Abstract

Introduction

Historic dust concentrations are available in a large-scale cohort study of workers in a chrysotile mine and processing factories in Asbest, Russian Federation. Parallel dust (gravimetric) and fibre (phase-contrast optical microscopy) concentrations collected in 1995, 2007 and 2013/14 were used to determine if dust to fibre conversion factors can be estimated.

Materials/subjects and methods

Daily medians of multiple parallel dust and fibre concentrations by sampling points were used to derive fibre to dust ratios. Applying linear mixed models, we estimated best linear unbiased predictions for the fibre to dust ratios.

Results and discussion

A total of 620 daily median fibre to dust ratios were derived. In the factories, modelled ratios varied by unit, increasing along the stages of asbestos enrichment as expected. In the mine, ratios were higher in winter compared to summer. Overall, the ratios showed a strong negative dependency on dust concentration.

Conclusions

Our study shows that dust to fibre conversion is possible by unit but extrapolations are needed. The patterns for exposure by dust and fibre will be similar but estimated fibre levels will show less contrast due to the conversion factor being smaller at higher dust concentrations.

Keywords: chrysotile, dust, fiber, conversion, asbestos

Introduction

Asbestos, a collective term given to a group of naturally forming minerals whose crystals occur in fibrous forms (1), is a known carcinogen (2). The identification of associated health risks has led to a large reduction in the commercial use of most types of asbestos and strict regulations to limit exposure in workplaces where it is still used. Of these minerals, chrysotile (white asbestos) is now the main type traded commercially and its extraction, preparation and use involves mining, milling, manufacturing, construction and the transportation, use and later disposal of products containing chrysotile (1).

Occupational exposure to asbestos is usually estimated using either dust or fibre concentrations, or a combination of both. Cumulative fibre years (either measured or estimated from dust) is the most common exposure index (3–10), however exposure has also been estimated based on profession or other occupational history characteristics (11–13). Fibre concentrations are considered to be a more relevant metric than dust concentration as fibres can be isolated from other airborne particles, where dust also includes other airborne materials, not exclusively asbestos (14,15). However, comprehensive fibre concentrations are not always available and often derived from historic dust concentrations using conversion factors, which is not without its challenges (4,16–21). Although there have been efforts to develop a standard conversion factor to convert asbestos dust concentrations to fibre (20), evidence shows that conversions are dependent on industry, asbestos based activity type, asbestos type and other environmental airborne materials (22,23). This has led to the conclusion that they should be specific to study settings (23). Even within studies, large variability in the conversion factors has been identified between factories on the same site and, to a lesser extent, between work processes within a given factory (21,23).

The Russian Federation is currently the main producer of chrysotile asbestos, accounting for over half of the world’s production (24). A historical cohort study (the Asbest Study) is currently underway to examine the workers of the open-pit mine and production factories of Joint Stock Company “Uralasbest”, in the city of Asbest in the Southern Urals (25). Almost 100,000 gravimetric dust concentrations recorded by sampling point from 1951 to 2001 were available for various parts of the mining and asbestos production at Uralasbest (26) as dust levels were used to monitor workplace exposures in Russian workplaces. The mean level of asbestos content in the ore at Uralasbest is 2.3% (27). Fibre measurements were not routinely collected but parallel fibre and dust concentrations were available from three independent projects carried out in 1995, 2007 and 2013/14. Here these data were examined to determine if conversion factors could be derived by unit to estimate fibre concentrations from dust concentrations.

Materials/subjects and method

The historical cohort study of which this work is a part was approved by the IARC Ethics Committee (IEC No. 12–22, September 2012). The present investigation does not include participant-level data.

Sampling:

Parallel dust and fibre measurements were taken at numerous stationary sampling points in the factories and mine of Uralasbest in 1995, 2007 and 2013/14 as part of three projects. They were pooled together and resulted in 620 fibre to dust ratios for analysis (Table 1). Sampling points correspond to various locations in the factories and mine which are broadly grouped into units relating to work processes associated with the mining and the enrichment of chrysotile asbestos (26). For the mine, the unit categories were mining, mine dump, drilling and rail transport (i.e., this unit includes rail transport associated with relocating the extracted ore to other locations). For the factories, the unit categories were crushing and sorting – main, crushing and sorting – drying and boiler, crushing and sorting – dust chamber/bag house filter, enrichment – main, enrichment – dust chamber/bag house filter, enrichment – dust/waste bunker, final product (packaging) and laboratory. In all projects the measurements were collected by the Central Laboratory for Production Control (CL) at Uralasbest. In 1995 and 2007, measurements were taken in two factories – Factory 4 and Factory 6. As Factory 4 closed in 2010, measurements collected in 2013/14 were only for Factory 6. In the mine, parallel measurements were only available for analysis in 2007 and 2013/14. Multiple dust measurements were taken per day by sampling point however the sampling strategy was not precisely the same between the three projects. For fibre, either one or two measurements per day by sampling point were taken in 1995 whereas multiple measurements per day by sampling point were taken for 2007 and 2013/14.

Table 1:

Dust- and Fibre-Concentrations and Fibre to Dust Ratios for all factories and mine

| Year of Sampling: 1995 | Year of Sampling: 2007 | Year of Sampling: 2013/14 | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N of daily medians | Daily median of fibre concentration (f/cm3) (A) | Daily median of dust concentration (mg/m3) (B) | Fibre to Dust Ratio (A/B) | N of daily medians | Daily median of fibre concentration (f/cm3) (A) | Daily median of dust concentration (mg/m3) (B) | Fibre to Dust Ratio (A/B) | N of daily medians | Daily median of fibre concentration (f/cm3) (A) | Daily median of dust concentration (mg/m3) (B) | Fibre to Dust Ratio (A/B) | ||||||||||||

| med | range | med | range | med | range | med | range | med | Range | med | range | med | range | med | range | med | range | ||||||

| MINE | Note: No parallel data were available in the mine for 1995 | 60 | 0.80 | 0.5–4.2 | 0.93 | 0.17–14.04 | 0.92 | 0.06–5.29 | 35 | 0.63 | 0.34–1.41 | 0.59 | 0.1–2.12 | 1.20 | 0.27–6.9 | ||||||||

| Mining | 22 | 0.80 | 0.5–2.2 | 0.52 | 0.17–11.2 | 1.37 | 0.15–5.29 | 14 | 0.63 | 0.34–1.41 | 0.77 | 0.16–1.41 | 0.85 | 0.43–2.13 | |||||||||

| Mine dump | 15 | 0.90 | 0.6–4.2 | 1.54 | 0.53–14.04 | 0.53 | 0.06–1.7 | 8 | 0.66 | 0.36–1.05 | 0.63 | 0.34–2.12 | 1.28 | 0.27–2.09 | |||||||||

| Drilling | 2 | 0.75 | 0.7–0.8 | 0.92 | 0.43–1.42 | 1.19 | 0.49–1.88 | 2 | 0.43 | 0.39–0.46 | 0.76 | 0.6–0.93 | 0.58 | 0.49–0.66 | |||||||||

| Rail transport | 21 | 0.70 | 0.6–1 | 1.02 | 0.35–1.94 | 0.86 | 0.32–2.29 | 11 | 0.63 | 0.49–0.79 | 0.41 | 0.1–1.24 | 1.40 | 0.44–6.9 | |||||||||

| FACTORY 4 | 9 | 1.11 | 0.17–3.7 | 0.6 | 0.1–6.2 | 1.22 | 0.42–5.6 | 170 | 2.5 | 0.7–24.28 | 2.7 | 0.4–15.6 | 1 | 0.14–5.18 | Note: Factory 4 was closed in 2010 | ||||||||

