Abstract

Objectives:

To fully realize the range of indication and clinical advantages of the new multi-layered zirconias, a comprehensive understanding of their chemical composition, microstructure, low temperature degradation (LTD) resistance, and translucency properties is paramount.

Methods:

A zirconia system (Katana, Kuraray Noritake), including 3 distinct grades of multi-layered zirconias, was selected for study: Ultra Translucent Multi-layered zirconia (UTML), Super Translucent Multi-layered zirconia (STML), and Multi-layered zirconia (ML). For different materials and their individual layers, the chemical composition, zirconia phase fractions, and microstructure were determined by x-ray fluorescence (XRF), x-ray diffraction (XRD), and field emission scanning electron microscopy (FE-SEM). Also, their resistance to LTD and translucency properties were characterized.

Results:

Our findings revealed no major differences amongst layers, but the 3 materials were very distinct—UTML: 5Y-PSZ (5 mol% yttria-partially-stabilized zirconia) with ~75 wt% cubic content and a 4.05 (±0.85) μm average grain size, STML: 4Y-PSZ with ~65 wt% cubic content and a 2.81 (±0.17) μm average grain size, and ML: 3Y-PSZ with <50 wt% cubic content and a 0.63 (±0.03) μm average grain size. After water aging at 120°C for 12 h, greater monoclinic content was found in ML. UTML and STML did not show detectable monoclinic phase. The translucency was similar among layers, and also between UTML and STML, which were superior to ML.

Significance:

For each multi-layered zirconia grades, the layers are only differed in pigment types and contents, which yield remarkably natural shade gradients. Also, despite the significant compositional difference between STML and UTML, both materials showed similar translucencies.

Keywords: Dental ceramics, multi-layered zirconia, phase content, chemical composition, microstructure, translucency properties, low temperature degradation

1. INTRODUCTION

Yttria-stabilized tetragonal zirconia (3Y-TZP) was introduced into dentistry twenty years ago, due to its exceptional strength and tooth-like color [1,2]. However, owing to its high opacity, the original intent of 3Y-TZP was for frameworks for crowns and fixed dental prostheses (FDPs), which are veneered with translucent porcelains, similarly to the traditional porcelain fused to metal (PFM) restorations [3,4]. However, veneer chipping and fracture, associated with residual thermal stresses induced from the production process, are major technical complications reported [3–7]. The concept of monolithic zirconia has been brought about as a possible solution. A traditional monolithic 3Y-TZP restoration would be too opaque compared to natural teeth [8,9]. To improve its translucency, strategies such as reducing the amount of Al2O3 sintering aids and increasing the sintering temperatures were used to diminish light scattering by impurities and grain boundaries [10].

For yttria stabilized zirconia, the translucency properties can also be tailored by its cubic content, which can be controlled by both sintering temperature and the yttria content [10]. In general, the higher the yttria content and sintering temperature is, the greater the cubic content and better the translucency. But, this also triggers a lower strength and toughness. Currently, 3 zirconia grades are available for monolithic dental restorations, namely 3Y-, 4Y-, and 5Y-PSZ (mol% yttria partially stabilized zirconia). In broad terms, these 3 grades exhibit a trade-off between translucency and strength, and thus have different clinical indications [2,10].

More recently, to further improve the esthetic properties of dental restorations, multi-layered zirconia systems have been developed. The multi-layered zirconia design aims to mimic the shade gradient observed in natural teeth: where the incisal area of a crown is most translucent, growing in chroma and opacity towards the gingival region. Different grades of such zirconias are advocated for various indirect dental restorative applications, according to their unique properties. The first multilayered zirconia system in the dental market was the Katana (Kuraray Noritake, Japan), including 3 zirconia grades: Ultra Translucent Multi Layered zirconia (UTML), Super Translucent Multi Layered zirconia (STML), and Multi Layered zirconia (ML). According to the manufacturer, these 3 materials can cover all monolithic restorative applications. Thus, since its first introduction to the dental market in Feb. 2015, this multi-layered monolithic zirconia system has drawn tremendous attention from clinicians and researchers [11–17]. To fully realize the clinical potential of these 3 grades of multi-layered zirconias, a comprehensive understanding of their structure-property relationship is of the utmost importance. Accordingly, this study aims to conduct a thorough investigation of the chemical composition, microstructure, low temperature degradation (LTD) resistance, and translucency properties of the 3 multi-layered zirconia materials and their constituent layers.

