Abstract

In paddy cultivation, harvesting is the most important operation, which needs suitable machinery. Thus, this study was carried out to compare field performances and energy and environmental effect between the conventional 5 m cutting width NEW HOLLAND CLAYSON 8080, 82 kW@2500 rpm combine harvester running on a total net area of 42.78 ha of plots for two rice (Oryza sativa L.) cultivation seasons and the new mid-size 2.7 m cutting width WORLD STAR WS7.0, 76 kW@2600 rpm combine harvester running on a total net area of 16.95 ha of plots for two rice cultivation seasons. The conventional combine as compared to mid-size combine showed 14.4% greater mean fuel consumptions (21.13 versus 18.46 l/ha), 31.1% greater mean effective field capacity (0.69 versus 0.53 ha/h), 5.23% greater cornering time (turning time) percentage of total time (8.28% versus 3.05%) and 1.41% greater reversing time percentage of total time (7.2% versus 5.79%) but 20.90% lesser mean operational speed (3.24 versus 4.10 km/h), 11.69% lesser effective time percentage of total time (60.0%versus 71.69%h/ha), 10.8% lesser mean field efficiency (64.3% versus 72.1%). In terms of total energy use the conventional combine showed 24.64% greater mean total energy use in the harvesting operation (1445.81 versus 1160.00 MJ/ha), 14.46% greater mean fuel energy (1010.014 versus 882.39 MJ/ha), 56.47% greater mean machinery energy (431.32 versus 275.65 MJ/ha) and 59.25% greater mean human energy (3.48 and 2.18 MJ/ha), this cause 26.12% greater mean total Green House Gas emission (GHG) than the mid-size combine. The results revealed that the mid-size combine is more suitable in conducting the harvest operation in rice field in Malaysia than the conventional combine.

Keyword: Environmental science

1. Introduction

Fig. 1 indicates that from the year 1982–2016, the population of Malaysia had increased by 113% with an increased in the rice cultivation area of only 3.8% and an increased in the rice production of only 19.6%. Currently, the government has difficulties in expanding the cultivation area for rice in the country since the availability of suitable land for rice is limited and the infrastructural development for its cultivation is an expensive investment. Rice is the staple food for Malaysian and the country is 72% self-sufficiency level in its production (Dilipkumar et al., 2018). The only promising way of increasing the country's rice production in order to achieve 100% self–sufficiently level will be through increasing the average rice yield within the available total cultivated area. Such an effort can be made, among others, by planting high yield varieties and adopting Good Agricultural Practices or GAP in the cultivation of rice. The scope of GAP covers the use of correct type, amount, placement and timing of plant inputs and also the use of appropriate type and size technologies and efficient management of the farms so that crop yield can be increased while post-harvest field losses can be minimized.

Fig. 1.

Rice cultivated area, rice production and population in Malaysia from 1982 to 2016 (FAOSTAT, 2018).

Maintaining working conditions and optimal performance of combine harvesters is a vital importance in agricultural and rice production due to the timeliness factor. The planning and selection of equipment for the harvest of crops can greatly impact the performance and profitability of a farm. The type and size of equipment used to affect the harvested yield and nutritive value of the crop as well as production costs (Rotz, 2001). The choice or selection of combine harvesters is dictated by multiple factors including the type and size of the machine, the field performance, field efficiency and access to finance.

The use of machines to replace human labor in the cultivation of rice should be looking in the aspect of increasing both the quantity and the quality of involved fieldwork. It has been for decades in Malaysia that harvesting of rice is done using a 5 m cutting width and 5 ton capacity self-propelled rice combine harvester. This combine has been used because of its good effective field capacity to justify the short time slot that is available for the farmers in the harvesting of the crop. In the most occasion, the field harvesting operations have to be completed as soon as possible to minimize the yield losses of the overripe crops due to the incoming weather storm. However, the used of these combines have been reported to give several operational problems. Among the problems includes, bogging of the combine during operation especially on soft and watery terrain, slightly high grain losses during the harvesting operations, and substantial damage to the terrain surface. Due to damages on the terrain surface from the combine movements, the farmers have to rotovate and level the back their field plots properly in the following crop season. In order to prepare the soil prior to seeding or transplanting operations, based on GAP, three rotovation and one leveling operations are good enough to create the necessary soil conditions for the germination of rice seeds or growth of rice seedlings for the plot. At times, if the damages of the surface terrain and soil conditions were too severe, some farmers had to proceed with four or five rotovation operations in the preparation of the soil for the subsequent seeding or planting operation. Three rotovation operations took 36.2% of the total fuel cost for a crop season by the farmers in Malaysia (Muazu et al., 2014a). Thus, with smaller size combine, there might be a possibility of less destruction to the field surface terrain and perhaps to the extent of reducing the number of rotovation operations that would be needed for the field plot. Besides that, maneuvering smaller combines would be much easier and the bogging problem of the machine in the field plot could be eliminated. The quality of work in the harvesting operations with such combine could be much easier to achieve than the currently used combine.

Energy consumption in agriculture has increased in response to increasing populations, desire for an increasing standard of living and the limited supply of arable land (Pishgar-komleh et al., 2013). A greenhouse gas (GHG) is a gas in an atmosphere that absorbs and emits radiation within the thermal infrared range. The GHG emissions of agriculture come from several sources such as machinery, diesel fuel, chemical fertilizers, biocides and electricity. So, the increase in the energy inputs can cause an increase in the GHG emissions in agricultural activity (Nabavi-Pelesaraei et al., 2016). A doubling of the current CO2 level in the atmosphere will cause an increase of 1.5–4.0 Co in average global surface air temperature, with changes in rainfall pattern by the end of the 21st century (Pathak and Wassmann, 2007). So research on GHG emissions of agricultural production is very important.

An initiative was taken up here to compare the field performance of conventional combine harvester NEW HOLLAND CLAYSON 8080 and the newly introduced mid-size combine harvester WORLD STAR WS7.0 PLUS under the actual field harvesting operation in the real field conditions in wetland rice cultivation in Malaysia. Specific objectives of this study to compare working performance, field time distribution in performing harvesting operation, distribution of energy expenditure of harvesting operation, greenhouse gas emissions from harvesting operation. Also, assess the performance of the combine harvester as influenced by different farm size.