| Crushing and sorting – main | 2 | 0.37 | 0.17–0.56 | 0.24 | 0.1–0.38 | 3.02 | 0.45–5.6 | 36 | 1.45 | 0.7–3.9 | 2.6 | 0.5–13.9 | 0.56 | 0.14–2.78 | |||||||||

| CS - drying and boiler | 3 | 0.61 | 0.18–2.31 | 0.50 | 0.43–1 | 1.22 | 0.42–2.31 | 12 | 1.25 | 0.9–1.9 | 1.5 | 0.4–2.9 | 0.83 | 0.64–3 | |||||||||

| CS - dust chamber/bag house filter | 4 | 1.95 | 1–2.5 | 1.15 | 0.9–1.8 | 1.5 | 1.11–1.79 | ||||||||||||||||

| Enrichment – main | 2 | 3.42 | 3.15–3.7 | 4.90 | 3.65–6.2 | 0.73 | 0.60–0.86 | 62 | 4.65 | 1.9–20.5 | 4.2 | 1.6–15.6 | 1.03 | 0.51–2 | |||||||||

| EN - dust/waste chamber | 8 | 1.45 | 1.3–3.7 | 1 | 0.4–1.6 | 1.84 | 1.08–3.25 | ||||||||||||||||

| Final product (packaging) | 2 | 1.97 | 1.11–2.82 | 1.21 | 0.63–1.8 | 1.67 | 1.57–1.78 | 48 | 2.2 | 0.8–24.85 | 2.45 | 0.4–10.7 | 1.15 | 0.21–5.18 | |||||||||

| Laboratory | |||||||||||||||||||||||

| FACTORY 6 | 3 | 0.91 | 0.84–0.94 | 0.93 | 0.74–1.2 | 0.91 | 0.75–1.27 | 211 | 2.4 | 0.5–12.1 | 2.7 | 0.5–15.8 | 0.96 | 0.12–3.78 | 132 | 2.22 | 0.56–11.05 | 2.88 | 0.54–11.63 | 0.66 | 0.22–3.48 | ||

| Crushing and sorting – main | 48 | 1.28 | 0.6–7.2 | 2.6 | 0.7–15.8 | 0.51 | 0.12–2.3 | 28 | 2.04 | 0.59–3.57 | 2.76 | 0.96–11.63 | 0.68 | 0.27–1.14 | |||||||||

| CS - drying and boiler | 28 | 1.15 | 0.7–4.3 | 2.05 | 0.5–7.8 | 0.73 | 0.28–1.6 | 16 | 1.36 | 0.7–6.91 | 2.30 | 0.99–7.39 | 0.59 | 0.25–1.03 | |||||||||

| Enrichment – main | 2 | 0.92 | 0.91–0.94 | 0.97 | 0.74–1.2 | 1.01 | 0.75–1.27 | 119 | 4.35 | 0.5–12.1 | 3.1 | 0.7–13.7 | 1.22 | 0.33–3.78 | 74 | 2.48 | 0.81–11.05 | 3.87 | 1.08–11.03 | 0.64 | 0.22–3.48 | ||

| EN - dust chamber/bag house filter | 4 | 2.05 | 1.8–2.75 | 4.15 | 3.9–4.4 | 0.5 | 0.41–0.69 | 2 | 3.91 | 3.71–4.1 | 3.99 | 1.53–6.45 | 1.63 | 0.58–2.68 | |||||||||

| Final product (packaging) | 1 | 0.84 | 0.93 | 0.91 | 12 | 1.4 | 0.65–3.5 | 1.15 | 0.5–3.2 | 1.18 | 0.39–3.3 | 8 | 0.68 | 0.56–0.99 | 0.97 | 0.54–1.3 | 0.68 | 0.59–1.21 | |||||

| Laboratory | 4 | 1.42 | 0.87–2.8 | 1.20 | 1.04–1.49 | 1.19 | 0.79–1.88 | ||||||||||||||||

CS: Crushing and Sorting EN: Enrichment

In June 1995, the project involved a consortium of research institutions* and was part of a larger 3-year occupational health safety program in the Russian Federation (28,29). From their report (29), we extracted the data reported by the Russian Academy of Medical Sciences, Institute of Occupational Health (only Factory 4 and 6) and allowed for matching of dust and fibre measurements by sampling start time and duration. This was not possible for the remaining data. From March to September 2007, data collection for the project was conducted by the CL as part of the regular Uralasbest monitoring program to which fibre measurements were added. Finally, the 2013/14 project included measurements taken in the winter period, November and December 2013 and again in January and February 2014, and in the summer period, June to September 2014, specifically for the Asbest Study. In 2013/14 measurements were intentionally collected at the same sampling points in summer and winter. The measurements from the three projects were categorised into seasons, broadly defined as summer (June-September) and winter (October to May). The parallel dust and fibre measurements were collected using two samplers, one for dust and the other for fibre, placed side by side at a height of 1.5 metres from the ground. The collection was started at the same time but the exact duration of the parallel dust and fibre sampling was not always identical.

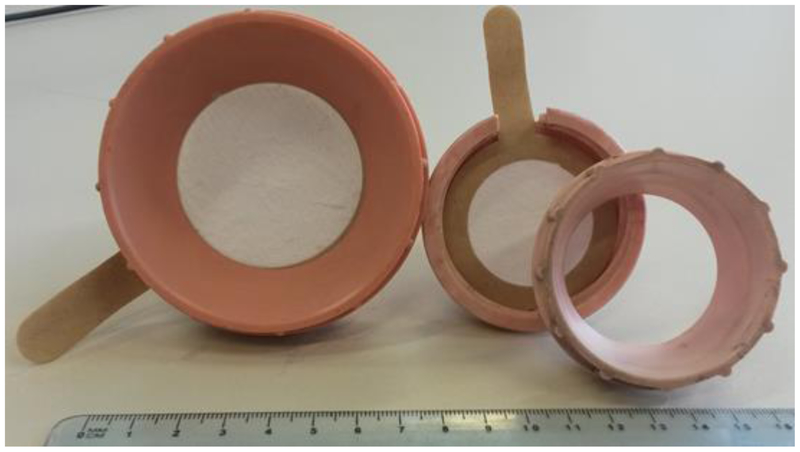

Gravimetric dust measurements were taken according to the Russian Methodological Regulations No. 4436–87 (30,31). Dust measurements were collected using stationary gravimetric samplers (air pumps “K-822” Krasnogvardeetzs Plant, Russia). Sampling times differed by time period, ranging from 30–107 minutes in 1995, either 10, 15 or 30 minutes in 2007 and with a fixed duration of 30 minutes in 2013/14. The samplers were typically run at 20 l/min or 70 l/min. The concave air sampling heads had a diameter of 73mm or 55mm with AFA VP 20 or AFA VP 10 filters and an exposed surface of 20 cm2 or 10cm2 respectively (Figure 1). For larger filters (AFA VP 20), the maximum possible weight of collected dust was 50 mg and for smaller filters (AFA VP 10), it was 25 mg. The size of the sampling head used was dependent on the expected dust levels around the sampling point. Where there was less dust in the area, the smaller sampling head was used with longer sampling duration and faster suction speed, and vice versa. The filters were pre- and post- weighed to determine mass gain and then converted into a dust concentration. The results are expressed as milligrams of dust per cubic metre of air (mg/m3).

