Abstract

Phytosterols are plant sterols recommended as adjuvant therapy for hypercholesterolemia and tocopherols are well-established anti-oxidants. However, thermo-sensitivity, lipophilicity and formulation-dependent efficacy bring challenges in the development of functional foods, enriched with phytosterols and tocopherols. To address this, we developed liposomes containing brassicasterol, campesterol and β-sitosterol obtained from canola oil deodorizer distillate, along with alpha, gamma and delta tocopherol. Three approaches; thin film hydration-homogenization, thin film hydration-ultrasonication and Mozafari method were used for formulation. Validated liquid chromatographic tandem mass spectrometry (LC-MS/MS) was utilized to determine the entrapment efficiency of bioactives. Stability studies of liposomal formulations were conducted before and after pasteurization using high temperature short time (HTST) technique for a month. Vesicle size after homogenization and ultrasonication (<200 nm) was significantly lower than by Mozafari method (>200 nm). However, zeta potential (−9 to −14 mV) was comparable which was adequate for colloidal stability. Entrapment efficiencies were greater than 89% for all the phytosterols and tocopherols formulated by all three methods. Liposomes with optimum particle size and zeta potential were incorporated in model orange juice, showing adequate stability after pasteurization (72 °C for 15 s) for a month. Liposomes containing phytosterols obtained from canola waste along with tocopherols were developed and successfully applied as a food additive using model orange juice.

Keywords: phytosterols, tocopherols, liposomes, canola oil deodorizer distillate, model orange juice

1. Introduction

Functional foods and nutraceuticals are increasing rapidly due to growing consumer preferences towards natural bioactives rather than synthetic drugs for disease prevention and treatment [1]. Phytosterols and tocopherols are such bioactives (plant metabolites) that have numerous health claims [2,3]. The primary health benefit of phytosterols is to lower low-density lipoprotein (LDL) cholesterol levels in plasma [2,4,5]. Due to this health claim, the National Cholesterol Education Program Adult Treatment Panel III (NCEP ATP III) has recommended phytosterols as adjuvant therapy to statins in hypercholesterolemia [6]. Phytosterols compete with cholesterol for their solubilization in bile salt micelles, hindering the absorption of cholesterol in blood [7,8]. Tocopherols, on the other hand, are free radical scavengers and natural anti-oxidants [9,10]. Due to their anti-oxidant properties, tocopherols are used in the treatment of age related macular degeneration [11], Alzheimer’s disease [12], glaucoma [3] and heart diseases [13].

Sources of phytosterols and tocopherols include oil seeds such as canola and sesame, as well as nuts [14,15,16]. Among these, canola is a major source for edible vegetable oils, and the most abundant oilseed crop in Canada [17]. It is a rich source of four phytosterols, namely beta-sitosterol, campesterol, stigmasterol and brassicasterol, and four tocopherols (alpha, beta, gamma and delta) [16,18]. Canola oil loses some of its valuable components during the refining process [16]. Significant amount of phytosterols and tocopherols are transferred to the waste stream, termed canola oil deodorizer distillate (CODD) [16] which offers an ideal source of these components.

However, formulation of these bioactives in functional foods has always been challenging due to their lipophilicity and light sensitivity [19]. In particular, degradation products of phytosterols, phytosterol oxidation products (POPs), are known to have some negative impact on human health [20,21]. Thus, the selection of suitable formulation approach is crucial during the development of functional food that contain these bioactives. Encapsulation techniques, such as spray drying, fluidized bed coating, microemulsification and liposomal entrapment are emerging in the food industry to address lipophilicity related challenges [22,23]. Unfortunately, most of these techniques have shortcomings such as usage of high temperature (can possibly degrade phytosterols and tocopherols) and the requirement of large quantities of emulsifiers and surfactants, which are deleterious to human health [23,24,25,26,27]. All of these shortcomings can be addressed by employing liposomal formulations that require low heat and low quantities of surfactants or emulsifiers [28].

Phytosterols in both the free and esterified forms have been used in the food industry [2,4]. Solubilization of esterified phytosterols in fat containing foods, like margarine [29,30], salad dressing [31] and yogurt [32] is prevalent in the food industry. However, this approach is not favorable to people who are on low fat diet [33]. To overcome this, various low fat or non-fat food matrices such as low fat milk [34,35], granola bars [36], orange juice [37] and non-fat beverages [38,39,40] are emerging as food products. However, for these type of food products, lipophilic phytosterols should be well formulated prior to their development into functional food. In addition to the choice of the food matrix, the biological efficacy should also be carefully considered.

Various clinical trials have shown that the efficacy of phytosterols depends on different parameters, such as solubility in the food matrix and the formulation [2,41]. Esterified phytosterols solubilized in fat/oil are driven favorably towards the bile salt micelles in the guts than the crystalline or the insolubilized forms [42,43]. Phytosterols ester containing food products such as milk, spread and yogurt have showed reduction in LDL-cholesterol by 7–12% at daily dose of 1.6–2 g relative to control research participants [44,45,46]. In contrast, some failed clinical trials are also prevalent [47,48]. For example, Ottestad et al. showed that phytosterol ester in the capsular formulation revealed no significant reduction of LDL cholesterol [47]. Similarly, Denke et al. showed no significance in cholesterol reduction by sitostanol capsule relative to control [48]. Unlike phytosterol capsule-based trials, lecithin-based free phytosterol formulations have shown to impart efficacy as high as 14.3% at a daily dose of only 1.9 g relative to control [39]. In sum, literature reports show that the efficacy of phytosterols depends greatly on the formulation approach, which provides insights regarding the possibility of further enhancing their efficacy by well formulating in suitable delivery systems.

The work of Shin at al. [38] and Spilburg at al. [39] provides a strong evidence that lecithin (phosphatiylcholine) can be effective carrier of phytosterols to increase cholesterol-lowering efficacy. Both of these studies used lecithin micelles to formulate sterol/stanol which have shown promising cholesterol-lowering efficacy [38,39]. Liposomes, which have same building blocks as micelles that is lecithin (i.e., phosphatidylcholine) but different architecture are another formulation strategy in which lecithin can be utilized, thus have potential of further enhancing its cholesterol-lowering efficacy. In addition, liposomes can prevent oxidation of thermo-sensitive bioactives and are biocompatible and biodegradable [49]. Further, co-formulation of tocopherols along with phytosterols can enhance oxidative stability of phytosterols [50].

Thus, in this work, with the aim of enhancing phytosterols’ oxidative stability and increasing its efficacy, we formulated phytosterols (obtained from CODD) and commercially available tocopherols into liposomes employing three different approaches, namely thin film hydration homogenization, thin film hydration ultra-sonication and Mozafari method. The liposomal formulation showing the highest entrapment efficiency, adequate size and zeta potential was incorporated into model orange juice (acidified solution). Thus, functional orange juice containing liposomal phytosterols and tocopherols was developed and its stability was assessed.

2. Materials

Chemicals and Reagents

Phytosterols were extracted from CODD obtained from LDM foods (Yorkton, SK, Canada). Briefly, 5 g of CODD was saponified with 1 M potassium hydroxide in 95% ethanol for 1 h at 65 °C after which water was added and the mixture was chilled at 9.5 °C for 1 h. After the crystallization of phytosterols, vacuum filtration was performed and the residue was washed before being dried under high vacuum. Tocopherols, chloroform, ethyl acetate and potassium hydroxide were purchased from Sigma Aldrich (Oakville, ON, Canada), and phosphatidylcholine (PC) was purchased from Avanti Polar Lipids (Alabaster, AL, USA). Purified water was obtained from Millipore (Bedford, MA, USA).

3. Methods

3.1. Formulation of Liposomes

Three different formulation techniques namely thin film hydration homogenization; thin film hydration ultrasonication and Mozafari method were used for formulation in order to evaluate the formulation technique that can produce liposomes with optimum physicochemical properties for both oral delivery and industrial scale up.