2. Materials and methods

The chosen study area was located at (3º29′47″N and 101º09′56″E) in Sungei Burong, Kuala Selangor. Fig. 2 shows the pictures of the conventional and mid-size combines that were being tested. Table 1 compares the technical specifications between the two combines. The involved field tests on the two combines were conducted in two cropping seasons; June to November 2017 for the first season and January to June 2018 for the second season. The paddy area is located within the total area that is under the management of North West Integrated Agricultural Development Authority (IADA) Rice Scheme. In the first season, 30 farms were involved in the data collection. While in the second season, 32 farms were involved, where 43 farms were harvested by using the 5 m cutting width conventional combine in two seasons and 19 farms were harvested with the 2.7 m cutting width mid-size combine harvester in two seasons. The farms that were harvested by the conventional combine in the two seasons involved a total area of 44.72 ha with average size area of 1.04 ± 0.07 ha while the farms that were harvested by the mid-size combine in two seasons involved a total area of 16.95 ha with average size area of 0.89 ± 0.13 ha. Harvestings of the crop in the first season were conducted from 14 to 30 November 2017 while harvestings of the crop in the second season were conducted from 25 May to 18 June 2018. The recorded average crop yield in the first season was6.682 6.7 ± 0.05 ton/ha and in the second season was 7.04 7.3 ± 0.05 ton/ha.

Fig. 2.

Farmer workers performing harvesting operation in one of the study farms.

Table 1.

Technical specifications of conventional combine and mid-size combine.

| Parameters | Conventional Combine | Mid-size Combine |

|---|---|---|

| Name | NEW HOLLAND combine | WORLD STAR combine |

| Model | CLAYSON 8080 | WS7.0 PLUS |

| Max power | 82 kW | 75KW |

| Rated speed | 2500 rpm | 2600 rpm |

| Total weight | 10000 kg | 3400 kg |

| Tracking tire | Half-track | Full track |

| Fuel type | Diesel | Diesel |

| Fuel tank capacity | 350 l | 130 l |

| Grain tank capacity | 3.5 ton | 0.80 ton |

| Unloading discharge | 8.70 kg/s | 1.68 kg/s |

| Working width | 5m | 2.2m |

| Worker | 1-2 Person | 1 Person |

2.1. Field performances

The measured combine field performance parameters include speed of operation, theoretical field capacity, actual field capacity, field efficiency, labor hour and fuel consumption. Field efficiency is the ratio between the harvester's productivity under actual working conditions and the theoretical maximum possible productivity and it calculated as shown in Eqs. (1), (2), and (3) as defined by ASAE standards S495.1 (ASAE Standards, 2005; Amponsah et al., 2017a).

| (1) |

| (2) |

| (3) |

The fuel consumed by the conventional combine was determined by refilling the combine fuel tank back to its full capacity after the harvesting operation using a measuring cylinder as defined by ASABE standards D497.7, 2011 (ASABE Standards, 2011; Amponsah et al., 2017b). While the fuel consumed by the mid-size combine was determined by directly reading of the difference in the fuel level gauge of the combine fuel tank after the harvesting operation. Time parameters were recorded using digital stopwatch which included the effective time (time spent in performing the actual harvesting operation), cornering time (turning time) and reversing time (time spent in turning and reversing by the combine harvesters without cutting the plant), dumping time (time spent in unloading the grain tank of the combine harvester and going to or from the paddy conveying trucks) and other time (time taken by the operator in resting and setting or maintaining the machine). The total time in terms of h/ha was obtained by summation of all time parameters then divided by the farm area. The average of time was determined as the summation of the time in all the farms divided by the total number of the farms. Forward speed of operation was obtained by recording time taken to harvest one row by using stopwatch and measured the distance of one row by using measuring tape, the average operation speed of one farm was then obtained by summation speed for all rows and divided by the number of rows, 16 rows/ha for conventional combine and 30 rows/ha for mid-size combine. The means for all the computed parameters were from 43 farms for the conventional combine and 19 farms for the mid-size combine.

2.2. Estimation of energy sources for harvesting operation

The recorded farm inputs from the three sources (namely machinery, fuel, human labor) used by the rice farmers in the harvesting operation were converted into equivalent energy values in MJ/ha by using the appropriate conversion coefficients (Table 2). Energy conversion coefficient is a value which expresses the energy input expended in the production and distribution of a unit physical material. Classical mathematical Eqs. (4), (5), (6), and (7) were used to estimate the equivalent energy sources of the harvesting operation of wetland rice production.

Table 2.

Energy conversion coefficients.

| Material | Conversion Coefficient | Unit | Source |

|---|---|---|---|

| Combine | 87.63 | MJ/kg | (Canakci et al., 2005) |

| Diesel | 47.80 | MJ/l | (Canakci et al., 2005) |

| Human labor | 1.96 | MJ/h | (Soni and Soe, 2015) |

Machinery energy is indirect energy assumed to be embodied in a piece of equipment during manufacturing. The general expression used to compute machinery energy as an integral part of the total energy input for harvesting operation is given as follows (Elsoragaby et al., 2019):

| (4) |

Where is machinery energy (MJ/ha), is the energy conversion coefficient for the combine (MJ/kg) (Table 2), is the weight of combine (kg), is the effective field capacity (ha/h) and is the economic life of combine (h).

Fuel energy per unit area is a function of the type (diesel or petrol) and quantity of fuel consumed by the machinery used to power engines in performing the harvesting operations. The general expression used to compute fuel energy as an integral part of the total energy input for harvesting operation is given as follows:

| (5) |

Where is fuel energy (MJ/ha), is the quantity of fuel consumed (l), is the fuel energy conversion coefficient (MJ/l) (Table 2) and is the farm area covered (ha).

Human energy expenditure in harvesting operation was evaluated based on the number of farm workers engaged in harvesting operation per unit area and the time they spent in performing the operations multiplied by an energy conversion coefficient (Table 2). The general expression used to compute human energy as an integral part of the total energy input for harvesting operation is given in Eq. (3) (Muazu et al., 2014b).

| (6) |

Where is human energy (MJ/ha), is the number of workers engaged in an operation, is the duration of operation (h), is the energy conversion coefficient for human labor (Table 2) and is the farm area covered (ha).

The total energy budget in harvesting operation per hectare was determined as the summation of energy from all the sources. The total energy input for harvesting operation was determined as follows:

| (7) |

Where TEI is total energy input of harvesting operation (MJ/ha) and ME, FE, HE, are as defined previously.

