Abstract

The effects of ultrasound pretreatment (US) before hot air drying (HAD) and microwave drying (MWD) of garlic slices were investigated. For this aim ultrasonic bath at 30 °C for 30 min (35 kHz), microwave oven at 540 W power and tray dryer at 60 °C and with 1.0 m/s air flow rate were used to reach the final moisture content of 5%. Drying rate increased in the US + HAD and the US + MWD groups by 19.30% and 13.82% respectively in comparison with control groups. The effective moisture diffusivity (Deff) of garlic slices were calculated from Fick’s diffusion model for the HAD, US + HAD, MWD and the US + MWD groups as 1.420 × 10−10, 1.826 × 10−10, 1.177 × 10−8, 1.363 × 10−8 m2/s respectively. The rehydration rates increased, and bulk densities were decreased in the US + HAD and the US + MWD compared to the control groups. The color values were significantly affected after ultrasound pretreatment. Redness, and yellowness increased most in the US + HAD group.

Keywords: Garlic slices, Ultrasound pretreatment, Drying, Rehydration rate, Color

Introduction

Garlic (Allium sativum), which has been farmed for centuries all over the world from its culinary and medical characteristics, is used as a spice in various food preparations such as flavorings, ketchup, sauce, spaghetti, stews, meat sauces etc. (Sharma and Prasad, 2001). It includes anthocyanin, glycosides, essential oil, flavonoids, lectins, fructan, adenosine, pectin, vitamins B1, B2, B6, C and E, prostaglandins, biotin, essential amino acids, nicotinic acid, glycolipids, fatty acids and phospholipids (Bozin et al., 2008).

Fresh garlic is easily spoiled with a high moisture content, around 70%. Dehydration process provides long-term storage of fruits and vegetables by preventing microbial spoilage and chemical deterioration reactions. The drying technique is one of the oldest method for food preservation that involves removal of moisture using heat energy (Afolabi, 2014). Drying is a cheaper preservation method than many other operations, requiring less equipment, less storage and transport costs (Cemeroğlu, 2004). There are a lot of studies related to dried garlic using different techniques such as vacuum microwave, hot air, microwave, infrared, freeze drying but mostly the effect of temperature and slice thickness were discussed (Baysal et al., 2003; Condori et al., 2001; Cui et al., 2003; Ertekin and Yaldiz, 2004; Figiel, 2009; Madamba, 1997; Sablani et al., 2007; Sacilik and Unal, 2005).

Convective air-drying is the most common technique that is used for production of dehydrated vegetables. However, there are many disadvantages of this method such as shrinkage, poor rehydration characteristics, unsuitable changes in color, texture, flavor and nutritive values (Baysal et al., 2003). Thus, some pre-treatment or novel drying applications have been applied to drying process (Çakmak et al., 2016). The microwave drying has become popular as an alternative drying method that provides significant energy savings with a decrease in drying time (Horuz et al., 2017). Microwave heating can be utilized for drying, cooking, thawing, tempering, sterilization, freeze-drying, heating, re-heating and baking in the food industry (Cui et al., 2004). The energy is transferred directly to the sample and distributed on the food material homogeneously in microwave processing (Ozkan et al., 2007). Microwave drying is more uniform than conventional drying equipment (Maskan, 2000).

The pre-treatments contain ultrasound, blanching, vacuum, electric pulses and electrical applications prevent negative effects of drying process to decrease the drying time by reducing the initial water content or by modifying the fruit tissue structure (Barba et al., 2015; Çakmak et al., 2016; Deng and Zhao, 2008; Fernandes and Rodrigues, 2007; Fernandes et al., 2008a; Fijalkowska et al., 2016; Horuz et al., 2017; Içier et al., 2013; Jambrak et al., 2007). The ultrasonic pre-treatment is the process that contains the immersion of the material in a hypertonic aqueous solution or in water to which ultrasound is applied. The using of ultrasounds with drying as a preliminary treatment, favorably affects the features of the acquired products (Nowacka et al., 2012). The ultrasound application can cause cavitation and create microscopic channels in food materials. This change increases the convective mass transfer (Azoubel et al., 2010). The advantage of the ultrasound pretreatment is that the process can be applied at atmospheric temperature and heating is not required, this causes a reduction in the probability of food degradation (Fernandes and Rodrigues, 2007). The ultrasound pre-treatment was studied for drying of jambo, banana, melon, genipap, papaya, strawberry, pineapple, carrot, mushroom, and basil (Azoubel et al., 2010; Çakmak et al., 2016; Fernandes and Rodrigues, 2008; Fernandes et al., 2008a; Gamboa-Santos et al., 2014; Śledź et al., 2017). Although the ultrasound pre-treatment has been applied for drying of some fruits and vegetables, to the best of the authors’ knowledge, there is a limited number of studies in the literature about using the ultrasound pretreatment before the drying of garlic slices. Consequently, the aim of this study is to investigate the effects of the ultrasound pretreatment on the drying rate and some quality properties of microwave and hot air dried garlic slices.