3.1.1. Method I. Thin Film Hydration–Homogenization

This method was adopted from Chung et al. [51] with some modifications. In brief, tocopherols (alpha, gamma and delta tocopherol), phytosterols mixture (brassicasterol, campesterol and beta-sitosterol) and PC were dissolved in 5 mL ethyl acetate (food grade) in 0.1:0.9:2, 0.1:0.9:3, 0.1:0.9:4 and 0.1:0.9:5 ratio of tocopherol: phytosterol: PC. Ethylacetate was evaporated using rotary evaporator at pressure of 90 mmHg. The thin lipid film containing bioactives and PC formed on the wall of the flask was lyophilized for 10 h to remove traces of ethylacetate and was hydrated with 20 mL of purified water for 3 h at 55°C with occasional vortexing in the presence of glass beads. The lipid dispersion was homogenized using recirculating high fluid pressure homogenizer (Microfluidics Corporation, Westwood, MA, USA) at 60 psi for 20 min. The prepared liposomes were left overnight at 4 °C prior to size analysis.

3.1.2. Method II: Thin Film Hydration Ultrasonication

This method was adopted from Akbarzadeh et al. [52]. Similar to thin film hydration homogenization; tocopherols (alpha, gamma and delta tocopherol), phytosterols mixture (brassicasterol, campesterol and beta-sitosterol) were dissolved, along with PC in 5 mL ethyl acetate, in 0.1:0.9:2 ratio of tocopherols: phytosterols: PC. Ethylacetate was evaporated using rotary evaporator at pressure of 90 mmHg. Thin lipid film containing bioactives and PC was formed at the bottom of the flask. Lipid film was lyophilized for 10 h to remove traces of ethylacetate and was hydrated with 20 mL of purified water maintained at 55°C. Lipid dispersion was ultrasonicated using bath sonicator (ELMA Corp.,Singen, Germany) for 30 min maintained at 55 °C then was allowed to cool at room temperature. The prepared liposomes were left overnight at 4 °C prior to size analysis.

3.1.3. Method III: Mozafari Method

This method was adopted from Colas et al. [53]. 50 mg of PC was hydrated with 20 mL of purified water for 1 h and was heated to 55 °C. Nine mg of the phytosterol mixture and 1 mg of the tocopherol mixture were heated with 3% v/v glycerol at 110 °C and 55 °C temperature, respectively for 15 min on a hot plate stirrer at approximately 1000 RPM (Corning Corporation, Midland, ON, Canada) and then was cooled down to 55 °C. PC dispersion, phytosterols and tocopherols were mixed together with stirring on a hot plate for 30 min at approximately 1000 RPM. The formed liposomes were cooled down to room temperature and kept overnight at 4 °C prior to size analysis.

3.2. Characterization of Particle Size, Size Distribution and Zeta Potential

Particle size and zeta potential measurement of the liposomes were performed using Zeta sizer, Nano ZS instrument, Malvern instruments Ltd. (Worcestershire, England). All measurements were conducted in triplicates at 25 °C and reported as mean ± SD.

3.3. Transmission Electron Microscopy (TEM) Analysis

TEM analysis was performed by negative staining. Briefly, a drop of liposomal sample was placed on copper- formvar coated TEM grid and was allowed to settle on grid surface for 1 min. Excess of the liquid was removed using absorbent tissue. Staining of grid was done using 0.5% phosphotungstic acid for 30 s and excess of stain is removed. Imaging was done using aHT 7700 TEM (Hitachi, Japan) at 80 kV.

3.4. LC-MS/MS Method Development and Validation

LC-MS/MS method was developed and was validated as per International Council for Harmonization of Technical Requirements for Pharmaceuticals for Human Use (ICH) guidance for bioanalytical method validation guideline [54]. Briefly, chromatographic separation of the analytes was carried out on an Agilent Acquity UPLC (Agilent Technologies, Mississauga, ON, Canada) with an Agilent Poroshell C18 column (2.1 mm × 150 mm, 5µm) protected by a guard column (2.1 mm × 4.7 mm, 2.7 µm) of the same packing material. The column temperature was set at 30 °C and the injection volume was 2.5 µL. An isocratic elution consisting of acetonitrile: methanol (99:1 v/v) with 0.1% acetic acid was used at a flow rate of 0.8 mL/min. The detection and quantification were performed using an API 6500 QTRAP® quadruple-linear ion trap (QqQ-LIT) mass spectrometer equipped with an atmospheric pressure chemical ionization (APCI) source obtained from AB Sciex(Mississauga, ON, Canada). The instrument was operated in the positive ion mode and tandem mass spectrometric analysis (MS/MS) was employed using the following interface parameters: source temperature 380 °C, curtain gas 30 psi (gas), nebulizer current 2.5 µA, declustering potential 30 V and an ion source gas1 30 psi (gas) [55].

The parameters, selectivity, accuracy, precision, reproducibility, sensitivity, matrix effects, dilution integrity, stability were assessed [55]

3.5. Entrapment Efficiency (EE)

In order to determine entrapment efficiency, free and entrapped bioactives were separated using ultracentrifugation. Ultracentrifuge (Beckman coulter, Inc., Indianapolis, IN, USA) with rotor SW 60Ti was used for ultracentrifugation. Briefly, 5 mL of liposomes was ultracentrifuged at 30, 60, 90 and 120 min at constant RPM 32,000 (G-force of 138000). The sediment at each time were analyzed using a validated LC-MS/MS method to optimize ultracentrifugation parameters. The liposomes (present in sediment) separated by ultracentrifugation were lyophilized using freeze dryer for 24 h. Similar lyophilization process was employed with 5 mL of unseparated liposomes for 24 h. Dried unseparated and separated liposomes were dissolved in 2 mL of chloroform separately. Aliquot of each were spiked with internal standard and diluted with acetonitrile. Samples were injected in LC-MS along with freshly prepared calibration and quality control standards, as described [55]. The entrapment efficiency was calculated by measuring the ratio of entrapped bioactives in the formulation to the total bioactives present in the formulation and was determined using following equation:

| (1) |

where, E bioactives = Entrapped bioactives in liposomes (present in sediment of separated liposomes); T bioactives = Total bioactives in liposomes (present in unseparated liposomes).

3.6. Development of Functional Juice Using Model Orange Juice

In order to preserve particle size during freeze drying, sucrose was added to liposomes as a cryoprotectant by adopting the procedure of Shaikh et al. [56]. Briefly, 5% w/v of sucrose was added to liposomes of well-defined size and was vortexed. Lyophilization then was employed for 24 h.

Freeze dried liposomes were re-suspended in model orange juice which is an orange juice mimic at 3.2 pH. A mimic was used instead of real orange juice to enable particle size analysis without the interference of particulate components existing in the orange juice. In fact, the acidified solution is considered a model juice and was prepared by using acetic acid as per the protocol of Marsansco et al. [57]. This protocol can be applied for fruit juice with a pH less than 5.0, such as orange juice and pineapple juice. Finally, liposomes with optimum entrapment efficiency in a dried form were incorporated into the model orange juice by vortexing for 5 min.

3.7. Pasteurization

High temperature short time (HTST) pasteurization technique was employed as described [58]. HTST is a commonly used strategy for the pasteurization of juice [59]. The liposomes containing model orange juice was pasteurized at 72 °C for 15 s. Unpasteurized formulation was used as a control. Both pasteurized and unpasteurized model juice were stored at 4 °C for stability evaluation.

3.8. Chemical Stability Studies

Both pasteurized and non-pasteurized model juice containing liposomal bioactives were analyzed using LC-MS/MS to assess the degradation of bioactive upon exposure to pasteurization temperature. Briefly, 5 mL each of pasteurized and non-pasteurized liposomal model juice were lyophilized. Dried sample were dissolved in chloroform and were diluted with acetonitrile for LC-MS/MS analysis. The LC-MS/MS response was compared to obtain relative quantification data.

3.9. Physical Stability Studies

Physical stability evaluation was conducted at the interval of 7 days for a month. Particle size of pasteurized and non-pasteurized liposomes incorporated both in model orange juice were analyzed.