2.3. Mechanization index

Mechanization index (MI) expressed by the percentage of machine energy to the sum of human energy, animal energy and machine energy and was computed as follows (Elsoragaby et al., 2019):

| (8) |

Where MI is the mechanization index; ME is the machinery energy (MJ/ha), AE is the draught animal energy (MJ/ha) and HE is the human energy (MJ/ha).

2.4. GHG emissions from harvesting operation

In crop production, CO2 emissions are the results of combusting fossil fuels, machinery, chemicals fertilizer, chemicals pesticide and electricity (Pishgar-Komleh et al., 2012). In this study, assessment of GHG emissions of harvesting operation comprises two major emission sources, namely emissions from fossil fuel combustion and from machinery that utilized in performing harvesting operation. The standard coefficients were applied to the computation of GHG emissions for diesel fuel and machinery (Table 3).

Table 3.

GHG emission Coefficients.

| Input | Unit | GHG coefficient (kgCO2eq/unit) | Reference |

|---|---|---|---|

| Diesel Fuel | l | 2.76 | Nabavi-Pelesaraei et al. (2014) |

| Machinery | MJ | 0.071 | Nabavi-Pelesaraei et al. (2014) |

The amount of GHG emissions was obtained by multiplying the input rate by its corresponding emission coefficient using Eqs. (9) and (10) (Nabavi-Pelesaraei et al. (2014).

| (9) |

Where Cf = CO2 emission due to fuel combustion (kgCO2eq/ha), ccf = CO2 conversion coefficient for fuel combustion (kgCO2eq/l) (Table 3), fcon = Quantity of fuel consumed (l) and A = Farm area covered (ha).

| (10) |

Where Cm = CO2 emission due to machinery utilizing for an operation (kgCO2eq/ha), ccm = CO2 conversion coefficient for machinery (kgCO2eq/MJ) (Table 3), me = machinery energy (MJ) and A = Farm area covered (ha).

The average CO2 emission in the study area was determined as the ratio of the summation of CO2 emissions in all the farms divided by the number of the farms covered.

2.5. Farm size analysis

The farm size analysis was made to assess the field performance, energy expenditure and GHG emission of the conventional combine and mid-size combine harvesters as influenced by different farm size in harvesting operation. 43 farms in the study area were harvested by using conventional combine in two seasons, 33 farms of them (total area of 37.93 ha) had a farm size greater than 1 ha with a mean size of 1.15 ± 0.01 ha and size range from 1.08 to 1.6 ha. The remaining 10 farms (total area of 6.55 ha) had a farm size less than 1 ha with a mean size of 0.65 ± 0.09 ha and size range from 0.52 to 0.88 ha. The total number of farms that harvested by the mid-size combine harvester were 19 farms, 10 of them (Total area of 11.58 ha) have a farm size greater than 1 ha with a mean size of 1.16 ± 0.02 ha and a size range from 1.08 to 1.2 ha. The remaining 9 farms (Total area of 5.37 ha) had a size lesser than 1 ha with a mean size of 0.6 ± 0.08 ha and size range from 0.40 to 0.84 ha.

3. Results and discussions

3.1. Field performance, energy expenditure and Green House Gas emissions of harvesting operation

3.1.1. Field performance of conventional combine and mid-size combine

Table 4 and Fig. 3 indicate that conventional combine shows 31.1% greater mean effective field capacity (0.69 versus 0.53 ha/h), 10.8% lesser mean field efficiency (0.64 versus 0.72), 14.4% greater mean fuel consumptions (21.13 versus 18.46 l/ha), 1.43 times greater mean effective working width (4.40 versus 1.81 m) and 20.9% lesser mean operation speed (3.24 versus 4.1 km/h) than the mid-size combine. The operating speed of conventional and mid-size was within the recommended operating speed of 3–6.5 km/h range for harvesting operation with a self-propelled combine by ASABE (ASAE Standards, 2009). The advantage of having large working width makes the conventional combine to have greater field capacity even though with a field operating speed that is much lower than the mid-size combine. Alizadeh and Allameh (2013) found that the theoretical and effective field capacities of whole-crop and head-feed combines were 0.495 and 0.361 ha/h, respectively.

Table 4.

Comparison of field performances between conventional and mid-size combines.

| Performance | Conventional | Mid-size | p value | Difference |

|---|---|---|---|---|

| Operating Speed, km/h | 3.24 ± 0.19§ | 4.10 ± 0.28 | 2.26E-08*** | -20.9% |

| Effective Field Capacity, ha/h | 0.69 ± 0.05 | 0.53 ± 0.071 | 0.00262** | +31.1% |

| Field efficiency | 0.64 ± 0.04 | 0.72 ± 0.12 | 0.00431** | -10.8% |

| Fuel Consumption, l/ha | 21.13 ± 0.95 | 18.46 ± 0.91 | 0.0035** | +14.4% |

| Effective cutting width, m | 4.40 ± 0.08 | 1.81 ± 0.05 | 1.91E-23*** | +1.43 |

***Significant at α = 0.001 and **Significant at α = 0.01.

§ At 95% confidence interval.

Fig. 3.

Comparison of field performances between Conventional and mid-size combines.