Figure 1:

Dust sampler heads and filters

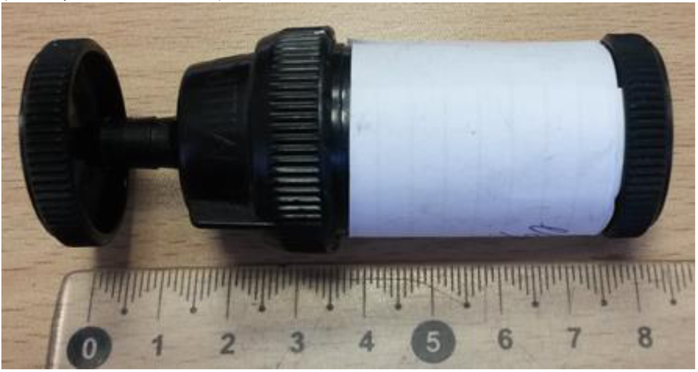

Fibre counting was done using the phase contrast optical microscopy (PCOM) method following the Asbestos International Association’s Recommended Technical Method № 1 Counting Criteria (32). Separate fibre samplers and filters were used to collect fibre measurements. The samplers had standard Millipore MAWO 025 AC cassettes with Millipore AC filters (25 mm diameter) (Figure 2). The fibre sampling duration ranged from 30 to 69 minutes in 1995 and, in 2007 and 2013/14, was 30, 20, 10, 5 or 1 minute(s) depending on the expected level of dust at the sampling point. Where the dust levels were higher, a shorter sampling time for the fibre measurements was set. This was determined largely by experience of a CL expert in the first instance, but then tested by a pilot fibre sample taken at a given sampling point for quality control. The resulting fibre concentrations were expressed as fibres per cubic centimetre of air (f/cm3).

Figure 2:

Fibre sampler cassette and filter

Exclusion of extreme values:

As asbestos fibre concentrations below 0.1 f/cm3 are not considered reliable (33), values below this level were excluded with the paired dust sample prior to analysis (only one concentration from 1995). Extreme dust or fibre concentrations, defined as over 20 mg/m3 or 50 f/cm3 respectively, were also excluded along with their paired fibre or dust concentration to eliminate outliers. These exclusions reduced the total sample of individual dust and fibre concentrations by 80 out of 2,144 (3.7%).

Fibre to dust ratio:

A daily median was calculated by sampling point and by measurement type (i.e. dust or fibre). A total of 620 parallel daily median dust and fibre concentrations were then used to calculate a daily median fibre to dust ratio by sampling point (1000 f/mg dust). The resulting ratios were assessed for normality which showed the distribution of the ratios was right skewed and they were subsequently log transformed, as in previous studies (15,16).

Statistical Methods:

Using the log transformed fibre to dust ratios, linear mixed models were built (34) to estimate the log transformed fibre to dust ratio separately for the mine and factories as a function of year of sampling, season and unit. The models included fixed effects of year of sampling (1995, 2007, 2013/14) and season (winter/summer) and random effects for unit. Preliminary analyses showed a dependence of the ratio on the median daily dust concentration, whereby the fibre to dust ratio decreased with increasing dust concentration. This was accounted for by including daily median dust concentration as a fixed effect in the model. The data were analysed using SAS version 9.3 (SAS Institute, Cary NC).

Sensitivity analysis:

We also considered an alternative approach by modelling the ratio of the daily (arithmetic) mean fibre concentration to mean dust concentration. That is, the daily mean was calculated by measurement type and then transformed to a daily mean fibre to dust ratio by sampling point and then modelled the log transformed ratios.

Estimating fibre concentration:

We subsequently estimated historic mean fibre concentrations based on measured dust concentrations. This was done initially by factory or mine and then for selected units. In order to estimate fibre concentration in the units, we applied the individual fixed effects estimates from the model plus the unit specific random effect by using the best linear unbiased predictions (BLUPs). As the range of measured dust concentrations used to model the conversion factors was 0.1 to ~15 mg/m3, we only estimated the fibre concentration for years in which the geometric mean calculated from the historic dust concentrations did not exceed 15 mg/m3.

Results

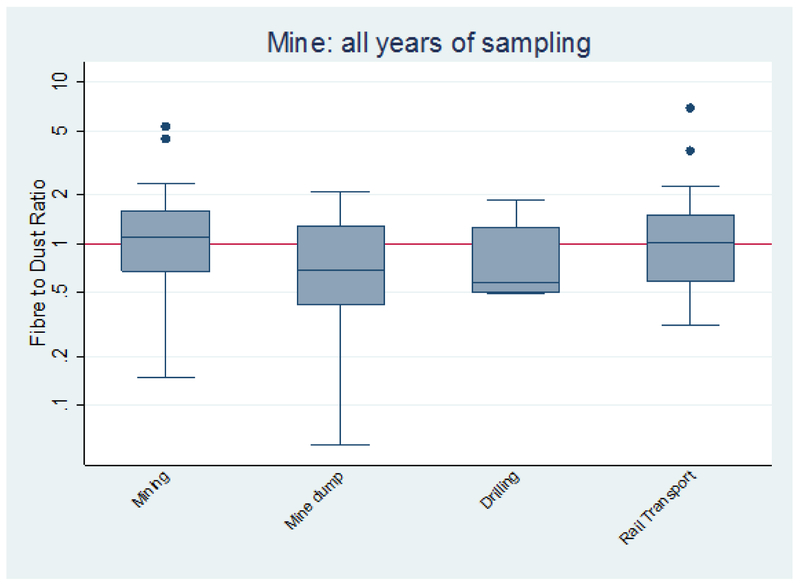

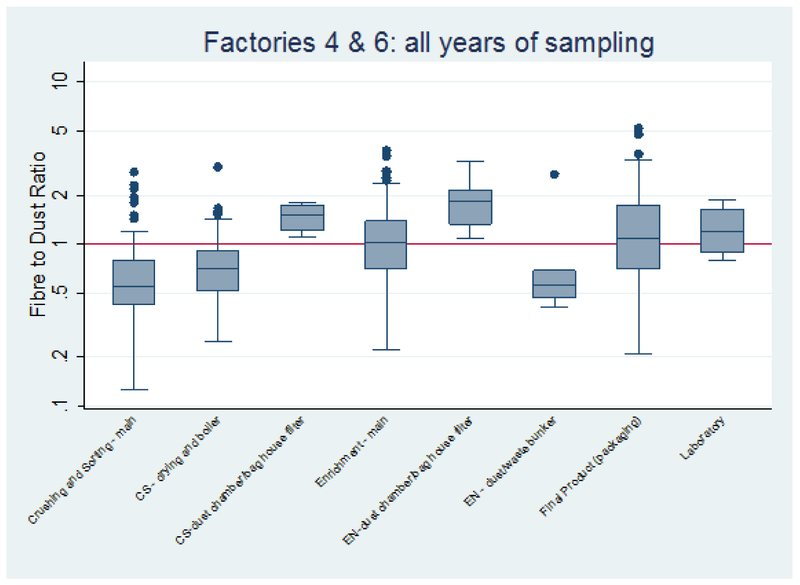

The overall daily median fibre concentration for the factories was 0.92 f/cm3 in 1995, 2.50 f/cm3 in 2007 and 2.22 f/cm3 in 2013/14. In the mine, the median fibre was 0.80 f/cm3 in 2007 and 0.63 f/cm3 in 2013/14. The overall daily median dust concentration for the factories was 0.80 mg/m3 in 1995, 2.70 mg/m3 in 2007 and 2.88 mg/m3 in 2013/14. In the mine, the median dust was 0.93 mg/m3 in 2007 and 0.59 mg/m3 in 2013/14. The overall fibre to dust ratio in the factories was 1.15 in 1995, 0.98 in 2007 and 0.66 in 2013/14. In the mine, the median fibre to dust ratio was 0.92 in 2007 and 1.20 in 2013/14. The fibre and dust concentrations and fibre to dust ratios are detailed by unit in Table 1 and Table 2. Figure 3 & Figure 4 show the distribution of the fibre to dust ratios for all years of sampling by unit in the mine and the factories, respectively. These figures show that the median fibre to dust ratios across the units in the mine ranged from 0.58 to 1.09. The ratios in the factories depended on unit and were in an a priori expected direction; that is there were increasing fibre to dust ratios as asbestos enrichment process progressed from the main unit of crushing and sorting through enrichment to final product (where chrysotile is packaged for sale).

