Abstract

In the present study, Indian mackerel was dried by microwave vacuum drying (MVD) method and compared its physico chemical quality to mackerel dried by hot air drying (HAD) method. Antioxidant effects of thyme oil (TMO) and clove leaf oils (CLO) during storage were also evaluated. Brine salted mackerel was dried in hot air oven (50–55 °C) and microwave vacuum dryer (600 W and 600 Hg mm). For essential oil treatment, mackerel was dipped in 0.75% TMO and CLO for 5 min. Moisture content of MVD and HAD samples was reduced to 30–32% in 1.2 h and 12 h, respectively. Rehydration ability and water absorption index of MVD samples were significantly higher to that of HAD samples. Mackerel dried by HAD showed significantly higher salt soluble and water soluble protein nitrogen fractions than that of MVD samples. Significantly higher hardness and chewiness values were observed for HAD samples. Color and appearance of uncooked MVD sample was superior to that of HAD samples. As per the results of PV and TBARS, TMO exhibited better antioxidant effect compared to CLO. The study demonstrated that fast drying can be achieved by microwave vacuum dryer and it can produce dried fish having better sensory and textural attributes.

Keywords: Microwave vacuum drying, Indian mackerel, Rehydration, Sensory quality, Essential oils

Introduction

Drying is an ancient technology used for preserving and improving the storage stability of food. During drying process, moisture content is reduced to an extent at which bacteria cannot grow and decompose the food (Duan et al. 2011). In India, 15% of the total catch is preserved by drying and the dried fish has good demand in domestic as well as international markets. Traditionally, the fishermen dry fish under sun which leading to a product of low hygienic quality. Several methods of mechanical drying have been developed for fish and fish products including hot air oven drying, combination of solar energy and mechanical drying, smoke drying, freeze drying, vacuum drying, fluidized bed drying etc. Hot air drying is the widely accepted drying method in the seafood industry as it is easy to implement, less costly and is simple to operate and maintain (Wang et al. 2013). However, hot air drying has few drawbacks that it involves more energy consumption and long drying period resulting in products of inferior quality.

Microwave drying is a recent technique adopted for drying vegetables and fruits (Paengkanya et al. 2015; Pu and Sun 2017). Microwave is strongly penetrable and because of this, food inside and outside is heated simultaneously along with a rise in temperature (Guo et al. 2017). In order to improve the drying rate and to enhance the quality of final products, other input such as vacuum is used in combination with microwave. Under vacuum, high energy water molecules diffuse to the surface and evaporate at a lower temperature. Hence, through microwave vacuum drying, high product quality can be achieved by the low temperature and the rapid energy transfer of microwave heating. Although many reports are available pertaining to microwave vacuum drying of fruits and vegetable, the studies on fish drying are not many and are limited to drying characteristics (Fu et al. 2015; Hu et al. 2013; Darvishi et al. 2013). It is essential to examine the physico-chemical qualities of the microwave vacuum dried fishes so as to evaluate its potential to replace the common drying techniques.

Indian mackerel is a medium pelagic fatty fish harvested in huge quantity along the Indian coast. It is mostly consumed fresh, refrigerated and exported in frozen condition. Dried mackerel also attract good demand both in domestic and international markets. Lipids of Indian mackerel are reported to possess high degree of unsaturation, making it highly susceptible to oxidation during thermal treatment. In general, antioxidants are employed to reduce lipid oxidation during processing and the interest on natural antioxidants is greatly increasing because of the adverse health impact of synthetic antioxidants. Essential oils (EOs) are naturally occurring antioxidants/antimicrobials, classified as generally regarded as safe (GRAS) and have been successfully applied for many food products including fish (Patel 2015). According to the literature review, clove leaf oil and thyme oil are two among the most frequently used essential oils for seafood applications and both have shown to delay lipid oxidation and microbial growth in chilled fish and fishery products. However, evaluation of these essential oils as antioxidant in dried fish, especially Indian mackerel is not reported elsewhere. Hence, the present study was aimed to evaluate the physicochemical characteristics of microwave vacuum dried Indian mackerel and also to assess the antioxidant effect of essential oils during drying and further storage.

Materials and methods

Fresh Indian mackerel (average length 20 cm and average weight 80 g) was purchased from Visakhapatnam harbor and brought to the institute immediately in iced condition. Essential oils [clove leaf oil (CLO) and thyme oil (TMO)] were procured from Kancore Ingredients limited, Kerala, India. Analytical grade chemicals and glass wares were purchased from Merck, Sigma, Borosil etc.

In-vitro antioxidant activity of essential oils

Antioxidant activities of essential oils were assessed by reducing power assay (Yildirim et al. 2001), DPPH free radical scavenging assay (Ali et al. 2015) and ABTS free radical scavenging assay (Arnao et al. 2001) following slight modifications of the reported methods.

Preparation of dried fish

The fresh fish was dressed in butterfly style and cleaned properly. The fishes were then brine salted in the ratio 4:1 (fish to salt) overnight, debrined and drained over mesh tray. The brined fishes were then divided into 6 lots. Two lots were dip treated in 0.75% CLO (1:1 fish to solution) and another two lots were dip treated in 0.75% TMO solution (v/v) for 5 min (1:1 fish to solution) and drained over mesh tray. EO treated fishes were further divided into 2 batches; one batch was dried by hot air drying method (HAD) in an air oven maintained at 55 ± 5 °C and another batch was dried in a microwave vacuum dryer (MVD), (600 W and 600 Hgmm) till the moisture content reduced to 31–34%. Similarly, two batches of control samples (dipped in potable water for 5 min) were dried by HAD and MVD methods. Totally, six batches of dried fishes were prepared and packed in LDPE packaging material for further analysis.

