Abstract

Great progress in the field of piezoelectricity of (K,Na)NbO3 (KNN) lead-free ceramics, driven by emerging rhombohedral-tetragonal (R-T) phase boundary, has instigated research activity regarding elaborate controls of the phase boundary structure. Through phase-microstructure-property mapping in KNN ceramics doped with Bi-containing perovskite oxides, in this study we for the first time report the existence of a certain R-T phase boundary state by which to create maximum piezoelectric response in KNN systems. This phase boundary condition is usually comprised of approximately 15% R phase and 85% T phase, regardless of the choice of dopant material. Any deviation from this phase composition, either by inclusion of orthorhombic (O) phase or by enrichment of R phase, has a negative effect on the value of d33. These findings can provide useful guidance for chemical doping control associated with the type of phase boundary and the phase composition for advanced KNN-based materials.

Introduction

A great deal of effort is being expended to develop viable and competitive lead-free piezoelectric materials. Among potential materials, KNN-based ceramics are widely considered a great candidate owing to excellent piezoelectric coefficient d33 and high Curie temperature TC1–3. Benefitting from facilitated polarization rotations for a state in which plural structural phases coexist with negligible difference in free energy4, research concerning the construction of a phase boundary at/near room temperature has been extensively pursued during the last decade by means of chemical modification.

It is well accepted that the shift of two intrinsic polymorphic phase transitions of KNN, i.e., the rhombohedral (R)-orthorhombic (O) transition at −123 °C (TR-O) and the orthorhombic (O)-tetragonal (T) transition at 200 °C (TO-T), close to room temperature can be possible when KNN materials are doped with special ions (Li+, Sb5+ and Ta5+) or/and ABO3-type perovskite compounds with different valence states of A- and B-sites, leading to enhanced piezoelectric activity owing to the formation of a phase boundary at room temperature. Because of great improvements of d33 to more than 300 pC/N, keen attention has been paid to the construction of the O-T phase boundary, rather than to the R-O phase boundary5–9.

The surprisingly high room-temperature d33 values (360–570 pC/N) recently achieved by the novel R-T10–16 and R-O-T phase boundaries17–20 have triggered strong interest in developing a new KNN system. To create such phase boundaries, more complicated compositional manipulation by means of two or more additives is typically involved, such that the discrete TR-O and TO-T values concurrently move to room temperature. Not only the proper choice of dopant material but also the meticulous control of material compositions is found to be critical to constructing the phase boundary. The highest d33 value (570 pC/N) reported to date among the randomly-oriented KNN-based ceramics is achieved by constructing a R-T phase boundary by doping with Sb5+, BaZrO3 and (Bi,K)HfO310. Nevertheless, this marked progress in d33 is achieved at the expense of TC (which has a value less than 200 °C), similar to the case of conventional lead zirconium titanate [Pb(Zr,Ti)O3 (PZT)] ceramics.

Even though the current upsurge of research interest has focused on these emerging phase boundaries, little is known about the exact role of ferroelectric R, O, and T phases or their coexistence constructing a phase boundary in piezoelectricity. This is mainly due to the lack of evidence for an actual phase and its quantitative composition in the involved phase boundaries, as most structural considerations for phase boundaries have been made by qualitative methods of research, typically based on XRD peak analysis coupled with analysis of temperature-dependent dielectric constant behaviors.

In this study, we fully illuminate the fundamental roles of ferroelectric R, O, and T phases and their coexistence in the piezoelectric activity and Curie temperature (TC) of KNN-based ceramics. On this basis, a certain R-T phase boundary condition to maximize the piezoelectric response is ultimately proposed. With regard to the control of the phase boundary structure, a comprehensive chemical modification of KNN is conducted by doping Bi-containing perovskite oxides (BiMO3, M = A- or/and B-site elements); this modification allows us to prepare ferroelectric R, O, and T phases constructing a phase boundary in different ratios. Perovskite oxides including Bi3+ ion are of special interest in lead-free piezo-/ferroelectrics and multiferroic materials21, because the Bi3+ ion has a stereochemically active 6 s2 lone pair, which results in structural distortion of the prototypical cubic phase owing to ion-off centering in its perovskite compounds, as is the case for the Pb2+ ion. Accordingly, these materials are currently in general use as doping agents for KNN and, besides, the doping with these compounds as end members has been shown to be very useful to tune the intrinsic phase transition temperatures of KNN2,3. Among BiMO3 compounds, in this work we introduce Bi0.5(Li0.7Na0.2K0.1)0.5ZrO3 (BNKLZ), in which dopants of Bi3+ and Zr4+ ions are known to play effective roles in decreasing TO-T and increasing TR-O, respectively22,23. Additionally, perovskite oxides of BiScO3 (BS), (Bi0.5Na0.5)TiO3 (BNT), and BiGaO3 (BG) are doped for further control of the phase boundary structure. The constituent phases and their actual compositions in the induced phase boundaries are thoroughly evaluated via the Rietveld refinement method.

