scholar]

- 8.Fröhlich-Wyder M.T., Bachmann H.P. Cheeses with propionic acid fermentation. In: Fox P.F., McSweeney P.H., Cogan T.M., Guinee T.P., editors. Cheese: Chemistry, Physics and Microbiology. 3rd ed. Volume 2. Elsevier Academic Press; London, UK: 2004. pp. 141–156. [Google Scholar]

- 9.Taylor K., Wick C., Castada H.Z., Kent K., Harper W.J. Discrimination of Swiss cheese from 5 different factories by high impact volatile organic compound profiles determined by odor activity value using Selected Ion Flow Tube Mass Spectrometry and odor threshold. J. Food Sci. 2013;78:C1509–C1515. doi: 10.1111/1750-3841.12249. [DOI] [PubMed] [Google Scholar]

- 10.Attaie R. Quantification of volatile compounds in goat milk Jack cheese using static headspace gas chromatography. J. Dairy Sci. 2009;92:2435–2443. doi: 10.3168/jds.2008-1732. [DOI] [PubMed] [Google Scholar]

- 11.Mulder H. Taste and flavor-forming substances in cheese. Neth Milk Dairy J. 1952;6:157–167. [Google Scholar]

- 12.Kosikowski F., Mocquot G. Advances in Cheese Technology. Volume 38. Food and Agriculture Organization; Rome, Italy: 1958. p. 236. [Google Scholar]

- 13.Langsrud T., Reinbold G.W. Flavor development and microbiology of Swiss cheese—A review. III. Ripening and flavor production. J. Milk Food Technol. 1973;36:593–609. doi: 10.4315/0022-2747-36.12.593. [DOI] [Google Scholar]

- 14.Flament I. Coffee Flavor Chemistry. John Wiley & Sons Ltd.; West Sussex, UK: 2002. [Google Scholar]

- 15.Belitz H.-D., Grosch W., Schieberle P. Aroma Compounds. In: Belitz H.-D., Grosch W., Schieberle P., editors. Food Chemistry. Springer; Heidelberg, Germany: 2009. pp. 340–402. [Google Scholar]

- 16.Weerawatanakorn M., Wu J.-C., Pan M.-H., Ho C.-T. Reactivity and stability of selected flavor compounds. J. Food Drug Anal. 2015;23:176–190. doi: 10.1016/j.jfda.2015.02.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Castada H.Z., Park C., Harper W.J., Barringer S.A. Suppression of propanoic acid, acetic acid and 3-methylbutanoic acid production by other volatiles in a Swiss cheese curd slurry system. Int. Dairy J. 2016;54:29–32. doi: 10.1016/j.idairyj.2015.10.007. [DOI] [Google Scholar]

- 18.Marsili R.T. Comparing sensory and analytical chemistry flavor analysis. In: Marsili R.T., editor. Sensory-Directed Flavor Analysis. Taylor & Francis; Boca Raton, FL, USA: 2006. pp. 1–22. [Google Scholar]

- 19.Drake M., Miracle R., Caudle A.D., Cadwallader K.R. Relating sensory and instrumental analyses. In: Marsili R.T., editor. Sensory-Directed Flavor Analysis. Taylor & Francis; Boca Raton, FL, USA: 2006. pp. 23–55. [Google Scholar]

- 20.Drake M. Invited review: Sensory analysis of dairy foods. J. Dairy Sci. 2007;90:4925–4937. doi: 10.3168/jds.2007-0332. [DOI] [PubMed] [Google Scholar]

- 21.Chambers E., IV, Koppel K. Associations of volatile compounds with sensory aroma and flavor: The complex nature of flavor. Molecules. 2013;18:4887–4905. doi: 10.3390/molecules18054887. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Castada H.Z., Wick C., Harper W.J., Barringer S. Headspace quantification of pure and aqueous solutions of binary mixtures of key volatile organic compounds in Swiss cheeses using selected ion flow tube mass spectrometry. Rapid Commun. Mass Spectrom. 2015;29:81–90. doi: 10.1002/rcm.7089. [DOI] [PubMed] [Google Scholar]

- 23.Smith D., Španěl P. Application of ion chemistry and the SIFT technique to the quantitative analysis of trace gases in air and on breath. Int. Rev. Phys. Chem. 1996;15:231–271. doi: 10.1080/01442359609353183. [DOI] [Google Scholar]

- 24.Spanel P., Smith D. Selected ion flow tube studies of the reactions of H3O+, NO+, and O2+ with some organosulphur molecules. Int. J. Mass Spectrom. 1998;176:167–176. doi: 10.1016/S1387-3806(98)14004-6. [DOI] [Google Scholar]

