Abstract

Multi-material 3D printing with several mechanically distinct materials at once has expanded the potential applications for additive manufacturing technology. Fewer material options exist, however, for additive systems that employ vat photopolymerization (such as stereolithography, SLA, and digital light projection, DLP, 3D printers), which are more commonly used for advanced engineering prototypes and manufacturing. Those material selections that do exist are limited in their capacity for fusion due to disparate chemical and physical properties, limiting the potential mechanical range for multi-material printed composites. Here, we present an ethylene glycol phenyl ether acrylate (EGPEA)-based formulation for a polymer resin yielding a range of elastic moduli between 0.6 MPa and 33 MPa simply by altering the ratio of monomer and crosslinker feedstocks in the formulation. This simple chemistry is also well suited to form seamless adhesions between mechanically dissimilar formulations, making it a promising candidate for multi-material DLP 3D printing. Preliminary tests with these polymer formulations indicate that variability due to molecular differences between hard and soft formulations is near net shape and less than 3% of the prescribed dimensions, comparable to existing commercial DLP and SLA resins, with unique advantages of a wide range of elastomer stiffness and seamless fusion for 3D printing of structurally detailed and mechanically heterogeneous composites.

Keywords: 3D printing, multi-material, Digital Light Processing (DLP), photopolymers, mechanically tunable

1. Introduction

3D printing, or additive manufacturing (AM), has become increasingly popular over the past several decades as a means of manufacturing for both pre-production prototypes and end-user products, due in large part to the increased prevalence of the technology in consumer and light industrial fields. While the number of 3D printers, additive manufacturing companies, and applications of 3D printing have all exponentially grown since the invention of 3D printing in the late 1980s,[1,2] the technology is still constrained by the limited functionality of the structures that can be produced. In particular, the product of a 3D printer is restricted by the physical properties of the one or two materials that can be combined into a given build cycle. As the range of 3D printing applications becomes increasingly diverse, research and development of materials for 3D printing continues to be active, with particular interest in developing printable materials that exhibit tunable properties, such as conductivity[3,4] or elasticity,[5] as well as the development of additive systems that can fuse these advanced materials together for practical purposes. The critical question being addressed in this study is the development of a polymeric feedstock that can facilitate simple modification of mechanical properties with little or no adjustment to the additive system.

Additive systems based on vat photopolymerization (also referred to as stereolithography, SLA, and digital light projection, DLP, technologies) are among the oldest forms of AM technology commercially available.[6] In SLA printing, the light source is a single laser beam of ultraviolet light, which is rastered across the printed layer by changing the position and angle of optical elements such as lenses and mirrors. In DLP printing, the cross-sectional area of each layer of the model is printed at once by projecting UV light onto a micromirror array that adjusts to form the pattern of the printed cross-section.[7] Originally only available in industrial settings, both SLA and DLP printing technologies have become accessible for small businesses, light manufacturing, and consumers. Meanwhile, there has been less progress with respect to the polymeric materials used as feedstock by such 3D printers. The photo-curable acrylate resins and epoxies that were used two decades ago remain the standard in today’s SLA and DLP systems.[5,8–14] There have been innovations applying embedded or encapsulated nanoparticles for the purposes of modifying properties such as pigmentation, melt-casting, and mechanical strength.[5] The mechanical properties of such modified acrylate materials, particularly the range of potential elastic moduli, remain narrow and dependent on the constituent monomers and oligomers.

Several technical hurdles have hampered the success of mechanically variable composite materials for DLP and SLA 3D printers. Lower elastic modulus has typically correlated with decreased feature resolution, compromising the ability of DLP and SLA printers using such materials to produce high fidelity models with complex geometries.[15] Additionally, the different physical factors at play when fabricating with a soft, elastic material versus a rigid, plastic material often complicate the 3D printing process, necessitating build cycle-specific parameter optimization.[16–18] Therefore, straightforward, high-resolution 3D printing with mechanically tunable materials would open up a wide range of opportunities in the prototyping and rapid fabrication of heterogeneous structures consisting of two or more distinct regions, each with its own elastic modulus. If comprised of the same base monomer, each region should also be capable of forming a seamless interface with its neighboring regions to help ensure mechanical integrity of the composite structure.