4. Statistical Analysis

The statistical analysis of the samples was conducted with SPSS statistical software version 24 (SPSS Inc., Chicago, IL, USA) using student t-test, and p-values < 0.05 were considered statistically significant. All data are reported as means ± standard deviations.

5. Results and Discussions

5.1. Physicochemical Characterization

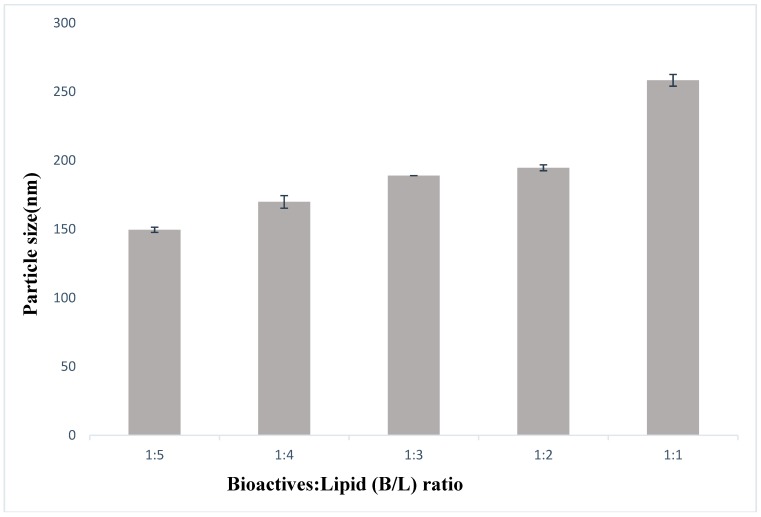

Size is an important parameter to assess the stability, the biological fate and the efficacy of formulated bioactives [60,61]. Optimization of bioactive to lipid weight ratio (B/L ratio) was performed at ratio of 1:5, 1:4. 1:3, 1:2, 1:1 using liposomes prepared by thin film hydration- homogenization approach. An increase in particle size was observed at high B/L ratio (1:1) as shown in Figure 1. At 1:5 B/L ratio, the particle size was 149.53 nm; however, when B/L ratio increased to 1:1, the particle size increased to 258.31 nm (Figure 1). This observation is reported previously [62,63], in which incremental vesicle size was observed when increasing the cholesterol (a sterol) concentration. While 1:1 ratio is preferable from a commercial point of view (less PC required for formulation), smaller particle size (less than 200 nm) attained at 1:2 ratio, is optimum for liposomal stability. This optimum vesicle size (less than 200 nm) is consistent with several food-based liposomes [64,65,66]. Thus, 1:2 B/L ratio was selected for follow-up experiments. Same optimum B/L ratio was selected for thin-layer ultrasonication approach. However, in case of the Mozafari method, B/L higher than 1:5 led to the appearance of visible white precipitate. Loading techniques along with the preparation procedures are found to influence drug/lipid ratio of liposomes [67]. In both thin film hydration homogenization and thin film hydration ultrasonication, hydrated bioactives-PC film is subjected to cavitation and shearing forces unlike the Mozafari method where less intense magnetic stirring is used during the loading process. This might have led to differences in the B/L ratio of the mozafari method in comparison with ultrasonication and homogenization methods. In this way, 1:5 B/L as optimum ratio was selected for formulations prepared by the Mozafari method.

Figure 1.

Particle size of liposomes prepared at different B/L ratio by homogenization method expressed as mean ± standard deviation.

The comparison of the vesicle size using the different formulation strategies is presented in Table 1. Thin film hydration homogenization and thin film hydration ultrasonication were comparable, showing sizes at 186.33 ± 4.38 nm and 196.2 ± 16.1 nm, respectively. On the other hand, the size was significantly larger in the case of the Mozafari method (260 ± 22.98 nm). It is possible that the high shear force and cavitation involved in size reduction during the homogenization and ultrasonication methods is the reason for the obtained smaller vesicles [68]. The Mozafari method uses a less intense magnetic stirring [69], probably yielding larger particles. Polydispersibility index (PDI) shown in Table 1 was found to be in the range from 0.29 to 0.37, which shows the desirable narrow size distribution for all formulations.

Table 1.

Average particle size (nm), polydispersibility index and zeta potential (mv) of liposomes prepared by thin film hydration homogenization, thin film hydration ultrasonication and Mozafari method expressed as mean ± standard deviation where * represents statistical significant (*p < 0.05) in average particle size of Mozafari method in comparison with homogenization and ultrasonication method.

| Formulation Techniques | Average Particle Size (nm) | Polydispersibility Index (PDI) | Zeta Potential (mV) |

|---|---|---|---|

| Thin film hydration Homogenization | 186.3 ± 4.4 | 0.370 ± 0.001 | −13.0 ± 5.0 |

| Thin film hydration ultra-sonication | 196.2 ± 16.1 | 0.294 ± 0.084 | −14.0 ± 3.4 |

| Mozafari method | 260.0 ± 23.0* | 0.348 ± 0.087 | −9.8 ± 0.3 |

Zeta potential (surface charge) is another important parameter that determines the stability of liposomal dispersions [70]. All the liposomes, demonstrated similar zeta potential values (Table 1), that is in the range of -9 mV to -14 mV, indicating relatively stable systems [71]. Thus, based on particle size and zeta potential, the developed liposomal formulations are theoretically stable that was confirmed experimentally by conducting the stability studies.

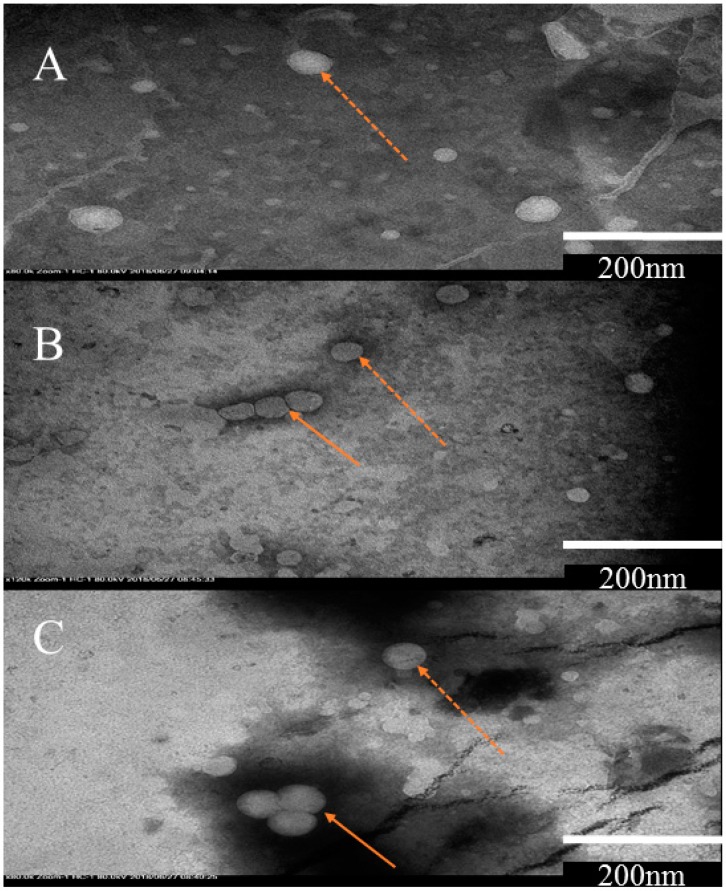

Finally, TEM analysis of liposomes shows spherical shaped particles with a single lipid bilayer (Figure 2), representing the expected morphology of unilamellar liposomal vesicles (ULV) [72,73]. The size of approximately 200 nm is consistent with the size range measured by dynamic light scattering (DLS) (Table 1). Some aggregated particles were observed in ultra-sonication and Mozafari method as shown in Figure 2.

Figure 2.