- 25.Spanel P., Smith D. Quantitative selected ion flow tube mass spectrometry: The influence of ionic diffusion and mass discrimination. J. Am. Soc. Mass Spectrom. 2001;12:863–872. doi: 10.1016/S1044-0305(01)00253-7. [DOI] [PubMed] [Google Scholar]

- 26.Milo C., Reineccius G.A. Identification and quantification of potent odorants in regular-fat and low-fat mild Cheddar cheese. J. Agric. Food Chem. 1997;45:3590–3594. doi: 10.1021/jf970152m. [DOI] [Google Scholar]

- 27.Van Gemert L.J. Odour Thresholds: Compilations of Odour Threshold Values in Air, Water and Other Media. Oliemans Punter & Partners; Utrecht, The Netherlands: 2011. [Google Scholar]

- 28.Drake M.A., Civille G.V. Flavor lexicons. Compr. Rev. Food Sci. Food Saf. 2003;2:33–40. doi: 10.1111/j.1541-4337.2003.tb00013.x. [DOI] [PubMed] [Google Scholar]

- 29.Singh T.K., Drake M.A., Cadwallader K.R. Flavor of Cheddar cheese: A chemical and sensory perspective. Compr. Rev. Food Sci. Food Saf. 2003;2:166–189. doi: 10.1111/j.1541-4337.2003.tb00021.x. [DOI] [PubMed] [Google Scholar]

- 30.Liggett R.E., Drake M.A., Delwiche J.F. Impact of flavor attributes on consumer liking of Swiss cheese. J. Dairy Sci. 2008;91:466–476. doi: 10.3168/jds.2007-0527. [DOI] [PubMed] [Google Scholar]

- 31.Meilgaard M., Civille G.V., Carr B.T. Sensory Evaluation Techniques. 4th ed. CRC Press; Boca Raton, FL, USA: 2006. [Google Scholar]

- 32.Lawless H.T., Heymann H. Sensory Evaluation of Food: Principles and Practices. 2nd ed. Springer Science & Business Media; New York, NY, USA: 2010. [Google Scholar]

- 33.Drake M.A., McIngvale S.C., Gerard P.D., Cadwallader K.R., Civille G.V. Development of a descriptive language for Cheddar cheese. J. Food Sci. 2001;66:1422–1427. doi: 10.1111/j.1365-2621.2001.tb15225.x. [DOI] [Google Scholar]

- 34.Kaiser H.F. The varimax criterion for analytic rotation in facot analysis. Psychometrika. 1958;23:187–200. doi: 10.1007/BF02289233. [DOI] [Google Scholar]

- 35.Abdi H., Williams L.J. Principal component analysis. Wiley Interdiscip. Rev. Comput. Stat. 2010;2:433–459. doi: 10.1002/wics.101. [DOI] [Google Scholar]

- 36.Yang H. Factor Loadings. In: Salkind N.J., editor. Encyclopedia of Research Design. SAGE Publications, Inc.; Thousand Oaks, CA, USA: 2010. pp. 481–483. [Google Scholar]

- 37.Mukaka M.M. A guide to appropriate use of correlation coefficient in medical research. Malawi Med. J. 2012;24:69–71. [PMC free article] [PubMed] [Google Scholar]

- 38.Hinkle D.E., Wiersma W., Jurs S.G. Applied Statistics for the Behavioral Sciences. 5th ed. Houghton Mifflin; Boston, MA, USA: 2003. [Google Scholar]

- 39.Heiman G.W. Basic Statistics for the Behavioral Sciences. Wadsworth; Belmont, CA, USA: 2011. [Google Scholar]

- 40.Mevik B.-H., Wehrens R. The pls Package: Principal Componnt and Partial Least Squares Regression in R. J. Stat. Softw. 2007;18:1–23. doi: 10.18637/jss.v018.i02. [DOI] [Google Scholar]

- 41.Gonzalez I., Le Cao K.-A., Davis M.J., Dejean S. Visualising associations between paired ‘omics’ data sets. BioData Min. 2012;5:1–23. doi: 10.1186/1756-0381-5-19. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Engels W.J., Visser S. Isolation and comparative characterization of components that contribute to the flavour of different types of cheese. Neth. Milk Dairy J. 1994;48:127–140. [Google Scholar]

