Abstract

The piezoelectric nanogenerator (PENG) has the potential to become a promising power supply for monitoring and sensors in Internet of Things (IoT) systems through wireless networks. In order to further increase the utilization of energy harvesters in an IoT system, we introduce a novel approach that greatly enhances the piezoelectric output performances by employing the layer-by-layer (LbL) method. Poly(vinylidenefluoride-co-trifluoroethylene) (PVDF-TrFE) polymer film, which has piezoelectric properties and mechanical flexibility, was used for the active layer in PENG. The maximum open-circuit voltage and closed-circuit current of the LbL multilayer PENG reached 34 V and 100 nA, respectively. In particular, the closed-circuit current of the LbL multilayer PENG was dramatically improved to be five times higher than that of the single-layer PENG. Furthermore, a supercapacitor was employed to investigate the energy storage capability of PENGs using different methods. The proposed LbL multilayer PENG is expected to be a candidate for a promising power supply for self-powered systems in the IoT system.

Subject terms: Devices for energy harvesting, Devices for energy harvesting, Supercapacitors, Supercapacitors

Introduction

A variety of sensors is used in the environment for measuring temperature, relative humidity, gas, motion, light, and so on. The need for sensors has increased more and more with the development of Internet of Things (IoT) technologies. Ubiquitous sensor networks, which are wireless sensor networks, are receiving much attention these days for promising IoT technology because they can obtain information from the local area and communicate with each other. As the area where sensors are used becomes wider, however, problems occur in the power supply with regard to battery replacement and wire connections. To overcome these shortcomings, one is that there are some methods that use sustainable energies such as solar, wind, thermal, and vibration. In particular, mechanical energy such as electromagnetic1,2, piezoelectric3–5, and triboelectric6–8 has been gathered mainly from human bodies and specific environments in vibration form. Among sustainable energies, the piezoelectric nanogenerator (PENG) has been noted as an efficient energy harvester of mechanical energy in the surrounding environment9,10. The other is a supercapacitor that is alternative to a primary battery. Briefly, supercapacitor is widely studied for one of the energy storage devices11–14 because it has advantages of fast charge-discharge rate, high power density, long term stability, superior rate capability, and low cost15,16. To operate sensors with the help of supercapacitor, employing energy harvesting which can supply the power consistently is useful because supercapacitor needs energy sources that would be stored in17.

Many piezoelectric materials, which are inorganics (i.e. PZT18, BaTiO319, ZnO20 etc.), generally have a high piezoelectric constants, high permittivity and ferroelectric properties. But it has a disadvantage of stiffness and brittleness. Organic materials (i.e. PVDF21, PVDF-TrFE7, PDMS22 etc.) could be a solution because it has flexibility and exhibits good piezoelectric performance.

Working a sensor device generally needs low voltage and high current. But a sensor network connected many sensor devices requires high voltage for operating system. However, piezoelectric energy harvesting, which has high impedance, generates a high voltage but low current. Therefore, additional components23–26 or structural transformation27,28 is needed in order for a piezoelectric energy harvester system to produce a high current. Multilayer structures, one type of structural transformation, can increase the current and reduce the impedance29. In addition, the PENG could have durability that endures fractures even under vibration or bending conditions. Therefore, the organic materials have been actively applied to applications such as tactile sensors30,31, pressure sensors32, and power harvesting applications33.

In this paper, we fabricated PVDF-TrFE multilayer film in order to increase the closed-circuit current and open-circuit voltage. By employing Cu tape simply between PVDF-TrFE multilayers, an LbL multilayer PENG was also fabricated and compared with a single-layer PENG. X-ray diffraction (XRD) measurement was performed to investigate the crystallinity of the PVDF-TrFE. Finally, we examined the capacitance of piezoelectric films with supercapacitor charging under bending conditions.