2. MATERIALS AND METHODS

2.1. Sample preparation

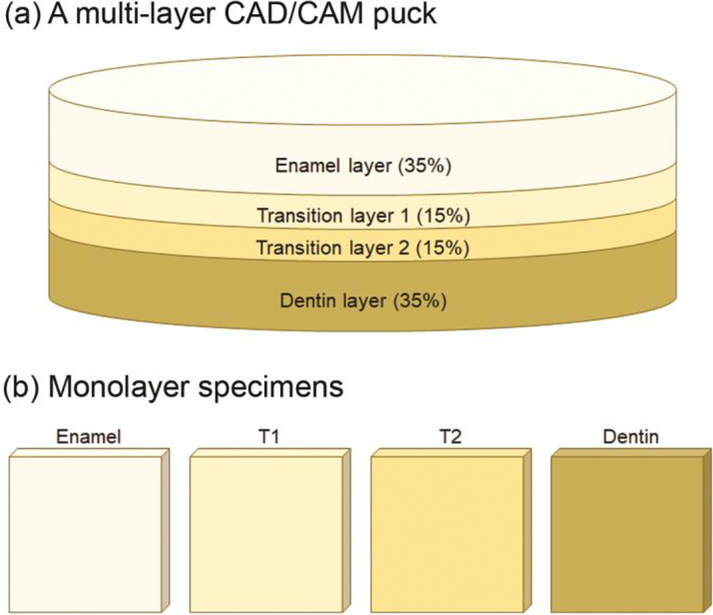

The Katana zirconia system (Kuraray Noritake, Japan) was investigated, since it includes 3 grades of multi-layered zirconias: Ultra Translucent Multi Layered zirconia (UTML: the highest translucency but lowest strength), Super Translucent Multi Layered zirconia (STML: intermediate translucency and strength), and Multi Layered zirconia (ML: the lowest translucency yet highest strength). Accordingly, the 3 zirconias have distinct clinical indications. Descriptions of the materials are given in Table 1, while the schematic of a multi-layered CAD/CAM puck is shown in Figure 1. Plate-shaped specimens were cut using a low speed saw (IsoMet 1000, Buehler, USA) under water irrigation. The configuration of the plate-shaped specimens prepared from each layer is shown in Figure 1. Sintering followed the manufacturer instructions (Table 1). Smooth surface was obtained by gridding and polishing down to a 0.5 μm finish (Diamond impregnated discs - DGD Buehler, USA).

Table 1.

Properties of the 3 grades of zirconias.

| Sintering Condition* | Sintered Density† (g/cm3) |

Flexural strength* (MPa) |

Transmittance* | Clinical indications* | |

|---|---|---|---|---|---|

| UTML | 1550°C for 2h | 6.00 | 557 | 43% | Veneers to single crowns |

| STML | 1550°C for 2h | 6.02 | 748 | 38% | Single crowns and 3- unit-bridges |

| ML | 1500°C for 2h | 6.04 | 1125 | 31% | Posterior crowns to long-spam-bridges |

Information from manufacturer’s data sheets.

Properties measured in the author’s laboratories.

Figure 1.

(a) Schematic of the multi-layer CAD/CAM zirconia pucks provided by the manufacturer and (b) the monolayer specimens prepared in this study.

2.2. Characterization

2.2.1. Elemental composition analysis by x-ray fluorescence

Chemical elements were traced from B (atomic number 5) to U (atomic number 92) for each individual layer: enamel, transition layer 1 (T1), transition layer 2 (T2), and dentin. As-machined green zirconia specimens (i.e. not sintered), measuring 12 × 12 × 2 mm, were analyzed by x-ray fluorescence (XRF), operated at 60 kV and 50 mA (ZSX Primus II, Rigaku, Japan).

2.2.2. Zirconia phase quantification by x-ray diffraction

Zirconia phase fractions were quantified for enamel and dentin layers on sintered and polished plate specimens (10 × 10 × 1 mm) using the x-ray diffraction analysis (XRD). XRD spectra were collected over a 2θ range between 20° and 80° using a powder diffractometer equipped with a Cu x-ray source (X’Pert3 Powder, PANalytical, Netherlands), operated at 40kV and 30 mA with a step size of 0.02° and a scan rate of 3 seconds/step. The acquired diffractograms were used to quantify tetragonal (t), monoclinic (m), and cubic (c) phases of zirconia by the Rietveld refinement method using MAUD (Materials Analysis Using Diffraction) software [18,19].

2.2.3. Microstructural analysis by field emission scanning electron microscopy

Sintered and polished plate specimens (10 × 10 × 1 mm) were thermally etched at 1200°C for 20 min for microstructural analysis using a field emission scanning electron microscope (FE-SEM, Merlin, Carl Zeiss). The specimens were coated with a 4 nm thick layer of Iridium and ground with the copper tape for electron conductivity. The grain size was measured on SEM micrographs using the linear intercept technique [20]. The average grain size, , was obtained using Equation 1:

| (1) |

where C is the length of the test line used, N the number of intercepts, and M the magnification of the micrograph. The shape factor, 1.56, is essential for random slices through a model system consisting of space-filling tetrakaidecahedral shaped grains with a log-normal size distribution.

2.3. Low temperature degradation

The t → m phase transformation due to LTD was investigated for enamel and dentin layers using sintered and polished plates (10 × 10 × 1 mm). The plates were stored in a hydrothermal vessel filled with distilled water and kept at a constant temperature of 120°C in an oven for 12 h. Identification and quantification of zirconia phase fractions were conducted by XRD using protocols described in section 2.2.2. The proportion of the m phase was estimated from the relative integrated intensity of m(111), , and c,t(101) profiles using the method of Garvie and Nicholson [21], and Toraya et. al. [22]. For 2θ between 26° and 33°, the volume fraction of the m phase Vm is given by Equation 2 [22]:

| (2) |

where the mass fraction Xm of the m phase can be calculated by Equation 3 [21]:

| (3) |

where and Im(111) denote the integrated intensity of the monoclinic peaks at 28.2° and 31.5°, respectively. It(101) is the integrated intensity of the tetragonal/cubic peaks at ~30°. The integrated peak areas were measured by profile fitting of the 3 peaks, around 28°, 30° and 32°.