Results and Discussion

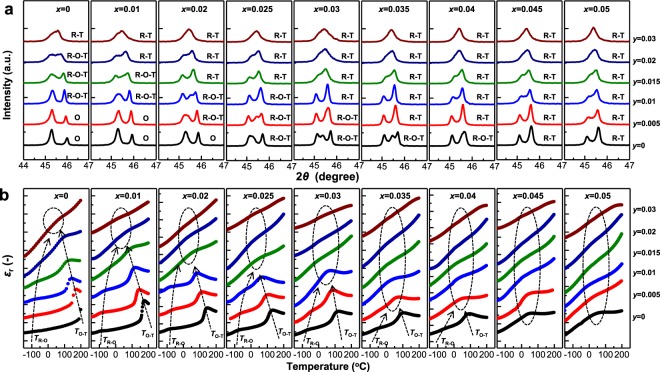

First, based on the room-temperature XRD patterns, it was confirmed that the (1 − x − y)KNN-xBNKLZ-yBS ternary ceramics (x = 0–0.05, y = 0–0.03) were a pure perovskite structure without second phases (Fig. S1). As a result, both the BNKLZ and BS dopants completely diffused into the KNN lattice, forming a stable solid solution in the investigated x and y ranges. To identify the structural evolution with the variation of x and y, Rietveld analysis was carried out for the corresponding XRD patterns. The analyzed phases are presented along with the amplified (2θ = 44–47°) XRD patterns (Fig. 1a). For ceramics with low x (0 ≤ x ≤ 0.02), the O phase initially appears and transforms via a triphasic R-O-T structure into a diphasic R-T structure, as y increases. For ceramics with 0.025 ≤ x ≤ 0.04, the transition of R-O-T into R-T occurs with an increase in y, accompanied by the shrinkage of the O phase. At higher x values (x ≥ 0.045), the O phase completely disappears, leaving only the coexisting R and T phases. In the R-T regions, gradual peak merging between tetragonal 002 and 200 reflections with increasing x and y values is likely induced by the increased content of R phase relative to T phase.

Figure 1.

(a) Amplified XRD patterns of (1 − x − y)KNN-xBNKLZ-yBS ternary ceramics (x = 0–0.05, y = 0–0.03) in the 2θ range of 44–47° measured at room temperature. The results of phase structure as identified by Rietveld refinements are presented in (a). (b) Temperature dependence of dielectric constant εr measured at 100 kHz in the temperature range of −150 to 200 °C. The dotted circles indicate regions corresponding to coexistence of R and T phases. The TR-O and TO-T converge at/near room temperature by doping with BNKLZ (x) and BS (y).

Phase transition temperatures and phase structures for ceramics with different x and y values were characterized by temperature-dependent dielectric constant (εr − T) measurement from −150 to 200 °C (Fig. 1b). Two dielectric anomalies involving the phase transitions of R-O and O-T are clearly separated in the absence of BNKLZ and BS. The measured TR-O and TO-T values are −120 and 200 °C, respectively, similar to the values in the literature for KNN; the O phase forms at room temperature. Both the transition peaks gradually approach the room-temperature region as the x and y values increase. Finally, the peaks converge to create a single and broad maximum peak centered at/near room temperature. The appearance of a single dielectric peak at room temperature indicates that, owing to the extinction of O phase, only the R and T phases coexist, eventually constructing the R-T phase boundary.

The critical dopant concentrations required to form a single dielectric peak at room temperature are as follows: x = 0 and y = 0.03, x = 0.01 and y = 0.02, x = 0.02 and y = 0.015, x = 0.03 and y = 0.01, x = 0.04 and y = 0.005, and x = 0.05 and y = 0. These critical x and y values are consistent with those corresponding to the formation of a pure R-T structure in the above XRD patterns (Fig. 1a). The decreased critical y values with increasing x (and vice versa) indicate that there are suitable doping levels (0.03–0.05 based on the sum of x and y values) to produce an R-T structure with the removal of the O phase. It can also be seen that, compared to doping of BNKLZ, the doping of BS results in more rapid change in the phase structure. Considering the elemental influence of the BiMO3 perovskites, this difference is believed to be due to the effect of different concentrations of Bi3+ ion between the BS and BNKLZ compounds, hinting at a strong contribution of Bi3+ to the formation of the phase boundary structure. The mole fractions of Bi3+ ion required for the coexistence of R and T phases are between 0.025–0.03. Further increase in x and y above these values can induce dielectric peak suppression, which can be correlated with XRD peak merging owing to increased R phase content (Fig. 1a). All the εr − T curves strongly support the structural evolution observed in the XRD patterns. Consequently, both the XRD and εr − T measurements confirm that the doping of BNKLZ and BS effectively promotes the shrinkage of the O phase, ultimately creating the R-T phase boundary near room temperature via the formation of a R-O-T structure. Similar phase evolution (O → R-O-T → R-T → R-rich) induced by chemical doping is observed in KNN ceramics doped with BNKZ and Sb11.

