Abstract

Background

Durable and locally fabricated prosthetic feet are important for developing countries. Modifications to the current CR solid ankle–cushion heel prosthetic foot could enhance current foot characteristics and reduce costs. The goal of this project was to modify the keel and rubber outer foot shell to enhance features and reduce costs of the current CR solid ankle–cushion heel offering.

Methods

The prosthetic foot was designed, fabricated and then tested mechanically for strain and displacement in a cyclic testing machine according to a component of the ISO-10328 testing protocol. Dynamic cyclic testing of both forefoot and heel portions of the foot was conducted.

Findings

Dynamic mechanical cyclic testing of the forefoot and heel at 1.28 kN for two million cycles at a rate of 1 Hz was successfully achieved. The final cost of producing the foot was roughly $16 USD. Limitations include the inability to perform the full battery of ISO-10328 foot testing, UV testing and a limitation to laboratory testing. Clinical studies examining practical application of the modified foot should be conducted.

Keywords: CR solid ankle–cushion heel, developing countries, limb prosthetics, mechanical loading, natural rubber, prosthetic foot, rehabilitation devices, resource-limited environments, stress analysis/testing (biomechanics)

Background

The SACH (solid ankle–cushion heel) prosthetic foot is one of the most commonly used types of prosthetic feet. Its low cost, strong, simple and non-articulated foot design is widely prescribed in developing countries.1,2 There have been various adaptions to the SACH foot design over the years. The CR Equipements SACH foot is one variation possessing a polypropylene keel that has improved its design to provide more durability than a previous version. The current offering of the foot has an external rubberized shell which is found to be more durable than polyurethane prosthetic feet.3 Vulcanized rubber feet tend to have fewer failures than polyurethane feet in resource-limited environments (RLEs).4,5 In RLEs, there is a need to provide access to good-quality assistive technologies that are affordable.6 The CR SACH foot has provided a quality low cost option for amputees as evidenced by its continued use in RLEs.3 A recent study took a closer look at the differences in kinematic, kinetic and spatiotemporal parameters for the CR Equipements SACH foot and SACH foot. The CR Equipements SACH foot offers improved biomechanics during walking when compared with a conventional SACH foot.7 In light of the advantages of the CR Equipements SACH foot, a few modifications to increase durability could be addressed. Therefore, the purpose of our study was to make modifications to the keel and rubber outer foot shell to enhance features and reduce costs of the current CR SACH offering. To do so, we adjusted the strength of the connection between the keel and outer rubber shell and believed an improvement in this aspect of the design would foster a stronger connected keel and outer foot. In addition, we wanted to lower the costs and promote local manufacturing by utilizing natural rubber sourced from South East Asia. We choose natural rubber as opposed to synthetic rubber as it is easily available from latex harvested from rubber trees in many South East Asian countries.8

Methods

Keel design

The keel of the foot is an integral piece of any prosthetic foot as it can play a role in the rigidity of the entire foot structure. The keel in our design was modified to address the potential of the keel to loosen from the rubber outer material, an issue that has been mentioned before,9 and that we anecdotally experienced within our clinic. Measurements were obtained of the keel of the CR Equipements SACH foot and used to create a computer-aided designed model which was then modified. The length of the keel was 14 cm for foot size of 24 cm and greater and 12 cm for foot size of 24 cm and below and total weight of the keel was 71 g. The distal tip of the keel had a 1.5-cm extension that angulated upwards to provide an undercut and stronger connection with the rubber outer. The main bridge of the keel had seven circular fenestrations (holes) approximately 12 mm in circumference which began distally and extended proximally to just below the proximal anterior border of the keel. A total of six circular fenestrations were made for foot sizes below 24 cm. In addition, two smaller holes approximately 8 mm in circumference were made. A triangle-shaped fenestration was placed along the proximal posterior border of the keel, and a vertical hole was extruded to allow for a bolt assembly to accept a foot bolt. Lastly, a square cube (2 cm × 2 cm) was extruded into the lateral aspect of the keel just interior to what would be the lateral malleolus on the outer rubber shell. Each of these adjustments to the keel design was created to provide an attachment point for rubber of the outer foot to anchor into (Figure 1).

Figure 1.

Keel of the prosthetic foot.