Transmission electron microscopy (TEM) analysis of liposomes prepared by; (A) homogenization method, (B) Ultrasonication and (C) Mozafari method. Sample of unilamellar vesicles are shown with a dotted arrow while aggregates are indicated by solid arrows. Scale bar in the figure A, B and C indicates 200nm, which represents the size of vesicle.

5.2. Entrapment Efficiency (%EE)

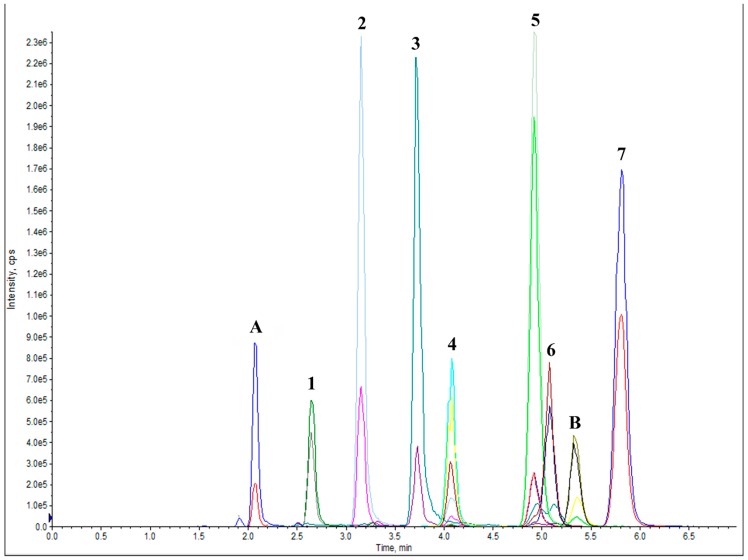

The developed LC-MS/MS method (representative chromatogram shown in Figure 3) was able to separate and quantify four phytosterols (brassicasterol, campesterol, stigmasterol and β-sitosterol) and three tocopherols (alpha, gamma and delta). Both ultracentrifugation parameters and entrapment efficiencies were determined by analyzing bioactive using LC-MS/MS. The separation of the liposomes during ultracentrifugation was time-dependent. Relatively low amounts of liposomes sedimented after 30 min (around 80% for all bioactives) of ultracentrifugation, whereas high sedimentation of liposomes was observed at 60, 90 and 120 min. There was no significant difference in sedimentation at 60, 90 and 120 min of ultracentrifugation. This supports the notion that after 60 min of ultracentrifugation at RPM 32,000 (G-force of 138000), a significant amount of liposomes was sedimented, leaving free bioactives in the supernatant.

Figure 3.

LC-MS/MS chromatogram of tocopherols: 1-δ tocopherol, 2-γ tocopherol, 3-α tocopherol; and phytosterols: 4-brassicasterol, 5-campesterol, 6-stigmasterol and 7-β-sitosterol. A-Rac tocol and B-cholestanol are internal standard.

The optimum entrapment efficiencies of phytosterols and tocopherols into the liposomes obtained by the thin film hydration homogenization, thin film hydration ultra-sonication and Mozafari method is shown in Table 2. The results demonstrate that all three methods resulted in entrapment efficiency > 89% for phytosterols and tocopherols. Table 2 does not show any specific pattern in entrapment efficiency for bioactives. For example, in case of thin film hydration homogenization method, brassicasterol showed the highest entrapment efficiency among all phytosterols; however, in the case of the Mozafari method, brassicasterol has the lowest entrapment efficiency. Similarly, the Mozafari method showed the highest entrapment efficiency for gamma tocopherols among all tocopherols. On the other hand, thin film hydration ultrasonication showed the lowest entrapment efficiency for gamma tocopherol. Thus, no concrete conclusion was obtained regarding entrapment differences between these bioactives. The entrapment efficiency of some of lipophilic compounds were reported to be almost close to 100% [74,75]. However, Table 2 shows EE in the range of 89–97% for various bioactives, evaluated in our work. It is possible that some of the liposomes were too small and failed to sediment during ultracentrifugation. This will lead to decreased EE (the amount of bioactives in the sediment were taken as a basis to calculate EE). Nevertheless, the obtained EE (shown in Table 2) is consistent with entrapment efficiency of nutraceuticals such as vitamin E, resveratrol and retinol specified in the literature [57,65,76]. High entrapment efficiency, that is, greater than 85% is considered economical for industrial application because it eliminates the cost of separating free and entrapped bioactives that will be required in case of low entrapment efficiency.

Table 2.

Entrapment efficiency of bioactives (phytosterols and tocopherols) into liposomes prepared by the thin film hydration homogenization, thin film hydration ultra-sonication and Mozafari method expressed as mean ± standard deviation.

| Methods | Entrapment Efficiency (EE %) | |||||

|---|---|---|---|---|---|---|

| Brassicasterol | Campesterol | β-Sitosterol | Alpha Tocopherol | Gamma Tocopherol | Delta Tocopherol | |

| Thin film hydration-Homogenization | 95.9 ± 1.7 | 94.0 ± 2.2 | 94.8 ± 3.0 | 91.6 ± 2.4 | 90.5 ± 2.9 | 91.6 ± 3.6 |

| Thin film hydration-Ultrasonication | 91.5 ± 2.4 | 92.3 ± 3.4 | 90.1 ± 1.9 | 91.2 ± 2.1 | 89.8 ± 3.1 | 90.1 ± 2.3 |

| Mozafari method | 89.4 ± 2.8 | 93.7 ± 6.0 | 93.1 ± 6.0 | 92.3 ± 7.5 | 97.4 ± 1.9 | 95.3 ± 1.4 |

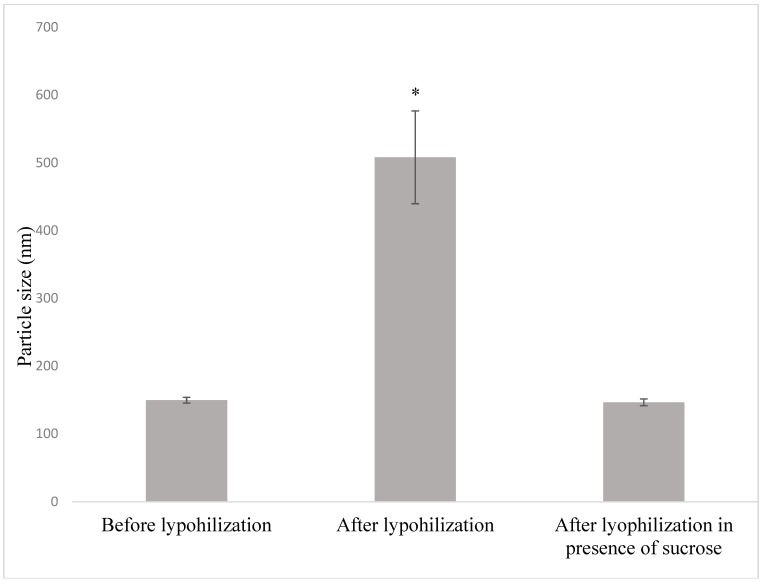

5.3. Effect of Lyophilization on the Physicochemical Properties

Freeze-drying of liposomes resulted in the increment in particle size, reaching up to 500 nm (Figure 4). Various food compatible cryoprotectants such as sucrose, mannitol and lactose can be used to address this issue [77]. Thus, food compatible sucrose was tested as a cryoprotectant [56]. The addition of sucrose maintained the desired particle size (Figure 4). The lyophilized liposomes were then incorporated into model orange juice. Lyophilization is one of the crucial steps used for stabilization of liposomes [78]. It extends the shelf life of liposomes and can prevent thermosensitive bioactives from degradation [78].

Figure 4.

Effect of addition of sucrose as a cryo-protectant on particle size of liposomes before and after lyophilization expressed as mean ± standard deviation where * represents statistical significant (*p < 0.05) in particle size after lyophilization in comparison to before lyophilization and after lyophilization in presence of sucrose.

