Abstract

Mimicking nature implies the use of bio-inspired hierarchical designs for the manufacturing of nanostructured materials. Such materials could be produced from sustainable sources (e.g., biomass) and through simple processes that use mild conditions, enabling sustainable solutions. The combination of different types of nanomaterials, and the implementation of different features at different length scales, can provide synthetic hierarchical nanostructures that mimic natural materials, outperforming the properties of their constitutive building blocks. Taking as starting point recent developments in flow-assisted assembly of nanocellulose crystals, here we review the state of the art to provide future perspectives in the field of hierarchical nanostructured materials from sustainable sources, their assembly techniques, and their potential applications.

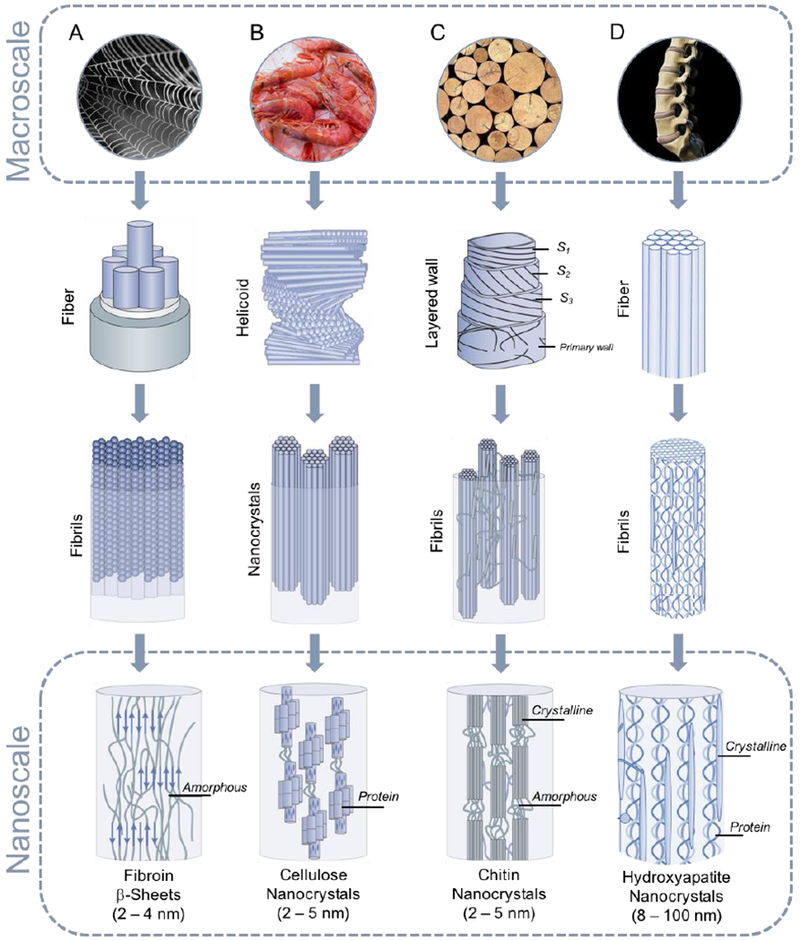

Nature creates sophisticated materials with remarkable properties and multiple functions. These materials are usually constituted by simple molecular building blocks (e.g., amino acids, carbohydrates) whose behavior is governed by their size, folding, assembly, interphases, and other features at the nanoscale [1]. This usually comes in finely-defined hierarchical structures that bridge the macro-scale properties with atomistic scale components. Many natural materials like cellulose in wood [2], chitin in crustaceous and insects [3], [4], fibroin in spider [5] and silkworm silk, exhibit hierarchical structures made of nanofibrils [6] (Figure 1). Others like nacre in pearls, present hierarchical structures in the form of brick and mortar architectures [7]. These and other natural materials (e.g. bone) share the capacity to display multiple functions and a mechanical performance superior to its individual building blocks.

Figure 1.

An overview of different hierarchical materials in Nature, and how do they go thorough different assembled structures from the macroscale down to the nanoscale.A. Schematic representation of spider silk hierarchical structure for which silk fibroin is the main component (Figure adapted from Ref. 8).B. Schematic representation of wood hierarchical structure emphasizing the role of cellulose nanocrystals (Figure adapted from Ref. 8).C. Schematic representation of chitin hierarchical structure in the scaffold of crustaceous (Figure adapted from Ref. 8). D. Schematic representation of bone hierarchical structure, with emphasis on hydroxyapatite crystals and collagen protein (Figure adapted from Ref. 2).

Inspired by Nature, nanoscale science and nanotechnology, supramolecular chemistry and self-assembly techniques have proven that indeed there is “plenty of room at the bottom” for the development of man-made hierarchical nanostructured materials [2], [8] with unique properties that differ from those of their bulk counterparts. This is owed to several factors, such as a high surface to volume ratio, quantum mechanics effects arising from a size comparable to the wavelengths of electrons and photons, or the high capacity of nanostructures to distribute stress or deflect cracks, just to name a few. All these provide additional room for engineers to invent novel, complex bioinspired nanoarchitectures with hierarchical designs and tailored properties [9], [10] that take Nature as a guide [11], [12], [13], [14].

There are two primary bottlenecks in the development of nanostructured hierarchical materials. The first one is that our technologies are still far from being able to truly mimic Nature, and thus transferring of the superior properties caused by nanoscale effects to the macroscale represents a great engineering challenge due to the necessity to organize fundamental building blocks from the nanoscale into hierarchical structures with high level of precision, while forestalling the appearance of defects emerging from processing and assembly at larger scales. The second bottleneck is related to the sustainability of nanostructured hierarchical materials. It is of the utmost importance to develop a circular economy that keeps resources in use as long as possible, manufacturing them in a facile, low-cost, and environmentally friendly manner. New synthetic and processing methods like the one reported by Mittal et al. [15] for the assembly of nanocrystals, in combination with multiscale modeling and machine learning techniques are the path to follow towards overcoming these bottlenecks. Starting from the recent progress in controlling the alignment of cellulose nanofibrils, we discuss current scientific research and the future improvements on utilizing biomass-derived nanostructured materials.

Natural nanostructured hierarchical materials: learning from Nature how to control small features

Natural materials consist of repetitive sequences made of simple building blocks that provide the wide variety of properties and functions [16], e.g., hydrophilic and hydrophobic segments of amino acids in silk, β-(1,4)-linked D-glucose units in cellulose, long-chain polymers of (1,4)-β-N-acetylglucosamine in chitin, aragonite brick and mortar structures in nacre, and hydroxyapatite crystals in bone. Besides their composition, these natural materials present some unique hierarchical designs that make them outperform their individual building blocks [9], [17], governing as well their deformation and fracture mechanisms [18], [19], [20]. Inspiration can be taken from them to develop smart nanostructured materials [21].

For instance, chitin is arranged in a 3D helicoid structural motif with important effects on both the mechanical and optical properties of the exoskeleton of arthropods and insects [3], [4], nacre has a relatively simple brick-wall-like architecture composed of polygonal tablets [22], while bone has a complex hierarchical structure [23], [24] with hydroxyapatite crystals (HAP) embedded in a matrix of self-assembled individual tropocollagen molecules interacting through coordinated hydrogen bonds [25].