Results and Discussion

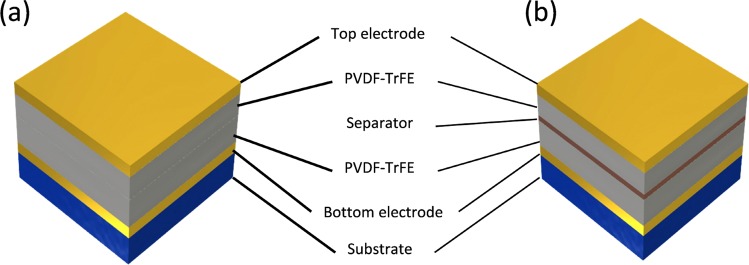

To increase the electrical performance of the multilayer energy harvester, a simple method was adopted to build PVDF-TrFE multilayer structures such as stack-up and layer by layer. Figure 1 illustrates a piezoelectric PVDF-TrFE multilayer structure. A stack-up multilayer is composed of two PVDF-TrFE films as active layers and Au electrodes. A Layer-by-Layer (LbL) multilayer was prepared by the following method. First, a 160-nm-thick Au bottom electrode was deposited on a flexible substrate. PVDF-TrFE film was spin-coated on the bottom electrode annealed on a hot plate. To fabricate the LbL multilayer, a separator of Cu tape was attached on the first active layer of the PVDF-TrFE film. The Au electrode was deposited as a separator electrode but is not suitable for this role. When the PVDF-TrFE solution was coated for the second active layer on the Au separator electrode by spin-coating, the Au electrode was not clearly coated. The PVDF-TrFE solution had poor dispersion with the Au electrode. Therefore, Cu tape was chosen as a separator electrode owing to its simplicity and good compatibility with PVDF-TrFE. Then, the PVDF-TrFE solution was coated again on the Cu tape for the second active layer. The LbL multilayer was connected in series with the top and bottom electrodes.

Figure 1.

Illustration of piezoelectric multilayer structures: (a) stack-up multilayer PENG and (b) layer-by-layer (LbL) multilayer PENG.