- 43.Molimard P., Spinnler H.E. Review: Compounds Involved in the Flavor of Surface Mold-Ripened Cheeses: Origins and Properties. J. Dairy Sci. 1996;79:169–184. doi: 10.3168/jds.S0022-0302(96)76348-8. [DOI] [Google Scholar]

- 44.Holland R., Liu S.Q., Crow V.L., Delabre M.L., Lubbers M., Bennet M., Norris G. Esterases of lactic acid bacteria and cheese flavour: Milk fat hydrolysis, alcoholysis and esterification. Int. Dairy J. 2005;15:711–718. doi: 10.1016/j.idairyj.2004.09.012. [DOI] [Google Scholar]

- 45.Smit G., Smit B.A., Engels W.J. Flavour formation by lactic acid bacteria and biochemical flavour profiling of cheese products. FEMS Microbiol. Rev. 2005;29:591–610. doi: 10.1016/j.fmrre.2005.04.002. [DOI] [PubMed] [Google Scholar]

- 46.McSweeney P.L., Sousa M.J. Biochemical pathways for the production of flavour compounds in cheeses during ripening: A review. Lait. 2000;80:293–324. doi: 10.1051/lait:2000127. [DOI] [Google Scholar]

- 47.Castada H.Z., Harper W.J., Barringer S.A. Volatile organic compounds of a Swiss cheese slurry system with and without added reduced glutathione, compared with commercial Swiss cheese. Int. Dairy J. 2015;49:72–77. doi: 10.1016/j.idairyj.2015.04.010. [DOI] [Google Scholar]

- 48.Fox P.F., Wallace J.M. Formation of flavour compounds in cheese. Adv. Appl. Microbiol. 1997;45:17–85. doi: 10.1016/s0065-2164(08)70261-2. [DOI] [PubMed] [Google Scholar]

- 49.Collins Y.F., McSweeney P.L., Wilkinson M.G. Lipolysis and free fatty acid catabolism in cheese: A review of current knowledge. Int. Dairy J. 2003;13:841–866. doi: 10.1016/S0958-6946(03)00109-2. [DOI] [Google Scholar]

- 50.Fox P.F., Guinee T.P., Cogan T.M., McSweeney P.L.H. Fundamentals of Cheese Science. Springer; New York, NY, USA: 2017. [Google Scholar]

- 51.Downey W.K. Lipid oxidation as a source of off-flavour development during the storage of dairy products. J. Soc. Dairy Technol. 1969;22:154–161. doi: 10.1111/j.1471-0307.1969.tb01070.x. [DOI] [Google Scholar]

- 52.Langsrud T., Reinbold G.W. Flavor development and microbiology of Swiss cheese - A review. J. Milk Food Technol. 1974;37:26–41. doi: 10.4315/0022-2747-37.1.26. [DOI] [Google Scholar]

- 53.Kristensen D., Orlien V., Mortensen G., Brockhoff P., Skibsted L.H. Light-induced oxidation in sliced Havarti cheese packaged in modified atmosphere. Int. Dairy J. 2000;10:95–103. doi: 10.1016/S0958-6946(00)00028-5. [DOI] [Google Scholar]

- 54.Wold J.P., Jørgensen K., Lundby F. Nondestructive measurement of light-induced oxidation in dairy products by fluorescence spectroscopy and imaging. J. Dairy Sci. 2002;85:1693–1704. doi: 10.3168/jds.S0022-0302(02)74242-2. [DOI] [PubMed] [Google Scholar]

- 55.Dirinck P., De Winne A. Flavour characterisation and classification of cheeses by gas chromatographic-mass spectrometric profiling. J. Chromatogr. A. 1999;847:203–208. doi: 10.1016/S0021-9673(99)00193-4. [DOI] [Google Scholar]

- 56.Alewijn M., Smit B.A., Sliwinski E.L., Wouters J.M. The formation mechanism of lactones in Gouda cheese. Int. Dairy J. 2007;17:59–66. doi: 10.1016/j.idairyj.2006.01.002. [DOI] [Google Scholar]

- 57.Stadhouders J., Veringa H.A. Fat hydrolysis by lactic acid bacteria in cheese. Neth Milk Dairy J. 1973;27:77–91. [Google Scholar]

- 58.Liu S.-Q., Holland R., Crow V.L. Esters and their biosynthesis in fermented dairy products: A review. Int. Dairy J. 2004;14:923–945. doi: 10.1016/j.idairyj.2004.02.010. [DOI] [Google Scholar]

- 59.Chamba J.-F., Perreard E. Contribution of propionic acid bacteris to lipolyis of Emmental cheese. Lait. 2002;82:33–44. doi: 10.1051/lait:2001003. [DOI] [Google Scholar]

