Abstract

Objective:

Individuals with neurological damage (e.g., stroke or cerebral palsy) often experience a significant loss of arm function. Robotic devices that address muscle strength deficits in a task-specific manner can assist in the recovery of arm function; however, current devices are typically large, bulky, and expensive to be routinely used in the clinic or at home. This study sought to address this issue by developing a portable planar passive rehabilitation robot, PaRRo.

Methods:

We designed PaRRo with a mechanical layout that incorporated kinematic redundancies to generate forces that directly oppose the user’s movement. Cost-efficient eddy current brakes were used to provide scalable resistances. The lengths of the robots linkages were optimized to have a reasonably large workspace for human planar reaching. We then performed theoretical analysis of the robot’s resistive force generating capacity and steerable workspace using MATLAB simulations. We also validated a prototype device by having a subject move the end-effector along different paths at a set velocity using a metronome while simultaneously collecting surface electromyography (EMG) and end-effector forces felt by the user.

Results:

Results from simulation experiments indicated that the robot was capable of producing sufficient end-effector forces for functional resistance training. We also found the end-effector forces from the user were similar to the theoretical forces expected at any direction of motion. EMG results indicated that the device was capable of providing adjustable resistances based on subjects’ ability levels, as the muscle activation levels scaled with increasing magnet exposures.

Conclusion:

These results indicate that PaRRo is a feasible approach to provide functional resistance training to the muscles along the upper-extremity.

Significance:

The proposed robotic device could provide a technological breakthrough that will make rehabilitation robots accessible for small outpatient rehabilitation centers and in-home therapy.

Keywords: Mechanism Design, Magnetic Braking, Kinematics, Reaching, Therapy

I. Introduction

LOSS of arm function is common in individuals with neurological damage, such as stroke or cerebral palsy [1]–[4]. This reduced arm function is often a result of a loss in strength and mobility, which can greatly affect quality of life and limit the patient’s independence, potentially even more so than lower limb impairment [5], [6]. Given the growing aging population, the incidence of neurological disorders is expected to increase [7], [8]. Moreover, there is currently a shortage of physical therapists and caregivers, and insurance coverage often limits the amount of time that patients spend in therapy [9], [10]. Hence, patients are not receiving sufficient dosage of rehabilitation, which is a critical factor for recovery from neurological injuries. Therefore, there is a great need for therapeutic interventions that are cost-efficient and are able to help restore arm function [7], [9].

A major goal of rehabilitation after neurological injury is to improve muscle strength and movement control, as they are integral to a patient’s road map to functional recovery. Rehabilitation specialists spend a considerable amount of time providing therapies that focus on alleviating muscle weakness, movement dysfunction, and abnormal coordination. Such therapies are often performed in a task-specific manner because evidence suggests that treatments that incorporate repetitive practice of a task that is specific to the intended outcome are more effective in improving functional outcomes when compared with traditional approaches (e.g. neurodevelopmental technique) [11]–[13]. The evidence for task-specific training is strongly founded in the psychology of motor learning and in the neuroscience of use-dependent plasticity [13], [14], A number of studies have shown that performance improvements occur most readily when training closely resembles the specific activity for which improved performance is desired [15]. The motor activity seen in this type of training is also known to facilitate neural plasticity and functional recovery after neurological injuries [13].

Robotic rehabilitation devices can effectively deliver task-specific training and potentially offset the heightened demand for care. Rehabilitation robots can also automate, standardize, and provide a greater dosage of therapy to patients following injury [8], [10]. Along these lines, there are many robotic interfaces and accompanying control algorithms that have been developed for upper-extremity rehabilitation [19]–[22]. Most of these robots are programmed to be assistive, and use large active actuators (i.e., motors) to assist in initiation or guidance of the movement [20]. These active actuators are often expensive and bulky, which makes them prohibitive to in-home use. Presumably, if made to be cost-efficient, robotic devices could be taken outside the clinic and used in home to allow for a greater volume of treatment [23]. However, if taken home, the device should ensure the safety of the patient. From a rehabilitation perspective, assistive therapies, though beneficial for highly impaired patients [19], [20], may not benefit less impaired patients. This is because the principles of motor learning and experience dependent neural plasticity indicate that active engagement and training intensity are vital for recovery after neural injury [24]. Progressive resistance training may be more suitable for these patients who already have some degree of strength and control. However, the benefits of resistance training are expected to translate maximally into improvements in arm function if the training incorporates task-specific elements [25]. Indeed, emerging evidence support that task-specific resistance training may facilitate motor recovery in a wide range of patient populations, including stroke, cerebral palsy, and spinal cord injury [26]–[32].

Although conventional active robots are capable of providing functional resistance training [33], the resistance required can be generated more efficiently by robots or devices that use passive [16], [17] or semi-passive (i.e., electronically controlled) dissipative actuators [34]–[39]. By efficient, we mean that passive actuators are typically lighter in weight, lower in cost, and safer than active actuators, while also having large torque generating capacity [36], [40]. We note that passive actuators, though efficient for resistive therapy, will not be able to add mechanical energy to the user, and therefore, cannot assist movement like typical active robots. Still, the safety and potential cost benefits of passive devices greatly increases the likelihood that a device could be bought by smaller clinics or taken home for therapy.

There are many types of passive devices for functional resistance training. The most simple and inexpensive form of passive devices include weights or elastic resistance bands. These devices are very versatile and can be manipulated so as to apply resistance to many different muscle groups given they are used in the correct posture. However, they are often used in gravity-resisted positions, which may not be suitable for patients who can only make movements in gravity-eliminated positions, where planar reaching is the most commonly used rehabilitation technique (e.g., towel slides, skateboard exercise, etc.). Further, these devices also store energy during use, which makes them potentially dangerous to operate (e.g., if a weight is dropped or a resistance band is released or fails). Passive exercise equipment that use brakes to provide resistance (e.g., Tailwind BATRAC, Reha-Slide, and MagnetTrainer devices [16]–[18]) provide a safer alternative, but these devices typically only permit resistance to one degree of freedom movements (i.e., straight line reaching or bicyclelike rotations).

To address many of these limitations, we propose a novel completely passive rehabilitation robot — PaRRo — that increases the functional capabilities of passive devices (Table I). This device guarantees safety since it uses brakes to provide resistance and allows for two-dimensional resistances that can be applied during planar reaching. Because this device does not have actuation and computer control (although this could be easily incorporated in future iterations), it falls under the category of passive robots [41]–[43]. There are many design challenges that must be addressed to realize such a robotic device. First, since the robot is passive, it will not be controllable, but should still allow for a wide range of resistances to directly oppose a patient’s movements. Given the lack of control, we feel that it is necessary to impose a unique mechanical layout of the robot’s linkages in order to provide force cancellation to allow for near direct opposition to movement. Second, the robot must include passive actuators that can also allow for scalable resistance based on the ability of the patient (i.e. higher resistance for higher functioning patients). There are many different forms of passive actuators, including but not limited to: friction brakes, viscous dampers, and elastic springs. Actuator selection could greatly affect the haptics and usability of the final device. Lastly, the device should include a large reachable workspace to allow for training on a wide array of functionally relevant reaching tasks.

TABLE I.