Table 2:

Fibre to dust ratios by unit

| Unit | Overall | Year of sampling | ||||||

|---|---|---|---|---|---|---|---|---|

| 1995 | 2007 | 2013/14 | ||||||

| Median Fibre to Dust Ratio | Range | Median Fibre to Dust Ratio | Range | Median Fibre to Dust Ratio | Range | Median Fibre to Dust Ratio | Range | |

| Mining | 1.09 | (0.15–5.29) | 1.37 | (0.15–5.29) | 0.85 | (0.43–2.13) | ||

| Mine dump | 0.69 | (0.06–2.09) | 0.53 | (0.06–1.7) | 1.28 | (0.27–2.09) | ||

| Drilling | 0.58 | (0.49–1.88) | 1.19 | (0.49–1.88) | 0.58 | (0.49–0.66) | ||

| Rail transport | 1.02 | (0.32–6.9) | 0.86 | (0.32–2.29) | 1.40 | (0.45–6.9) | ||

| Crushing and sorting – main | 0.56 | (0.13–5.6) | 3.08 | (0.57–5.6) | 0.54 | (0.13–2.78) | 0.68 | (0.27–1.14) |

| Crushing and sorting - drying and boiler | 0.71 | (0.25–3) | 1.53 | (0.4–2.31) | 0.75 | (0.28–3) | 0.59 | (0.25–1.03) |

| Crushing and sorting - dust chamber/bag house filter | 1.50 | (1.11–1.79) | 1.50 | (1.11–1.79) | ||||

| Enrichment – main | 1.01 | (0.22–3.78) | 0.78 | (0.6–1.39) | 1.15 | (0.33–3.78) | 0.64 | (0.22–3.48) |

| Enrichment - dust chamber/bag house filter | 1.84 | (1.08–3.25) | 1.84 | (1.08–3.25) | ||||

| Enrichment - dust/waste bunker | 0.56 | (0.41–2.68) | 0.50 | (0.41–0.69) | 1.63 | (0.58–2.68) | ||

| Final Product (packaging) | 1.09 | (0.21–5.18) | 1.57 | (0.91–1.85) | 1.16 | (0.21–5.18) | 0.68 | (0.59–1.21) |

| Laboratory | 1.19 | (0.79–1.88) | 1.19 | (0.79–1.88) | ||||

Figure 3:

Fibre to dust ratios by unit: Mine

Figure 4:

Fibre to dust ratios by unit: Factory 4 & 6

The results of the linear mixed model for the mine and factories are shown in Table 3 and Table 4, respectively, including the estimated average fibre to dust ratios (geometric mean ratios) by unit and other factors. In the mine, the fibre to dust ratios collected in 2007 were 31% higher than in 2013/14, with the difference for 2007 approaching statistical significance (p=0.06). In the factories, the fibre to dust ratios collected in 1995 and 2007 were 48% and 36% higher than in 2013/14, respectively, both being statistically significant. In the factories there was no statistical difference in ratios between summer and winter. However, in the open-pit mine the ratios based on concentrations from the winter season were 67% higher than those in summer (p=0.01). The fibre to dust ratio was also significantly dependant on the median dust concentration, for every 1 mg/m3 increase in the dust concentration the fibre to dust ratio decreased by 9% in the factories and 20% in the mine. The p-value for the variance between units was approaching statistical significance in the factories (p=0.06), supporting what was seen in Figure 4, and was not statistically significant in the mine (p=0.39) suggesting that there was no difference between the mine units.

Table 3:

Mine Linear Mixed Model: Fixed and Random Effects

| Original Model (Median Daily Concentrations) n= 95 | Alternative Model (Mean Daily Concentrations) n= 95 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model Parameters/variance components | |||||||||

| Estimate | GMRa | SEb | p-value | Estimate | GMRa | SEb | p-value | ||

| Intercept | −0.05 | 0.95 | 0.13 | 0.70 | Intercept | −0.05 | 0.95 | 0.13 | 0.69 |

| Year of sampling: 2007 | 0.27 | 1.31 | 0.14 | 0.06 | Year of sampling: 2007 | 0.23 | 1.25 | 0.13 | 0.09 |

| Year of sampling: 2013/14 | 0.00 | Year of sampling: 2013/14 | 0.00 | ||||||

| Season: Winter | 0.51 | 1.67 | 0.18 | 0.01 | Season: Winter | 0.51 | 1.66 | 0.17 | 0.00 |

| Season: Summer | 0.00 | Season: Summer | 0.00 | ||||||

| Median Dust Concentration | −0.23 | 0.80 | 0.02 | <.0001 | Mean Dust Concentration | −0.21 | 0.81 | 0.02 | <.0001 |

| Random effects terms | |||||||||

| Estimate | GMRa | SEb | p-value | Estimate | GMRa | SEb | p-value | ||

| Mining | −0.02 | 0.98 | 0.06 | 0.78 | Mining | −0.03 | 0.97 | 0.08 | 0.73 |

| Mine dump | −0.02 | 0.98 | 0.06 | 0.70 | Mine dump | −0.05 | 0.95 | 0.07 | 0.50 |

| Drilling | 0.04 | 1.04 | 0.06 | 0.45 | Drilling | 0.07 | 1.08 | 0.07 | 0.31 |

| Rail transport | 0.00 | 1.00 | 0.06 | 0.96 | Rail transport | 0.01 | 1.01 | 0.07 | 0.93 |

| Variance components | |||||||||

| Estimate | SEb | p-value | Variancec | Estimate | SEb | P-value | Variancec | ||

| Between units | 0.00 | 0.01 | 0.39 | 1.38% | Between units | 0.008 | 0.01628 | 0.31 | 3.20% |

| Residual | 0.28 | 0.04 | <.0001 | 98.62% | Residual | 0.2418 | 0.03637 | <.0001 | 96.80% |

GMR: Geometric Mean Ratio

SE: Standard Error

variance from model with random effects

Table 4:

Factory Linear Mixed Model: Fixed and Random Effects

| Original Model (Median Daily Concentrations) n= 525 | Alternative Model (Mean Daily Concentrations) n= 525 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model Parameters/variance components | |||||||||

| Estimate | GMRa | SEb | p-value | Estimate | GMRa | SEb | p-value | ||

| Intercept | −0.04 | 0.96 | 0.12 | 0.72 | Intercept | −0.03 | 0.97 | 0.12 | 0.83 |

| Year of sampling: 1995 | 0.39 | 1.48 | 0.15 | 0.01 | Year of sampling: 1995 | 0.38 | 1.46 | 0.14 | 0.01 |

| Year of sampling: 2007 | 0.31 | 1.36 | 0.05 | <.0001 | Year of sampling: 2007 | 0.31 | 1.37 | 0.05 | <.0001 |

| Year of sampling: 2013/14 | 0.00 | Year of sampling: 2013/14 | 0.00 | ||||||

| Season: Winter | 0.04 | 1.04 | 0.04 | 0.34 | Season: Winter | 0.02 | 1.02 | 0.04 | 0.63 |

| Season: Summer | 0.00 | Season: Summer | 0.00 | ||||||

| Median Dust Concentration | −0.09 | 0.91 | 0.01 | <.0001 | Mean Dust Concentration | −0.09 | 0.91 | 0.01 | <.0001 |