5.4. Chemical Stability Studies

Pasteurization technique did not compromise the stability of bioactives as shown in Table 3. There was no significant change in the LC-MS/MS response for pasteurized and non-pasteurized formulations, ranging from 0.5 to 2.59% (Table 3). This shows that exposure to temperature of 72 °C for short time of 15 s does not degrade bioactives entrapped within liposomes in the model juice

Table 3.

Relative change in the concentration (represented by area under curve, AUC) of phytosterols and tocopherol before and after pasteurization.

| Bioactives | AUC of Non-Pasteurized Bioactives | AUC of Pasteurized Bioactives | Percentage Relative Change in AUC (%) of Pasteurized and Non-Pasteurized |

|---|---|---|---|

| Brassicasterol | 5.63 × 106 | 5.60 × 106 | 0.53 |

| Campesterol | 2.32 × 107 | 2.26 × 107 | 2.59 |

| β-sitosterol | 3.40 × 106 | 3.37 × 106 | 0.88 |

| α-tocopherol | 2.76 × 107 | 2.72 × 107 | 1.45 |

| γ-tocopherol | 4.94 × 106 | 4.89 × 106 | 1.01 |

| δ-tocopherol | 4.84 × 106 | 4.73 × 106 | 2.27 |

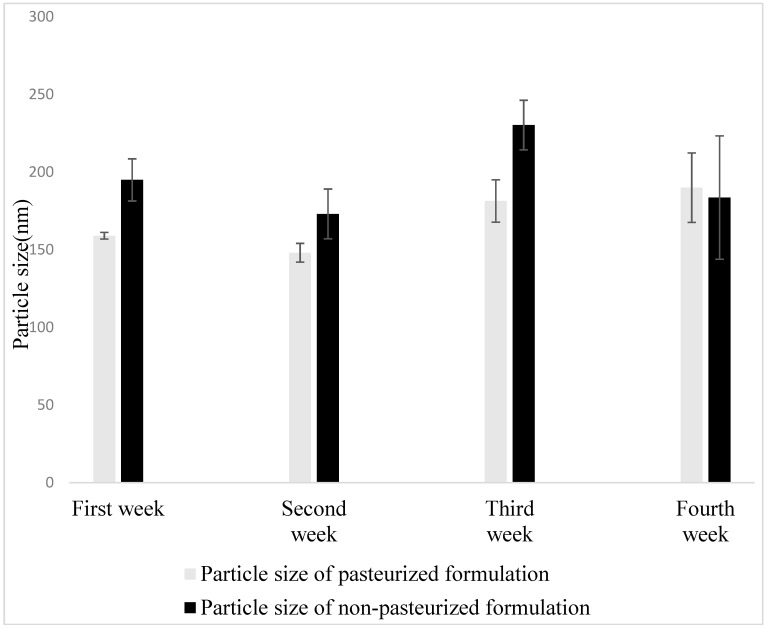

5.5. Physical Stability Studies

Both pasteurized and non-pasteurized liposomes in model orange juice showed similar trend in particle size (Figure 5). This implies that high temperature in HTST pasteurization process did not compromise the stability of the liposomes. Further, particle size of vesicle did not change significantly during the one-month storage at 4 °C (Figure 5). This shows that liposomal orange juice can be stored in 4 °C for a month with adequate stability. Regarding zeta potential, unlike liposomes in purified water, liposomal model juice was found to have positive zeta potential in the range of 5.6–8.9 mV. Even though this zeta potential value is generally considered an indicator of instability to the colloidal system [71], liposomal model orange juice showed adequate storage stability. Probably, the optimized smaller vesicular size maintained the stability of particles preventing its aggregation.

Figure 5.

Particle size of pasteurized and non-pasteurized liposomes incorporated in model orange juice during storage period of 1 month at 4 °C expressed as mean ± standard deviation.

6. Conclusions

To address the lipophilicity, heat and light sensitivity challenges, unilamellar liposomes containing phytosterols obtained from CODD and tocopherols were formulated and were applied to develop a functional juice. Three different formulation approaches were employed and were compared for their suitability in formulating phytosterols and tocopherols. All three methods showed optimum physicochemical properties and excellent entrapment efficiencies that were greater than 89%. Mozafari method was found to be simple and quick for formulating liposomes; however, the use of high temperature can possibly degrade thermosensitive bioactives. In addition, its low B/L ratio (not economical for scaling up) makes the Mozafari method less suitable method for phytosterols and tocopherols in comparison to thin film hydration ultrasonication and thin film hydration homogenization method. Both ultrasonication and homogenization seemed to be equally suitable at a laboratory scale. At an industrial scale, however, the homogenization method is more feasible due to the availability of homogenizers of large capacity. Thus, thin film hydration-homogenization seems to be the best method for scaling-up the liposomal formulation containing phytosterols and tocopherols. The pasteurization technique did not affect the chemical stability of tested bioactives. Moreover, model orange juice containing liposomes maintained an adequate physical stability during a period of one-month storage at 4 °C. In the future, liposomes containing phytosterols will be tested for cholesterol-lowering efficacy by conducting animal and human trials.

Acknowledgments

Ellen K Wasan is acknowledged for her great insights to this work. Amal Makhlouf and Deborah Michel is acknowledged for their technical help and training of Poudel. We acknowledge LaRhonda Sobchishin from Western College of Veterinary Medicine Imaging Centre, University of Saskatchewan, for her technical help with transmission electron microscopy.

Abbreviations

| LDL | Low-density lipoprotein |

| CODD | Canola oil deodorizer distillate |

| POPs | Phytosterol oxidation products |

| LC-MS/MS | Liquid Chromatography Tandem Mass Spectrometry |

| PC | Phosphatidylcholine |

| TEM | Transmission electron Microscopy |

| HTST | High temperature short time |

| B/L | Bioactive/lipid |

| RPM | Revolution per minute |

| %EE | percentage entrapment efficiency |

| DLS | Dynamic light scattering |

| PDI | Polydispersibility Index |

Author Contributions

Conceptualization, I.B., A.E., Z.D.B., K.M.W.; Methodology, A.E., I.B., A.P., G.G.; Software, A.E., A.P., G.G.; Validation, A.E., A.P., G.G.; Formal analysis, I.B., A.E., A.P., G.G.; Investigation, A.E., I.B., A.P.; Resources, A.E., Z.D.B.; Data curation, A.P., G.G.; Writing original draft preparation, A.P.; Writing—Review and Editing, A.E., I.B., K.M.W., G.G.; Visualization, A.E., I.B., A.P.; Supervision, A.E., I.B.; Funding administration, A.E.; Funding acquisition, A.E., Z.D.B., I.B.

Funding

This research was funded by Agriculture Development Fund, Ministry of Agriculture, Government of Saskatchewan, grant number 20150216. QTRAP 6500 mass spectrometer was funded by Western Diversification Canada grant. Poudel was provided scholarship funding from Sask Canola.

Conflicts of Interest

The authors declare no conflict of interest.