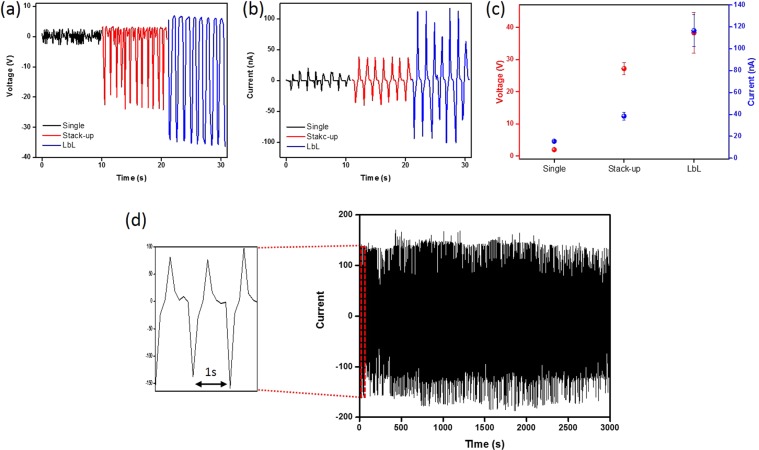

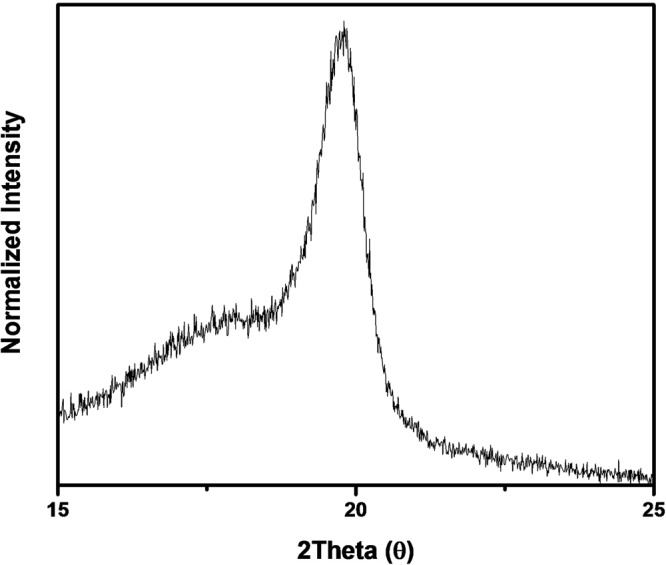

To confirm the PVDF-TrFE crystalline phase, XRD analysis was carried out. As can be seen in Fig. 2, the XRD peaks of the PVDF-TrFE exhibit an intense β-phase peak diffraction at an angle of 2θ at around 19.8º, which indicates the presence of the pyroelectric phase34. Figure 3 shows the output performance of PENGs with single layer, stack-up, and LbL multilayer, respectively. The output voltage and closed-circuit current were measured under repeated bending at a frequency of 1 Hz. The single-layer PENG generated an output voltage of 2.3 V and closed-circuit current of 15.4 nA as shown in Fig. 3(a,b). This result is similar to that of other research35. However, the output performance of the single layer was not sufficient to charge the supercapacitor for IoT sensor network systems. Thus, we tried to find other methods such as the stack-up structure and layer-by-layer structure. The stack-up multilayer PENG generated output voltage of 25 V and closed-circuit current of 38 nA. The electrical output performance of the stack-up multilayer PENG increased but it was not dramatically improved because of the internal resistance increment with the thickness of the active layers36. The output voltage and closed-circuit current of the stack-up multilayer PENG increased by 10 times and were 2 times higher than those of the single layers, respectively. Although the electrical output performance was improved in the stack-up multilayer PENG, it was still not sufficient for charging a supercapacitor owing to a low closed-circuit current. Therefore, we used Cu tape as a separator to decrease the internal resistance between the PVDF-TrFE layers. The LbL multilayer was prepared in the same way as a stack-up multilayer except that a Cu tape separator was added.

Figure 2.

XRD result of β-phase of PVDF-TrFE film.

Figure 3.

Open circuit voltage and closed circuit current of PVDF-TrFE energy harvester. Measured (a) open circuit voltage and (b) closed circuit currents of the single layer, stack-up multilayer, LbL multilayer, respectively. (c) Compare to open circuit voltages and closed circuit currents with single layer, stack-up multilayer, LbL multilayer and (d) durability test of LbL multilayer PENG during 3000 cycles under repeated bending cycle at frequency of 1 Hz.

