Abstract

Collagen, the most abundant extracellular matrix protein in animal kingdom belongs to a family of fibrous proteins, which transfer load in tissues and which provide a highly biocompatible environment for cells. This high biocompatibility makes collagen a perfect biomaterial for implantable medical products and scaffolds for in vitro testing systems. To manufacture collagen based solutions, porous sponges, membranes and threads for surgical and dental purposes or cell culture matrices, collagen rich tissues as skin and tendon of mammals are intensively processed by physical and chemical means. Other tissues such as pericardium and intestine are more gently decellularized while maintaining their complex collagenous architectures. Tissue processing technologies are organized as a series of steps, which are combined in different ways to manufacture structurally versatile materials with varying properties in strength, stability against temperature and enzymatic degradation and cellular response. Complex structures are achieved by combined technologies. Different drying techniques are performed with sterilisation steps and the preparation of porous structures simultaneously. Chemical crosslinking is combined with casting steps as spinning, moulding or additive manufacturing techniques. Important progress is expected by using collagen based bio-inks, which can be formed into 3D structures and combined with live cells. This review will give an overview of the technological principles of processing collagen rich tissues down to collagen hydrolysates and the methods to rebuild differently shaped products. The effects of the processing steps on the final materials properties are discussed especially with regard to the thermal and the physical properties and the susceptibility to enzymatic degradation. These properties are key features for biological and clinical application, handling and metabolization.

Introduction

More than 2000 years ago early surgeons already used collagen-based materials as skin or intestine to close wounds and for reconstructive surgery. However, only the past 50 years brought a more frequent use of collagen as medical product because technologies of intensive cleaning and sterilization procedures were developed [1]. Applications among others are wound closure, treatment of burns, hemostasis, hernia repair, repair of bone and cartilage defects, as well as various dental applications including guided bone repair [2–4].

In tissues collagen is the scaffold material which provides an optimal environment for physiologically highly active cells and cellular components. Therefore, recent developments focus on the decellularization of organ parts or whole organs, maintaining the tissue architecture followed by recellularization to overcome the high need of organs for organ transplantation. Important progress is also expected by using collagen-based bioinks which can be combined with live cells and which are formed into 3D structures.

During the last decades many reviews summarized the different applications of collagen as biomaterial because of this important function of collagen as structure forming material [2, 3, 5–9]. It is used as drug delivery system [4, 10, 11], as matrices for tissue engineering [12, 13], topical hemostyptics [14], for soft tissue repair [15], and as membrane for diverse applications [16, 17]. Recent contributions reviewed technological aspects but mainly for organ and tissue decellularization [18–25].

This review will give an overview about the principles of processing collagen-rich tissues down to collagen hydrolysates, the rebuilding of differently shaped materials and the effects of the processing steps on the final materials properties especially the thermal and the physical properties and the susceptibility to enzymatic degradation. These properties are key features for clinical handling and degradation behaviour. This is all the more important with regard to the technological progress in organ decellularization, that aims to save structures and additive manufacturing, where new structures are rebuilt from smaller units [26].

Collagen processing technologies are organized as a series of steps. Several steps are combined in different ways to manufacture structurally versatile materials with varying properties with regard to shape, mechanics, physiological behaviour and handling. Processing may either maintain the collagen structure or affect it by intensive chemical, mechanical and physical treatment. Reassembly of fibres and shaping allows to generate new structures. The different processing steps to treat tissues are summarized to discuss the effects of these steps on the final properties and to serve as a playground for a plethora of different ECM derived structures which can be used in medical and pharmaceutical applications in solid or liquid form as well as to manufacture 2D or 3D structures.

Collagen raw materials and sources for medical uses

Many collagen-rich tissues are used as raw materials to manufacture medical products for surgical purposes e.g. as soft tissue augmentation to support wound healing, in dental applications and other applications. Typically skin, pericard, small intestine, urinary bladder and tendon are applied [27] but also many other tissues as bone, fasica lata, heart valves etc. Beside tendon and bone all of these tissues can be described as stratified compositions of fibrous proteins, associated with different non-fibrous substances, cells and cellular components. According to their function the tissues are composed of layers. These layers can take over mechanical forces or they act as highly metabolic part of the tissue with high cell load. The metabolic layers show membraneous activity responsible to separate or transport chemical molecules or cellular components.

Biomedical companies manufacture implants from those tissues from human or animal sources. The tissues are purified and often processed in many ways. Table 1 summarizes selected products differing in structure, crosslinking technology, tissue source and species and their sterilization technique. More comprehensive collections are published by other authors [27–31]. Recent investigations described principles to decellularize organs and organ parts, which shall be recellularized, but such products have not yet come into the market. In the following sections histological images of the most common tissues, which require a more intensive technological treatment to prepare medical products, are described as well as the parts of the tissues which are saved during the process.

Table 1.

Selected marketed collagen products

| Company | Product | Raw Material | Species | CL | Additive | Form | Sterilisation | Indication | |

|---|---|---|---|---|---|---|---|---|---|

| Geistlich Biomaterials | Biogide | Dermis | Porcine | – | – | Membrane | 2b | Gamma | Dental |

| Zimmerdental | Biomend | Tendon | Bovine | GA | – | Membrane | 2 | Ethylenoxide | Dental |

| Arthrothek | CuffPatch | SIS | Porcine | + | – | Hydrated sheet | 1 | Soft tissue augmentation | |

| Synovis Surgical Baxter | Dura-Guard | Pericardium | Bovine | GA | – | Hydrated sheet | 1 | Aseptic prod | Spinal and cranial repaeir |

| DIZG | Epiflex | Dermis | Human | – | – | Membrane | 1 | Aseptic prod | Dermis replacement; soft tissue reconstruction |

| Gelita Medical | GelitaSpon | Gelatin | Bov or porc | FA | – | Sponge | 3 | Gamma | Hemostasis |

| Resorba | Gentacoll | Tendon | Equine | – | Antibiotic | Sponge | Ethylenoxide | Hemostasis, dental | |

| Medskin solutions Dr. Suwelack | Matriderm | Dermis | Bovine | DHT | Elastin | Membrane | 2 | Gamma | Burns IIb–III; trauma, reconstructive and surgical wounds |

| Medskin solutions Dr. Suwelack | Matristypt | Dermis | Bovine | DHT | – | Membrane | 2 | Gamma | Hemostasis |

| MBP | MB-collagen | Dermis | Porcine | – | – | Membrane | 2 | Gamma | Burns IIb–III; trauma, reconstructive and surgical wounds |

| Cook Biotech | Oasis | SIS | Porcine | – | – | Membrane | 1 | Ethylenoxide | Burns IIb–III; trauma, reconstructive and surgical wounds |

| Resorba | Parasorb Cone | Tendon | Equine | – | – | Sponge | 2 | Ethylenoxide | Hemostasis, dental |

| Covidien | Permacol | Dermis | Porcine | HMDI | – | Membrane | 1 | Gamma | Soft tissue repair |

| Lifecell Corp. | Strattice | Dermis | Porcine | – | – | Membrane | 1 | eBeam | Hernia and abdominal wall repair |

| MBP | Surgicoll | Dermis | Porcine | – | – | Sponge | 2 | Gamma | Hemostasis |

| C.R. Bard | XenMatrix | Dermis | Porcine | – | Antibiotic | Membrane | 1 | eBeam | Soft tissue and hernia repair |

| MBP | Xenoderm | Dermis | Porcine | – | – | Membrane | 1 | Gamma | Soft tissue and hernia repair |

| MBP | Xenoguard | Pericardium | Porcine | – | – | Membrane | 1 | ETO | Soft tissue reconstruction |

| Zyderm | Dermis | Bovine | – | – | Solution | 3 | Filtration | Soft tissue augmentation in plastic surgery |

The products differ in structure, crosslinking degree and technology, tissue and species source, and its indication and additives [16, 28–31]

GA, glutaraldehyde; DHT, dehydrothermal treatment; HMDI, hexamethylendiisocyanate; FA, formaldehyde; 1, intact tissue structure; 2, suspension; 2b, combination of 1 and 2; 3, solution

Skin

The skin of vertebrates encloses the whole body and shields it against environmental impact. For long time skin has been discussed as largest organ [32, 33] but neither by weight nor by area this seems to be true [34]. However, skin is an organ which can be easily transferred into final materials with large area.

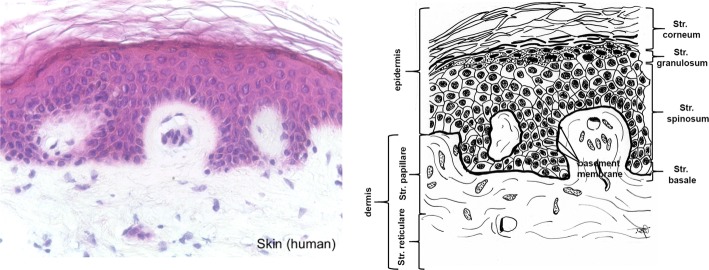

In mammals the skin consists of the three layers epidermis, dermis and subcutis (Fig. 1). Thick, highly keratinized skin with 12–20 cell epidermal layers is found in the areas of the body with high tear (palms, soles), thin skin (2–4 cell layers) covers the rest of the body. The epidermis of thick skin is subdivided into four layers: stratum basale, stratum spinosum, stratum granulosum, and stratum corneum. The basal layer (stratum basale or germinativum) consists of mitotically active keratinocytes on a basement membrane which consists of collagen type IV adjacent to the dermis [35]. The other layers consist of cells in different states of transformation. As the most external layer the stratum corneum consists of cells without nucleus which are keratinized and which desquamate. The colour of the skin is caused by pigments produced by melanocytes originating from the neural crest, and which are found in the basal layer [32, 36].

Fig. 1.

Histological cut (left) of human skin and corresponding drawing. Epidermal layers and the cellular components of the dermis are removed during processing, while saving the structural components of the dermis. (All histological pictures and drawings were kindly supplied by Gundula Schulze-Tanzil, Institut für Anatomie, Paracelsus Medizinische Privatuniversität (PMU), Salzburg and Nürnberg, Nürnberg, Germany)

The dermis is subclassed into papillary layer (Str. papillare) and reticulary layer (Str. reticulare). The papillary layer forms papillae at the dermal–epidermal junction zone. These papillae increase the surface of the junction zone and improve adhesion of the layers. Hair follicles extend into the papillary layer. They are faced with epidermis and contain the hair root with the bulb. Bulb cells proliferate to build the hair.

While the epidermis consists of the structure protein keratin, the dermis is mainly built from collagen fibres which partly co-organize with elastin fibers [37]. Furthermore, the fibrous tissue contains a mixture of diverse macromolecules (hyaluronic acid, dermatane sulfate, chondroitin sulfate, fibronectin, tenascin, epimorphin and others), which bind high amounts of water, filling the space between the fibres [33].

