Abstract

This study aimed to develop a new type of Citrus junos beverage (known as yuja in Korean and yuzu in Japanese) based on a traditional drink preparation method (Galsu). Processing conditions (yuja extract, sugar, and soybean milk) were optimized using response surface methodology (RSM) to develop the beverage. The polynomial models developed by RSM were based on physicochemical characteristics and sensory attributes. Sugar, vitamin C, and total phenolic compound contents, DPPH free radical scavenging activity, sweet odor, yuja flavor, sweet taste, and pungent sensation were used as indices of positive product quality. Beany flavor, astringent taste, beany aftertaste, and astringent aftertaste, were used as indices of negative product quality. Sour odor and sour taste, which are the major characteristics of the traditional yuja beverage, were set in a range to optimize the numerical model. The predicted optimum formulation of yuja beverage (Galsu) as a final product was determined to be 28.4% yuja extract, 36.6% sugar, and 35.0% soybean milk.

Keywords: Response surface methodology, Yuja, Citrus junos, Beverage, Antioxidant, Descriptive analysis

Introduction

Yuja (Citrus junos Sieb. ex Tanaka) originated in China and spread to Korea and Japan in the eighth century. Yuja is widely consumed in Northeast Asia (Korea, China, and Japan) and its juice is used as an aromatic ingredient in various processed foods, including drinks, teas, and dressings. Owing to its special flavor and effectiveness against colds, yuja is commonly processed into herbal medicines and beverages (Lee and Lee 2012).

Yuja contains higher amounts of vitamin C and phenolics than other citrus fruits (Yoo et al. 2004). In addition to its aromatic properties, yuja offers health benefits owing to its antioxidant (Hirota et al. 2010), anti-inflammatory (Hirota et al. 2010), and anticarcinogenic properties (Kim et al. 2014; Sawamura et al. 2005). Furthermore, various studies have been conducted to improve the antioxidant activity of yuja, employing controlled extraction conditions (Ndayishimiye and Chun 2017) and underwater shockwave pretreatment (Kuraya et al. 2017). As yuja use has been limited to date, new recipes should be developed to exploit its functionality.

Galsu is a traditional Korean beverage made from medicinal plants and fruits, along with sugar or honey, the proportions of which need to be optimized and standardized. Galsu was described in the book Imwonshibyukji, written in 1827 during the Joseon Dynasty. There are various kinds of Galsu, including Omi-Galsu, yuja-Galsu, Eobang-Galsu, Imgeum-Galsu, grape Galsu, and quince Galsu, although these beverages are not in modern production (Han 2009). Galsu has pharmaceutical effects, such as in thirst elimination, physical activity enhancement, and the treatment of several diseases, depending on the recipe (Shin and Choi 1998).

As food is essential for nation growth, many countries have made efforts to discover, modernize, standardize, and commercialize traditional foods (Vanhonacker et al. 2013). To successfully commercialize traditional foods, systematic food manufacturing technologies and analysis methods must be established, such as scientific identification. Furthermore, appropriate statistical analysis models, such as response surface methodology (RSM), must be applied during product development. RSM can be used to systematically determine the effects of multiple variables on response variables while minimizing the number of evaluations conducted (Henika 1982). When RSM is used as a designed regression analysis, it can predict the value of a dependent variable or response based on independent variables or controlled values of experimental factors (Meilgaard et al. 2007). RSM has been used to study traditional foods, such as baked cassava cake (Gan et al. 2007), yogurt (Kristo et al. 2003), puri (a traditional Indian food) (Vatsala et al. 2001), and northern-style Chinese steamed bread (Huang et al. 1993), enabling the identification of ingredient combinations that optimize the processing conditions, sensory acceptance, textural properties, and physical effects. RSM has also been used to explore ingredient interactions in various traditional Korean foods, including makgeolli (traditional Korean rice wine) (Kim and Park 2013), rice gruel (Ku et al. 2013), and chogochujang (traditional Korean condiment made from red chili) (Seog and Lee 2008).

Therefore, this study aimed to standardize and commercialize a traditional yuja beverage based on optimum ingredient ratios identified by RSM.

Materials and methods

Materials

Yuja (Citrus junos Sieb. ex Tanaka) extract was purchased from Eden Co. (Goheung-gun, Jeollanam-do, South Korea) and stored at 2 °C. Soybeans (Glycine max (L.) Merrill) were obtained from Boeun Farm (Boeun-gun, Chungcheongnam-do, South Korea) and stored at − 18 °C for quality maintenance. Sugar produced by Q-one Co. (Ulsan Metropolitan City, South Korea) and bottled water from Jeju Province Development Co. (Samdasoo, Jeju Island, South Korea) were used.

Soybean milk was produced using the following method. Soybeans (100 g) were washed and then soaked in bottled water (500 mL) at 2 °C for 24 h. After soaking, the soybeans were ground with water for 1 min in a food grinder (HGBPBKS6, Waring, USA). The liquefied soybean suspension was then filtered through a cotton cloth to yield raw soybean milk.

Preparation of traditional yuja beverage samples

Traditional yuja beverage samples were prepared from water, yuja extract, and soybean milk (100 mL total volume) with different mixing ratios. Water and yuja extract were stored at 2 °C and soybean milk was freshly prepared before use. Each mixture was heated to 170 °C for 1 min in a glass pot while stirring with a wooden spatula. Sugar was then added, and the mixture was heated to 85 °C for 1.5 min. The resulting traditional yuja beverage samples were prepared before the experiment and stored in a refrigerator at 2 °C until further use.