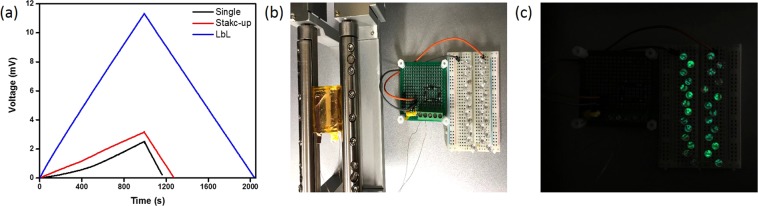

The expected benefits of the Cu-tape separator electrode for LbL multilayer were an increase in the pathway and helping the dipoles to align with the electrical field37,38. As the number of layers was increased, the output voltage and closed-circuit current increased compared to those of a single layer. For the LbL multilayer PENG, the highest values of electrical properties indicated an output voltage and closed-circuit current of approximately 34 V and 100 nA, respectively, under a bending state. This was over 13 times and 6 times higher than those of the single-layer PENG, respectively. As shown in Fig. 3(c), this tended to enhance the electrical performance of the multilayer owing to increased capacitance39. Table 1 lists the capacitances of PENGs of single, stack-up, and LbL types. An increase in capacitance could cause an increase in electrical output performance. And we measured LbL multilayer of the variety of external load resistance. The value of voltage and current can reach the 33 V and 310nA, respectively. The power density shows the 7.8 mW/m2 at 100 MΩ (Fig. S1(a,b)). To estimate the electrical and mechanical stability of the LbL multilayer further, we performed cycling over 3000 times (Fig. 3(d)). As for the charging-discharging performance, Fig. 4(a) shows the measured voltages of the chip-type supercapacitor for energy harvesting as charged by each of the PENGs. The charging speed was enhanced by about four times in the LbL multilayer PENG compared to the single-layer PENG because the LbL multilayer PENG showed a higher value of current density than the others. The discharge also follows the same trend as charging. The LbL multilayer PENG with outstanding electrical output performance could operate as a self-powered electric device using a full-bridge rectifier and electrical circuit system (Fig. 4(b,c)). During the bending cycle with the LbL multilayer PENG, 28 green LEDs were turned on immediately. The LbL multilayer PENG could be a candidate for a real-time self-powered generator that is suitable for sensor device applications.

Table 1.

Capacitance measurement of PENGs with single layer, stack-up multilayer, and LbL multilayer.

| Single | Stack-up | LbL | |

|---|---|---|---|

| Capacitance (nF) | 12.614 | 12.627 | 13.482 |

Figure 4.

(a) Charging-discharging performance of PENGs in chip-type supercapacitor for energy harvesting with constant discharge current density, snapshots of instantaneous lighting of 28 green LEDs in series with LbL multilayer PENG (b) before and (c) during moment of bending cycles.

Conclusions

To increase the output voltage and closed-circuit current, we successfully demonstrated an LbL multilayer PENG based on PVDF-TrFE film. Through the presence of Cu tape as a separator electrode between two active layers, the piezoelectric electrical properties of the output voltage and closed-circuit current were effectively improved. The output voltage and closed-circuit current of the stack-up multilayer PENG were improved by 10 times and were 2 times higher than those of the single layer, respectively. Although the electrical output performance of the stack-up multilayer PENG was also enhanced, it produced an insufficient level of current. With the utilization of Cu tape as a separator electrode, the electrical output performance was effectively enhanced. The resulting LbL multilayer generated an output voltage and closed-circuit current of about 34 V and 100 nA, respectively. And the power density showed the 7.8 mW/m2. These were improved by 14 times and were 6 times higher than those of the single layer. As for charging a supercapacitor with PENGs, the charging speed of the LbL multilayer PENG was improved by about four times that of the single-layer PENG. The results show that the LbL multilayer PENG can be sufficient for charging a supercapacitor efficiently. We hope that the LbL multilayer PENG can be used as a self-powered generator for wireless sensor networks.

Methods

Fabrication of piezoelectric generator

PVDF-TrFE (70–30 mol%) copolymer powder and dimethylformamide (DMF) were purchased from Piezotech and Sigma Aldrich, respectively. The PVDF-TrFE copolymer powder was dissolved in DMF with 20% of volume content. The solution was prepared by stirring for 12 h at 35 °C. Then, PVDF-TrFE solution was spin-coated on a Au electrode deposited on a 20 mm × 20 mm PET substrate (thickness of 220 μm) at 3000 rpm for 30 s. The PVDF-TrFE films were annealed at 50 °C for 30 min on a hot plate. For the bottom and top electrodes, an Au electrode (thickness of 160 nm) was deposited by thermal evaporation. Cu tape, which was purchased from 3M Conductive Tape, was employed as separator between multilayers. A chip-type supercapacitor for energy harvesting was prepared by using CPH3225A (Seiko Instruments Inc., Japan) (Table S1). The charging-discharging voltage of the supercapacitor connected to different PVDF-TrFE films was compared under bending conditions with a full bridge. The discharge testing at a constant current of 100 nA was conducted with a Bio-Logics VSP potentiostat using a two-electrode system.