Rubber outer shell

Measurements were obtained of the outer foot of the CR SACH and were used to create a more accurate model for the design of the modified foot. The rubber outer shell was made from natural rubber harvested from the Hevea brasiliensis species of tree in Myanmar. Locally sourcing the rubber and working with a local manufacturer made tapping, processing, rolling, vulcanization and fabrication of the rubber outer foot simple. The latex was combined with various percentages of the following: titanium dioxide, calcium carbonate, aluminum silicate, zinc oxide, mercaptobenzothiazole accelerator, antioxidant butylated hydroxytoluene, sulfur and zinc diethyldithiocarbamate (ZDEC). Water cooling allowed for a seamless integration of each substance into the latex. The rubber was combined with accelerants ZDEC and steric acid as this is a widely used and successful additive for vulcanization (Figure 2).10 Rubber and rubber sheets 2 mm and 5 mm thick were pre-cut for later fabrication.

Figure 2.

Rubber mastication process.

Manufacturing process

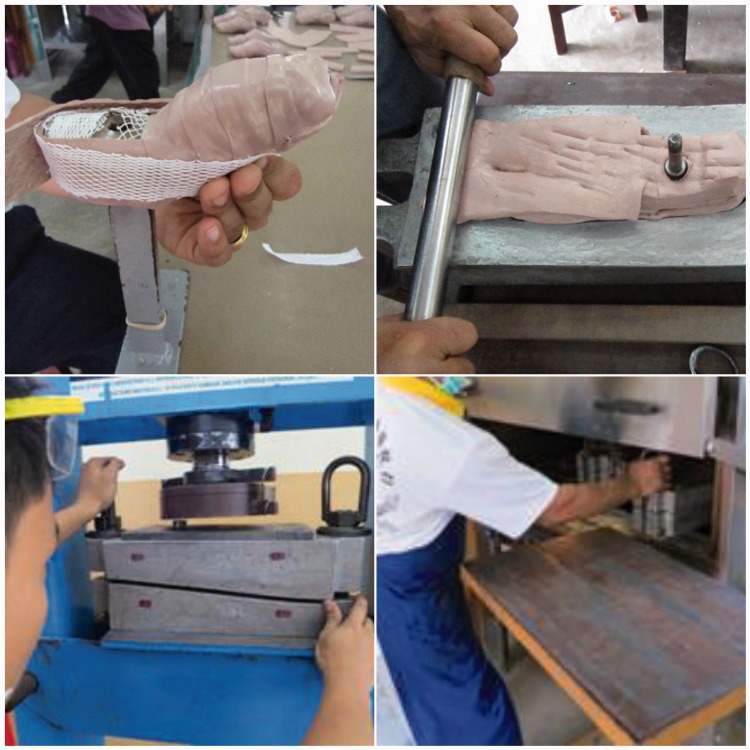

The keel was fabricated out of heated polypropylene from a negative mold of the redesigned polypropylene keel. The final keel design included all fenestrations with design adjustments and a hole for an attachment bolt was formed vertically through the ankle section. Once the keel was successfully fabricated, short strips of nylon netting approximately 11 cm × 2 cm and 25 cm × 2 cm were manually inserted through each of the fenestrations of the keel (Figure 3). The keel and surrounding layers of rubber were fit into a mold which was mechanically bonded together in a hydraulic press multiple times at 30 psi before final oven vulcanization for 120 min at 140℃ (Figure 4). A final foot resulted in a foot weighing 625 g with a shore A of 35–40 (Figure 5).

Figure 3.

Keel with nylon netting.

Figure 4.

Foot manufacturing process and vulcanization.

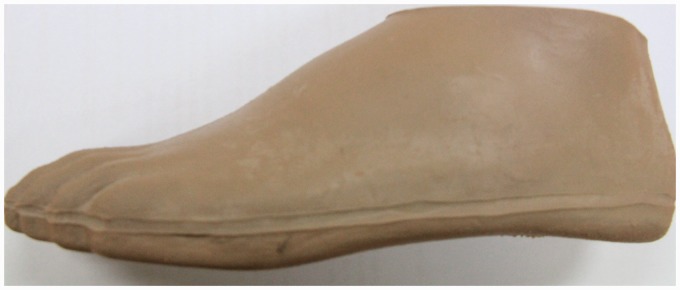

Figure 5.

The modified natural rubber CR SACH foot.