Featuring a different multiscale arrangement, wood is organized in a hierarchical structure with highly oriented cellulose nanofibrils, which helically wind along the longitudinal cell axis, controlling its mechanical anisotropy [13]. Wood is mainly composed of three major molecules: cellulose, hemicellulose and lignin (see Figure 1). Despite this simple chemical composition, it shows exceptional mechanical properties because of its hierarchical structure. Cellulose is arranged into crystalline ultra slim crystals with lateral dimensions of a few nanometers, and a length of hundreds of nanometers. Hydrogen bonds stabilize the cellulose nanofibril bundles, while the continuous covalent bonding along the nanofibrils provides outstanding stiffness and strength: ∼ 150 GPa of modulus and ∼ 6 GPa of tensile strength [26], [27]. The amorphous matrix composed of a mixture of hemicellulose and lignin contributes to the toughness by introducing the intermolecular sliding mechanisms that can dissipate energy under stress [28], [29], [30].

In silk, the excellent mechanical properties originate from its protein sequence, which triggers a self-assembly process that results in a highly ordered nanostructure stabilized through non-covalent interactions, i.e., hydrogen bonds and electrostatic interactions. For many years, silk has been considered the gold standard of highly organized lightweight biopolymers, due to its extremely high strength and toughness. The building blocks {i.e., amino acids) are confined to a critical nanoscale with β-sheet nanocrystals of a few nanometers (2-5 nm) that optimizes strength, stiffness and toughness, through a consequent dissipative molecular stick–slip deformation that would not be possible with larger nanocrystals [31].

Overall, nanoconfinement, nanofibril orientation, helicoidal stacking, and nanocrystals alignment are common features to most of the materials that we just discussed. Understanding the mechanisms that govern these and other natural materials will help us in designing a new generation of processing techniques and nanostructured materials with superior mechanical performance, stimuli-responsive features, self-healing mechanism, or slow crack propagation behaviors.

Biomass-derived materials: towards a circular economy

Mimicking Nature in material science goes beyond hierarchical designs of nanostructured materials and also into the development of more efficient and sustainable pathways to produce them. It includes searching resources for a sustainable production of materials to move towards a circular economy that mimics the well-integrated cycles that Nature has developed over millions of years to efficiently reuse scarce resources. Although the utilization of biomass has typically focused on biofuel research, it has arisen as a widely-available source for the synthesis of carbon materials [32], [33]. Many interesting building blocks (e.g., cellulose, lignin, chitin, amino acids) can be obtained from the depolymerization of biomass. The development of advanced biomass-processing technologies is a great challenge[34] that has impact in many different areas, such as energy storage [35], [36], catalysis, civil infrastructure or CO2 capturing. Thus far, biomass-derived materials have been generated from a wide range of sources including bacterial cellulose, lignin, cornstalk, corn starch, sweet potato, peanut shells, pinecone hull, banana skins, cherry stones, or bamboo chopsticks [37], [38].

Wood (i.e., lignocellulosic biomass) is of special interest because of the chemical composition of its fundamental building blocks [39]. There are two approaches for the utilization of wood. On the one hand, the hierarchical cellular structure of wood itself is a great platform for engineering applications. Wood is a lightweight material that can rival with steel and other engineering materials in specific modulus and strength. On the other hand, technological advances in the past decades have facilitated the depolymerization of wood into its building blocks (cellulose, hemicellulose and lignin) and its implementation for different applications. Cellulose can be isolated into a one-dimensional crystalline material referred to as nanocellulose [40], [41], [42], [43], which can be mainly classified into cellulose nanocrystals and cellulose nanofibers. The potential applications of cellulose nanomaterials [44] are countless. In biomedicine, it can be used for in situ softening of implants, cartilage replacements, drug delivery systems, DNA extraction, antibacterial additive, wound healing and tissue engineering [45], [46]. Hydrogels purely based on nanocellulose or in combination with other materials can be also applied to tissue engineering scaffolds, wound healing materials, and drug delivery systems [47]. Ultralight, strong and flexible foams and aerogels can be formed mainly by ice templating to generate iso- or anisotropic foams for its implementation as scaffolds in biomedical applications, as well as in energy storage systems [48]. Also related to energy applications [49], [50], nanocellulose has been used to manufacture high strength electrodes, flexible devices [51] and supercapacitors [52]. Moreover, the multi-channel feature of wood has been utilized to develop sustainable water-treatment membranes [53]. The strong cellulose fibrils can be also used as reinforcement agent for high-performance composite materials [54]. It is expected that self-assembly [55] and biomimetics [56], [57] will have a high impact on the developments related to nanocellulose.

Chitin is the second most abundant natural polysaccharide on Earth, and it has similar functionalities to cellulose. While cellulose is a structural material in the cell walls of plants, chitin is the main constituent of the cell walls of fungi, the exoskeletons of insects, crustaceans and radulae of mollusks. Although composite materials from self-assembled chitin nanofibers and microporous chitin materials has been produced [58], the potential of chitin has been largely under-utilized due to poor solubility and processing difficulties. Future research could be directed towards two areas. The first one is the production of oriented nanofibrils with controlled anisotropy effects. New techniques like the microfluidic one developed by Mittal et al. [15] are a good approach in this regard. The second area is the combination of chitin fibers with other materials, such as chitin-nanocellulose blends, for the development of advanced composites with enhanced mechanical properties [59].

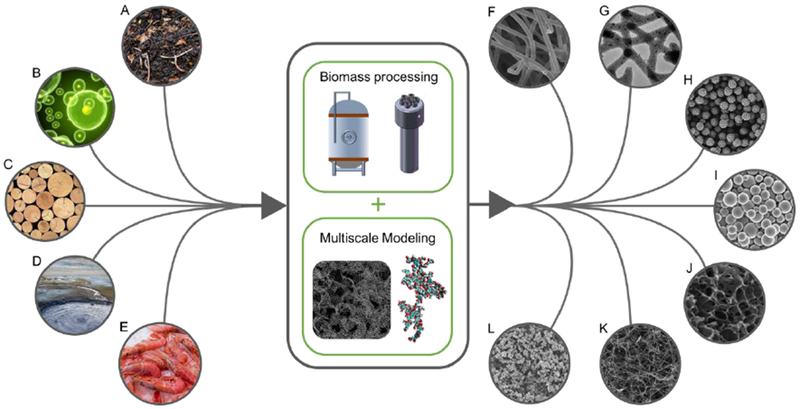

Research on biomass-derived nanostructures materials should not only focused on the mimicry of natural polymers. It also offers the possibility of creating de novo advanced carbon materials. As shown in Figure 2, the processing of natural sources in combination with multiscale modeling techniques has the potential to produce a wide range of nanostructured materials. Hydrothermal conversion is one of the most promising techniques in this regard. It offers the possibility of depolymerize biomass into simple building blocks and combined them with other components, to form composite materials with special chemical and physical properties [60], [61]. As a leader in this field, the Titirici group [33] has applied hydrothermal conversion to produce carbon materials with different sizes, shapes, and controllable morphology and surface functional groups, e.g. morphology-controlled synthesis of carbonaceous nanospheres from sugar, glucose, cyclodextrins, fructose, sucrose, cellulose, and starch. The performance of this materials has shown promising results in areas like photovoltaics, batteries, microbial fuel cells or catalysis [62]. Hydrothermal conversion holds great promises for the utilization of biomass resources in the manufacture of nanostructured hierarchical materials. Moreover, differently from fossil carbon materials, the use of biomass can provide doping elements to the resulting materials, which confer them unique electronic properties. Research in this area should focus on understanding how key process parameters (e.g., temperature, pressure, reaction time, biomass:water ratio) affect the nanostructure and chemistry of the resulting carbon materials.