A comparison of devices that can be used for functional resistance training

| Device Type | Advantages | Disadvantages |

|---|---|---|

| Active Robots | • Can resist and assist motions | • Expensive |

| • Can usually provide limb-weight support | • Bulky and heavy | |

| • Can be instrumented and interfaced with games | • Not typically portable | |

| • Controllable | • Potentially unsafe if device malfunctions | |

| Weights | • Very low-cost | • Primarily resist against gravity |

| • Versatilea | • Cannot provide limb-weight support | |

| • Can resist 3D motions | • Bulky and less portable | |

| • Not controllable | ||

| • Potentially unsafe if dropped | ||

| Elastic Bands | • Very low-cost | • Can only directly resist straight-line reaching |

| • Versatilea | • Not controllable | |

| • Portable | • Potentially unsafe if band breaks or is released | |

| • Can resist 3D motions | ||

| Specialty Rehabilitation Equipmentb | • Low-cost | • Typically restricted to 1D motions |

| • Portable | • Generally not controllable | |

| • Safe using passive actuators | ||

| PaRRo | • Low-cost | • Cannot assist motions |

| • Portable | • Cannot currently resist 3D motions | |

| • Safe using passive actuators | • Cannot provide limb-weight support for 3D motions | |

| • Resist 2D planar motions | ||

| • Planar reaching does not require limb-weight support | ||

| • Can directly resist arbitrary planar movements | ||

| • Can be instrumented and interfaced with games | ||

| • Can be made controllable |

This study aimed to address these design challenges to create this portable passive rehabilitation robot. We designed PaRRo with a mechanical layout that incorporates kinematic redundancies to provide resistances that are able to directly oppose the user’s movement. In order to provide scalable resistances, we implemented cost-efficient eddy current brakes as our form of passive actuation. We then scaled the lengths of our linkages to optimize the workspace of the device for human reaching. We performed theoretical analysis of the robot’s resistive force generating capacity and steerable workspace using MATLAB simulations, then constructed the robot based on these design inputs. We also validated a prototype of the robotic device by comparing the theoretical forces (both magnitudes and directions) obtained from MATLAB simulations to those generated by the actual device when moved across different directions as well as its effect on muscle recruitment while performing planar reaching.

II. Materials and Methods

A. Determining a Configuration for the Passive Robot

To create a robotic device that provides resistance to directly oppose the movement of the end-effector (e.g., if the user pushes forward on the end-effector the robot pushes backward), we investigated different robotic layouts that provide kinematic redundancy. Our proposed configuration combines two 2-link manipulators in parallel (Fig. 1) [44]. Typically, planar reaching robots that use active actuators are constructed with a single 2-link manipulator that is not kinematically redundant; however, when using passive brakes, this configuration would not allow for resistances that directly oppose the end-effector movement. For example, if the end-effector of a 2-link manipulator with passive brakes located over joints 1 and 2 (Fig. 1) was moved along , velocities and would be generated at the joints, and the resulting resistive force would would be relegated to the green cone between vectors f1 and f2. Notably, the desired force (F) lies outside of this cone. By combining two 2-link manipulators in parallel, the resistive force generated due to the second link (i.e., the cone between force vectors f3 and f4) cancels out many of the indirect forces (i.e., off-directional) created by the first set of links, so the resultant force is more likely to align with F. Although this cancellation will not be perfect for every movement direction, it greatly improves the ability of passive devices to directly resist the motion of the end-effector. Additionally, the parallel manipulators increase the force generating capacity of the robot because two additional brakes are contributing to resist the user (i.e. ).

Fig. 1.

Diagram of the kinematically redundant link configuration. Two 2-link manipulators are connected in parallel at the end-effector. Moving the end-effector along , joint i produces an angular velocity () and the brake resists by producing a resistive force (fi) with resistive torque (τi). The total resistive force is the summation of the forces produced by each brake, i.e. . This allows for F that directly oppose , which was an important constraint to the robot. For reference, the brakes located on the base (i.e., brakes 1 and 3) are referred to as ‘shoulder brakes’ while the ones on the arm (i.e., brakes 2 and 4) are ‘elbow brakes’.

The equations pertaining to the proposed robotic layout with kinematic redundancy are listed below [44]. With the inverse kinematics function finv, which relates the end-effector position x to the joint variables q, i.e.

| (1) |

we capture the relationship between end-effector motions on one side of an equation and joint motions on the other,

| (2) |

where is the inverse Jacobian matrix. By using the conservation of power, , where F is the generated force, we obtain

| (3) |

These equations will be applied further in the next section, after selection of the passive actuator.

B. Selecting a Passive Actuator: The Eddy Current Brake

There are numerous passive actuators that could provide scalable resistance for a robotic device. We selected custom miniature passive eddy current brakes to act at each of the robot’s joints [45]. Eddy current brakes are a low-cost and easily scalable method for providing viscous (i.e., velocity dependent) resistance. Viscous forcefields have long been applied for upper-extremity training [46]–[51], and some postulate advantages for viscous training [52]. To give a brief summary of these viscous passive actuators: eddy current brakes consist of a conductor moving through a magnetic field, creating eddy currents, or circular electric currents, in the conductor. These currents will create an opposing magnetic field, producing a resistive force that is opposite and proportional to the relative velocity [53] (Fig. 2a). Eddy current brakes are preferable over friction brakes, as they are contact free and velocity dependent. The brakes feel smooth to the user, allow for a large range of resistive forces, and do not wear out easily.

Fig. 2.

Diagram showing the eddy current braking mechanism. (a) Top view showing the magnetic field (M) and eddy currents (I) that form as the disc rotates with angular velocity (). (b) Eddy current brake setup in our device, with additional parameters affecting the resistive torque (τ) and the magnetic field created by a pair of magnets on a backiron. (c) Braking coefficients corresponding to different magnet displacements (δ) for a single eddy current brake. Magnet exposure is in units of the fraction of magnet diameter exposed to the disk (i.e., 0.00 indicates the magnet is unexposed and 1.00 indicates the magnet is fully exposed 1 in or 2.54 cm over the disk).

For eddy current disc brakes, the resistive torque, τ, is determined by the following equation: [45], [53], [54]

| (4) |

where the parameters represent the conductivity (σ), thickness (t), effective radius (R), angular velocity () of the disc, area (A) of the magnet exposed, and strength (M) of the magnetic field (Fig. 2).

The eddy current brakes used for PaRRo each consist of a pair of permanent magnets (DX08B-N52, KJ Magnetics, Pipersville, PA) 1 in (2.54 cm) in diameter mounted to a ferromagnetic backiron to create a strong magnetic field. Each backiron was mounted to linear sliding rail (LMN4005_0, Phidgets, Calgary, Alberta, Canada) and a bearing block (LMN4204_0, Phidgets, Calgary, Alberta, Canada), which allowed for adjustable resistance (β) for each brake (i.e., the distance (δ) of the slider could be adjusted to alter the acting area (A) of the magnets exposed to the disk). A non-ferrous, 4 in diameter, 5 mm thick aluminum disc (6061 aluminum alloy) was chosen as the conductor for the eddy current brakes. The thickness was chosen from a previous experiment concluding 5 mm was an effective disc thickness to generate adequate torque [45], and aluminum was chosen because it is conductive, lightweight, and nonferromagnetic; therefore it can provide a high resistance while keeping a low inertia [55]. Lastly, a gearbox (P60, BaneBots, Loveland, CO) with a 26:1 ratio was used to increase the angular velocity of the discs and, thus, amplify the resistive torque.