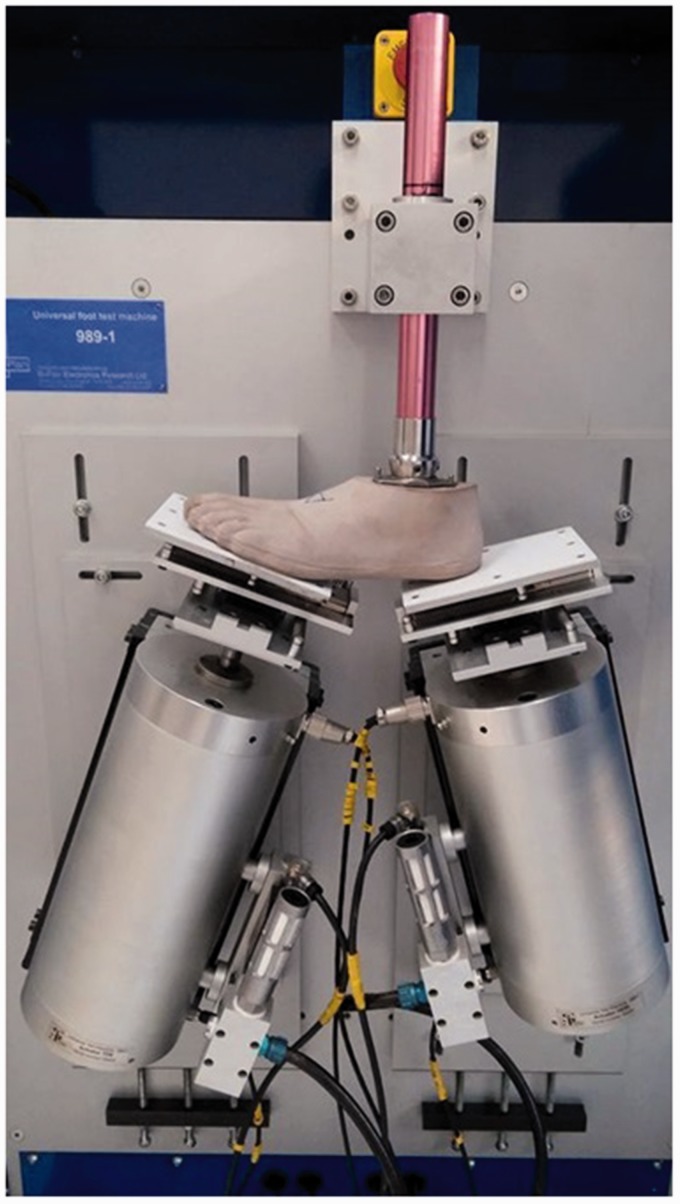

Cyclic foot testing

We adopted the cyclic foot testing portion of the ISO-10328 (structural testing of lower-limb prostheses) protocol. A reduced instruction set chip computer controlled two servo-pneumatic actuators Si-Plan Electronics Research Ltd. (Stratford-upon-Avon, UK). A 34-mm stainless steel pylon tube with a bonded on female tube adapter was securely fastened to a proximal anchor point of the machine. A foot adapter and bolt were securely fastened to our foot. All screws were zeroed to the foot adapter and tightened at 15 Nm, Loctite was used on all screws. The forefoot footplate of the machine was positioned to 20° and heel footplate to 15°. A maximum load of 1.28 kN was applied dynamically at the speed of 1 Hz for two million cycles (Figure 6). This method was chosen because of its previous use in foot cycling testing research designed to represent realistic free-living amputee walking activity.11

Figure 6.

Cyclic testing of the prosthetic foot.