Experimental design

In this study, a D-optimal design was used to conduct the experiments. Three independent variables, namely, yuja extract (X1), sugar (X2), and soybean milk (X3), were taken into account in the experimental design. Based on preliminary trials, the volume fractions of these three materials used in the study were 0.10 ≤ X1 ≤ 0.50, 0.10 ≤ X2 ≤ 0.45, and 0.30 ≤ X3 ≤ 0.75, respectively. The sum of fractions X1, X2, and X3 in each mixture was 1. The responses were physicochemical values and sensory values. Traditional yuja beverage samples were prepared as 12 different formulations based on the D-optimal design (Table 1). The main goal of the experimental design was to maximize the antioxidant and positive sensory properties of the product by optimizing the dependent variables. The ranges of all three manipulated parameters were used to construct the experimental design. Experimental planning and statistical analyses were performed with the Design Expert 8 statistical package (Stat-Easy Co., Minneapolis, MN, USA).

Table 1.

Experimental D-optimal design of the traditional yuja beverage

| Run | Pseudo componenta | Actual component | ||||

|---|---|---|---|---|---|---|

| A: Yuja extract | B: Sugar | C: Soybean milk | A: Yuja extract (%) | B: Sugar (%) | C: Soybean milk (%) | |

| 1 | 0.482b | 0.100 | 0.418 | 48.2 | 10.0 | 41.8 |

| 2 | 0.252 | 0.100 | 0.648 | 25.2 | 10.0 | 64.8 |

| 3 | 0.100 | 0.450 | 0.450 | 10.0 | 45.0 | 45.0 |

| 4 | 0.160 | 0.220 | 0.620 | 16.0 | 22.0 | 62.0 |

| 5 | 0.100 | 0.150 | 0.750 | 10.0 | 15.0 | 75.0 |

| 6 | 0.500 | 0.200 | 0.300 | 50.0 | 20.0 | 30.0 |

| 7 | 0.240 | 0.277 | 0.483 | 24.0 | 27.7 | 48.3 |

| 8 | 0.375 | 0.100 | 0.525 | 37.5 | 10.0 | 52.5 |

| 9 | 0.357 | 0.302 | 0.341 | 35.7 | 30.2 | 34.1 |

| 10 | 0.250 | 0.450 | 0.300 | 25.0 | 45.0 | 30.0 |

| 11 | 0.100 | 0.348 | 0.552 | 10.0 | 34.8 | 55.2 |

| 12 | 0.100 | 0.150 | 0.750 | 10.0 | 15.0 | 75.0 |

Experimental runs were performed in random order from the Design Expert 8 program (Stat-Easy Co., Minneapolis, MN, USA)

aPseudo components:

bYuja extract ranged from 0.1 to 0.5, sugar ranged from 0.1 to 0.45, and soybean milk ranged from 0.3 to 0.75

pH

A traditional yuja beverage sample (5 mL) was homogenized in distilled water (45 mL) using a homogenizer (T18 basic, Ultra-Turrax, IKA, Staufen, Germany). The pH was then measured using a pH meter (Orion Star A222, Thermo Scientific, Rockford, IL, USA).

Total acidity

A traditional yuja beverage sample (5 mL) was dissolved in distilled water (45 mL). The resulting solution was titrated with 0.1 N NaOH to pH 8.23. The NaOH factor was 1.000.

Sugar content

The sugar content of the traditional yuja beverage was determined using a digital refractometer (SCM-1000, HM Digital, Seoul, South Korea) and expressed as a Brix value.

Color parameters

The color of the traditional yuja beverages was measured with a spectrophotometer (ColorQuest XE, HunterLab, Reston, VA, USA) and expressed as L*, a*, and b* values using the CIE method (Commission Internationale de l’Eclairage [International Commission on Illumination]). The L*, a*, and b* values were determined as averages of five replicates. The standard white plate for reference was L* = 92.46, a* = − 0.90, and b* = − 0.07.

Total vitamin C

The total vitamin C levels in the traditional yuja beverage samples were determined using an indophenol titration method based on the procedure outlined in the Korea Food Code issued by the Ministry of Food and Drug Safety (2015). The following solutions were prepared: 6% Metaphosphoric acid–24% acetic acid; 2% 2,4-dinitrophenylhydrazine in 9 N H2SO4; 0.2% 2,6-dichloroindophenol sodium salt hydrate; 5% metaphosphoric acid; 85% H2SO4; and 2% thiourea–5% metaphosphoric acid. After titration was complete, the solutions were measured at a wavelength of 520 nm using a spectrophotometer (UV-1800, Shimadzu, Japan).

Total phenolic compounds

The total phenolic compound contents of the samples were determined spectrophotometrically using gallic acid as a standard according to the method described by Pawar et al. (2014). Samples (100 μL) were added to distilled water (2.3 mL) and the Folin–Ciocalteu reagent (400 μL) and reacted for 7 min. Sodium carbonate aqueous solution (1.2 mL, 20%) was added, followed by homogenization using a vortex mixer (VG3, IKA, Germany) and storage in a dark room at room temperature for 1 h. The absorbance was measured at a wavelength of 765 nm using a UV spectrophotometer (UV-1800, Shimadzu, Japan). The total phenolic compound content was calculated from the standard calibration obtained from the analysis conducted with gallic acid as a standard material using the same method described above for sample analysis.

DPPH free radical scavenging activity

The DPPH free radical scavenging activity was evaluated using the spectrophotometric 1,1-diphenyl-2-picrylhydrazyl (DPPH) free radical scavenging method of Jiang et al. (2014). DPPH solution (4 × 10−4 M) was added to the test samples (0.2 mL), shaken for 2 min, and left in the dark for 20 min before measurement at 517 nm using a spectrophotometer (UV-1800, Shimadzu, Japan). Methanol was used as the control for the test samples.