Figure 2.

Schematic representation of some examples of biomass sources to be transformed into tailored nanostructured materials through different processing techniques in combination with predictive multiscale modeling. A. Manure. B. Microalgae. C. Wood. D. Sewage sludge. E. Crustaceous scaffolds. F. SEM micrograph of silver-carbon nanostructured composites from Ref. 61. G. TEM micrograph of Pt nanoparticles loaded coating carbon nanofibers from ref. 60. H. SEM micrograph of sucrose-derived carbon nanospheres produced from ref. 62. I. SEM micrograph of furfural-derived carbon nanospheres produced from ref. 62. J. SEM micrograph of microporous chitin from ref. 58. K. SEM micrograph of a freeze dried bacterial cellulose sample from ref 43.L. SEM micrograph of fructose-derived carbon nanospheres produced from ref. 62.

Energy storage is the archetype of how overcoming the two aforementioned bottlenecks in nanostructured materials (capacity of controlling nanoscale features and using sustainable resources) could greatly impact the economic success of a sector. The is a great deal of attention devoted to the development of nanostructured materials to replace conventional materials [63] for hydrogen storage systems [64], supercapacitors [65], Li/ion batteries [66], [67], biofuel cells [68], and redox flow batteries [66]. Coming developments are expected to provide high specific surface area, controllable porosity, high electronic conductivity, better-performing electroactive sites, high thermal stability [65], and engineered water pathways in electrodes [69], [70]. Producing those electrodes with controlled porosity and surface chemistry from biomass sources through hydrothermal conversion can improve the electron transfer [71] due to e.g., the effect of nitrogen-doping.

Multiscale control of assembly and self-organization

The current advances in nanotechnology, characterization of materials, microfluidics, and synthesis techniques, among others, has enabled the control of the arrangement of atoms and molecules at the nanoscale to produce nanostructured materials with 1D, 2D and 3D structures, that incorporate oriented nanofibrils, nanocrystals, and other geometrical features at the nanoscale, with properties arising from the nanoconfinement of electrons or from electrostatic interactions, among others. Spinning techniques mimic spider’s mechanism to produce ID nanofibrils. More complex mechanisms that incorporate electric or magnetic fields can lead the formation of 2D materials such as membranes and nanopapers. All these approaches provide avenues for the replication and expansion of the properties of nature self-assembled biomaterials like chitin, wood or silk, to yield lightweight, biocompatible and mechanically resistant novel biomaterials with unique electrical, thermal or optical properties.

The combination of different building blocks into complex architectures has opened unprecedented opportunities in materials science and engineering, with impact in all areas of humans’ life, like biomedicine [72], [73], infrastructure [74], hydrogen production [75], water desalination [76], and even preservation of cultural heritage [77], just to mention a few. Many of these nanostructured materials need very good mechanical performance in addition to properties specific to their area of application. Whether they are biomaterials, polymer-based materials, inorganic nanoparticles, carbon nanomaterials, or a combination of all of them, the implementation of bioinspired hierarchical designs that mimic natural materials, will improve the durability and performance under working conditions.

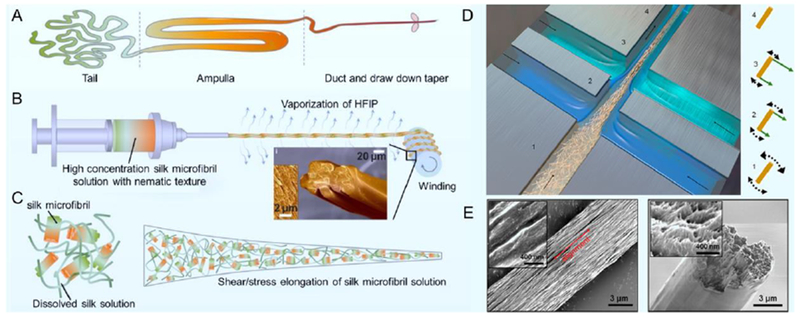

An area of great interest is the development of dense macroscopic fibers from nanocellulose fibrils that can synergistically take load to maximize the stiffness and strength, in the same way as silk, chitin or cellulose fibers do in Nature. Various techniques are being developed in this regard, including wet and dry spinning techniques. All these processes resemble how spiders convert an aqueous solution of short amino acid chains into a robust silk fiber. This process is based on the application of shear stress to stabilize interactions within nanofibrils so that they self-assemble aligned fibers (Figure 3. A-C) [78]. The mechanical properties of the resulting fibers appeared to be highly dependent on the extrusion and reeling speed.

Figure 3.

A. An illustration of the silkworm spinning process in the spinning gland. B. A bioinspired spinning process that ensambles nematic silk microfibril solution into regenerated silk fibers. The inset shows a SEM image of the fiber cross section, showing the silk microfibrils are well aligned. C. Schematic of how the silk microfibrils are aligned under the shear/stress elongation. (Figures A-C adapted from Ref. 78). D. The double flow-focusing channel used for cellulose nanofibril assembly in Ref. 15. Hydrodynamic and electrostatic interactions at different positions are arranged to maximize the nanofibril alignment. E. SEM image of the fiber surface and cross sections, showing the aligned nanofibrils (Figures D-E adapted from Ref. 15).

While this approach has made it possible to regenerate silk in the lab that surpasses the mechanical properties of natural silk[78], the mechanical properties of the nanocellulose fibers are usually far from the theoretical limits of crystalline cellulose. This calls for new techniques to enhance the alignment of the cellulose nanofibrils during the spinning process. The obstacle lies in front of forming perfectly aligned fibrils is the colloidal gelation of the nano-fibrils, which reduces the mobility of the fibrils under flow. Spiders play with the ionic concentration in the spinning solution to prevent this, and this has served as inspiration for the development of microfluidic setups for cellulose [79], [15]. Soderberg et al. proposed to combine electrostatic and hydrodynamic interactions to maximize the fibril alignment. The surface of cellulose fibrils was oxidized with carboxylic groups, which introduced electrical repulsions between the fibrils. As result, the fibrils were free to move and rotate before undergoing an extensional flow that aligned the fibrils. A second stage of extensional flow was incorporated before the final settling down, in order to prevent disorder because of the Brownian motion. Eventually, the fibrils were fixed thorugh colloidal gelation by removing the electrical repulsion through a protonation of the carboxylic groups. (Figure 3. D,E) The resulting fibrils feature a modulus up to 86 GPa and strength above 1 GPa.