Materials and methods

Material

Garlic (Allium sativum L.) bulbs were purchased from a local market in Izmir, Turkey.

Method

Drying procedure

Ultrasound pretreatment

Sonorex Super Ultrasonic Bath-RK-106 (Sonorex Super RK-106, 100% power: 480 W, 35 kHz, volume: 5.6 L, Berlin, Germany) was used for the ultrasound pretreatment. Before the ultrasound pretreatment the samples were cut by 2 mm thickness. An amount of 250 g slices were immersed in 1 kg water and ultrasound was carried out for 10, 20, 30 min at 30 °C (Azoubel et al., 2010; Çakmak et al., 2016; Fernandes and Rodrigues, 2007). The 30 min experiment was selected because it has the lowest drying time. The temperature was determined as 30 ± 2 °C after the 30 min ultrasound pretreatment.

Convective drying

Garlic slices were dried in a laboratory drier Model UOP8 (Armfield Limited., Ringwood, Hampshire, England) at 60 °C and with 1.0 m/s air flow rate. During the process, the weights (initial was 75 g) of the samples were measured at every 5 min. The drying process was performed from initial moisture content of 60.94% to final moisture content of 5%. Moisture contents of samples was identified as 60.94 ± 0.07 g/100 g by the infrared moisture equipment named MOC-63U Shimadzu (AOAC, 1990).

Microwave drying

Garlic slices were dried in an microwave oven (Arcelik MW 595, Istanbul, Turkey) with 2450 MHz operated at 540 W, rotating glass. The power above 540 W caused to burning in the surface of the samples. The microwave drying was 30 s On–15 s Off. In the process the weights (initial was 75 g) of the samples were measured at every 30 s.

Drying rate

During the drying period data were taken as W: total weight of the wet solid at different times (t). The weight of the dry matter in kilograms was indicated as Ws,

| 1 |

Xe: equilibrium water content (kg H2O/kg dry matter) was identified and the free water content X (kg H2O/kg dry matter) was calculated for each value of Xt for the constant drying.

| 2 |

The drying rate (R) is determined from the Eq. (3) for each drying time:

| 3 |

where A is the subject to surface field for drying in m2 (Baysal et al., 2003).

Moisture ratio (MR): MR was computed according to Eq. 4.

| 4 |

where Mt was the water content in the period drying (kg H2O/kg dry matter), Mi was the initial water content (kg H2O/kg dry matter), and Me was equilibrium water content of the samples (kg H2O/kg dry matter) (Demiray et al., 2017). The effective moisture diffusivity (Deff) of samples was calculated from Fick’s diffusion model (Eq. 5).

| 5 |

where MR was the moisture, t was the time (s), Deff was the effective diffusivity (m2/s) and L was the thickness of garlic slices. For long drying time, the first term of Eq. (6) was used.

| 6 |

The slope was taken from plotting ln (MR) versus time according to Eq. (7) (Caliskan and Dirim, 2017; Demiray et al., 2017).

| 7 |

Methods of analyses

Moisture contents were determined by using 5 g sliced samples with Shimadzu MOC-63U infrared moisture equipment (Kyoto, Japan) at 105 °C for 1 h. Water activity was measured by the water activity equipment named TestoAG 400 (Lenzkirch, Germany). Rehydration capacity was analyzed according to Cui et al. (2008). Rehydration ratio was computed by the Eq. 8.

| 8 |

Bulk density was calculated by the Eq. (9) after slicing and obtaining the volume of (graduated cylinder) 2 g of dry sample (Goula and Adamopoulos, 2005).

| 9 |

Color determination (L*, a*, and b* values) of dried garlic slices was carried by a color measuring instrument (Hunter Lab Color CX1633 Flex, Reston, Va, USA.).

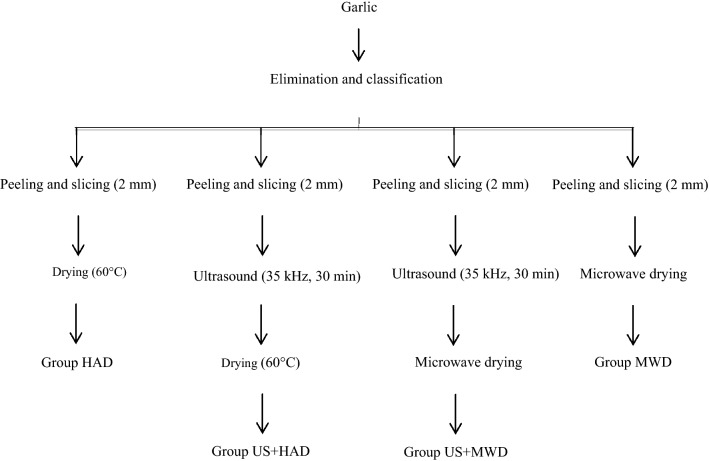

Analysis of variance (ANOVA) was performed to analyze the results statistically using the software SPSS 20 (SPSS 20.0 for Windows Version; SPSS Inc., Chicago, IL, USA). One-way analysis of variance and Duncan’s multiple range test (p ≤ 0.05) were made to determine the difference between groups. The experiments were replicated at least three times (Fig. 1).