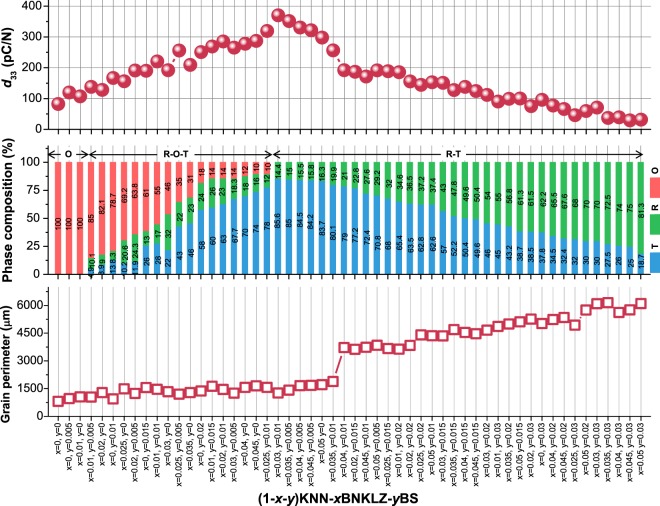

To manifest the role of each ferroelectric phase (R, O, and T phases) of a phase boundary in the piezoelectric performance, Rietveld refinement analysis is used to determine the quantitative compositions of constituent phases for the ceramics prepared as a function of the BNKLZ (x) and BS (y) contents (Fig. S2 and Table S1). Together with room-temperature measurements of d33, the values of grain perimeter length (or grain boundary length) are also estimated for the corresponding ceramics (Fig. S3). This enables mapping of the phase boundary structure (constituent phases and their composition), grain perimeter length (grain size) and piezoelectric d33 properties of the KNN-xBNKLZ-yBS ternary ceramics. Finally, a cross-correlation analysis of such maps establishes a correlation shown in Fig. 2.

Figure 2.

Correlation of piezoelectric coefficient d33 with phase composition and grain perimeter length results for (1 − x − y)KNN-xBNKLZ-yBS ternary ceramics (x = 0–0.05, y = 0–0.03). The quantitative composition data (R, O, and T phases) identified by Rietveld refinements are given in this figure.

The most significant finding from this correlation is that the involved phases and their compositions impact greatly on the d33 property. Given the well-established grain-size effect in lead-based piezoceramics, it should be noted that the d33 behavior does not tally with the grain size behavior: note that the variation of grain perimeter length is relatively small in the O and R-O-T regions, whereas the d33 trend shows a clear increase in the same structural regions. Meanwhile, the observed d33 behavior is strongly influenced by the nature of the phase and its quantitative composition. Overall, the d33 value increases with decreases in content of O and R phases, accompanied by simultaneous increase of the T phase. More importantly, the d33 value reaches its maximum (370.2 pC/N), when the phase boundary possesses 14.4% of R phase and 85.6% of T phase, without O phase.

The d33 behavior, directly affected by the phase structure, can be clearly seen in Fig. S4 (redrawn from Fig. 2), showing the concentration dependency of the dopants. The peaking behavior of d33 is evident; it is induced by the decrease in the content of O and R phases and the simultaneous increase in the T phase. To obtain a higher d33 value at the peak, Fig. S4 also implies that it is particularly important for a phase boundary to be controlled so as to have a phase composition close to 15% R phase and 85% T phase. This R-T phase boundary condition is not easily obtained, because the types and compositional progress of formed phases are sensitive to the dopant material and its concentration. Indeed, an optimal R-T phase composition (15% R phase-85% T phase) appears almost immediately after the O phase disappears during R-O-T phase coexistence, showing the necessity of precise doping control in the vicinity of the transition zone from R-O-T to R-T structure. In this work, only a few combinations of x and y values can lead to this phase boundary condition, with the highest d33 values between 320–370 pC/N. Namely, these values are x = 0.03 and y = 0.01, x = 0.035 and y = 0.005, x = 0.04 and y = 0.005, and x = 0.045 and y = 0.005 (0.04–0.05 based on total mole fractions of dopants). Consequently, the results shown in Figs 2 and S4 suggest the existence of a particular phase boundary condition that can lead to enhanced piezoelectric activity of KNN ceramics.

On the other hand, one can see in Fig. 2 that the grain perimeter length increases suddenly for the ceramic with x = 0.04 and y = 0.01. As has been shown for many KNN systems24–26, low levels of doping can promote grain growth via the formation of a liquid phase caused by low-melting-point Bi; however, at high doping levels the dopants can locate at the grain boundaries and, owing to their solubility limit, prohibit grain growth. Accordingly, the corresponding ceramic exhibits a sharp decrease in d33 because the increased grain boundaries generally constrain the domain wall motion. In terms of phase composition, the observed grain size reduction arises when the R phase content exceeds about 20%; this is followed by progressive reduction in the grain size with further increase in the R phase content. In addition to the grain size reduction, the increased R phase content is another contribution to the decline of d33 observed in the R-T region. This result directly shows the need for the determination of suitable doping levels to produce the optimum R-T phase composition. Otherwise, the phase boundary becomes enriched above the optimum level with R phase, accompanied by grain size reduction.