The subcutis contains a mixture of collagen fibres and associated components, especially elastin and fat tissue, which can be a layer beneath the skin in well nourished animals, but which can also be organized in form of papillae which provide an insight into the dermis (e.g. porcine skin). The collagen fibres of the subcutis interweave with the collagen fibres in the dermis. The skin also contains diverse glands (sweat, odour, sebaceous), muscles (e.g. musculus attractor pili), nerves, receptors and cells.

The fibre orientation in skin is in homogenous regarding the area, the cross-sections and between skins of different animals of the same species [38–40]. The skin shows an internal tension which is observed along the Langer lines (± 10°) and which is caused by a passive pretension of the collagen fibres. The most homogenous part with lowest tension is found in the central region which covers the loins. The ventral zones and the extremities show higher pre-stress and are much more elastic [41, 42]. Furthermore, the mechanical constitution of the skin depends on species and age and presumably other factors [40–42]. Purification procedures usually remove epidermis and subcutis. Depending on the thickness of the raw material the dermis can be split into a grain part, which contains the papillary layer and a part which consists mainly of the reticularis.

Pericardium

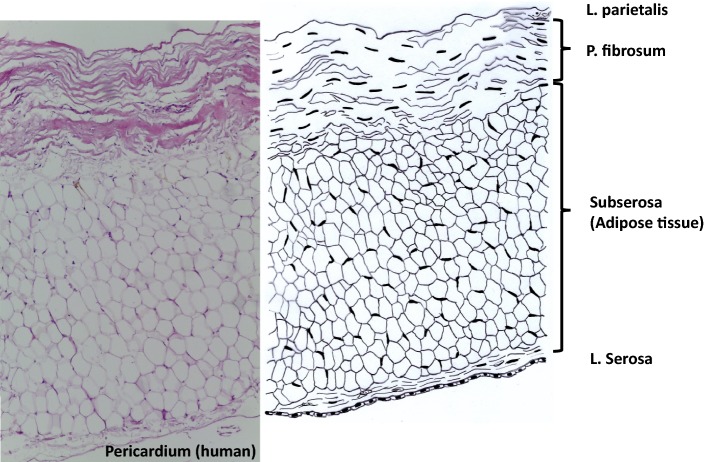

The pericardium completely covers the heart in form of a sac. It consists of three layers and additionally surrounding adipose tissue and a serosa covering the latter (Fig. 2). The Pericardium fibrosum is responsible to prevent the heart from overexpansion and the P. serosum is further divided in two layers. The Lamina parietalis is tightly adhered to the P. fibrosum, the Lamina visceralis (not shown) is separated from the other lamina by a slippy liquid layer and covers the myocardium [43]. P. fibrosum and L. visceralis consist of collagen and elastic fibers [44]. The collagen fibers especially in the P. fibrosum are highly oriented. The mechanical stability is therefore not uniformly distributed, but the tissue behaves anisotropic [45]. Decellularization removes the serosae and adipose tissue [46].

Fig. 2.

Histological cut (left) of human pericardium and corresponding drawing. During processing only the P. fibrosa is saved

Intestine

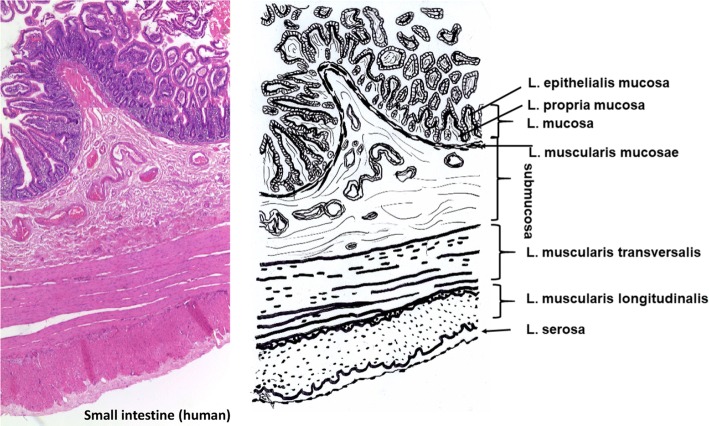

Small intestine constists of five layers beginning with the lumen (Fig. 3): Laminae mucosae (3 laminae), submucosa, L. muscularis transversalis, L. muscularis longitudinalis and L. serosae [47]. During decellularization only the submucosa and parts of the muscularis transversalis persist. The other layers are completely removed.

Fig. 3.

Histological cut (left) of human small intestine and corresponding drawing. Processing saves submucosa and parts of muscularis transversalis. Mucosa, muscularis longitudinalis and serosa are removed

Urinary bladder

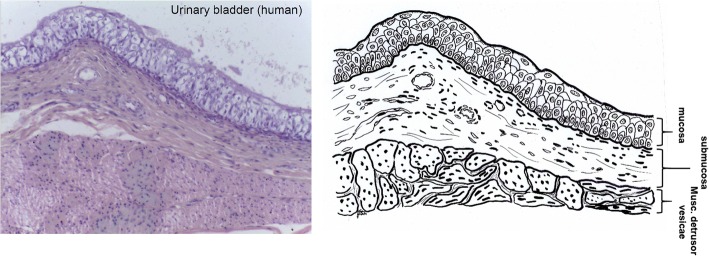

Similar to intestine, the urinary bladder tissue is formed of Laminae mucosae, submucosa, three muscularis layers, and L. serosa (not shown) as part of the peritoneum [47] (Fig. 4). During purification the connective tissue (submucosa) is saved while non collagenous parts are separated by mechanical and chemical means.

Fig. 4.

Histological cut (left) of human urinary bladder and corresponding drawing. Processing saves only the submucosa

Tendon

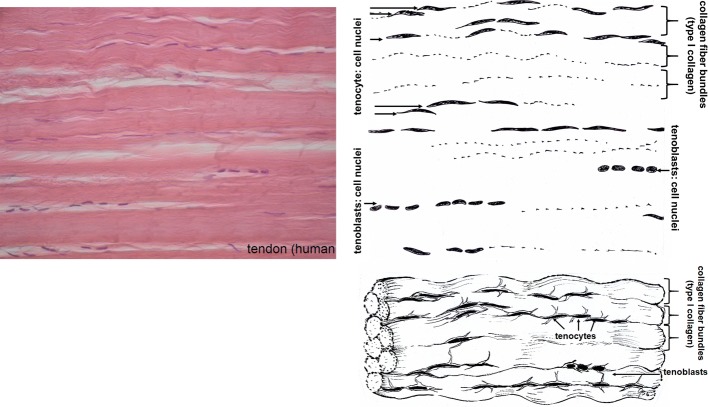

Tendons (Fig. 5) transfer mechanical load from muscle to bone. Therefore, tendons have to withstand high mechanical forces in the direction of pull. They are white coloured and show a fibrous texture with a low number of cells (tendocytes, tendoblasts) between the fibre bundles. Tendons are surrounded by an epitenon and diverse structures as retinaculae (cartilage covered floors), pulleys and sheaths which keep them in their anatomically correct position in rest and under load. Number and shape of these surrounding structures are different for different tendons e.g. Achilles tendon or the tendons of fingers and feet. Synovial sheath, bursae and paratenon are partly fibrous structures which reduce friction between tendon and their bony environment. The epitenon, a collagenous structure of thin transversal, oblique, and longitudinal fibrils of 8–10 nm each encloses one whole tendon. The endotenon covers fibre bundles, holds them together and enables mutual gliding of the bundles. It consists of reticular connective tissue with a typical crisscross pattern and glucosaminoglycans which are highly hydrated. Endotenon is interspersed with blood vessels, nerves and lymphatics to provide the underlying collagen tissue.

Fig. 5.

Histological cut (left) of human tendon and corresponding drawing. The fibre bundles are covered by an endotenon layer, the complete tendon by the epitenon (not visible). During processing the complete cellular components (tendoblasts and tendocytes) have to be removed

The collagen fibres in the fascicles of tendon are crimped and oriented longitudinally, but also transversally and horizontally, crossing each other. Therefore, load can be buffered in longitudinal direction, but to some extent also transversal, horizontal and rotational moves are transferred. Defining an exact size of the different levels of the structure of tendon (fibril, fibre, subfascicle, fascicle) is not reasonable because these sizes vary depending e.g. on anatomy, species and maybe individual variation [48–50].

Recombinant sources

Currently collagen for biomaterials is extracted from human donators or xenogenic sources, mostly bovine, porcine or equine and it remains the gold standard to obtain collagen from these biological sources. Collagen and collagen peptides have also been produced from transgenic organisms, such as E. coli, yeast, mammalian cell culture, insects, and also plants [11, 51, 52]. The low yields, which correlate with high prices, limit the use and explain why such sources have not yet been established as alternative. Secondly, posttranslational modification such as hydroxylation of Pro and Lys in the right amount, glycosylation and the heterotrimeric compositions are challenges which have not completely been solved successfully [53, 54]. Therefore, it is obvious that animal sources remain the major source to manufacture collagen-based biomaterials for the next years.

Collagen composition, formation, structure, stability and properties

The collagens comprise a family of animal derived fibrous glycoproteins. The composition of different collagen types and the resulting various structures have been a research topic since almost one century of researchers from all over the world. This will not be the key topic of the present review, because many others have summarized the basic knowledge about collagen and its versatility in building diverse complex structures that finally end up in the various structural different tissues [55–63]. However, a short summary will present some key features which appear to be important with regard to collagen processing by mechanical, thermal and chemical techniques.

Collagen types

In vertebrates the collagens account for 28 different types coded by at least 45 different genes. Collagens are main structural components of connective tissue. Especially, in load bearing tissues such as tendon, bone, skin and cartilage the rope like proteins assume the load transmission. In these tissues only a small number of collagen types dominate. Collagen type I is the most abundant collagen in skin, tendon and bone beside the less frequent types III and V. Cartilage mainly consists of type II collagen. But, collagens are found in almost all tissues. Other types are arranged more like a network or like a rope of pearls, some types (FACIT) are associated in low amounts with the fibril forming types and others are found as part of membranes [55, 64, 65] (Table 2).

Table 2.

Different collagen types are organized in various suprastructures

| Supra structure | Collagen types |

|---|---|

| Fibril | I, II, III, V, XI, XXIV, XXVII |

| Fibril associated (FACIT) | IX, XII, XIV, XVI, XIX, XX, XXI, XXII |

| Network | IV, VI, VIII, X |

| Anchoring fibrils | VII |

| Transmembrane collagens | XIII, XVII, XXIII, XXV |

| Multiplexin | XV, XVIII |

Type I dominates the tissues which are used as raw material for medical devices [55]

All collagens consist at least partly of triple helices which are formed by the same or very similar polypeptide chains leading to homo- or heterotrimers. Usually one collagen molecule is named monomer and the triple helix is called collagen molecule [66] in contrast to the nomenclature in polymer chemistry, where the monomer is the smallest unit before polymerization, e.g. ethylene/polyethylene or lactic acid/polylactic acid.