As additive manufacturing emerges as an advanced technique of fast and reliable fabrication of hierarchical structures, spinning and self-assembly finds its role in this area. Printable inks composed cellulose fibrils have been developed and applied to build 3D structures, such as all-cellulose hydrogels or composite structures where cellulose fibrils work as mechanical reinforcement [80], [81], [82], [83]. As the ink is extruded from the printer syringe, the cellulose fibrils experience hydrodynamic forces that force the fibrils to be aligned along the printing direction. This results into anisotropic printed structures with higher mechanical stability along the printing direction. The anisotropy of the printed material opens possibility of creating patterned structures with various responses. In the work performed by Jeniffer Lewis’ group [81], various patterns were printed with the anisotropic swelling properties of the printed fibrils. The structures can achieve moisture-induced responsive deformation, which adds another dimensional of deformation. Future research in microfluidic or 3D printing of robust fibers could focus on the various ways of tuning the properties of the extruded fibers. This includes selecting the dimensions of the nanofibrils, which has been shown to a fundamental factor for controlling the macro-scale properties [84] or playing with the degree of repulsion in the nanofibrils suspension, for example by varying the degree of cellulose oxidization and the flow velocity. Printing hybrid, gradient structures with varying mechanical properties is also an area worth exploring.

While the cellulose alignment within natural wood inspires the development of techniques for aligning the fibrils. The wood cell wall itself is already an existing fibrils-aligned structure. Different from the approach of regenerating cellulose fibers from nano-fibrils, the research by Liangbing Hu et al. [85] choose to generate cellulose aligned materials directly from wood. By extracting most of the soft matrix molecules composed of lignin and hemicellulose, the resulted wood was further compressed into densified material for maximizing the inter-fibril interactions between the cellulose fibrils. The resulted material features modulus above 50 GPa and strength around 600 MPa. Although these are lower compared with all-cellulose materials because of the existence of residue hemicellulose and cellulose, this technique tends to be easier to be realized and is more suitable for bulk production. Due to the anisotropy from the alignment of nanocellulose fibrils, the materials developed from this technique also have been demonstrated for directional thermal conduction and mass transportation [86], [87].

Multiscale Modeling and computational challenges: materials by design

The material-by-design paradigm is expected to guide coming developments of hierarchical nanostructured materials, as it has been implemented for biomaterials, proteins, polymers, and nanomaterials. This paradigm synergistically integrates theoretical design at the atomic level, modeling of materials at the nano-meso-micro-scale, and additive manufacturing, synthetic chemistry, and process engineering at the macroscale, to develop materials according to specific rational designs. Recent progress in controlling the alignment of cellulose nanofibrils, and future improvements on utilizing biomass materials, also open fundamental questions for theory, and the opportunity to experimentally realize model designs.

Multiscale modeling provides a deep understanding of the structure-function and structure-properties relationships of materials. It implies quantum mechanics calculations, like those provided by Density Functional Theory (DFT), to describe the electronic structure of individual building blocks, and also larger-scale models to understand the structure of the materials up to the continuum level. In the case biomass-derived materials like cellulose, silk or chitin, it also aids in the development of better synthesis and processing techniques, as well as depolymerization strategies. Lignocellulosic biomass is a good example of a multiscale modeling approach that is able to describe all key fundamental features of such hierarchical material along different length scales [88]. This has made it possible to understand the role of the different components of wood and its spatial arrangements on the mechanical strength of lignocellulosic biomass. Multiscale modeling unlocked the role of hydrogen–bonding interactions of cellulose–hemicellulose systems and the covalent bond linkages of hemicellulose–lignin systems [89], as well as those related to the lignin-carbohydrate complex [90], in which the nature of the polysaccharide matrix induces selective binding with preferred orientations, affecting the architecture of the hemicellulose in the cell wall[91]. New computational tools have made possible to build virtual cellulose-hemicellulose networks by stochastic self-assembly [92]. Standalone models for lignin are needed to understand its structure and its role in lignocellulosic wood. New force fields [93], with special attention b–O–4 linkages open new perspectives for computational simulations of lignin and lignocellulosic biomass. CHARMM force field has been applied to study the influence of hydrogen–bonding assembly of cellulose and lignin [94].

The conversion of biomass-derived materials into usable materials, such as carbon fibers, membranes or hydrogels, can greatly benefit from the development of accurate computational models. In the case of lignocellulosic biomass, the development of tailored reactive force fields (ReaxFF) [95] or finite element models [96] are research efforts worth mentioning. In the case of silk, atomistic and coarse-grained molecular dynamics simulations have been used in combination with experiments to understand how processing conditions and design parameters control the anisotropy and self-assembly of fibers upon spinning [97], [98].

The complexity of the hierarchical structure along different large scales, together with computational limitations, call for the implementation of new methodologies in the field. Combined Quantum Mechanics/Molecular mechanics (QM/MM) approaches have become the method of choice for modeling reactions in many biomolecular systems [99]. They enable the modeling of reactive biomolecular systems at a reasonable computational effort while providing the necessary accuracy. Additionally, the use of machine learning (ML) is a rising instrumental tool for designing new molecules, materials and composites for future engineering applications. It allows computers to leam from past experience to detect patterns that are hard to discern in large complex data sets. ML is being increasingly used in materials science for speeding up simulations and designing new materials [100], compared to FEM and other traditional evaluation models.

Conclusions and outlook

The creation of nanostructured hierarchical materials with bioinspired and biomimetic designs will provide new sustainable functional materials. Wood, chitin and silk are examples of natural materials that possess multiple functions with superior mechanical properties mainly attributed to their hierarchical structure of nanofibrils, which are efficiently self-assembled under mild conditions with widely available bioresources. Current material production techniques impose the restriction that both macro- and nanoscales are manipulated simultaneously, which is expected to change with coming advanced nanotechnologies. Using computational modeling to understand and mimic the assembly and structural features of these materials enables multiscale, rational material design strategies to optimize structure–property–function relationships. Harnessing control over self-assembly processes, plus understanding the intricate connection between hierarchical structure and macroscopic properties, expands the materials space domain to rationally manufacture new bioinspired nanostructured materials. This allows us to aspire to go beyond the pure imitation Nature, creating novel properties through the combination of natural and/or non-natural building blocks. Some approaches in this direction has been already used in combination with microfluidic techniques to obtain nanocellulose macroscale fibers [15], or using solvent-biopolymer interactions for the development of robust silk hydrogels [101] and fibers [98]. Additionally, combined bottom-up and top-down approaches to simultaneously control macroscopic shape and nanoscale orientation of silk [102], or controlled self-assembly of short peptides into semiconductors [103], are promising strategies. Furthermore, creating composite materials that combine the properties of two or more of the natural biopolymers is also an innovative approach to obtain biomaterials with emerging properties, e.g., combining silk and nanocellulose through microfluidics processing [15] to create mechanically robust and bioactive materials, or using recombinant DNA techniques to combine silk and elastin domain into silk-elastin-like proteins (SELPs) to create novel protein-based biopolymers that present unique responses to changes in temperature, pH or biological triggers [104]. More complex processing routes (e.g., hydrothermal conversion) can turn widely available resources like wood or chitin into novel carbon-based materials. This has been achieved for instance by the thermal treatment of chitin to obtain carbon nanoparticles [105] that can significantly heat up upon laser irradiation [106], and could be use as stimuli receptors for thermoresponsive materials; or by carbonizing silk fabrics to yield conductive materials that preserve the nanostructure from silk but with a high conductivity that enables their use in highly sensitive wearable sensors [107].