| Random effects terms | |||||||||

| Estimate | GMRa | SEb | p-value | Estimate | GMRa | SEb | p-value | ||

| Crushing and sorting - main | −0.43 | 0.65 | 0.12 | 0.00 | Crushing and sorting - main | −0.43 | 0.65 | 0.12 | 0.00 |

| Crushing and sorting –dust chamber/bag house filter | 0.13 | 1.14 | 0.20 | 0.50 | Crushing and sorting - dust chamber/bag house filter | 0.14 | 1.15 | 0.20 | 0.49 |

| Crushing and sorting - drying and boiler | −0.31 | 0.73 | 0.12 | 0.01 | Crushing and sorting - drying and boiler | −0.32 | 0.73 | 0.13 | 0.01 |

| Enrichment – main | 0.18 | 1.20 | 0.12 | 0.12 | Enrichment - main | 0.17 | 1.19 | 0.12 | 0.14 |

| Enrichment - dust chamber/bag house filter | 0.30 | 1.35 | 0.17 | 0.08 | Enrichment - dust chamber/bag house filter | 0.31 | 1.37 | 0.17 | 0.07 |

| Enrichment - dust/waste bunker | −0.14 | 0.87 | 0.18 | 0.45 | Enrichment - dust/waste bunker | −0.14 | 0.87 | 0.18 | 0.44 |

| Final Product (packaging) | 0.07 | 1.08 | 0.12 | 0.56 | Final Product (packaging) | 0.08 | 1.09 | 0.12 | 0.50 |

| Laboratory | 0.19 | 1.21 | 0.20 | 0.34 | Laboratory | 0.18 | 1.20 | 0.20 | 0.37 |

| Variance components | |||||||||

| Estimate | SEb | p-value | Variancec | Estimate | SEb | p-value | Variancec | ||

| Between units | 0.08 | 0.05 | 0.06 | 26.67% | Between units | 0.09 | 0.05 | 0.05 | 28.04% |

| Residual | 0.22 | 0.01 | <.0001 | 73.33% | Residual | 0.22 | 0.01 | <.0001 | 71.96% |

GMR: Geometric Mean Ratio

SE: Standard Error

variance from model with random effects

The results of the sensitivity analysis using the mean are also shown in Table 3 and Table 4. The fixed and random effect estimates were similar to the original and the Akaike information criterion (AIC) was 737.0 for the mean concentrations vs 744.9 in the model using medians concentrations for the factories and 169.2 vs 162.8 for the mine, respectively, suggesting that the quality of the models was similar (35). This indicated a slightly better fit using the mean concentrations than the model using the median concentrations for the factories and the inverse for the mine.

