Abstract

The United States Environmental Protection Agency (US EPA) publishes annual mass estimates for seven material types for the construction and demolition debris stream in the United States. However, the quantities of these materials in different end-of-life management pathways are not published or otherwise made available. Quantification of end-of-life management pathways is useful for identifying approaches to decrease disposal and increase material recovery. An issue for construction and demolition debris is that data needed for a nationwide estimate of management pathways are not tracked in a single system. We propose and outline a method that draws on a combination of data sources, including nationwide generation estimates, state data, industry association data, and recovery facility reports. Capturing the available data and using the proposed method, we can estimate what end-of-life pathways are used for the seven materials in US EPA’s annual reports of CDD generation (steel, wood products, drywall and plaster, brick and clay tile, asphalt shingles, concrete and asphalt concrete), and five additional materials managed within the CDD waste stream (carpet, plastic, glass, cardboard and organics). Method results indicate that the vast majority of CDD concrete and asphalt pavement, which in 2014 constituted ~80% of the overall mass of the stream’s components, were reclaimed for use, primarily in road projects. A significant opportunity for material recovery still exists for the remaining 20% of the stream. In 2014, approximately 68% of these remaining materials in the US was ultimately routed for landfill disposal.

1. INTRODUCTION

Construction and demolition debris (CDD) represents one of the larger solid waste streams generated from municipal and commercial activities of modern society. Despite its size, however, CDD has not received the same attention as other streams, such as municipal solid waste (MSW) or hazardous waste. The sheer mass and heterogeneity of CDD materials requiring end-of-life (EOL) management has deterred large-scale characterization efforts, and lack of data consistency across non-standardized tracking systems has added to the challenge. Yet, a comprehensive characterization effort is critical if CDD is to be managed sustainably. Sustainable materials management (SMM) is a systematic approach to using and reusing materials more productively over their entire life cycles.1 To manage CDD using SMM, one must first understand the magnitude (most importantly the mass) of CDD materials undergoing EOL management, as well as the material and management composition of the CDD waste stream.

In the US, mass and composition data for trash and garbage (typically referred to as MSW) have been tracked annually for decades, but up until recently only sporadic efforts had been made to produce similar estimates for CDD. Many CDD facility operators, such as recycling facilities or landfills, do not report mass data. When mass data is missing, extrapolation from smaller datasets or surrogate parameters are typically used to compensate.

As data tracking procedures, data availability, and regulatory needs have evolved over time, so have methods used to estimate CDD. For example, in 2009 the US EPA published estimates of building-related CDD generation for the years 1996 and 2003 by combining per-project material generation factors (e.g., mass of debris per footprint of construction) with economic and building statistics for six different sectors (e.g., residential and commercial construction, demolition, and renovation).2 More recently, Cochran and Townsend (2010) used material flow analysis (MFA) to estimate nationwide CDD generation, including CDD materials generated from buildings, roads, bridges, and other structures.3 The US EPA has since adopted the MFA approach for its national CDD generation statistics, as presented in the annual reporting series, Advancing Sustainable Materials Management: Facts and Figures (abbreviated herein as FF).4

The US EPA has also evaluated a bottom-up approach, in which state-reported CDD data from state-registered and permitted solid waste management facilities were extrapolated to the entire US. These data were combined with survey data from the National Asphalt Pavement Association’s (NAPA’s) survey of asphalt-mix producers to provide estimates of CDD generation and disposition by mass and composition (for diversion and landfilling).5 The Construction and Demolition Recycling Association (CDRA) also uses “on-the-ground”, member-reported information in combination with MFA to estimate CDD generation in the US.6 On-the-ground information is also used for site-specific management efforts, such as quantifying and tracking CDD in the wake of a natural disaster.7 Across the aforementioned efforts, the data sources, including scopes of pertinent data sets, shape the extent and magnitude of generation estimates.

Once the background data were identified and CDD generation estimates made, the final disposition of CDD materials (i.e., in landfills or along material- or energy-reclamation pathways) could be calculated. In this paper, we propose a method, CDDPath, for estimating the final disposition of CDD by material and mass in the US. Where possible, the method uses data from state reporting agencies and the CDD recycling industry, and balances the results against MFA generation estimates. CDDPath extends the value of existing CDD estimates while also apportioning CDD materials across each EOL management pathway, comparable to what is done for MSW materials.

2. METHODS

2.1. Data sources

The FF 2014 used MFA to estimate total generation of select CDD materials in 2014.4 The MFA approach includes building materials scrapped during construction, as well as previously used materials that have reached the end of their service lives in the target year. The MFA does not estimate the amount of material processed for use or disposed via landfill.