Fig. 1.

The production of dried garlic slices

Results and discussion

Effects of pretreatments on the drying rate

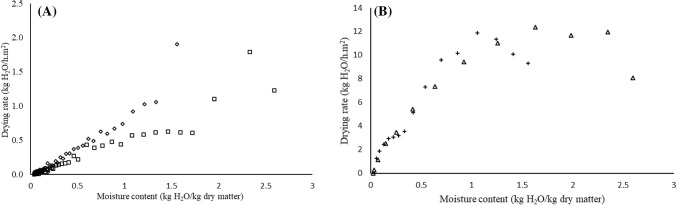

The drying rate was calculated at different times for different treatments and plotted against moisture content as shown in Fig. 2. Drying rates were high at the beginning of the conventional treatment due to the absorption of the water from the surface of the product, then the rate decreased through the end of the process. This situation was the same in the previous studies (Arslan and Özcan, 2010; Sharma et al., 2009).

Fig. 2.

Drying rate versus the moisture content for garlic slices (A) ◊HAD, □US + HAD, (B) + MWD, ΔUS + MWD)

Drying rates were determined as 0.257 kg H2O/h m2 in control group (HAD); 0.306 kg H2O/h m2 in US + HAD group, 6.204 kg H2O/h m2 in MWD and 7.061 kg H2O/h m2 in the US + MWD groups. Drying rate raised in US + HAD and US + MW groups by 19.30% and 13.82% respectively in comparison with control groups. In other study, it was noticed that the drying rate in the ultrasound pretreated mushroom slices (30 min) was identified higher (0.684 H2O/h m2) than the untreated samples (0.507 H2O/h m2) (Çakmak et al., 2016). Similarly, it was reported that the drying rate in the ultrasound pretreated apple cubes (30 min) was determined higher (0.052 kg/kg db min) than the untreated samples (0.042 kg/kg db min) (Nowacka et al., 2012). Similar to these results, it was reported that the drying rate raised in persimmon, tomato slices, carrot slices, apples and, scallop muscles treated by an ultrasound pretreatment (Bai et al., 2017; Cárcel et al., 2007; Horuz et al., 2017; Ricce et al., 2016). The ultrasound as a pretreatment improved the drying process in MWD and HAD group due to the cavitation effect that can be helpful to take out strongly bonded moisture (Fernando et al., 2008a). After this effect of ultrasound, microwave heating provides the dehydration in a very short time.

The garlic slices came up to dried condition in the falling rate period mostly. Drying rate decreased parallel to decreasing moisture content and increasing drying time. The plot was far from linearity, this situation was explained by the effect of nonuniform initial moisture content, changes in the temperature, moisture diffusivity and shrinkage during drying period (Younis et al., 2017).

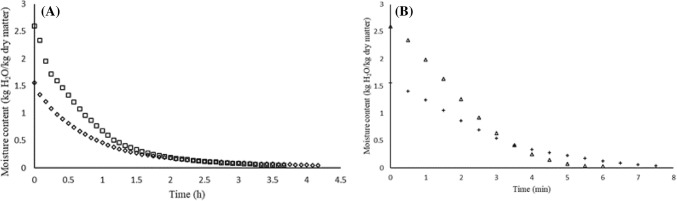

The changes of moisture content with the time of drying at different methods were demonstrated in Fig. 3. The moisture content decreased during the drying time. The water loss was comparatively fast; when the drying process progressed, the water loss reduced in the HAD group. The moisture contents of garlic slices were about 1.56 and 2.59 kg H2O/kg d.m. for HAD and MWD, and US + HAD and US + MWD groups, respectively. The ultrasound pre-treatment raised the moisture content of the US + HAD and US + MWD groups, respectively. Likewise, these results, the ultrasound pre-treatment raised the moisture content of sliced apple from 5.6 to 7.5 H2O/kg d.m. (35 kHz for 30 min) (Fijalkowska et al., 2016). Furthermore, the ultrasound, which was used as a pre-treatment in the drying of banana slices, created an increase in the moisture content (Azoubel et al., 2010; Fernandes and Rodrigues, 2007).

Fig. 3.