Physico-chemical evaluation of dried fish

For comparison of physicochemical properties, control samples dried by both the methods were chosen. Proximate composition was analyzed by standard AOAC (1990) methods. Salt content was determined by AOAC method (AOAC 1975). pH of the ground samples (homogenizing 5 g sample in 20 ml distilled water) was determined by using digital pH meter (LABMAN, LMPH-10). Water soluble nitrogen and salt soluble nitrogen fractions were extracted by Winton and Winton (1958) and Ironside and Love (1958), respectively and nitrogen content of those fractions was determined by micro-Kjeldhal method (AOAC, 1975). Water absorption index was calculated following the method of Anderson et al. (1969). Rehydration kinetics assessment was carried out according to Duan et al. (2011) with slight modifications. Three samples each of known weight were soaked in water (1:30 ratio) at 40 °C for 1 h and samples were withdrawn at 10 min interval to find out the gain in weight and moisture content during soaking. Rehydration rate was expressed as the ratio of weight of rehydrated sample to the weight of dried sample. Moisture content at every 10 min was monitored to analyse the moisture absorption characteristics. Rehydration kinetics was analysed by using Peleg model (1998) using the following equation

where X is the moisture content (g %) at a known process time ‘t’ (min), X0 is the initial moisture content (g %), ‘t’ is the process time (min), K1 is the peleg rate constant and K2 is the Peleg capacity constant. Rehydration experiment was done in triplicate.

Texture profile analysis was done using a food texture analyser (Lloyd Instruments, AMETEK Ltd., Bognor Regis, UK) as per Anderson et al. (1994) equipped with a load cell of 50 N. For texture analysis, uniform samples devoid of bones were cut from the dried fish and rehydrated for 20 min. For measuring color values, only muscle was collected and L*, a* and b* values of the ground muscle sample were determined by Hunter’s colorimeter (ColorFlex EZ, Hunter Lab, Reston, VA, USA). Sensory analysis was done after rehydrating uniform pieces of the dried fish for 20 min, followed by cooking for 5 min in boiling water. A panel of 5 members have evaluated the sensory attributes (color and appearance, odour, texure and flavor) based on a 9 point hedonic scale (Amerine et al. 1965). Score of individual attributes were summed up and divided by total number of attributes to determine the overall acceptability score.

Lipid oxidation

Lipid oxidation of the dried samples were evaluated by measuring the amount of primary lipid oxidation products i.e., hydroperoxides (Yildiz 2015) and one of the secondary lipid oxidation products i.e., malonaldehyde (Tarladgis et al. 1960). The results were expressed as peroxide value (milliEq O2/kg sample) and TBARS (mg malonaldehyde/kg sample), respectively. Lipid oxidation was monitored for a period of 6 months storage at ambient temperature.

Statistical analysis

Statistical analysis of the data in triplicate was performed by SPSS version 16. Analysis of variance was found out to compare the data. Duncan’s multiple range test was performed to find out the statistically significant difference at 5% level of significance.