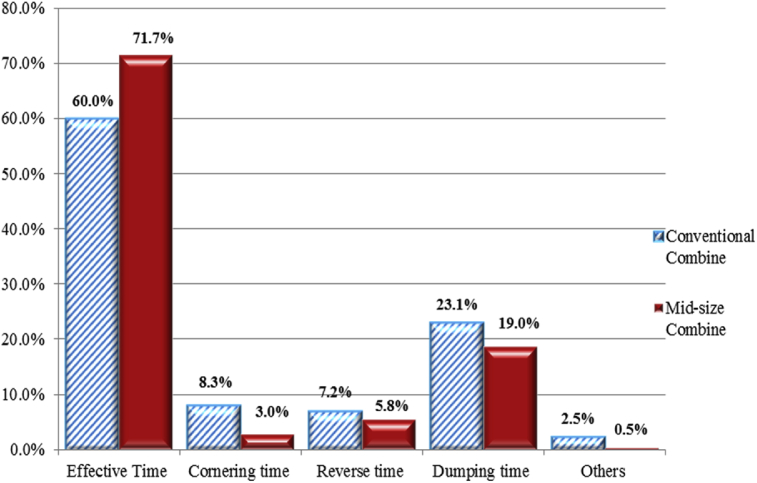

3.1.2. Field time distribution in performing harvesting operation

The result shows that the conventional combine spent 60.0% (or 0.78 h/ha) of the total harvesting operation time in the actual harvesting of the grain while the remaining 40% of the total harvesting operation time was expended in cornering (turning), reversing and dumping time. In the other hand, the mid-size combine spent 71.69% (or 1.36 h/ha) of the total time in the actual harvesting of the grain while the remaining 28.31% of the total harvesting operation time was expended in cornering, reversing and dumping time. Cornering (turning) time represented 8.28% (0.11 h/ha) and 3.05% (0.06 h/ha) of the total time spent with using conventional and mid-size combine, respectively. Mid-size combine avoids this problem by full rubber track size 550 × 90 × 56 which is used for help machine work faster in a deep mud field. The reverse time represented 7.2% (0.01 h/ha) and 5.79% (0.11 h/ha) of the total time when using conventional and mid-size combine, respectively. The result also reveals that 23.1% of the total harvesting operation time was expended by a conventional combine in dumping time compared with the 18.95% of the total time expended by mid-size combine (Table 5 and Fig. 4).

Table 5.

Time distribution in harvesting operation of conventional and mid-size combines.

| Mean time | Conventional Combine |

Mid-size Combine |

p value | Difference% | ||

|---|---|---|---|---|---|---|

| Average (h/ha) | % Total time | Average (h/ha) | % Total time | |||

| Effective Time | 0.78 ± 0.08 § | 60.00% | 1.36 ± 0.180 | 71.69% | 0.00258*** | -11.69 |

| Cornering time | 0.11 ± 0.005 | 8.28% | 0.06 ± 0.005 | 3.05% | 0.00361** | +5.23 |

| Reverse time | 0.10 ± 0.031 | 7.20% | 0.11 ± 0.011 | 5.79% | 0.0356* | +1.41 |

| Dumping time | 0.31 ± 0.030 | 23.10% | 0.36 ± 0.052 | 18.95% | 0.0423* | +4.15 |

| Others | 0.04 ± 0.007″ | 2.50% | 0.01 ± 0.041 | 0.52% | 0.1872 ns | +1.98 |

| Total time | 1.33 ± 0.095 | 100.00% | 1.9 ± 0.121 | 100.00% | ----- | 0.00 |

***Significant at α = 0.001, **Significant at α = 0.01, *significant at α = 0.05 and ns = not significant.

§ At 95% confidence interval.

” Others” means operator time and maintenance time.

Fig. 4.

Time distribution comparison in harvesting operation between conventional and mid-size combines.

Turning time to harvester machine is a loss factor operation need good planning to make turns without slowing or using extra motion to line up the next row. Muazu et al. (2014a) reported that 66% (60.98 min/ha) of the total harvesting time, was used in performing the actual harvesting activities while turning and reverse time represent 13% of the total harvesting operation by using conventional combine. Also, they found that the paddy harvesting had the highest field time (1.54 h) and least field capacity (0.67 ha/h) among all the operations covered in their study.

3.1.3. Distribution of energy expenditure of harvesting operation

The distribution of energy expenditures due to the three energy sources used in harvesting operation (fuel, machinery and human) when using conventional combine and mid-size combine are presented in Table 6. Analysis of result shows that when using conventional combine in performing harvesting operation an average total energy expenditure of 1445.81 MJ/ha was utilized. The highest contribution of 1010.01 MJ/ha representing 69.85% of the total average energy budget came from fuel energy. The share contributions for machinery utilization and human labor are 29.83% and 0.24% (431.32 and 3.48 MJ/ha) respectively. The same distribution of energy expenditure was obtained when using mid-size combine harvester, the total energy expenditure utilized in performing harvesting operation was 1160 MJ/ha. Fuel energy represents the highest contributor to the total energy budget by 76.10% (882.84 MJ/ha). The share contributions for machinery utilization and human labor are 23.70% and 0.2% (275 and 2.18 MJ/ha) respectively. Human labor represents the lowest contributor to the total average energy budget. The same result was obtained by Muazu et al. (2014a), they found that the total energy expended by a conventional combine in the harvesting operation in wetland paddy cultivation system in Malaysia was 1289 MJ/ha, the difference from our study due to the difference of the modules and weights of the combines. The distributions of energy sources were 73.62%, 26.14% and 0.23% for fuel, machinery and human energy respectively which it similar to our study. Bockari-gevao et al. (2005) found that the average operational energy consumption of the rice production in Malaysia was highest for tillage followed by harvesting operation (1171.44 MJ/ha) which accounted for about 32.6% of the total operational energy consumption.

Table 6.

Comparison of energy expenditure and Mechanization Index of harvesting operations between conventional and mid-size combines.

| Mean | Conventional Combine | Mid-size Combine | p value | Difference % |

|---|---|---|---|---|

| Mechanization Index | 0.99 ± 0.002§ | 0.99 ± 0.002 | 0.2471 ns | ns |

| Fuel Energy, MJ/ha | 1010.01 ± 40.62 | 882.39 ± 43.34 | 0.02446* | +14.46 |

| Machinery Energy, MJ/ha | 431.32 ± 74.24 | 275.65 ± 59.49 | 0.00291** | +56.47 |

| Human Energy, MJ/ha | 3.48 ± 0.28 | 2.18 ± 0.314 | 1.486E-04*** | +59.25 |

| Total Energy, MJ/ha | 1445.81 ± 85.56 | 1160 ± 99.62 | 0.00348** | +24.64 |

***Significant at α = 0.001, **Significant at α = 0.01, *significant at α = 0.05 and ns = not significant.

§ At 95% confidence interval.

The comparison of energy expenditure between conventional combine and mid-size combine revealed that in terms of the total energy use in harvesting operation the conventional combine showed 24.64% greater mean total energy expenditure (1445.81 versus 1160 MJ/ha), 14.46% greater mean fuel energy (1010.01 versus 882.84 MJ/ha), 56.47% greater mean machinery energy (431.32 versus 275 MJ/ha) and 59.25% greater mean human energy (3.48 versus 2.18 MJ/ha) than the mid-size combine harvester (Table 6 and Fig. 5).

Fig. 5.

Comparison of energy expenditure of harvesting operations between conventional and mid-size combines.