Drying curves of the garlic slices groups (A) ◊HAD, □US + HAD, (B) + MWD, ΔUS + MWD)

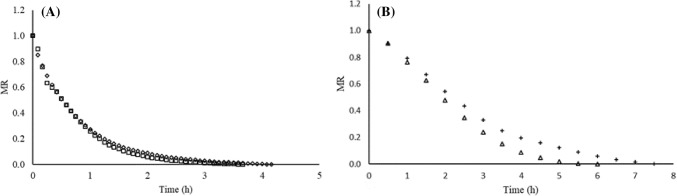

The effectiveness of applications on the dehydration of garlic slices was shown in Fig. 4. It was seen that drying time was 4.17 h for HAD. This time was 3.67 h for US + HAD, 7.5 min for MWD and 6.0 min for US + MWD group. Similarly, previous studies such as: ultrasound pretreatment reduced the drying time by 36% for pineapple, 16% for papaya, 28% for melon, 5–40% for banana, and 17% for apple (Azoubel et al., 2010; Fernandes and Rodrigues, 2007; Fernandes et al., 2008a, b, c; Fijalkowska et al., 2016).

Fig. 4.

Dimensionless moisture content in untreated and pretreatment garlic slices during drying (A) ◊HAD, □US + HAD, (B) + MWD, ΔUS + MWD)

The ultrasound pretreatment can create cavitation and channels in foodstuff, so water from the damaged cells transfer easily. After microwaves heating, heat is generated directly into the material, leading to faster heating rates, compared to conventional heating where heat is usually transferred from the surface to the interior (Hill, 2000). More water evaporates compared to the conventional heating in a short time (Datta, 1990). For example, 50% reduction was obtained after the same power of MW (540 W) was applied with fluidized bed drying (Reyes et al., 2007). After the combination of treatments drying became faster, this provided time saving.

The diffusion coefficients were found for the HAD, US + HAD, MWD and the US + MWD groups as 1.420 × 10−10, 1.826 × 10−10, 1.177 × 10−8, 1.363 × 10−8 m2/s. Sharma and Prasad (2004) studied convective drying assisted by the microwaves and found the diffusion coefficient of dried (40–70 °C) garlic slices as 3.3 × 10−10–6.0 × 10−10 m2/s. Madamba et al. (1996) reported that the effective diffusivities for garlic varied from 2.02 × 10−10 to 4.24 × 10−10 m2/s over the temperature range of 50–90 °C for thin-layer drying of 2–4 mm slices. Younis et al. (2017) studied thin layer drying of garlic slices and found the Deff between 5.83 × 10−11 m2/s and 7.66 × 10−10 m2/s. In a previous study, during the first minutes of garlic drying the samples were heated to a constant temperature, the effective diffusivity reduced with moisture content. They also confirmed that the drying rate was limited because of the slow diffusion in the garlic slices (Vázquez et al., 1999). The minimum diffusion coefficient was found in HAD group and the maximum was found at US + MWD group. Similar to these results, it was noticed that the effective diffusivity values of ultrasound pre-treated (30 min) hot air-dried apples (70 °C and 1.5 m/s) increased (2.168 × 10−9 m2/s) in comparison with untreated sample group (1.829 × 10−9 m2/s) (Nowacka et al., 2012). Likewise, the value of the effective diffusivity of ultrasound pre-treated hot air-dried apple slices (70 °C and 2 m/s) was higher than that of the control group (Fijalkowska et al., 2016).

In a research done by Reyes et al. (2007) it was clarified that microwaves was effective in the increase of Deff and especially when combined with the conventional drying, the mechanism of mass transfer changes. Hydrodynamic mechanism occurs due to the pressure increase during the evaporation of water from the solid material. It was also reported that the absorption of microwave power depends on the moisture content and microwave effect decreases parallel to water loss. They determined the minimum Deff in the combined application of microwaves and fluid bed dryer.

Evaluation of quality characteristics

The results of physical and chemical analyses are shown in the Table 1. Moisture content was targeted to reach 5%. The minimum moisture content was found in MWD and the maximum moisture content was found in US + MWD groups. A significant difference was found between the moisture contents of the samples (p < 0.05). Cui et al. (2003) dried the garlic slices using microwave-vacuum until the moisture content was 10% (wet basis). It was reported that the moisture contents of the dried garlic slices using microwave-vacuum air drying (45 °C), hot-air drying, and freeze drying were 4.2 4.5, and 4.7% (wet basis), respectively.

Table 1.