In order to characterize these brakes, the braking coefficients (β) corresponding to different magnet displacements (δ) were determined using an isokinetic dynamometer (System Pro 4, Biodex, Shirley, NY). The eddy current brakes were fixed onto the dynamometer, and the resistive torque was recorded at angular velocities of 10, 20, 30, 45, and 60 degrees/s at eight even increments of magnet displacement (i.e., 1 corresponds to full displacement of the magnet diameter over the disk). The value for torque was calculated as the average torque when the dynamometer was rotating at its programmed velocity (Fig. 2c). Using the data from this experiment and given that σ, t, R, and M were constants, Eq. (4) could be condensed and then generalized for each brake so that

| (5) |

where the braking coefficient β is a function of δ, and after generalizing for all brakes, τ, , and β represent vectors of τ, , and β. With this, Eqs. (2) and (3) could be expanded to:

| (6) |

where describes the relationship between and F.

C. Determining the Robot’s Workspace

The robot’s reachable workspace was determined based on anthropometric norms of the end user. We assumed that the subject would sit with their torso against the edge of the table (i.e., would be unable to compensate using their trunk), so only the arm length of the subject was factored into our calculation. Using anthropometric tables, we found that the average arm length from the shoulder to wrist was 0.332 × H, with H being the body height [56]. We assumed the body height was 1.88 m, which encompasses >99% of females and 95% of males [57], and this yielded an arm length of 0.62 m (Fig. 3). To calculate link length, a MATLAB (Mathworks, Natick, MA, USA) simulation program was used that took the distance between the shoulder brakes (brakes 1 and 3; Fig. 1a) on the base (0.25 m) and optimized link lengths to cover the reaching workspace. This simulation used inverse kinematics to determine the maximum reaching distance allowed at each potential link length. To simplify the optimization, all four links of the robot were assumed to be the same length. This process gave an optimal link length of 0.56 m (22 in) so that the robot’s workspace encompassed the desired reachable workspace (Fig. 1b). With this link length, we then simulated how the proposed robot would behave.

Fig. 3.

(a) The structure of the device was designed to allow for a workspace that encompasses patient’s reach distances as measured using an anthropometric table. (b) Using this normative data, Eq. (1) was used to calculate linkage lengths for the robot so that the robot’s workspace could accommodate participants of different heights.

D. Theoretical Evaluation of Force Generating Capacity

Prior to constructing the robot, we ran a MATLAB simulation to predict the force generating capacity of the robot (i.e., the magnitude and direction of theoretical forces when moving in the workspace) (Fig. 4). The simulation was performed over a grid of 2002 discrete points on the workspace. The simulation swept over each individual grid point and assumed that the end-effector was moving with a set velocity (0.304 m/s) at one out of eight different directions (center panel of Fig. 4). Eq. (6) was evaluated to determine the resulting force at each grid point. Note that the braking coefficients (i.e., magnet exposures) were assumed to be the same for each eddy current brake, i.e. B = βI4, with β = β (δ = 1).

Fig. 4.

Theoretical force plots for a magnet exposure of δ = 1.00 at eight different directions of the end-effector’s motion. The varying colors on the heat maps indicate the force level. Calculations were made using a constant velocity of 0.3 m/s, link lengths of 0.56 m, and 0.25 m between the shoulder brakes on the base. The red arrows indicate direction of the resistive force at various points on the workspace.

The resulting force maps for each direction are shown in Fig. 4. From Eqs. 3 and 5, we know that the force is linear to the braking coefficient β and thus, force magnitude would be scaled by magnet displacement. At full resistance, the robot was expected to produce approximately 30N of force at the end-effector while moving through the center of the workspace. Typically, the angle of the force was within 15 ° of the desired force angle (i.e., directly against the motion of the end-effector) within this same region. Overall the force level appeared sufficient, and the force direction generally opposed the movement direction. We noticed the largest forces occurred along the the top of the reaching workspace. We believe these areas of higher force occurred because the robots configuration approached a singularity (singularities occur when the linkages are fully bent or extended) at these points, but note that most subjects will not be operating in these regions as they lay outside their reachable workspace. Additionally, these are locations where a user would typically begin or end their reaching movement (i.e., the brakes would be rotating at a slow velocity), so the theoretical values do not necessarily represent physiological reaching. This phenomenon was later controlled for, based on the end-effector velocities measured during the experimental evaluation. We also saw that the resulting force angles did not directly resist motion over the entire space. This was likely because the robots configuration was asymmetric at these locations, and the forces generated by the two parallel links were not completely offset from one another.

Once the theoretical analysis confirmed that the robot could supply sufficient force at the end-effector and that the force was generally opposite to the direction of movement, PaRRo was then constructed from extruded aluminum tubing and an eddy current brake was incorporated into each joint. Additionally, two bi-directional load cells with a load capacity of 20 kg (3134_0, Phidgets, Calgary, Alberta, Canada) were attached to the end-effector of the manipulator using pin joints to measure the loads produced by the robot during use. Note, we attached the load cells using pin joints, instead of rigidly mounting them, to isolate them from each other and eliminate force shielding and cross-talk between the sensors. This was verified through 3-point calibration of the load cells, which did not show force shielding and crosstalk. Fig. 5 displays the final design and prototype of PaRRo. In total, the prototype cost approximately $3,800, including all parts and professional fabrication.

Fig. 5.

(a) Three-dimensional CAD rendering of the passive rehabilitation robot (PaRRo). An Eddy current brake is located at each joint and a linear slider is used to adjust the resistive properties of each brake. Two load cells measure forces felt at the end-effector. For reference, the brakes located on the base are referred to as ‘shoulder brakes’ while the ones on the arm are ‘elbow brakes’, (b) The final prototype of the upper-extremity device. LED lights are placed on the end-effector and left shoulder brake to track end-effector position and joint angles. The device can easily be fixed to, and is compatible with, most tables.

E. Experimental Evaluation of Theoretical Analysis

We then performed an experiment to validate the PaRRo prototype against our theoretical evaluation and models. This evaluation tested the device’s ability to convey forces to a user while controlling for their reaching direction and speed at varying magnet exposure levels. Throughout the experiment, we measured the position as well as the magnitude and direction of the force at the end-effector. After the experiment the position and velocity data were re-input into the model used for our theoretical analysis. This was done so that our theoretical analysis was comparable to the experimental data. Additionally, we measured the subject’s muscle activation of many of the key muscles used during reaching.

After signing an University of Michigan IRB consent form, a single healthy subject (male) with no neurological or orthopedic impairments used the device. Before beginning the experiment, nine surface electromyographic (EMG) electrodes (Trigno, Delsys, Natick, MA) were secured using self-adhesive tapes and elastic bandages over the following muscles: flexor carpi radialis (wrist flexors), extensor carpi radialis brevis (wrist extensors), biceps brachii, triceps brachii, anterior deltoid, lateral deltoid, posterior deltoid, serratus anterior, and pectoralis major. The subject then performed maximum voluntary contractions (MVCs) of each of these muscles against a manually imposed resistance, which was used to normalize the data collected during reaching trials.