To confirm the existence of the optimum phase boundary in other doped KNN systems, different dopant materials of BNT and BG were added instead of BS to the KNN-BNKLZ system. Similar to the KNN-BNKLZ-BS system, both the KNN-xBNKLZ-yBNT and KNN-xBNKLZ-yBG systems showed peaking behavior of d33 induced by decrease in the content of O and R phases (Figs S5a,b). The measured d33 peak values are lower (260.1 pC/N for BNT doping and 302.7 pC/N for BG doping) than that obtained by BS doping. However, the highest piezoelectric response is likewise acquired from similar R-T phase compositions: 13.2% R phase and 86.8% T phase for BNT doping and 14% R phase and 86% T phase for BG doping. The corresponding mole fractions of the dopants (sum of the x and y values) are 0.045 and 0.047 for the BNT and BG dopings, respectively; these values are similar to those for BS doping. From the results shown in Figs 2 and S5, it is reasonable to assume that the R-T phase composition guaranteeing a maximum piezoelectric response is almost constant independent of the dopant material, although the obtainable d33 peak value may change depending on the dopant material. Furthermore, as observed for the KNN-0.03BNKLZ-0.02BNT ceramic (Fig. S6a), increased T phase content up to 93.3% in the R-T phase boundary at room temperature, owing to the drop of TR-T (i.e., rhombohedral-tetragonal transition) below room temperature, results in decreased d33 (Fig. S5a). This can be complementary evidence for the existence of the aforementioned optimum R-T phase composition, which might have been missed in previous studies on chemically doped KNN systems.

For KNN-based ceramics, piezoelectric sensitivity of a phase composition in coexisting phases has rarely been reported on, excluding a few studies. Ahn et al. first stressed the need to construct a T-rich O-T phase boundary for piezoelectric enhancement, although their structural evidence was inconclusive given the phase composition determination27. As for the R-T phase boundary, Lv et al. recently reported that a higher T phase content (up to about 80%) benefits the piezoelectric performance, which is induced by larger degrees of lattice distortion and induced internal stress produced by T phase rather than by R phase28. According to recent in-situ synchrotron XRD work, there is a close relationship between an electric-induced phase transition and the piezoelectricity of KNN ceramics13,29–31; the enhanced piezoelectricity achieved by a T-rich R-T phase boundary is attributed to the more positive role of the irreversible tetragonal-electric induced phase transition compared to the rhombohedral-electric induced phase transition with a certain degree of reversibility13. It has also been confirmed via Rayleigh analysis (Fig. S7a–c) that the intrinsic (lattice distortion or reversible domain wall vibration) and extrinsic (irreversible motion of domain wall or phase boundaries) contributions to piezoelectric activity are highest at optimum R-T phase composition. Our findings are reasonably in line with the previous investigations, providing further conclusive evidence for an ideal phase composition of the R-T phase boundary. Despite our efforts to elucidate the roles of the phase boundary structure, the physical mechanism of such a particular T-rich phase composition, related to the piezoelectric enhancement, will require further investigation.

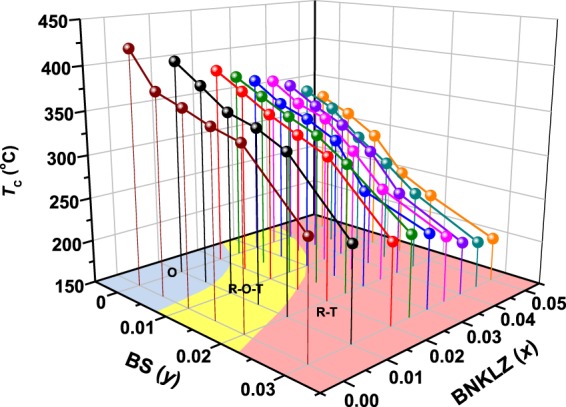

In Fig. 3, the values of Curie temperature (TC) determined from the dielectric peak positions (Fig. S8) are plotted as a function of both the x and y. A gradually decreasing trend in TC can be seen with the increase of the x and y values, indicating that the addition of BNKLZ and BS lowers TC. With increase of x and y up to 0.05 and 0.03, respectively, the TC value drops from 420 °C to 200 °C. Regarding the effects of the dopant, the decrease rate of TC is found to be higher for BS doping (34.7 ± 2.0 °C/0.01 mol) than for BNKLZ doping (15.8 ± 2.3 °C/0.01 mol). In the cases of BNT and BG doping, the decrease rates of TC are estimated to be 15.0 ± 1.7 °C/0.01 mol and 69.9 ± 7.4 °C/0.01 mol, respectively (data not shown here). As a result, the choice of dopant material can have a critical impact on the decrease rate of TC (BG > BS > BNKLZ ≈ BNT). It is also revealed that the dopant materials (e.g. BNKLZ and BNT), which are structurally similar to and have the same chemical valences of A- and B-sites, can have similar effects on TC, as compared to BS and BG. The decrease rates of TC observed for BNT or BNKLZ doping in this work are nearly comparable to those reported by previous studies19,32,33.