The need for greener chemical processes imposes an additional requirement in the development of novel materials. These should be obtained from sustainable resources, and also display a combination of no toxicity and, especially in the biomedical sector, biocompatibility. This provides significant room for improvement, as many of the processes for converting bioresources like wood or silk into nanostructured materials make use of toxic chemical solvents and harsh processing conditions to depolymerize and convert those feedstocks into usable materials. So far, this is not transferable to scaled-up production, which is a significant hindrance in the use of these feedstock for commercialization of novel materials. Further improvements in scaled-up process are required to make these materials suitable for their real application.

Finally, it is important to remark the great potential that computational modeling holds for all these challenges. It can be applied for unlocking the structure-function relationships of natural materials, for assisting the development of synthetic materials, and for the discovery of advanced processing routes that maximize the properties of the resulting products. Developing more scalable quantum mechanics calculation codes, more accurate force fields for atomistic simulations, more advanced algorithms and theories that build and combine on the exiting ones, will improve additional prediction capabilities of specific functional outcomes. High-throughput computational screening and more importantly new artificial intelligence and machine learning algorithms applied to the field of materials discovery may provide unprecedented methodologies for the computational design of materials, as well as novel, even more effective routes, to improve the validation of nanostructured materials screening and design.

The combination of bioinspiration, multiscale modeling, high-throughput supercomputing, machine learning, nanotechnology, microfluidics, additive manufacturing, and processes engineering, is expected to generate a rise of hierarchical nanostructured materials from renewable sources in the years to come. Mimicking Nature is the way to go in terms of both designing and manufacturing nanostructured materials, and a combination of the above-mentioned techniques has the potential to face most of the challenges associated to such goal.

Bibliography

- [1].Meyers MA and Chen P-Y, Biological Materials Science: Biological Materials, Bioinspired Materials, and Biomaterials. Cambridge University Press, 2014. [Google Scholar]

- [2].Barthelat F, Yin Z, and Buehler MJ, “Structure and mechanics of interfaces in biological materials,” Nat. Rev. Mater, vol. 1, 2016. [Google Scholar]

- [3].Raabe D, Sachs C, and Romano P, “The crustacean exoskeleton as an example of a structurally and mechanically graded biological nanocomposite material,” Acta Mater, vol. 53, no. 15, pp. 4281–4292, 2005. [Google Scholar]

- [4].Fabritius H-O., et al. “Functional adaptation of crustacean exoskeletal elements through structural and compositional diversity: a combined experimental and theoretical study,” Bioinspir. Biomim, vol. 11, no. 5, p. 55006, 2016. [DOI] [PubMed] [Google Scholar]

- [5].Tao H, Kaplan DL, and Omenetto FG, “Silk materials - A road to sustainable high technology,”. Adv. Mater, vol. 24, no. 21, pp. 2824–2837, 2012. [DOI] [PubMed] [Google Scholar]

- [6].Neville AC, “Biology of fibrous composites: development beyond the cell membrane’ Cambridge University Press, 1993. [Google Scholar]

- [7].Gao HU., et al. “Mass production of bulk artificial nacre with excellent mechanical properties,”. nat. Commnn, vol. 8, no. 1, 2017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [8].Uing S, Kaplan DU, and Buehler MJ, “Nanofibrils in nature and materials engineering.” Nat. Rev. Mater, vol. 3, 2018. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [9].Sun H, Uuo Q, Hou C, and Uiu J, “Nanostructures based on protein self-assembly: From hierarchical construction to bioinspired materials,” Nano Today, vol. 14, pp. 16–41,2017. [Google Scholar]

- [10].Buehler MJ, “Uarge-Scale Hierarchical Molecular Modeling of Nanostructured Biological Materials,” J. Compnt. Theor. Ncmosci, vol. 3, no. 5, 2006. [Google Scholar]

- [11].Buehler MJ, Keten S, and Ackbarow T, “Theoretical and computational hierarchical nanomechanics of protein materials: Deformation and fracture,” Prog. Mater. Sci, vol. 53, no. 8, pp. 1101–1241,2008. [Google Scholar]

- [12].Pieters BJGE, van Eldijk MB, Nolte RJM, and Mecinović J, “Natural supramolecular protein assemblies,” Chem. Soc. Rev, vol. 45, no. 1, pp. 24–39, 2016. [DOI] [PubMed] [Google Scholar]

- [13].Fratzl P and Weinkamer R, “Nature’s hierarchical materials,” Prog. Mater. Sci, vol. 52, no. 8, pp. 1263–1334, 2007. [Google Scholar]

- [14].Ren Z, Guo Y, Uiu C-H, and Gao P-X, “Hierarchically nanostructured materials for sustainable environmental applications,” Front. Chem, vol. 1, no. November, pp. 1–22, 2013. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [15].Mittal N et al. , “Multiscale Control of Nanocellulose Assembly:,” ACS Nano, p. acsnano.8b01084, May 2018. [DOI] [PubMed] [Google Scholar]

- [16].Buehler MJ and Yung YC, “Deformation and failure of protein materials in physiologically extreme conditions and disease,” Nat. Mater, vol. 8, p. 175, Mar. 2009. [DOI] [PubMed] [Google Scholar]

- [17].Roth WJ, Gil B, Makowski W, Marszalek B, and Eliášová P, “Layer like porous materials with hierarchical structure,” Chem. Soc. Rev, vol. 45, no. 12, pp. 3400–3438, 2016. [DOI] [PubMed] [Google Scholar]

- [18].Dunlop JWC, Weinkamer R, and Fratzl P, “Artful interfaces within biological materials,” Mater. Today, vol. 14, no. 3, pp. 70–78, 2011. [Google Scholar]

- [19].Barthelat F, “Architectured materials in engineering and biology: fabrication, structure, mechanics and performance,” Int. Mater. Rev, vol. 60, no. 8, pp. 413–430, Nov. 2015. [Google Scholar]

- [20].Spivak DI, Giesa T, Wood E, and Buehler MJ, “Category theoretic analysis of hierarchical protein materials and social networks,” PLoS One, vol. 6, no. 9, 2011. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [21].Ragni R, Cicco SR, Vona D, and Farinola GM, “Multiple Routes to Smart Nanostructured Materials from Diatom Microalgae: A Chemical Perspective,” Adv. Mater, vol. 1704289, pp. 1–23, 2017. [DOI] [PubMed] [Google Scholar]

- [22].Barthelat F, Tang H, Zavattieri PD, Li CM, and Espinosa HD, “On the mechanics of mother-of-pearl: A key feature in the material hierarchical structure,” J. Mech. Rhys. Solids, vol. 55, no. 2, pp. 306–337, 2007. [Google Scholar]