Findings

ISO-10328 cyclic testing was successful and allowed repetitive loading at 1.28 kN continuously with a speed of 1 Hz for two million cycles. Maximum displacement of the forefoot was 32.03 mm and heel 8.77 mm, respectively. The production cost for our modified version of the CR Equipements SACH foot is approximately $16 USD. The final weight of the modified CR Equipements SACH foot is 625 g for a 25 cm foot. There are limitations to the current research, particularly with regard to mechanical testing. The full battery of ISO-10328 testing measures was not conducted. We opted to perform dynamic cyclic testing as it was a suitable method to continuously test two million cycles of forefoot and heel loading at 1.28 kN. However, static and final proof testing is also a part of ISO testing, future studies could perform this and determine performance of the foot at a constant force of 30 + 3 s. The addition of finite element analysis testing of the foot could provide a method for performing parametric analysis of stress and elastic stress of future design modifications to our inner keel as new materials become available, which also might lead to a reduction in the overall weight of the foot. In South East Asian environments, sun exposure can have adverse effects on the prosthesis.12 The important, but time-consuming UV test for prosthetic foot testing was not performed in this current study but is something that could provide important durability information. Furthermore, our cyclic testing was limited to a single foot, and future testing could repeat testing in an increased number of feet. We sought out to modify the CR Equipements SACH keel from its current form to allow for a greater connection between keel and outer foot shell. The increased fenestrations and adjustments made to the keel provide multiple points for the outer foot to anchor too. The rubber outer foot was created from locally harvested natural rubber. These two modifications alone lowered the costs of the foot. Clinical testing of the foot is currently being conducted and will help to elucidate the potential for real-world applications. This research could lead to further testing that could offer a more robust and locally fabricated prosthetic foot for developing countries.

Key points

We added fenestrations and adjustments to a prosthetic keel to allow for a stronger connection between keel and rubber outer foot.

Locally harvested natural rubber was used to fabricate the outer foot shell of a modified CR SACH foot.

Manufacturing costs of the modified foot is inexpensive at approximately $16 USD.

Our preliminary design could be used in clinical testing to better understand if the keel modification and local natural rubber harvesting are advantageous to developing country prosthetic clinics.

Acknowledgments

We wish to thank the Sirindhorn National Medical Rehabilitation Center, Hpa-an Orthopaedic Rehabilitation Centre (HORC) and Myanmar Red Cross Society (MRCS) for their valuable assistance with this study.

Declaration of conflicting interests

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Funding

The author(s) received no financial support for the research, authorship, and/or publication of this article.

References

- 1.Versluys R, Desomer A, Lenaerts G, et al. From conventional prosthetic feet to bionic feet: a review study. In: 2008 2nd IEEE RAS & EMBS international conference on biomedical robotics and biomechatronics, Scotsdale, Arizona, 19 October–22 October 2008, pp.49–54. IEEE.

- 2.Jensen JS, Nilsen R, Zeffer J. Quality benchmark for trans-tibial prostheses in low-income countries. Prosthet Orthot Int 2009; 29: 53–58. [DOI] [PubMed] [Google Scholar]

- 3.Gauthier P. Follow up on foot lifespan used in developing countries. In: 13th World Congress of the International Society for Prosthetics and Orthotics, Leipzig, Germany, 10 May–15 May, 2010, pp.1261–1262. ISPO.

- 4.Jensen JS, Raab W. Clinical field testing of vulcanized Jaipur rubber feet for trans-tibial amputees in low-income countries. Prosthet Orthot Int 2007; 31: 105–115. [DOI] [PubMed] [Google Scholar]

- 5.Ikeda AJ, Grabowski AM, Lindsley A, et al. A scoping literature review of the provision of orthoses and prostheses in resource-limited environments 2000-2010. Part two: research and outcomes. Prosthet Orthot Int 2014; 38: 343–362. [DOI] [PubMed] [Google Scholar]

- 6.World Health Organization. WHO global disability action plan 2014–2021. Better health for all people with disability. Action Plan, WHO, 2015.

- 7.Turcot K, Sagawa Y, Lacraz A, et al. Comparison of the International Committee of the Red Cross foot with the solid ankle cushion heel foot during gait: a randomized double-blind study. Arch Phys Med Rehabil 2013; 94: 1490–1497. [DOI] [PubMed] [Google Scholar]

- 8.Ziegler A, Fox J, Xu J. The rubber juggernaut. Science 2009; 324: 1024–1025. [DOI] [PubMed] [Google Scholar]

- 9.Craig J. Prosthetic feet for low-income countries. J Prosthet Orthot 2005; 17: S47–S49. [Google Scholar]

- 10.Coran AY. Chemistry of the vulcanization and protection of elastomers: a review of the achievements. J Appl Polym Sci 2003; 87: 24–30. [Google Scholar]

- 11.Jensen JS, Treichl HB. Mechanical testing of prosthetic feet utilized in low-income countries according to ISO-10328 standard. Prosthet Orthot Int 2007; 31: 177–206. [DOI] [PubMed] [Google Scholar]

- 12.Jensen S and Sexton S. Appropriate prosthetic and orthotic technologies in low income countries (2000–2010). Report, ISPO, Belgium, 2010.