In CDDPath, additional data sources provide data useful for understanding disposition of CDD waste. A few state governments track and report data on CDD managed in state-registered and permitted disposal and processing facilities. These data sources were analyzed and included as a component of the “bottom-up” CDD measurement approach, which was recently developed by the US EPA and previously referenced as “US EPA 2015”.5 These state data range in scope from tracking a single material to tracking over ten different materials—but most states focus on one or both of two quantities: CDD material landfilled and CDD material processed for use. In addition, CDD landfill waste composition studies describe the fractions of CDD materials in landfilled CDD. Five CDD landfill studies conducted since 2006 were used in US EPA 2015 to develop an average national composition mix of landfilled CDD. This average national composition mix is then used in CDDPath.

Data from facilities that process commingled CDD, i.e. mixed-CDD processing facilities, are used in CDDPath to estimate specific material quantities processed and managed via pathways other than landfilling. These data were available from surveys conducted by CDRA in 2014 and 2016.6 Other data sources provided data for CDD materials processed outside of mixed CDD facilities. For asphalt concrete (also referred to as reclaimed asphalt pavement (RAP)), quantities managed along each pathway were determined using the National Asphalt Pavement Association’s (NAPA’s) 2013 Asphalt Pavement Industry Survey.8 Table S1 lists the material data sources used in CDDPath. Table S2 summarizes and describes the variables used in the analysis and identifies the respective data sources.

The CDDPath method is structured to begin with total generation amounts for seven CDD materials in the FF reports (here FF 2014): steel, wood products, drywall and plaster, brick and clay tile, asphalt shingles, concrete, and asphalt concrete. However, beyond these seven, the CDDPath method also estimates quantities of additional materials that appear in the waste streams at mixed CDD processing facilities and landfills alongside the seven identified CDD materials. The additional materials include glass, plastic, fines, carpet, and cardboard. The CDDPath method is defined below in a manner that includes these other materials, but calculations can also be performed without them. They are referred to below as “non-MFA” materials because they are not included in the FF 2014 report, which primarily relies on MFA, whereas the “MFA” materials are materials included in the FF 2014 report.

2.2. CDDPath Method

Generation quantities of CDD concrete, wood products, gypsum drywall and plasters, asphalt shingles, steel, brick and clay tile, and asphalt concrete are included in FF 2014; however, they are not apportioned across EOL management pathways. To develop pathway-specific estimates, CDDPath applies the data from the composition studies of CDD landfill and processing streams and uses the relative prevalence of each material in these CDD streams. A factor is applied to set the sum of material quantities along each pathway equal to the per-material generation estimate in FF 2014.

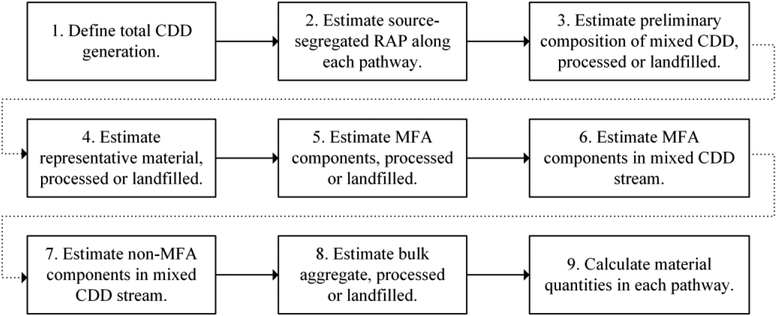

Figure 1 illustrates the steps of CDDPath, which ultimately calculates the material disposition along each EOL pathway. A full listing of terms used in the analysis is provided in Table S2.

Figure 1.

Schematic representation of the CDDPath method. Numbers correspond to each step of the method.

Step 1: Define total CDD generation.

The summation of mixed CDD, plus reclaimed asphalt pavement (RAP) and bulk aggregate concrete, yields the total CDD generation, as shown in Eq. (1). An estimate of total generation for several CDD materials is published in FF 2014; however, the analysis here includes generation amounts for additional material types not included in FF 2014.

| (1) |

In Eq. (1), CDDT is the total CDD generated; CDDMx is the quantity of mixed CDD generated; CDDBA is the quantity of bulk aggregate CDD generated; and CDDRAP is the quantity of CDD RAP generated.

| (2) |

In Eq. (2), CDDMx, MFA is the quantity of mixed CDD comprised of materials included in FF 2014 and estimated by MFA, whereas CDDMx, No-MFA is the quantity of mixed CDD comprised of materials excluded from FF 2014 or not estimated by MFA.

Step 2: Estimate reclaimed asphalt pavement and asphalt shingles processed by the asphalt pavement industry along each end-of-life management pathway.