Descriptive sensory analysis

A total of nine panelists participated in the descriptive analysis. The panelists were all females aged 22–33 years. Six training sessions were conducted in 2 weeks. Sessions consisted of a ranking method used to number reference samples, four basic tastes (sweet, bitter, sour, and savory tasted) with four different intensities, according to their intensity. Sessions also consisted of a method that classified reference samples by taste intensity. During the six training sessions, the panelists were presented with each product from the final set at least once, as well as additional products such as oligosaccharide, lemon juice, tofu, boiled soybean, and roasted rice. The experimental procedures were approved by the institutional review board of Ewha Womans University (IRB No. 107-14) and participants provided informed consent for all testing procedures. A lexicon and set of corresponding reference standards were developed and refined by consensus for the sessions (Table 2). Panelists agreed on the definitions, references, and procedures for every attribute and were trained to score the intensity of these attributes on a 15-point scale (1 = absence, 15 = very strong). Panelist proficiency was checked at the end of training to ensure the consensus, repeatability, and discriminative power of each panelist.

Table 2.

Definitions and reference materials of the descriptive attributes of the traditional yuja beverage

| Categories | Sensory attributes | Definitions | Reference materials |

|---|---|---|---|

| Odor attributes | Sweet | The smell associated with oligosaccharides | Grain syrup (The Healthy Oligosaccharide, CJ Cheiljedang Co., Ltd., Incheon, South Korea) |

| Sour | The smell associated with lemon juice | Lemon juice (Lazy Lemon Juice, Polenghi LAS s.r.l., San Rocco al Porto (LO), Milano, Italy) | |

| Yuja | The smell associated with yuja undistilled solution | Yuja undistilled solution (Yuja undistilled solution, Eden Food Co., Goheung, South Korea) | |

| Tofu | The smell associated with tofu | Tofu (Korean Soybean Tofu, Pulmuone Co. Ltd., Chuncheon, South Korea) | |

| Boiled soybean | The smell associated with boiled soybeans | Boiled soybeans (Soybeans, Boeun Farm Co., Boeun, South Korea) | |

| Roasted rice | The smell associated with roasted rice | Roasted rice (Seongkyeong Roasted Rice, Osung Co., Gimje, South Korea) | |

| Taste/flavor attributes | Sweet | Fundamental taste sensation typical of sucrose | 3% Sucrose (White Sugar, Q.-one, Samyang Co. Ltd., Ulsan, South Korea) solution |

| Sour | Fundamental taste sensation typical of citric acid | 0.35% Citric acid (Daejung Chemicals and Metals Co. Ltd., Siheung-si, Gyeonggi-do, South Korea) solution | |

| Beany | The flavor associated with raw soybeans | Soybeans (Soybeans, Boeun Farm Co., Boeun, South Korea) | |

| Nutty | Roasted carbohydrate flavor | 10% Misutkaru (3 Black Grains Plus Misutkaru, Taekwang Foods Co., Paju-si, Gyeonggi-do, South Korea) | |

| Texture attributes | Astringency | Complex mouthfeel associated with dryness, roughness, and lingering residual | |

| Viscosity | Thickness of the fluid | ||

| Throat hit | Smoothness of the beverage on the throat when swallowed | ||

| Pungency | The sharp, physically penetrating sensation in the nasal cavity when the sample is swallowed | Carbonated water (Perrier Plain, Nestle waters supply sub, France) | |

| Aftertaste | Sweet | Aftertaste associated with sucrose | 3% Sucrose (White Sugar, Q.-one, Samyang Co. Ltd., Ulsan, South Korea) solution |

| Sour | Aftertaste associated with citric acid | 0.35% Citric acid (Daejung Chemicals and Metals Co. Ltd., Siheung-si, Gyeonggi-do, South Korea) solution | |

| Beany | Aftertaste associated with raw soybeans | Soybeans (Soybeans, Boeun Farm Co., Boeun, South Korea) | |

| Astringent | Aftertaste associated with astringency | ||

| Appearance | Turbidity | Clarity of the beverage | |

| Yellowness | Degree of yellowness |

Panelists attended sessions 3 days per week for 2 weeks for descriptive sensory analysis. Two 1.5-h sessions were conducted each day, and six samples were presented per session. Sessions were conducted in the sensory evaluation room of Ewha Womans University. Traditional yuja beverage samples were prepared based on the mixture design formulations and their intensities were evaluated. Panelists examined the products in individual booths under red light to mask differences in color. The product appearance was evaluated under regular fluorescent white light, separate from the other attributes. The 12 traditional yuja beverage samples were presented in a sequential design according to a Williams Latin square. Panelists were asked to score the odor, taste/flavor, texture, aftertaste, and appearance on a 15-point scale.

All samples were used within 1 week and equilibrated at refrigeration temperature (2 ± 2 °C) until used. An aliquot (40 mL) of each sample was poured into a disposable cup (100 mL, polystyrene container, polypropylene lid) coded with a random three-digit number. Tasteless and odorless bottled spring water (Samdasoo, Jeju Island, South Korea) was provided to the panelists to rinse their mouths between samples.