2.4. Translucency

Sintered and polished plate specimens (10 × 10 × 1 mm) were prepared for enamel and dentin layers, into 3 thicknesses, according to the clinical recommendations from the manufacturer: 0.4 mm for veneers, 0.8 mm for full crowns for anterior teeth, and 1 mm for full crowns for posterior teeth.

Color coordinates were measured according to the CIEL*a*b* color space, from the Commission Internationale de l’Eclairge [23]. This is a 3-dimensional color space system, where L* is the lightness coordinate, while a* and b* are the chromatic coordinates in the red-green and yellow-blue axis, respectively. Measurements were carried out on a standard white (L* = 95.7, a* = −1.3, b* = 2.6) and black (L* = 1.8, a* = 1.3, b* = −1.5) background. A calibrated dental colorimeter (SpectroShade TM Micro) was used. A drop of glycerol (n = 1.472) was placed between the specimen and background to ensure optical continuity [24]. The translucency parameter (TP), defined by the color difference onto white and black backgrounds, was calculated using equation 4 [23]:

| (4) |

where the subscript “W” denotes the coordinates read on a white background, and “B” on a black background.

The TP data was analyzed for normality and homoscedasticity. Accordingly, two-way ANOVA was performed testing the following factors: Material (UTML, STML, ML) and Layer (Enamel, Dentin), separately for each clinical indication (different thicknesses). The level of significance was set at 5% (α = 0.05) and the power of the analysis at 80% (β = 0.8).

3. RESULTS

3.1. Characterization

3.1.1. Elemental analysis by XRF

The yttrium content was similar among the 4 layers, yet very distinct for each zirconia grade (Table 2). UTML showed the highest yttrium content ~7.55 wt%, which is equivalent to 5.4 mol% Y-PSZ; STML had ~6.75 wt% Y, which is 4.8 mol% Y-PSZ; and, ML had the lowest content ~5.2 wt%, which is 3.7 mol% Y-PSZ (Table 3). The content of aluminum as a sintering aid was also distinct among materials: UTML had no detectible Al, STML had <0.01 wt% Al, and ML had ~0.06 wt% Al. Other trace elements were detected, which are commonly used as pigments, namely Fe, Ti, and others. Regardless of material or layer, ~60 wt% Zr, ~30 wt% O, and ~1.3 wt% Hf were consistently observed.

Table 2.

Yttrium weight percentage in each layer of the 3 zirconias tested. Data are presented as mean (standard deviation).

| Yttrium content (wt%) in various layers | ||||

|---|---|---|---|---|

| Enamel | Transition 1 | Transition 2 | Dentin | |

| UTML | 7.7 (0.008) | 7.5 (0.007) | 7.5 (0.007) | 7.5 (0.007) |

| STML | 6.6 (0.007) | 6.9 (0.007) | 6.9 (0.007) | 6.6 (0.007) |

| ML | 5.2 (0.007) | 5.2 (0.007) | 5.1 (0.007) | 5.2 (0.007) |

Table 3.

Yttria (Y2O3) content reported in various studies.

| Harada 2016[11] | Flinn 2017[12] | Putra 2017[13] | Inokoshi 2018[14] | Camposilvan 2018[15] | This Study* | |

|---|---|---|---|---|---|---|

| UTML | 9.3 wt% | - | 10.1 wt% | ~5.4 mol% | >6 mol% | 9.5 wt% |

| 5.4 mol% | ||||||

| STML | 8.2 wt% | - | 8.9 wt% | ~4.8 mol% | - | 8.5 wt% |

| 4.8 mol% | ||||||

| ML | - | 10.9 wt% | - | - | - | 6.6 wt% |

| 3.7 mol% |

Calculated based on the elemental yttrium weight percent determined in this study (Table 2).

3.1.2. Zirconia phase fractions by XRD and Rietveld refinement

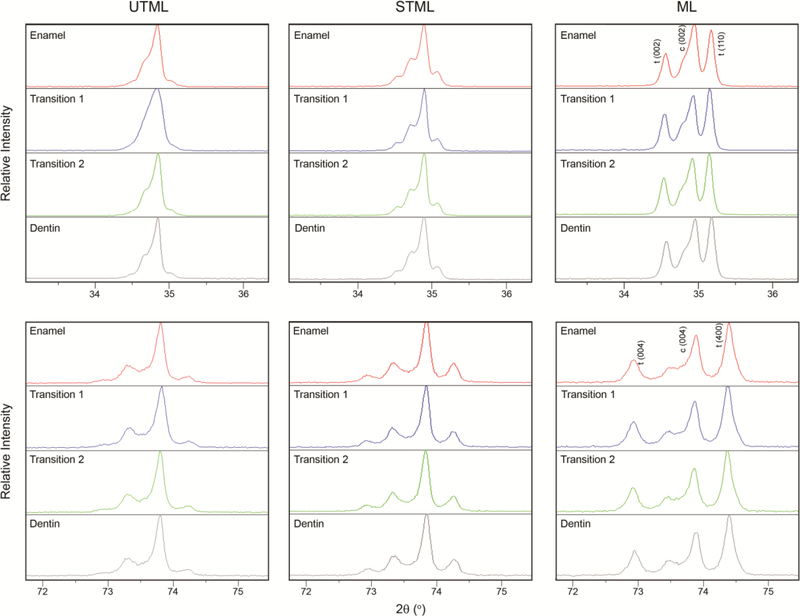

The x-ray diffractograms were identical for all 4 layers within each material. Monoclinic peaks were not detected in any of the materials and layers. Focusing on 2θ ~35° and 2θ ~74°, UTML showed simultaneous peaks combining the c-ZrO2 (200) and the 2 t-ZrO2 (002 and 110) peaks, or c-ZrO2 (004) and the 2 t-ZrO2 (004 and 400) peaks, respectively. In contrast, ML showed 1 c-ZrO2 peak in between 2 distinct t-ZrO2 peaks, as shown in Figure 2. Similar zirconia phase fractions were found for all layers using Rietveld refinement. However, the zirconia grades presented considerable differences, with cubic contents in accordance with yttria mol% and sintering temperatures: UTML ~75 wt% c-ZrO2, STML ~70 wt% c-ZrO2, ML <50 wt% c-ZrO2 (Table 4).