The result revealed that no differences were recorded for mechanization index in harvesting operations when using conventional combine and mid-size combine harvester (0.994 versus 0.990). Muazu et al. (2014a) found that the mechanization index of the harvesting operation for paddy production in Malaysia was 0.99 which it close to mechanization index of our study. The marginal contribution from human labor to the total energy expended in the harvesting operation represents the high mechanization index of the harvesting operation when using both conventional combine and mid-size combine harvester. In most literature among the paddy cultivation operation in Malaysia, harvesting operation had the highest mechanization index of 0.99, this indicating the near exclusion of labor in carrying out the operation because the farmers in Malaysia generally use self-propelled combine harvesters in performing harvesting operation for that, the energy use in paddy harvesting operation in Malaysia is like that of developed countries such as Canada and America. Rathke et al. (2007) reported that for a corn production system in USA the manpower represents a very small percentage (<0.02%) of energy input. Recently, machinery and labor are the main resources for agricultural operations, but the machinery is gradually replacing labor, where savings in time and improving the quality of agricultural operations (Singh, 2006).

3.1.4. Green House Gas emissions of harvesting operation

The conventional combine showed 26.12% greater mean total Green House Gas emission (GHG) from harvesting operation (88.94 versus 70.52 kgCO2eq/ha), 14.46% greater mean fuel GHG emission (58.32 versus 50.95 kgCO2eq/ha) and 56.47% greater mean machinery GHG emission (30.624 versus 19.571 kgCO2eq/ha) than the mid-size combine harvester (Table 7 and Fig. 6). Fuel GHG emission represents the highest contributor of the total GHG emission in using two machines, conventional combine and mid-size combine and it represents 64.3% and 72.26% of the total GHG emission respectively. Fossil fuel combustion is considered responsible for more than 75% of human-caused CO2 emissions (Pishgar-Komleh et al., 2013).

Table 7.

Comparison of GHG emission between Conventional Combine and Mid-size Combine.

| GHG (kgCO2eq/ha) | Conventional Combine | Mid-size Combine | Difference % | p value |

|---|---|---|---|---|

| Fuel | 58.32 ± 2.345 § | 50.95 ± 2.503 | 14.46 | 0.0245* |

| Machinery | 30.62 ± 5.271 | 19.57 ± 4.224 | 56.47 | 0.0029** |

| Total GHG | 88.94 ± 6.815 | 70.52 ± 6.453 | 26.12 | 0.0032** |

**Significant at α = 0.01 and *significant at α = 0.05.

§ At 95% confidence interval.

Fig. 6.

Comparison of GHG emission in harvesting operation between conventional combine and mid-size combine.

3.2. Field performance, energy expenditure and GHG emissions of combines based on farm size

3.2.1. Field performance of harvesting operation based on farm size

From Tables 8 and 9, the results show that in large size farms the conventional combine shows 20% greater mean actual field capacity (0.72 versus 0.60 ha/h), 8.4% lesser mean field efficiency (69.10% versus 0.75%) and 14.6% greater mean fuel consumption (19.75 versus 17.23 l/ha) than the mid-size combine. When harvesting operations were performing in small size farms the conventional combine shows 24.0% greater mean actual field capacity (0.62 versus 0.50 ha/h), 5.93% lesser mean field efficiency (65.00% versus 69.10%) and 3.94% greater mean fuel consumption (20.527 versus 19.748 l/ha).

Table 8.

Field performance of conventional and mid-size combine in harvesting operations based on large size farm (i.e equal and greater than 1 ha).

| Performance | Conventional Combine | Mid-size Combine | p value | Difference% |

|---|---|---|---|---|

| Effective Field Capacity (ha/h) | 0.72 ± 0.13§ | 0.60 ± 0.15 | 0.0008*** | +20 |

| Field efficiency % | 0.69 ± 0.12 | 0.75 ± 0.24 | 0.00711** | -8.4 |

| Fuel Consumption (l/ha) | 19.75 ± 0.75 | 17.23 ± 0.38 | 6.35E-05*** | +14.6 |

***Significant at α = 0.001 and ***Significant at α = 0.01.

§ At 95% confidence interval.

Table 9.

Field performance of conventional and mid-size combine in harvesting operation based on small size farm (i.e less than 1 ha).

| Performance | Conventional Combine | Mid-size Combine | p value | Difference% |

|---|---|---|---|---|

| Effective Field Capacity (ha/h) | 0.62 ± 0.09 | 0.50 ± 0.13 | 0.00015*** | +24.0 |

| Field efficiency % | 0.65 ± 0.044 | 0.69 ± 0.12 | 0.00634** | -5.93 |

| Fuel Consumption (l/ha) | 20.53 ± 2.19 | 19.74 ± 0.75 | 0.44525 ns | +3.94 |

***Significant at α = 0.001, **Significant at α = 0.01 and ns = not significant.

§ At 95% confidence interval.

As indicated in Fig. 7 the conventional combine harvester shows 16.12% greater mean field capacity, 4.3% greater mean field efficiency and 3.8% lesser mean fuel consumption were recorded in large farms compared with that in small farms. The mid-size combine harvester shows 20.0% greater mean actual field capacity, 9.11% greater mean field efficiency and 12.75% lesser mean fuel consumption in large farms compared with that in the small farms. From the previous, the result reveals that the field capacity and field efficiency of both combines are significantly affected by a decrease in the size of the farm area. The same result was obtained by ASAE Standards (2009), he found that the small or irregularly shaped fields may cause a substantial reduction in field efficiency of the machines.

Fig. 7.

Field performance of conventional and mid-size combines in harvesting operations based on farm sizes.

3.2.2. Time distribution of harvesting operation based on farm size

From Table 10, in the large farms the conventional combine shows 12.08% lesser percentage effective time of the total time (59.95% versus 72.02%), 3.21% greater percentage of cornering time from the total time (6.84% versus 3.63%), 4.47% greater reverse time percentage of the total time (9.59% versus 5.12%) and 1.35% greater dumping time percentage of the total time (19.80% versus 18.45%) than the mid-size combine (Fig. 8).

Table 10.