Statistical analysis

Experimental design and statistical analysis were performed using Design Expert 8 software (Stat-Easy Co., Minneapolis, MN, USA). The default settings in Design Expert 8 software were used, as follows. Model points, 6; to estimate lack of fit, 5; replicates, 1; additional center points, 0; total runs, 12. Responses were evaluated by analysis of variance (ANOVA) to determine the significance of the regression model at the 5% level (F-test) and the adjusted coefficient of determination (R2). Principal component analysis (PCA) of the data for each sensory attribute was performed in SensoMineR 1.18 (Francois Husson, Sebastien Le and Marine Cadoret) of R statistical system 3.2.3 (R Development Core Team 2015).

Results and discussion

RSM analysis of physicochemical properties

For each property, the mean of the physicochemical data was subjected to RSM analysis using response surface regression, and a predictive equation was developed (Table 3). The pH and total acidity exhibited a special quartic model. Sugar exhibited a reduced special quartic model, while L* was a reduced quadratic model and a* was a quadratic model. The vitamin C content, total phenolic compounds, and DPPH free radical scavenging activity were linear models. Predictive physicochemical analysis showed that yuja extract was the element with the greatest influence on acidity, a*, b*, vitamin C content, total phenolic compound content, and DPPH free radical scavenging activity; as the fraction of yuja extract increased, the acidity, b*, vitamin C content, total phenolic compound content, and DPPH free radical scavenging activity increased, while a* decreased. Sugar was confirmed as the element that most affected sugar content; as the sugar fraction increased, the sugar content also increased. Soybean milk was confirmed as the element with the greatest influence on pH and L*; as the soybean milk fraction increased, the pH and L* also increased.

Table 3.

Analysis of the fitted model equations for the physicochemical properties of 12 traditional yuja beverage types

| Model | Mean ± SD | R2a | F-value | P value | Polynomial equation | |

|---|---|---|---|---|---|---|

| pH | Special cubic | 3.70 ± 0.014 | 0.9998 | 2166.44 | < 0.0001 | + 3.45Ab + 4.18B + 4.56C − 3.44AB − 2.70AC − 0.53BC + 74.78A2BC − 73.40AB2C + 16.28ABC2 |

| Total acidity (%) | Special quartic | 1.24 ± 0.09 | 0.9982 | 210.26 | 0.0005 | + 1.80A − 0.04B + 0.31C + 2.74AB + 1.11AC + 1.39BC − 1142.61A2BC + 1519.81AB2C − 373.51ABC2 |

| Sugar content (°Brix %) | Reduced special quartic | 14.14 ± 0.17 | 0.9997 | 2072.37 | < 0.0001 | +6.86A + 29.78B + 6.76C + 6.75AB + 4.10AC + 5.02BC + 338.28A2BC − 326.30AB2C |

| L* | Reduced quadratic | 74.17 ± 0.65 | 0.9765 | 72.68 | < 0.0001 | + 71.99A + 66.93B + 76.17C + 19.87AC + 4.76BC |

| a* | Quadratic | − 3.15 ± 0.19 | 0.9879 | 98.07 | < 0.0001 | − 3.83A − 3.39B − 0.54C − 4.78AB − 5.45AC − 2.04BC |

| b* | Linear | 13.89 ± 1.36 | 0.6362 | 7.87 | 0.0106 | + 17.22A + 10.03B + 14.01C |

| Vitamin C content (mg/100 mL) | Linear | 29.65 ± 3.19 | 0.9772 | 192.92 | < 0.0001 | + 73.97A + 11.48B + 9.73C |

| Total phenolic compounds (mg/100 mL) | Linear | 32.39 ± 2.12 | 0.8057 | 18.67 | 0.0006 | + 48.36A + 23.05B + 32.74C |

| DPPH free radical scavenging activity (%) | Linear | 40.94 ± 6.55 | 0.8949 | 38.30 | < 0.0001 | + 81.31A + 25.77B + 21.88C |

a0 ≤ R2 ≤ 1, close to 1 indicates regression fit mathematics the date well

bA yuja extract, B sugar, C soybean milk

Pronounced color differences were observed among the traditional yuja beverage samples. The yellowness of the yuja extract and white color of the soybean milk affected the color of the traditional yuja beverage. These results were in agreement with the findings of previous studies in which yuja was applied to pyun (a traditional Korean snack) (Nam et al. 2004) and chocolate (Yoo et al. 2008), wherein the yellowness of the products increased as the yuja extract content increased.

In this study, samples with large amounts of sugar and soybean milk, and small amounts of yuja extract, had low vitamin C levels. The vitamin C levels in yuja (ranging from 22.6 to 73.4 mg%) are known to be larger than those in other citrons (Jeong et al. 1994; Hwang et al. 2013). Overall, vitamin C in yuja had the greatest effect on the vitamin C content of the traditional yuja beverages.

Furthermore, the yuja extract contents in the traditional yuja beverages were positively correlated with the antioxidant properties. The DPPH free radical scavenging activity increased as the yuja extract fraction increased owing to the polyphenolic compounds in yuja. Electron-donating ability (EDA) is a marker of antioxidant effects, such as those of flavonoids, phenolic acids, and other phenolic compounds. As the reducing power of these materials increases, the EDA increases (Kang et al. 1996). Lee et al. (2008) added yuja to yogurt and obtained similar results to those of the present study, demonstrating that the DPPH free radical scavenging activity increased as the yuja extract fraction increased.