Some quality characteristics of dried garlic slices

| HAD | US + HAD | MWD | US + MWD | |

|---|---|---|---|---|

| Moisture content (g/100 g) | 5.393 ± 0.045b | 4.580 ± 0.026c | 3.907 ± 0.045d | 5.497 ± 0.050a |

| Water activity | 0.571 ± 0.002a | 0.567 ± 0.001b | 0.503 ± 0.003d | 0.544 ± 0.002c |

| Rehydration rate | 2.413 ± 0.021d | 2.928 ± 0.004a | 2.470 ± 0.010c | 2.635 ± 0.015b |

| Bulk density (g/ml) | 0.402 ± 0.003a | 0.309 ± 0.004b | 0.258 ± 0.004c | 0.239 ± 0.006d |

| L* | 77.80 ± 0.28a | 67.14 ± 0.09b | 65.92 ± 0.19d | 66.72 ± 0.13c |

| a* | 4.74 ± 0.08c | 10.61 ± 0.05a | 10.57 ± 0.08a | 9.07 ± 0.07b |

| b* | 27.13 ± 0.16d | 37.32 ± 0.10a | 31.66 ± 0.12b | 29.81 ± 0.06c |

Different letters (a–d) within columns represent significant difference at the level of p < 0.05

Water activities, as expected, decreased after drying and this decrease was statistically significant (p < 0.05). Rehydration property of dried slices has major importance especially for the consumer. Rehydration rate was found at most in the US + HAD group. The ultrasound assisted microwave process increased the rehydration capacity more than MWD drying due to the cavitation and cell portion of ultrasound effect. In another study, it was found that the increasing microwave power increased the water absorption capacity. It was also mentioned that shrinkage after drying changed the density and decreased the rehydration capacity of the samples. The internal heating in the microwave technique causes more porous structure due to the quick transfer of vapor inside the material and high internal pressure compared to the conventional drying (Reyes et al., 2007). The shrinkage and collapse were present during the whole hot-air drying, causing lower transport rate of water, longer drying time and tough texture while the porous structure collapsed due to the high rate of water evaporation in the last stage of microwave vacuum air drying. The rehydration capacity was similar between the samples of freeze dried, hot air dried and microwave vacuum air dried garlic powder samples (Cui et al., 2003). They found the rehydration capacities for hot air drying as 2.56 ± 0.05; freeze drying as 2.60 ± 0.05 and microwave vacuum air drying as 2.69 ± 0.05, which was similar to US + MW group in this study. They expressed that microwave vacuum air drying method is a better way for drying garlic slices (Cui et al., 2003). Rehydration rates were found between 2.37 and 2.84 by Sacilik and Unal (2005), who studied the effects of the temperature and sample thickness of the the convective hot air dried Kastamonu garlic. Vázquez et al. (1999) found the rehydration ratios of 1.5–5.0 thickness slices between 1.35 and 1.75 dried at different temperatures (40, 50, and 60 °C). In addition, bulk densities shown in Table 1 decreased after the applications due to water loss. The effect of drying methods on the bulk densities of garlic slices was statistically significant (p < 0.05). Microwave application decreased the bulk density at most.

Color values which have an important role for the specification of the the quality of the dried materials are shown in the Table 1. Lightness was decreased significantly after the drying processes as expected (p < 0.05). L* value was found minimum after MWD. The ultrasound pretreatment before MWD preserved the L* value compared to MWD group, but the ultrasound pretreated convective drying protected the L* value better between the application groups. Long drying time and high temperature change the product’s color values (Cui et al., 2003). In microwave application it is well known that some disadvantages such as restricted amount of water is present during the later stages of the drying, the foodstuff’s temperature is easy to increase and difficult to control so some hot spots could occur after process (Cui et al., 2003).

a* value, which was found as 4.74 ± 0.08 in HAD, increased after the drying processes significantly (p < 0.05). There was no significant difference between the a* values of US + HAD and MWD treated sample groups. b* value which showed the yellowness increased after the drying processes. It was stated that garlic becomes redder when it loses its yellow pigment due to the temperature (Prachayawarakorn et al., 2004). Figiel (2009), who studied the vacuum microwave drying of garlic determined a brighter color compared to fresh samples. L*, a* and b* of fresh garlic cloves was determined as 63.74, 2.68, 21.58, whereas these values were changed to 59.8, 7.2, and 28.87 after convective drying, and, also after microwave drying at 480 W garlic slices have the L*, a* and b* values as 71.52, 1.37, and 17.57. In another study, Cui et al. (2003) expressed that b* value was more associated with the maillard reaction. They found b* value much smaller in the microwave vacuum air drying group than in the air drying group. Prachayawarakorn et al. (2004) studied with the color changes of dried garlic slices during storage at different temperatures and relative humidity. They found that the relative humidity lower than 50% was not effective on the L* values, but yellowness and redness increased, so color become darker with the increasing temperature in garlic slices. In a study, sun, oven and microwave oven drying of onion slices were carried out. They found that sun and microwave oven provided better color values (Arslan and Özcan, 2010). Reyes et al. (2007) determined similar color values after microwave drying of potato slices compared to convective air drying but they indicated that the reduced drying time decreased the color degradation.