In order to measure the position of the end effector during reaching, two LED lights were placed on the left shoulder brake and end-effector of the device (Fig. 5B). A webcam system [58] was mounted on the ceiling, directly over the table to track the LEDs. Using this camera system, the end-effector was first moved to the origin and calibrated to obtain a conversion factor of the distance from pixels to meters. The subject then sat with his dominant hand gripping the end-effector. The end-effector was then moved along eight 0.61m (24 in) distance paths all crossing the origin (i.e., moving across the workspace and not in a center-out motion) at magnet exposures of 0, 0.25, 0.5, 0.75, and 1 (Fig. 6a). To keep a similar velocity profile for each trial, the subject used the cue from a metronome that was programmed to sound every 2 seconds continuously (i.e., the subject moved at approximately 0.3 m/s). Throughout the experiment the EMG, load cell, and camera data were measured using custom software written in LabVIEW 2011 (National Instruments Corp., Austin, TX, USA).

Fig. 6.

(a) Schematic of the experimental evaluation. The subject held the end-effector of the device, and moved along eight reaching paths. Note, the paths spanned the workspace and it was not a center-out task. In the figure, the subject is moving along the path between points 1 and 2 (i.e., 0 °). The subject moved along with a metronome and had 2 seconds to traverse the 0.61 m path (i.e., they moved with an approximate average velocity of 0.3 m/s). This same procedure was performed for each reaching path as we measured the force at the end-effector and the subject’s muscle activation. (b–f) Experimental evaluation force plots of different magnet exposures (δ) at the eight different end-effector paths (0 °−315 °). δ is the fraction of the magnet diameter that is exposed to the disk. The varying colors on the plot indicate the force level in N. The red arrows indicate direction of the resistive force at various points along each path.

F. Data Processing

1). Direction and Magnitude of Forces:

Throughout the experiment, load cell data were sampled at a rate of 125 Hz, while the data from the camera system (i.e., end-effectir position) were sampled at a rate of 30 Hz. Load cell readings were resolved into the global coordinates based on position data that were interpolated to 125 Hz.

2). Revised Theoretical Analyses:

The initial theoretical analyses (Section D1) were performed to provide broad insight into the force generating capacity (i.e., the potential force magnitudes and directions) of PaRRo and serve as a guide for design. However, these analyses did not consider physiological reaching velocity profiles (i.e., they assumed a constant speed at each point on the grid). Therefore, we sought to revise the actual theoretical analyses to more closely resemble the actual velocity of the end-effector during experimental evaluation. These revised theoretical analyses used the same MATLAB simulation as the previous theoretical analyses; however, it was used to calculate the force generating capacity at the end-effector positions and velocities that were experienced during the experimental evaluation. This allowed us to compare our model of PaRRo to the final device that was constructed based on the design inputs from the initial theoretical analyses.

3). Electromyography:

EMG data were collected to examine the distribution of muscle activation over the various reaching directions and whether muscle activation scaled with increasing resistance. These data were then used to both validate whether the device engaged the subject as would be expected with a direct resistance, or if the subject was required to compensate during resisted reaching as would occur if there were off-axis forces. For every reaching trial, the EMG data were sampled at a rate of 1000 Hz for all muscles. During processing, the raw EMG data were first band-pass filtered (20-500 Hz) to remove the DC offset and extraneous high frequency noise, and then rectified and passed through a low pass filter (6 Hz cutoff, Butterworth, 8th order) to obtain a linear envelope of the EMG signals. The resulting EMG data were normalized using the MVCs of each muscle. We then calculated the average muscle activation over the reach, by detecting the indices where the force data exceeded a threshold of 20% of the maximum force during the trial, then taking the average of the EMG data between these two indices. This average activation was calculated for each muscle at different magnet exposures.

III. Results

A. Direction and Magnitude of Forces

As expected from the theoretical analysis, data from the experiment indicated that the end-effector forces scaled as a function of magnet exposure (Figs. 6b–6f; Table II). With the current brake setup and configuration, the device was able to provide an average maximum (across all directions) of approximately 35 N of resistance with full magnet exposure. Meanwhile, with no magnet exposure, where weaker forces (e.g., dynamics/inertia of the device and joint friction) are more prominent, on average, the device generated about 7 N of force at the end-effector. Also, the average direction of the force generally opposed to the motion of the end effector (Table III). Although we would theoretically expect that the force direction and magnitude are independent, we actually found that there were smaller errors in the force direction as magnet exposure (i.e., resistance) was increased (6 ° at max exposure compared with 13 ° with no exposure). These increased errors in force direction at lower resistances most likely resulted because joint friction, nonlinearities in the brakes, and inertia would have a larger relative effect on the force direction at lower magnet exposures.

TABLE II.

Average force value (N) along each path and magnet exposure from the experimental evaluation.

| Exposure (δ) | 0 ° | 45 ° | 90 ° | 135 ° | 180 ° | 225 ° | 270 ° | 315 ° |

|---|---|---|---|---|---|---|---|---|

| 0.00 | 6.7 | 7.7 | 4.8 | 7.8 | 6.7 | 6.6 | 5.5 | 7.5 |

| 0.25 | 9.4 | 9.2 | 7.7 | 10.4 | 10.0 | 8.7 | 6.1 | 9.8 |

| 0.50 | 17.8 | 20.7 | 16.3 | 23.1 | 19.9 | 19.6 | 14.4 | 22.8 |

| 0.75 | 28.3 | 32.6 | 24.1 | 36.8 | 29.0 | 30.4 | 24.9 | 32.7 |

| 1.00 | 31.9 | 41.4 | 30.8 | 39.0 | 36.3 | 37.2 | 25.3 | 35.9 |

δ is the fraction of the magnet diameter that is exposed to the disk

TABLE III.

Average direction (degrees) of resistive force along each path and magnet exposure from the experimental evaluation.

| Exposure (δ) | 0 ° | 45 ° | 90 ° | 135 ° | 180 ° | 225 ° | 270 ° | 315 ° |

|---|---|---|---|---|---|---|---|---|

| Desired | 180 | 224 | 270 | 315 | 360 | 45 | 90 | 135 |

| 0.00 | 152 | 224 | 274 | 331 | 356 | 14 | 90 | 152 |

| 0.25 | 169 | 216 | 267 | 324 | 354 | 25 | 88 | 157 |

| 0.50 | 178 | 217 | 270 | 322 | 354 | 33 | 88 | 151 |

| 0.75 | 175 | 217 | 272 | 320 | 345 | 29 | 88 | 150 |

| 1.00 | 182 | 225 | 269 | 319 | 348 | 30 | 89 | 150 |

δ is the fraction of the magnet diameter that is exposed to the disk

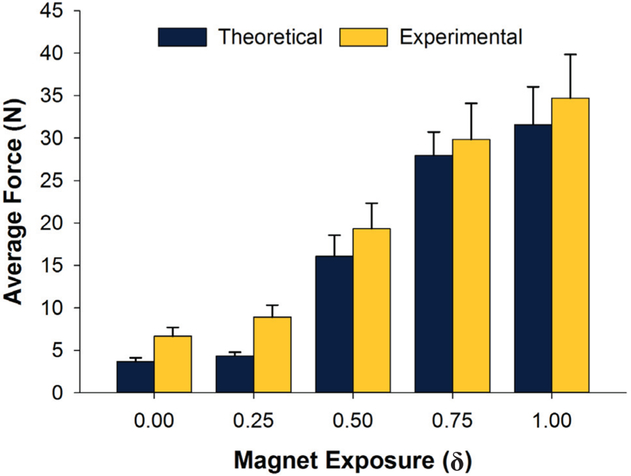

B. Revised Theoretical Analyses

Using the velocity profiles and end-effector position obtained from the experimental data for each path and magnet exposure, the expected force values along each path were revised for a better representation of how our theoretical model of the robot matches the experimental results. The model’s prediction for the force magnitudes and directions can be found in Tables IV and V. Like we saw in the experimental results, the theoretical model also predicted the scaling of force with magnet exposure (Fig. 7), where the average difference between the two sets of results was 3.46 N. When comparing the resistive force directions from the experimental evaluation to the revised theoretical values, the average of the absolute differences was <5 ° (Fig. 8).