- [23].Rho J-Y, Kuhn-Spearing L, and Zioupos P, “Mechanical properties and the hierarchical structure of bone” Med. Eng. Rhys, vol. 20, no. 2, pp. 92–102, Mar. 1998. [DOI] [PubMed] [Google Scholar]

- [24].Weiner S and Wagner HD, “THE MATERIAL BONE: Structure-Mechanical Function Relations,” Annn. Rev. Mater. Sci, vol. 28, no. 1, pp. 271–298, Aug. 1998. [Google Scholar]

- [25].Buehler MJ, “Nature designs tough collagen: Explaining the nanostructure of collagen fibrils,”Proc. Natl. Acad. Sci, vol. 103, no. 33, pp. 12285–12290, 2006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [26].Iwamoto S, Kai W, Isogai A, and Iwata T, “Elastic Modulus of Single Cellulose Microfibrils from Tunicate Measured by Atomic Force Microscopy,” Biomacromolecules, vol. 10, no. 9, pp. 2571–2576, Sep. 2009. [DOI] [PubMed] [Google Scholar]

- [27].Saito T, Kuramae R, Wohlert J, Berglund LA, and Isogai A, “An Ultrastrong Nanofibrillar Biomaterial: The Strength of Single Cellulose Nanofibrils Revealed via Sonication-Induced Fragmentation,” Biomacromolecules, vol. 14, no. 1, pp. 248–253, Jan.2013. [DOI] [PubMed] [Google Scholar]

- [28].Keckes J et al. , “Cell-wall recovery after irreversible deformation of wood,” Nat. Mater, vol. 2, no. 12, pp. 810–813, Dec. 2003. [DOI] [PubMed] [Google Scholar]

- [29].Jin K, Qin Z, and Buehler MJ, “Molecular deformation mechanisms of the wood cell wall material,” J. Mech. Behav. Biomed. Mater, vol. 42, pp. 198–206, Feb. 2015. [DOI] [PubMed] [Google Scholar]

- [30].Adler DC and Buehler MJ, “Mesoscale mechanics of wood cell walls under axial strain,” Soft Matter, vol. 9, no. 29, p. 7138, Jul. 2013. [Google Scholar]

- [31].Keten S, Xu Z, Ihle B, and Buehler MJ, “Nanoconfinement controls stiffness, strength and mechanical toughness of β-sheet crystals in silk,” Nat. Mater, vol. 9, p. 359, Mar. 2010. [DOI] [PubMed] [Google Scholar]

- [32].Kruse A, Funke A, and Titirici M, “Hydrothermal conversion of biomass to fuels and energetic materials,” Curr. Opin. Chem. Biol, vol. 2, no. 2, pp. 515–521, 2013. [DOI] [PubMed] [Google Scholar]

- [33].Hu B, Wang K, Wu L, Yu SH, Antonietti M, and Titirici MM, “Engineering carbon materials from the hydrothermal carbonization process of biomass,” Adv. Mater, vol. 22, no. 7, pp. 813–828, 2010. [DOI] [PubMed] [Google Scholar]

- [34].Singhvi MS, Chaudhari S, and Gokhale DV, “Lignocellulose processing: a current challenge,” RSC Adv, vol. 4, no. 16, p. 8271, 2014. [Google Scholar]

- [35].Yao Y and Wu F, “Naturally derived nanostructured materials from biomass for rechargeable lithium/sodium batteries,” Nano Energy!, vol. 17, pp. 91–103, 2015. [Google Scholar]

- [36].Long W, Fang B, Ignaszak A, Wu Z, Wang Y-J, and Wilkinson D, “Biomass-derived nanostructured carbons and their composites as anode materials for lithium ion batteries’ Chem. Soc. Rev, pp. 7176–7190, 2017. [DOI] [PubMed] [Google Scholar]

- [37].Kalyani P and Anitha A, “Biomass carbon & its prospects in electrochemical energy systems,” Int. J. Hydrogen Energy!, vol. 38, no. 10, pp. 4034–4045, 2013. [Google Scholar]

- [38].Deng J, Li M, and Wang Y, “Biomass-derived carbon: synthesis and applications in energy storage and conversion,” Green Chem, vol. 18, no. 18, pp. 4824–4854, 2016. [Google Scholar]

- [39].Calvo-Flores FG, Dobado JA, Isac-Garcia J, and Martin-Martinez FJ, “Front Matter’ in Lignin and Lignans as Renewable Raw Materials, Wiley-Blackwell, 2015. [Google Scholar]

- [40].Rojas OJ, Cellulose Chemistry and Properties : Fibers, Nanocelluloses and Advanced Materials. 2016.

- [41].Kargarzadeh H et al. , Advances in cellulose nanomaterials, vol. 25, no. 4 Springer Netherlands, 2018. [Google Scholar]

- [42].Trache D, Hussin MH, Haafiz MKM, and Thakur VK, “Recent progress in cellulose nanocrystals: sources and production,” Nanoscale, vol. 9, no. 5, pp. 1763–1786, 2017. [DOI] [PubMed] [Google Scholar]

- [43].Torres FG, Troncoso ΟP, Lopez D, Grande C, and Gomez CM, “Reversible stress softening and stress recovery of cellulose networks,” Soft Matter, vol. 5, no. 21, p. 4185, 2009. [Google Scholar]

- [44].Foster EJ et al. , “Current characterization methods for cellulose nanomaterials,” Chem. Soc. Rev, vol. 47, no. 8, pp. 2609–2679, 2018. [DOI] [PubMed] [Google Scholar]

- [45].Xue Y, Mou Z, and Xiao H, “Nanocellulose as Sustainable Biomass Material: Structure, Properties, Present Status and Future Prospects in Biomedical Applications,” Nanosccde, pp. 14758–14781,2017. [DOI] [PubMed] [Google Scholar]

- [46].Jorfi M and Foster EJ, “Recent advances in nanocellulose for biomedical applications,” J. Appl. Polym. Sci, vol. 132, no. 14, pp. 1–19, 2015.25866416 [Google Scholar]

- [47].De France KJ, Hoare T, and Cranston ED, “Review of Hydrogels and Aerogels Containing Nanocellulose,” Chem. Mater, vol. 29, no. 11, pp. 4609–4631, 2017. [Google Scholar]

- [48].Lavoine N and Bergström L, “Nanocellulose-based foams and aerogels: processing, properties, and applications,” J. Mater. Chem. A, vol. 5, no. 31, pp. 16105–16117, 2017. [Google Scholar]

- [49].Wang X, Yao C, Wang F, and Li Z, “Cellulose-Based Nanomaterials for Energy Applications,” Small, vol. 13, no. 42, pp. 1–19, 2017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [50].Chen W, Yu H, Lee S-Y, Wei T, Li J, and Fan Z, “Nanocellulose: a promising nanomaterial for advanced electrochemical energy storage,” Chem. Soc. Rev, vol. 47, pp.2837–2872, 2018. [DOI] [PubMed] [Google Scholar]

- [51].Hoeng F, Denneulin A, and Bras J, “Use of nanocellulose in printed electronics: a review,” Nanoscale, vol. 8, no. 27, pp. 13131–13154, 2016. [DOI] [PubMed] [Google Scholar]