Calín-Sánchez et al. (2014) studied drying of garlic slices using convective pre-drying and vacuum microwave finishing drying. They reported that there were no significant differences between the fresh and conventional dried samples at 60 °C but convective pre-drying and vacuum microwave finishing drying of samples showed green colors. In previous studies, it was also mentioned that garlic slices were darker in hot air drying than vacuum microwave drying (Calín-Sánchez et al., 2014; Cui et al., 2003; Rasouli et al., 2011). In previous studies, it was reported that microwave drying preserved the color of garlic bright (Calín-Sánchez et al., 2014; Figiel, 2009; Sharma and Prasad 2004).

In summary, ultrasound had a significant effect on accelerating the drying rate of garlic slices before hot air and microwave drying applications. In order to obtain time saving and high quality, these methods could be used as an alternative to, and/or combined with conventional methods. Microwave drying was better than convective drying in terms of drying time. The ultrasound assisted microwave dried samples had the most effective diffusivity as 1.363 × 10−8 m2/s. Rehydration rates were increased significantly after all treatments, which was maximum at US + HAD which also had the minimum bulk density value. Lightness was decreased due to the increase in the redness and yellowness of the all samples after drying. The effects of these combined applications on the nutritive value of other fruits and vegetables maybe discussed in further studies.

Compliance with ethical standards

Conflict of interest

The authors declare they they have no conflict of interest.

References

- Afolabi IS. Moisture migration and bulk nutrients interaction in a drying food systems: a review. Food Nutr Sci. 2014;5:692–714. [Google Scholar]

- AOAC. Official Methods of Analysis. 17th ed. Association of Official Analytical Chemists. Gaithersburg, MD, USA (1990)

- Arslan D, Özcan MM. Study the effect of sun, oven and microwave drying on the quality of onion slices. LWT Food Sci. Technol. 2010;43:121–1127. doi: 10.1016/j.lwt.2010.02.019. [DOI] [Google Scholar]

- Azoubel PM, Baima MAM, Amorim MR, Oliveira SSB. Effect of ultrasound on banana cv Pacovan drying kinetics. J Food Eng. 2010;97:194–198. doi: 10.1016/j.jfoodeng.2009.10.009. [DOI] [Google Scholar]

- Bai L, Yuan Z, Sun J, Georgescu R, O’Donnell ME, Li H. Architecture of the Saccharomyces cerevisiae Replisome. Adv. Exp. Med. Biol. 2017;1042:207–228. doi: 10.1007/978-981-10-6955-0_10. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Barba FJ, Parniakov O, Pereira SA, Wiktor A, Grimi N, Boussetta N, Vorobiev E. Current applications and new opportunities for the use of pulsed electric fields in food science and industry. Food Res. Int. 2015;77:773–798. doi: 10.1016/j.foodres.2015.09.015. [DOI] [Google Scholar]

- Baysal T, Icier F, Ersus S, Yıldız H. Effects of microwave and infrared drying on the quality of carrot and garlic. Eur. Food Res. Technol. 2003;218:68–73. doi: 10.1007/s00217-003-0791-3. [DOI] [Google Scholar]

- Bozin B, Mimica-Dukic N, Samojlik I, Goran A, Igic R. Phenolics as antioxidants in garlic (Allium sativum L., Alliaceae) Food Chem. 2008;111:925–929. doi: 10.1016/j.foodchem.2008.04.071. [DOI] [Google Scholar]

- Çakmak RŞ, Tekeoğlu O, Bozkır H, Ergün AR, Baysal T. Effects of electrical and sonication pretreatments on the drying rate and quality of mushrooms. LWT Food Sci. Technol. 2016;69:197–202. doi: 10.1016/j.lwt.2016.01.032. [DOI] [Google Scholar]

- Calín-Sánchez A, Figiel A, Wojdyło A, Szarycz M, Carbonell-Barrachina AA. Drying of garlic slices using convective pre-drying and vacuum-microwave finishing drying: kinetics, energy consumption, and quality studies. Food Bioprocess Technol. 2014;7:398–408. doi: 10.1007/s11947-013-1062-3. [DOI] [Google Scholar]

- Caliskan G, Dirim SN. Drying characteristics of pumpkin (Cucurbita moschata) slices in convective and freeze dryer. Heat Mass Transf. 2017;53:2129–2141. doi: 10.1007/s00231-017-1967-x. [DOI] [Google Scholar]

- Cárcel JA, García-Pérez JV, Riera E, Mulet A. Influence of high-intensity ultrasound on drying kinetics of persimmon. Dry. Technol. 2007;25:185–193. doi: 10.1080/07373930601161070. [DOI] [Google Scholar]

- Cemeroğlu B. Meyve Sebze İşleme Teknolojisi, 2. cilt. ISBN 975-98578-2-0 (2004)

- Condori M, Echazu R, Sarvia L. Solar drying of sweet pepper and garlic using the tunnel greenhouse drier. Renew. Energy. 2001;22:447–460. doi: 10.1016/S0960-1481(00)00098-7. [DOI] [Google Scholar]