Figure 3.

Variation of Curie temperature TC as function of x and y values for (1 − x − y)KNN-xBNKLZ-yBS ternary ceramics (x = 0–0.05, y = 0–0.03).

It is further noted that the TC values for ceramics possessing near-optimum phase compositions (around 15% R and 85% T) remain almost unchanged with ΔTC ≈ 9 °C: ~332 °C for x = 0.03 and y = 0.01, ~335 °C for x = 0.035 and y = 0.005, ~331 °C for x = 0.04 and y = 0.005, and ~326 °C for x = 0.045 and y = 0.005. Despite differences of microstructure, grain size, and piezoelectric/ferroelectric properties among those samples, the observed steady TC characteristic can be attributed to structural similarities in phase structure, phase composition, tetragonality, and so on (Fig. S9). The present levels of d33 (~370 pC/N) and TC (~332 °C) values achieved by constructing the optimum R-T phase boundary condition are not only almost record-high compared with those of the recently developed polycrystalline KNN ceramics, which have high TC values above 300 °C (Fig. S10)2,3, but are also comparable to those of commercial ‘soft’ PZT ceramics34.

Even if the ceramics are controlled to have a near-optimum R-T phase composition, the maximum obtainable d33 value can be different (260–370 pC/N) depending on the applied dopant material as mentioned earlier. On the contrary, TC values for ceramics with near-optimum R-T phase composition produced at relatively modest doping levels of BiMO3 (0.04–0.05 in the mole fraction) not only remain at high levels of 332–343 °C, but are also almost unchanged for the three KNN ternary ceramic systems (Fig. S11). In consideration of the universal trade-off relationship between the two technologically important properties, d33 and TC, it is therefore promising that achieving an optimum R-T phase boundary structure by way of doping with Bi-containing perovskites (BiMO3) can benefit the balanced development of d33 and TC in KNN-based ceramics. With the great emphasis on the importance of the manipulation of the phase composition, the observed piezoelectric sensitivity to different dopant materials certainly encourages us to work concerning the construction of an optimum R-T phase boundary by employing other beneficial dopant materials.

Through phase-microstructure-property mapping in KNN piezoceramics doped with various useful Bi-containing perovskite oxides (BiMO3), this work proposes some novel ideas on doping control for developing new KNN-based ceramics as follows:

For doping-induced structural progress (O → R-O-T → R-T → R-rich), it is particularly important for the phase boundary structure to be optimized to have a particular phase composition of about 15% R and 85% T to maximize the piezoelectric response. As obtained at modest doping levels, this optimum R-T phase composition can also guarantee high TC values without serious doping-induced loss, enabling balanced development between the d33 and TC properties (d33 ~370 pC/N, TC ~332 °C in this work).

To obtain the optimum R-T phase composition (15% R-85% T), precise doping control is necessary in the vicinity of the transition zone from the R-O-T to R-T structure because this optimum condition usually arises immediately after the O phase disappears from the R-O-T structure during structural progress. Particular attention should be paid to doping control for dopant materials whose inputs have a sensitive influence on the type and compositional progress of the forming phases (for instance, BiGaO3).

When the phase boundary structure of an existing material system is R-O-T rather than R-T, there is more room to use additional dopant materials to improve a d33 peak value. When the ceramics possess an R-T phase boundary with more than 15% of R, however, doping control is no longer effective because further doping will certainly induce a R-richer phase boundary, accompanied by decreased grain sizes, with poor piezoelectric performance.

Methods

Materials

(1 − x − y)KNN-xBNKLZ-yBS (x = 0–0.05, y = 0–0.03) ternary ceramics including (1 − x − y) KNN-xBNKLZ-yBNT (x = 0.03, y = 0–0.04) and (1 − x − y)KNN-xBNKLZ-yBG (x = 0.045, y = 0–0.01) were prepared using the conventional solid-state powder method. The starting powders were K2CO3 (≥99.0%, 150 μm, Sigma-Aldrich), Na2CO3 (≥99.5%, 10 μm, Sigma-Aldrich), Li2CO3 (99.997%, 20 μm, Sigma-Aldrich), Nb2O5 (99.9%, 2 μm, Sigma-Aldrich), Bi2O3 (99.9%, 10 μm, Sigma-Aldrich), ZrO2 (99.0%, 5 μm, Sigma-Aldrich), Sc2O3 (≥99.9%, 10 μm, Sigma-Aldrich). TiO2 (≥99.9%, 5 μm, Sigma-Aldrich) and Ga2O3 (≥99.99%, 10 μm, Sigma-Aldrich). With an eye to practical applications, toxic Sb and high-cost Ta, although in common use and useful as doping elements for KNN, were avoided in this work.