Key motif of all triple helical parts of the collagen molecules is the repeating glycine at every third position (Gly–X–Y)n with X and Y being one of the 21 amino acids each. The amino acid composition of different collagen preparations of various tissues and species show only slight variation (Table 3). Specific actions of chemical treatments, which affect some amino acids such as Cys, Met (reduction/oxidation), Gln, Asn (alkaline treatment) or reactions with Lys and Hyl (chemical crosslinking), are discussed in the corresponding chapters.

Table 3.

Comparison of the amino acid composition of different collagen preparations

| Source | Bovine | Rat | Porcine | Equine | Human | Bovine | Bovine | Rat | Bovine | Bovine | Bovine |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tissue | Skin | Tail | Skin | Tendon | Meniscus | Pericardb | Skina | Taila | Skina | In silicoa | In silicoa |

| Preparation | Soluble | Soluble | Soluble | Dispersion | Solid | Solid | Solublec | Soluble | ? | Type I | Type III |

| Asx | 49 | 52 | 48 | 47 | 50 | 52 | 37 | 35 | 46 | 44 | 49 |

| Hyp | 92 | 91 | 81 | 90 | 88 | 99 | 95 | 91 | 89 | 104 | 139 |

| Thr | 19 | 23 | 19 | 19 | 18 | 17 | 16 | 21 | 19 | 18 | 13 |

| Ser | 34 | 40 | 31 | 33 | 32 | 30 | 32 | 39 | 34 | 35 | 44 |

| Glx | 82 | 84 | 75 | 79 | 76 | 68 | 67 | 68 | 78 | 72 | 69 |

| Pro | 122 | 115 | 130 | 131 | 112 | 113 | 131 | 121 | 131 | 115 | 95 |

| Gly | 309 | 302 | 321 | 331 | 316 | 321 | 340 | 332 | 318 | 330 | 348 |

| Ala | 109 | 105 | 112 | 92 | 115 | 102 | 107 | 105 | 103 | 114 | 86 |

| Val | 22 | 24 | 25 | 24 | 24 | 25 | 22 | 26 | 24 | 22 | 14 |

| Met | 7 | 7 | 7 | 8 | 9 | 5 | 6 | 7 | 7 | 6 | 9 |

| Ile | 14 | 13 | 12 | 12 | 15 | 15 | 12 | 12 | 12 | 11 | 14 |

| Leu | 29 | 30 | 29 | 27 | 30 | 34 | 23 | 27 | 26 | 25 | 15 |

| Tyr | 5 | 6 | 4 | 4 | 6 | 7 | 2 | 3 | 5 | 4 | 4 |

| Phe | 14 | 15 | 14 | 15 | 15 | 17 | 11 | 11 | 17 | 12 | 9 |

| Hyl | 8 | 8 | 6 | 10 | 11 | 8 | 13 | 12 | 6 | 6 | 5 |

| Lys | 30 | 30 | 30 | 23 | 24 | 28 | 27 | 27 | 24 | 28 | 31 |

| His | 5 | 6 | 5 | 6 | 7 | 8 | 5 | 5 | 5 | 4 | 8 |

| Arg | 51 | 50 | 51 | 52 | 50 | 51 | 55 | 55 | 52 | 51 | 47 |

| Cys | 1 | 1 | 2 | 0 | 2 |

Glycine (Gly) is the smallest amino acid and its hydrogen atom side chain always occupies the position in the centre of the triple helix, while X and Y are often proline and hydroxiproline and their side chains protrude from the central axis. In the Y positions of mammalian collagens almost all prolines (Pro) and some lysines (Lys) are hydroxylated. In skin two of these hydroxylysines per alpha chain are further enzymatically glycosylated prior to triple helix formation. This glycosylation is tissue specific and it is much higher e.g. in collagen of cornea or cartilage than in skin or tendon [67–69].

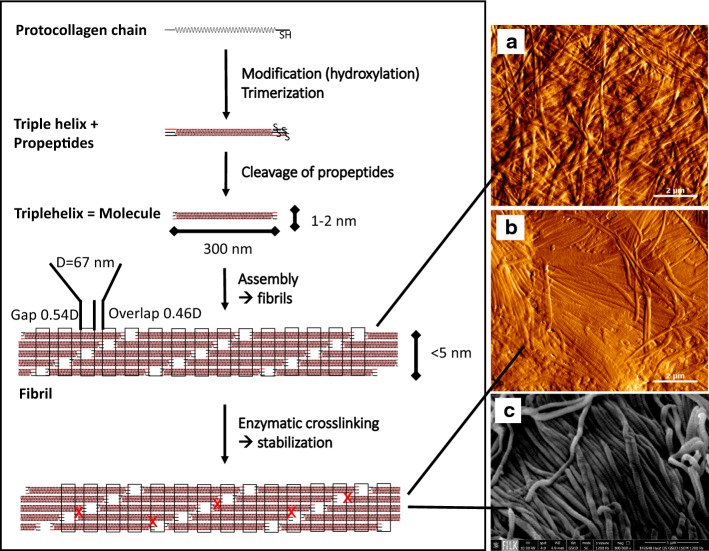

Triple helix formation

The complete assembly of single protocollagen chains into triple helices is a key step of collagen formation and a complex intracellular procedure. Trimerisation begins at the C-terminal end of the chains, which are fixed by S-double bonds, and proceeds zipper-like in the same direction of each chain (Fig. 6 schema). It is initiated by additional globular non-collagenous domains which regulate mixture and orientation of the different collagen chains. After trimerisation the propeptides are cleaved off [49, 70–72].

Fig. 6.

Schema: Monomeric protocollagen chains trimerize, the propeptides are cleaved off and the collagen molecules self-assemble to microfibrils and fibrils. Oxidation of lysine and hydroxylysine by lysyloxidase initiates the formation of the various natural enzyme-derived crosslinks [62, 508]. a Atomic force microscopic image (AFM) of reassembled collagen (dried); b AFM image and c scanning electron microscopic image of dried porcine skin splits (dried). AFM and REM images were prepared by Diana Voigt and Ralf Bittmann, FILK

Trimerisation requires all amino acids in trans configuration. Because the cis form of the iminoacids proline and hydroxiproline is energetically favoured, an isomerisation is required which is presumably enzymatically enhanced [65, 73]. In denatured non triple helical collagen 16% of X-Pro and 8% of X-Hyp were found to be in cis configuration. Because trimer formation is 1000 times faster than the cis–trans isomerisation, this isomerisation is the rate limiting step in collagen trimerisation [74]. In vitro denatured collagen reassembles only partly into triple helical structures. Nucleation begins randomly at different sites where the iminoacids are in cis configuration [75].

Fibril assembly and formation of higher structures

Solved collagen molecules assemble into fibrils by an entropy driven process caused by the loss of solvent molecules which leads to an energetically minimized area/volume ratio [59]. In vivo fibrils show a spatially resolved organization and a defined stoichiometry of different collagen types (e.g. III and V combined with type I). Their assembly is thought to be cell and enzymatically supported by additional molecular organisers as fibronectin, integrins and minor collagens [60].

In vitro in buffering solutions, at neutral pH and temperatures > 20 °C, mammalian collagen assembles into microfibrils and fibrils leading to the typical cross-striation which is observed in electron microscopic and atomic force microscopic images (Fig. 6a–c). At deviating conditions (pH ≠ neutral, different salts, organic solvents) the collagen molecules solidify in a disordered structure as white or transparent precipitate.

Natural crosslinks

Collagen is crosslinked intra- and inter-triplehelically. The natural crosslinks are formed by two different mechanisms. One is enzymatically controlled leading to specific divalent products which further react spontaneously to more complex, stable crosslinks. Enzymatically regulated crosslinking varies between different tissues [76]. The ε-aminogroup of telopeptidal lysine is oxidized by lysyloxidase to a carbanion which then reacts with lysine of the telopeptides to the aldimines dH-HLNL (dehydro-hydroxylysinonorleucine) and in the helical region to dH-LNL (dehydrolysinonorleucine). These Schiff bases are stable under physiological conditions but they are susceptible to acidic cleavage. Further, during maturation dH-HLNL reacts with histidine to histidino-hydroxylysinonorleucine (HHL) which is chemically stable. Telopeptidal hydroxylysine reacts to Schiff bases, which undergo an Amadori rearrangement, to form the stable ketoimines hydroxylysino-5-ketonorleucine (HLKNL) in the non-helical part of collagen molecules, and a lysine-5-ketonorleucine (LKNL), respectively in the helical part. Aldimines predominate in skin and tendon, in calcifying tissues and cartilage typically the ketoimines are found.

The second mechanism comprises a multitude of different spontaneous, not specific reactions, which are correlated to glucose and its oxidation products, leading to advanced glycation end products (AGEs) [77]. These AGEs became increasingly important with regard to aging mechanisms of tissues and organs, and diseases e.g. diabetes [76, 78–86]. Glucose, ribose and other sugars and sugar oxidation products react with lysine, hydroxylysine and arginine to form complex products from which only a few have been characterized to date [76, 87].

The maturated enzymatically induced crosslinks and the non enzymatic crosslinks cause the low solubility of collagen in buffers and weak acids of tissues from old aged animals and humans. They are very stable against enzymatic and chemical cleavage. This directly influences further processing as yield during dissolution, processing time and the kind of chemicals which are used.

Elastin

Elastin is a fibrillar protein which is usually associated with collagen. It is found in different concentrations especially in blood vessels, ligaments and to some extent in skin [47, 88, 89]. In the mentioned tissues the content of elastin changes dependent on the topology. In ascending aortae the elastin content is higher than in descending aortae [47], in skin the content varies between grain and flesh side [90]. Concentrations up to 70% elastin are found in ligamentum nuchae of cattle and horses [91]. It assures the recovery of connective tissues under low load conditions and it endures billions of flexes without failing [13, 92, 93].

Elastin is composed of 72 kDa tropoelastin molecules. Similar to blockcopolymers these molecules consist of hydrophobic blocks, which coacervate directly after extrusion from the cell, and hydrophilic blocks, which are crosslinked by enzymatic control over desmosine and isodesmosine crosslinks including lysine [94]. The crosslinks highly stabilize the resulting network against hydrolysis. In contrast to triple helical collagen, which shows a distinct denaturation temperature, elastin has a glass transition temperature in fully hydrated state of 30 °C [95]. Elastin can be degraded by specific elastases while the collagen structure is saved [96]. In contrast, by treatment of elastin-rich tissue e.g. with hot 0.1 N sodium hydroxide for 50 min it was possible to extract pure elastin and to separate other proteins. This is only one possible method and others exist, e.g. treatment with BrCN in formic acid [97].