- [52].Qiu X and Hu S, “‘Smart’ materials based on cellulose: A review of the preparations, properties, and applications,”Materials (Basel), vol. 6, no. 3, pp. 738–781, 2013. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [53].Chen F et al. , “Mesoporous, Three-Dimensional Wood Membrane Decorated with Nanoparticles for Highly Efficient Water Treatment,” ACS Nano, vol. 11, no. 4, pp. 4275–4282, Apr. 2017. [DOI] [PubMed] [Google Scholar]

- [54].Bledzki A. and Gassan J, “Composites reinforced with cellulose based fibres,” Prog. Polym. Sci, vol. 24, no. 2, pp. 221–274, May 1999. [Google Scholar]

- [55].Yang J and Li J, “Self-assembled cellulose materials for biomedicine: A review,” Carbohydr. Polym, vol. 181, no. September 2017, pp. 264–274, 2018. [DOI] [PubMed] [Google Scholar]

- [56].Natarajan B and Gilman JW, “Bioinspired Bouligand cellulose nanocrystal composites: a review of mechanical properties,” Philos. Trcms. R. Soc. A Math. Eng. Sci, vol. 376, no. 2112, p. 20170050, 2018. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [57].Almeida APC, Canejo JP, Fernandes SN, Echeverria C, Almeida PL, and Godinho MH, “Cellulose-Based Biomimetics and Their Applications,” Acv. Mater, vol. 1703655, pp. 1–31,2018. [DOI] [PubMed] [Google Scholar]

- [58].Kadokawa J, “Fabrication of nanostructured and microstructured chitin materials through gelation with suitable dispersion media,” RSC Adv, vol. 5, no. 17, pp. 12736–12746,2015. [Google Scholar]

- [59].Khalil H. P. S. Abdul et al. , “A review on chitosan-cellulose blends and nanocellulose reinforced chitosan biocomposites: Properties and their applications,” Carbohydr. Polym, vol. 150, pp. 216–226, 2016. [DOI] [PubMed] [Google Scholar]

- [60].Luo L-B, Yu S-H, Qian H-S, and Gong J-Y, “Large scale synthesis of uniform silver@carbon rich composite (carbon and cross-linked PVA) sub-microcables by a facile green chemistry carbonization approach’ Chem. Commnn, no. 7, p. 793, 2006. [DOI] [PubMed] [Google Scholar]

- [61].Qian HS, Antonietti M, and Yu SH, “Hybrid ‘golden fleece’: Synthesis and catalytic performance of uniform carbon nanofibers and silica nanotubes embedded with a high population of noble-metal nanoparticles,” Adv. Fnnct. Mater, vol. 17, no. 4, pp. 637–643, 2007. [Google Scholar]

- [62].Titirici M-M, White RJ, Falco C, and Sevilla M, “Black perspectives for a green future: hydrothermal carbons for environment protection and energy storage,” Energy Environ. Sci, vol. 5, no. 5, p. 6796, 2012. [Google Scholar]

- [63].Kumar P, Kim KH, Bansal V, and Kumar P, “Nanostructured materials: A progressive assessment and future direction for energy device applications,” Coord. Chem. Rev, vol. 353, pp. 113–141, 2017. [Google Scholar]

- [64].Yu X, Tang Z, Sun D, Ouyang L, and Zhu M, “Recent advances and remaining challenges of nanostructured materials for hydrogen storage applications,” Prog. Mater. Sci, vol. 88, pp. 1–48, 2017. [Google Scholar]

- [65].Jiang J et al. , “Progress of Nanostructured Electrode Materials for Supercapacitors,” Adv. Sustain. Syst, vol. 2, no. 1, p. 1700110, 2018. [Google Scholar]

- [66].Zhang X, Cheng X, and Zhang Q, “Nanostructured energy materials for electrochemical energy conversion and storage: A review,” J. Energy Chem, vol. 25, no. 6, pp.967–984, 2016. [Google Scholar]

- [67].Rehman S, Khan K, Zhao Y, and Hou Y, “Nanostructured cathode materials for lithium–sulfur batteries: progress, challenges and perspectives,” J. Mater. Chem. A, vol. 5, no. 7, pp. 3014–3038, 2017. [Google Scholar]

- [68].Zhao C, Gai P, Song R, Chen Y, Zhang J, and Zhu J-J, “Nanostructured material-based biofuel cells: recent advances and future prospects,” Chem. Soc. Rev, vol. 46, no. 5, pp. 1545–1564,2017. [DOI] [PubMed] [Google Scholar]

- [69].Fomer-Cuenca A, Biesdorf J, Manzi-Orezzoli V, Gubler L, Schmidt TJ, and Boillat P, “Advanced Water Management in PEFCs: Diffusion Layers with Patterned Wettability,” J. Electrochem. Soc, vol. 163, no. 13, pp. F1389–F1398, 2016. [Google Scholar]

- [70].Fomer-Cuenca A, Biesdorf J, Gubler L, Kristiansen PM, Schmidt TJ, and Boillat P, “Engineered Water Highways in Fuel Cells: Radiation Grafting of Gas Diffusion Layers”. Adv. Mater., vol. 27, no. 41, pp. 6317–6322, 2015. [DOI] [PubMed] [Google Scholar]

- [71].Yu YY, Guo CX, Yong YC, Li CM, and Song H, “Nitrogen doped carbon nanoparticles enhanced extracellular electron transfer for high-performance microbial fuel cells anode,” Chemosphere, vol. 140, pp. 26–33, 2015. [DOI] [PubMed] [Google Scholar]

- [72].Biagiotti G et al. , “Combined therapies with nanostructured carbon materials: there is room still available at the bottom,” J. Mater. Chem. B, vol. 6, no. 14, pp. 2022–2035, 2018. [DOI] [PubMed] [Google Scholar]

- [73].Zhao F, Wang J, Guo H, Liu S, and He W, “The effects of surface properties of nanostructured bone repair materials on their performances,” J. Nanomater, vol. 2015, 2015. [Google Scholar]

- [74].Lu S-N et al. , “Applications of Nanostructured Carbon Materials in Constructions: The State of the Art’ J. Nanomater., vol. 2015, 2015, pp. 1–10, 2015. [Google Scholar]

- [75].Chen S, Thind SS, and Chen A, “Nanostructured materials for water splitting - State of the art and future needs: A mini-review” Electrochem. commnn, vol. 63, pp. 10–17, 2016. [Google Scholar]

- [76].Humplik T., et al. “Nanostructured materials for water desalination,” Nanotechnology, vol. 22, no. 29, 2011. [DOI] [PubMed] [Google Scholar]

- [77].Valentini F, Carbone M, and Palleschi G, “Carbon nanostructured materials for applications in nano-medicine, cultural heritage, and electrochemical biosensors,” Anal. Bioanal. Chem, vol. 405, no. 2–3, pp. 451–465, 2013. [DOI] [PubMed] [Google Scholar]