Figure 2.

XRD patterns of each layer for the 3 zirconia grades investigated. First row shows peaks at 35° (2θ), and second row at 74° (2θ). Cubic (c) and tetragonal (t) peaks are identified in ML spectra, since for UTML and STML the peaks are more superimposed.

Table 4.

Zirconia phase fractions (wt%) reported in various studies.

| Inokoshi 2018[14] | Camposilvan 2018[15] | This Study | |||||

|---|---|---|---|---|---|---|---|

| m-ZrO2 | c-ZrO2 | t-ZrO2 | c-ZrO2 | t-ZrO2 | c-ZrO2 | t-ZrO2 | |

| UTML | 0.2 | 70.6 | 28.9 | 31.1 | 68.9 | 75 | 25 |

| STML | 0.4 | 59.9 | 39.5 | - | - | 70 | 30 |

| ML | - | - | - | - | - | 50 | 50 |

Note: m-ZrO2, c-ZrO2, and t-ZrO2 refer to monoclinic, cubic, and tetragonal zirconia, respectively.

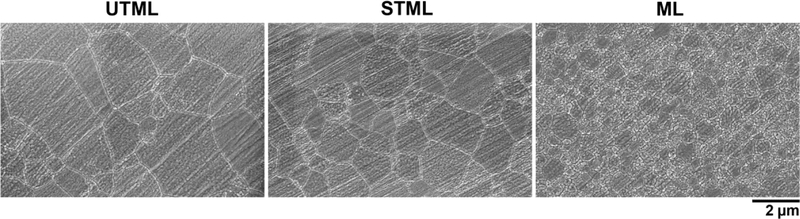

3.1.3. Microstructural analysis by FE-SEM

Figure 3 shows representative micrographs of the 3 zirconia grades. Porosity was not observed in any of the zirconias. Microstructures were in accordance with the yttrium and cubic phase contents, with UTML having the biggest grains and ML the smallest. Average grain size determined by the linear intercept method confirmed these observations: UTML = 4.05 ± 0.85 μm, STML = 2.81 ± 0.17 μm, and ML = 0.633 ± 0.029 μm (Table 5). Also, the standard deviation for UTML was very large in accordance with the SEM images, showing various grain sizes. In contrast, ML had a small standard deviation, which refers to a narrower grain size distribution.

Figure 3.

Representative FE-SEM micrographs for UTML, STML, and ML.

Table 5.

Average grain size (μm) reported in various studies.

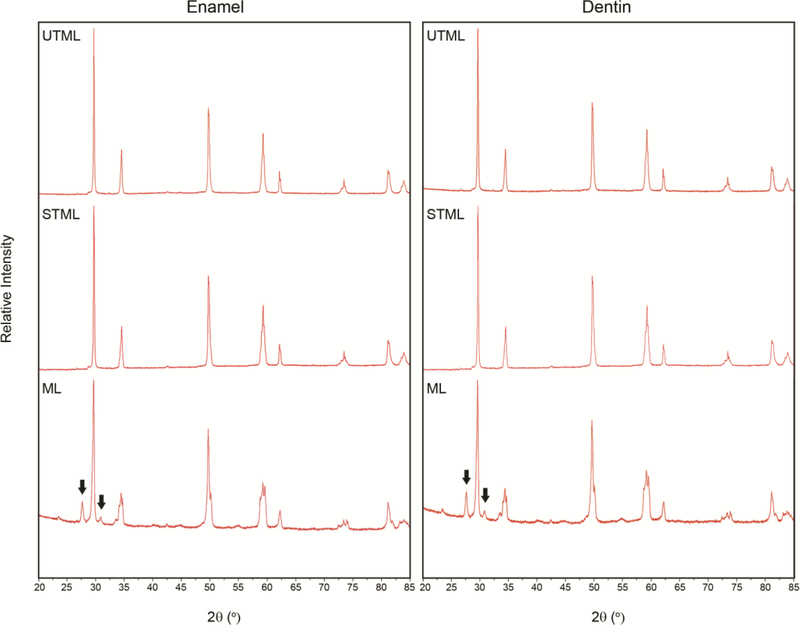

3.2. Resistance to LTD

Although enamel and dentin layers have the same phase contents within each zirconia, these layers have very different pigments that can interfere with the tetragonal grain stability. Thus, specimens from both enamel and dentin layers were subjected to accelerated LTD conditions. The high cubic-containing UTML and STML did not show any t → m transformation after 12 h aging (Table 6). On the contrary, significant monoclinic contents were observed in aged ML, with higher values in the dentin layer compared to enamel layer. XRD patterns of each material before and after hydrothermal aging for 12 h are shown in Figure 4.

Table 6.