RSM analysis of sensory properties

Sweet odor, sour odor, yuja odor, tofu odor, roasted rice odor, sweet taste, viscosity, astringency, turbidity, and yellowness showed linear models (Table 4). Boiled soybean odor exhibited a special cubic model, while astringency exhibited a reduced cubic model, sweet taste, sour taste, throat hit, and beany showed quadratic models, and beany flavor, nutty flavor, sweet aftertaste, and sour aftertaste showed reduced quadratic models. Pungency showed a special quartic model. The sensory analysis findings indicated that yuja extract was the greatest contributor to sour odor, yuja odor, sour taste, sour aftertaste, and yellowness; as the fraction of yuja extract increased, the degree of these sensory attributes increased. Sugar was the element that most affected the overall intensity, sweet taste, nutty flavor, viscosity, sweet aftertaste, astringent taste, and astringent aftertaste; as the sugar fraction increased, the degree of these sensory attributes increased, while astringent taste and astringent aftertaste decreased. Soybean milk was confirmed as the element with the greatest influence on most odor properties (such as sweet, tofu, boiled soybean, and roasted grain odor), beany flavor, throat hit, pungent sensation, beany aftertaste, and turbidity; as the fraction of soybean milk increased, the degree of these sensory attributes increased.

Table 4.

Analysis of the model equations for the sensory properties of 12 traditional yuja beverage types

| Model | Mean ± SD | R2a | F-value | P value | Polynomial equation | |

|---|---|---|---|---|---|---|

| Odor attributes | ||||||

| Sweet | Linear | 6.33 ± 0.44 | 0.8111 | 19.32 | 0.0006 | + 4.59Ab + 6.36B + 7.54C |

| Sour | Linear | 5.01 ± 0.67 | 0.8341 | 22.62 | 0.0003 | + 7.95A + 4.77B + 3.05C |

| Yuja | Linear | 6.31 ± 0.55 | 0.9240 | 54.72 | < 0.0001 | + 10.07A + 5.93B + 3.87C |

| Tofu | Linear | 4.32 ± 0.43 | 0.8990 | 40.07 | < 0.0001 | +2.09A + 3.90B + 6.19C |

| Boiled soybean | Special cubic | 2.89 ± 0.27 | 0.9644 | 22.55 | 0.0018 | + 0.94A + 1.53B + 3.62C + 3.42AB + 2.57AC + 6.48BC − 41.15ABC |

| Roasted rice | Linear | 1.86 ± 0.20 | 0.7037 | 10.69 | 0.0042 | + 1.39A + 1.65B + 2.33C |

| Taste/flavor attributes | ||||||

| Sweet | Quadratic | 10.19 ± 0.38 | 0.9654 | 33.47 | 0.0003 | + 12.13A + 13.25B + 6.58C − 7.15AB + 3.26AC + 3.53BC |

| Sour | Quadratic | 8.99 ± 0.43 | 0.9907 | 128.02 | < 0.0001 | + 3.46A + 10.65B + 6.87C + 18.50AB − 3.27AC + 15.82BC |

| Beany | Reduced quadratic | 7.20 ± 0.50 | 0.9876 | 139.82 | < 0.0001 | + 12.38A + 2.69B + 3.40C + 6.41AB + 12.59AC |

| Nutty | Reduced quadratic | 3.48 ± 0.26 | 0.9694 | 84.56 | < 0.0001 | + 2.09A + 2.67B + 5.89C − 5.22AC |

| Sweet | Linear | 2.05 ± 0.15 | 0.8998 | 40.40 | < 0.0001 | + 1.10A + 2.56B + 2.40C |

| Texture attributes | ||||||

| Astringency | Reduced cubic | 6.21 ± 0.17 | 0.9894 | 34.93 | 0.0070 | + 4.86A + 7.80B + 3.98C + 0.28AB + 5.21AC + 6.96BC − 40.98ABC − 5.71AC(A–C) − 22.93BC(B–C) |

| Viscosity | Linear | 5.84 ± 0.87 | 0.8279 | 21.65 | 0.0004 | + 2.02A + 9.51B + 6.18C |

| Throat hit | Quadratic | 7.49 ± 0.21 | 0.9927 | 162.34 | < 0.0001 | + 4.39A + 8.26B + 9.48C + 2.82AB − 6.48AC + 2.29BC |

| Pungency | Special Quartic | 2.92 ± 0.14 | 0.9970 | 123.62 | 0.0011 | + 5.12A + 1.93B + 1.58C − 1.13AB + 4.62AC − 0.98BC − 202.71A2BC + 331.50AB2C − 147.60ABC2 |

| Aftertaste | ||||||

| Sweet | Reduced Quadratic | 7.27 ± 0.23 | 0.9965 | 499.32 | < 0.0001 | + 1.81A + 10.59B + 4.78C + 12.39AB + 13.37BC |

| Sour | Reduced Quadratic | 6.25 ± 0.37 | 0.9928 | 242.98 | < 0.0001 | + 11.67A + 2.21B + 2.49C + 3.82AB + 11.64AC |

| Beany | Quadratic | 3.13 ± 0.35 | 0.9592 | 28.20 | 0.0004 | + 3.01A + 4.10B + 5.76C − 7.38AB − 8.64AC − 3.60BC |

| Astringency | Linear | 6.00 ± 0.43 | 0.6530 | 8.47 | 0.0085 | + 4.73A + 6.78B + 6.39C |

| Appearance | ||||||

| Turbidity | Linear | 8.92 ± 0.50 | 0.7957 | 17.52 | 0.0008 | + 7.59A + 7.89B + 10.53C |

| Yellowness | Linear | 7.82 ± 0.49 | 0.8745 | 31.37 | < 0.0001 | + 10.22A + 7.98B + 5.99C |

a0 ≤ R2 ≤ 1, close to 1 indicates regression-fit mathematics the date well

bA yuja extract, B sugar, C soybean milk

Norio et al. (2009) first identified odor-active volatiles in yuja, such as yuzunone and yuzuol, which are not found in other citrus fruits. This study found that the distinct yuja aromas of yuzunone and yuzuol were highly correlated with the yuja extract content and positive sensory attributes. This seemed to agree with previous studies, which indicated that yuja odor was a positive sensory characteristic determinant of products with added yuja extract, such as chocolate (Yoo et al. 2008) and yogurt (Lee et al. 2008). Furthermore, antioxidants, such as phenolic compounds, DPPH free radical scavengers, and vitamin C, have positive characteristics owing to their ability to prevent or delay oxidative stress caused by oxygen-free radicals.