Synthetic procedures

Stoichiometric powder mixtures with different x and y concentrations were homogenized in ethanol for 24 h using a roller mill machine operating at 70 rpm and dried at 120 °C for 24 h. All treatments of these powders, including weighing and drying, were carefully performed within a glove box filled with Ar gas. Calcination was then carried out at 850 °C for 6 h. The calcined powders were mixed with poly-vinyl alcohol (PVA) as a binder and axially compacted into disks 10 mm in diameter. After burning off the PVA at 650 °C, traditional pressureless sintering was carried out at 1100 °C for 3 h in air. The sintered ceramics were ground to a thickness of 1 mm. The resulting ceramics had similar densities of 4.25–4.32 g/cm3 (greater than 95% of the theoretical density), determined based on the Archimedes method.

Phase structure

The crystal structures of the unpoled samples were characterized by an X-ray diffractometer (XRD; D/Max-2500; Rigaku, Tokyo, Japan) using Cu Kα radiation at a power of 40 kV and 15 mA and at a scan speed of 1°/min. Rietveld refinement of XRD patterns was performed to accurately determine the phases and their quantitative compositions using Rigaku’s PDXL software with the Whole Pattern Powder Fitting (WPPF) method, connected to Inorganic Crystal Structure Database (ICSD; FIZ Karlsruhe, Germany). The initial models used for refinement were three KNbO3 crystal structures, i.e., orthorhombic (Amm2; JCPDS 01–071–0946; ICSD code 9533), rhombohedral (R3m; JCPDS 01–071–0947; ICSD code 9534), and tetragonal (P4mm; JCPDS 01–071–0948; ICSD code 9535); their crystal structure parameters were acquired from the ICSD. The refinements were carried out by checking the fitting quality of the powder patterns by means of two parameters, i.e., the goodness-of-fit indicator S and the reliability factor Rwp. Here, the low Rwp of less than 10% as well as the S value close to 1 ensure the high reliability of the refinement results.

Grain structure

The morphology of the sintered samples was studied using a field-emission scanning electron microscope (FE SEM; Sirion; FEI, Eindhoven, Netherlands) with an operating voltage of 20 kV equipped with an energy-dispersive X-ray spectrometer (EDXS). Since the grain boundaries generally play a role of hindering the domain wall motion, the values of grain perimeter length (or grain boundary length), together with the grain size, were estimated to investigate the effect of the grain boundary area on the piezoelectric response for all sintered ceramics. The quantitative measurements were carried out using automatic image analysis software (Matrox imaging library 10) for SEM images taken from each sample: number of analyzed images = 4–8 per sample, measurement area per image = 19.1 × 25.6 μm, total number of grains = about 400 to several thousands.

Electrical characterization

For the electrical measurements of the sintered ceramics, both sides of the disks were polished and painted with a silver paste, after which disks were fired at 650 °C for 10 min. The samples were then poled in silicon oil at room temperature. After optimization through pre-tests of poling over time and in an electric field, poling field and time were set at 40 kV/mm and 10 min, respectively. Dielectric constant εr at low temperatures ranging from −150 to 200 °C was measured for the unpoled samples using an impedance analyzer (HP 4294 A; Agilent; USA) at a frequency of 100 kHz. Measurements between 30–500 °C were also conducted using an impedance analyzer (SI 1260; Solartron; Farnborough, England) combined with a dielectric interface (SI 1287; Solartron; Farnborough, England). Hence, the effects of the addition of BiMO3 dopants on the phase transition temperatures (TR-O, TO-T and TC) of KNN were fully characterized. The longitudinal piezoelectric coefficients (d33) were measured for the poled samples at room temperature using a piezo-d33 meter (ZJ-6B; IACAS; Beijing, China).

Supplementary information

Acknowledgements

This research was supported by the Korean Nuclear R&D program organized by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP) (NRF-2017M2A8A4017220) and by the Korea Atomic Energy Research Institute (KAERI) R&D program.

Author Contributions

M.L. and S.Y. contributed equally to this work. M.L. designed the work and interpreted the phase composition data by Rietveld refinement. S.Y. prepared the KNN samples and characterized piezo-/ferroelectric properties. J.P. performed XRD and SEM experiments of the KNN samples. G.L. organized the work and discussed the collected data. M.L. and G.L. analyzed the whole results and wrote the paper. All authors have given approval to the final version of the manuscript.

Competing Interests

The authors declare no competing interests.

Footnotes

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Min-Ku Lee and Sun-A Yang contributed equally.

Supplementary information

Supplementary information accompanies this paper at 10.1038/s41598-019-40943-6.