Results and discussion

Antioxidant activity of essential oils

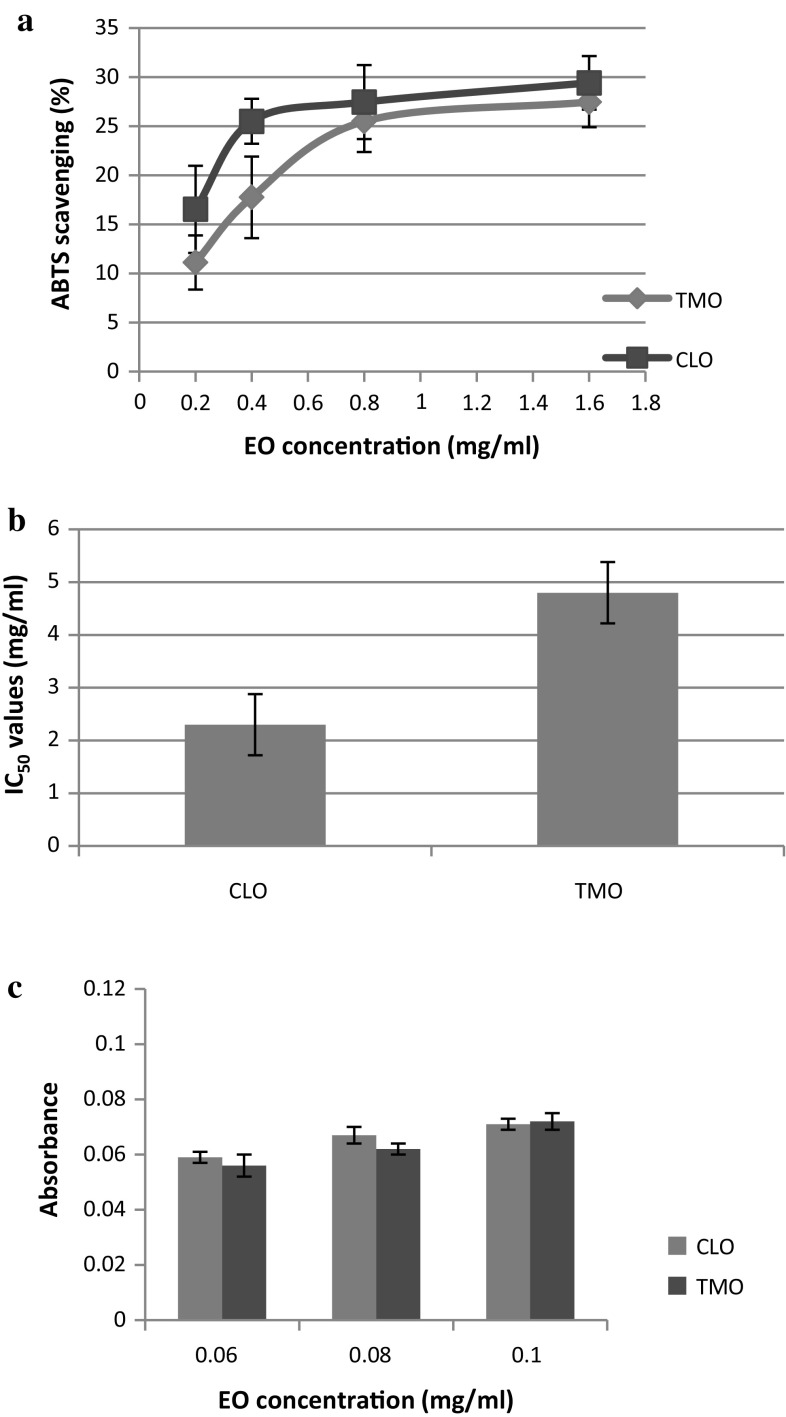

Since the in vitro activities of the EOs varies with method of extraction, genotype, geographical origin, harvesting period, season etc., it becomes essential to evaluate the in vitro antioxidant activities of the essential oil before every food application. Owing to their multifarious composition, antioxidant activities of essential oils are usually ascertained by more than one assay. Assay evaluating the scavenging of DPPH. and ABTS+. radicals are among the most popular spectrophotometric methods for determination of the antioxidant capacity of food, beverages and vegetable extracts. In the present study, CLO exhibited higher free radical scavenging activities as measured from ABTS and DPPH scavenging assays (Fig. 1). In fact, the IC50 (the concentration required to scavenge 50% of the free radical) value of DPPH scavenging assay shown by CLO was less than half of that required by TMO. Similarly, Zengin and Baysal (2015) also reported higher antioxidant activity in clove oil compared to thyme oil. The antioxidant activity of TMO and CLO is attributed to its major active compound like eugenol in clove (Wei and Shibamoto, 2010) and m-thymol in thyme (Bozin et al. 2006). It is often difficult to compare the result of antioxidant activities with those reported in literature because of the differences in methodologies followed and expression of results. Reducing power assay measures another mechanism of antioxidants i.e., the ability of an antioxidant to reduce ferric ion to ferrous ion. The increase in absorbance indicates increase in concentration of ferrous ions. i.e., higher reducing power of the compounds. Unlike ABTS and DPPH assays, reducing power of thyme oil followed the similar trend of clove oil. It has been reported that the reducing power might be due to hydrogen-donating ability and is generally associated with the presence of reductones (Duh 1998).

Fig. 1.

In-vitro antioxidant activities of essential oils. a ABTS free radical scavenging assay, b IC50 values of DPPH scavenging assay and c metal reducing power

Physico chemical qualities of dried fish

Proximate composition and salt content

Proximate composition and few chemical qualities of mackerel dried by hot air and microwave vacuum methods are presented in Table 1. As observed from the table, there was no significant difference between the protein, moisture and fat content of MVD and HAD samples. However, muscle of fishes dried in MVD had significantly higher ash content (p < 0.05) than those dried in hot air dryer which may owe to the higher amount of salt present in MVD samples. It was important to note that period of drying required to reduce the moisture content to 31–34% in microwave vacuum dryer and hot air dryer was 1.2 h and 12 h, respectively (moisture content of brine salted fishes was 58.83%). In fact, a ten fold reduction in drying time was achieved by microwave vacuum dryer. Similar to our study, a higher drying rate is recorded for many products; few of them are mushroom (Giri and Prasad, 2007) and durian chips (Paengkanya et al. 2015), banana, grapes, and carrot (Monteiro et al. 2015) and mango slices (Pu and Sun, 2017). Fu et al. (2015) could achieve a 27 fold reduction in drying period for silver carp slices when dried by microwave vacuum drying method compared to conventional oven drying method. During microwave vacuum drying, heat is simultaneously generated internally and externally, liquid moisture get intensively evaporated and transported to the surface leading to faster dehydration of the material (Li et al. 2011).

Table 1.

Proximate composition, salt, WSN and SSN of dried mackerel

| Parameters | MVD | HAD |

|---|---|---|

| Proximate composition | ||

| Moisture (%) | 32.45 ± 1.2 | 31.11 ± 1.86 |

| Protein (%) | 44.53 ± 1.71 | 43.38 ± 1.26 |

| Fat (%) | 4.02 ± 0.38a | 5.28 ± 0.74b |

| Ash (%) | 21.61 ± 0.85b | 17.9 ± 0.36a |

| Salt content (%) | 20.43 ± 0.76b | 15.03 ± 0.62a |

| Water soluble nitrogen (% wet weight) | 11.25 ± 1.06 | 12.81 ± 0.89 |

| Salt soluble nitrogen (% wet weight) | 28.13 ± 1.64a | 32.81 ± 1.29b |

For each parameter, mean values (n = 3 with standard deviation) followed by different letters (a, b) denote significant differences (p < 0.05) between the sources

Microwave vacuum dried fishes had significantly higher (p < 0.05) salt content in muscle than its counterparts dried by hot air drying. After drying, HAD fishes developed a white crusty salt film on the surface which was rid off by touching; whereas such precipitation was not observed in MVD samples. This point out that, during hot air drying process, salt particles got precipitate over the surface. Being a fast process and also because of the difference in dehydration mechanisms, the aforementioned surface precipitation was not observed in MVD fishes, accounted for a higher salt concentration in the muscle of the same.