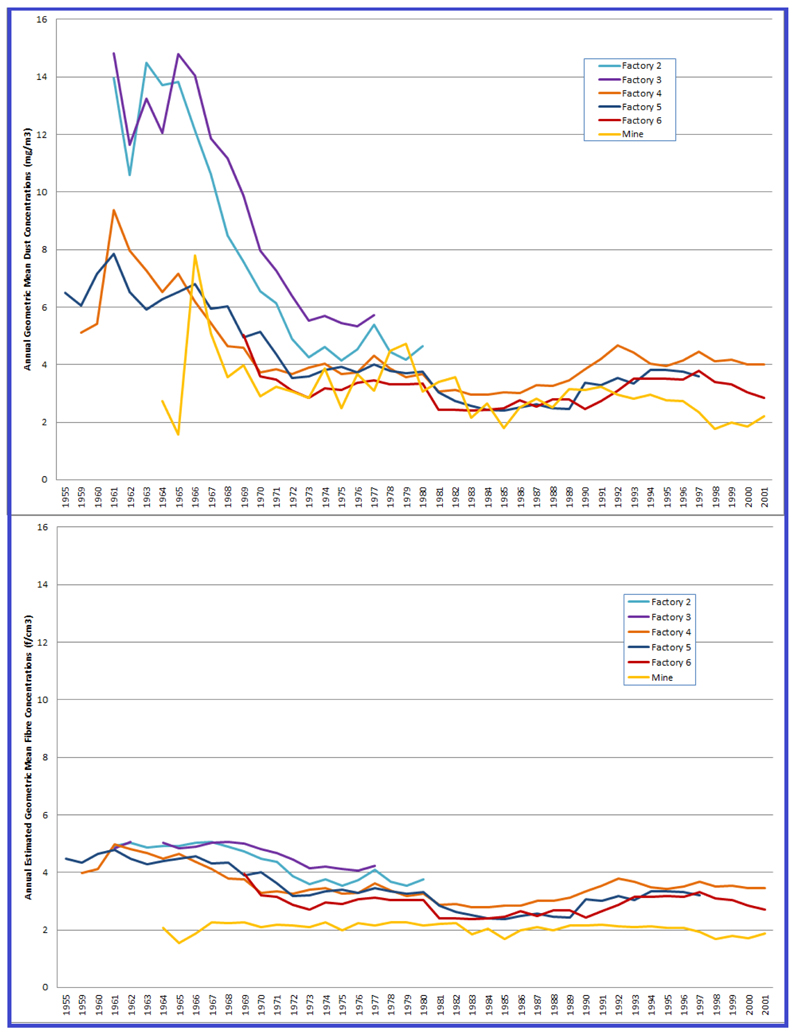

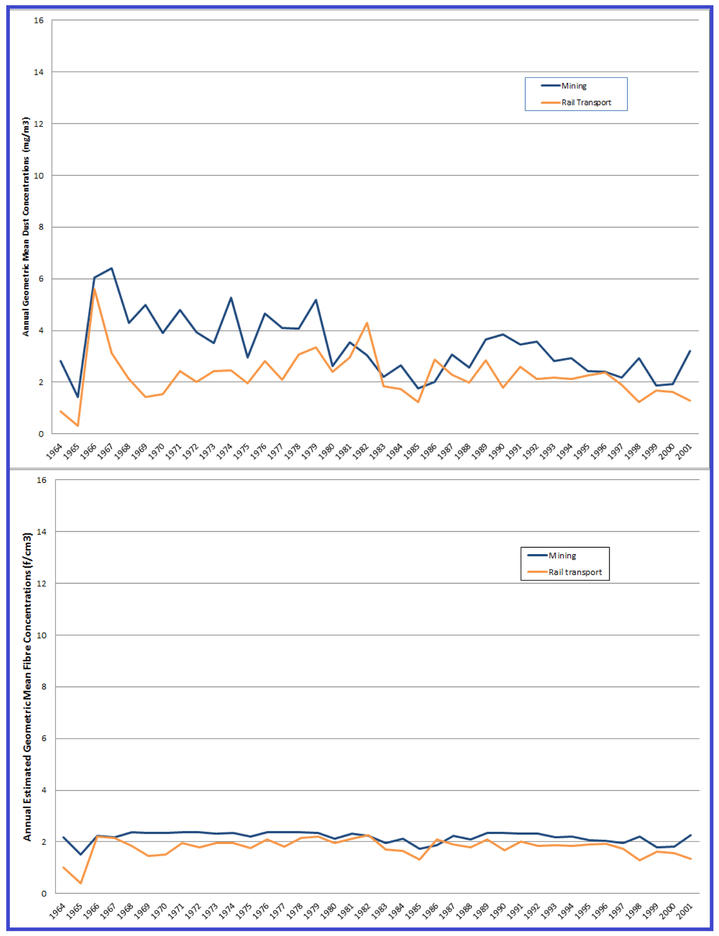

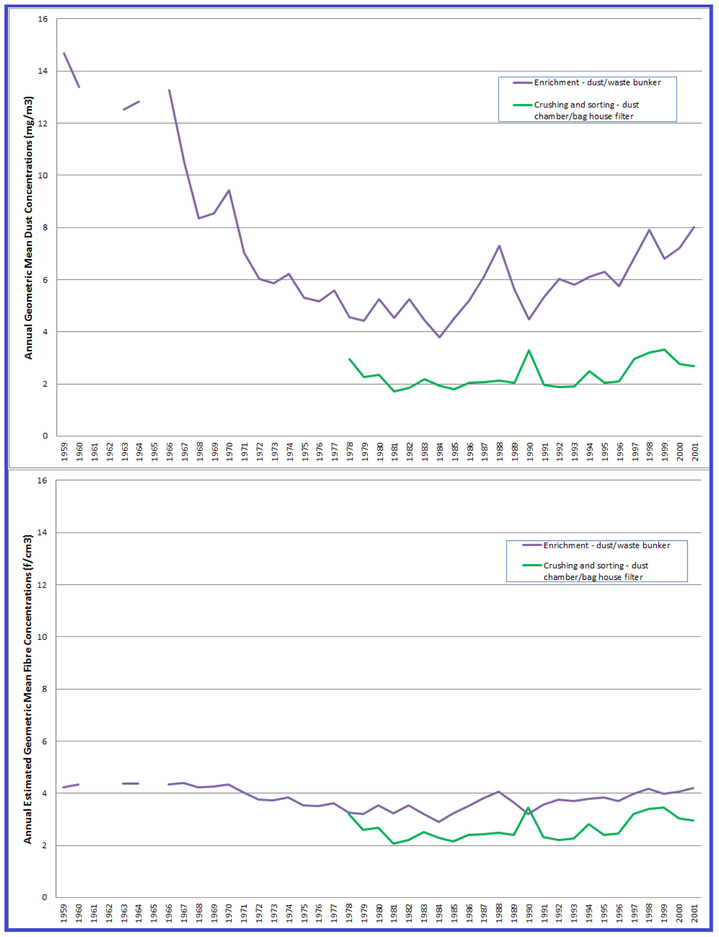

Figure 5, figure 6 and figure 7 show the annual geometric mean dust concentrations from the historical database and the estimated annual mean fibre concentrations derived using the estimates from the conversion model. Historic measured dust concentrations showed more contrast between the factories and mine as well as between units within the factories and mine than seen for the estimated fibre concentrations. The patterns for exposure by dust and fibre will be similar but estimated fibre levels will show less contrast due to the conversion factor being smaller at higher dust concentrations.

Figure 5:

Annual Mean Dust Concentrations and Annual Estimated Mean Fibre Concentrations: Factories (1955–2001) and Mine (1964–2001)

Figure 6:

Annual Mean Dust Concentrations and Annual Estimated Mean Fibre Concentrations: Selected Mine Units 1964–2001

Figure 7:

Annual Mean Dust Concentrations and Annual Estimated Mean Fibre Concentrations: Selected Factory Units 1959–2001

Discussion

The Asbest Study provides one of the largest pools of parallel dust and fibre measurement from which conversion factors could be derived for chrysotile mining and processing. Our comparison showed differences in the modelled fibre to dust ratio by unit in the factories, and season in the open-pit mine, which were strongly dependent on measured dust levels. There was very little difference between the modelled data using the daily median concentrations and daily mean concentrations. We chose to use the daily median concentrations as they are less sensitive to individual outliers. The three major findings from our analysis were 1) the variability of fibre to dust ratio by unit in the factories, 2) the dependency of the fibre to dust ratio on dust level, and 3) higher fibre to dust ratios in the winter in the mine.

Previous work has highlighted differences between and within study sites when deriving conversion factors. For example, Puledda and Marconi (23)’s pooled analysis included a chrysotile mining and milling plant divided into four categories with three ranges of conversion factors per process: splitting (0.4–0.7), oven drying (1.8–3.4), silo sorting (4.0–4.9), and packing (1.7–2.1) (23). For the broadly equivalent units of Uralasbest, the random unit effect estimates were 0.65 (“Crushing and sorting: main”), 0.73 (“Crushing and sorting: drying and boiler”), 1.20 (“Enrichment: main”) and 1.08 (“Final product (packaging)”), respectively. The individual dust and fibre concentrations in the Puledda and Marconi study were lower than those measured at the UralAsbest data. The fibre to dust ratios increased when the dust concentration decreased in both studies.

Other studies reporting conversions of dust were predominantly in other industries or using different measurement methods or units of measurements thus making the resulting conversion factors difficult to compare (4,7,21,36). Many were in textile factories where finished, enriched asbestos is used compared to Uralasbest where the processing involved multiple stages of crushing and enriching asbestos containing ore. Some parts of textile manufacturing could be compared to the Uralasbest “Final product (packaging)” unit, where the enriched asbestos is packaged for commercial use. A chrysotile asbestos textile plant in Chongqing, China, the fibre to dust ratio in the raw materials workshop was 2.32, twice as high as the ratio from Uralasbest for “Final product (packaging)” (4). This study used a similar gravimetric measurement method for assessing the dust concentration and a similar counting method for fibres as the Asbest Study but, although it was not reported by Deng et al (4), the samplers used and their efficiency were most likely different to those used at Uralasbest. Thus, fibre to dust ratios from the few reported in textile industries appear to be comparably higher, perhaps reflecting higher levels of airborne fibre concentrations as part of the textile treatment process or lower levels of dust as only the enriched product is used. From these comparisons, we can also see that fibre to dust ratios and conversion factors are industry, work process and study site specific.

There was a clear dependency of the fibre to dust ratio on measured dust levels in the Uralasbest data; for every 1 mg/m3 increase in dust concentration the fibre to dust ratio decreased by 9% in the factories and 20% in the mine. Identifying the same phenomenon, Puledda and Marconi (23) noted two potential explanations. One, increased dust concentrations might result in overloading of the filter rendering fibre counting more difficult and less precise. Two, the presence of other dust sources in the environment increases the dust concentration but has no impact on the fibres and thus lowers the fibre to dust ratio. In their study, dust and fibre measurements were taken using the same filters from which they saw a direct effect of excessive dust on the ability to count fibres (23). They noted that non-asbestos particulates interfered with the fibre count and influenced the conversion factor, but no adjustment was made to allow for excessive dust density (23). Supplementary analyses on our data considered measured dust and sampling duration of the fibre sample. We saw that fibre sampling duration was clearly dependent on dust concentration. That is, when high dust concentrations (over 10 mg/m3) were recorded at a sampling point, the parallel fibre sampling duration at that sampling point was only 1 or 5 minutes. Whereas at sampling points with low dust concentrations, the fibre sampling durations were over 10 minutes. This was a result of the CL’ s measurement strategy and procedures which included pilot fibre and dust measurements at each sampling point to minimize the risk of overloaded filters. Therefore overloading of fibre filters from non-asbestos dust particles was unlikely in our study and the lower fibre to dust ratios are not expected to be a result of problematic fibre counting due to overloading of filters used in the fibre measurements but more likely to be a result of non-asbestos fibres containing dusts from other sources.

We saw evidence of seasonal differences in ratios in the mine, with ratios from the winter months being 67% higher than those from the summer months. In an open-pit mine such as this, snow coverage reduces the amount of airborne dust in the air leading to lower dust concentrations but this does not seem to impact fibre counts to the same extent thus resulting in higher fibre to dust ratios in winter. Seasonal differences should be interpreted cautiously in the mine as the winter measurements were all collected in 2013/14 (n=21) whereas the summer concentrations taken in 2007 (n=60) and 2013/14 (n=21). Other factors may have played a role, but seasonal differences appear to be the most likely explanation for the higher ratios seen in the winter. On the other hand, in the factories, the fibre to dust ratio increased only slightly in the winter compared to the summer suggesting that season did not affect the ratios.