NAPA produces a survey of asphalt pavement and asphalt shingles8 that estimates generation of reclaimed asphalt pavement (RAP) (CDDRAP−SS) and reclaimed asphalt shingles (CDDAS) and the amounts directed to end-of-life pathways. This source provides survey data for these two materials which are used to capture these material flows.

Some reclaimed asphalt pavement and asphalt shingles are expected to be managed as part of the mixed CDD stream—either processed by mixed CDD facilities, as reflected in facility-collected data5, 6, or landfilled as mixed CDD waste, as reflected in waste composition studies.5 These amounts are not included in the NAPA data and are added into the analysis in Step 5. Some overlap occurs for asphalt shingle generation as reported by NAPA and found in the mixed CDD stream; this is addressed in an adjustment in the final step.

Step 3: Estimate the preliminary composition of the processed and landfilled streams of mixed CDD.

Facility data from 49 mixed CDD processing facilities and data from landfill composition studies are used to estimate the preliminary composition of the mixed CDD material streams. In Steps 5 and 7, these data are normalized to the materials quantified in FF 2014, as well as the materials commonly commingled within the mixed CDD stream but not quantified in FF 2014.

The compositions of processed or landfilled mixed CDD streams are preliminary at this step because, for materials quantified in FF 2014, the total generation after estimating the quantities managed along each end-of-life pathway will in Step 5 be set equal to the generation value published in FF 2014. The managed quantities are then adjusted accordingly, altering their relative predicted prevalence in the mixed CDD materials stream.

CDD materials not quantified in FF 2014 but reflected in landfill composition studies include organics, fines, and “other materials”. The CDD glass, plastic, carpet, and cardboard are also not included in the MFA analysis of CDD in FF 2014, but these materials are processed in non-trivial quantities by mixed-waste CDD processors. The material “fines” represents a combination of materials that were crushed in the CDD material removal, transport, or processing steps. In this method, they are recognized as an additional material type due to lack of sufficient characterization data to assign them to other materials. Fines may also have distinct end uses that are independent of the parent material, and thus are tracked separately here. In the absence of a precise definition for the “other materials” category in landfill composition studies and lack of better information on relative proportions of glass, plastic, carpet and cardboard in the mixed-CDD landfill stream, these four materials are assumed to make up the “other materials” category of the mixed-CDD landfill stream in the same relative proportions as in the processed mixed-CDD stream.

Step 4: Estimate processed and landfilled totals for a representative material.

A total estimate of processed vs. landfilled CDD materials is needed to employ the material fractions of the processed and landfilled CDD streams determined in Step 3. In the absence of reported national totals for processed and landfilled CDD, this method uses a single, representative material along with state-reported averages of processed:landfilled CDD materials to estimate total quantities of CDD processed vs. CDD landfilled. In Step 4, the representative material is selected and the total processed and landfilled amounts for the representative material are calculated.

Wood is used as a representative CDD material for two reasons. First, it is assumed not to be processed on the site from which it is reclaimed, and therefore is assumed to be either immediately landfilled or processed at a mixed CDD facility. Second, wood is the most prevalent material in the mixed-CDD processing and landfill streams, excluding Portland cement concrete (PCC) which is also source-separated. Therefore, wood is assumed to be a good proxy for other materials processed exclusively in CDD processing facilities or landfilled.

State-reported data are used as the source of processing and landfilling rates for mixed CDD, and FF 2014 are used to obtain the quantities of CDD wood generated. Processing rates or landfilling rates for mixed CDD are developed from data for states reporting total quantities of both mixed CDD processed as well as landfilled. Sources of state data include publicly available reports from state regulatory agencies and the State Data Measurement Sharing Program.9 The most recent year’s data from each state were used for the estimate. The states used to determine weighted average processing and landfilling rates for mixed CDD are: FL, GA, HI, IL, MD, ME, NC, NV, PA, SC, TN, TX, VA, VT, and WA.

Fractions of CDD wood processed or landfilled are estimated by assuming that wood is processed or landfilled at approximately the same rates as the overall mixed CDD stream. The processing and landfilling rates for mixed CDD are applied to the CDD wood generation amount. Eq. (3) estimates the amount of CDD wood processed in the US annually, CDDW,R. Eq. (4) estimates the amount of CDD wood landfilled, CDDW,LF.

| (3) |

| (4) |

In the above equations, CDDW is the amount of wood from the FF 2014 generation estimate, CDDLF−RS is the total CDD landfilled in US states reporting the quantity of CDD recycled and landfilled (i.e., reporting states), and CDDR−RS is the total CDD recycled in the same reporting states.

Processing operations included in state-reported data are assumed to exclude source-separated bulk-aggregate facilities. However, some portion of RAP and concrete processing that takes place at mixed CDD processing facilities, rather than the bulk-aggregate facilities, is reflected in these data.