TABLE IV.

Average theoretical force values (N) along each path and magnet exposure using velocity profiles and corresponding positions of the end-effector obtained from the experimental evaluation.

| Exposure (δ) | 0 ° | 45 ° | 90 ° | 135 ° | 180 ° | 225 ° | 270 ° | 315 ° |

|---|---|---|---|---|---|---|---|---|

| 0.00 | 4.0 | 4.2 | 3.0 | 3.9 | 3.1 | 3.9 | 3.9 | 3.3 |

| 0.25 | 4.2 | 4.0 | 4.1 | 4.9 | 4.3 | 4.4 | 3.8 | 5.0 |

| 0.50 | 14.1 | 16.9 | 13.9 | 17.7 | 14.7 | 18.2 | 13.0 | 20.0 |

| 0.75 | 25.0 | 27.3 | 27.0 | 31.8 | 25.1 | 31.4 | 25.9 | 30.1 |

| 1.00 | 26.4 | 37.5 | 28.5 | 32.3 | 31.8 | 37.5 | 26.0 | 32.8 |

δ is the fraction of the magnet diameter that is exposed to the disk

TABLE V.

Average theoretical directions (degrees) of resistive force along each path and magnet exposure using velocity profiles and corresponding positions of the end effector obtained from the human subject experiment.

| Exposure (δ) | 0 ° | 45 ° | 90 ° | 135 ° | 180 ° | 225 ° | 270 ° | 315 ° |

|---|---|---|---|---|---|---|---|---|

| Desired | 180 | 225 | 270 | 315 | 360 | 45 | 90 | 135 |

| 0.00 | 181 | 227 | 277 | 324 | 364 | 47 | 92 | 137 |

| 0.25 | 183 | 224 | 274 | 325 | 364 | 51 | 95 | 142 |

| 0.50 | 183 | 223 | 273 | 325 | 361 | 44 | 92 | 144 |

| 0.75 | 184 | 222 | 274 | 324 | 363 | 42 | 91 | 143 |

| 1.00 | 183 | 223 | 273 | 325 | 361 | 42 | 98 | 144 |

δ is the fraction of the magnet diameter that is exposed to the disk

Fig. 7.

Average force magnitude measured experimentally and calculated from the revised theoretical model. The magnet exposures were measured in inches. Error bars represent the standard deviations across each reaching direction from the experiment.

Fig. 8.

Average absolute difference in force direction from desired. These values were measured experimentally and calculated from the revised theoretical model. Error bars represent the standard deviations across each magnet exposure.

C. Electromyography

The EMG data are depicted using polar plots, where the amplitudes of muscle activation are plotted with the directions of the reaching movement (Fig. 9). In these plots, the amplitudes of the muscle activation increased based on the resistance level. Thus, we believe that the exercise could be intensified by increasing the magnet exposure. After inspection, it also does not appear that the subject was required to compensate to overcome off axis forces. We saw that a majority of muscles were most active while the subject performed anatomical motions that corresponded to the muscles’ action. For example, the pectoralis major is a known should adductor and showed larger activations during movements that required shoulder adduction (i.e., 180 °) and was less activated during abduction. similar observations were seen for the posterior deltoid (shoulder abductor), biceps brachii (pulling backward), and triceps brachii (pushing forward).

Fig. 9.

Polar plots showing activation many of the key muscles used during reaching while using PaRRo. EMG was recorded from the muscles while reaching along eight different paths. Five magnet exposures are shown for each muscle. The EMG for each muscle was normalized using respective maximum voluntary contractions (MVC), where the subjects performed MVCs of each of these muscles against a manually imposed resistance. The amplitude of the EMGs are shown in % MVC. Arrows in the key indicate the anatomical movements for the reaching paths.

IV. Discussion

To our knowledge, this is the first demonstration of the feasibility of a fully passive, portable rehabilitation robot for multi-directional upper-extremity functional resistance training. To create this robot, we utilized passive eddy current brakes along with a mechanical layout that provided kinematic redundancies to allow for direct resistance to movement of the end-effector and a functional reachable workspace. We first ran simulations to determine if the robot could provide the forces necessary to provide functional resistance training. A prototype of the PaRRo robot was then developed and actual force data were collected from load cells on the robot while a subject performed reaching motions. We also verified the intensity of the training by measuring the subject’s muscle activation while reaching under different resistive loads. The robotic device that we designed met all the design criteria that were specified for a passive planar reaching robot. The results from the experimental evaluation were, on average, within 3.5 N of the theoretical values obtained from simulations. Further, we found that the robot allowed for scalable intensity, as increasing the resistance of the device also increased EMG amplitude of many of the key upper-extremity muscles.

PaRRo represents a substantial departure from typical rehabilitation robots, regardless of if they are active or passive. Although active robots provide a large amount of flexibility in the type of training that can be administered to a subject, they typically operate using bulky motors and can cost more than $100,000. This makes them largely unobtainable for small rehabilitation clinics or in-home use. As a result, therapists usually opt to apply rehabilitation methods that are low-cost and completely passive for task-specific or resistance training. Examples include using towel slides and skateboards to perform unweighted reaching, or using weights, resistance bands, or specialized rehabilitation equipment (e.g., Tailwind BATRAC, Reha-Slide, and MagnetTrainer) to address muscle weakness. Although many of these resistive devices could be applied for functional resistance training, which is a fusion of task-specific and resistance training, there are numerous trade-offs to these applications (Table I). A weight could be incorporated into a towel-slide to provide frictional forces, however, excessively large weights would be required in order to experience similar resistances to what PaRRo can provide. Elastic bands can be fastened to a tabletop, but these cannot provide resistance along arbitrary reaching paths, nor can they provide bidirectional resistances or scale resistance level without exchanging bands. A larger concern is that they store energy during exercise and are liable to break with extended use, potentially causing bodily injury. Because specialty rehabilitation equipment apply brakes to resist the user, they are a very safe alternative, but their functional capabilities are limited, as they typically only allow one degree of freedom movement (i.e., linear reaching). PaRRo is unique because it is a manipulandum that uses brakes in concert with kinematic redundancies in its linkages. Therefore, it is able to provide near direct resistance to movements over two degrees of freedom (i.e., planar) reaching, which allows for functional movements similar to towel slides. Moreover, the resistance is easily scaled by altering the magnet exposure on the brakes, and the device can be instrumented in order to monitor patient progress and interface with games for rehabilitation. The application of the device could be further expanded to allow for three dimensional reaching training. Quite simply, this could be accomplished by placing the device onto a tiltable surface, such that the device can be operated on an incline. This would allow for more diverse training and require minimal alterations to the current device.