Time distribution of harvesting operation based on large size farm (greater and equal than 1 ha).

| Time Distribution | Conventional Combine |

Mid-size Combine |

p value | Difference % | ||

|---|---|---|---|---|---|---|

| (h/ha) | % of total | (h/ha) | % of Total | |||

| Effective Time | 0.675 ± 0.058§ | 59.95 | 1.21 ± 0.058 | 72.02 | 1.372E-011*** | -12.08 |

| Cornering time | 0.077 ± 0.005 | 6.84 | 0.061 ± 0.005 | 3.63 | 0.0137* | +3.21 |

| Reverse time | 0.108 ± 0.007 | 9.59 | 0.086 ± 0.007 | 5.12 | 0.0021** | +4.47 |

| Dumping time | 0.223 ± 0.035 | 19.80 | 0.31 ± 0.035 | 18.45 | 0.41005 ns | ns |

| Others” | 0.043 ± 0.075 | 3.82 | 0.013 ± 0.075 | 0.77 | 0.0034** | +3.05 |

| Total operation time | 1.126 ± 0.123 | 100 | 1.68 ± 0.123 | 100 | ---- | 0 |

***Significant at α = 0.001, **Significant at α = 0.01, *significant at α = 0.05 and ns = not significant.

§ At 95% confidence interval.

” Others” means operator time and maintenance time.

Fig. 8.

Time distribution of harvesting operation based on Large Size Area <1 ha.

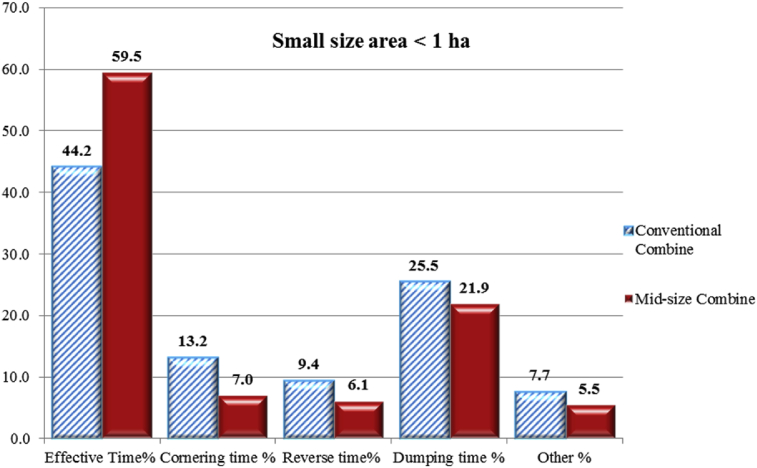

From Table 11 and Fig. 9, in the small farms the conventional combine shows 15.3% lesser percentage effective time of the total time (44.21% versus 59.50%), 6.2% greater percentage of cornering time from the total time (13.18% versus 7.0%), 3.3% greater reverse time percentage of the total time (9.41% versus 6.1%) and 3.6% greater dumping time percentage of the total time (25.52% versus 21.90%) than the mid-size combine.

Table 11.

Time distribution of harvesting operation based on small size area (i.e less than 1 ha).

| Time Distribution | Conventional Combine |

Mid-size Combine |

p value | Difference % | ||

|---|---|---|---|---|---|---|

| (h/ha) | % of Total | (h/ha) | % of Total | |||

| Effective Time | 0.634 ± 0.132§ | 44.21 | 1.19 ± 0.156 | 59.50 | 0.00634** | -15.3 |

| Cornering time | 0.189 ± 0.025 | 13.18 | 0.14 ± 0.156 | 7.00 | 0.00028*** | 6.2 |

| Reverse time | 0.135 ± 0.02 | 9.41 | 0.122 ± 0.021 | 6.10 | 0.41005 ns | 3.3 |

| Dumping time | 0.366 ± 0.061 | 25.52 | 0.438 ± 0.075 | 21.90 | 0.00021*** | 3.6 |

| Others” | 0.11 ± 0.006 | 7.67 | 0.110 ± 0.007 | 5.50 | 0.00761** | 2.2 |

| Total operation time | 1.434 ± 0.212 | 100.00 | 2.0 ± 0.213 | 100.00 | --- | 0.0 |

***Significant at α = 0.001, **Significant at α = 0.01 and ns = not significant.

” Others” means operator time and maintenance time.

§ At 95% confidence interval.

Fig. 9.

Time distribution of harvesting operation based on small size area (i.e less than 1 ha).

The result shows that when using conventional combine the effective time recorded in large farms represents 35.6% lesser percentage of the total time that was spent in harvesting operation in small farms. The percentage of cornering time from the total time was 48.1% greater in case of small farms than the case of large farms. Also, the percentage of dumping time and reverse time from the total time were 22.41% and 1.91% greater in small farms than in large farms respectively (Figs. 9 and 11).

Fig. 11.

Distribution of human energy expenditure in harvesting operation based on farm size.

A similar result was obtained in case of using mid-size combine harvester and it presents in Tables 10 and 11. When using mid-size combine harvester in performing harvesting operation, 21.04% greater percentage effective time of the total time, 48.14% lesser percentage cornering time of the total time, 16.0% lesser percentage reversing time of the total time and 15.75% lesser percentage dumping time of the total harvesting operation time were recorded in large farms compared with that in the small farms.

Most lost-time factors can be reduced with advanced planning and management. On rice fields the fields are small and lost time large, harvest management and selection of suitable machine and field patterns are more critical than with other cereal crops. The experience of the operator of the harvester machine is very important because he faces a compromise in the way he tackles a given area of crop. Operators usually figure out a strategy on the spot, the aim is to minimize harvesting time, maintain a full cut and maximum uninterrupted length of the run. If there is not enough space at the end of the run for a continuous turn and backing is required, turning time may be doubled. Turning time can be 50 percent or more of total field time in rice farms because the area of rice farms is usually small due to the effects of wind. The result revealed that both combine machines showed better performance in large farms than in small farms when they performed harvesting operation.

3.2.3. Distribution of energy expenditure in harvesting operation based on farm size

Results in Tables 12 and 13 shows that in large size farms there was no significant difference in mechanization index between using conventional combine and mid-size combine harvesters (0.994 and 0.99). Also, the conventional combine shows 25.9% greater mean total energy (1263.787 and 1004.29 MJ/ha), 14.6% greater mean fuel energy (943.957and 844.798 MJ/ha), 77.51% greater mean machinery energy (317.373 and 178.787 MJ/ha) and 62.7% greater mean human energy (3.11 and 1.91 MJ/ha) were recorded compared with using of mid-size combine harvester in large farms.

Table 12.