Ideally, a mechanically-tunable acrylate polymer would consist of a small number of distinct base monomers or oligomers, with the potential addition of a cross-linking agent. Such systems have been successfully employed in the tissue engineering field as substrate coatings that can recapitulate a wide range of tissue mechanical environments.[19,20] Fluid dynamic requirements during the 3D printing process, particularly polymer viscosity, have hampered the development of a similar system for easily tuning the elastic modulus of a printable acrylate resin. wide range of elastic moduli can be achieved with current resins, however, soft and hard polymer mixtures typically consist of several distinct acrylate monomers and oligomers and do not use the same monomers and oligomers for each elastic modulus. As a result, adjusting the elastic modulus of a polymer mixture cannot be achieved by simply modulating the relative amounts of constituent monomers, oligomers, and crosslinkers, as has been done with biomimetic substrates.

In this paper, we demonstrate on a DLP 3D printing system an acrylate-based resin consisting of only a single monomer and crosslinker that is mechanically tunable with elastic moduli ranging from sub-MPa to tens 4 of MPa. This represents a wider range of elastic properties than is available from any single polymeric compound currently available commercially, while also retaining consistent performance and printability across the full range of elastic moduli. Additionally, we present proof-of-concept models demonstrating the ability of this resin to produce multi-modulus materials with abrupt transitions that retain structural integrity. This inexpensive, commercially available material makes high-resolution, low-cost 3D printing of complex heterogeneous models a practical option for consumers and DIY makers.

2. Materials and Methods

2.1. Polymer Synthesis

Ethylene glycol phenyl ether acrylate (Sigma Aldrich, St. Louis, MO), abbreviated as EGPEA, was used as the acrylate monomer for all synthesized polymers in all experiments. The crosslinker used for polymer synthesis was 1,6-hexanediol diacrylate (Sigma Aldrich) and the photoinitiator was 2-Benzyl-2-(dimethylamino)-4′-morpholinobutyrophenone (Sigma Aldrich). All prepared polymers used a fixed amount of photoinitiator (2.5g/100mL) to a combined EGPEA-crosslinker volume of 100mL, based on exploratory testing. Polymers of increasing rigidity were fabricated by incrementally increasing the volumetric monomer-to-crosslinker ratio From 1:0 to 1:1(see Results, Figure 1). Polymersamples were initially formulated in two batches. The first batch increased the volume ratio of crosslinker from 1:0 to 1:1 in 0.25 increments. The second batch added additional formulations of 1:0, 1:0.05, 1:0.1, and 1:0.4 in order to refine the elastic modulus versus formulation curve. A third batch of 1:0.05, 1:0.4, and 1:1 formulations was subsequently prepared in order to evaluate inter-batch variability, yielding a final sample size of n = 3 to 6 samples per formulation.

Figure 1.

Plot and table showing the average mechanical properties of all of the polymer resin formulations, determined from uniaxial extension of dogbone-shaped test specimens for each formulation. With increasing volumetric ratio of 1,6-hexanediol diacrylate crosslinker, there was a corresponding increase in average elastic modulus and ultimate tensile stress. Maximum pre-failure strain, however, decreased as the crosslinker content of the polymer resin formulation increased. Error bars and table values are mean ± SD; n = sample size. Error bars are difficult to see for some data points due to small standard deviation.

2.2. Mechanical characterization

To evaluate quantitative mechanical properties of each polymer, the mixtures were polymerized to the form factor of an ASTM Type 638 dogbone mold for tensile testing (see Figure S1). Specifically, positive molds were machined out of CPVC (McMaster, Robbinsville, NJ) on a Tormach PCNC 1100 mill (Tormach, Waunakee, WI). Negative molds were then cast in poly(dimethylsiloxane) (PDMS; Sylgard 184, Dow Corning, Auburn MI). A volume of 1700 uL of prepared liquid polymer was then injected into the PDMS mold, covered with fluorinated ethylene propylene (FEP) film (McMaster) to avoid meniscus formation, and polymerized in a UV curing chamber (MelodySusie, Evergreat Inc., Union City, CA) at 365nm for 2 minutes. In addition to the cast samples, a subset of elastic modulus formulations (1:0.05, 1:0.4, 1:1) were also 3D printed to form test specimens with the same dogbone geometry using the ProJet 1200. These printed specimens allowed quantification of possible changes in mechanical properties related to layer interface bonds that can be weak points in printed models. Due to size limitations imposed by the build plate of the printer, samples were printed with the z-axis oriented along the length of the sample, i.e. with inter-layer surfaces perpendicular to the uniaxial testing direction.