In terms of resistance level, PaRRo offers a wide range of potential resistances (4.8 - 41.4 N) at moderate movement speeds (0.304 m/s). This is comparable to, although slightly less than, existing devices such as the Reha-Slide, which offers a range of 5 - 80 N using a friction based linear slider [17]. We note that the resistive properties of PaRRo can be easily scaled to facilitate a larger range of resistances by increasing the size/number of magnets used in the eddy current brake. For example, by having two pairs of magnets attached to the backiron the force capacity of the robot could be doubled.

We also note that the resistive properties of PaRRo were selected based on usage of the device for the intended patient population. During resisted reaching in our experiment, which was performed on a healthy subject, PaRRo elicited an overall average muscle amplitude of approximately 20% of the subjects maximum contraction. Although 20% of MVC could be applied for endurance based training in healthy subjects [59]–[62], approximately 40 N of resistance would be substantial for patients with neurological injury. It has been shown that stroke survivors have a 50 - 58% lower strength in their impaired arm when compared with their less impaired arm [63]. Hence, the current configuration of the brakes may be sufficient if PaRRo were to be used in the rehabilitation of individuals with neurological injury. However, we also feel that PaRRo could be useful for rehabilitating patients with other conditions such as orthopedic injury/surgery. If used in these populations, the resistive capabilities of the device may have to be increased.

PaRRo was designed in order to provide direct resistance to the movement of the end-effector. Generally, the force angle was within approximately 20 ° of the desired angle during the experimental evaluation. Although these force angles were not perfectly aligned opposite to the end-effector’s motion, we do believe that PaRRo could be used in its current condition in order to provide resistance to reaching movements. This is because the muscle activation patterns were physiologically normal and did not show any noticeable compensatory activation patterns (e.g., the pectoralis major is a shoulder adductor and was primarily active during arm adduction; Fig. 9). This would not have been the case if the force angle errors were providing large perturbations to the subject, as the subject would have to make unwanted co-contractions to resist the perturbations. It is possible that some of the errors measured with respect to the desired angle during the experimental evaluation occurred due to human operation of the device. That is, if the subject did not move perfectly along the path, it would be likely that the force measured at the end-effector would be misaligned as well. Although this method of testing replicates how the device may behave during actual use, future iterations of PaRRo could be improved in order to better control the magnitude and direction of the displayed force (see below).

Theoretical analyses were performed in this study for two reasons: 1) we wanted to create a model that could be used to predict the outcomes of our design decisions and 2) we wanted to validate that model during real testing conditions so that it could eventually be used for controls. With this validated model in place, it would also be possible to add some basic controls to the eddy current brakes that can be used to prescribe a desired force amplitude and direction to the user. That is, instead of manually controlling the magnet exposure as in this study, each eddy current brake and slider could be fit with a servo motor under micro-processor control. These controllable brakes could be used to programatically adjust the magnet exposure by inverting Eq. (6) and solving for δ with a desired force magnitude and direction. With this, one can generate either more precise resistive forces, or by purposefully setting different magnet exposures at the joints of the device, forces could be created that are purposefully off-axis and meant to perturb/guide the user and elicit adaptations [64]. Control over the brakes would allow PaRRo to create forces anywhere within the force cone between f1 and f3 (Fig. 1). This would allow for training similar to error augmentation and reduction training [20], [65], [66], and feedback control would even be permitted by incorporating the load cell in the loop. Even with the addition of these controls, the device would remain passive and safe, since the motor would not act directly on the subject. Still, there are some limitations to the controllability of completely passive robotic systems. In many instances, our experimental results had slight deviations from the theoretical analyses, such as a systematic underestimation of force magnitude and seemingly variable deviations between force angles. We believe that many of these differences are primarily due to unaccounted dynamics of the eddy current brakes and robot linkages. Regardless, controls would minimize errors in the displayed force at the end-effector, and could increase the usability and scope of passive robots; albeit, while somewhat increasing the cost.

V. Conclusion

In summary, we developed and validated a portable planar passive rehabilitation robot that allows for scalable resistances over a large workspace. Experimental analyses indicated that end-effector forces observed were similar to the theoretical forces expected at any direction of motion. Our results indicated that the device was capable of providing adjustable resistances, which could be scaled based on a subject’s ability. Additionally, the magnitude of the subject’s muscle activity scaled with increasing magnet exposures. These results indicate that PaRRo is a feasible low-cost approach to provide functional resistance training to the muscles of the upper-extremity.

Acknowledgments

This work was partly supported by the (1) Disability and Rehabilitation Engineering Program of the National Science Foundation (NSF) (Grant No. 1804053), (2) NSF Graduate Research Fellowship (DGE #1256260) (3) National Institutes of Health (Grant# R01 EB019834 and Grant# R21 HD092614), and (4) the University of Michigan MCubed seed funding.

Contributor Information

Edward P. Washabaugh, Department of Biomedical Engineering, University of Michigan, Ann Arbor, MI 48108 USA..

Jane Guo, Department of Biomedical Engineering, University of Michigan, Ann Arbor, MI 48108 USA..

Chih-Kang Chang, Department of Physical Medicine and Rehabilitation, University of Michigan, Ann Arbor, MI 48108 USA.

C. David Remy, Department of Mechanical Engineering and Michigan Robotics, University of Michigan, Ann Arbor, MI 48109 USA.

Chandramouli Krishnan, Department of Physical Medicine and Rehabilitation, Michigan Robotics, and the Department of Biomedical Engineering, University of Michigan, Ann Arbor, MI 48108 USA..

References

- [1].Pohl PS et al. , “Sensorymotor control in the ipsilesional upper extremity after stroke,” Neurorehabilitation, vol. 9, no. 1, pp. 57–69, 1997. [DOI] [PubMed] [Google Scholar]

- [2].Raghavan P, “Upper limb motor impairment after stroke,” Physical Medicine and Rehabilitation Clinics, vol. 26, no. 4, pp. 599–610, 2015. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [3].Krakauer JW, “Arm function after stroke: from physiology to recovery,” in Seminars in neurology, vol. 25, no. 04 Citeseer, 2005, pp. 384–395. [DOI] [PubMed] [Google Scholar]

- [4].Lemmens RJ et al. , “Arm hand skilled performance in cerebral palsy: activity preferences and their movement components,” BMC Neurology, vol. 14, no. 52, pp. 1–10 2014. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [5].Olsen TS, “Arm and leg paresis as outcome predictors in stroke rehabilitation.” Stroke, vol. 21, no. 2, pp. 247–251, 1990. [DOI] [PubMed] [Google Scholar]

- [6].Likhi M et al. , “Does trunk, arm, or leg control correlate best with overall function in stroke subjects?” Topics in stroke rehabilitation, vol. 20, no. 1, pp. 62–67, 2013. [DOI] [PubMed] [Google Scholar]