As the proportion of soybean milk increased, the sweet odor increased. Previous descriptive sensory analyses of soybean milk identified a sweet odor as a major characteristic (Torres-Penaranda and Reitmeier 2001). Lesschaeve and Nobel (2005) reported that the beany flavor and astringency of soybean milk were negative characteristics. The soybean milk fraction contributes to the beany flavor of products because soybean milk contains compounds such as pentanol, hexanol, heptanol, hexanal, and ethyl vinyl ketone (Wilkens and Lin 1970; Sessa and Rackis 1977). A higher fraction of soybean milk leads to greater astringency due to phenolic compounds. Adding sugar can reduce the astringency of soybean milk (Bouras et al. 2015), with sugar added to commercial soybean milk to increase preference. Furthermore, the viscosity of the traditional yuja beverages increased with increasing sugar content, in agreement with the results of a previous study (Greenwood et al. 2006).

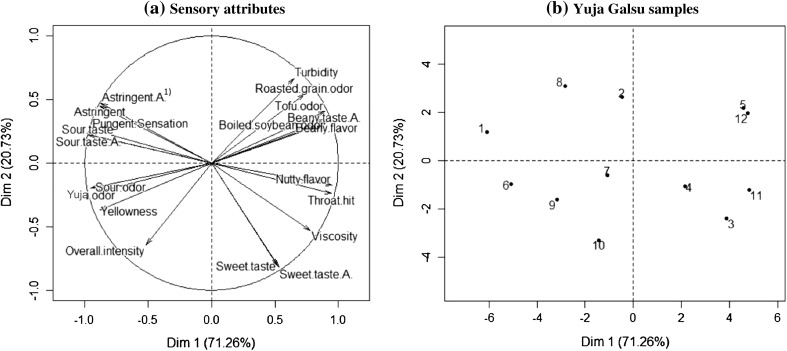

Data exploration with PCA

PCA was used to determine relationships among the descriptive analysis-rated attribute intensities in the 12 traditional yuja beverage samples, as shown in Fig. 1. PCs 1 and 2 accounted for 91.99% of the total variation, at 71.26% and 20.73%, respectively.

Fig. 1.

Principal component (PC) loadings and scores of the sensory attributes (a) and yuja Galsu samples (b) for components 1 and 2. 1)A means aftertaste

Turbidity, roasted grain odor, tofu odor, boiled soybean odor, beany aftertaste, and beany flavor were all closely related to each another in the positive direction of PC1. This group of properties was strongly associated with soybean milk. In contrast, sour taste, sour odor, yuja odor, sour aftertaste, pungent sensation, and yellowness, which were associated with the yuja extract, exhibited strong correlations with each another in the negative direction of PC1. Therefore, it can be interpreted that PC1 represents the variance between the attributes associated with soybean milk and those associated with yuja extract. PC2 was marked by sweet taste, sweet aftertaste, and viscosity, which were loaded in the negative direction.

Samples 5 and 12 were highly loaded in the positive PC1 dimension and were, therefore, characterized by strong soybean milk-related attributes. Samples 1, 2, and 8, which had the smallest amount of sugar, had significantly weaker sweet attributes than the other samples. Furthermore, samples 1 and 6, which contained large amounts of yuja extract, had a significantly stronger sour odor/taste, yuja odor, and yellowness.

Optimization of traditional yuja beverage

The optimum composition of the traditional yuja beverage was determined by varying the proportions of yuja extract (A), sugar (B), and soybean milk (C) as manipulated variables (Table 5). Among the response variables, the properties that had positive features as their levels increased (sugar content, vitamin C content, total phenolic compound content, DPPH free radical scavenging activity, sweet odor, yuja flavor, sweet taste, and pungent sensation) were set to be maximized. The items that had negative features as their levels were decreased (beany flavor, astringent taste, beany aftertaste, and astringent aftertaste) were set to be maximized. Finally, sour odor and sour taste, the major characteristics of the traditional yuja beverage, were set in a range to optimize the numerical model.

Table 5.