- [78].Ling S, Qin Z, Li C, Huang W, Kaplan DL, and Buehler MJ, “Polymorphic regenerated silk fibers assembled through bioinspired spinning,” Nat. Commnn, vol. 8, no. 1,2017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [79].Håkansson KMO et al. , “Hydrodynamic alignment and assembly of nanofibrils resulting in strong cellulose filaments,” Nat. Commnn, vol. 5, no. 1, p. 4018, Dec. 2014. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [80].Yang J and Han C, “Mechanically Viscoelastic Properties of Cellulose Nanocrystals Skeleton Reinforced Hierarchical Composite Hydrogels,” ACS Appl. Mater. Interfaces, vol. 8, no. 38, pp. 25621–25630, Sep. 2016. [DOI] [PubMed] [Google Scholar]

- [81].Sydney Gladman A, Matsumoto EA, Nuzzo RG, Mahadevan L, and Lewis JA, “Biomimetic 4D printing,” Nat. Mater, vol. 15, no. 4, pp. 413–418, Apr. 2016. [DOI] [PubMed] [Google Scholar]

- [82].Håkansson KMO et al. , “Solidification of 3D Printed Nanofibril Hydrogels into Functional 3D Cellulose Structures.” Acv. Mater. Technol, vol. 1, no. 7, p. 1600096, Oct. 2016. [Google Scholar]

- [83].Siqueira G et al. , “Cellulose Nanocrystal Inks for 3D Printing of Textured Cellular Architectures.” Adv. Funct. Mater, vol. 27, no. 12, p. 1604619, Mar. 2017. [Google Scholar]

- [84].Zhu H et al. , “Anomalous scaling law of strength and toughness of cellulose nanopaper.,” Proc. Natl. Acad. Sci. U. S. A, vol. 112, no. 29, pp. 8971–6, Jul. 2015. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [85].Song J et al. , “Processing bulk natural wood into a high-performance structural material,” Nature, vol. 554, no. 7691, pp. 224–228, Feb. 2018. [DOI] [PubMed] [Google Scholar]

- [86].Zhu M et al. , “Anisotropic, Transparent Films with Aligned Cellulose Nanofibers,” Adv. Mater, vol. 29, no. 21, p. 1606284, Jun. 2017. [DOI] [PubMed] [Google Scholar]

- [87].Li T et al. , “Anisotropic, lightweight, strong, and super thermally insulating nanowood with naturally aligned nanocellulose,” Sci. Adv, vol. 4, no. 3, p. eaar3724, Mar. 2018. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [88].K. SA Loukas P, C. SJ, Angela Z, and M. PJ, “Molecular simulation as a tool for studying lignin,” Environ. Prog. Sustain. Energy, vol. 31, no. 1, pp. 47–54. [Google Scholar]

- [89].Zhang X, Yang W, and Blasiak W, “Modeling Study of Woody Biomass: Interactions of Cellulose, Hemicellulose, and Lignin,” Energy & Fuels, vol. 25, no. 10, pp. 4786–4795, Oct. 2011. [Google Scholar]

- [90].Shevchenko SM and Bailey GW, “The mystery of the lignin-carbohydrate complex: a computational approach,” J. Mol. Struct. THEOCHEM, vol. 364, no. 2, pp. 197–208, 1996. [Google Scholar]

- [91].Houtman CJ and Atalla RH, “Cellulose-Lignin Interactions (A Computational Study).’ Plant Physiol, vol. 107, no. 3, pp. 977–984, Mar. 1995. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [92].Kha H, Tuble SC, Kalyanasundaram S, and Williamson RE, “WallGen, Software to Construct Layered Cellulose-Hemicellulose Networks and Predict Their Small Deformation Mechanics, “ Plant Physiol, vol. 152, no. 2, pp. 774–786, 2010. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [93].Loukas P and C. SJ, “A molecular mechanics force field for lignin’ J. Comput. Chem, vol. 30, no. 3, pp. 457–467. [DOI] [PubMed] [Google Scholar]

- [94].Besombes S and Mazeau K, “The cellulose/lignin assembly assessed by molecular modeling. Part 2: seeking for evidence of organization of lignin molecules at the interface with cellulose’ Plant Physiol. Biochem, vol. 43, no. 3, pp. 277–286, 2005. [DOI] [PubMed] [Google Scholar]

- [95].Beste A, “ReaxFF Study of the Oxidation of Lignin Model Compounds for the Most Common Linkages in Softwood in View of Carbon Fiber Production,” J. Phys. Chem. A, vol. 118, no. 5, pp. 803–814, Feb. 2014. [DOI] [PubMed] [Google Scholar]

- [96].Hindman DP and Lee JN, “Modeling wood strands as multi-layer composites: Bending and tension loads,” Wood Fiber Sci, vol. 39, no. 4, pp. 515–526, 2007. [Google Scholar]

- [97].Giesa T, Perry CC, and Buehler MJ, “Secondary Structure Transition and Critical Stress for a Model of Spider Silk Assembly,” Biomacromolecules, vol. 17, no. 2, pp. 427–436, 2016. [DOI] [PubMed] [Google Scholar]

- [98].Ling S, Qin Z, Huang W, Cao S, Kaplan DL, and Buehler MJ, “Design and function of biomimetic multilayer water purification membranes,” Sci. Adv, vol. 3, no. 4, p. 1 DUMMY, 2017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [99].Martin SH and Walter T, “QM/MM Methods for Biomolecular Systems,” Angew. Chemie Int. Ed, vol. 48, no. 7, pp. 1198–1229, Jan. 2009. [DOI] [PubMed] [Google Scholar]

- [100].Gu GX, Chen CT, and Buehler MJ, “De novo composite design based on machine learning algorithm,” Extrem. Mech. Lett, vol. 18, pp. 19–28, 2018. [Google Scholar]

- [101].Zhu Z, et al. “High-Strength, Durable All-Silk Fibroin Hydrogels with Versatile Processability toward Multifunctional Applications,” Adv. Funct. Mater, vol. 28, no. 10, pp. 1–10, 2018. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [102].Tseng P et al. , “Directed assembly of bio-inspired hierarchical materials with controlled nanofibrillar architectures,” Nat. Nanotechnol, vol. 12, no. 5, pp. 474–480, 2017. [DOI] [PubMed] [Google Scholar]

- [103].Tao K, Makam P, Aizen R, and Gazit E, “Self-assembling peptide semiconductors,” Science (80-. ), vol. 358, no. 6365, 2017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [104].Huang W et al. , “Design of Multistimuli Responsive Hydrogels Using Integrated Modeling and Genetically Engineered Silk–Elastin-Like Proteins.” Adv. Funct. Mater, vol. 26, no. 23, pp. 4113–4123, 2016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [105].Marinovic A, Kiat LS, Dunn S, Titirici MM, and Briscoe J, “Carbon-Nanodot Solar Cells from Renewable Precursors,” ChemSusChem, vol. 10, no. 5, pp. 1004–1013, 2017. [DOI] [PubMed] [Google Scholar]

- [106].Geng B et al. , “NIR-responsive carbon dots for ef fi cient photothermal cancer therapy at low power densities,” Carbon N. Y, vol. 134, pp. 153–162, 2018. [Google Scholar]

- [107].Wang C et al. , “Carbonized Silk Fabric for Ultrastretchable, Highly Sensitive, and Wearable Strain Sensors,” Adv. Mater, pp. 6640–6648, 2016. [DOI] [PubMed] [Google Scholar]