Comparison of the monoclinic content (vol%) in various zirconia materials after hydrothermal aging with other studies.

Figure 4.

XRD patterns of the enamel and dentin layers of each zirconia grade after hydrothermal aging at 120°C for 12 h. For ML, arrows indicate the monoclinic diffraction peaks at 2θ = 28° and 32°.

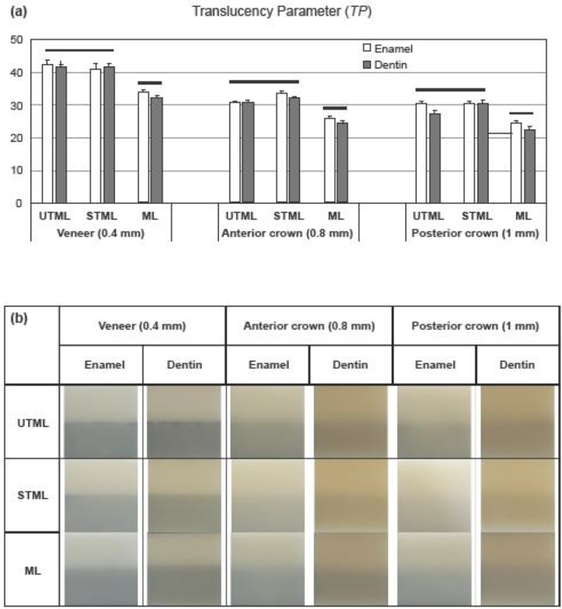

3.3. Translucency

The translucency parameter (TP) data are presented in Figure 5a and Table 7, whereas representative digital photographs are shown in Figure 5b. ML showed significantly lower TP value than UTML and STML at all thicknesses and layers (p < 0.001). UTML and STML have no significant difference in translucency (p > 0.16). Also, enamel and dentin layers have similar TP for all materials (p > 0.062). 0.4 mm thickness showed the highest translucency for all materials, whereas 0.8 and 1 mm thick specimens were similar. The digital images show a marked difference in chroma for each pair of enamel and dentin (within material and thickness), yet the background can be similarly seen through both ceramic plates (Figure 5b).

Figure 5.

(a) Translucency parameter (average and standard deviation) for each of the clinical indications (thicknesses), comparing various zirconia grades, as well as the enamel and dentin layers for each material. Lines link statistically similar groups. (b) Digital photographs of the enamel and dentin plate-specimens on white and black backgrounds for each of the 3 thicknesses.

Table 7.

Comparing translucency and transmittance rate with other studies.

| UTML | STML | ML | |||

|---|---|---|---|---|---|

| 0.4/0.5 mm | Harada 2016 (Tt%)[11] | 33.7 ± 0.1 | 31.7 ± 0.2 | - | |

| Inokoshi 2018 (TP)[14] | 36.7 ± 1.8 | 34.2 ± 0.7 | - | ||

| This study (TP) | Enamel | 42.2 ± 1.5 | 40.9 ± 1.9 | 33.5 ± 0.2 | |

| Dentin | 41.0 ± 0.3 | 41.8 ± 0.9 | 32.4 ± 0.6 | ||

| 1 mm | Ueda 2015 (Tt%)[17] | Enamel | - | - | 32.8 ± 1.5 |

| T1 | - | - | 31.2 ± 1.3 | ||

| T2 | - | - | 25.4 ± 1.3 | ||

| Dentin | - | - | 21.7 ± 1.1 | ||

| Harada 2016 (Tt%)[11] | 23.4 ± 0.3 | 21.9 ± 0.1 | - | ||

| Putra 2017 (Tt%)[13] | 23.4 ± 0.2 | 22.6 ± 0.1 | - | ||

| Kwon 2017 (ΔE00)[35] | Enamel | 8.3 | - | - | |

| This study (TP) | Enamel | 30.2 ± 0.3 | 30.5 ± 0.1 | 24.3 ± 0.9 | |

| Dentin | 27.3 ± 0.2 | 30.2 ± 1.3 | 22.1 ± 1.4 | ||

Tt% is designated as the total light transmittance (%). TP refers to the translucency parameter calculated by the CIEL*a*b* equation, and ΔE00 refers to the translucency parameter calculated by the CIE2000 equation. T1 and T2 denote the transition layer 1 and 2, respectively.

4. DISCUSSION

This study investigated the composition, microstructure, and translucency of 3 grades of multi-layered dental zirconias. From XRF and XRD analyses, ML showed the lowest yttrium content along with the lowest cubic phase percentage, while UTML has the highest yttrium content, thus the highest cubic phase percentage. Consequently, ML, STML and UTML could be referred as 3Y-, 4Y-, and 5Y-PSZ, respectively. These findings are in accordance with previous studies showing that an increase in yttrium content causes increased cubic phase fraction [2,10,25,26]. Various studies report different yttria contents for UTML, STML and ML [11–15] as shown in Table 3 [11–15,27]. Most of the studies, however, have consistent results with those found herein, with ML having the least and UTML having the most yttria (or yttrium) content. Only the results of Flinn et al. [12] were contrary to our findings and the above mentioned studies, showing that ML has a higher yttria content than all the materials tested. Unfortunately, Flinn did not provide information on what test was used to determine the yttria content. The test method may explain the difference in yttria content observed among studies. For instance, Inokoshi [14] and Camposilvan [15] used XRD to analyze the yttria content, whereas we used XRF to obtain the elemental percentage of yttrium and then used that information to calculate the yttria content. XRF is arguably the most direct and accurate method for elemental analysis of ceramics and glass. For each individual material, UTML, STML, and ML, the same yttrium content and cubic fraction were observed in the enamel and dentin layers. In addition, small differences were observed in trace concentration of some elements, such as Ti and Fe, which are used as pigments. As a result, according to the manufacturer and our independent investigations, the mechanical properties of the enamel and dentin layers are very similar. This is true for all 3 grades of multi-layered zirconia.