Step 5: Estimate preliminary total amounts of landfilled or processed MFA components.

Preliminary composition data were normalized to the six material types included in the FF 2014 which are managed as mixed CDD (concrete, asphalt shingles, gypsum drywall and plasters, wood, steel, and brick and clay tiles), such that these components in the FF 2014 accounted for 100% of the total mixed CDD flow. Asphalt concrete is a special case, as some portion thereof is managed in mixed CDD facilities, but the portion estimated in FF 2014 is source-separated asphalt concrete. Only the materials, or portions of FF 2014 materials, managed in mixed CDD streams are of interest in this step.

As given in Eq. (5), the preliminary estimate of the sum of the processed amounts of the six materials, CDDMx−MFA,R,Pre is derived as a ratio of the processed wood and the normalized fraction of wood.

| (5) |

CDDw,R is the total quantity of wood processed, and fw,MFA,R is the fraction of wood from the CDD processing facility survey, normalized using the total fraction of MFA materials in the survey. The generalized form of the MFA-normalized fraction of processed materials is

| (6) |

where fx,R is the fraction of material, x, in the CDD processing surveys, and fMFA,R is the sum of the fractions of MFA materials in the survey.

Similarly, Eq. (7) describes the preliminary estimate of the landfilled materials:

| (7) |

CDDMx-MFA,LF,Pre is the total quantity (preliminary sum) of the six materials landfilled as mixed CDD, CDDw,LF is the total quantity of wood landfilled, and fw,MFA,LF is the fraction of CDD wood as determined in the weighted average of landfill composition studies normalized by the total fraction of MFA materials in the composition studies. The generalized form of the MFA-normalized fraction of landfilled materials, fx,MFA,LF, is:

| (8) |

where fx,LF is the fraction of material, x, in the landfill composition studies, and fMFA,LF is the sum of the fractions of MFA materials in the survey.

Estimates of processed or landfilled amounts for each of the six materials are calculated using the normalized composition fractions (Eq. (6) and (8)) and applying them to the processed and landfilled preliminary values calculated in Eqs. (5) and (7). These estimates are preliminary per-material estimates. For each of the materials in the mixed CDD stream, a differential, Δ, is calculated between the total generation (preliminary quantity processed plus landfilled) and the generation given in the FF 2014 (Eq. (9)). This differential is applied to the landfilled quantity, with the assumption that the composition of mixed CDD materials in the processing stream is based on higher quality and more representative data, therefore not changing the composition of the processing stream (Eq. (10)). Total processed and landfilled quantities of material present in other streams, including concrete, brick, and RAP, are corrected in Step 9 with stream-specific data.

| (9) |

| (10) |

Step 6: Estimate total MFA waste components in mixed CDD.

Eq. (11) describes the annual processed quantity, CDDMx,MFA,R, of mixed CDD materials included in the FF 2014.

| (11) |

Each term of the summation refers to one of the processed mixed CDD materials: CDDw,R for wood, CDDAS,R for asphalt shingles, CDDGD,R for gypsum drywall, and CDDM.R for metal. The terms CDDPCC,R−Mx and CDDBr,R−Mx pertain to component-specific management within mixed CDD, separate from bulk aggregate management of the mixed CDD stream. In Eq. (11), CDDPCC,R−Mx is for Portland cement concrete and CDDBr,R−Mx for brick and masonry.

Similarly, Eq. (12) describes the annual landfilled quantity, CDDMx,MFA,LF.

| (12) |

The sum of the annual quantities processed (CDDMX,MFA,R) and landfilled (CDDMX,MFA,LF) equals the total annual mixed CDD waste stream captured by the FF 2014 (CDDMx,MFA), as given in Eq. (13).

| (13) |

Step 7: Estimate total non-MFA components in mixed CDD.

Step 7 accounts for, and normalizes, those materials excluded from the FF 2014 that are managed in mixed CDD streams. These materials include glass, organics, plastics, carpet, fines, and cardboard. They are assumed to be processed or landfilled as mixed CDD and not sorted into material-specific streams. Eq. (14) describes the processed quantity, CDDMx,Non-MFA,R, of these materials excluded from the FF 2014.

| (14) |

fMx,MFA,R is the fraction of the processed mixed CDD stream comprised of FF 2014 materials, whereas fMx,Non-MFA,R is the fraction comprised of materials excluded from the FF 2014. CDDMx,MFA,R is the estimated quantity of FF 2014 mixed CDD that was processed, as calculated in Step 6.