Characterization

X-ray diffraction measurement (XRD, D/max-2500pc, Rigaku, Japan) was used to investigate the structures of PVDF-TrFE films coated on silicon substrate. The electrical output performance of the piezoelectric films was measured with an electrometer (Keithley 6514, Keithley Instruments Inc., USA). The capacitance was measured with a potentiostat (Model 263A, EG&G, USA). A bending machine (JIBT-210, Junil Tech, Republic of Korea) was used for bending tests under controlled conditions.

Supplementary information

Supplementary Information_Enhanced output performance on LbL multilayer PVDF-TrFE piezoelectric films for charging supercapacitor

Acknowledgements

This work was conducted under the framework of Research and Development Program of the Korea Institute of Energy Research (B9–2435). It was also supported by a National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (2017R1A2B4009213).

Author Contributions

M.H.C. conducted most of the investigation and wrote the manuscript. S.H.Y. and H.J.K. analyzed the data and provided the valuable suggestion on the research. J.J.Y. provided and analyzed the supercapacitor. S.Y.H. and K.H.Y. helped with bending cycle and X-ray diffraction analysis. And H.G.J. supervised the study. All authors reviewed the manuscript.

Competing Interests

The authors declare no competing interests.

Footnotes

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary information accompanies this paper at 10.1038/s41598-019-43098-6.

References

- 1.Fan K, et al. Scavenging energy from ultra-low frequency mechanical excitations through a bi-directional hybrid energy harvester. Applied Energy. 2018;216:8–20. doi: 10.1016/j.apenergy.2018.02.086. [DOI] [Google Scholar]

- 2.He X, Wen Q, Sun Y, Wen Z. A low-frequency piezoelectric-electromagnetic-triboelectric hybrid broadband vibration energy harvester. Nano Energy. 2017;40:300–307. doi: 10.1016/j.nanoen.2017.08.024. [DOI] [Google Scholar]

- 3.Zhao J, You Z. A shoe-embedded piezoelectric energy harvester for wearable sensors. Sensors (Basel) 2014;14:12497–12510. doi: 10.3390/s140712497. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Singh D, Deepak, Garg A. An efficient route to fabricate fatigue-free P(VDF-TrFE) capacitors with enhanced piezoelectric and ferroelectric properties and excellent thermal stability for sensing and memory applications. Phys Chem Chem Phys. 2017;19:7743–7750. doi: 10.1039/c7cp00275k. [DOI] [PubMed] [Google Scholar]

- 5.Ducrot PH, Dufour I, Ayela C. Optimization Of PVDF-TrFE Processing Conditions For The Fabrication Of Organic MEMS Resonators. Sci Rep. 2016;6:19426. doi: 10.1038/srep19426. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Han C, Zhang C, Tang W, Li X, Wang ZL. High power triboelectric nanogenerator based on printed circuit board (PCB) technology. Nano. Research. 2014;8:722–730. doi: 10.1007/s12274-014-0555-3. [DOI] [Google Scholar]

- 7.Seung W, et al. Boosting Power-Generating Performance of Triboelectric Nanogenerators via Artificial Control of Ferroelectric Polarization and Dielectric Properties. Advanced Energy. Materials. 2017;7:1600988. doi: 10.1002/aenm.201600988. [DOI] [Google Scholar]

- 8.Jiang T, et al. Spring-assisted triboelectric nanogenerator for efficiently harvesting water wave energy. Nano Energy. 2017;31:560–567. doi: 10.1016/j.nanoen.2016.12.004. [DOI] [Google Scholar]

- 9.Song H-C, et al. Multilayer piezoelectric energy scavenger for large current generation. Journal of Electroceramics. 2008;23:301–304. doi: 10.1007/s10832-008-9439-9. [DOI] [Google Scholar]

- 10.Kim, S. et al. P(VDF-TrFE) Film on PDMS Substrate for Energy Harvesting Applications. Applied Sciences8, 10.3390/app8020213 (2018).