- Cui ZW, Li CY, Song CF, Song Y. Combined microwave vacuum and freeze drying of carrot and apple chips. Dry. Technol. 2008;26:1517–1523. doi: 10.1080/07373930802463960. [DOI] [Google Scholar]

- Cui Z, Xu S, Sun D. Dehydration of garlic slices by combined microwave-vacuum and air drying. Dry. Technol. 2003;21:1173–1184. doi: 10.1081/DRT-120023174. [DOI] [Google Scholar]

- Cui ZW, Xu SY, Sun DW. Microwave–vacuum drying kinetics of carrot slices. J. Food Eng. 2004;65:157–164. doi: 10.1016/j.jfoodeng.2004.01.008. [DOI] [Google Scholar]

- Datta AK. Heat and mass transfer in the microwave processing of food. Chem. Eng. Process. 1990;86:47–53. [Google Scholar]

- Demiray E, Seker A, Tülek Y. Drying kinetics of onion (Allium cepa L.) slices with convective and microwave drying. Heat Mass Transf. 2017;53:1817–1827. doi: 10.1007/s00231-016-1943-x. [DOI] [Google Scholar]

- Deng Y, Zhao Y. Effect of pulsed vacuum and ultrasound osmopretreatments on glass transition temperature, texture, microstructure and calcium penetration of dried apples (Fuji) LWT Food Sci. Technol. 2008;41:1575–1585. doi: 10.1016/j.lwt.2007.10.018. [DOI] [Google Scholar]

- Ertekin C, Yaldiz O. Drying of eggplant and selection of a suitable thin layer drying model. J. Food Eng. 2004;63:349–359. doi: 10.1016/j.jfoodeng.2003.08.007. [DOI] [Google Scholar]

- Fernandes FAN, Linhares JFE, Rodrigues S. Ultrasound as pre-treatment for drying of pineapple. Ultrason. Sonochem. 2008;15:1049–1054. doi: 10.1016/j.ultsonch.2008.03.009. [DOI] [PubMed] [Google Scholar]

- Fernandes FAN, Oliveira FIP, Rodrigues S. Use of ultrasound for dehydration of papayas. Food Bioprocess Technol. 2008;1:339–345. doi: 10.1007/s11947-007-0019-9. [DOI] [Google Scholar]

- Fernandes FAN, Gallão MI, Rodrigues S. Effect of osmotic dehydration and ultrasound pre-treatment on cell structure: melon dehydration. LWT-Food Sci. Technol. 2008;41(4):604–610. doi: 10.1016/j.lwt.2007.05.007. [DOI] [Google Scholar]

- Fernandes FAN, Rodrigues S. Ultrasound as pre-treatment for drying of fruits: dehydration of banana. J. Food Eng. 2007;82:261–267. doi: 10.1016/j.jfoodeng.2007.02.032. [DOI] [Google Scholar]

- Fernandes FAN, Rodrigues S. Application of ultrasound and ultrasound-assisted osmotic dehydration in drying of fruits. Dry. Technol. 2008;26:509–1516. [Google Scholar]

- Figiel A. Drying kinetics and quality of vacuum-microwave dehydrated garlic cloves and slices. J. Food Eng. 2009;94:98–104. doi: 10.1016/j.jfoodeng.2009.03.007. [DOI] [Google Scholar]

- Fijalkowska A, Nowacka M, Wiktor A, Sledz M, Witrowa-Rajchert D. Ultrasound as a pretreatment method to improve drying kinetics and sensory properties of dried apple. J. Food Process Eng. 2016;39:256–265. doi: 10.1111/jfpe.12217. [DOI] [Google Scholar]

- Gamboa-Santos J, Montilla A, Cárcel JA, Villamiel M, Garcia-Perez JV. Air-borne ultrasound application in the convective drying of strawberry. J. Food Eng. 2014;128:132–139. doi: 10.1016/j.jfoodeng.2013.12.021. [DOI] [Google Scholar]

- Goula AM, Adamopoulos KG. Spray drying of tomato pulp in dehumidified air: II. The effect on powder properties. J. Food Eng. 2005;66:35–42. doi: 10.1016/j.jfoodeng.2004.02.031. [DOI] [Google Scholar]

- Hill MJ. The microwave palaeointensity technique and its application to lava. PhD thesis, University of Liverpool, England (2000)

- Horuz E, Jaafara H, Maskan M. Ultrasonication as pretreatment for drying of tomato slices in a hot air–microwave hybrid oven. Dry. Technol. 2017;35:849–859. doi: 10.1080/07373937.2016.1222538. [DOI] [Google Scholar]

- Içier F, Yıldız H, Eroğlu S, Sabancı S, Eroğlu E. Effect of electrical and ultrasonic pre-treatments during osmotic dehydration of quince slices. Acad. Food J. 2013;1:60–69. [Google Scholar]