Constraints and targets of multiobjective optimization with fitted models

| Constraint name | Goal | Numerical optimization | Graphical optimization |

|---|---|---|---|

| Yuja extract | In range | 0.284 | 0.284 |

| Sugar | In range | 0.366 | 0.366 |

| Soybean milk | In range | 0.350 | 0.350 |

| Sugar content (°Brix %) | Maximum | 19.84 | 19.837 |

| Total phenolic compounds (mg/100 mL) | Maximum | 30.38 | 30.3798 |

| DPPH free radical scavenging activity (%) | Maximum | 45.80 | 45.7979 |

| Vitamin C content (mg/100 mL) | Maximum | 34.28 | 34.279 |

| Sweet odor | Maximum | 11.97 | 5.827 |

| Sour odor | In range | ||

| Yuja odor | Maximum | 7.25 | 7.249 |

| Sweet taste | Maximum | 11.97 | 11.9728 |

| Sour taste | In range | ||

| Beany flavor | Minimum | 2.58 | 2.58218 |

| Astringency | Minimum | 5.34 | 5.336 |

| Pungent sensation | Maximum | 4.67 | 4.670 |

| Aftertaste_beany flavor | Minimum | 1.91 | 1.90864 |

| Aftertaste_astringent | Minimum | 5.18 | 5.177 |

The optimum predicted formulation of the traditional yuja beverage as a final product was found to be 28.4% yuja extract, 36.6% sugar, and 35.0% soybean milk, resulting in a desirability score of 0.621. Interestingly, the percentages of sugar and soybean milk were similar, and this composition agrees with recipes found in old Korean books. Mung beans were used in historical Galsu recipes, and equal amounts of mung bean milk and honey (sugar) are found in Imwonshibyukji and Traditional Healthy Drink (1996). The optimum mixing ratio of Omi-Galsu was 1:1:0.2 for Omija extract, mung bean milk, and sugar, respectively.

In summary, as the mixing ratio in this study was similar to that found in old Korean books, the optimized mixing ratio of the traditional yuja beverage appears to be reasonable. These results also showed the possibility of selling the optimized yuja beverage on the market. Based on the results of this study, various traditional beverages can be restored and modernized.

Conclusion

RSM was successfully used to assess the model effects of three ingredients (yuja extract, sugar, and soybean milk) on the physicochemical and sensory properties of a traditional yuja beverage. Furthermore, optimization studies of the traditional yuja beverage using a mixture design showed that the best combination of ingredients was 28.4% yuja extract, 36.6% sugar, and 35.0% soybean milk. Based on these results, various traditional beverages could be restored and modernized. For the product to be successful, more research is needed to determine how to stabilize floating matter originating from soymilk during the distribution period. Although this study focuses on the restoration of traditional beverages, it is important to consider the use of functional sugar instead of sugar as a health consideration.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Bouras AD, Bouthiba K, Assal NE. Test of improvement of the soymilk quality. Acad platform. J Eng Sci. 2015;3:22–25. [Google Scholar]

- Gan HE, Karim R, Muhammad SKS, Bakar JA, Hashim DM, Rahman RA. Optimization of the basic formulation of a traditional baked cassava cake using response surface methodology. LWT Food Sci Technol. 2007;40:611–618. doi: 10.1016/j.lwt.2006.05.005. [DOI] [Google Scholar]

- Greenwood MS, Adamson JD, Bond LJ. Measurement of the viscosity-density product using multiple reflections of ultrasonic shear horizontal waves. Ultrasonics. 2006;44:e1031–e1036. doi: 10.1016/j.ultras.2006.05.093. [DOI] [PubMed] [Google Scholar]

- Han ES. The optimal dilution magnification for Omi-Galsu. J East Asian Soc Diet Life. 2009;19:62–70. [Google Scholar]

- Henika RG. Use of response surface methodology in sensory evaluation. J Food Technol. 1982;36:96–101. [Google Scholar]

- Hirota R, Roger NN, Nakamura H, Song HS, Sawamura M, Suganuma N. Anti-inflammatory effects of limonene from yuzu (Citrus junos Tanaka) essential oil on eosinophils. J Food Sci. 2010;75:H87–H92. doi: 10.1111/j.1750-3841.2010.01541.x. [DOI] [PubMed] [Google Scholar]

- Huang S, Batker S, Quail K, Moss R. An optimized processing procedure by response surface methodology (RSM) for northern-style Chinese steamed bread. J Cereal Sci. 1993;18:89–102. doi: 10.1006/jcrs.1993.1037. [DOI] [Google Scholar]

- Hwang SH, Kim MJ, Kim KS. Biochemical properties, volatile compounds and total phenol contents of yuza variety. Korean J Food Nutr. 2013;26:685–692. doi: 10.9799/ksfan.2013.26.4.685. [DOI] [Google Scholar]

- Jeong JW, Kwon DJ, Hwang JB, Jo YJ. Influence of the extraction method on quality of citron juice. Korean J Food Nutr. 1994;26:704–708. [Google Scholar]

- Jiang S, Ma Y, Yan D. Antioxidant and antimicrobial properties of water soluble polysaccharide from Arachis hypogaea seeds. J Food Sci Technol. 2014;51:2839–2844. doi: 10.1007/s13197-012-0786-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kang YH, Park YK, Lee GD. The nitrite scavenging and electron donating ability of phenolic compounds. Korean J Food Nutr. 1996;28:232–239. [Google Scholar]

- Kim JY, Park GS. Optimization of ingredient for the preparation of Asparagus cochinchinensis Makgeolli by response surface methodology. J East Asian Soc Diet Life. 2013;23:799–809. [Google Scholar]

- Kim SH, Shin EJ, Hur HJ, Park JH, Sung MJ, Kwon DY, Hwang JT. Citrus junos Tanaka peel extract attenuates experimental colitis and inhibits tumour growth in a mouse xenograft model. J Funct Food. 2014;8:301–308. doi: 10.1016/j.jff.2014.03.024. [DOI] [Google Scholar]

- Kristo E, Biliaderis CG, Tzanetakis N. Modelling of the acidification process and rheological properties of milk fermented with a yogurt starter culture using response surface methodology. Food Chem. 2003;83:437–446. doi: 10.1016/S0308-8146(03)00126-2. [DOI] [Google Scholar]

- Ku KH, Choi EJ, Koo MS. Optimal mixture ratio for rice (Oryza sativa L.) gruel supplemented with puffed rice by mixture design. J East Asian Soc Diet Life. 2013;23:218–226. [Google Scholar]