- 11.Xu, G., Chen, S., Liu, Y. & Fan, W. A novel binder-free electrode of graphene film upon intercalation of hollow MoS2 spheres for enhanced supercapacitor performance. Functional Materials Letters11, 10.1142/s1793604718500741 (2018).

- 12.Shan, P. et al. In-situ activation for optimizing meso-/microporous structure of hollow carbon shells for supercapacitors. Functional Materials Letters11, 10.1142/s1793604718500492 (2018).

- 13.Laasri, H. A. et al. Investigation of Sr1-xCaxTiO3 ceramics dedicated to high-frequency lead-free components. Functional Materials Letters11, 10.1142/s1793604718500054 (2018).

- 14.Tian, Z. et al. Superconcentrated aqueous electrolyte to enhance energy density for advanced supercapacitors. Functional Materials Letters10, 10.1142/s1793604717500813 (2017).

- 15.Hong, C. et al. MnO2 nanowires-decorated carbon fiber cloth as electrodes for aqueous asymmetric supercapacitor. Functional Materials Letters11, 10.1142/s1793604718500340 (2018).

- 16.Qin, S. et al. Hybrid Piezo/Triboelectric-Driven Self-Charging Electrochromic Supercapacitor Power Package. Advanced EnergyMaterials8, 10.1002/aenm.201800069 (2018).

- 17.Wu, F., Rudiger, C. & Yuce, M. R. Real-Time Performance of a Self-Powered Environmental IoT Sensor Network System. Sensors (Basel)17, 10.3390/s17020282 (2017). [DOI] [PMC free article] [PubMed]

- 18.Park KI, et al. Highly-efficient, flexible piezoelectric PZT thin film nanogenerator on plastic substrates. Adv Mater. 2014;26:2514–2520. doi: 10.1002/adma.201305659. [DOI] [PubMed] [Google Scholar]

- 19.Park KI, et al. Piezoelectric BaTiO(3) thin film nanogenerator on plastic substrates. Nano Lett. 2010;10:4939–4943. doi: 10.1021/nl102959k. [DOI] [PubMed] [Google Scholar]

- 20.Zhu G, Yang R, Wang S, Wang ZL. Flexible high-output nanogenerator based on lateral ZnO nanowire array. Nano Lett. 2010;10:3151–3155. doi: 10.1021/nl101973h. [DOI] [PubMed] [Google Scholar]

- 21.Lee, J. W. et al. Robust nanogenerators based on graft copolymers via control of dielectrics for remarkable output power enhancement. Science Advances3, 10.1126/sciadv.1602902 (2017). [DOI] [PMC free article] [PubMed]

- 22.Han M, et al. r-Shaped Hybrid Nanogenerator with Enhanced Piezoelectricity. ACS NANO. 2013;7:8554–8560. doi: 10.1021/nn404023v. [DOI] [PubMed] [Google Scholar]

- 23.Zhao Y, et al. High output piezoelectric nanocomposite generators composed of oriented BaTiO3 NPs@PVDF. Nano Energy. 2015;11:719–727. doi: 10.1016/j.nanoen.2014.11.061. [DOI] [Google Scholar]

- 24.Yaqoob, U. & Chung, G.-S. Effect of reduced graphene oxide on the energy harvesting performance of P(VDF-TrFE)-BaTiO3 nanocomposite devices. Smart Materials and Structures26, 10.1088/1361-665X/aa81a0 (2017).