For a long time, elastin was tolerated as “contaminating” component during purification of tissues, which had not been specifically removed, but which did not mind the final use at all. On the one hand the exact elastin content was difficult to control, on the other hand elastin is very stable against degradation, and mechanical damage of the materials composites should be prevented. Recent developments add elastin as elastic component to prevent wound contraction (Matriderm®) to improve angiogenesis, and elastin is as well proposed to be used as sole biomaterial [13, 94, 98].

Fibre architecture, orientation and mechanical stability

Tendon fibres, especially that of rats are easy to prepare and much more uniform than fibres of ligaments or even intestine and skin. Therefore, many ultrastructure studies in the past focussed on rat tail tendon collagen which was investigated such as tissue or reassembled soluble collagen. But some investigations of a broad range of tissues showed that fibril diameters and distribution vary depending on age, tissue, the layer in stratified tissue such as skin, and the species [99–101].

One of the main known functions of the collagen fibres is to take over mechanical load. The composition of the fibre distributions determines whether fibres may creep (smaller diameters e.g. lung, nerves or cornea) or transfer high loads (large diameters in tendons) [102]. The fibres are preferentially aligned in the main load bearing direction and they anticipate possible loads. Thus, the diameter of the fibres, the orientation of which differs tissue- and species-specific, plays an important role in tissue stability [40, 103–105].

In mammalian skin the fibres in dermis are oriented according to the Langer lines. Fibre bundles of collagen are connected by thin elastic fibres [106–111]. The collagen fibre network of the skin is denser at the back compared to the ventral side. Large differences of the thickness of fibre bundles are observed between papillaris and reticularis [33, 35, 112]. When skin is used as raw material for medical devices, this inhomogeneity causes different mechanical stabilities depending on sampling site and fibre orientation.

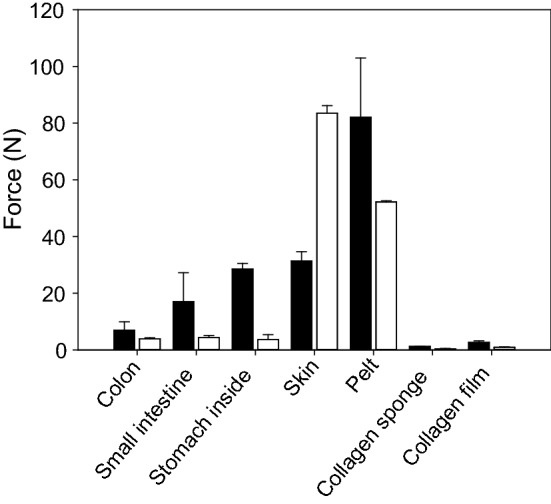

The collagen fibres in tendons are predominantly oriented longitudinally and to a much lower extent also transversely and horizontally. The longitudinal fibrils cross each other and form spirals and plaits. They are able to buffer longitudinal, and to some extent transversal, horizontal and rotational forces during movement [50]. Furthermore, tendon collagen fibres are crimped in contrast to skin fibres which are even. Small intestine submucosa (SIS) shows fibres in longitudinal orientation, the fibres of pericard and also urinary bladder are locally oriented but not over larger areas [45, 113, 114].

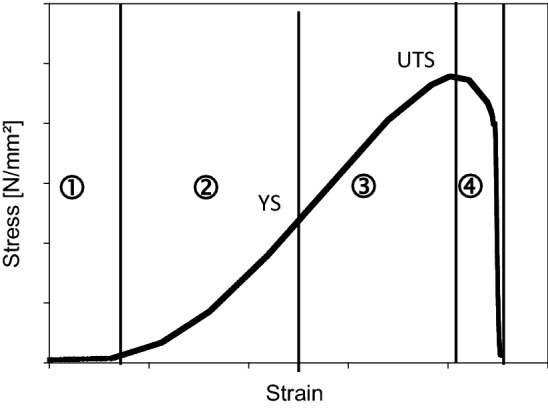

On which structural level which mechanical stability is generated is still intensively discussed. Stress–strain curves of collagenous tissues are typically S-shaped [Fig. 7; (1) to (4)]. Several authors [115–117] could show that each part of the curve reflects different structural effects at different structural levels.

Fig. 7.

Stress-strain curve of the middle layer of wet porcine hide as an example for typical stress–strain behaviour of collagen tissues (own measured values). ① Toe region: Fibre and fibril crimps are straightened (tendon) and fibres are aligned (skin); the gap overlap ratio increase; resetting is caused by elastin fibres; ② Elastic region: Elastic fibres are deformed and fibres, fibrils and microfibrils begin to slide against each other; microfibrillar super twist causes torque transfer at crosslinks; molecules begin to stretch and to shear; ➂ Plastic region: Tissue begins to yield; interfacial delamination; plastic fibres deform and slide against each other; partial disruption of entanglements; exudation of bound water; helices uncoil and slide against each other. ④ Rupture: Tissue delaminates (skin) and disrupts in layer; fibres, fibrils and microfibrils defibrillate, disrupt and pull out; crosslinks between the molecules disrupt. YS, yield strain; UTS, ultimate tensile strength; [116, 509]

In the toe to heel region of such curve (1) the whole structure is straightened at low strain. The network of collagen molecules is arranged in parallel e.g. in skin. In tendon and pericardium the zig–zag shaped parallel oriented molecules are lengthened. Kinks on every structural level such as fibres, fibrils, and molecules are drawn out. The elastin network stores the energy and resets after unloading [41, 116, 118, 119].

At increasing strain during elastic deformation (2) the slope becomes linear and the collagen takes over the applied forces. Collagen prevents the elastin network from overloading and stores the energy as well by elastic regions of the collagen fibres. The properties depend on the fibre composition and architecture which is regulated among other things by proteoglycans [120, 121].

Higher loads let the collagen molecules slip against each other (3), the fibres become stretched which then results in variations of the D-bands. Finally, fibres and crosslinks begin to crack (4). Depending on the tissue (e.g. skin) this cracking is often observed in layers, as not every layer shows the same elasticity. During tension measurement the tension curves then decrease not abruptly but stepwise with slight oscillation [42, 104, 115].

The physical stability of connective tissues relies on the network of fibrous proteins. In hydrated tissues the crosslinking density (reducible, mature crosslinks) determines whether a tissue behaves more brittle or is able to creep [102]. Synthetic crosslinks especially introduced by chemical agents are known to stabilize tissue additionally in wet state [122–125].

In recent years, computer modelling of the mechanical behaviour was increasingly used to simulate and predict the behaviour of collagen molecules and fibrils under load in wet and dry state. The data are based on collagen-like peptides, because for molecular dynamic simulations of complete collagen molecules and more complex higher structures the computing power is still not sufficient. It was found that the amino acid sequence substantially influences the mechanical properties of single tropocollagen molecules. These mechanical properties are not homogenously distributed along the collagen molecules, but show blocks of lower and blocks of higher stiffness which may result in concentrations of stress under load only in some regions. This has also been proposed to be the link between genetics, biochemistry and biomechanics [126, 127]. The principle of softer and stiffer regions is found again on the fibril level reflected by kinks [128] and again on the tissue level as zig-zag shape in tendon or non-parallel fibre orientation in skin (see above). Therefore, it can be assumed that this is an important principle presumably to regulate the elastic and plastic properties of the ECM.

Computer modelling but also other methods as AFM, light scattering and X-ray diffraction have also been used to calculate the mechanical properties such as stiffness and tensile strength of collagen-like peptides. For collagen molecules a stiffness of ~ 5 ± 2 GPa has been found, for microfibrils in wet state ~ 0.6 ± 0.2 GPa and for dry microfibrils 3.3 (2–7) GPa [126, 129]. Goh et al. [116] comprehensively reviewed the “Hierarchical mechanics of connective tissues” and summarized the physical properties for whole tissues in comparison to collagen fibrils and collagen molecules. The mechanical values e.g. stiffness and yield stress of tissues, fibre bundles (fascicles), fibrils, microfibrils and collagen molecules, which they collected from literature, showed very broad ranges (50–100% mean deviation) on every hierarchical level (Table 4). Surely, this high deviation is caused by different measuring conditions and also the broad range of tissues which were considered. However, the collection shows that the fibre bundles are the most flexible structural unit, slightly more flexible than whole tissue. But the fibre bundles are 4 times less stiff than microfibrils and 20 times less stiff than a collagen molecule. Similar factors between the different structural levels have also been observed for the yield strength.

Table 4.

Stiffness and strength values of the different hierarchial levels summarized by Goh et al. [116], sponge by Jain 1988 [504], film by Koide and Daito [250], threads by Pins et al. [503]

| Stiffness (young module) (Mpa) | Yield strength (Mpa) | Molecule | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tissue | Bundle | Fibril | Molecule | Film | Sponge | Thread | Tissue | Bundle | Fibril | ||

| Average | 701 | 276 | 1192 | 5150 | 1000 | 0.014 | 500 | 61 | 22 | 212 | 629 |

| Mean absolute deviation | 318 | 132 | 905 | 1653 | 18 | 10 | 148 | 589 | |||

| Molecule: x | 7.4 | 18.7 | 4.3 | 1.0 | 5.2 | 370000 | 10 | 10.4 | 28.7 | 3.0 | 1.0 |

Molecule: x is the factor of the physical properties of collagen molecules compared to the presented structure

