Abstract

Mixolab properties of different Indian extraordinarily soft (Ex-SW), hard (HW) and medium hard (MHW) wheat varieties were evaluated and related to damaged starch content, particle size distribution, pasting, Farinographic and Mixographic properties. Water absorption (WA) of HW varieties was higher as compared to other varieties. Higher damaged starch led to more WA in HW varieties while lower in Ex-SW varieties. Unextratable polymeric protein, damaged starch and arabinoxylans were related to dough consistency. Mixolab measurement C3 (peak viscosity) and C5 (starch retrogradation) decreased with increase in grain hardness index, damaged starch content, and sodium solvent retention capacity. Dough stability (DS) and dough development time (DDT) measured by Mixolab and farinograph were significantly correlated. Mixolab parameters (C3, C4 and C5) related positively to DDT and DS while negatively to WA. HW varieties showed higher shear thinning as compared to MHW and Ex-SW varieties. C4 (hot paste stability) was lower for HW but higher for Ex-SW varieties. SuSRC was negatively related to C4 indicating that HW flours had lower starch retrogradation due to higher arabinoxylans. C3, C4 and C5 related positively to small size particles while negatively to large size particles. Slope beta (β) measured by mixolab indicated that the speed of starch gelatinization was lower for Ex-SW varieties than MHW and HW varieties.

Electronic supplementary material

The online version of this article (10.1007/s13197-019-03756-z) contains supplementary material, which is available to authorized users.

Keywords: Wheat flour, Mixolab, Pasting, Mixograph, Farinograph

Introduction

Mixolab was used to measure dough rheological properties during heating and cooling period. This instrument has been used for evaluation of dough rheological behaviour of different wheat varieties (Rosell et al. 2013) and involves the working principle of both Farinograph and Rapid Viscoanalyzer (RVA). Farinograph measures the characteristics of dough at constant temperature during mixing while RVA evaluates paste characteristics during heating and cooling. Mixolab properties were in relation with empirical rheological properties (farinograph and RVA), sedimentation value and bread volume (Koksel et al. 2009). Mixolab measurements involve changes in starch and protein properties in one test during heating and cooling (Koksel et al. 2009). Hrušková et al. (2013) reported relationship between Farinograph, RVA and Mixolab parameters amongst commercial wheat fine flour. Mixolab has also been used to evaluate the quality of other cereals. Moza and Gujral (2018) related the differences in consistency of barley flour blends to variation in non-starchy polysaccharides content which showed positive correlations of consistency with total β-glucan content and arabinoxylans content. Sandhu et al. (2018) evaluated brown and milled rice flour by Mixolab to see the effect of degree of milling. They reported that degree of milling significantly affected Mixolab properties and milled rice at 8% degree of milling showed higher C3, C4 and C5. This was attributed to change in non-starch constituents with successive removal of branny layers. Most of the studies have not used wheat varieties with wide range of hardness index as well as monomeric and polymeric protein distribution. The dough characteristics of flours have traditionally been evaluated using Farinograph, Extensigraph and Alveograph at 30 °C, however, Mixolab described the changes in consistency of dough during cooling and heating cycle. This instrument gives information about DDT, starch gelatinization, breakdown of protein and gel strength (Dubat 2010; Sharma et al. 2017). Mixolab is a relatively new instrument and has not been used extensively. Moreover, this instrument gives information regarding different aspect of utilization of wheat flour that have been reported in some studies (Banu et al. 2011; Codina et al. 2010; Papouskova et al. 2011). Mironeasa et al. (2012) and Rosell et al. (2011) reported that there is less number of research results for composite flours. Torbica et al. (2016) related Mixolab parameters to amylolytic activity and falling number values of wheat flours. Flours with lower values of Mixolab parameters were shown to have lower falling number values while higher amylolytic activity. The objective of present study was to evaluate Mixolab properties and damaged starch content of different Indian wheat varieties with diverse hardness (medium hard, hard and extraordinarily soft) and relate these to slurry paste properties and dough properties measured by other instruments (Farinograph, Mixograph and Dynamic Rheometer).

Materials and methods

Materials

Various varieties of wheat used in present study had varied grain hardness index (GHI) that ranged from 83 to 95 for hard, 72 to 80 for medium hard and 17 to 29 for extraordinarily soft. K307, HD2733, HD2932, DPW621-50 were hard while HI977, DBW39, UP2672, HD2967 were medium hard. QBP12-8, QBP12-9, QBP12-11, QBP12-10 were extraordinarily soft wheat varieties (Katyal et al. 2017).