- [7].Prange GB et al. , “Systematic review of the effect of robot-aided therapy on recovery of the hemiparetic arm after stroke,” Journal of Rehabilitation Research & Development, vol. 43, no. 2, pp. 171–184, 3 2006. [DOI] [PubMed] [Google Scholar]

- [8].Volpe BT et al. , “Robotic devices as therapeutic and diagnostic tools for stroke recovery,” Archives of Neurology, vol. 66, no. 9, pp. 1086–1090, 9 2009. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [9].Maciejasz P et al. , “A survey on robotic devices for upper limb rehabilitation,” Journal of Neuroengineering and Rehabilitation, vol. 11, no. 3, pp. 1–29 2014. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [10].Richards L et al. , “Driving motor recovery after stroke,” Topics in Stroke Rehabilitation, vol. 15, no. 5, pp. 397–411, 9 2008. [DOI] [PubMed] [Google Scholar]

- [11].Veerbeek JM et al. , “What is the evidence for physical therapy poststroke? a systematic review and meta-analysis,” PloS one, vol. 9, no. 2, p. e87987, 2014. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [12].Sullivan KJ et al. , “Effects of task-specific locomotor and strength training in adults who were ambulatory after stroke: results of the steps randomized clinical trial,” Physical therapy, vol. 87, no. 12, pp. 1580–1602, 2007. [DOI] [PubMed] [Google Scholar]

- [13].Hubbard IJ et al. , “Task-specific training: evidence for and translation to clinical practice,” Occupational therapy international, vol. 16, no. 3–4, pp. 175–189, 2009. [DOI] [PubMed] [Google Scholar]

- [14].Shepherd RB, “Exercise and training to optimize functional motor performance in stroke: driving neural reorganization?” Neural Plasticity, vol. 8, no. 1–2, pp. 121–129, 2001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [15].Morrissey MC et al. , “Resistance training modes: specificity and effectiveness.” Medicine and science in sports and exercise, vol. 27, no. 5, pp. 648–660, 1995. [PubMed] [Google Scholar]

- [16].Hesse S et al. , “A new mechanical arm trainer to intensify the upper limb rehabilitation of severely affected patients after stroke: design, concept and first case series.” Europa medicophysica, vol. 43, no. 4, pp. 463–468, 2007. [PubMed] [Google Scholar]

- [17].Hesse S et al. , “Mechanical arm trainer for the treatment of the severely affected arm after a stroke: a single-blinded randomized trial in two centers,” American journal of physical medicine & rehabilitation, vol. 87, no. 10, pp. 779–788, 2008. [DOI] [PubMed] [Google Scholar]

- [18].Whitall J et al. , “Repetitive bilateral arm training with rhythmic auditory cueing improves motor function in chronic hemiparetic stroke,” Stroke, vol. 31, no. 10, pp. 2390–2395, 2000. [DOI] [PubMed] [Google Scholar]

- [19].Lo HS and Xie SQ, “Exoskeleton robots for upper-limb rehabilitation: State of the art and future prospects,” Medical Engineering and Physics, vol. 34, no. 3, pp. 261–268, 4 2012. [DOI] [PubMed] [Google Scholar]

- [20].Marchal-Crespo L and Reinkensmeyer DJ, “Review of control strategies for robotic movement training after neurologic injury,” Journal of neuroengineering and rehabilitation, vol. 6, no. 1, p. 20, 2009. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [21].Merians AS et al. , “Robotically facilitated virtual rehabilitation of arm transport integrated with finger movement in persons with hemiparesis,” Journal of neuroengineering and rehabilitation, vol. 8, no. 27, pp. 1–10, 2011. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [22].Jack D et al. , “Virtual reality-enhanced stroke rehabilitation,” IEEE transactions on neural systems and rehabilitation engineering, vol. 9, no. 3, pp. 308–318, 2001. [DOI] [PubMed] [Google Scholar]

- [23].Lu EC et al. , “Development of a robotic device for upper limb stroke rehabilitation: A user-centered design approach,” Paladyn, vol. 2, no. 4, pp. 176–184, 12 2011. [Google Scholar]

- [24].Kleim JA and Jones TA, “Principles of experience-dependent neural plasticity: Implications for rehabilitation after brain damage,” Journal of Speech, Language, and Hearing Research, vol. 51, no. 1, pp. S225–S239, 2 2008. [DOI] [PubMed] [Google Scholar]

- [25].Patten C et al. , “Concurrent neuromechanical and functional gains following upper-extremity power training post-stroke,” Journal of neuroengineering and rehabilitation, vol. 10, no. 1, pp. 1–19, 2013. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [26].Cooke EV et al. , “Efficacy of functional strength training on restoration of lower-limb motor function early after stroke: phase i randomized controlled trial.” Neurorehabilitation and Neural Repair, vol. 24, no. 1, pp. 88–96, 8 2009. [DOI] [PubMed] [Google Scholar]

- [27].Donaldson C et al. , “Effects of conventional physical therapy and functional strength training on upper limb motor recovery after stroke: a randomized phase ii study,” Neurorehabilitation and Neural Repair, vol. 23, no. 4, pp. 389–397, 12 2008. [DOI] [PubMed] [Google Scholar]

- [28].Xu G et al. , “An intelligent control framework for robot-aided resistance training using hybrid system modeling and impedance estimation,” in Engineering in Medicine and Biology Society (EMBC), 2015 37th Annual International Conference of the IEEE IEEE, 2015, pp. 3602–3606. [DOI] [PubMed] [Google Scholar]

- [29].van Vulpen LF et al. , “Improved walking capacity and muscle strength after functional power-training in young children with cerebral palsy,” Neurorehabilitation and neural repair, vol. 31, no. 9, pp. 827–841, 2017. [DOI] [PubMed] [Google Scholar]

- [30].Wu M et al. , “Robotic resistance treadmill training improves locomotor function in human spinal cord injury: a pilot study,” Archives of physical medicine and rehabilitation, vol. 93, no. 5, pp. 782–789, 2012. [DOI] [PubMed] [Google Scholar]

- [31].Wu M et al. , “Robotic resistance treadmill training improves locomotor function in children with cerebral palsy: A randomized controlled pilot study,” Archives of physical medicine and rehabilitation, vol. 98, no. 11, pp. 2126–2133, 2017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [32].Washabaugh EP and Krishnan C, “A wearable resistive robot facilitates locomotor adaptations during gait,” Restorative neurology and neuroscience, vol. 36, no. 2, pp. 215–223, 2018. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [33].Stein J et al. , “Comparison of two techniques of robot-aided upper limb exercise training after stroke,” American journal of physical medicine & rehabilitation, vol. 83, no. 9, pp. 720–728, 2004. [DOI] [PubMed] [Google Scholar]

- [34].Kikuchi T et al. , “Quasi-3-dof rehabilitation system for upper limbs: its force-feedback mechanism and software for rehabilitation,” in Rehabilitation RoboFtics, 2007. ICORR 2007. IEEE 10th International Conference on. IEEE, 2007, pp. 24–27. [Google Scholar]

- [35].Haraguchi M and Furusho J, “Passive-type rehabilitation system for upper limbs which can display the exact resistance force in the orientation opposite to hand motion,” in Rehabilitation Robotics (ICORR), 2013 IEEE International Conference on. IEEE, 2013, pp. 1–6. [DOI] [PubMed] [Google Scholar]