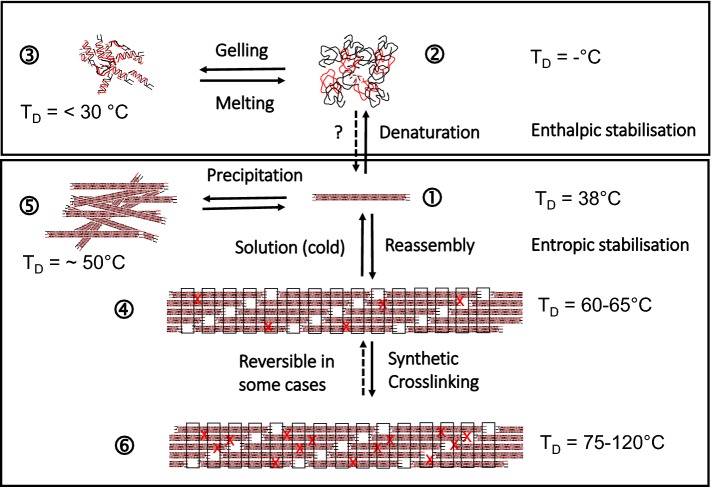

Thermal stability of collagen

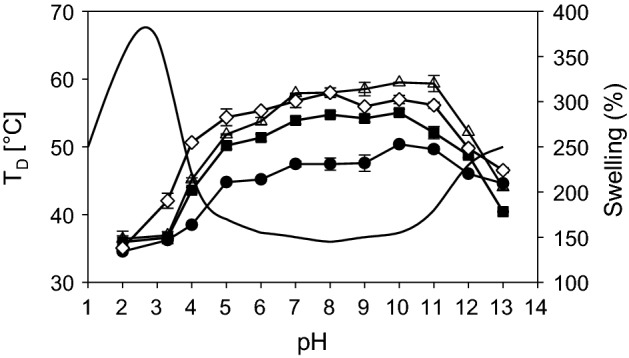

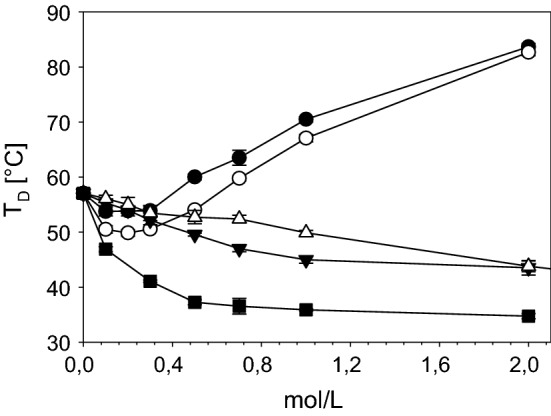

Processing of collagen requires to discuss the thermal stability of different structural levels of collagen. Heating of collagen leads to uncoupling of the triple helices at a typical temperature which is called denaturation temperature TD and can be measured by differential scanning calorimetry (DSC) [130]. TD differs between the different processing states or organization levels of collagen material [Fig. 8 (1) to (6)] and it directly correlates with the enzymatic degradation behaviour, the mechanical stability in wet state, antigenic properties, and the interaction with cells. TD of fully hydrated soluble collagen (1) is near body temperature of mammals [131]. The absolute value deviates between mammals and poikilotherms [132]. Soluble collagen of warm-blooded animals shows denaturation temperatures of 36–40 °C. Poikilotherms can have lower denaturation temperatures adjusted to their habitats, e.g. coldwater fish such as antarctic ice fish shows a TD of 6 °C. The hydroxiproline content correlates with TD and it is assumed that the thermal stability of collagen is adjusted by the hydroxylation intensity of proline [67, 133].

Fig. 8.

Structures of different collagen materials and derivatives and the corresponding denaturation temperatures TD. (1) soluble collagen; (2) gelatine solution; (3) gelatine gel; (4) reassembled fibrous collagen/tissue; (5) disordered precipitated collagen; (6) crosslinked (X) assembly/tissue; TD. Shrinkage temperature/denaturation temperature/melting (fully hydrated)

The thermal stability of triple helical collagen molecules is markedly higher than that of globular proteins and the reasons for this have been disputed controversially for many years [62, 134–137]. Though many different ideas were formulated about the stabilising principles of the triple helix, such as hydrogen bonds, electrostatic interactions, van der Waals interactions but also hydrophobic interactions and stereoelectronic effects, it is now mostly accepted that a ladder of hydrogen bonds internally stabilizes the fully hydrated collagen triple helix to around one-fifth. X-ray diffraction studies in the middle of the 20th century and further biochemical and physicochemical investigations showed that these stabilizing bonds are located between N–H of glycine (Gly) and the C=O of other amino acids in X-position of the following strand [138].

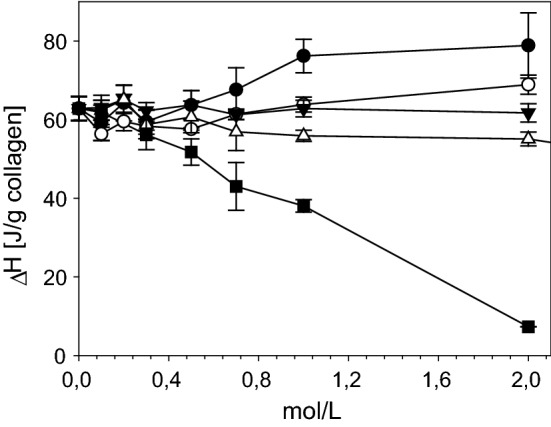

The triple helices are surrounded by a network of water molecules that increases the thermal stability of the triple helices and supports their high denaturation enthalpy ΔHD [137, 139, 140]. As TD also ΔHD can be measured by calorimetric measurements and it is assumed that ΔHD directly reflects the number of hydrogen bonds, while TD reflects an entropic and an enthalpic contribution to the stability of the collagen triple helix. The exact enthalpic and entropic part to TD is not easy to estimate and to explain [133]. However, the denaturation enthalpy ΔHD is a sensitive parameter of the degree of triple helical structure. For soluble samples this degree can also be estimated by polarimetry measurement that of insoluble samples is usually measured by calorimetry.

The hydroxyl group of hydroxyproline (Hyp) has an important influence on the stabilising principle of the triple helix, because a species-dependent increase of Hyp can be correlated to an increase in TD and ΔHD [130]. While most investigations only rendered indirect hints regarding such water network [133, 141, 142], Bella et al. [143] could measure, model and calculate the surrounding water structure for collagen-like peptides. It was deduced that water molecules additionally stabilize the triple helical structure though this was not possible to prove until today.

The entropy-driven assembly of collagen (4) increases TD by approx. 20 K to achieve values of around 60 °C for skin and tendon collagen of mammals. Additional crosslinking (6) further increases the thermal stability: glucose-based crosslinking during maturation by several degrees [77, 87, 144] and synthetic chemical agents by 15 K up to 60 K and more. Assembly and disassembly of non-crosslinked collagen molecules is reversible [(1) ⇔ (4)] and likewise the differences of TD, while ΔHD remains unaffected. Disordered precipitation of soluble collagen (5) also increases TD but not as much as it can be achieved by an ordered reassembly (4).

By application of temperatures higher than TD or by addition of hydrotropic agents at ambient temperature (e.g. Urea, LiBr, SCN−) collagen molecules in solution denature into single protein strands. In contrast to the assembly and reassembly of collagen molecules into fibrils the denaturation of the triple helix of soluble collagen is only partly reversible leading to physical gels [(1) ⇎ (2); (2) ⇔ (3)]. The complete formation of collagen molecules from single chains in vitro seems to be only possible under restricted conditions [145–149].

Gelatine is a hydrolysate of collagen, which is manufactured by topochemical hydrolysis, that means selective cleavage of specific bonds to make the collagenous tissue soluble [150]. In contrast to denatured soluble collagen gelatines show broad molecular weight distributions. The gelation of gelatine solutions by cooling [(2) ⇔ (3)] is interpreted as imperfect reassembly of the collagen chains. Firstly, this only incomplete trimerization in vitro is presumably caused by these broad molecular weight distributions of the gelatine molecules and a “contamination” with process-induced collagen peptides and aggregates which markedly deviate from the distinct peaks of original collagen molecules [151, 152]. Secondly, the chemical structure of collagen especially during the gelatine process is modified through desamidation of Gln and Asn [153]. Not least, the gelling rate of gelatine gels depends on the isomerization of the iminoacids in cis configuration to trans [154] and the triple helix content of gelatine gels is increasing over months [152]. Therefore, the melting temperature of a gelatine gel is always lower than TD of the corresponding collagen molecules (3).

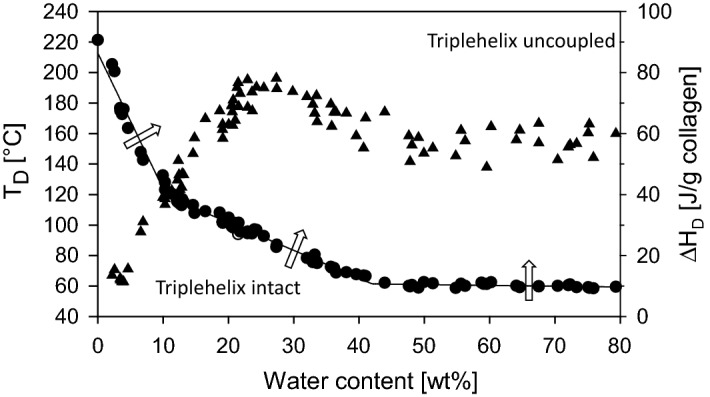

Upon drying TD increases and ΔHD decreases. This shows that the entropic contribution to TD becomes more and more important, while the number of hydrogen bonds is decreased by water removal lower than ~ 15 wt% (Fig. 9). Almost water-free collagen shows TD of up to 220 °C, while the denaturation enthalpies decrease up to a minimum value of one-fifth of the value of fully hydrated collagen. This is consistent with the enthalpic part of the hydrogen bonds in the center of the triple helix. The increasing entropic part correlates with the decreasing mobility of the collagen molecules. It predominates more and more upon increasing dehydration of collagen [142, 155, 156]. The denaturation temperatures and the enthalpies give important hints about the organization degree and the nativity of collagen. It allows to control processes and to prevent denaturation.

Fig. 9.

Denaturation temperature TD (filled circle) and denaturation enthalpy ΔHD (filled triangle) of decellularized bovine skin at different water contents. If TD is exceeded (arrows) collagen triple helices uncouple. At dry conditions TD increases, while ΔHD decreases [156]

Diffusion and adsorption

Diffusion and adsorption of chemical additives and their reaction kinetics have to be considered intensively, when collagenous tissues such as skin, tendon, pericardium or small intestine are purified from non-collagenous material: (1) the tight fibrous structure as well as alternating layers of different tissue structures are massive obstacles for molecular diffusion. (2) The tissue structure separates molecules regarding their hydrodynamic volume which corresponds to their molecular weight. (3) As any protein and in contrast to many other natural polymers, collagen acts as an exchanger for anions, cations including protons, hydrophilic, and hydrophobic substances, and (4) the exchange of collagen depends on pH and temperature.

Diffusion, especially through skin and intestine, is not only important for processing, but it is as well an important parameter for the cosmetics and the pharmaceutical industry. To describe the permeability of substances through e.g. skin or intestine in vitro and in vivo, many different models were developed. These are partly mathematical models with references to chemical properties (hydrophobicity, molecular weight), or mechanistic models (brick and mortar models) which assume different mechanisms of permeation through hydrophobic cell layers. Currently, the published models neglect mixture of substances e.g. hydrophobic additives emulsified with surfactants, or combinations of differently hydrophobic substances and their partial coefficients during application [157–165]. For skin, these models assume the Stratum Corneum consisting mainly of dead keratinocytes and keratin as strongest barrier. The intestine models consider the mucosa and active membrane transports.