Flour characteristics

The detailed analysis except Mixolab properties and damaged starch content of flour from selected varieties has been published earlier (Katyal et al. 2017).

Damaged starch content

Damaged starch content was determined as described earlier by Sharma et al. (2017).

Mixolab properties

The dough mixing behaviour of flours from various wheat varieties was evaluated using Mixolab 2 (Chopin Technologies, France) as described earlier by Sharma et al. (2017).

Statistical analysis

PCA and Pearson correlation (r) were carried out for determining relationship between various variables by using Statistical Software (Minitab Release 14).

Results and discussion

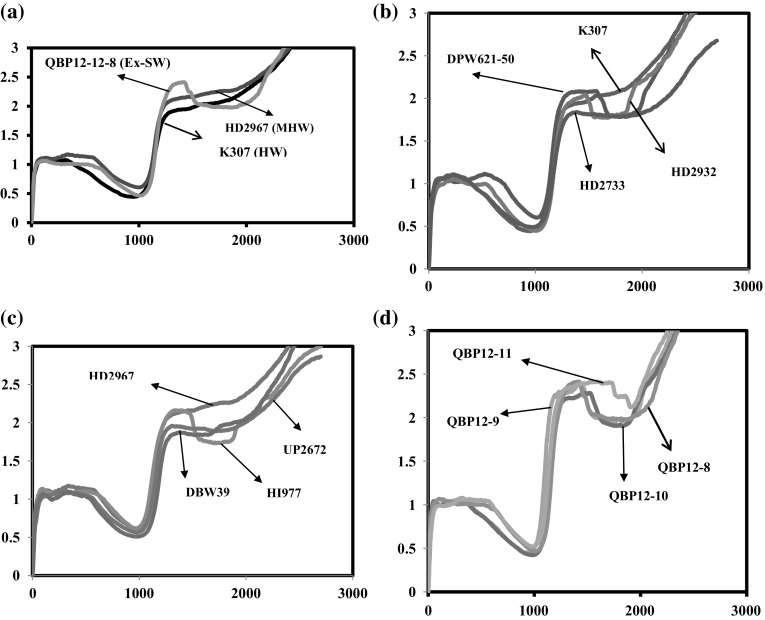

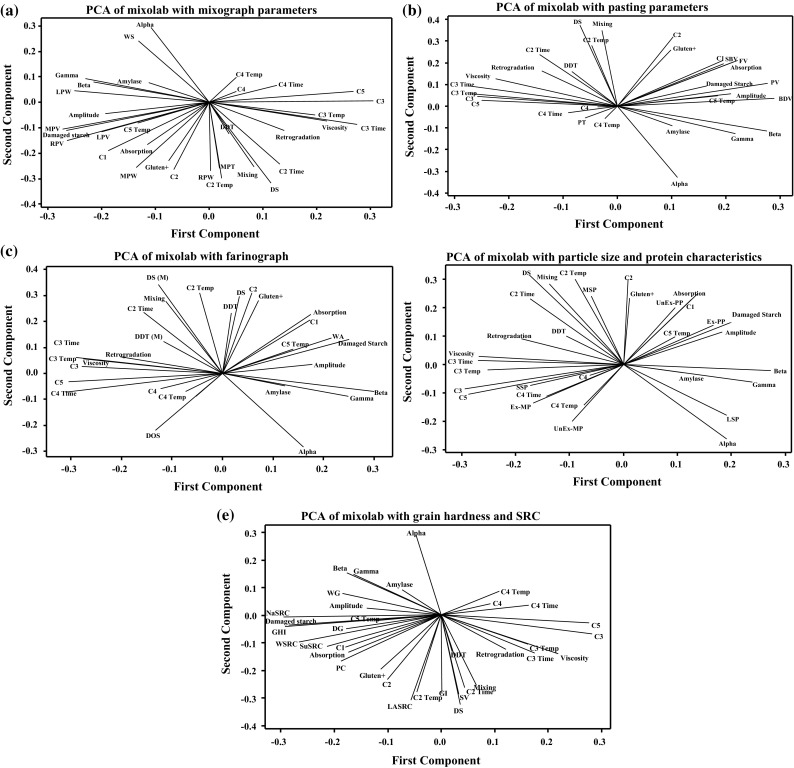

Mixolab measures changes in the dough system during simultaneous heating and mixing which can effectively be used for quality evaluation of wheat varieties. Mixolab analysis of flours from different wheat varieties with varying GHI showed that there was a rise in torque during initial mixing (C1) which reduced during the continuous mixing stage (C2), a further increase in torque was observed during heating due to starch gelatinization (C3) that reduced to a value that is C4 during holding temperature (Cb), and then again increased to a value (C5) on cooling (Cs) (Table 1). Mixolab curves of flours milled from MHW, HW and Ex-SW varieties are given in Fig. 1a–d. The quantity of water required by the dough to reach an optimum torque of 1.1 Nm (C1) during initial mixing in Mixolab is known as water absorption (Sharma et al. 2017). Water absorption of MHW varieties was the highest followed by HW varieties (except HD2733) and the lowest for Ex-SW varieties (Table 1). It was observed that among HW varieties, the lowest value of water absorption was observed for HD2733 while HD2932 showed the highest water absorption. C2 represented the resistance to mixing whereas C5, C4 and C3 demonstrated retrogradation of starch, stability of gelatinized starch granules and starch gelatinization, respectively (Sharma et al. 2017; Heo et al. 2013). C1 and C2 were related to protein quality, while C5, C4 and C3 were related to starch characteristics (Koksel et al. 2009). With an increase in temperature of dough, weakening of proteins occurred that led to a decrease in torque till C2 was reached. C2 was also considered as the start of pasting of dough (Sharma et al. 2017). The highest C2 among all the three classes of wheat has been demonstrated by MHW varieties which indicated that MHW varieties showed less protein weakening. The varieties with lower C2 value were known to have more weakening of gluten protein network on simultaneous mixing and heating. The time to C2 did not show any regular trend. However, the highest C2 among all of the varieties was shown by DPW621-50 (HW). The temperature at C2, which is an indicator of the initial gelatinization temperature, was found to be the highest for DPW621-50 which is a HW variety (Table 1), while no consistent trend was observed amongst MHW, and Ex-SW varieties. QBP12-11 and HD2967 revealed higher C3, C4 and C5, nevertheless, HD2733, HI977 and HD2733 showed lower C3, C4 and C5. K307 and HD2967 showed higher Cb and Cs while UP2672 and HD2932 showed lower Cb and Cs. C1 torque that denotes the maximum dough consistency during mixing phase at 30 °C (Gujral et al. 2018) was