Within 1 week of sample fabrication, uniaxial tensile tests were performed with an nstron 8872 Testing System (Instron, Norwood, MA) using a MLP50 225N load cell (Transducer Techniques, Temecula, CA).[21] The testing protocol used 30mm axial displacement control at a constant pulling rate of 100μm/s. The measured force was normalized by the undeformed cross-sectional area to obtain a Lagrangian stress, and the extension was normalized by the undeformed segment length to compute Lagrangian strain. From the resulting stress-strain curve (Figure S4), the elastic Young’s modulus was obtained from the slope of a line fit to the elastic loading regime, the ultimate tensile stress was obtained from the maximum stress value measured during loading, and the maximum strain was obtained from the data point just prior to failure.

2.3. Evaluation for 3D Printing Applications

To evaluate the performance of these polymers in an additive system, three models were designed for printing using Fusion 360 software (Autodesk, San Raphael, CA). First, a cube was used to assess dimensional accuracy, which can be confounded by resin contraction or expansion during polymerization. The cube was printed at 3 different model sizes (0.5cm, 1.0cm, 1.5cm) and, initially, two polymer mixtures (1:0 and 1:1). A subsequent dimensional evaluation used polymer mixtures of the same monomer and crosslinker ratios, but a much higher concentration of photoinitiator in order to reduce potential effects due to through-plane overcuring[14]. All models were printed using the same settings on the ProJet 1200.

Printed model dimensions in X, Y, and Z were measured with digital image processing using ImageJ software (NIH) to quantify deviations from the prescribed dimensions. Measurements were made by determining the length of 5 lines, drawn top to bottom, along the length of the cubes (Figure S2). As a standard for comparison, one cube of each size was also printed in FTX Green (3D Systems, Rock Hill, SC), an industrial resin specifically formulated for DLP 3D printing. The dimensions for each face and size were compared using overlaid plots of each face’s dimensional measurements (Figure S3). All models were printed on a ProJet 1200 DLP printer (3D Systems).

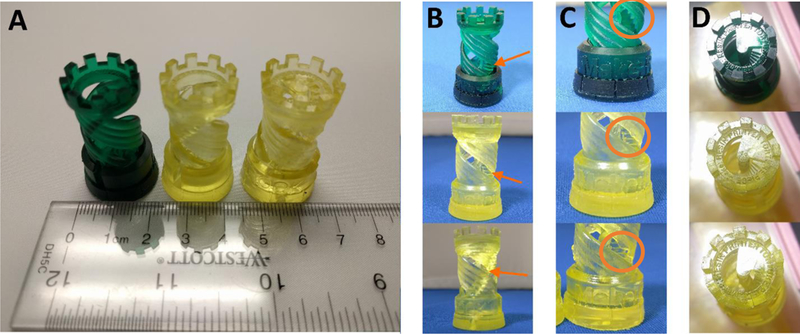

Second, a model of a rook chess piece (Figure 2) was printed to determine how well each polymer mixture could retain complex, high-detail geometry. This model[22,23] was selected due to its small, detailed surface features as well as complex internal structures, making it a standard reference model for DLP and SLA 3D printing applications.[12,16,24] The rook model was printed on a ProJet 1200 with two initial experimental polymer mixing ratios (1:0 and 1:1) and two subsequent polymer formulations of the same mixing ratios but with additional photoinitiator (not pictured), again to parse out any effects due to overcuring in the first two prints. FTX Green was again used as a control material. The printed models were inspected both visually and using a binocular dissecting microscope (Olympus SZ61) with a trinocular mount equipped with a color digital camera (Pixelink PL-A662).

Figure 2.

A standard rook model was used to assess how well the resins could resolve fine geometric features. (A) Models were printed in (from left to right) FTX Green, 1:1 and 1:0 EGPEA resin. All resins were able to resolve fine geometric features including (B) the interior staircase (indicated by the arrows), (C) The “Make: ROOK” text at the base of the model, and (D) the “Make: RESIN PRINTER TORTURE PIECE” at the top of the model.

Finally, a multi-material model (Figure 3), consisting of both soft (0%) and hard (100%) EGPEA polymer mixtures was printed to demonstrate the polymers’ ability to seamlessly bond to self-similar mixtures. This multi-material model was prepared for printing with CreationWorkshop software (DataTree3D, Dallas, TX) and printed on a LittleRP DLP printer (LittleRP.com) using an Acer H6510 BD DLP Projector (Acer, San Jose, California). The multi-material model was printed in three segments using the same printing settings and polymerization parameters for each segment. The resulting model had a shock-absorber structure consisting of a soft polymer portion sandwiched between two hard polymer portions, similar to a vertebra-disc-vertebra functional unit (or “motion segment”) in the spine.[25] This model was printed with a plus-shaped cross section to demonstrate the extent to which the central, soft polymer region could be manipulated while the outer regions experienced much less deformation. More details on the printing procedure used to make the multi-material model can be found in the supplemental information.