Similarly, Eq. (15) describes the total landfilled quantity, CDDMx,Non-MFA,LF, of these excluded materials.

| (15) |

Here, CDDMx,MFA,LF is the estimated quantity of mixed CDD materials in the FF 2014 that was landfilled, fMx,MFA,LF is the fraction of the landfilled mixed-CDD stream comprised of FF 2014 materials, and fMx,Non-MFA,LF is the fraction of the landfilled mixed CDD stream comprised of materials excluded from the FF 2014. The quantity of each material excluded from the FF 2014 was determined by multiplying the fraction of each material in the normalized CDD stream by the total sum quantity of these materials, processed or landfilled, as determined in Eq. (11) or (12).

Step 8: Estimate quantities of bulk aggregate processed or landfilled.

Bulk aggregate is processed in a single waste stream, managed by bulk aggregate processors. Total bulk aggregate, i.e. concrete in this study, was calculated by subtracting the quantity of concrete included in mixed CDD (see Step 6) from the generated quantities of concrete estimated in the FF 2014. The processing rate of bulk aggregate was assumed to be 85%.6

Step 9: Determine material quantities in each end-of-life pathway.

End-of-life processing data were collected from 49 processing facilities in the US.6 Of these 49 facilities, 26 facilities provided end-of-life pathway information for all processed materials.

Eq. (16) describes the total annual mass of CDD material i managed via pathway p.

| (16) |

Here, CDDi represents the calculated CDD stream for material i, and fi,p is the fraction of material i managed through pathway p. The fractions fi,p were based on the same survey data collected for the CDRA estimate.6

Recycling pathways for bulk aggregate were assumed to be proportional to those reported by mixed CDD processing facilities. For example, Eq. (17) demonstrates the calculation for Portland cement concrete recycled as road base, CDDPCC,rb.

| (17) |

Here, CDDPCC,BA is the quantity of concrete debris generated as bulk aggregate (with an assumed recycling rate of 85%), CDDPCC,rb−mx, is the quantity of mixed CDD concrete processed into the road base, and CDDPCC,R−mx is the total quantity of concrete processed as mixed CDD.

Asphalt shingles are a special case of data overlap. NAPA (2013) reported the amounts of asphalt shingles processed by the asphalt industry for remanufacture of RAP (as hot-mix asphalt (HMA) or warm-mix-asphalt (WMA)). These data are assumed to include all processed shingles received from mixed CDD processing facilities, and therefore the amount calculated from Eq. (12) from the mixed CDD stream for this final disposition is omitted from the CDDPath results. The amounts estimated for other end uses of asphalt shingles from the mixed CDD stream, including fuel, aggregate, and other, are retained because material from these end uses are not assumed to be handled by the asphalt industry before final disposition.

3. RESULTS AND DISCUSSION

For 2014, the CDDPath method estimates the total amount of material managed in the CDD waste stream as 526 MMT. Of these materials, 74% are processed for some type of further use. This percentage, however, is strongly influenced by the large contributing percentages of asphalt pavement and concrete (~93% and ~82%, respectively), as these two materials constitute 80% of the CDD stream. For the remaining MFA materials (asphalt shingles, drywall, wood, metal, bricks), only 30% of the material generated is processed, and 68% goes to landfill. For the non-MFA materials (which are typically considered MSW materials) in this waste stream (~19 MMT), the processing rate is 39%. Overall, approximately 137 MMT of the materials from the CDD stream go to landfill. This exceeds the quantity of MSW going to landfill in the same year (~123 MMT), but includes higher rates of recovery (34.5% of MSW recycled or composted and 12% combusted with energy recovery). The CDDPath method, including input data, steps, and results used for the 2014 data are documented in a public dataset available online.10