- Kuraya E, Nakada S, Touyama A, Itoh S. Improving the antioxidant functionality of Citrus junos Tanaka (yuzu) fruit juice by underwater shockwave pretreatment. Food Chem. 2017;216:123–129. doi: 10.1016/j.foodchem.2016.08.026. [DOI] [PubMed] [Google Scholar]

- Lee KG, Lee SK. Monitoring and risk assessment of pesticide residues in yuza fruits (Citrus junos Sieb. Ex Tanaka) and yuza tea samples produced in Korea. Food Chem. 2012;135:2930–2933. doi: 10.1016/j.foodchem.2012.06.111. [DOI] [PubMed] [Google Scholar]

- Lee YJ, Kim SI, Han YS. Antioxidant activity and quality characteristics of yogurt added yuza (Citrus junos Sieb ex Tanaka) extract. Korean J Food Nutr. 2008;21:135–142. [Google Scholar]

- Lesschaeve I, Nobel AC. Polyphenols: factors influencing their sensory properties and their effects on food and beverage preferences. Am J Clin Nutr. 2005;81:330S–335S. doi: 10.1093/ajcn/81.1.330S. [DOI] [PubMed] [Google Scholar]

- Meilgaard M, Civille GV, Carr BT. Sensory evaluation techniques. 4. Boca Raton: CRC Press; 2007. [Google Scholar]

- Ministry of Food and Drug Safety (2015) Korean food code. Chapter 7. General test methods https://www.foodsafetykorea.go.kr/foodcode/01_03.jsp?idx=317. Accessed 10 May 2018

- Nam HW, Hyun YH, Pyun JW. A study on the optimum ratio of starch and dilution factors of yuza extract in preparation of yuza Pyun. J East Asian Soc Diet Life. 2004;14:591–597. [Google Scholar]

- Ndayishimiye J, Chun BS. Optimization of carotenoids and antioxidantactivity of oils obtained from a co-extraction of citrus (Yuzu ichandrin) by-productsusing supercritical carbon dioxide. Biomass Bioenerg. 2017;106:1–7. doi: 10.1016/j.biombioe.2017.08.014. [DOI] [Google Scholar]

- Norio M, Naomi T, Yoshiko K, Akira N, Yasutaka O, Tomoko M, Akira F. Novel character impact compounds in yuzu (Citrus junos Sieb. ex Tanaka) peel oil. J Agric Food Chem. 2009;57:1990–1996. doi: 10.1021/jf803257x. [DOI] [PubMed] [Google Scholar]

- Pawar N, Gandhi K, Purohit A, Arora S, Singh RRB. Effect of added herb extracts on oxidative stability of ghee (butter oil) during accelerated oxidation condition. J Food Sci Technol. 2014;51:2727–2733. doi: 10.1007/s13197-012-0781-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sawamura M, Wu Y, Fujiwara C, Urushibata M. Inhibitory effect of yuzu essential oil on the formation of N-nitrosodimethylamine in vegetables. J Agric Food Chem. 2005;53:4281–4287. doi: 10.1021/jf047816u. [DOI] [PubMed] [Google Scholar]

- Seog EJ, Lee JH. Sensory evaluation of Prunus mume extracted-added vinegared red pepper paste using response surface methodology. Prev Nutr Food Sci. 2008;13:40–44. doi: 10.3746/jfn.2008.13.1.040. [DOI] [Google Scholar]

- Sessa DJ, Rackis JJ. Lipid derived flavors of legume protein products. J Am Oil Chem Soc. 1977;54:468–473. doi: 10.1007/BF02671039. [DOI] [Google Scholar]

- Shin MJ, Choi YJ. Literature review on the pharmaceutical effect of traditional non-alcoholic beverages in ⌈Lim Won Sib Yuk Gi⌋. J East Asian Soc Diet Life. 1998;8:81–92. [Google Scholar]

- Torres-Penaranda AV, Reitmeier CA. Sensory descriptive analysis of soymilk. J Food Sci. 2001;66:352–356. doi: 10.1111/j.1365-2621.2001.tb11345.x. [DOI] [Google Scholar]

- Vanhonacker F, Kuhne B, Gellynck X, Guerrero L, Hersleth M, Verbeke W. Innovations in traditional foods: impact on perceived traditional character and consumer acceptance. Food Res Int. 2013;54:1828–1835. doi: 10.1016/j.foodres.2013.10.027. [DOI] [Google Scholar]

- Vatsala CN, Saxena CD, Rao PH. Optimization of ingredients and process conditions for the preparation of puri using response surface methodology. Int J Food Sci Technol. 2001;36:407–414. doi: 10.1046/j.1365-2621.2001.00474.x. [DOI] [Google Scholar]

- Wilkens WF, Lin FM. Gas chromatographic and mass spectral analyses of soybean milk volatiles. J Agric Food Chem. 1970;18:333–336. doi: 10.1021/jf60169a003. [DOI] [Google Scholar]

- Yoo KM, Lee KW, Park JB, Lee HJ, Hwang IK. Variation in major antioxidants and total antioxidant activity of yuzu (Citrus junos Sieb ex Tanaka) during maturation and between cultivars. J Agric Food Chem. 2004;52:5907–5913. doi: 10.1021/jf0498158. [DOI] [PubMed] [Google Scholar]

- Yoo KM, Lee CH, Hwang IK. Preparation of chocolate added with yuza (Citrus junos Seib ex TANAKA) and its antioxidant characteristics. Korean J Food Cook Sci. 2008;24:222–227. [Google Scholar]