- 60.Thierry A., Collins Y.F., Abeijon Mukdsi M.C., McSweeney P.L., Wilkinson M.G., Spinnler H.E. Lipolysis and metabolism of fatty acids in cheese. In: McSweeney P.L., Fox P.F., Cotter P.D., Everetts D.W., editors. Cheese: Chemistry, Physics and Microbiology. Vol 1: General Aspects. 4th ed. Volume 1. Elsevier Ltd; London, UK: 2017. pp. 423–444. [Google Scholar]

- 61.Curtin A.C., McSweeney P.L. Catabolism of amino acids in cheese during ripening. In: Fox P.F., McSweeney P.L.T., Cogan M., Guinee T.P., editors. Cheese: Chemistry, Physics and Microbiology. Vol 1: General Aspects. 3rd ed. Elsevier; London, UK: 2004. pp. 435–454. [Google Scholar]

- 62.Marilley L., Casey M.G. Flavours of cheese products: Metabolic pathways, analytical tools and identification of producing strains. Int. J. Food Microbiol. 2004;90:139–159. doi: 10.1016/S0168-1605(03)00304-0. [DOI] [PubMed] [Google Scholar]

- 63.Harper W., Kocaoglu-Vurma N.A., Wick C., Elekes K., Langford V. Analysis of volatile sulfur compounds in Swiss cheese using selected ion flow tube mass spectrometry (SIFT-MS) In: Qian M.C., Fan X., Mahattanatawee K., editors. Volatile Sulfur Compounds in Food. Volume 1068. American Chemical Society; Washington, DC, USA: 2011. pp. 153–181. [Google Scholar]

- 64.Aston J.W., Douglas K. The production of volatile sulphur compounds in cheddar cheeses during accelerated ripening. Aust. J. Dairy Technol. 1983;38:66–70. [Google Scholar]

- 65.Urbach G. Contribution of lactic acid bacteria to flavour compound formation in dairy products. Int. Dairy J. 1995;5:877–903. doi: 10.1016/0958-6946(95)00037-2. [DOI] [Google Scholar]

- 66.Yvon M., Rijnen L. Cheese flavour formation by amino acid catabolism. Int. Dairy J. 2001;11:185–201. doi: 10.1016/S0958-6946(01)00049-8. [DOI] [Google Scholar]

- 67.Lawlor J.B., Delahunty C.M., Wilkinson M.G., Sheehan J. Swiss-type and Swiss-Cheddar hybrid-type cheeses: Effects of manufacture on sensory character and relationships between the sensory attributes and volatile compounds and gross compositional constituents. Int. J. Dairy Technol. 2003;56:39–51. doi: 10.1046/j.1471-0307.2003.00075.x. [DOI] [Google Scholar]

- 68.Calbert H.E., Price W.V. A study of the diacetyl in cheese. I. Diacetyl content and flavor of Cheddar cheese. J. Dairy Sci. 1949;32:515–520. doi: 10.3168/jds.S0022-0302(49)92073-1. [DOI] [Google Scholar]

- 69.Bradley R.L., Smukowski M. Butter. In: Clark S., Costello M., Drake M.A., Bodyfelt F., editors. The Sensory Evaluation of Dairy Products. Springer; New York, NY, USA: 2009. pp. 135–165. [Google Scholar]

- 70.Curioni P.M.G., Bosset J.O. Key odorants in various cheese types as determined by gas chromatography-olfactometry. Int. Dairy J. 2002;12:959–984. doi: 10.1016/S0958-6946(02)00124-3. [DOI] [Google Scholar]

- 71.Thierry A., Maillard M.-B., Richoux R., Lortal S. Ethyl ester formation is enhanced by ethanol addition in mini Swiss cheese with and without added propionibacteria. J. Agric. Food Chem. 2006;54:6819–6824. doi: 10.1021/jf060673m. [DOI] [PubMed] [Google Scholar]

- 72.Richoux R., Maillard M.-B., Kerjean J., Lortal S., Thierry A. Enhancement of ethyl ester and flavour formation in Swiss cheese by ethanol addition. Int. Dairy J. 2008;18:1140–1145. doi: 10.1016/j.idairyj.2008.05.011. [DOI] [Google Scholar]

- 73.Lawlor J.B., Delahunty C.M., Wilkinson M.G., Sheehan J. Relationships between the sensory characteristics, neutral volatile composition and gross composition of ten cheese varieties. Lait. 2001;81:487–507. doi: 10.1051/lait:2001147. [DOI] [Google Scholar]