When tissues are processed to manufacture biomaterials, the non collagenous parts are removed as completely as possible. Often collagen raw materials are processed in an excess of aqueous floats in moving drums or stirred reaction vessels with built-in baffles. To avoid mechanical stress, collagenous tissues are also fixed in batch vessels, or purification fluids are only pumped past in a circle. Processing lasts from a few hours to several days at temperatures between 5 and 30 °C. In these agitated systems, the float can be assumed as ideally mixed already a few minutes after addition of chemicals. Therefore, a first approach does not have to discuss diffusion in the float in contrast to diffusion through the tissue structures, because of the forced agitation [20, 166].

The collagen structure shows a cutoff for different molecular weights. Own unpublished results in a diffusion chamber system (two agitated chambers which were separated by a collagen membrane as described in [167]) demonstrated (Fig. 10a) that sodium chloride diffuses very fast through a commercial porcine dermis based membrane (Biogide®), while hyaluronic acid (molecular weight Mw ~ 1.2 MDa) is widely excluded. A similar model was also used to investigate the cutoff of more complex diffusion barriers, such as collagen sponges and collagen threads, which confirmed this observation [168]. Ho et al. [169] used films of soluble collagen which had been crosslinked and found that the crosslinking degree affects the diffusion behaviour.

Fig. 10.

a, b Permeability of different substances through collagen membranes (Biogide®) prepared from porcine skin. The diffusion rate between chambers A and B depends on molecular weight and the chemical nature of the substances (a). Sodium chloride is absorbed at low concentrations until saturation (b). Filled triangle: Tryptophane; filled circle: NaCl; filled square: glucose; filled diamond: hyaluronic acid (Mw ~ 1.2 MDa); (own unpublished data)

For a low quantity of permeating molecules collagen behaves like an exchanger. Glucose (Mw 180 g/mol) with many hydroxyl groups diffused slower through the investigated Biogide® membrane than tryptophan (Mw 204 g/mol) which is a hydrophobic amino acid but of similar molecular weight as glucose. Adsorption was observed for ions such as sodium chloride (Fig. 10b), and other authors observed adsorption for calcium ions [166, 170], surfactants [167, 171, 172], growth factors [173–176], but also endotoxins [177–180]. Low concentrations of adsorbed molecules can only be removed with high amounts of washing floats and by an excess quantity of molecules which are able to replace (ions, protons) or bind (chelating agents) the unwanted adsorbate.

The structure of the raw materials is usually not homogenous. Skin as an example is highly asymmetric and thick enough that diffusion becomes a relevant parameter. The asymmetry leads to different diffusion coefficients from both sides that has to be considered when processing agents diffuse into and out of the skin from both sides.

When treating thin collagen materials such as intestine submucosa or pericardium, diffusion plays only a minor role. Big tendons (e.g. tendo calcaneus from equine, bovine or porcine sources) in contrast have to be treated for long periods of time to achieve sufficient diffusion. Not least, organ decellularization is a particular challenge, because a laminar flow in the vessels has to be assumed. Diffusion then occurs similar to the in vivo situation across the membranes of vessels, and large washing volumes are necessary to remove all non-structural material. Because of the complex architecture of the vessel trees and their unpredictable hydrodynamic behaviour, it is very difficult to predict or model diffusion scenarios. However, to optimise the cleaning procedures, this would be very important.

Reaction kinetics

Reaction kinetics were investigated and calculated for the structural transformations of collagen such as for denaturation and fibre assembly as well as for many different chemical reactions e.g. crosslinking and modifications of collagen and of gelatine (denatured collagen). The different kinetics not only depend on the temperature, but also on pH and additives like salts or organic components, and the kind and amount of solvent. Not least, there is an interaction between the different kinetics. Table 5 compares the reaction rates of different reactions and structural transitions.

Table 5.

Different kinetics have to be considered which influence the processing times during tissue decellularization, purification and processing

| Time scale | T; T opt (°C) | Reaction rate | Remark | Refs. | ||

|---|---|---|---|---|---|---|

| pH 3 | pH 7 | pH 12 | ||||

| Denaturation | > TD | Seconds | Seconds to hours | Seconds | Depending on the degree of structural organization, crosslinking degree, solvent concentration and additives | [181, 480–483] |

| Renaturation | 0 to ~ 20; 4 to 10 | Hours to months | Hours to months | Hours to months | Dependent on the sequence, molecular length and covalent crosslinks | [152, 481, 484, 485] |

| Reassembly/fibrillation | 10 to 38; 20 to 35 | – | Minutes to hours | – | Only possible in neutral conditions | [186, 190, 191, 486–488] |

| Disassembly | < 37; < 5 | Seconds | Minutes to hours | Seconds | At pH deviating from the IEP a high swelling is observed which can be assumed as disassembly [343] | [189, 191, 487] |

| Crosslinking reaction | Seconds to hours | Seconds to hours | Seconds to hours | Highly dependent on the kind of reaction | [192, 248, 420, 421, 489–491] | |

| Diffusion | Hours | Minutes to hours | Hours | See special section | ||

The denaturation process of the collagen triple helix (helix ↔ coil) in solution had been discussed controversially over decades. Miles [181] assumed an irreversible rate process, while others interpreted the calorimetric results as an equilibrium of monomers and trimers [58, 134, 136, 148]. Denaturation is a fast process which lasts only in the range of seconds if the collagen molecules are separated (pH ≠ IEP).

Complete renaturation of the triple helices is possible in idealised systems (collagen type III, crosslinked in one position by disulfide bonds, diluted solution, long reaction rate). It is hindered by cis–trans transitions, structural features and partial cleavages [134, 148]. The renaturation kinetics is determined by the cis–trans transitions and is a slow process.

Gelatine is a denatured, partially cleaved collagen with very broad molecular weight distributions which often still contains crosslinked particular components resulting from the manufacturing process. Therefore, the setting rate, which corresponds to the renaturation of collagen triple helices, is much slower than that of idealised collagen. Setting begins very fast by cooling a gelatine solution, but does not end in practically measurable time [152, 182–184].

In vitro collagen assembles into microfibrils and fibrils of varying length and thickness which depends on temperature, pH, and additives [185, 186]. Fibrillation only occurs in the isoelectric range with the highest fibrillation rate in the range of minutes at pH 9.2 in saline phosphate buffer (PBS) [187]. Not only the rate of assembly but also distributions of fibre length and thickness depend on further additives (e.g. glycine) and temperature [188].

Disassembly of reassembled collagen occurs when the fibres are exposed to lower temperatures. The higher the cooling rate the faster is the disassembly. However, some small filaments remain. In contrast to earlier investigations, which assumed crosslinking as a reason of these stable aggregates [189, 190], de Wild et al. [191] assumed that they are stabilized kinetically, because the stable aggregates can be completely dissolved again in acid.

Finally, collagen and gelatine are widely modified and stabilized by versatile chemical reactions which comprise almost all possible reactions of the side chains, especially amine (Lys) and carboxylic groups (Glu, Asp). Examples of possible reactants are mentioned below (section crosslinking). Reaction times and conditions are as manifold as the reactions and a comprehensive consideration is beyond the focus of the present review. From the practical point of view, the reaction times have to be adapted to the manufacturing processes which usually do not last longer than hours. But the reaction time must not be too fast, for diffusion and equilibration to be still possible. As examples, aldols or condensed tannins often show reaction rates of several hours up to days, while aldehydes may react in less than seconds [192–196].

In collagen tissues, which comprise complex structures, the chemical reaction always competes with diffusion of chemicals in the tissues. Therefore, there is no easy rule about which process is favoured—diffusion or chemical reaction. Uncoupling of these sub-processes can be achieved most easily by adjusting the pH. Possible reactive groups (e.g. –NH2) are only available as non reactive (–NH3+) at acidic pH until diffusion of the chemicals achieved an equilibrium. The same applies to alkaline pH and carboxylic side chains of the amino acids. By cautious adjustment of the pH the reaction can be regulated.

Molecular weight distributions and particle sizes

The molecular weights of human type I collagen chains without propeptides (UniProt, P02452, P08123; Expasy ProtParam) are calculated to be 94.8 kDa (α1(I)) and 93.6 kDa (α2(I)). The calculated molecular weight of a collagen molecule would then be 283 kDa. When the molecular weight of the collagen chains type I was measured by SEC-MALS, it was found to be 92 kDa that of one denatured triple helix around 300 kDa. A chromatographic separation of α1(I) and α2(I) chains was not possible [151]. Other methods of protein chemistry as SDS-PAGE allow to separate the different collagen chains and also specific peptides [197–199]. In tissue the collagen is crosslinked intra- and intertriplehelically by covalent bonds. The number of crosslinks increases with age [77]. This results in extremely high molecular weights which cannot be measured anymore. Table 6 shows the molecular weights of differently processed materials. Permacol® and Xenoderm® are decellularized tissues whose connective tissue architecture is saved. In contrast, Surgicoll® and Resodont® are manufactured from purified wet ground tissue.

Table 6.

Different commercial forms of collagen materials and their properties solubility under different conditions, their estimated molecular weight and its distribution, helical degree and estimated crosslinking content

| Material | Example | Possible supplier | Solubility (aqueous saline buffer 0.1% < 40 °C) | Solubility (aqueous saline buffer 0.1% > 40 °C) | Solubility (acetic acid 0.1 M < 15 °C) | Average molecular weight | Molecular weight distribution | Crosslinking content | Triple helix content native (+) denatured (−) |

|---|---|---|---|---|---|---|---|---|---|

| HMDI crosslinked porcine skin | Permacol | Covidien | − | − | − | ∞ | ∞ | ++++ | + |

| Lyophilised porcine skin | Xenoderm | MBP | − | − | − | ∞ | ∞ | ++ | + |

| Lyophilised sponge from porcine skin dispersion | Surgicoll | MBP | − | − | − | ∞ | ∞ | ++ | + |

| Convection dried sheet from equine tendon dispersion | Resodont | Resorba | − | − | − | ∞ | ∞ | ++ | + |

| Denatured powder from skin collagen | Thermoplastic collagen | FILK | − | ± | − | Several millions | ++++ | + | − |

| Acidic extract (cold) from calf skin | Soluble collagen | Symatese | + | + | + | 270 kDa | + | ± | + |

| Aqueous extract (hot) from limed skin or bone | Gelatine | Gelita | ± | + | ± | Ca. 50–150 kDa | +++ | − | − |

| Enzymatically treated extract (hot) from skin or bone | Collagen hydrolysate | Gelita | + | + | + | Ca. 5–20 kDa | ++ | − | − |

Wet grinding is an established technology to prepare collagen suspensions for the food industry and to prepare e.g. collagen sponges and membranes for medical applications. It is very difficult to determine particle sizes of wet ground collagen, because of the shape of the particles, intensive interactions of the particles themselves, and the low contrast between the particles and the usually water-based dispersing medium. The microscopic appearance in swollen state has been found to be fibrous, lobe-shaped, partly solved partly gel-like, and hence neither homogenous in size nor in shape. Some correlations to the grinding degree are found by ultracentrifugation, by microscopy or by particle counting. In contrast to chromatographic procedures or particle size measurements a repetitious accuracy is difficult to achieve, not least because physical entanglements and physicochemical interactions cannot be excluded completely. The moment of measurement only reflects a single observation which is again markedly varied by pH, ions and water content. Therefore, in industrial processes, especially the viscosity is measured to evaluate the processability [200–202].