References

- 1.Saito Y, et al. Lead-free piezoelectrics. Nature. 2004;432:84–87. doi: 10.1038/nature03028. [DOI] [PubMed] [Google Scholar]

- 2.Wu J, Xiao D, Zhu J. Potassium-sodium niobate lead-free piezoelectric materials: past, present, and future of phase boundaries. Chem. Rev. 2015;115:2559–2595. doi: 10.1021/cr5006809. [DOI] [PubMed] [Google Scholar]

- 3.Wu J, Xiao D, Zhu J. Potassium-sodium niobate lead-free piezoelectric ceramics: recent advances and perspectives. J. Mater. Sci.: Mater. Electron. 2015;26:9297–9308. [Google Scholar]

- 4.Damjanovic D. Ferroelectric, dielectric and piezoelectric properties of ferroelectric thin films and ceramics. Rep. Prog. Phys. 1998;61:1267–1324. doi: 10.1088/0034-4885/61/9/002. [DOI] [Google Scholar]

- 5.Zheng T, Wu W, Wu J, Zhu J, Xiao D. Balanced development of piezoelectricity, Curie temperature, and temperature stability in potassium-sodium nobate lead-free ceramics. J. Mater. Chem. C. 2016;4:9779–9787. doi: 10.1039/C6TC03389J. [DOI] [Google Scholar]

- 6.Liu Q, Zhu FY, Zhang BP, Li L, Li JF. Dielectric and ferroelectric properties of AgSbO3-modified (Li,K,Na)(Nb,Ta)O3 lead-free piezoceramics. J. Mater. Sci.: Mater. Electron. 2015;26:9309–9315. [Google Scholar]

- 7.Wang K, et al. Temperature-insensitive (K,Na)NbO3-based lead-free piezoactuator ceramics. Adv. Func. Mater. 2013;23:4079–4086. doi: 10.1002/adfm.201203754. [DOI] [Google Scholar]

- 8.Wang K, Li JF. Domain engineering of lead-free Li-modified (K,Na)NbO3 polycrtstals with highly enhanced piezoelectricity. Adv. Func. Mater. 2010;20:1924–1929. doi: 10.1002/adfm.201000284. [DOI] [Google Scholar]

- 9.Liu Q, et al. Further enhancing piezoelectic properties by adding MnO2 in AgSbO3-modified (Li,K,Na)(Nb,Ta)O3 lead-free piezoceramics. J. Am. Ceram. Soc. 2016;99:3670–3676. doi: 10.1111/jace.14412. [DOI] [Google Scholar]

- 10.Xu K, et al. Superior piezoelectric properties in potassium-sodium niobate lead-free ceramics. Adv. Mater. 2016;28:8519–8523. doi: 10.1002/adma.201601859. [DOI] [PubMed] [Google Scholar]

- 11.Wang X, et al. Giant piezoelectricity in potassium-sodium niobate lead-free ceramics. J. Am. Chem. Soc. 2014;136:2905–2910. doi: 10.1021/ja500076h. [DOI] [PubMed] [Google Scholar]

- 12.Wu B, et al. Giant piezoelectricity and high Curie temperature in nanostructured alkali niobate lead-free piezoceramics through phase coexistence. J. Am. Chem. Soc. 2016;138:15459–15464. doi: 10.1021/jacs.6b09024. [DOI] [PubMed] [Google Scholar]

- 13.Wang X, et al. Characteristics of giant piezoelectricity around the rhombohedral-tetragonal phase boundary in (K,Na)NbO3-based ceramics with different additives. J. Mater. Chem. A. 2015;3:15951–15961. doi: 10.1039/C5TA03511B. [DOI] [Google Scholar]

- 14.Wang X, et al. Large d33 in (K,Na)(Nb,Ta,Sb)O3-(Bi,Na,K)ZrO3 lead-free ceramics. J. Mater. Chem. A. 2014;2:4122–4126. doi: 10.1039/c3ta15075e. [DOI] [Google Scholar]

- 15.Zheng T, et al. Potassium-sodium niobate lead-free ceramics: modified strain as well as piezoelectricity. J. Mater. Chem. A. 2015;3:1868–1874. doi: 10.1039/C4TA05423G. [DOI] [Google Scholar]

- 16.Zheng T, Wu J. Enhanced piezoelectricity over a wide sintering temperature (400–1050 °C) range in potassium sodium niobate-based ceramics by two step sintering. J. Mater. Chem. A. 2015;3:6772–6780. doi: 10.1039/C5TA00732A. [DOI] [Google Scholar]

- 17.Lv X, Wu J, Yang S, Xiao D, Zhu J. Identification of phase boundaries and electrical properties in ternary potassium-sodium niobate-based ceramics. ACS Appl. Mater. Interfaces. 2016;8:18943–18953. doi: 10.1021/acsami.6b04288. [DOI] [PubMed] [Google Scholar]

- 18.Xing J, et al. Structure and electrical properties of (0.965-x)(K0.48Na0.52)NbO3-xBiGaO3-0.035(Bi0.5Na0.5)ZrO3 piezoelectric ceramics. RSC Adv. 2016;6:57210–57216. doi: 10.1039/C6RA10227A. [DOI] [Google Scholar]

- 19.Chen B, Ma J, Wu S, Wu B. Phase structure and electrical properties of (1-x)K0.48Na0.52NbO3-xBi0.46La0.04(Na0.82K0.18)0.5ZrO3 lead-free piezoceramics. J. Mater. Sci.: Mater. Electron. 2017;28:3299–3308. [Google Scholar]