Protein solubility

As shown in Table 1, microwave vacuum dried samples showed significantly lower (p < 0.05) water soluble and salt soluble nitrogen fraction than HAD fishes. As the protein solubility is mainly affected by denaturation, the present result indicates that the extent of denaturation is slightly higher in MVD samples. Information on microwave induced changes on protein is scarce while most of the reports are pertaining to microwave drying of vegetables/grains and fruits. Caprita and Caprita (2010) evaluated the protein solubility of microwave heated and air oven heated soy bean flour (SBF) and observed a rapid reduction of solubility in microwave heated SBF protein. The authors assume that the difference in solubility is because of the difference in heating mechanism of microwave and oven heating. Microwave heating begins within the cells and molecules where water is present whereas in air forced oven, heat transfers convectionally from outer surface to inner side of the material. Iuliana et al. (2015) demonstrated that microwave treatment reduced the protein content in cow milk as microwave heating transfer free sulfhydril groups from soluble to insoluble fractions and those inaccessible sulfhydril groups become exposed during protein unfolding, allowing new covalent inter and intra molecular disulfide bonds. Additionally, a non thermal effect of microwave on protein structural rearrangement is reported by Porcelli et al. (1997). All these literature suggests that the extent of protein structural alteration is more during microwave heating.

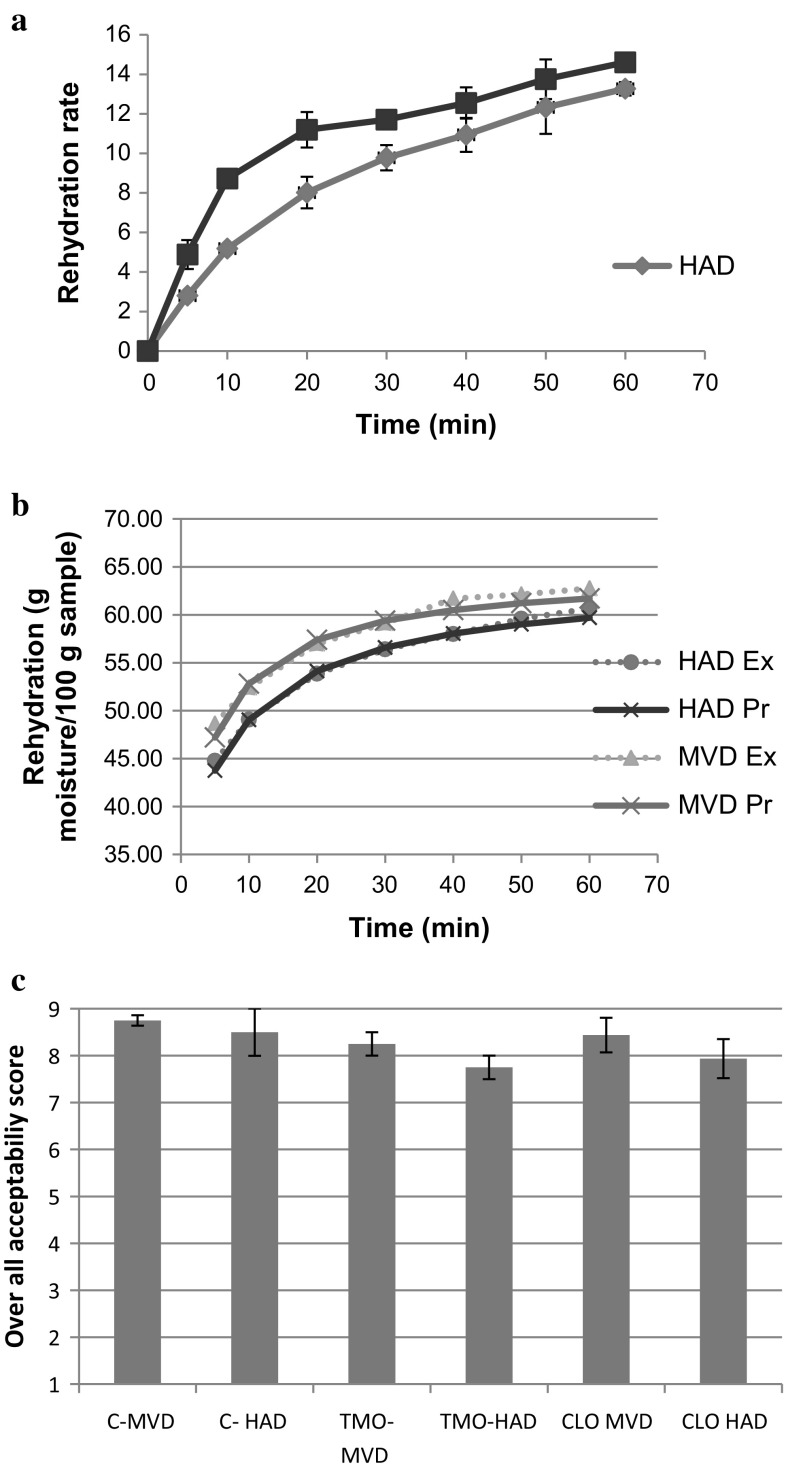

Moisture absorption, WAI and rehydration kinetics

It is recommended that dried fish should have good rehydration ability as they are mostly rehydrated before usage. Rehydration rate of the dried samples is presented in Fig. 2a and moisture absorption/rehydration (experimental and predicted) is depicted in Fig. 2b. As seen in the Fig. 2a, rehydration rate was higher for initial 20 min of soaking period, there after rate of rehydration proceeded slowly for both the samples. Microwave vacuum dried samples had significantly higher (p < 0.05) RR than HAD mackerel during the period of soaking. Moisture absorption as measured by the moisture content during rehydration period followed the similar trend of RR where MVD fishes exhibited elevated moisture absorption characteristic (Fig. 2b). Increased level of moisture absorption during the beginning of soaking period is attributed to surface adsorption and capillary action (Seremet et al. 2016), while the reduction after 30 min is attributed to the drop in driving force required for moisture uptake when the rehydration progresses and approaches the equilibrium (Moreira et al. 2008). WAI also gives a measure of water uptake by food, the value of which was significantly higher (p < 0.05) in MVD samples (2.6) than HAD sample (2.04). This was in agreement with the finding of Hu et al. (2013) where microwave vacuum dried meat gel from hair tail fish exhibited higher WAI than those of oven dried gel.