positively correlated to unextratable polymeric protein (UnEx-PP) and sucrose solvent retention capacity (SuSRC). The results clearly showed the contribution of UnEx-PP and arabinoxylans (reflected by SuSRC) to dough consistency. C1 was positively correlated to NaSRC which is an indicator of damaged starch content while SuSRC indicated pentosan and arabinoxylans content (Gaines 2000). Damaged starch indicated the amount of starch mechanically damaged during milling. Also, the Ex-SW varieties showed the lowest water absorption owing to less damaged starch content. The present result was supported by the fact that the water absorption had a positive correlation with damaged starch content (r = 0.72, p ≤ 0.05) (Supplementary Table 1). A variable trend was observed in damaged starch content with HW varieties having damaged starch in the range of 9.20 to 9.98%. K307 (HW) showed the highest while QBP12-9 (Ex-SW) variety showed the lowest damaged starch (Table 2). Thus the higher damaged starch could have led to more water absorption in HW varieties. Amongst MHW varieties, the range of damaged starch was higher than Ex SW varieties and was observed to be varied from 6.98 to 8.45%. The lowest content of damaged starch was shown by HD2967 amongst the MHW varieties. C2 is the lowest value of torque produced by dough when subjected to thermal and mechanical constraints and has been attributed to the weakening of proteins (Sharma et al. 2017). This is also taken as start of pasting of dough. C2 was closely associated with gluten and LASRC. Earlier, we have related LASRC with UnEx-PP (Katyal et al. 2017) and confirmed the contribution of glutenins to flour swelling that assisted in extensive gluten network formation. Katyal et al. (2016) and Xiao et al. (2006) also observed the relationship between LASRC and UnEx-PP. Flours with high gluten or glutenin showed higher C2 as well time to C2. C2 as well as time to C2 and temperature at C2 was positively correlated to sedimentation value and gluten index. This was expected since sedimentation value and gluten index has been related to gluten and glutenin content (Katyal et al. 2016). Time to C2 and temperature at C2 were correlated negatively with the proportion of large size granules (Singh et al. 2016). Both the viscous (G’) and elastic modulus (G’’) was significantly correlated with C2 (r = 0.789 and 0.778, respectively, p ≤ 005) (Supplementary Table 1). C3 and C5 showed significant negative correlation with damaged starch content, GHI and NaSRC. Results revealed that C3 and C5 of dough decreased with increase in GHI (Fig. 2e). PCA also reflected that C5, C4 and C3 related positively to LASRC, UnEx-MP and GI while negatively related to UnEx-PP, Ex-PP, SuSRC and NaSRC (Fig. 2e). C3 and C5 as well as time and temperature to C3 were negatively correlated to damaged starch content (Fig. 2a). DDT is the time required by dough to reach torque of 1.1 Nm (Gujral et al. 2018). HW varieties showed DDT values on the lower side except DPW621-50, which could be attributed to its higher water absorption among HW varieties. Similarly MHW varieties showed an irregular trend with DDT which was as high as 5.68 min and as low as 1.50 min. Ex-SW varieties demonstrated DDT values ranging from 1.70 to 6.48 min. Stability refer to the time for which Mixolab curve remains within maximum consistency of 11% observed while mixing and