Figure 3.

Resins of varying elastic modulus were successfully printed together with a seamless interface. (A) Soft (1:0) EGPEA formulation was printed between two layers of hard (1:1) EGPEA. The soft region of this structure preferentially deformed under (B) compression, (C) torsion, and (D) bending.

3. Results

3.1. Mechanical Characterization

All samples exhibited a similarly characteristic force-displacement relationship during tensile testing (Figure S4), consisting of an initially linear elastic regime, reaching a maximum yield stress, and then followed by a rapid failure regime in which the sample typically snapped in the central region of the dogbone configuration (Figure S5). The elastic modulus was calculated for each sample from the slope of the linear elastic region. he average elastic modulus for each monomer-to-crosslinker ratio is listed in the table in Figure 1. As illustrated in the formulation versus elastic modulus plot in Figure 1, the elastic modulus increased monotonically from about 0.6 MPa with no added crosslinker (1:0 ratio) to a maximum of about 31 MPa achieved with 1:0.75 mixing ratio. After the 1:0.75 mixing ratio, the modulus curve reached a plateau suggesting saturation of available monomer binding sites with essentially no further increase of modulus despite adding crosslinker up to a 1:1 mixing ratio. The printed test specimens followed the same trends that were observed in the cast specimens, although their elastic moduli tended to be larger than those of the cast specimens, especially for the 1:0.4 and 1:1 formulations.

3.2. Dimensional Accuracy

All three sizes of the cube models for testing dimensional accuracy successfully printed using all polymer mixtures, with the exception of the 1.5cm cube at 1:1, high photoinitiator mixture. Across all sizes and formulations, the X-face saw the greatest deviation followed by the Z-face and, with the least overall deviation, the Y-face (Figure S3). However, no cube dimensions varied from the intended dimensions by more than ±3% maximum error. For all models and formulations, though, the Y-faces had the greatest tendency to undershoot the prescribed dimension. This coupled with the relatively high variability of the X-face suggest that these dimensional deviations could be due to surface tensions between solid polymer, transitioning polymer, and liquid polymer. These dimensional deviations exhibited a trend for soft polymer formulations to produce cubes slightly larger than designed and hard polymer formulations to produce cubes slightly smaller than designed (see Figure S3). This trend in print size variation is likely a consequence of differences in size between the larger acrylate monomers and the smaller crosslinker molecules. In the stiff (1:1) formulation, the available acrylate bonding sites would be filled by both other monomers and the acrylic crosslinker, whereas a soft (1:0) formulation would only have other monomers available for acrylate polymerization. Therefore, the stiff formulation would see all of its binding sites saturated over a shorter length scale than the soft formulation, resulting in smaller print dimensions for the stiffer resin.

3.3. Feature Detail

The detailed rook model had several key features that needed to be reproduced by the printed resin in order to indicate suitable feature resolution. First, and easiest to resolve, was the internal spiral staircase, which runs up the inner wall of the model (Figure 2B). Second, and more difficult to resolve was the embossed text spelling “MAKE: ROOK” at the base of the model (Figure 2C). Lastly, and by far the most difficult to resolve was the text at the top of the model spelling “Make: RESIN PRINTER TORTURE PIECE” (Figure 2D), the successful printing of which is indicative not only of a well-calibrated optical system but also a polymer resin with high spatial restriction of the photopolymerization reaction. Upon inspection, all three tested resins – FTX Green, 1:1 EGPEA, and 1:0 EGPEA – successfully resolved all model features with comparable accuracy and resolution. Measuring the text on top of each printed model, no character size deviated from the prescribed 1.3-mm CAD dimensions by more than 100µm (see Table S7 for more details), representing less than 8% error in these fine details. The 1:1 and 1:0 mixtures experienced a small amount of over-curing, seen in the slight over-polymerization in the space between outer wall helices (refer to Figures 2B, 2C and Figure S6). When those same mixtures were modified to reduce overcuring by adding additional photoinitiator[14], the over-curing artifacts were no longer visible (Figure S6C). The modified soft formulation of EGPEA, however, did not consistently print successfully, suggesting addition of excess photoinitiator might also compromise inter-layer adhesion, as others have noted [26,27]. An alternative approach might be to add a small quantity of UV-absorbing or otherwise photo-opaque agent to the current polymer formulation to limit over-curing beyond the actively printed layer, as described elsewhere.[26]