References

- 1.Siró I., Kápolna E., Kápolna B., Lugasi A. Functional food. Product development, marketing and consumer acceptance—A review. Appetite. 2008;51:456–467. doi: 10.1016/j.appet.2008.05.060. [DOI] [PubMed] [Google Scholar]

- 2.Demonty I., Ras R., van Der Knaap H., Duchateau G., Meijer L., Zock P., Geleijnse J., Trautwein E. Continuous Dose-Response Relationship of the LDL-Cholesterol-Lowering Effect of Phytosterol Intake1,2. J. Nutr. 2009;139:271–284. doi: 10.3945/jn.108.095125. [DOI] [PubMed] [Google Scholar]

- 3.Engin K.N., Engin G., Kucuksahin H., Oncu M., Guvener B. Clinical evaluation of the neuroprotective effect of alpha- tocopherol against glaucomatous damage. Eur. J. Ophthalmol. 2007;17:528–533. doi: 10.1177/112067210701700408. [DOI] [PubMed] [Google Scholar]

- 4.Abumweis S., Barake R., Jones P. Plant sterols/stanols as cholesterol-lowering agents: A meta-analysis of randomized controlled trials. Food Nutr. Res. 2008;52 doi: 10.3402/fnr.v52i0.1811. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Katan M.B., Grundy S.M., Jones P., Law M., Miettinen T., Paoletti R. Efficacy and Safety of Plant Stanols and Sterols in the Management of Blood Cholesterol Levels. Mayo Clin. Proc. 2003;78:965–978. doi: 10.1016/S0025-6196(11)63144-3. [DOI] [PubMed] [Google Scholar]

- 6.NIH Publication No. 01-3305 . ATP III Guidelines at-a-Glance Quick Desk Reference. NIH; Bethesda, MD, USA: 2001. [Google Scholar]

- 7.Ikeda I., Sugano M. Some aspects of mechanism of inhibition of cholesterol absorption by β-sitosterol. BBA Biomembr. 1983;732:651–658. doi: 10.1016/0005-2736(83)90243-2. [DOI] [PubMed] [Google Scholar]

- 8.Plat J., Mensink R.P. Plant Stanol and Sterol Esters in the Control of Blood Cholesterol Levels: Mechanism and Safety Aspects. Am. J. Cardiol. 2005;96:15–22. doi: 10.1016/j.amjcard.2005.03.015. [DOI] [PubMed] [Google Scholar]

- 9.Frei B. Reactive oxygen species and antioxidant vitamins: Mechanisms of action. Am. J. Med. 1994;97:S5–S13. doi: 10.1016/0002-9343(94)90292-5. [DOI] [PubMed] [Google Scholar]

- 10.Niki E., Noguchi N. Dynamics of antioxidant action of vitamin E. Acc. Chem. Res. 2004;37:45–51. doi: 10.1021/ar030069m. [DOI] [PubMed] [Google Scholar]

- 11.Taylor H.R., Tikellis G., Robman L.D., McCarty C.A., McNeil J.J. Vitamin E supplementation and macular degeneration: randomised controlled trial. (Papers) Br. Med. J. 2002;325:11. doi: 10.1136/bmj.325.7354.11. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Frank B., Gupta S. A review of antioxidants and Alzheimer’s disease. Ann. Clin. Psychiatry Off. J. Am. Acad. Clin. Psychiatr. 2005;17:269–286. doi: 10.1080/10401230500296428. [DOI] [PubMed] [Google Scholar]

- 13.Vivekananthan D.P., Penn M.S., Sapp S.K., Hsu A., Topol E.J. Use of antioxidant vitamins for the prevention of cardiovascular disease: Meta- analysis of randomised trials. Lancet. 2003;361:2017–2023. doi: 10.1016/S0140-6736(03)13637-9. [DOI] [PubMed] [Google Scholar]

- 14.Ryan E., Galvin K., O’Connor T., Maguire A., O’Brien N. Phytosterol, Squalene, Tocopherol Content and Fatty Acid Profile of Selected Seeds, Grains, and Legumes. Plant Foods Hum. Nutr. 2007;62:85–91. doi: 10.1007/s11130-007-0046-8. [DOI] [PubMed] [Google Scholar]

- 15.Maguire L.S., O’Sullivan S.M., Galvin K., O’Connor T.P., O’Brien N.M. Fatty acid profile, tocopherol, squalene and phytosterol content of walnuts, almonds, peanuts, hazelnuts and the macadamia nut. Int. J. Food Sci. Nutr. 2004;55:171–178. doi: 10.1080/09637480410001725175. [DOI] [PubMed] [Google Scholar]

- 16.Verleyen T., Verhe R., Garcia L., Dewettinck K., Huyghebaert A., De Greyt W. Gas chromatographic characterization of vegetable oil deodorization distillate. J. Chromatogr. A. 2001;921:277–285. doi: 10.1016/S0021-9673(01)00881-0. [DOI] [PubMed] [Google Scholar]

- 17.Heale J.B., Karapapa V.K. The verticillium threat to canada’s major oilseed crop: canola. Can. J. Plant Pathol. 1999;21:1–7. doi: 10.1080/07060661.1999.10600114. [DOI] [Google Scholar]

- 18.Schwartz H., Ollilainen V., Piironen V., Lampi A.-M. Tocopherol, tocotrienol and plant sterol contents of vegetable oils and industrial fats. J. Food Compos. Anal. 2008;21:152–161. doi: 10.1016/j.jfca.2007.07.012. [DOI] [Google Scholar]

- 19.McClements D.J., Decker E.A., Park Y., Weiss J. Structural Design Principles for Delivery of Bioactive Components in Nutraceuticals and Functional Foods. Crit. Rev. Food Sci. Nutr. 2009;49:577–606. doi: 10.1080/10408390902841529. [DOI] [PubMed] [Google Scholar]

- 20.Alemany L., Barbera R., Alegría A., Laparra J.M. Plant sterols from foods in inflammation and risk of cardiovascular disease: A real threat? Food Chem. Toxicol. 2014;69:140–149. doi: 10.1016/j.fct.2014.03.038. [DOI] [PubMed] [Google Scholar]

- 21.Liang Y.T., Wong W.T., Guan L., Tian X.Y., Ma K.Y., Huang Y., Chen Z.-Y. Effect of phytosterols and their oxidation products on lipoprotein profiles and vascular function in hamster fed a high cholesterol diet. Atherosclerosis. 2011;219:124–133. doi: 10.1016/j.atherosclerosis.2011.06.004. [DOI] [PubMed] [Google Scholar]

- 22.Nedovic V., Kalusevic A., Manojlovic V., Levic S., Bugarski B. An overview of encapsulation technologies for food applications. Procedia Food Sci. 2011;1:1806–1815. doi: 10.1016/j.profoo.2011.09.265. [DOI] [Google Scholar]

- 23.Desai K.G., Jin Park H. Recent Developments in Microencapsulation of Food Ingredients. Dry. Technol. 2005;23:1361–1394. doi: 10.1081/DRT-200063478. [DOI] [Google Scholar]

- 24.Ray S., Raychaudhuri U., Chakraborty R. An overview of encapsulation of active compounds used in food products by drying technology. Food Biosci. 2016;13:76–83. doi: 10.1016/j.fbio.2015.12.009. [DOI] [Google Scholar]

- 25.Anandharamakrishnan C. Spray Drying Technique for Food Ingredient Encapsulation. John Wiley & Sons; Hoboken, NJ, USA: 2015. [Google Scholar]

- 26.Gibbs B.F., Kermasha S., Alli I., Mulligan C.N. Encapsulation in the food industry: A review. Int. J. Food Sci. Nutr. 1999;50:213–224. doi: 10.1080/096374899101256. [DOI] [PubMed] [Google Scholar]

- 27.Sagalowicz L., Leser M.E. Delivery systems for liquid food products. Curr. Opin. Colloid Interface Sci. 2010;15:61–72. doi: 10.1016/j.cocis.2009.12.003. [DOI] [Google Scholar]

- 28.Mozafari M.R. Nanoliposomes: Preparation and analysis. Methods Mol. Biol. (Clifton, N.J.) 2010;605:29–50. doi: 10.1007/978-1-60327-360-2_2. [DOI] [PubMed] [Google Scholar]

- 29.Noakes M., Clifton P., Ntanios F., Shrapnel W. An increase in dietary carotenoids when consuming plant sterols or stanols is effective in maintaining plasma carotenoid concentrations. Am. J. Clin. Nutr. 2002;75:79–86. doi: 10.1093/ajcn/75.1.79. [DOI] [PubMed] [Google Scholar]

- 30.Cleghorn C.L., Skeaff C.M., Mann J., Chisholm A. Plant sterol-enriched spread enhances the cholesterol-lowering potential of a fat-reduced diet. Eur. J. Clin. Nutr. 2003;57:170–176. doi: 10.1038/sj.ejcn.1601531. [DOI] [PubMed] [Google Scholar]