If collagen tissue is ground in dry state, the smallest particle size is in the range of a hundred microns or larger. The particles appear as fragments of fibres [203, 204]. Partly denatured tissue can be ground into much smaller sphere-like particles which can be processed by thermoplastic machines (thermoplastic collagen) [205].

Very broad molecular weight distributions of molecular disperse collagen preparations accrue by combined thermal and chemical degradation of tissue e.g. during gelatine manufacture. They range from particular components with Mw > 107 up to < 103 Da. Depending on how the tissue is processed, distinct peaks (gelatine type B) or broad peakless distributions (gelatine type A) are observed [151, 152, 206, 207].

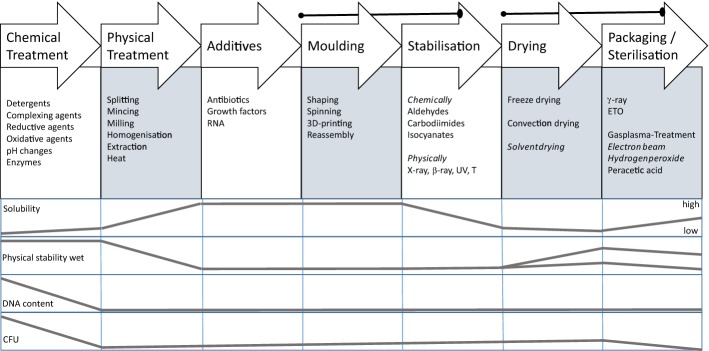

Processing collagen—the toolbox

Processing of collagen materials is organized as a sequence of technological steps lasting several hours up to several days each. Many of these steps require manual handling and often the degree of automatization is low. The technological steps comprise mechanical, chemical and physical treatments [3, 4, 20, 21, 208, 209]. Figure 11 presents the principal combination of such technological steps as a sequence, applied chemical agents or variants of physical treatments and their effects on the important parameters solubility, physical stability in wet state, the DNA content and the microbiological quality (CFU—colony forming units). To manufacture collagen-based biomaterials, tissue has to be purified, (disintegrated, reshaped, stabilized, dried), packed and sterilized. The steps in brackets are optional. The effects of the several chemical agents on the collagen structure are discussed in the following chapter in more detail.

Fig. 11.

State of the art of collagen processing technologies, their processing steps and their effect on the parameters solubility, physical stability, DNA content and colony forming units (CFU). The brackets connect process steps which are usually combined in this order

The order of the steps is not necessarily fixed but it is often used as shown. Stabilization (crosslinking) is not only used to adjust degradation in vivo but usually follows shaping to fix the new form. Packaging is enqueued as last step to market a sterile and save product [210]. Sometimes sterilization is performed at earlier stages, especially when wet products are produced which then cause aseptical downstream processing and packaging [210].

By application of different variants of the mentioned series of technological steps, such different materials are prepared as for instance decellularized membranes from dermis, pericardium, small intestine or urinary bladder, injectable solution, injectable suspension, membranes from tendon and minced skin, powder, and sponges and finally hydrolysed, denatured collagen [1, 3, 7, 27, 208, 209, 211].

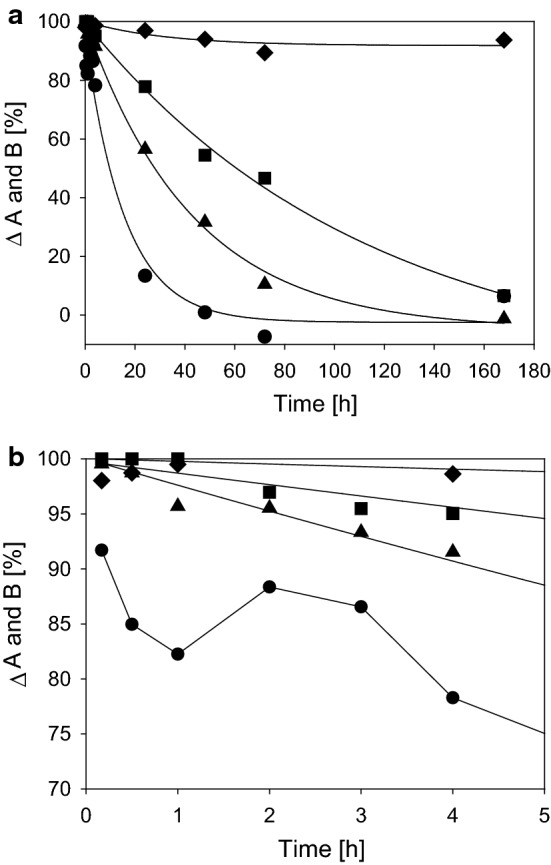

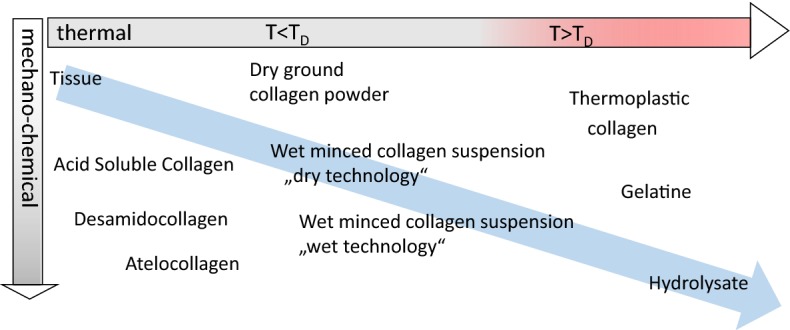

Figure 12 discriminates the field of collagen-derived materials in two main processing directions. One direction comprises mechano–chemical processes, the second one shows thermal denaturation. Both directions lead to fundamentally different materials. Physico–chemical extraction from tissue saves the triple helical structure (acid soluble collagen) and chemical (Desamidocollagen) and enzymatic treatment (Atelocollagen) comprise modified triple helical collagen molecules.

Fig. 12.

Collagen materials manufactured by different technologies. The blue arrow marks the degree of desintegration of the collagen structure, the red range a thermal treatment of the material higher than the TD

Solubility of tissue increases slightly by chemical treatment but markedly by physical disintegration. Reciprocally the physical stability decreases by mechanical disintegration. Wadding-like collagen powder (dry grinding) or suspensions (wet mincing) are achieved by mechanical disintegration. It is necessary to mention that prior to these mechanical disintegration steps the tissues have to be purified as much as possible. Long-lasting chemical treatment and especially thermal treatment, which affects the structure of collagen, is prevented, however. The powders reflect collagen fibres and fibre bundles which collapsed by drying. Impurities are completely encapsulated and removing them becomes impossible. Collagen minced in wet state is highly viscous. Furthermore, diffusion is very slow and even pH adjustment in small volumes (millilitre to litre) usually lasts several hours up to days.

Thermal treatment uncouples the triple helices. It is again necessary to purify the raw material as much as possible prior to thermal treatment. While thermoplastic collagen describes an intermediate which sustained only a short treatment with chemicals and thermal uncoupling of the triple helices [205], gelatine and hydrolysates are intensively processed by chemical, mechanical and heat treatment. The latter both are soluble products which can be easily purified by many different techniques such as filtration and chromatographic methods as well [212, 213].

In addition to the molecular weights, Table 6 shows other properties of the differently processed materials. Every material except thermoplastic collagen also reflects marketed products. It is obvious that the solubility increases with the degradation degree and that the molecular weight decreases, accordingly. Crosslinking prevents solubility and crosslinked samples often show very high molecular weights. The triple helix content directly correlates with a heat treatment that exceeds TD.

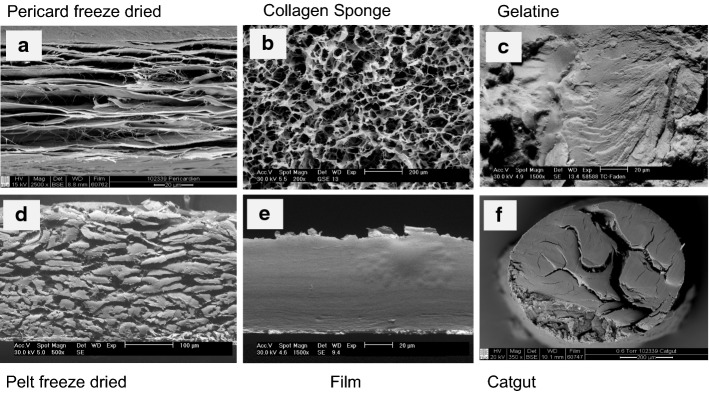

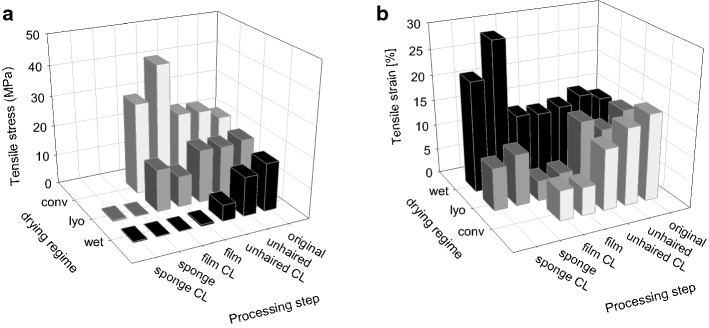

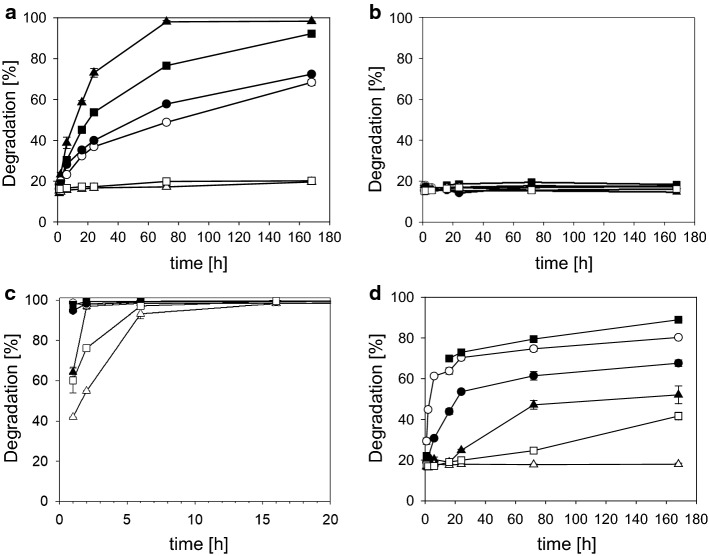

Figure 13a–f compare the scanning electron microscopic appearance of a selection of the different materials manufactured by variants of the processing sequence [209]. Freeze-dried decellularized pericardium (Fig. 13a) and unhaired decellularized skin (Fig. 13d) reflect the corresponding structures of the raw tissues. While the pericardial fibrosa delaminates to some extent, in skin the collagen fibre bundles agglutinate. Catgut (Fig. 13f) is manufactured from purified SIS which is cut in small strands, twisted and convection dried under tension. A common technique to manufacture intermediates is to decellularize hide followed by homogenization in wet state, and drying. Porous sponges (Fig. 13b) are achieved by freeze drying, and compact films (Fig. 13d) by convection drying. Not least, gelatine is the only material in this series of microscopic pictures which reflects denatured collagen (Fig. 13c). Microscopically no difference can be observed between the film in which the triple helices are still present, and gelatine, however.