3.4. Multi-Material Printing

Finally, the multi-material model printed successfully, with seamless bonds between the soft and hard polymer formulations, and was capable of being manipulated through compression (Fig. 3B), torsion (Fig. 3C), and bending (Fig. 3D) without cleavage at the material interface. Furthermore, this material interface was an abrupt transition between hard and soft polymers, requiring no spatial gradation of elastic moduli to facilitate a strong bond between materials. Based on the minimal (<3%), and consistent dimensional deviations seen in single-material models, we neglected minor differences in shrinkage at the interface between hard and soft formulations during multi-material printing, which permitted successful multi-material models without having to adjust the printer settings for each material.

4. Discussion

A key factor that has hindered more widespread adoption of desktop/consumer 3D printing of functional prototypes has been the lack of material variability that can be produced within a single model. The polymeric resins presented here can easily have their elastic modulus varied by 50-fold without fundamentally altering the polymeric structure. While some FDM 3D printers are capable of printing two or more materials at a time, poor inter-layer adhesion limits the variability of materials that can be printed simultaneously.[28] This approach, however, allows the different formulations to readily bond to one another according to the same acrylic acid step polymerization process, enabling the construction of complex, physically detailed, materially heterogeneous, and mechanically robust 3D models.

Despite many advances in the speed and resolution of photopolymerization-based 3D printing systems, no commercial ACCEPTED SLA or DLP printer is currently capable of printing with more than one material at a time.[29] Although individual resins for DLP and SLA printers are available with a variety of elastic moduli, differences in formulation chemistry complicate the combination of hard and soft materials integrated into a single model.[12] Furthermore, even in commercial systems that offer a selection of chemically similar polymers, only a relatively limited variety of mechanical properties are provided. An industrial multi-material printing system (using a 3D printing method different than SL or DLP) may offer materials with a range of elastic moduli from a few MPa to several GPa; however, this wide range is divided over fewer than 10 pre-formulated resins, providing only a coarse gradation of mechanical options,[30] with no capability for customization. By using a non-proprietary and readily available polymer formulation,[31,32] we can precisely produce printed constructs with elastic moduli anywhere between the upper and lower bounds of our EGPEA resin formulations, spanning the range from a stiff “shoe heel”-like material to a soft “gummy bear” consistency.

As expected from the rapid failure of most specimens following the linear elastic regime, the ultimate tensile stress (multiplied by 10x in Figure 1 for visual clarity) followed the same increasing trend with higher crosslinker concentration as the elastic modulus. It was also anticipated that the maximum strain would decrease with increasing crosslinker concentration, as the polymer formulations became less elastic and more brittle. The apparent exponential decrease in maximum strain, however, was not anticipated and may indicate the saturation of available monomer binding sites earlier than the 1:0.75 mixing ratio. In this scenario, the rapid decrease in maximum strain would be the result of the crosslinks between monomers and the further increase in elastic modulus and ultimate tensile stress would be due to additional crosslinks between crosslinker molecules.

An unexpected result of our mechanical characterization tests was the trend of the printed dogbone specimens to have a higher elastic modulus than their corresponding cast specimens. Despite a printing orientation that would have maximized the chance that those specimens would be weaker due to interface bonds orthogonal to the tensile testing axis, all three printed formulations were at least as strong as or stronger than their corresponding cast specimens. These results support previously published results demonstrating isotropy of chemical bonds in commercially available resins [33] as well as our own results showing seamless bonding between hard and soft polymer formulations.

While there was little intra- or inter-batch variability in both printed and cast specimens, in the case of the cast samples the 1:0.4 and 1:1 mixing ratios were notable exceptions. For both of these formulations, all test specimens from the third formulation batch failed at the neck of the dogbone samples, rather than the central portion, suggesting premature failure due to stress concentrations at the testing clamp. The same testing clamp was used for all experiments, however, the samples being ultimately fixed by screws tightened by hand, there is a chance these specimens were more tightly clamped than the other specimens. Ultimately, we recommend future users of these polymer formulations provide their own mechanical tests if they seek to produce samples with a particular elastic modulus.