- [36].Stienen AH et al. , “Dampace: dynamic force-coordination trainer for the upper extremities,” in Rehabilitation Robotics, 2007. ICORR 2007. IEEE 10th International Conference on. IEEE, 2007, pp. 820–826. [Google Scholar]

- [37].Dellon B and Matsuoka Y, “Path guidance control for a safer large scale dissipative haptic display,” in Robotics and Automation, 2008. ICRA 2008. IEEE International Conference on. IEEE, 2008, pp. 2073–2078. [Google Scholar]

- [38].Book WJ et al. , “The concept and implementation of a passive trajectory enhancing robot.” Georgia Institute of Technology, 1996. [Google Scholar]

- [39].Chang CK, Washabaugh EP, Gwozdziowski A, Remy CD, Krishnan C. A Semi-passive Planar Manipulandum for Upper-Extremity Rehabilitation. Ann Biomed Eng 2018. Jul;46(7):1047–1065. doi: 10.1007/s10439-018-2020-z. PubMed PMID: 29626272; PubMed Central PMCID: PMC5980770. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [40].Cho C et al. , “Performance analysis of a 2-link haptic device with electric brakes,” Proceedings - 11th Symposium on Haptic Interfaces for Virtual Environment and Teleoperator Systems, HAPTICS 2003, pp. 47–53, 2003. [Google Scholar]

- [41].Collins S et al. , “Efficient bipedal robots based on passive-dynamic walkers,” Science, vol. 307, no. 5712, pp. 1082–1085, 2005. [DOI] [PubMed] [Google Scholar]

- [42].Collins SH et al. , “A three-dimensional passive-dynamic walking robot with two legs and knees,” The International Journal of Robotics Research, vol. 20, no. 7, pp. 607–615, 2001. [Google Scholar]

- [43].Goswami A et al. , “Passive robotics: An exploration of mechanical computation,” in Robotics and Automation, 1990. Proceedings., 1990 IEEE International Conference on. IEEE, 1990, pp. 279–284. [Google Scholar]

- [44].Gao D and Book WJ, “Steerability in planar dissipative passive robots,” The International Journal of Robotics Research, vol. 29, no. 4, pp. 353–366, 4 2010. [Google Scholar]

- [45].Washabaugh EP et al. , “A novel application of eddy current braking for functional strength training during gait,” Annals of Biomedical Engineering, vol. 44, no. 9, pp. 2760–2773, 9 2016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [46].Shadmehr R and Mussa-Ivaldi F. a., “Adaptive representation of dynamics during learning of a motor task,” The Journal of Neuroscience, vol. 14, no. 5, pp. 3208–3224, 1994. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [47].Conditt M. a. et al. , “The motor system does not learn the dynamics of the arm by rote memorization of past experience.” Journal of neurophysiology, vol. 78, no. 1, pp. 554–560, 1997. [DOI] [PubMed] [Google Scholar]

- [48].Krakauer JW et al. , “Independent learning of internal models for kinematic and dynamic control of reaching.” Nature neuroscience, vol. 2, no. 11, pp. 1026–31, 1999. [DOI] [PubMed] [Google Scholar]

- [49].Scheidt R. a. et al. , “Persistence of motor adaptation during constrained, multi-joint, arm movements.” Journal of neurophysiology, vol. 84, no. 2, pp. 853–862, 2000. [DOI] [PubMed] [Google Scholar]

- [50].Kluzik J et al. , “Reach Adaptation: What Determines Whether We Learn an Internal Model of the Tool or Adapt the Model of Our Arm?” Journal of Neurophysiology, vol. 100, no. 3, pp. 1455–1464, 2008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [51].Huang FC and Patton JL, “Evaluation of negative viscosity as upper extremity training for stroke survivors,” in Rehabilitation Robotics (ICORR), 2011 IEEE International Conference on. IEEE, 2011, pp. 1–6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [52].Stoeckmann TM et al. , “Elastic, Viscous, and Mass Load Effects on Poststroke Muscle Recruitment and Co-contraction During Reaching: A Pilot Study,” Physical Therapy, vol. 89, no. 7, pp. 665–678, 2009. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [53].Gosline AHC and Hayward V, “Eddy current brakes for haptic interfaces: Design, identification, and control,” IEEE/ASME Transactions on Mechatronics, vol. 13, no. 6, pp. 669–677, 2008. [Google Scholar]

- [54].Simeu E and Georges D, “Modeling and control of an eddy current brake,” Control Engineering Practice, vol. 4, no. 1, pp. 19–26, 1996. [Google Scholar]

- [55].Baharom MZ et al. , “Eddy current braking study for brake disc of aluminium, copper and zink,” in Regional Engineering Postgraduate Conference, pp. 1–6 2011. [Google Scholar]

- [56].Winter DA, Biomechanics and motor control of human movement, 4th ed. Hoboken, N.J.: John Wiley & Sons, 2009. [Google Scholar]

- [57].CD F et al. , “Anthropometric reference data for children and adults: United states, 20072010.” Vital Health Stat, vol. 11, no. 252, pp. 1–48, 10 2012. [PubMed] [Google Scholar]

- [58].Krishnan C et al. , “A low cost real-time motion tracking approach using webcam technology,” Journal of Biomechanics, vol. 48, no. 3, pp. 544–548, 2 2015. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [59].Jiang C et al. , “Motor effort training with low exercise intensity improves muscle strength and descending command in aging,” Medicine, vol. 95, no. 24, p. e3291, 6 2016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [60].Thiebaud RS et al. , “Effects of low-intensity concentric and eccentric exercise combined with blood flow restriction on indices of exercise-induced muscle damage,” Interventional Medicine and Applied Science, vol. 5, no. 2, pp. 53–59, 6 2013. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [61].Burd NA et al. , “Bigger weights may not beget bigger muscles: evidence from acute muscle protein synthetic responses after resistance exercise,” Applied Physiology, Nutrition, and Metabolism, vol. 37, no. 3, pp. 551–554, 6 2012. [DOI] [PubMed] [Google Scholar]

- [62].Weiss A et al. , “High intensity strength training improves strength and functional performance after stroke,” American Journal of Physical Medicine and Rehabilitation, vol. 79, no. 4, pp. 369–376, 7 2000. [DOI] [PubMed] [Google Scholar]

- [63].Bertrand AM et al. , “Reliability of maximal static strength measurements of the arms in subjects with hemiparesis,” Clinical Rehabilitation, vol. 21, no. 3, pp. 248–257, 2007. [DOI] [PubMed] [Google Scholar]

- [64].Gao D and Book WJ, “Steerability in planar dissipative passive robots,” The International Journal of Robotics Research, vol. 29, no. 4, pp. 353–366, 2010. [Google Scholar]

- [65].Abdollahi F et al. , “Error augmentation enhancing arm recovery in individuals with chronic stroke: a randomized crossover design,” Neurorehabilitation and neural repair, vol. 28, no. 2, pp. 120–128, 2014. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [66].Marchal-Crespo L et al. , “Effect of error augmentation on brain activation and motor learning of a complex locomotor task,” Frontiers in neuroscience, vol. 11, no. 526, pp. 1–16, 2017. [DOI] [PMC free article] [PubMed] [Google Scholar]