As mentioned above, the c-ZrO2 content increases with the rise in yttria content. Two very recent studies [14, 15] reported contradictory results with regards to the phase fractions of UTML (Table 4). The cubic and tetragonal fractions of UTML and STML from Inokoshi [14] were in agreement with our study, whereas Camposilvan [15] showed opposing results. Focusing on the XRD pattern of each material, the 3 different patterns in each material identified the difference of cubic content. UTML which contained the highest cubic phase exhibited a broad peak, composed of 1 cubic and 2 tetragonal peaks, corresponding to c-ZrO2 (200), and t-ZrO2 (002) and t-ZrO2 (110) peaks. On the other hand, ML which contained the lowest cubic content displayed 3 separate peaks at the same position as UTML and STML, with the c-ZrO2 (200) peak situated between the 2 t-ZrO2 (002) and (110) peaks. Our XRD patterns were similar to those of Inokoshi’s [14] study for UTML and STML.

Moreover, looking at the microstructures obtained by FE-SEM, it becomes apparent that UTML had the largest grain size followed by STML and then ML. These findings are in accordance with the yttria content and cubic fraction, since cubic grains are considerably larger than tetragonal grains. Previous studies have also reported the grain sizes for these materials (Table 5). Our results are in accordance with Putra’s study [13], but had a considerable difference from Inokoshi [14] and Camposilva [15]. However, those authors did mention that some of UTML grains were bigger than 3 μm along with the most recent study by Pereira [16] whom described the UTML grains being 5 μm in length. Nevertheless, none of the studies reported the presence of porosity in these materials.

From the aspect of LTD, ML which had the lowest yttrium content as well as the lowest cubic content and the highest tetragonal content showed phase transformation to monoclinic after hydrothermal aging at 120°C for 12 h. For UTML and STML, which had a higher yttrium content resulting in a higher cubic phase content, did not show any phase transformation after aging. In theory, 1 h of hydrothermal aging at 134°C is correlated to 3 to 4 years in vivo [28]. Based on this analysis, the current study which employed 12 h but 120°C could simulate at least 30 years in vivo. Giving the small amount of m-ZrO2 phase in ML and no detectable phase transformation in STML and UTML, LTD should not be a major concern for the clinical use of these multi-layered zirconia materials. Even though the yttrium content and tetragonal fraction of ML were similar across the layers, the dentin layer was more susceptible to LTD than the enamel layer. This could be explained by different color pigments in the material giving different LTD behaviors [29,30]. ML had Fe additives in its dentin layer whereas the enamel layer did not.

Due to concerns of LTD, previously occurred in hip replacements, several studies have focused on this issue [1,31,32]. Putra et al. [13] found that UTML was not susceptible to LTD due to the fact that no monoclinic phase was revealed even after hydrothermal aging at 134°C for 100 h and STML showed an increase of the monoclinic phase after 50 h. Flinn [33] studied the effect of hydrothermal degradation on flexural strength of the material and found that even ML showed an increase of monoclinic fraction (~11%) in the material after 50 h and reached to 35% after 100 h but the strength of the material remained virtually unchanged. However, any in vitro observation needs to be carefully assessed due to the environment of oral cavity is very different compared to that employed in in vitro experimentations [12]. Comparing to our study which using 12 h at a relatively low temperature (120°C), our results were similar to Flinn [12] at 50 h in ML. However, Putra [13] reported higher values of the monoclinic fraction than us in both STML and UTML at 0 h and even at 5 h, which was much less than the current study (12 h). In addition, Flinn [12] revealed that the flexural strength of ML remained unaffected by any aging duration, whereas Putra [13] reported minimal effects on translucency properties could be found in UTML and STML after hydrothermal aging.

Regarding the Translucency Parameter (TP), we observed that UTML and STML have quite similar translucency, whereas ML had significantly lower TP values for any thickness and layer. These findings are in accordance with the higher yttria content in UTML and STML, causing higher cubic content and larger grain size, which are known to result in lower strength but higher translucency [2]. This is because c-ZrO2 is optically isotropic, which can successfully circumvent the birefringent light scattering in t-ZrO2 [10]. On the other hand, a larger grain size can effectively reduce the number of grain boundaries in the materials, thus reducing the grain boundary light scattering [10]. In addition to the yttria content, higher sintering temperature can also give rise to higher cubic content and larger grain size [2]. Our samples were sintered at 1500°C for ML and 1550°C for UTML and STML. Other factors that affect the translucency are residual pores and impurities [10,34,35]. Pores and impurities create volumes of different refractive indices which lead to light scattering [10]. This was confirmed by Putra [13] showing a material (Bruxir) with many pores had significantly lower total transmittance rate (Tt%), despite having similar grain size to that of UTML and STML.