Fig. 2.

Rehydration properties and sensory score of dried fish. a Rehydration rate, b moisture absorption (n = 3, mean ± standard deviation) and c over all acceptability score of dried fishes (n = 5)

The data of moisture absorption was fitted in Peleg model which could explain the experimental data very well with R2 values 0.99 for both the samples. The Peleg rate K1 is related to mass transfer rate i.e., lower the K1, higher the moisture absorption (rehydration). Peleg capacity constant, K2 is related to water retention capacity and maximum moisture content after long rehydration time. K1 of MVD mackerel (0.161) was significantly lower (p < 0.05) to HAD sample (0.283), indicating higher moisture uptake in MVD samples. It has been accounted that microwave vacuum drying develop a more porous product which can be rehydrated more quickly than the air dried product (Giri and Prasad, 2007). To the best of our knowledge, this is the first report on rehydration characteristics of a whole microwave vacuum dried fish. Higher rehydration rate is reported for microwave dried mushroom (Giri and Prasad, 2007). There was no significant difference between the absolute values of K2 of dried mackerel. This could be due to the reason that, K2 is related to the rehydration temperature and chemical composition of a material (Peleg 1998), which was not varied for the present experiment.

Sensory evaluation

Overall acceptability scores of cooked control and essential oil treated samples are depicted in Fig. 2c. The figure, score of control MVD samples was the highest among all samples and that of TMO HAD sample was the lowest. Panelists detected slightly higher essential oil odour in MVD fishes compared to those dried under hot air method. Among the two EOs, clove oil treated mackerel showed better acceptability than thyme oil treated samples. Thyme oil treatment has given strong EO odour in the product, in addition to imparting negative effect on its color attribute. However, because of the advanced appearance and color, MVD samples rated superior to HAD samples irrespective of essential oil treatment.

Texture profile analysis

Generally, hardness, springiness, cohesiveness and chewiness characterize the textural properties of dried fish while hardness is the most important textural attribute. As evident from Table 2, hardness was significantly influenced by the drying methods. HAD mackerel exhibited higher values for maximum force than did MVD, suggesting that HAD samples are hardier than its counterpart dried in microwave vacuum drier. One possible explanation for difference in hardness can be the alterations in protein structure induced by microwave heating. It has been proven that protein denaturation tend to affect hardness (Lin et al. 2012). Our results suggest that protein denaturation was slightly more during microwave vacuum drying which could result in softening of the tissue. It is also important to note that the samples were rehydrated for 20 min prior to analysis and the microwave vacuum dried samples absorbed more moisture than did the hot air dried one, leading to more moisture content and softness in the same. Wang et al. (2013) also observed significantly lower hardness in microwave vacuum dried restructured product from silver carp.

Table 2.

Instrumental textural attributes of mackerel dried by hot air and microwave vacuum drying methods

| Parameter | Hardness 1 (N) | Springiness (mm) | Cohesiveness | Adhesiveness (kg F mm) | Chewiness (N mm) |

|---|---|---|---|---|---|

| HAD | 64.04 ± 16.10a | 1.80 ± 0.377 | 0.29 ± 0.048 | 0.0067 ± 0.002a | 32.84 ± 12.49a |

| MVD | 103.47 ± 29.33b | 1.89 ± 0.198 | 0.303 ± 0.025 | 0.033 ± 0.027b | 58.64 ± 25.67b |

Values are represented as mean ± SD (n = 6), different superscript in the same column denotes statistical difference (p < 0.05)

Szczesniak (1963) defined sensorial cohesiveness as ‘‘the strength of the internal bonds making up the body of the product’’ and springiness as ‘‘the rate at which a deformed material goes back to its undeformed condition after the deforming force is removed’’. Springiness and cohesiveness values didn’t vary significantly among the samples while chewiness and adhesiveness of HAD samples were significantly higher (p < 0.05) than that of MVD samples. There is a direct relationship between hardness and chewiness of food material as higher hardness increases the number of masticatory cycles required to disrupt the muscle fibres before swallowing. Chumngoen and Tan (2015) also agrees with our finding that harder the product, the more chewy it is. Results of the present study agrees with Wang et al. (2013) where the microwave vacuum dried restructured fish products exhibited lowest hardness, springiness, cohesivenes and chewiness values compared to products dried by other methods including hot air drying and vacuum drying. They also justify their finding as a result of microstructural changes and better rehydration rate of microwave vacuum dried samples.

Instrumental color analysis

Color is an important sensory attribute influencing the appeal and acceptability of a material. Since essential oil is expected to have a strong impact on color of the final product, the instrumental L*, a*, and b* values of all the 6 products were analysed and the result is presented in Table 3. L* indicate lightness with 100 being white and 0 being black; a* represent intensity of greenness (−) to redness (+) and b* measures blueness (−) to yellowness (+). The impact of drying methods was quite promising seeing that the MAD mackerel had significantly higher L* value (indicating whiteness) irrespective of the essential oil treatment except in case of TMO treated mackerel. It is assumed that long period of drying in hot air dryer augmented non enzymatic browning reactions; leading to significantly lower L* values of HAD dried mackerel. Consequently, redness (+ a*) was also significantly higher (p < 0.05) in hot air dried samples. Our findings are in agreement with those of Wang et al. (2013) who reported lower lightness and higher hardness values for microwave vacuum dried restructured product from silver carp compared to air dried products. It is also noted that charring did not occur in microwave vacuum drying. Treatment with TMO seems to have interfered with the color attributes because the L* value of thyme oil treated samples were the lowest compared to its counterparts. The value of a* of TMO treated mackerel was significantly higher to that of control and clove oil treated samples dried in microwave vacuum dryer. Earlier, superior color of microwave/microwave vacuum/microwave air dried food products than conventionally dried has been reported. Alibas (2007) and Pu and Sun (2017) noticed superior color values for microwave dried Pumkin slices and mango slices respectively and Paengkanya et al. (2015) reported better color attributes for microwave vacuum dried Durian chips.