This study also highlights some of the design issues that have yet to be fully resolved in multi-material SLA/DLP printing, in particular dimensional accuracy. Previous studies on multi-material stereolithography have performed only qualitative assessments of multi-material printed constructs and have not taken into account potential structural differences that could arise during fabrication as the molecular environment changes from one material to another.[12,16,18] In those studies, instead, all of the polymer resins that were investigated were specifically modified with chemical dilutants, creating resins with similar printing performance with respect to viscosity and, relatedly, similar mechanical properties, despite differences in composition such as monomer and oligomer composition or the presence of different dyes and colors. While this study used only a single acrylate monomer and crosslinker, the variation of crosslinker composition in the resins that were investigated was shown to yield consistent, if small, variations in printed dimensions. The consistent split between undersized models with low crosslinker content and oversized models with high crosslinker content, even when adjusted to minimize effects due to optical overcuring and leaking, clearly demonstrates the molecular factors that can impact printing resolution and accuracy. The soft polymer formulations, comprised only of monomers and photoinitiator and with fewer available binding sites in a given area, will tend to react and bind over a larger area in order to saturate all the available binding sites. Hard formulations, on the other hand, have crosslinker molecules in addition to monomers present and thus a higher density of acrylate groups to bind with in the same area, resulting in less spread of the polymerization reaction in order to saturate all available bonds. Further fine-tuning of the chemical composition of these resin mixtures could reduce the current spatial variations, although software-based fixes to adjust optical parameters could also be employed to correct for inter-polymer variation.

Broad mechanical tunability and ease of chemical bonding between mechanically distinct layers makes these EGPEA polymer resins particularly interesting for advanced structural models with features such as living hinges, shock absorbers, or textured surfaces. To truly take advantage of these advanced mechanical properties, however, new SLA and DLP systems will need to be developed that enable the co-localization of different polymer mixtures on the same model layer, as opposed to the inter-layer bonding demonstrated in this paper. While our current printing scheme for multi-material models involved manually swapping material trays within the DLP printer, it is not hard to imagine a modified DLP printer that is capable of moving the build platform between two or more different resin trays in order to print more elaborate and spatially complex multi-material structures. Such systems have already been demonstrated as research prototypes constructed from modified SLA printers, although further engineering and design will be needed in order to enter the commercial setting.[12,16,34,35] As of yet, the approaches used in these SLA systems have not been adapted for use in DLP systems. With similar chemistry and machinery, however, it is likely to see an adaption for DLP in the not-too-distant future.

5. Conclusion

In this paper, we demonstrate an acrylate photopolymer resin of facile and mechanically tunable formulation that is suitable for use with SLA and DLP 3D printing systems. Through simple adjustments of monomer and crosslinker ratios, we achieved a 50-fold change in elastic modulus. These formulations are reliably printed across the full range of these elastic moduli, retaining mechanical integrity, dimensional accuracy and high feature resolution. Furthermore, multiple mechanical formulations can be printed adjacently and seamlessly, due to a common underlying material chemistry . While there is still room to improve the resin formulation with regards to optics and spatial restriction of the photopolymerization reaction, the current photopolymer formulation should be suitable for a number of mechanically diverse applications and holds promise for future multi-material printing development.

Supplementary Material

Acknowledgements

The authors would like to thank Peter Backeris and David Sachs for assistance with machining, 3D printing, and access to fabrication equipment. Funding for this work was partially supported by the NIH/NIGMS-funded Integrated Pharmacological Sciences Training Program (T32 GM062754). Funding was also provided by the Cardiovascular Research Center and Translational and Molecular Imaging Institute at Mount Sinai. This work was also supported in part through the resources and staff expertise provided by the Sinai BioDesign Center at the Icahn School of Medicine at Mount Sinai.

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- [1].Gardan J, Additive manufacturing technologies: state of the art and trends, Int. J. Prod. Res 54 (2016) 3118–3132. doi: 10.1080/00207543.2015.1115909. [DOI] [Google Scholar]

- [2].Yeh C-C, Trend Analysis for the Market and Application Development of 3D Printing, Int. J. Autom. Smart Technol 4 (2014) 1–3. doi: 10.5875/ausmt.v4i1.597. [DOI] [Google Scholar]

- [3].Leigh SJ, Bradley RJ, Purssell CP, Billson DR, Hutchins DA, A Simple, Low-Cost Conductive Composite Material for 3D Printing of Electronic Sensors, PLOS ONE 7 (2012) e49365. doi: 10.1371/journal.pone.0049365. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [4].Kwok SW, Goh KHH, Tan ZD, Tan STM, Tjiu WW, Soh JY, Ng ZJG, Chan YZ, Hui HK, Goh KEJ, Electrically conductive filament for 3D-printed circuits and sensors, Appl. Mater. Today 9 (2017) 167–175. doi: 10.1016/j.apmt.2017.07.001. [DOI] [Google Scholar]