A previous study has shown that a small amount of Al2O3 additives can effectively prevent LTD of zirconia [36]. However, the same Al2O3 gives material an opaque color [36]. For high-translucency zirconias, the present study found that UTML has no Al2O3 additives while ML possesses the highest content of Al2O3 among the 3 materials. This can be explained by the fact that the cubic phase which is the predominant phase of UTML is more resistant to LTD. In contrast, ML had more tetragonal and less cubic phases with a higher amount of Al2O3, showing a higher content of monoclinic phase in LTD samples and less translucency than both UTML and STML. Several studies have investigated the translucency properties of these multi-layered zirconias (Table 7). Inokoshi [14] measured the TP of UTML and STML. Their samples were 0.5 mm thick, and the TP values fall in the range of our study, for 0.4 and 0.8 mm thick samples. However, Inokoshi did not provide information on which layer was used to measure translucency. Kwon [35] also measured the TP, yet the CIEDE2000 equation was used instead of the CIEL*a*b* equation [23]. Other studies used different translucency test methods, thus different values are expected.

5. CONCLUSIONS

UTML has the highest yttria content along with a high cubic phase fraction, followed by STML and then ML.

ML shows the lowest translucency amongst the 3 materials and there is no significant difference between UTML and STML.

Only pigment composition is different between the enamel and dentin layers of each material, resulting in obviously different color but no significant difference in translucency.

Only ML presented t → m transformation after hydrothermal aging for 12 h, with the dentin layer showing a higher monoclinic fraction than enamel.

HIGHLIGHTS.

Composition differs amongst various grades of multi-layered zirconia materials (i.e. UTML, STML, and ML), but similar among the layers within each material.

UTML has the highest cubic content, followed by STML and ML.

ML exhibits the lowest translucency, whereas UTML and STML show a similar level of translucency.

Only pigment composition differs between the enamel and dentin layers of each material, resulting in different shades but similar translucency.

Only ML is susceptible to hydrothermal degradation.

ACKNOWLEDGMENTS

Funding was provided by the National Institutes of Health / National Institute of Dental and Craniofacial Research (grants No. R01DE026772 and R01DE026279). The authors declare no potential conflicts of interest with respect to the authorship and/or publication of this article.

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

REFERENCES

- 1.Chevalier J What future for zirconia as a biomaterial? Biomaterials 2006; 27:535–543. [DOI] [PubMed] [Google Scholar]

- 2.Zhang Y, Lawn BR. Novel zirconia materials in dentistry. J Dent Res 2018; 97:140–147. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Pjetursson BE, Sailer I, Makarov NA, Zwahlen M, Thoma DS. All-ceramic or metal-ceramic tooth-supported fixed dental prostheses (FDPs)? A systematic review of the survival and complication rates. Part II: Multiple-unit FDPs. Dent Mater 2015; 31:624–639. [DOI] [PubMed] [Google Scholar]

- 4.Sailer I, Makarov NA, Thoma DS, Zwahlen M, Pjetursson BE. All-ceramic or metal-ceramic tooth-supported fixed dental prostheses (FDPs)? A systematic review of the survival and complication rates. Part I: Single crowns (SCs). Dent Mater 2015; 31:603–623. [DOI] [PubMed] [Google Scholar]

- 5.Pang Z, Chughtai A, Sailer I, Zhang Y. A fractographic study of clinically retrieved zirconia-ceramic and metal-ceramic fixed dental prostheses. Dent Mater 2015; 31:1198–1206. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Kim J, Dhital S, Zhivago P, Kaizer MR, Zhang Y. Viscoelastic finite element analysis of residual stresses in porcelain-veneered zirconia dental crowns. J Mech Behav Biomed Mater 2018; 82:202–209. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Tanaka CB, Ballester RY, De Souza GM, Zhang Y, Meira JBC. Influence of residual thermal stresses on the edge chipping resistance of PFM and veneered zirconia structures: Experimental and FEA study. Dent Mater 2018; in press. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Kelly JR, Denry I. Stabilized zirconia as a structural ceramic: An overview. Dent Mater 2008; 24:289–298. [DOI] [PubMed] [Google Scholar]

- 9.Tong H, Tanaka CB, Kaizer MR, Zhang Y. Characterization of three commercial Y-TZP ceramics produced for their high-translucency, high-strength and high-surface area. Ceram Int 2016; 42:1077–1085. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Zhang Y Making yttria-stabilized tetragonal zirconia translucent. Dent Mater 2014; 30:1195–1203. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Harada K, Raigrodski AJ, Chung KH, Flinn BD, Dogan S, Mancl LA. A comparative evaluation of the translucency of zirconias and lithium disilicate for monolithic restorations. J Prosthet Dent 2016; 116:257–263. [DOI] [PubMed] [Google Scholar]

- 12.Flinn BD, Raigrodski AJ, Mancl LA, Toivola R, Kuykendall T. Influence of aging on flexural strength of translucent zirconia for monolithic restorations. J Prosthet Dent 2017; 117:303–309. [DOI] [PubMed] [Google Scholar]

- 13.Putra A, Chung KH, Flinn BD, Kuykendall T, Zheng C, Harada K, Raigrodski AJ. Effect of hydrothermal treatment on light transmission of translucent zirconias. J Prosthet Dent 2017; 118:422–429. [DOI] [PubMed] [Google Scholar]

- 14.Inokoshi M, Shimizu H, Nozaki K, Takagaki T, Yoshihara K, Nagaoka N, Zhang F, Vleugels J, Van Meerbeek B, Minakuchi S. Crystallographic and morphological analysis of sandblasted highly translucent dental zirconia. Dent Mater 2018; 34:508–518. [DOI] [PubMed] [Google Scholar]