Table 3.

Instrumental color attributes of mackerel dried by hot air oven and microwave vacuum drying method

| Parameter | L* | a* | b* |

|---|---|---|---|

| Control HAD | 69.96 ± 0.06a | 3.95 ± 0.11bc | 26.71 ± 0.33c |

| Control MVD | 75.74 ± 0.15b | 2.44 ± 0.37a | 23.89 ± 0.63b |

| CLO HAD | 68.88 ± 0.36a | 4.27 ± 0.14c | 26.86 ± 0.28c |

| CLO MVD | 76.52 ± .32b | 2.83 ± 0.14a | 23.97 ± 0.42b |

| TMO HAD | 67.63 ± 0.38a | 3.41 ± 0.32b | 22.35 ± 0.42a |

| TMO MVD | 69.94 ± 0.30a | 3.22 ± 0.31b | 25.69 ± 0.28bc |

Values are represented as mean ± SD (n = 5), different superscript in the same column denotes statistical differences (p < 0.05) between the sources

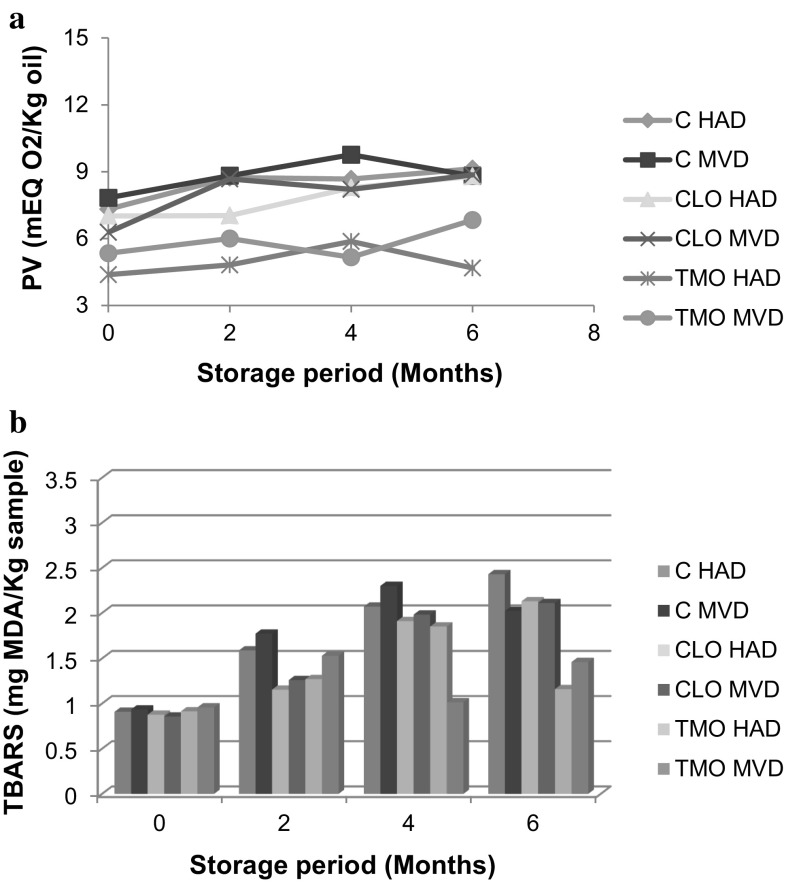

Lipid oxidation during storage

Lipid oxidation for essential oil treated and control dried mackerel was monitored over 6 month storage at ambient temperature. As seen from Fig. 3a, PV of TMO treated fishes were significantly lower immediately after drying and during storage. Control samples indicated more primary oxidation among all the samples. The values were fluctuating and didn’t show a definite trend as the peroxides are unstable and get oxidized further. In case of secondary oxidation, there was no significant difference between TBARS values among the samples immediately after drying (Fig. 3b). However, a gradual but significant increase in TBARS was noticed in all samples during storage at ambient temperature. Control samples dried by HAD and MVD methods showed significantly higher (p < 0.05) oxidation compared to their counterparts. Similar to PV result, TMO treated samples showed the lowest (p < 0.05) TBARS values during storage. It was also noticed that TBARS values of MVD samples were slightly higher to HAD samples irrespective of essential oil treatment. In contrary to our results, Fu et al. (2015) reported milder oxidation in MVD silver carp slices compared to hot air dried slices (60–90 °C) while using lower microwave power (up to 460 W for 7 min) than of the present study (600 W for 1.2 h). It was appeared that because of the high mass transfer efficiency of high microwave power used in our study, fat also got exuded to the surface of MVD fishes, making the lipid exposed and promoted its oxidation while drying and upon further storage. This assumption was confirmed from the result of proximate composition analysis where the muscle of MVD fishes had lower fat content compared to HAD fishes (Table 1).

Fig. 3.