- 74.Bills D.D., Morgan M.E., Libbey L.M., Day E.A. Identification of compounds responsible for fruity flavor defect of experimental Cheddar cheeses. J. Dairy Sci. 1965;48:1168–1173. doi: 10.3168/jds.S0022-0302(65)88421-1. [DOI] [PubMed] [Google Scholar]

- 75.Avsar Y.K., Karagul-Yuceer Y., Drake M.A., Singh T.K., Yoon Y., Cadwallader K.R. Characterization of nutty flavor in Cheddar cheese. J. Dairy Sci. 2004;87:1999–2010. doi: 10.3168/jds.S0022-0302(04)70017-X. [DOI] [PubMed] [Google Scholar]

- 76.Whetstine M.C., Drake M.A., Broadbent J.R., McMahon D. Enhanced nutty flavor formation in Cheddar cheese made with a malty Lactococcus lactis adjunct culture. J. Dairy Sci. 2006;89:3277–3284. doi: 10.3168/jds.S0022-0302(06)72364-5. [DOI] [PubMed] [Google Scholar]

- 77.Barbieri G., Bolzoni L., Careri M., Mangia A., Parolari G., Spagnoli S., Virgili R. Study of volatile fraction of Parmesan cheese. J. Agric. Food Chem. 1994;42:1170–1176. doi: 10.1021/jf00041a023. [DOI] [Google Scholar]

- 78.Preininger M., Warmke R., Grosch W. Identification of character impacts flavor compounds of Swiss cheese by sensory studies of models. Z Lebensm Unters Forsch. 1996;202:30–34. doi: 10.1007/BF01229680. [DOI] [Google Scholar]

- 79.Thierry A., Maillard M.-B., Le Quere J.-L. Dynamic headspace analysis of Emmental aqueous phase as a method to quantify changes in volatile flavour compounds during ripening. Int. Dairy J. 1999;9:453–463. doi: 10.1016/S0958-6946(99)00052-7. [DOI] [Google Scholar]

- 80.Rychlik M., Bosset J.O. Flavour and off-flavour compounds of Swiss Gruyere cheese. Evaluation of potent odorants. Int. Dairy J. 2001;11:895–901. doi: 10.1016/S0958-6946(01)00108-X. [DOI] [Google Scholar]

- 81.Rychlik M., Bosset J.O. Flavour and off-flavour compounds of Swiss Gruyere cheese. Identification of key odorants by quantitative instrumental and sensory studies. Int. Dairy J. 2001;11:903–910. doi: 10.1016/S0958-6946(01)00109-1. [DOI] [Google Scholar]

- 82.Qian M., Reineccius G.A. Identification of aroma compounds in Parmigianno Reggiano by gas chromatography-olfactometry. J. Dairy Sci. 2002;85:1362–1369. doi: 10.3168/jds.S0022-0302(02)74202-1. [DOI] [PubMed] [Google Scholar]

- 83.Andres A.I., Cava R., Ruiz J. Monitoring volatile compounds during dry-cured ham ripening by solid-phase microextraction coupled to a new direct-extraction device. J. Chromatogr. A. 2002;963:83–88. doi: 10.1016/S0021-9673(02)00139-5. [DOI] [PubMed] [Google Scholar]

- 84.Andres A.I., Ventanas S., Ventanas J., Cava R., Ruiz J. Physicochemical changes throughout the ripening of dry cured hams with different salt content and processing conditions. Eur. Food Res. Technol. 2005;221:30–35. doi: 10.1007/s00217-004-1115-y. [DOI] [Google Scholar]

- 85.Song H., Cadwallader K.R., Singh T.K. Odour-active compounds of Jinhua ham. Flavour Fragr. J. 2008;23:1–6. doi: 10.1002/ffj.1844. [DOI] [Google Scholar]

- 86.Bossett J.O., Gauch R. Comparison of the volatile flavour compounds of six European ‘AOC’ cheeses by using a new dynamic headspace GC-MS method. Int. Dairy J. 1993;3:359–377. doi: 10.1016/0958-6946(93)90023-S. [DOI] [Google Scholar]

- 87.Engels W.J., Dekker R., de Jong C., Neeter R., Visser S. A comparative study of volatile compounds in the water-soluble fraction of various types of ripened cheese. Int. Dairy J. 1997;7:255–263. doi: 10.1016/S0958-6946(97)00003-4. [DOI] [Google Scholar]