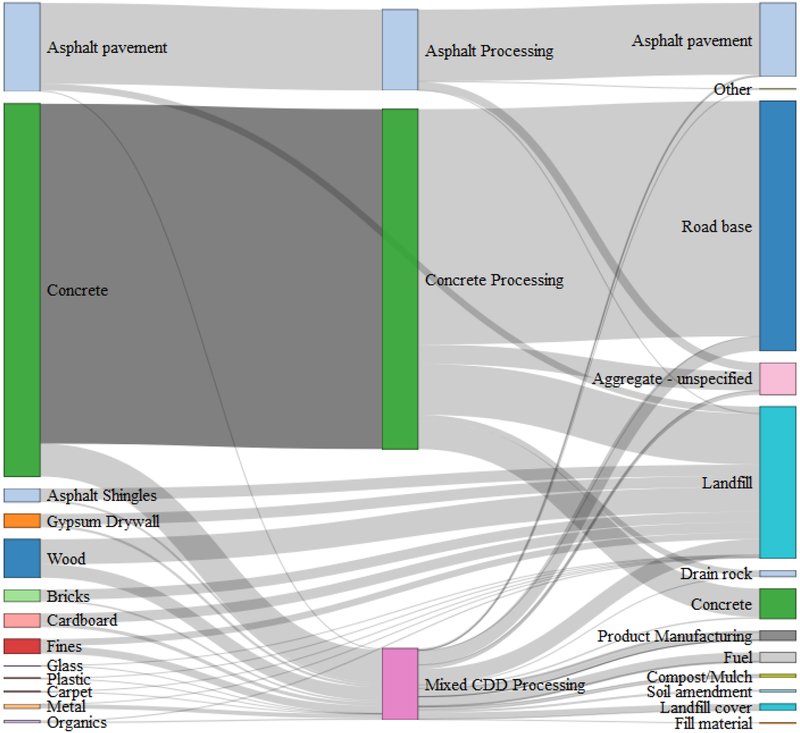

Figure 2 illustrates the flow of materials, from generation to processing and final pathways, and Table 1 lists the end-use products and their respective quantities for each CDD material. Ninety-one percent of asphalt pavement generated (74 MMT of 81 MMT) is estimated to be processed by industry, of which the largest streams are processed back into asphalt pavement (65 MMT) or used as an aggregate material (8MMT). The concrete industry processes 310 MMT of concrete, the largest stream of which is added to road base. The second and third largest streams from concrete processing go to landfill (47 MMT) and concrete products (26 MMT). Materials processed in the mixed CDD stream have a variety of secondary uses, including road base, aggregate, fuel, compost/mulch, landfill cover, soil amendment, concrete, drain rock, and other product manufacturing. The largest flows to landfill are from concrete (47 MMT) and wood (23 MMT), with a total estimated inflow of 139 MMT. Aside from use of RAP in asphalt pavement, and concrete in road base, the most significant secondary uses of recovered CDD materials are as aggregate (29 MMT), concrete (27 MMT), fuel (9 MMT), and remanufacture of other products (9 MMT).

Figure 2.

CDD material flows and dispositions. Sankey diagram created using the d3Network package in the R software.11

Table 1.

Summary of CDD disposition: mass-based quantities of materials landfilled and end-use products processed.

| Component | Landfilled (metric tons) | Processed by disposition (metric tons) | Processed total (metric tons) | Total (metric tons) | |

|---|---|---|---|---|---|

| Wood | 22,827,546 | Fuel | 8,234,764 | 12,262,360 | 35,089,906 |

| Mulch | 2,559,758 | ||||

| Remanufacture | 1,336,068 | ||||

| Compost | 131,771 | ||||

| Asphalt Shingles | 10,362,785 | Fuel | 22,916 | 1,922,311 | 12,285,096 |

| HMA/WMA | 1,781,711 | ||||

| Aggregate | 112,241 | ||||

| Other | 5,443 | ||||

| Gypsum | 10,021,441 | Agricultural | 2,065,299 | 2,307,200 | 12,328,641 |

| Drywall | Remanufacture | 241,901 | |||

| Metal | 44,316 | Remanufacture | 3,901,031 | 3,901,031 | 3,945,346 |

| Concrete | 61,009,202 | Aggregate- Road Base | 227,608,268 | 279,454,509 | 340,463,711 |

| Aggregate- Drain Rock | 5,712,635 | ||||

| Aggregate- Other Construction | 18,684,312 | ||||

| Remanufacture | 27,449,294 | ||||

| Bricks | 9,316,147 | Aggregate | 1,607,265 | 1,607,265 | 10,923,411 |

| Reclaimed | 5,373,328 | Remanufacture | 65,413,964 | 74,758,222 | 80,131,550 |

| Asphalt | Aggregate | 8,799,948 | |||

| Pavement | Other | 544,311 | |||

| Fines | 6,155,127 | Landfill Cover | 5,921,608 | 7,015,645 | 13,170,771 |

| Fill Material | 540,249 | ||||

| Road Base | 553,787 | ||||

| Cardboard | 9,334,123 | Remanufacture | 3,187,705 | 3,187,705 | 12,521,828 |

| Glass | 262,017 | General Recycled | 89,482 | 89,482 | 351,499 |

| Organics (e.g., Land Clearing Debris) | 1,240,626 | Compost/Mulch | 390,980 | 1,285,981 | 2,526,607 |

| Fuel | 895,001 | ||||

| Plastic | 877,518 | Remanufacture | 199,994 | 299,682 | 1,177,200 |

| Fuel | 99,688 | ||||

| Carpet | 822,812 | Remanufacture | 3,645 | 280,999 | 1,103,811 |

| Landfill Cover | 277,354 | ||||

| TOTAL | 137,646,986 | 388,372,392 | 526,019,378 | ||

The 2014 CDDPath generation estimate (526 MMT) is ~42 MMT greater than the total FF 2014 generation estimate (484 MMT), primarily because it includes some materials typically characterized as MSW.