- Jambrak AR, Mason TJ, Paniwnyk L, Lelas V. Accelerated drying of button mushrooms, Brussels sprouts and cauliflower by applying power ultrasound and its rehydration properties. J. Food Eng. 2007;81:88–97. doi: 10.1016/j.jfoodeng.2006.10.009. [DOI] [Google Scholar]

- Madamba PS. Optimization of the drying process: an application to the drying of garlic. Dry. Technol. 1997;15:117–136. doi: 10.1080/07373939708917221. [DOI] [Google Scholar]

- Madamba PS, Driscollb RH, Buckleb KA. The thin-layer drying characteristics of garlic slices. J. Food Eng. 1996;29:15–97. doi: 10.1016/0260-8774(95)00062-3. [DOI] [Google Scholar]

- Maskan M. Microwave/air and microwave finish drying of banana. J. Food Eng. 2000;44:71–78. doi: 10.1016/S0260-8774(99)00167-3. [DOI] [Google Scholar]

- Nowacka M, Wiktor A, Sledz M, Jurek N, Witrova-Rjchert D. Drying of ultrasound pretreated apple and its selected physical properties. J. Food Eng. 2012;113:427–433. doi: 10.1016/j.jfoodeng.2012.06.013. [DOI] [Google Scholar]

- Ozkan IA, Akbudak B, Akbudak N. Microwave drying characteristics of spinach. J Food Eng. 2007;78:577–583. doi: 10.1016/j.jfoodeng.2005.10.026. [DOI] [Google Scholar]

- Prachayawarakorn S, Sawangduanpen S, Saynampheung S, Poolpatarachewin T, Soponronnarit S, Nathakakule A. Kinetics of colour change during storage of dried garlic slices as affected by relative humidity and temperature. J. Food Eng. 2004;62:1–7. doi: 10.1016/S0260-8774(03)00163-8. [DOI] [Google Scholar]

- Rasouli M, Seiiedlou S, Ghasemzadeh HR, Nalbandi H. Convective drying of garlic (Allium sativum L.): part I: drying kinetics, mathematical modeling and change in color. Aust. J. Crop Sci. 2011;5:1707–1714. [Google Scholar]

- Reyes A, Ceron S, Zuniga R, Moyano P. Comparative study of microwave assisted air drying potato slices. Biosyst. Eng. 2007;98:310–318. doi: 10.1016/j.biosystemseng.2007.07.006. [DOI] [Google Scholar]

- Ricce C, Rojas ML, Miano AC, Siche R, Augusto PED. Ultrasound pretreatment enhances the carrot drying and rehydration. Food Res. Int. 2016;89:701–708. doi: 10.1016/j.foodres.2016.09.030. [DOI] [PubMed] [Google Scholar]

- Sablani SS, Rahman MS, Al-Kuseibi MK, Al-Habsi NA, Al-Belushi RH, Al-Marhubi I, Al-Amri IS. Influence of shelf temperature on pore formation in garlic during freeze-drying. J. Food Eng. 2007;80:68–79. doi: 10.1016/j.jfoodeng.2006.05.010. [DOI] [Google Scholar]

- Sacilik K, Unal G. Dehydration characteristics of Kastamonu garlic slices. Biosyst. Eng. 2005;92:207–215. doi: 10.1016/j.biosystemseng.2005.06.006. [DOI] [Google Scholar]

- Sharma GP, Prasad S. Drying of garlic (Allium sativum) cloves by microwave-hot air combination. J. Food Eng. 2001;50:99–105. doi: 10.1016/S0260-8774(00)00200-4. [DOI] [Google Scholar]

- Sharma GP, Prasad S. Effective moisture diffusivity of garlic cloves undergoing microwave-convective drying. J. Food Eng. 2004;65:609–617. doi: 10.1016/j.jfoodeng.2004.02.027. [DOI] [Google Scholar]

- Sharma GP, Prasad S, Chahar VK. Moisture transport in garlic cloves undergoing microwave-convective drying. Food Bioprod. Process. 2009;87:11–16. doi: 10.1016/j.fbp.2008.05.001. [DOI] [Google Scholar]

- Śledź M, Wiktor A, Nowacka M, Witrowa-Rajchert D. Drying kinetics, microstructure and antioxidant properties of basil treated by ultrasound. J. Food Process Eng. 2017;40:1–13. [Google Scholar]

- Vázquez G, Chenlo F, Moreira R, Costoyas A. The dehydration of garlic. 1. Desorption isotherms and modelling of drying kinetics. Dry. Technol. 1999;17:1095–1108. doi: 10.1080/07373939908917596. [DOI] [Google Scholar]

- Younis M, Abdelkerim D, El-Abdein AS. Kinetics and mathematical modeling of infrared thin-layer drying of garlic slices. Saudi J. Biol. Sci. 2017;25:332–338. doi: 10.1016/j.sjbs.2017.06.011. [DOI] [PMC free article] [PubMed] [Google Scholar]