- [5].Stampfl J, Baudis S, Heller C, Liska R, Neumeister A, Kling R, Ostendorf A, Spitzbart M, Photopolymers with tunable mechanical properties processed by laser-based high-resolution stereolithography, J. Micromechanics Microengineering 18 (2008) 125014. doi: 10.1088/0960-1317/18/12/125014. [DOI] [Google Scholar]

- [6].Hull CW, Spence ST, Albert DJ, Smalley DR, Harlow RA, Steinbaugh P, Tarnoff HL, Nguyen HD, Lewis CW, Vorgitch TJ, Remba DZ, Methods and apparatus for production of three-dimensional objects by stereolithography, US5059359 , 1991. http://www.google.com/patents/US5059359 (accessed December 29, 2016).

- [7].Backeris P, Borrello J, Rapid Prototyping Technologies, in: Rapid Prototyp. Card. Dis. - 3D Print. Heart, 1st ed., Springer International Publishing AG, 2017. [Google Scholar]

- [8].Gauvin R, Chen Y-C, Lee JW, Soman P, Zorlutuna P, Nichol JW, Bae H, Chen S, Khademhosseini A, Microfabrication of complex porous tissue engineering scaffolds using 3D projection stereolithography, Biomaterials 33 (2012) 3824–3834. doi: 10.1016/j.biomaterials.2012.01.048. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [9].Lu Y, Mapili G, Suhali G, Chen S, Roy K, A digital micro-mirror device-based system for the microfabrication of complex, spatially patterned tissue engineering scaffolds, J. Biomed. Mater. Res. A 77A (2006) 396–405. doi: 10.1002/jbm.a.30601. [DOI] [PubMed] [Google Scholar]

- [10].Shanjani Y, Pan CC, Elomaa L, Yang Y, A novel bioprinting method and system for forming hybrid tissue engineering constructs, Biofabrication 7 (2015) 045008. doi: 10.1088/1758-5090/7/4/045008. [DOI] [PubMed] [Google Scholar]

- [11].Sun C, Fang N, Wu DM, Zhang X, Projection micro-stereolithography using digital micro-mirror dynamic mask, Sens. Actuators Phys 121 (2005) 113–120. doi: 10.1016/j.sna.2004.12.011. [DOI] [Google Scholar]

- [12].Wicker RB, MacDonald EW, Multi-material, multi-technology stereolithography, Virtual Phys. Prototyp 7 (2012) 181–194. doi: 10.1080/17452759.2012.721119. [DOI] [Google Scholar]

- [13].Zhou Chi, Chen Yong, Yang Zhigang, Khoshnevis Behrokh, Digital material fabrication using mask‐image‐projection‐based stereolithography, Rapid Prototyp. J 19 (2013) 153–165. doi: 10.1108/13552541311312148. [DOI] [Google Scholar]

- [14].Leigh SJ, Gilbert HTJ, Barker IA, Becker JM, Richardson SM, Hoyland JA, Covington JA, Dove AP, Fabrication of 3-Dimensional Cellular Constructs via Microstereolithography Using a Simple, Three-Component, Poly(Ethylene Glycol) Acrylate-Based System, Biomacromolecules 14 (2013) 186–192. doi: 10.1021/bm3015736. [DOI] [PubMed] [Google Scholar]

- [15].Understanding Kudo3D High Resolution Calibration Model, Kudo3D Inc (2016). https://www.kudo3d.com/understanding-kudo3d-high-resolution-calibration-model/ (accessed August 3, 2017).

- [16].Choi J-W, Kim H-C, Wicker R, Multi-material stereolithography, J. Mater. Process. Technol 211 (2011) 318–328. doi: 10.1016/j.jmatprotec.2010.10.003. [DOI] [Google Scholar]

- [17].Choi JW, Ha YM, Lee SH, Choi KH, Design of microstereolithography system based on dynamic image projection for fabrication of three-dimensional microstructures, J. Mech. Sci. Technol 20 (2006) 2094–2104. doi: 10.1007/BF02916326. [DOI] [Google Scholar]

- [18].Wicker R, Medina F, Elkins C, Multiple Material Micro-Fabrication: Extending Stereolithography to issue Engineering and Other Novel Applications, in: Proc. Annu. Solid Free. Fabr. Symp, Austin, TX, 2004: pp. 754–764. [Google Scholar]