Fig. 13.

Comparison of microscopic structures of principally different processed materials. Pericardium (a) and skin (d) are decellularized and freeze-dried, for sponge (b) purified skin is minced and freeze-dried, for films convection-dried (e), instead. Catgut (f) consists of purified small intestine (SIS) which is cut in strands, twisted, stabilized by crosslinking, and convection-dried. Gelatine (c) is hydrolyzed collagen of skin or bone which have been convection-dried

The step chemical treatment (Fig. 11) is commonly the rate-limiting step of the whole process. Processing times depend on concentration and concentration gradients of agents, treatment temperatures, and the intensity of washing, which directly correlate with diffusion and reaction times. The processing times vary considerably between different tissues, their structure and the treated volumes. While skin and tendon are thick and compact, pericardium is much thinner but compact as well, and small intestine is thin and rather elastic. Table 7 compares selected published processing times for different materials. Many more processes have been applied for patents [210] and it is not easy to find realistic values. The published times vary in a broad range even for the same tissue and it seems that there is serious potential for optimisation which is not directly correlated to the specifications and limits.

Table 7.

Frame of wet technologies to decellularize diverse tissues

| Tissue | Species | Form [2D; 3D] | Freeze/thaw cycles | Washing cycles | Surfactant | Acid/base | Enzyme treatment | Complexing agents | Mechanical treatment | Sterilisation /decontamin. | Time (h) | Refs. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Water, buffer, salts | SDS, Triton X, others | Organic, inorganic | DNAse, protease | CHAPS, EDTA, etc | ||||||||

| SIS | Porcine | 2D | + | 125 | 13 | − | − | − | (−) | − | 138 | [492] |

| Pericardium | Bovine | 2D | − | 1 | − | 3 | − | − | − | Gamma | 4 | [46] |

| Tendon | Diverse | 3D | 5–48 (96) | [493] | ||||||||

| Dermis | Human | 2D | + | 19 | − | − | 3 | 47 | − | Gamma | 69 | [494] |

| Dermis | Porcine | 2D | + | 18*** | 22** | − | 6 | (+) | (+) | PAA; H2O2* | 49 | [495] |

| Dermis | Porcine | Dispers | + | 4 | 2 | 8 | − | − | + | − | 13 | [496] |

| Dermis | Porcine | Dispers | + | 35 | − | 39 | − | − | + | H2O2 | 74 | Own trials, unpublished |

The numbers reflect hours of treatment

as, antiseptic processing; ab, addition of antibiotics

* Additionally other sterilization techniques were investigated

** Complexing agents and surfactant are applied together

*** Washing comprised 12 h ethanol treatment

Examples—selected technologies varying physical, thermal and enzymatic stability

Processing connective tissue causes structure downgrading to different extents by mechanical, physical and chemical means. The resulting materials comprise stable tissue up to soluble collagen hydrolysates based on the same raw material collagen only differing in degree of destruction and depending on the mechanism of degradation (Fig. 12). To cover the entire range of possible collagen materials, five examples of different technologies and the resulting materials will be subsequently discussed, which vary fundamentally regarding their stability to temperature and enzymatic degradation.

Saved tissue structure—hernia implant

Decellularization usually aims to save the mechanical structure of the grown tissue. The mechanical properties shall be affected as little as possible. Mostly it is also aimed to remove all non-collagenous materials except elastin. This concerns e.g. globular proteins, bound glucose and galactose molecules, lipids, DNA, components of cell membrane, nuclei and if necessary processing agents. To some extent growth factors may be saved or removed as well. Nevertheless, after one or repeated freeze–thaw cycles, decellularization comprises an intensive treatment with complexing agents, surfactants, also alkaline and acids and possibly enzymes [3, 4, 20, 21]. By saving the structure of connective tissue skins, pericardium, small intestine and fascia are manufactured from human, porcine, bovine and equine sources (Epiflex®, Xenoderm®, Xenoguard®, Oasis®). Examples for marketed materials are listed in Table 1. To further stabilize these decellularized tissues to enzymatic degradation, they can be crosslinked by chemical means (Permacol®, CuffPatch™, Dura-Guard®).

The decellularization strategies fed the hope that complex structures of whole organs can be sufficiently purified and, if freed from any contaminants, recellularized for organ replacement. However, currently the quality of decellularization and its evaluation has to be approved and recellularization is still an important challenge [214–218].

Saved fibre bundles, fibres and triple helices—hemostyptic sponges and dental films

The technologies to decellularize tissue are used as well to purify raw materials which are further desintegrated to fibrous preparations. The subsequent key steps are grinding and mincing in the cold after intensive acidification of the tissue. The mechanical desintegration steps lead to suspensions with highly swollen gel-like collagen fibres. The triple helices remain largely intact, however. If skin or tendon is used as raw material the masses of which consist of more than 95% collagen, low amounts of fat and some non-collagenous proteins (especially elastin), they are still part of the system. When skin is used as raw material, such technologies often comprise very intensive treatments with strong acids and alkaline covering a pH range of pH 1 to pH 13 [219]. Then glucosaminoglycans and nucleic acids are removed completely during purification.

It is almost impossible to remove contaminations from these highly swollen gels. Extrudable masses show very high viscosity at dry matter contents of 5 to 10% and low diffusion rates of agents and even protons. Adjusting the pH lasts several hours, mixing and homogenization require high mechanical energy. A real homogenous distribution of chemical substances needs several days. Castable suspensions are achieved only at dilutions to 1% and lower. It is impossible to filter these suspensions on a molecular level and therefore it is convenient to remove as much as possible accompanying substances prior to the mechanical homogenization. By varying the viscosity, suspensions can be shaped easily into tubes, threads, films or sponge-like shaped articles of many dimensions [4, 200, 220–222], such as a loophole for the limited dimensions of decellularized tissues which correlate to the dimension of the source material. Marketed materials based on restructuring of fibrous suspensions are MBcollagen®, Matristypt® or Parasorb® to name examples.

Injectables and solid articles from reassembled soluble collagen

Soluble collagen is extracted by organic acid as described and filtrated to achieve sterility. These solutions reassemble to form gels by buffering acid soluble collagen in cold state and increasing the temperature to body temperature [223]. This principle has been used for a long time not only in vitro but also as injectable for soft tissue augmentation in situ (Zyderm®). Cold buffered soluble collagen was injected and reassembled in situ initiated by body temperature [3]. Reassembled collagen shows the typical cross-striation and fibre dimensions depending on the temperature, additives, buffering concentration, and the collagen source and preparation.

Soluble collagen can also be used to coat surfaces of cell culture well plates and to manufacture films, and it was used to prepare more complex materials such as multiple layered sheets, tube-like structures and capsules [224]. Hard tissue replacement materials were manufactured by combined reassembly and silicification of pre-polymerized siloxanes or by combination of reassembled gels with hydroxyapatite [225–228]. Not least, soluble collagen can be spun by diverse techniques (see below). Disadvantage of soluble collagen is its comparably high price per gram when solid articles are manufactured.

Thermally treated, insoluble collagen

Fibrous collagen cannot be transferred into powder with spherical particles but only into wadding-like material. But, if the collagen is partly denatured, the fibrous structure collapses and allows to process the collagen in thermoplastic machines similar to synthetic polymers. To prepare this thermoplastic collagen (TC), skin is unhaired and decellularized. The collagen triple helix has to be denatured, which can be achieved by treatment in excess hot water (80 °C), by extrusion of the wet material (115°) in a microwave or by treatment in a drying oven in hot vapour. The material is then dried and ground into powder. This powder is prepared for extrusion by addition of water, glycerol and other additives [205, 229].

Because of its partial denaturation TC shows some properties of a gelatine. Dried material becomes gel-like when soaked in water. It takes up several hundred percent of water by swelling, and it is easily degradable by proteases. In contrast to gelatine, it is almost not soluble in warm water [205, 230–232].

In the presence of 15 to 20% of water, the material can be processed by extrusion into films, threads, tubes or by injection moulding into 3D articles, and this seems to be unique compared to other proteins [229]. By thermoplastic processing it can be mixed in broad ranges with synthetic polymers not only acting as filler but also as a second polymeric component. Furthermore, TC was mixed with hydroxyapatite to generate bone-like materials by thermoplastic processes. The resulting dry and machinable parts showed mechanical properties like bone. By exposure to saline buffering solution, the collagen became gel-like again. Materials made of thermoplastic collagen have not been tested in animal and clinical trials yet.

Medical applications of gelatine

Gelatine as well has some tradition in medical and associated applications. It is used as pharmaceutical auxiliary to produce capsules and microspheres, to coat surfaces of cell culture plates, to coat textile-based vascular implants, to prepare hemostyptic sponges, films for ophtamologic applications and finally plasma substitutes and adhesives [6, 233–237]. In contrast to the food industry, where the gelling ability of gelatine and its melting temperature of 20 °C to 25 °C are the most important properties [150], in medical applications the high biocompatibility is the main advantage. Gelatine can also be modified, e.g. succinylated to adjust the chemical resistance to aldehydic reactions, e.g. reducible sugars and plant-derived pharmaceuticals. Gelatine is crosslinked by many chemical agents as well as transglutaminase, and the enzymatic degradability is modified by additional stabilisation. In the field of materials prepared from connective tissue up to gelatine, the latter is the most degraded structure with the lowest stability to further degradation (Fig. 12).