- 20.Lv X, et al. (1-x)(K0.48Na0.52)(Nb0.95-y-zTazSby)O3-xBi0.5(Na0.82K0.18)0.5ZrO3 lead-free ceramics: composition dependence of the phase boundaries and electrical properties. Dalton Trans. 2015;44:4440–4448. doi: 10.1039/C4DT04038D. [DOI] [PubMed] [Google Scholar]

- 21.Rödel J, Jo W, Seifert KTP, Anton E-M, Granzow T. Perspective on the development of lead-free piezoceramics. J. Am. Ceram. Soc. 2009;92:1153–1177. doi: 10.1111/j.1551-2916.2009.03061.x. [DOI] [Google Scholar]

- 22.Wang H, Wu J, Cheng X, Xiao D, Zhu J. New phase boundary and piezoelectric properties in (K,Na)NbO3 based ceramics. J. Alloys Compd. 2014;585:748–752. doi: 10.1016/j.jallcom.2013.10.016. [DOI] [Google Scholar]

- 23.Du H, Liu D, Tang F, Zhu D, Zhou W. Microstructure, piezoelectric, and ferroelectric properties of Bi2O3-added (K0.5Na0.5)NbO3 lead-free ceramics. J. Am. Ceram. Soc. 2007;90:2824–2829. doi: 10.1111/j.1551-2916.2007.01846.x. [DOI] [Google Scholar]

- 24.Cheng X, et al. Giant d33 in (K,Na)(Nb,Sb)O3-(Bi,Na,K, Li)ZrO3 based lead-free piezoelectrics with high TC. Appl. Phys. Lett. 2013;103:052906. doi: 10.1063/1.4817517. [DOI] [Google Scholar]

- 25.Cheng X, et al. Dielectric, ferroelectric, and piezoelectric properties in potassium sodium niobate ceramics with rhombohedral-orthorhombic and orthorhombic-tetragonal phaseboundaries. Ceram. Int. 2014;40:5771–5779. doi: 10.1016/j.ceramint.2013.11.016. [DOI] [Google Scholar]

- 26.Malic B, Bernard J, Bencan A, Kosec M. Influence of zirconia addition on the microstructure of K0.5Na0.5NbO3 ceramics. J. Eur. Ceram. Soc. 2008;28:1191–1196. doi: 10.1016/j.jeurceramsoc.2007.11.004. [DOI] [Google Scholar]

- 27.Ahn CW, et al. Correlation between phase transitions and piezoelectric properties in lead-free (K,Na,Li)NbO3-BaTiO3 ceramics. Jpn. J. Appl. Phys. 2008;47:8880–8883. doi: 10.1143/JJAP.47.8880. [DOI] [Google Scholar]

- 28.Lv X, Wu J, Zhu J, Xiao D, Zhang X. A new method to improve the electrical properties of KNN-based ceramics: tailoring phase fraction. J. Eur. Ceram. Soc. 2018;38:85–94. doi: 10.1016/j.jeurceramsoc.2017.08.016. [DOI] [Google Scholar]

- 29.Fu J, et al. Electric field induced intermediate phase and polarization rotation path in alkaline niobate based piezoceramics close to the rhombohedral and tetragonal phase boundary. Appl. Phys. Lett. 2012;100:122902. doi: 10.1063/1.3696071. [DOI] [Google Scholar]

- 30.Iamsasri T, et al. Electric field-induced phase transitions in Li-modified Na0.5K0.5NbO3 at the polymorphic phase boundary. J. Appl. Phys. 2015;117:024101. doi: 10.1063/1.4905613. [DOI] [Google Scholar]

- 31.Fu J, Zuo R, Gao X. Electric field induced monoclinic phase in (Na0.52K0.48)(Nb1-ySby)O3 ceramics close to the rhombohedral-orthorhombic polymorphic phase boundary. Appl. Phys. Lett. 2013;103:182907. doi: 10.1063/1.4828713. [DOI] [Google Scholar]

- 32.Cheng X, et al. Lead-free piezoelectric ceramics based on (0.97−x)K0.48Na0.52NbO3-0.03Bi0.5(Na0.7K0.2Li0.1)0.5ZrO3-xB0.5Na0.5TiO3 ternary system. J. Appl. Phys. 2013;114:124107. doi: 10.1063/1.4822316. [DOI] [Google Scholar]

- 33.Cheng X, et al. Rhombohedral-tetragonal phase coexistence and piezoelectric properties based on potassium-sodium niobate ternary system. J. Alloys Compd. 2014;610:86–91. doi: 10.1016/j.jallcom.2014.04.194. [DOI] [Google Scholar]

- 34.Shrout TR, Zhang SJ. Lead-free piezoelectric ceramics: Alternatives for PZT? J. Electroceram. 2007;19:111–124. doi: 10.1007/s10832-007-9047-0. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.