- 15.Camposilvan E, Leone R, Gremillard L, Sorrentino R, Zarone F, Ferrari M, Chevalier J. Aging resistance, mechanical properties and translucency of different yttria-stabilized zirconia ceramics for monolithic dental crown applications. Dent Mater 2018; 34(6):879–890. [DOI] [PubMed] [Google Scholar]

- 16.Pereira GKR, Guilardi LF, Dapieve KS, Kleverlaan CJ, Rippe MP, Valandro LF. Mechanical reliability, fatigue strength and survival analysis of new polycrystalline translucent zirconia ceramics for monolithic restorations. J Mech Behav Biomed Mater 2018; 85:57–65. [DOI] [PubMed] [Google Scholar]

- 17.Ueda K, Guth JF, Erdelt K, Stimmelmayr M, Kappert H, Beuer F. Light transmittance by a multi-coloured zirconia material. Dent Mater J 2015; 34:310–314. [DOI] [PubMed] [Google Scholar]

- 18.Lutterotti L, Scardi P. Simultaneous structure and size-strain refinement by the rietveld method. Journal of Applied Crystallography 1990; 23:246–252. [Google Scholar]

- 19.Lutterotti L, Matthies S, Wenk HR. Maud: A friendly java program for material analysis using diffraction. IUCr: Newsletter of the CPD 1999; 21:14–15. [Google Scholar]

- 20.Wurst JC, Nelson JA. Lineal intercept technique for measuring grain size in two-phase polycrystalline ceramics. J Am Ceram Soc 1972; 55:109–109. [Google Scholar]

- 21.Garvie RC, Nicholson PS. Phase analysis in zirconia systems. J Am Ceram Soc 1972; 55:3. [Google Scholar]

- 22.Toraya H, Y M, Somiya S. Calibration curve for quatitative analysis of monoclinic-tetragonal zro2 systems. J Am Ceram Soc 1984; 67:C199–221. [Google Scholar]

- 23.CIE. Technical committee: Colorimetry. CIE pub no 15.3. Vienna, Austria: CIE Central Bureau; 2004; [Google Scholar]

- 24.Nogueira AD, Della Bona A. The effect of a coupling medium on color and translucency of cad-cam ceramics. J Dent 2013; 41 Suppl 3:e18–23. [DOI] [PubMed] [Google Scholar]

- 25.Pecho OE, Ghinea R, Ionescu AM, Cardona Jde L, Paravina RD, Perez Mdel M. Color and translucency of zirconia ceramics, human dentine and bovine dentine. J Dent 2012; 40 Suppl 2:e34–40. [DOI] [PubMed] [Google Scholar]

- 26.Denry I, Kelly JR. State of the art of zirconia for dental applications. Dent Mater 2008; 24:299–307. [DOI] [PubMed] [Google Scholar]

- 27.Cie technical committee 1.3. Cie colorimetry committee-working program on color differences. J Opt Soc Am 1974; 64:894–895. [Google Scholar]

- 28.Chevalier J, Cales B, Drouin JM. Low-temperature aging of Y-TZP ceramics. J Am Ceram Soc 1999; 82:2150–2154. [Google Scholar]

- 29.Sedda M, Vichi A, Carrabba M, Capperucci A, Louca C, Ferrari M. Influence of coloring procedure on flexural resistance of zirconia blocks. J Prosthet Dent 2015; 114:98–102. [DOI] [PubMed] [Google Scholar]

- 30.Shah K, Holloway JA, Denry IL. Effect of coloring with various metal oxides on the microstructure, color, and flexural strength of 3Y-TZP. J Biomed Mater Res B Appl Biomater 2008; 87:329–337. [DOI] [PubMed] [Google Scholar]

- 31.Lughi V, Sergo V. Low temperature degradation -aging- of zirconia: A critical review of the relevant aspects in dentistry. Dent Mater 2010; 26:807–820. [DOI] [PubMed] [Google Scholar]

- 32.Kim JW, Covel NS, Guess PC, Rekow ED, Zhang Y. Concerns of hydrothermal degradation in cad/cam zirconia. J Dent Res 2010; 89:91–95. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Flinn BD, Raigrodski AJ, Singh A, Mancl LA. Effect of hydrothermal degradation on three types of zirconias for dental application. J Prosthet Dent 2014; 112:1377–1384. [DOI] [PubMed] [Google Scholar]

- 34.Harada R, Takemoto S, Hattori M, Yoshinari M, Oda Y, Kawada E. The influence of colored zirconia on the optical properties of all-ceramic restorations. Dent Mater J 2015; 34:918–924. [DOI] [PubMed] [Google Scholar]

- 35.Kwon SJ, Lawson NC, McLaren EE, Nejat AH, Burgess JO. Comparison of the mechanical properties of translucent zirconia and lithium disilicate. J Prosthet Dent 2018; 120(1):132–137. [DOI] [PubMed] [Google Scholar]

- 36.Nakamura K, Harada A, Ono M, Shibasaki H, Kanno T, Niwano Y, Adolfsson E, Milleding P, Ortengren U. Effect of low-temperature degradation on the mechanical and microstructural properties of tooth-colored 3Y-TZP ceramics. J Mech Behav Biomed Mater 2016; 53:301–311. [DOI] [PubMed] [Google Scholar]