Distribution of energy expenditure in harvesting operation based on large size farm (greater than 1ha).

| Mean | Conventional Combine | Mid-size Combine | p value | Difference% |

|---|---|---|---|---|

| Mechanization Index | 0.99 ± 0.001§ | 0.99 ± 0.002 | 0.5624114 ns | ns |

| Fuel Energy, MJ/ha | 943.957 ± 35.737 | 823.59 ± 18.186 | 6.3542E-05*** | +14.6 |

| Machinery Energy, MJ/ha | 317.373 ± 25.632 | 178.787 ± 24.12 | 6.4521E-10*** | +77.5 |

| Human Energy, MJ/ha | 3.11 ± 0.172 | 1.91 ± 0.428 | 1.3566E-13*** | +62.7 |

| Total Energy, MJ/ha | 1264.44 ± 59.022 | 1004.29 ± 99.62 | 1.4239E-07*** | +25.9 |

***Significant at α = 0.001 and ns = not significant.

§ At 95% confidence interval.

Table 13.

Distribution of energy expenditure in harvesting operation based on small size farm (less than 1ha).

| Mean | Conventional Combine | Mid-size Combine | p value | Difference% |

|---|---|---|---|---|

| Mechanization Index | 0.995 ± 0.001§ | 0.990 ± 0.002 | 0.12457 ns | ns |

| Fuel Energy, MJ/ha | 981.193 ± 104.705 | 943.95 ± 80.716 | 0.44525 ns | ns |

| Machinery Energy, MJ/ha | 697.2 ± 120.683 | 383.278 ± 79.227 | 0.0010*** | +3.9 |

| Human Energy, MJ/ha | 3.61 ± 0.424 | 2.385 ± 0.425 | 0.00579** | +81.9 |

| Total Energy, MJ/ha | 1682.0 ± 210.765 | 1329.66 ± 156.637 | 0.01985* | +48.5 |

***Significant at α = 0.001, **Significant at α = 0.01, *significant at α = 0.05 and ns = not significant.

§ At 95% confidence interval.

When harvesting operations were performing in small size farms the conventional combine shows 48.5% greater mean total energy (1682.635 and 1329.66 MJ/ha), 81.90% greater mean machinery energy (697.2 and 383.278 MJ/ha) and 81.9% greater mean human energy (3.61 and 2.385 MJ/ha) than the mid-size combine harvester. From Figs. 10 and 11 the result revealed that in case of using both machines conventional combine and mid-size combine the recorded energies were greater in small farms compared with that in the large farms due to in small farm the machine made more number of corners per ha, extra reversing movement per ha and need more time to perform the harvesting operation per ha and all these caused more fuel consumption, more human energy and more machinery energy but in case of mid-size combine the increasing in energies were lesser than the conventional combine this due to the size, weight and track type of mid-size combine help it to work in small size farm in a smooth way without making extra movement without interrupted length of run.

Fig. 10.

Distribution of energy expenditure in the harvesting operation based on farm size.

3.2.4. Distribution of GHG emission in harvesting operation based on farm size

When harvesting operations were performing in large size farms the conventional combine shows 25.32% greater mean total GHG emission (77.038 and 61.473 kgCO2eq/ha), 11.73% greater mean fuel GHG emission (54.50 and 48.779 kgCO2eq/ha), 77.51% greater mean machinery GHG emission (22.533 and 12.694 kgCO2eq/ha) than the case of using Mid-size Combine (Table 14 and Fig. 12).

Table 14.

Distribution of GHG Emission in Harvesting Operation based on Large Size Farm >1 ha.

| GHG (kgCO2eq/ha) | Conventional Combine | Mid-size Combine | p value | Difference% |

|---|---|---|---|---|

| Fuel | 54.50 ± 2.063§ | 48.779 ± 1.050 | 6.3542E-05*** | +11.73 |

| Machinery | 22.533 ± 1.819 | 12.694 ± .645 | 6.4521E-10*** | +77.51 |

| Total GHG | 77.038 ± 3.719 | 61.473 ± 1.306 | 7.69792E-08*** | +25.32 |

***Significant at α = 0.001.

§ At 95% confidence interval.

Fig. 12.

Distribution of GHG Emission in Harvesting Operation based on Farm Size.

When harvesting operations were performing in small size farms the conventional combine shows 31.66% greater mean total GHG emission (106.155and 80.6294 kgCO2eq/ha), 6.06% greater mean fuel GHG emission (56.654 and 53.416 kgCO2eq/ha), 81.90% greater mean machinery GHG emission (49.501and 27.213 kgCO2eq/ha) than the case of using Mid-size Combine (Table 15 and Fig. 12).

Table 15.

Distribution of GHG Emission in Harvesting Operation based on Small Size Farm <1 ha.

| GHG (kgCO2eq/ha) | Conventional Combine | Mid-size Combine | p value | Difference% |

|---|---|---|---|---|

| Fuel | 56.654 ± 6.045§ | 53.416 ± 4.166 | 0.445ns | +6.06 |

| Machinery | 49.501 ± 8.568 | 27.213 ± 5.625 | 0.00130** | +81.90 |

| Total GHG | 106.155 ± 13.69 | 80.6294 ± 10.053 | 0.01431* | +31.66 |

**Significant at α = 0.01, *significant at α = 0.05 and ns = not significant.

§ At 95% confidence interval.

However, a higher in GHG emission was recorded in small farms compared with that in large farms during the harvesting operation performed using a conventional combine and mid-size combine for the same reasons in terms of energy expenditure.

From the previous results we concluded that if the sizes of farmlands are enlarged to more than 1 ha, the combine harvester can easily be turned in corners and easily reverse. This leads to improvements in the field performance of the combine, resulting from better harvesting time and lesser time requirements for field movement and paddy unloading activities for harvesting operation. Generally, for mechanization in paddy production to be in the paddy cultivation system, farm areas must be large enough (above 1 ha) to facilitate higher field capacity for the combine harvesters, thereby lowering of operation time. Also, decrease the use of energy expenditure and GHG emission in harvesting operation in the paddy cultivation system. Also, the result shows that the mid-size combine harvester is more suitable to work in the paddy field in Malaysia than the conventional combine due to the small size of rice farms in Malaysia. The mid-size combine harvester shows better performance, lesser energy use, lesser GHG emission, greater field capacity, greater field efficiency lesser percentage of cornering time, a lesser percentage of damping time and a greater percentage of the effective time.