- [19].Yeung T, Georges PC, Flanagan LA, Marg B, Ortiz M, Funaki M, Zahir N, Ming W, Weaver V, Janmey PA, Effects of substrate stiffness on cell morphology, cytoskeletal structure, and adhesion, Cell Motil. Cytoskeleton 60 (2005) 24–34. doi: 10.1002/cm.20041. [DOI] [PubMed] [Google Scholar]

- [20].Alakpa EV, Jayawarna V, Lampel A, Burgess KV, West CC, Bakker SCJ, Roy S, Javid N, Fleming S, Lamprou DA, Yang J, Miller A, Urquhart AJ, Frederix PWJM, Hunt NT, Péault B, Ulijn RV, Dalby MJ, Tunable Supramolecular Hydrogels for Selection of Lineage-Guiding Metabolites in Stem Cell Cultures, Chem 0 (2016). doi: 10.1016/j.chempr.2016.07.001. [DOI] [Google Scholar]

- [21].Cruz MA, McAnany S, Gupta N, Long RG, Nasser P, Eglin D, Hecht AC, Illien-Junger S, Iatridis JC, Structural and Chemical Modification to Improve Adhesive and Material Properties of Fibrin-Genipin for Repair of Annulus Fibrosus Defects in Intervertebral Disks, J. Biomech. Eng 139 (2017) 084501–084501–7. doi: 10.1115/1.4036623. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [22].barrand, Rook, Thingiverse (2015). https://www.thingiverse.com/thing:1159688.

- [23].Make: Rook - 2015 3D Printer Shoot Out Test Models, Thingiverse (2014). https://www.thingiverse.com/thing:533652.

- [24].Annual Guide to 3D Printing 2015, Make Mag 42 (2015). [Google Scholar]

- [25].Serhan H, Labrom R, Hawkins J, Dunbar W, Borgstrom A, Kwak S, Dooris A, Slivka M, Functional spinal unit prosthetic, US20050055096 A1, 2005. http://www.google.com/patents/US20050055096.

- [26].Choi Jae‐Won, Wicker Ryan B., Cho Seok‐Hyun, Ha Chang‐Sik, Lee Seok‐Hee, Cure depth control for complex 3D microstructure fabrication in dynamic mask projection microstereolithography, Rapid Prototyp. J 15 (2009) 59–70. doi: 10.1108/13552540910925072. [DOI] [Google Scholar]

- [27].Gong H, Bickham BP, Woolley AT, Nordin GP, Custom 3D printer and resin for 18 μm × 20 μm microfluidic flow channels, Lab. Chip (2017). doi: 10.1039/C7LC00644F. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [28].The Ultimate Guide to Stereolithography (SLA) 3D Printing, (n.d.). https://formlabs.com/blog/ultimate-guide-to-stereolithography-sla-3d-printing/ (accessed August 3, 2017).

- [29].Truby RL, Lewis JA, Printing soft matter in three dimensions, Nature 540 (2016) 371–378. doi: 10.1038/nature21003. [DOI] [PubMed] [Google Scholar]

- [30].ProJet MJP 5600, (2017). www.3dsystems.com.

- [31].Chen H, Maliakal A, Alignment of Janus Particles In Dielectric Elastomer Films and Their Effect On Mechanical Actuation, in: Part. Technol Forum, New York, 2011. [Google Scholar]

- [32].Chen H, Maliakal AJ, Kretzschmar I, Effect of Janus particles as filler materials for acrylatebased dielectric elastomers, in: International Society for Optics and Photonics, 2012: p. 83402W. doi: 10.1117/12.922943. [DOI]

- [33].Validating Isotropy in SLA 3D Printing, Formlabs (2016). https://formlabs.com/blog/isotropy in-SLA-3D-printing/ (accessed June 25, 2018).

- [34].Chan V, Jeong JH, Bajaj P, Collens M, Saif T, Kong H, Bashir R, Multi-material biofabrication of hydrogel cantilevers and actuators with stereolithography, Lab Chip 12 (2012) 88–98. doi: 10.1039/C1LC20688E. [DOI] [PubMed] [Google Scholar]

- [35].Ge Q, Sakhaei AH, Lee H, Dunn CK, Fang NX, Dunn ML, Multimaterial 4D Printing with Tailorable Shape Memory Polymers, Sci. Rep 6 (2016) 31110. doi: 10.1038/srep31110. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.