Changes in a PV and b TBARS of dried samples during storage

Both the essential oils significantly delayed lipid oxidation of dried mackerel. In contrast to the in vitro antioxidant activity thyme oil showed significantly higher antioxidant effect compared to clove oil towards lipid oxidation of mackerel dried under hot air and microwave vacuum drying methods. This could be attributed to the difference in sensitivity of various active compounds present in thyme and clove oil towards microwave or thermal energy. Thyme oil exhibited more antioxidant effect than rosemary oil in lowering TBARS of hot smoked rainbow trout during storage (Yildiz 2015). The limit of acceptability for TBARS is 2 mg MDA/kg sample, beyond which the products tend to develop an objectionable odour and taste (Connell 1990). Control samples have crossed this limit at 4th month of storage and CLO treated samples reached the limit at 6 months storage. TMO treated fishes haven’t crossed this limit during the entire storage indicating higher efficiency of thyme oil as antioxidant in fish muscle.

Conclusion

The present study compared, physico-chemical characteristics of microwave vacuum dried and conventionally dried mackerel. The vacuum dried mackerel was superior in color and appearance and other sensory attributes. Rehydration and textural attributes of the microwave vacuum dried mackerel were also superior to hot air oven dried mackerel. Case hardening due to precipitation of salt over the skin surface, a major quality defect in air drying method was not observed during microwave vacuum drying. Essential oil treatment on inhibition of lipid oxidation was evaluated over a period of 6 months where the thyme oil showed good antioxidant activities in comparison to clove oil in the muscle of dried mackerel. The study revealed that drying period can be significantly reduced by microwave vacuum drying, yielding a better quality product compared to conventional drying method. However, changes in microstructure of protein induced by thermal and non thermal effect of microwave have to be further investigated.

Acknowledgements

We thank the technical staff of Visakhapatnam Research Centre of ICAR-CIFT for their assistance during the work. The authors would like to acknowledge the support of Indian Council of Agricultural Research, New Delhi, India.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Ali IBE, Chaouachi M, Bahri R, Chaieb I, Boussaïd M, Harzallah-Skhiri F. Chemical composition and antioxidant, antibacterial, allelopathic and insecticidal activities of essential oil of Thymus algeriensis Boiss. et Reut. Ind Crops Prod. 2015;77:631–639. doi: 10.1016/j.indcrop.2015.09.046. [DOI] [Google Scholar]

- Alibas I. Microwave, air and combined microwave-air drying parameters of pumpkin slices. LWT Food Sci Technol. 2007;40:1445–1451. doi: 10.1016/j.lwt.2006.09.002. [DOI] [Google Scholar]

- Amerine MA, Pongborn RH, Roescler EB. Principles of sensory evaluation of food. New York: Academic; 1965. [Google Scholar]

- Anderson RA, Conway HF, Pfeifer VF, Griffin EL. Roll and extrusion-cooking of grain sorghum grits. Cer Sci Today. 1969;14:372–375. [Google Scholar]

- Anderson UB, Stomsnes AN, Thomassen MS, Steinsholt K. Fillet gaping in farmed Atlantic salmon. J Agric Food Chem. 1994;8:165–179. [Google Scholar]

- AOAC . Official methods of analysis. 12. Washington: Association of Official Analytical Chemists; 1975. pp. 417–418. [Google Scholar]

- AOAC . Official methods of analysis. 15. Washington: Association of Official Analytical Chemists; 1990. [Google Scholar]

- Arnao M, Cano A, Acosta M. The hydrophilic and lipophilic contribution to total antioxidant activity. Food Chem. 2001;73:239–244. doi: 10.1016/S0308-8146(00)00324-1. [DOI] [Google Scholar]

- Bozin B, Mimica-Dukic N, Simin N, Anackov G. Characterization of the volatile composition of essential oils of some Lamiaceae spices and the antimicrobial and antioxidant activities of the entire oils. J Agric Food Chem. 2006;54:1822–1828. doi: 10.1021/jf051922u. [DOI] [PubMed] [Google Scholar]

- Caprita A, Caprita R. Modification of the soluble protein content of heat-processed soybean flour. Notulae botanicae Horti Agrobotanici Cluj-Napoca. 2010;38:98–101. [Google Scholar]

- Chumngoen W, Tan FJ. Relationships between descriptive sensory attributes and physicochemical analysis of broiler and taiwan native chicken breast meat. Asian Australas J Anim Sci. 2015;28:1028–1037. doi: 10.5713/ajas.14.0275. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Connell JJ. Control of fish quality. 3. Oxford: Fishing News Books; 1990. [Google Scholar]

- Darvishi H, Azadbakht M, Rezaeiasl A, Farhang A. Drying characteristics of sardine fish dried with microwave heating. J Saudi Soc Agric Sci. 2013;12:121–127. [Google Scholar]

- Duan Z, Jiang L, Wang J, Yu X, Wang T. Drying and quality characteristics of Tilapia fish fillets dried with hot air-microwave heating. Food Bioprod Process. 2011;89:472–476. doi: 10.1016/j.fbp.2010.11.005. [DOI] [Google Scholar]

- Duh PD. Antioxidant activity of Budrock (Arctiumlappa Linn) its scavenging effect on free radical and active oxygen. J Am Oil Chem Soc. 1998;75:455–461. doi: 10.1007/s11746-998-0248-8. [DOI] [Google Scholar]

- Fu X, Lin Q, Xu S, Wang Z. Effect of drying methods and antioxidants on the flavor and lipidoxidation of silver carp slices. LWT Food Sci Technol. 2015;61:251–257. doi: 10.1016/j.lwt.2014.10.035. [DOI] [Google Scholar]

- Giri SK, Prasad S. Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. J Food Eng. 2007;78:512–521. doi: 10.1016/j.jfoodeng.2005.10.021. [DOI] [Google Scholar]