These materials are not always defined as CDD materials in state regulations, yet they are found in the CDD waste stream. Here, in CDDPath, they comprise ~6% of the total estimate, or ~31 MMT. Asphalt concrete is largely processed separately as RAP (~73 MMT), but ~6 MMT were estimated to be present in the mixed CDD stream. The latter quantity of asphalt pavement, was excluded from FF 2014.12 The FF 2014 estimate also used the total accepted RAP reported by NAPA, whereas CDDPath included the NAPA values reported for RAP used, which resulted in 4 additional MMT asphalt pavement generated. The differences in the asphalt pavement totals sum to 10.7 MMT. Totals for all other materials are equal in both estimates.

The CDDPath method uses the best available US data to establish fractions of CDD by material type, treatment pathway, and ultimate disposition. These fractions are applied to generation estimates based on a materials flow approach. However, they could also be applied to generation estimates from other methods. The ultimate quantities of CDD material disposition, as presented in Table 1, depend on the method used to estimate the generation of these material streams. It should be noted that CDD generation estimates, just like MSW generation estimates,13 vary widely when sourced from a site sampling approach versus a materials flow approach; MFA estimates are often considered to be more comprehensive and typically result in larger estimates.3 Due to geographic and temporal variability in regional waste characterization, MFA estimates are proposed for use in national-scale estimates of waste disposition, and only as reference amounts for regional studies.

Since there is no federal statute requiring explicit tracking of CDD, as there is for hazardous waste,14 there is no single reporting system that would provide an authoritative source for tracking CDD disposal. Therefore, the CDDPath method synthesizes data from several data sources, including both public sources (e.g., US EPA and US states) and private sources (e.g., industry associations). This practice of combining data sources for development of federal statistics aligns with recent recommendations from the Committee on National Statistics of the National Academy of Sciences, in which the Committee recognizes the need to evaluate data source quality for fitness, i.e. appropriateness, of use.15 Furthermore, in a follow-up report,16 the Committee discusses frameworks for the formal assessment of data quality17. Here, it may be possible to adapt data quality assessment procedures from a field such as life cycle assessment, where disparate sources are frequently combined and systems for data quality scoring and aggregation have already been defined. Data quality assessment may also be complemented with descriptions of statistical spreads or ranges of error for data used in the method. This information can then be used in deterministic or probabilistic uncertainty or error assessment. Formal data quality assessments or uncertainty assessments have not yet been performed for the CDDPath estimates, but it would be a natural next step for understanding uncertainty associated with the disposition estimates and identifying where quality of the underlying data could most be improved.

Management of CDD materials has significant implications for sustainability in the US, particularly with regard to environmental life-cycle impacts.18 Given the growing interest in quantifying life-cycle benefits of sustainable management of building materials associated with federal, state, and local programs as well as green building codes and voluntary standards, there is an increasing need for data to accurately represent these materials. End-of-life management data have largely been excluded from life cycle assessments in the US; sometimes data from Europe have been used as a proxy. However, EOL management estimates, coupled with appropriate life cycle inventory data describing EOL activities, are crucial in supporting more complete life cycle assessments of building materials and practices.

CDDPath represents the first known method for estimating final disposition of CDD materials by material and mass for the US. The method can be applied independently of generation estimates, so it can be applied across different estimates as they vary over time. It incorporates the best available sources for CDD materials data, including those from US state reports of CDD generation and disposition, as well as data on composition of the CDD waste stream from CDD processing facilities and CDD landfills. Future opportunities include researching how well CDDPath estimates align with known quantities and existing practices on the ground at various state facilities and regionally. There are also opportunities for the CDDPath method to be refined as state and national reporting practices evolve, and for it to be used as a starting point for answering similar EOL questions in other countries around the world.

Supplementary Material

ACKNOWLEDGMENT

This work was conducted under USEPA Contract No. EP-C-15–012 with CSC Government Solutions LLC, Work Assignment No. 00–19. The Construction and Demolition Recycling Association sponsored the survey of CDD recycling facilities, which was conducted by the University of Florida. The authors furthermore acknowledge the technical input of Ksenija Janjic of the USEPA Office of Resource Conversation and Recovery.

Footnotes

Supporting Information. One document with supporting tables.

Notes

The authors declare no competing financial interest.

Publisher's Disclaimer: DISCLAIMER

Publisher's Disclaimer: This document is distributed solely for the purpose of pre-dissemination peer review under applicable information quality guidelines. It has not been formally disseminated by the U.S. Environmental Protection Agency. It does not represent and should not be construed to represent any agency determination or policy.