- 25.Yang X, Daoud WA. Synergetic effects in composite-based flexible hybrid mechanical energy harvesting generator. Journal of Materials Chemistry A. 2017;5:9113–9121. doi: 10.1039/c7ta01524k. [DOI] [Google Scholar]

- 26.Lee J-H, et al. Highly sensitive stretchable transparent piezoelectric nanogenerators. Energy Environ. Sci. 2013;6:169–175. doi: 10.1039/c2ee23530g. [DOI] [Google Scholar]

- 27.Kim Y, et al. Layer-by-Layer Controlled Perovskite Nanocomposite Thin Films for Piezoelectric Nanogenerators. Advanced Functional Materials. 2014;24:6262–6269. doi: 10.1002/adfm.201401599. [DOI] [Google Scholar]

- 28.Li L, Xu J, Liu J, Gao F. Recent progress on piezoelectric energy harvesting: structures and materials. Advanced Composites and Hybrid. Materials. 2018;1:478–505. doi: 10.1007/s42114-018-0046-1. [DOI] [Google Scholar]

- 29.Oh, S. R., Wong, T. C., Tan, C. Y., Yao, K. & Tay, F. E.-H. Fabrication of piezoelectric polymer multilayers on flexible substrates for energy harvesting. Smart Materials and Structures23, 10.1088/0964-1726/23/1/015013 (2014).

- 30.Nilsson E, Lund A, Jonasson C, Johansson C, Hagström B. Poling and characterization of piezoelectric polymer fibers for use in textile sensors. Sensors and Actuators A: Physical. 2013;201:477–486. doi: 10.1016/j.sna.2013.08.011. [DOI] [Google Scholar]

- 31.Sang-Soo, Je., Sharma, T., Lee, Y., Gill, B. & Zhang, J. X. A thin-film piezoelectric PVDF-TrFE based implantable pressure sensor using lithographic patterning (2011).

- 32.Parida K, Bhavanasi V, Kumar V, Bendi R, Lee PS. Self-powered pressure sensor for ultra-wide range pressure detection. Nano Research. 2017;10:3557–3570. doi: 10.1007/s12274-017-1567-6. [DOI] [Google Scholar]

- 33.Zi Y, et al. Triboelectric-pyroelectric-piezoelectric hybrid cell for high-efficiency energy-harvesting and self-powered sensing. Adv Mater. 2015;27:2340–2347. doi: 10.1002/adma.201500121. [DOI] [PubMed] [Google Scholar]

- 34.Kim, J. et al. High-Performance Piezoelectric, Pyroelectric, and Triboelectric Nanogenerators Based on P(VDF-TrFE) with Controlled Crystallinity and Dipole Alignment. Advanced Functional Materials27, 10.1002/adfm.201700702 (2017).

- 35.Persano L, et al. High performance piezoelectric devices based on aligned arrays of nanofibers of poly(vinylidenefluoride-co-trifluoroethylene) Nat Commun. 2013;4:1633. doi: 10.1038/ncomms2639. [DOI] [PubMed] [Google Scholar]

- 36.Park SH, et al. Bulk heterojunction solar cells with internal quantum efficiency approaching 100% Nature Photonics. 2009;3:297–302. doi: 10.1038/nphoton.2009.69. [DOI] [Google Scholar]

- 37.Yaqoob U, Uddin ASMI, Chung G-S. A novel tri-layer flexible piezoelectric nanogenerator based on surface- modified graphene and PVDF-BaTiO 3 nanocomposites. Applied Surface Science. 2017;405:420–426. doi: 10.1016/j.apsusc.2017.01.314. [DOI] [Google Scholar]

- 38.Zhang L, Oh SR, Wong TC, Tan CY, Yao K. Piezoelectric polymer multilayer on flexible substrate for energy harvesting. IEEE Trans Ultrason Ferroelectr Freq Control. 2013;60:2013–2020. doi: 10.1109/TUFFC.2013.2786. [DOI] [PubMed] [Google Scholar]

- 39.Woo MS, et al. Study on increasing output current of piezoelectric energy harvester by fabrication of multilayer thick film. Sensors and Actuators A: Physical. 2018;269:524–534. doi: 10.1016/j.sna.2017.12.025. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary Information_Enhanced output performance on LbL multilayer PVDF-TrFE piezoelectric films for charging supercapacitor