- Hu Y, Quea T, Fangb Z, Liua W, Chena S, Liua D, Ye X. Effect of different drying methods on the protein and product quality from hairtail fish meat gel. Dry Technol. 2013;31:1707–1714. doi: 10.1080/07373937.2013.794831. [DOI] [Google Scholar]

- Guo Q, Sun DW, Cheng JH, Han Z. Microwave processing techniques and their recent applications in the food industry. Trends Food Sci Technol. 2013;67:236–247. doi: 10.1016/j.tifs.2017.07.007. [DOI] [Google Scholar]

- Ironside JIM, Love RM. Studies on protein denaturation in frozen fish, biological factors influencing the amount of solubleand insoluble protein present in the muscle of North Sea cod. J Sci Food and Agricul. 1958;9:597–599. doi: 10.1002/jsfa.2740090911. [DOI] [Google Scholar]

- Iuliana C, Rodica C, Sorina R, Oana M. Impact of micro-waves on physico-chemical characteristics of cow milk. Rom Rep Phys. 2015;67:423–430. [Google Scholar]

- Li ZY, Wang RF, Kudra T. Uniformity issue in microwave drying. Dry Technol. 2011;29:652–660. doi: 10.1080/07373937.2010.521963. [DOI] [Google Scholar]

- Lin WL, Zeng QX, Zhu ZW, Song GS. Relation between protein characteristics and TPA texture characteristics of crisp grass carp (Ctenopharyngodon idellus c. et v) and grass carp (Ctenopharyngodon idellus) J Texture Stud. 2012;43:1–11. doi: 10.1111/j.1745-4603.2011.00311.x. [DOI] [Google Scholar]

- Monteiro RL, Carciofi BAM, Marsaioli A, Laurindo JB. How to make a microwave vacuum dryer with turn table. J Food Eng. 2015;166:276–284. doi: 10.1016/j.jfoodeng.2015.06.029. [DOI] [Google Scholar]

- Moreira R, Chenlo F, Chaguri L, Fernandes C. Water absorption, texture and color kinetics of air- dried chestnuts during rehydration. J Food Eng. 2008;86:584–594. doi: 10.1016/j.jfoodeng.2007.11.012. [DOI] [Google Scholar]

- Paengkanya S, Soponronnarit S, Nathakaranakule S. Application of microwaves for drying of Durian chips. Food Bioprod Process. 2015;9:1–11. doi: 10.1016/j.fbp.2015.06.001. [DOI] [Google Scholar]

- Patel S. Plant essential oils and allied volatile fractions as multifunctional additives in meat and fish-based food products. Food Addit Contam. 2015;32:1049–1064. doi: 10.1080/19440049.2015.1040081. [DOI] [PubMed] [Google Scholar]

- Peleg M. An empirical model for description of moisture sorption curves. J Food Sci. 1998;53:1216–1218. doi: 10.1111/j.1365-2621.1988.tb13565.x. [DOI] [Google Scholar]

- Porcelli M, Cacciapuoti G, Fusco S, Massa R, d’Ambrosio G, Bertoldo C, De Rosa M, Zappia V. Non-thermal effects of microwaves on proteins: thermophilic enzymes as model system. FEBS Lett. 1997;402:102–106. doi: 10.1016/S0014-5793(96)01505-0. [DOI] [PubMed] [Google Scholar]

- Pu YY, Sun DW. Combined hot-air and microwave-vacuum drying for improving drying uniformity of mango slices based on hyperspectral imaging visualization of moisture content distribution. Biosys Eng. 2017;156:108–119. doi: 10.1016/j.biosystemseng.2017.01.006. [DOI] [Google Scholar]

- Seremet L, Botez E, Nistor OV, Andronoiu DG, Mocanu GD. Effect of different drying methods on moisture ratio and rehydration of Pumpkin slices. Food Chem. 2016;195:104–109. doi: 10.1016/j.foodchem.2015.03.125. [DOI] [PubMed] [Google Scholar]

- Szczesniak AS. Classification of textural characteristics. J Food Sci. 1963;28:385–389. doi: 10.1111/j.1365-2621.1963.tb00215.x. [DOI] [Google Scholar]

- Tarladgis BG, Watts BM, Youthan MT. A distillation method for the quantitative determination of malonaldehyde in rancid foods. J Am Oil Chem Soc. 1960;37:44–52. doi: 10.1007/BF02630824. [DOI] [Google Scholar]

- Wang Y, Zhang M, Arun S, Mujumdar, Mothibe KJ. Quality changes of dehydrated restructured fish product from silver carp (Hypophthalmichthys molitrix) as affected by drying methods. Food Bioprocess Technol. 2013;6:1664–1680. doi: 10.1007/s11947-012-0812-y. [DOI] [Google Scholar]

- Wei A, Shibamoto T. Antioxidant/lipoxygenase inhibitory activities and chemical compositions of selected essential oils. J Agric Food Chem. 2010;58:7218–7225. doi: 10.1021/jf101077s. [DOI] [PubMed] [Google Scholar]

- Winton AL, Winton KB. The analysis of foods. London: Wiley; 1958. [Google Scholar]

- Yildirim A, Mavi A, Kara AA. Determination of antioxidant and antimicrobial activities of Rumex crispus L. extracts. J Agricul Food Chem. 2015;9:4083–4089. doi: 10.1021/jf0103572. [DOI] [PubMed] [Google Scholar]

- Yildiz PO. Effect of essential oils and packaging on hot smoked rainbow trout during storage. J Food Process Preserv. 2015;39:806–815. doi: 10.1111/jfpp.12291. [DOI] [Google Scholar]

- Zengin H, Baysal AH. Antioxidant and antimicrobial activities of thyme and clove essential oils and application in minced beef. J Food Process Preserv. 2015;39:1261–1271. doi: 10.1111/jfpp.12344. [DOI] [Google Scholar]