- 31.Davidson M.H., Maki K.C., Umporowicz D.M., Ingram K.A., Dicklin M.R., Schaefer E., Lane R.W., McNamara J.R., Ribaya-Mercado J.D., Perrone G., et al. Safety and Tolerability of Esterified Phytosterols Administered in Reduced-Fat Spread and Salad Dressing to Healthy Adult Men and Women. J. Am. Coll. Nutr. 2001;20:307–319. doi: 10.1080/07315724.2001.10719051. [DOI] [PubMed] [Google Scholar]

- 32.Hyun Y.J., Kim O.Y., Kang J.B., Lee J.H., Jang Y., Liponkoski L., Salo P. Plant stanol esters in low-fat yogurt reduces total and low-density lipoprotein cholesterol and low-density lipoprotein oxidation in normocholesterolemic and mildly hypercholesterolemic subjects. Nutr. Res. 2005;25:743–753. doi: 10.1016/j.nutres.2005.08.004. [DOI] [Google Scholar]

- 33.Miettinen T.A., Puska P., Gylling H., Vanhanen H., Vartiainen E. Reduction of serum cholesterol with sitostanol-ester margarine in a mildly hypercholesterolemic population. N. Engl. J. Med. 1995;333:1308–1312. doi: 10.1056/NEJM199511163332002. [DOI] [PubMed] [Google Scholar]

- 34.Thomsen A.B., Hansen H.B., Christiansen C., Green H., Berger A. Effect of free plant sterols in low-fat milk on serum lipid profile in hypercholesterolemic subjects. Eur. J. Clin. Nutr. 2004;58:860–870. doi: 10.1038/sj.ejcn.1601887. [DOI] [PubMed] [Google Scholar]

- 35.Noakes M., Clifton P., Doornbos A., Trautwein E. Plant sterol ester–enriched milk and yoghurt effectively reduce serum cholesterol in modestly hypercholesterolemic subjects. Zeitschrift für Ernährungswissenschaft. 2005;44:214–222. doi: 10.1007/s00394-004-0513-z. [DOI] [PubMed] [Google Scholar]

- 36.Yoshida M., Vanstone C.A., Parsons W.D., Zawistowski J., Jones P.J.H. Effect of plant sterols and glucomannan on lipids in individuals with and without type II diabetes. Eur. J. Clin. Nutr. 2006;60:529–537. doi: 10.1038/sj.ejcn.1602347. [DOI] [PubMed] [Google Scholar]

- 37.Devaraj S., Jialal I., Vega-Lopez S. Plant sterol-fortified orange juice effectively lowers cholesterol levels in mildly hypercholesterolemic healthy individuals. Arteriosc. Thromb. Vasc. Biol. 2004;24:e25–e28. doi: 10.1161/01.ATV.0000120784.08823.99. [DOI] [PubMed] [Google Scholar]

- 38.Shin M.-J., Lee J.H., Jang Y., Lee-Kim Y.C., Park E., Kim K.M., Chung B.C., Chung N. Micellar Phytosterols Effectively Reduce Cholesterol Absorption at Low Doses. Ann. Nutr. Metab. 2005;49:346–351. doi: 10.1159/000087880. [DOI] [PubMed] [Google Scholar]

- 39.Spilburg C.A., Goldberg A.C., McGill J.B., Stenson W.F., Racette S.B., Bateman J., McPherson T.B., Ostlund R.E. Fat-free foods supplemented with soy stanol-lecithin powder reduce cholesterolabsorption and LDL cholesterol. J. Am. Diet. Assoc. 2003;103:577–581. doi: 10.1053/jada.2003.50110. [DOI] [PubMed] [Google Scholar]

- 40.Jones P.J.H., Vanstone C.A., Raeini-Sarjaz M., St-Onge M.-P. Phytosterols in low- and nonfat beverages as part of a controlled diet fail to lower plasma lipid levels. J. Lipid Res. 2003;44:1713–1719. doi: 10.1194/jlr.M300089-JLR200. [DOI] [PubMed] [Google Scholar]

- 41.Zhao J., Gershkovich P., Wasan K.M. Evaluation of the effect of plant sterols on the intestinal processing of cholesterol using an in vitro lipolysis model. Int. J. Pharm. 2012;436:707–710. doi: 10.1016/j.ijpharm.2012.07.040. [DOI] [PubMed] [Google Scholar]

- 42.Ostlund R.E., Spilburg C.A., Stenson W.F. Sitostanol administered in lecithin micelles potently reduces cholesterol absorption in humans. Am. J. Clin. Nutr. 1999;70:826–831. doi: 10.1093/ajcn/70.5.826. [DOI] [PubMed] [Google Scholar]

- 43.Miettinen T.A., Vanhanen H. Dietary sitostanol related to absorption, synthesis and serum level of cholesterol in different apolipoprotein E phenotypes. Atherosclerosis. 1994;105:217–226. doi: 10.1016/0021-9150(94)90052-3. [DOI] [PubMed] [Google Scholar]

- 44.Clifton P.M., Noakes M., Sullivan D., Erichsen N., Ross D., Annison G., Fassoulakis A., Cehun M., Nestel P. Cholesterol-lowering effects of plant sterol esters differ in milk, yoghurt, bread and cereal. Eur. J. Clin. Nutr. 2004;58:503–509. doi: 10.1038/sj.ejcn.1601837. [DOI] [PubMed] [Google Scholar]

- 45.Amir Shaghaghi M., Harding S.V., Jones P.J.H. Water dispersible plant sterol formulation shows improved effect on lipid profile compared to plant sterol esters. J. Funct. Foods. 2014;6:280–289. doi: 10.1016/j.jff.2013.10.017. [DOI] [Google Scholar]

- 46.Judd J.T., Baer D.J., Chen S.C., Clevidence B.A., Muesing R.A., Kramer M., Meijer G.W. Plant sterol esters lower plasma lipids and most carotenoids in mildly hypercholesterolemic adults. Lipids. 2002;37:33–42. doi: 10.1007/s11745-002-0861-y. [DOI] [PubMed] [Google Scholar]

- 47.Ottestad I., Ose L., Wennersberg M.H., Granlund L., Kirkhus B., Retterstøl K. Phytosterol capsules and serum cholesterol in hypercholesterolemia: A randomized controlled trial. Atherosclerosis. 2013;228:421–425. doi: 10.1016/j.atherosclerosis.2013.03.001. [DOI] [PubMed] [Google Scholar]

- 48.Denke M.A. Lack of efficacy of low-dose sitostanol therapy as an adjunct to a cholesterol-lowering diet in men with moderate hypercholesterolemia. Am. J. Clin. Nutr. 1995;61:392–396. doi: 10.1093/ajcn/61.2.392. [DOI] [PubMed] [Google Scholar]

- 49.Allen T.M. Liposomal drug formulations. Rationale for development and what we can expect for the future. Drugs. 1998;56:747–756. doi: 10.2165/00003495-199856050-00001. [DOI] [PubMed] [Google Scholar]

- 50.Kaikkonen J., Porkkala-Sarataho E., Morrow J.D., Roberts L.J., Nyyssönen K., Salonen R., Tuomainen T.-P., Ristonmaa U., Poulsen H.E., Salonen J.T. Supplementation with vitamin E but not with vitamin C lowers lipid peroxidation in vivo in mildly hypercholesterolemic men. Free Radic. Res. 2001;35:967–978. doi: 10.1080/10715760100301461. [DOI] [PubMed] [Google Scholar]

- 51.Chung S.K., Shin G.H., Jung M.K., Hwang I.C., Park H.J. Factors influencing the physicochemical characteristics of cationic polymer-coated liposomes prepared by high-pressure homogenization. Colloid. Surf. A Physicochem. Eng. Asp. 2014;454:8–15. doi: 10.1016/j.colsurfa.2014.03.095. [DOI] [Google Scholar]