REFERENCES

- 1.Sustainable Materials Management: The Road Ahead; EPA530-R-09–009; U.S. Environmental Protection Agency: Washington, DC, 2009; https://www.epa.gov/sites/production/files/2015-08/documents/sustainable_materials_management_the_road_ahead.pdf. [Google Scholar]

- 2.Characterization of Building-Related Construction and Demolition Debris in the United States; EPA530-R-98–010; U.S. Environmental Protection Agency; Prepared by Franklin Associates: Prairie Village, KS, 1998; https://www.epa.gov/sites/production/files/2016-03/documents/charact_bulding_related_cd.pdf. [Google Scholar]

- 3.Cochran KM; Townsend TG Estimating construction and demolition debris generation using a materials flow analysis approach. Waste Management 2010, 30 (11), 2247–2254; DOI 10.1016/j.wasman.2010.04.008. [DOI] [PubMed] [Google Scholar]

- 4.Advancing Sustainable Materials Management: 2014 Fact Sheet; EPA530-R-17–01; U.S. Environmental Protection Agency: Washington, DC, 2016; https://www.epa.gov/sites/production/files/2016-11/documents/2014_smmfactsheet_508.pdf. [Google Scholar]

- 5.Methodology to Estimate the Quantity, Composition, and Management of Construction and Demolition Debris in the United States; EPA/600/R-15/111; U.S. Environmental Protection Agency: Cincinnati, OH, 2015; http://nepis.epa.gov/Adobe/PDF/P100NDZ0.pdf. [Google Scholar]

- 6.Townsend TG; Wilson C; Beck B The Benefits of Construction and Demolition Materials Recycling in the United States; Construction & Demolition Recycling Association, 2014. [Google Scholar]

- 7.Dubey B; Solo-Gabriele HM; Townsend TG Quantities of Arsenic-Treated Wood in Demolition Debris Generated by Hurricane Katrina. Environ. Sci. Technol 2007, 41 (5), 1533–1536; DOI 10.1021/es0622812. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.NAPA Information Series 138: 6th Annual Asphalt Pavement Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage 2015; National Asphalt Paving Association: Lanham, MD, 2017; https://www.asphaltpavement.org/PDFs/IS138/IS138-2015_RAP-RAS-WMA_Survey_Final.pdf. [Google Scholar]

- 9.U.S. Environmental Protection Agency; Sustainable Materials Management: U.S. State Data Measurement Sharing Program. https://www.epa.gov/smm/sustainable-materials-management-us-state-data-measurement-sharing-program (Accessed: 3 March 2018).

- 10.Townsend TG; Ingwersen WW; Niblick B; Jain P; Wally J Construction and Demolition Debris 2014 US Final Disposition Estimates Using the CDDPath Method. Dataset in U.S. Environmental Protection Agency, Ed. 2018. [Google Scholar]

- 11.Allaire J; Gandrud C; Russell K; Yetman C networkD3: D3 JavaScript Network Graphs from R, 0.4; 2017. [Google Scholar]

- 12.Construction and Demolition Debris Generation in the United States 2014; U.S. Environmental Protection Agency, Office of Resource Conservation and Recovery: Washington, DC, 2016. [Google Scholar]

- 13.Chowdhury M Searching quality data for municipal solid waste planning. Waste Management 2009, 29 (8), 2240–2247; DOI 10.1016/j.wasman.2009.04.005. [DOI] [PubMed] [Google Scholar]

- 14.U.S. Environmental Protection Agency, Hazardous Waste Generator Improvements Rule. In U.S. Environmental Protection Agency, Ed. 2016; Vol. 2050-AG70, pp 85732–85829. [Google Scholar]

- 15.National Academies of Sciences, Engineering, and Medicine; Innovations in Federal Statistics: Combining Data Sources While Protecting Privacy; The National Academies Press: Washington, DC, 2017; p 150; DOI 10.17226/24652. [DOI] [PubMed] [Google Scholar]

- 16.National Academies of Sciences, Engineering, and Medicine; Federal Statistics, Multiple Data Sources, and Privacy Protection: Next Steps; The National Academies Press: Washington, DC, 2017; p 169; DOI 10.17226/24893. [DOI] [PubMed] [Google Scholar]

- 17.Edelen A; Ingwersen W Guidance on Data Quality Assessment for Life Cycle Inventory Data; EPA/600/R-16/096; U.S. Environmental Protection Agency: Washington, DC, 2016; https://cfpub.epa.gov/si/si_public_record_report.cfm?dirEntryId=321834. [Google Scholar]

- 18.U.S. Environmental Protection Agency; Sustainable Management of Construction and Demolition Materials; https://www.epa.gov/smm/sustainable-management-construction-and-demolition-materials (Accessed: 16 November 2017).

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.