It is important to note the inherent assumptions in this analysis and the potential to introduce error when converting dust to fibre concentrations. Although 620 parallel dust and fibre concentrations were analysed to derive these conversion factors, samples were available for only two factories of Uralasbest and only from recent years of production. The parallel samples were taken either at the end or after the time period (1951 to 2010) for which exposure will have to be estimated in the cohort study (25). Applying conversion factors from these data to dust concentrations collected 40–60 years earlier will be challenging. Dust concentrations measured and included in the conversion data (for all years of sampling) were up to 15 mg/m3. Applying our model to estimate fibre concentrations at dust levels above 15 mg/m3 (which occurred prior to 1960) would lead to unrealistically low fibre concentrations. For this reason, in this analysis we calculated the annual geometric means from the historic dust concentrations and only estimated the annual fibre concentrations were the dust geometric mean was ≤ 15mg/m3. We are also aware that exposure to asbestos might have altered over time for instance due to change in the percentage of asbestos in the ore. The ratios derived using data from three independent projects conducted in different time periods showed that the ratios generally decreased over time and were not constant. Extrapolating to earlier years should be done with caution, especially considering that process automation and the introduction of more modern technologies, changed mining and asbestos processing practices and allowed for enrichment of ore with lower chrysotile content. We have no ability to account for these changes in our model.

Conclusion

In conclusion, our analysis has shown that the ratios of fibre to dust concentrations from Uralasbest are significantly different by unit in the factory and, in the mine, by season. The fibre to dust ratio also appeared to be strongly dependent on the airborne dust levels present. Our study shows that the conversion of asbestos dust to fibre is possible for dust exposure under 15 mg/m3. However, it should be done at the unit level with adjustment for actual dust concentrations present. Applying the derived fibre to dust ratios where dust concentrations were >15 mg/m3 will require additional assumptions to be made. From this we will be able to estimate historical fibre exposure for epidemiological exposure response analyses in the Asbest Study. However, estimates of (cumulative) airborne dust exposure will remain an unequivocal measure of exposure compared to estimated fibre concentrations given the availability of dust exposure measurements over 5 decades.

Highlights:

This is one of the largest reported analyses of parallel dust and fibre measurements in a chrysotile mine and processing factories to date.

Conversion factors from dust to fibres varied by unit and, in the mine, by season. They were also dependent on actual dust concentrations.

These results enable estimation of historical fibre exposure for epidemiological exposure response analyses.

Acknowledgements

We acknowledge the work conducted by the extended study team, especially those involved in data entry. The study is monitored by an independent Scientific Advisory Board (SAB), which oversees the progress of the study, and we thank the SAB members - Professor Franco Merletti, Professor Mads Melbye, Professor Julian Peto and Dr Antti Tossavainen – for their helpful comments.

Funding

This study is funded by the Ministry of Health of the Russian Federation in the framework of the Federal target programme “National System of Chemical and Biological Safety of the Russian Federation (2009–2014)” under a general framework of action between the Federal state budgetary scientific institution “Scientific Research Institute of Occupational Health” and the International Agency for Research on Cancer (IARC). EF’s work is being undertaken during the tenure of an IARC-Australia Postdoctoral Fellowship from the International Agency for Research on Cancer, supported by Cancer Council Australia (CCA). This research was supported in part by the National Cancer Institute (NCI) intramural research program, National Institutes of Health.

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

Conflict of Interest

In relation to the Declarations of Interests from the Russian collaborators from SRIOH (Dr Evgeny Kovalevskiy; EK) and the Yekaterinburg Medical Research Center (Dr Sergey Kashansky; SK), the following was declared: EK and SK reported receiving, on behalf of their institutes and personally through consulting firms, payments from companies to evaluate exposure to asbestos and risk of asbestos-related disease in those workplaces. EK and SK reported attending meetings organized by the International Chrysotile Association and reported that all expenses for attendance were paid by their respective institutes. EK reported participation as an occupational and environmental health expert as part of the delegation of the Russian Ministry of Health at multiple World Health Assembly meetings as well as at the Conference of the Parties to the Basel and Rotterdam Conventions. The authors have no other conflicts of interest to declare.

Russian Academy Medical Sciences (SRIOH), Ekaterinburg Medical Research Center (EMRC), Finnish Institute Occupational Health (FOH) and US National Institute for Occupational Safety and Hygiene (NIOSH).

Contributor Information

Eleonora Feletto, Section of Environment and Radiation, International Agency for Research on Cancer, Lyon, France.

Sara J Schonfeld, Division of Cancer Epidemiology and Genetics, National Cancer Institute, National Institutes of Health, Bethesda, MD, USA.

Sergey V Kashanskiy, Yekaterinburg Medical Research Center for Prophylaxis and Health Protection in Industrial Workers, Yekaterinburg, Russian Federation.

Monika Moissonnier, Section of Environment and Radiation, International Agency for Research on Cancer, Lyon, France.

Kurt Straif, Section of IARC Monographs, International Agency for Research on Cancer, Lyon, France.

Joachim Schüz, Section of Environment and Radiation, International Agency for Research on Cancer, Lyon, France.

Hans Kromhout, Division of Environmental Epidemiology, Institute for Risk Assessment Sciences, Utrecht University, Utrecht, The Netherlands.

References

- 1.World Health Organization; WHO air quality guidelines for Europe [Internet]. Copenhagen: World Health Organization Regional Office for Europe; 2000. [cited 2015 May 18]. Report No.: 2nd Edition Available from: http://www.euro.who.int/en/health-topics/environment-and-health/air-quality/publications/pre2009/who-air-quality-guidelines-for-europe,−2nd-edition,−2000-cd-rom-version [Google Scholar]

- 2.IARC Working Group on the Evaluation of Carcinogenic Risks to Humans. IARC Monographs: Arsenic, Metals, Fibres, and Dusts [Internet] Vol. Volume 100C A review of human carcinogens. Lyon: International Agency for Research on Cancer; 2012. Available from: http://monographs.iarc.fr/ENG/Monographs/vol100C/ [PMC free article] [PubMed] [Google Scholar]

- 3.Dement JM, Harris RL, Symons MJ, Shy CM. Exposures and mortality among chrysotile asbestos workers. Part II: mortality. Am J Ind Med. 1983;4(3):421–33. [DOI] [PubMed] [Google Scholar]

- 4.Deng Q, Wang X, Wang M, Lan Y. Exposure-response relationship between chrysotile exposure and mortality from lung cancer and asbestosis. Occup Environ Med. 2012. February;69(2):81–6. [DOI] [PubMed] [Google Scholar]

- 5.Elliott L, Loomis D, Dement J, Hein MJ, Richardson D, Stayner L. Lung cancer mortality in North Carolina and South Carolina chrysotile asbestos textile workers. Occup Environ Med. 2012. January 20;oemed-2011–100229. [DOI] [PubMed] [Google Scholar]

- 6.Hein MJ, Stayner LT, Lehman E, Dement JM. Follow-up study of chrysotile textile workers: cohort mortality and exposure-response. Occup Environ Med. 2007. September;64(9):616–25. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Loomis D, Dement JM, Wolf SH, Richardson DB. Lung cancer mortality and fibre exposures among North Carolina asbestos textile workers. Occup Environ Med. 2009. August;66(8):535–42. [DOI] [PubMed] [Google Scholar]

- 8.Loomis D, Dement JM, Elliott L, Richardson D, Kuempel ED, Stayner L. Increased lung cancer mortality among chrysotile asbestos textile workers is more strongly associated with exposure to long thin fibres. Occup Environ Med. 2012. August;69(8):564–8. [DOI] [PubMed] [Google Scholar]