- 52.Akbarzadeh A., Rezaei-Sadabady R., Davaran S., Joo S., Zarghami N., Hanifehpour Y., Samiei M., Kouhi M., Nejati-Koshki K. Liposome: classification, preparation, and applications. Nanoscale Res. Lett. 2013;8:1–9. doi: 10.1186/1556-276X-8-102. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.Colas J.-C., Shi W., Rao V.S.N.M., Omri A., Mozafari M.R., Singh H. Microscopical investigations of nisin- loaded nanoliposomes prepared by Mozafari method and their bacterial targeting. Micron. 2007;38:841–847. doi: 10.1016/j.micron.2007.06.013. [DOI] [PubMed] [Google Scholar]

- 54.Guideline I.H.T. Validation of analytical procedures: text and methodology Q2 (R1); Proceedings of the International Conference on Harmonization; Geneva, Switzerland. 10 November 2005; pp. 11–12. [Google Scholar]

- 55.Poudel A., Gachumi G., Bashi Z.D., Badea I., El-Aneed A. Lipid based liposomal formulation of phytosterols and tocopherols into functional food; Proceedings of the Canadian Society for Pharmaceutical Sciences Annual Conference; Toronto, ON, Canada. 22–25 May 2018. [Google Scholar]

- 56.Shaikh J., Ankola D.D., Beniwal V., Singh D., Kumar M.N.V.R. Nanoparticle encapsulation improves oral bioavailability of curcumin by at least 9-fold when compared to curcumin administered with piperine as absorption enhancer. Eur. J. Pharm. Sci. 2009;37:223–230. doi: 10.1016/j.ejps.2009.02.019. [DOI] [PubMed] [Google Scholar]

- 57.Marsanasco M., Marquez A.L., Wagner J.R., Alonso S.D.V., Chiaramoni N.S. Liposomes as vehicles for vitamins E and C: An alternative to fortify orange juice and offer vitamin C protection after heat treatment. Food Res. Int. 2011;44:3039–3046. doi: 10.1016/j.foodres.2011.07.025. [DOI] [Google Scholar]

- 58.Nelson P.E., Tressler D.K. Fruit and Vegetable Juice Processing Technology. AVI Pub. Co.; Westport, CT, USA: 1980. [Google Scholar]

- 59.Charles-Rodríguez A.V., Nevárez-Moorillón G.V., Zhang Q.H., Ortega-Rivas E. Comparison of Thermal Processing and Pulsed Electric Fields Treatment in Pasteurization of Apple Juice. Food Bioprod. Process. 2007;85:93–97. doi: 10.1205/fbp06045. [DOI] [Google Scholar]

- 60.Zhao L., Temelli F., Chen L. Encapsulation of anthocyanin in liposomes using supercritical carbon dioxide: Effects of anthocyanin and sterol concentrations. J. Funct. Foods. 2017;34:159–167. doi: 10.1016/j.jff.2017.04.021. [DOI] [Google Scholar]

- 61.Reza Mozafari M., Johnson C., Hatziantoniou S., Demetzos C. Nanoliposomes and Their Applications in Food Nanotechnology. J. Liposome Res. 2008;18:309–327. doi: 10.1080/08982100802465941. [DOI] [PubMed] [Google Scholar]

- 62.López-Pinto J.M., González-Rodríguez M.L., Rabasco A.M. Effect of cholesterol and ethanol on dermal delivery from DPPC liposomes. Int. J. Pharm. 2005;298:1–12. doi: 10.1016/j.ijpharm.2005.02.021. [DOI] [PubMed] [Google Scholar]

- 63.Padamwar M.N., Pokharkar V.B. Development of vitamin loaded topical liposomal formulation using factorial design approach: Drug deposition and stability. Int. J. Pharm. 2006;320:37–44. doi: 10.1016/j.ijpharm.2006.04.001. [DOI] [PubMed] [Google Scholar]

- 64.Marsanasco M., Piotrkowski B., Calabró V., Alonso S., Chiaramoni N. Bioactive constituents in liposomes incorporated in orange juice as new functional food: thermal stability, rheological and organoleptic properties. J. Food Sci. Technol. 2015;52:7828–7838. doi: 10.1007/s13197-015-1924-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 65.Isailović B.D., Kostić I.T., Zvonar A., Đorđević V.B., Gašperlin M., Nedović V.A., Bugarski B.M. Resveratrol loaded liposomes produced by different techniques. Innov. Food Sci. Emerg. Technol. 2013;19:181–189. doi: 10.1016/j.ifset.2013.03.006. [DOI] [Google Scholar]

- 66.Cui H., Zhao C., Lin L. The specific antibacterial activity of liposome- encapsulated Clove oil and its application in tofu. Food Control. 2015;56:128–134. doi: 10.1016/j.foodcont.2015.03.026. [DOI] [Google Scholar]

- 67.Chountoulesi M., Naziris N., Pippa N., Demetzos C. The Significance of Drug-to-Lipid Ratio to the Development of Optimized Liposomal Formulation. Volume 28. Taylor & Francis; Abingdon, UK: 2018. pp. 249–258. [DOI] [PubMed] [Google Scholar]

- 68.Taylor T., Davidson P., Bruce B., Weiss J. Liposomal Nanocapsules in Food Science and Agriculture. Crit. Rev. Food Sci. Nutr. 2005;45:587–605. doi: 10.1080/10408390591001135. [DOI] [PubMed] [Google Scholar]

- 69.Mozafari M.R. Liposomes: An overview of manufacturing techniques. Cell. Mol. Biol. Lett. 2005;10:711–719. [PubMed] [Google Scholar]

- 70.Heurtault B., Saulnier P., Pech B., Proust J.-E., Benoit J.-P. Physico-chemical stability of colloidal lipid particles. Biomaterials. 2003;24:4283–4300. doi: 10.1016/S0142-9612(03)00331-4. [DOI] [PubMed] [Google Scholar]

- 71.Patel V., Agrawal Y. Nanosuspension: An approach to enhance solubility of drugs. J. Adv. Pharm. Technol. Res. 2011;2:81–87. doi: 10.4103/2231-4040.82950. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 72.Peer D., Florentin A., Margalit R. Hyaluronan is a key component in cryoprotection and formulation of targeted unilamellar liposomes. BBA Biomembr. 2003;1612:76–82. doi: 10.1016/S0005-2736(03)00106-8. [DOI] [PubMed] [Google Scholar]

- 73.Jung H., Coldren B., Zasadzinski J., Iampietro D., Kaler E. The origins of stability of spontaneous vesicles. Proc. Natl. Acad. Sci. USA. 2001;98:1353–1357. doi: 10.1073/pnas.98.4.1353. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 74.Xuan T., Zhang J.A., Ahmad I. HPLC method for determination of SN-38 content and SN-38 entrapment efficiency in a novel liposome-based formulation, LE-SN38. J. Pharm. Biomed. Anal. 2006;41:582–588. doi: 10.1016/j.jpba.2005.10.051. [DOI] [PubMed] [Google Scholar]

- 75.Ugwu S., Zhang A., Parmar M., Miller B., Sardone T., Peikov V., Ahmad I. Preparation, Characterization, and Stability of Liposome-Based Formulations of Mitoxantrone. Drug Dev. Ind. Pharm. 2005;31:223–229. doi: 10.1081/DDC-200047850. [DOI] [PubMed] [Google Scholar]

- 76.Lee S.-C., Lee K.-E., Kim J.-J., Lim S.-H. The Effect of Cholesterol in the Liposome Bilayer on the Stabilization of Incorporated Retinol. J. Liposome Res. 2005;15:157–166. doi: 10.1080/08982100500364131. [DOI] [PubMed] [Google Scholar]

- 77.Wang L., Ma Y., Gu Y., Liu Y., Zhao J., Yan B., Wang Y. Cryoprotectant choice and analyses of freeze-drying drug suspension of nanoparticles with functional stabilisers. J. Microencapsul. 2018;35:241–248. doi: 10.1080/02652048.2018.1462416. [DOI] [PubMed] [Google Scholar]

- 78.Chen C., Han D., Cai C., Tang X. An overview of liposome lyophilization and its future potential. J. Control. Release. 2010;142:299–311. doi: 10.1016/j.jconrel.2009.10.024. [DOI] [PubMed] [Google Scholar]