4. Conclusion

This study presents a comparison of the working performance, the energy and GHG emissions of two combines (one conventional combine harvester NEW HOLLAND CLAYSON 8080 and one newly introduced mid-size combine harvester WORLD STAR WS7.0 PLUS) under the actual field harvesting operation in the real field conditions and in the different area sizes of farms for two rice cultivation seasons in wetland rice cultivation in Malaysia. From the results of the study the following conclusions are drawn:

-

•

Although, the effective working width of the conventional combine was 1.43 times greater than the working width of mid-size combine but because of 20.90% lesser mean travel speed during harvesting operation and lesser effective time the conventional combine shows 10.8% lesser mean field efficiency than the mid-size-combine harvester (0.64 versus 0.72).

-

•

The conventional combine showed 24.64% greater mean total energy and 26.12% greater mean total Green House Gas emission (GHG) than the mid-size combine harvester. Those make the mid-size combine more efficient in energy use in paddy cultivation system and also make it more environmental friend and lesser contributor to global warming than the conventional combine harvester.

-

•

Both combine machines showed better performance in large farms than in small farms when they performed harvesting operation but the effect of farm size in case of using mid-size combine was lesser than that in case of the using of conventional combine due to the size, weight and track type of mid-size combine help it to work in small size farm as well as large size farm in good performance and smooth turning and make a reverse moving without making an interrupted length of run.

-

•

Generally, for mechanization in paddy cultivation system, farm areas must be large enough (above 1 ha) to facilitate higher field capacity for the combine harvesters, thereby lowering of operation time and decrease the use of energy expenditure and GHG emission in harvesting operation.

Declarations

Author contribution statement

Suha Elsoragaby: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Azmi Yahya, Modather Mairghany: Conceived and designed the experiments; Contributed reagents, materials, analysis tools or data.

Muhammad Razif Mahadi, Nazmi Mat Nawi: Contributed reagents, materials, analysis tools or data.

Funding statement

This work was supported by the Universiti Putra Malaysia, who provided a research grant.

Competing interest statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- Alizadeh M.R., Allameh A. Evaluating rice losses in various harvesting practices. Int. Res. J. Appl. Basic Sci. 2013;4:894–901. [Google Scholar]

- Amponsah S.K., Addo A., Dzisi K.A., Moreira J., Ndindeng S.A. Performance evaluation and field characterization of the sifang mini rice combine harvester. Appl. Eng. Agric. 2017;33(4):479–489. [Google Scholar]

- Amponsah S.K., Addo A., Dzisi K., Moreira J., Ndindeng S.A. Comparative evaluation of mechanised and manual threshing options for Amankwatia and AGRA rice varieties in Ghana. J. Agric. Eng. 2017;48 [Google Scholar]

- ASABE Standards . ASABE; St. Joseph, MI: 2011. D497.7: Agricultural Machinery Management Data. [Google Scholar]

- ASAE Standards . ASAE; St. Joseph, MI: 2005. S495.1: Uniform Terminology for Agricultural Machinery Management. [Google Scholar]

- ASAE Standards ASAE D497.4 agricultural machinery management data. Science. 2009;85(2210):350–357. [Google Scholar]

- Bockari-Gevao S.M., bin Wan Ismail W.I., Yahya A., Wan C.C. Analysis of energy consumption in lowland rice-based cropping system of Malaysia. Energy. 2005;27(4):820. [Google Scholar]

- Canakci M., Topakci M., Akinci I., Ozmerzi A. Energy use pattern of some field crops and vegetable production: case study for Antalya Region, Turkey. Energy Convers. Manag. 2005;46(4):655–666. [Google Scholar]

- Dilipkumar M., Burgos N.R., Chuah T.S., Ismail S. Cross-resistance to imazapic and imazapyr in a weedy rice (oryza sativa) biotype found in Malaysia. Planta Daninha. 2018;36(0) [Google Scholar]

- Elsoragaby S., Yahya A., Mahadi M.R., Nawi N.M., Mairghany M. Energy utilization in major crop cultivation. Energy. 2019;173:1285–1303. [Google Scholar]

- Faostat F. 2018. Agriculture organization corporate statistical database. Accessed on, 12-06. [Google Scholar]

- Muazu A., Yahya A., Ishak W.I.W., Khairunniza-Bejo S. Machinery utilization and production cost of wetland, direct seeding paddy cultivation in Malaysia. Agric. Agric. Sci. Procedia. 2014;2:361–369. [Google Scholar]

- Muazu A., Yahya A., Ishak W.I.W., Khairunniza-Bejo S. Yield prediction modeling using data envelopment analysis methodology for direct seeding, wetland paddy cultivation. Agric. Agric. Sci. Procedia. 2014;2:181–190. [Google Scholar]

- Nabavi-Pelesaraei A., Abdi R., Rafiee S., Mobtaker H.G. Optimization of energy required and greenhouse gas emissions analysis for orange producers using data envelopment analysis approach. J. Clean. Prod. 2014;65:311–317. [Google Scholar]

- Nabavi-Pelesaraei A., Abdi R., Rafiee S. Neural network modeling of energy use and greenhouse gas emissions of watermelon production systems. J. Saudi Soc. Agric. Sci. 2016;15(1):38–47. [Google Scholar]

- Pathak H., Wassmann R. Introducing greenhouse gas mitigation as a development objective in rice-based agriculture: I. Generation of technical coefficients. Agric. Syst. 2007;94(3):807–825. [Google Scholar]

- Pishgar-Komleh S.H., Ghahderijani M., Sefeedpari P. Energy consumption and CO2 emissions analysis of potato production based on different farm size levels in Iran. J. Clean. Prod. 2012;33:183–191. [Google Scholar]

- Pishgar-Komleh S.H., Omid M., Heidari M.D. On the study of energy use and GHG (greenhouse gas) emissions in greenhouse cucumber production in Yazd province. Energy. 2013;59:63–71. [Google Scholar]

- Rathke G.-W., Wienhold B.J., Wilhelm W.W., Diepenbrock W. Tillage and rotation effect on corn–soybean energy balances in eastern Nebraska. Soil Tillage Res. 2007;97(1):60–70. [Google Scholar]

- Rotz C.A. Proc. XIX International Grassland Congress. 2001, February. Mechanization: planning and selection of equipment; pp. 763–768. [Google Scholar]

- Singh G. Estimation of a mechanisation index and its impact on production and economic factors—a case study in India. Biosyst. Eng. 2006;93(1):99–106. [Google Scholar]

- Soni P., Soe M.N. Energy balance and energy economic analyses of rice production systems in Ayeyarwaddy Region of Myanmar. Energy Effic. 2015;9(1):223–237. [Google Scholar]