- 9.Sichletidis L, Chloros D, Spyratos D, Haidich A-B, Fourkiotou I, Kakoura M, et al. Mortality from occupational exposure to relatively pure chrysotile: a 39-year study. Respir Int Rev Thorac Dis. 2009;78(1):63–8. [DOI] [PubMed] [Google Scholar]

- 10.Wang X, Yano E, Lin S, Yu ITS, Lan Y, Tse LA, et al. Cancer Mortality in Chinese Chrysotile Asbestos Miners: Exposure-Response Relationships. PLoS ONE. 2013. August 21;8(8):e71899. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Acheson ED, Gardner MJ, Pippard EC, Grime LP. Mortality of two groups of women who manufactured gas masks from chrysotile and crocidolite asbestos: a 40-year follow-up. Br J Ind Med. 1982. November;39(4):344–8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Mirabelli D, Calisti R, Barone-Adesi F, Fornero E, Merletti F, Magnani C. Excess of mesotheliomas after exposure to chrysotile in Balangero, Italy. Occup Environ Med. 2008. December;65(12):815–9. [DOI] [PubMed] [Google Scholar]

- 13.Ohlson CG, Hogstedt C. Lung cancer among asbestos cement workers. A Swedish cohort study and a review. Br J Ind Med. 1985. June;42(6):397–402. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Harries PG. A Comparison of Mass and Fibre Concentrations of Asbestos Dust in Shipyard Insulation Processes. Ann Occup Hyg. 1971. September 1;14(3):235–40. [DOI] [PubMed] [Google Scholar]

- 15.Dement JM, Kuempel ED, Zumwalde RD, Smith RJ, Stayner LT, Loomis D. Development of a fibre size-specific job-exposure matrix for airborne asbestos fibres. Occup Environ Med. 2008. September;65(9):605–12. [DOI] [PubMed] [Google Scholar]

- 16.Dement JM, Harris RL, Symons MJ, Shy CM. Exposures and mortality among chrysotile asbestos workers. Part I: exposure estimates. Am J Ind Med. 1983;4(3):399–419. [DOI] [PubMed] [Google Scholar]

- 17.Lin S, Wang X, Yano E, Yu I, Lan Y, Courtice MN, et al. Exposure to chrysotile mining dust and digestive cancer mortality in a Chinese miner/miller cohort. Occup Environ Med. 2014. May;71(5):323–8. [DOI] [PubMed] [Google Scholar]

- 18.Liddell FDK, McDonald AD, McDonald JC. The 1891–1920 Birth Cohort of Quebec Chrysotile Miners and Millers: Development from 1904 and Mortality to 1992. Ann Occup Hyg. 1997. January 1;41(1):13–36. [DOI] [PubMed] [Google Scholar]

- 19.McDonald AD, Fry JS, Woolley AJ, McDonald JC. Dust exposure and mortality in an American chrysotile asbestos friction products plant. Br J Ind Med. 1984. May;41(2):151–7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Council of the European Communities. Council Directive of 19 March 1987 on the prevention and reduction of environmental pollution by asbestos OJL 85, 28.3.1987, p.40). 1987. [Google Scholar]

- 21.Dodic-Fikfak M An experiment to develop conversion factors to standardise measurements of airborne asbestos. Arh Hig Rada Toksikol. 2007. June;58(2):179–85. [DOI] [PubMed] [Google Scholar]

- 22.Peto J Fibre carginogensis and environmental hazards In: Bignon J, Peto J, Saracci R, editors. Non-Occupational Exposure to Mineral Fibres. Lyon: International Agency for Research on Cancer; 1989. [Google Scholar]

- 23.Puledda S, Marconi A. Study of the count-to-mass conversion factor for asbestos fibres in samples collected at the emissions of three industrial plants. Ann Occup Hyg. 1991. Oct;35(5):517–24. [DOI] [PubMed] [Google Scholar]

- 24.Virta RL, Flanagan DM. US Geological Survey: 2014 Minerals Yearbook: Asbestos. Washington DC: US Department of the Interior; 2015. [Google Scholar]

- 25.Schüz J, Schonfeld SJ, Kromhout H, Straif K, Kashanskiy SV, Kovalevskiy EV, et al. A retrospective cohort study of cancer mortality in employees of a Russian chrysotile asbestos mine and mills: Study rationale and key features. Cancer Epidemiol. 2013. August;37(4):440–5. [DOI] [PubMed] [Google Scholar]

- 26.Schonfeld SJ, Kovalevskiy EV, Feletto E, Bukhtiyarov IV, Kashanskiy SV, Moissonnier M, et al. Temporal trends in airborne dust concentrations at a large chrysotile mine and its asbestos-enrichment factories in the Russian Federation during 1951–2001. Unpublished results; [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Kashansky SV, Domnin SG, Kochelayev VA, Monakhov DD, Kogan FM. Retrospective View of Airborne Dust Levels in Workplace of a Chrysotile Mine in Ural, Russia. Ind Health. 2001;39(2):51–6. [DOI] [PubMed] [Google Scholar]

- 28.Tossavainen A, Riala R, Zitting A, Parker J, Jones W, Groce D, et al. Health and exposure surveillance of Siberian asbestos miners: A joint Finnish–American–Russian project. Am J Ind Med. 1999. September 1;36(S1):142–4. [DOI] [PubMed] [Google Scholar]

- 29.Finnish Institute of Occupational Health, National Institute for Occupational Safety and Health, Russian Academy of Medical Services, Institute of Occupational Health, Medical Research Center for Prophylactic and Health Protection of Industrial Workers. Dust Measurements in the Chrysotile Mining and Milling Operations of UralAsbest Company, Asbest, Russia. Helsinki; 1996. [Google Scholar]

- 30.GOST. (State Standard) 12.1.005–88. SSBT. Working Environment Air. General Sanitary Requirements. Moscow: Izd. Standartov; 1988. [Google Scholar]

- 31.R 2.2.2006–05. Rukovodstvo po gigienicheskoy otsenke faktorov rabochey sredy i trudovogo protsessa. Kriterii i klassifikatsiya usloviy truda (Guidance 2.2.2006–05. Guidance for hygienic assessment of factors of working environment and labor process. Criterion and classification of labor conditions)2005. No. 3. (in Russian).Byulleten normativnykh i metodicheskikh dokumentov Gossanepidnadzora = Bulletin of normative and methodical documents of Russian Federation Oversight Committee for Sanitation and Epidemiology. 2005;3. [Google Scholar]

- 32.Asbestos International Association. Reference method for the determination of airborne asbestos fibre concentrations at workplaces by light microscopy (membrane filter method). London: Asbestos International Association; 1988. Report No.: (AIA Recommended Technical Method No. 1). [Google Scholar]

- 33.Agency for Toxic Substances & Disease Registry. Toxicological Profile for Asbestos [Internet]. Georgia: Agency for Toxic Substances & Disease Registry; 2001. [cited 2015 Jul 21]. Report No.: CAS#: 1332-21-4. Available from: http://www.atsdr.cdc.gov/ToxProfiles/tp.asp?id=30&tid=4 [PubMed] [Google Scholar]

- 34.Robinson GK. That BLUP is a Good Thing: The Estimation of Random Effects. Stat Sci. 1991. February 1;6(1):15–32. [Google Scholar]

- 35.Greven S, Kneib T. On the behaviour of marginal and conditional AIC in linear mixed models. Biometrika. 2010. December 1;97(4):773–89. [Google Scholar]

- 36.Dement JM, Myers D, Loomis D, Richardson D, Wolf S. Estimates of historical exposures by phase contrast and transmission electron microscopy in North Carolina USA asbestos textile plants. Occup Environ Med. 2009. September;66(9):574–83. [DOI] [PubMed] [Google Scholar]