depicts the mixing resistance of dough (Sharma et al. 2017). HW varieties observed stability ranged from 6.19 to 10.98 min whereas MHW and Ex-SW varieties showed stability varied from 8.59 to 10.50 min and 6.91 to 9.94 min, respectively. MHW varieties were characterized with higher stability that depicts the dough strength (Table 1). Dough stability (DS) and DDT measured by Mixolab and Farinograph were significantly correlated (Supplementary Table 1 and Fig. 2a). Mixolab parameters of dough were in agreement with Farinograph parameters as reported earlier by Katyal et al. (2017). Maximum torque during heating phase (C3) was higher for flours with lower NaSRC and SuSRC. PCA also reflected that C5, C4 and C3 related positively to DDT and DS while negatively to WA (Fig. 2c). C3 indicated peak torque during starch gelatinization phase, i.e. higher dough viscosity. C3 is maximum torque obtained during the heating cycle which in other words is also known as the peak viscosity (Gujral et al. 2018). The maximum peak viscosity was observed for Ex-SW varieties followed by the MHW varieties and the least viscosity was shown by HW varieties. The temperature at C3 is an indication of the peak temperature. The lowest peak temperature was observed for MHW varieties among all the three wheat classes. No consistent trend in peak temperature was observed for HW and Ex-SW varieties. The variation between maximum and minimum torque (C3–C4) during heating of dough was lower for MHW followed by HW and Ex-SW varieties (Table 2). This indicated that lesser amylolytic activity which was consistent with results of peak viscosity that has been related to amylolytic activity (Sharma et al. 2017). C4 is a measure of minimum torque reached during cooling to 50 °C and reflected the hot gel stability/shear thinning of dough. The torque increased due to reassociation of starch molecules during cooling which is a measure of retrogradation (Sharma et al. 2017; Gujral et al. 2018). HW varieties except K307 showed higher shear thinning. In general the lowest shear thinning or breakdown was observed for HD2967 which was MHW variety. In contrary, the highest shear thinning was also observed by MHW variety, HI977. C4 indicated lower stability of hot paste for HW and higher for Ex-SW varieties. C5 reflected starch retrogradation in dough and was also higher in flours with lower SuSRC. This reflected the role of arabinoxylans in inhibiting the retrogradation of starch. Higher resistance to retrogradation (C5–C4) was distinctively lower for dough from HW and higher for those from Ex-SW varieties. Wheat varieties with higher proportion of small and lesser proportions of large size particles revealed higher values of C1 and C3. This confirmed the significance of particle size distribution. Kaur et al. (2016) and Shevkani et al. (2011) reported that the viscosity of wheat starches and flours also vary with starch granule size and protein content and composition. PCA also indicated that C5, C4 and C3 were positively related to SSP while negatively related to LSP (Fig. 2d). Paste viscosity varied with starch granules rigidity, which in turn depends upon swelling capacity of starch granules (Sandhyarani and Bhattacharaya 1989) and amount of amylose leached out in the solution (Morris 1990). PCA also showed that C5, C4 and C3 were related negatively to paste properties (Fig. 2b). Paste viscosities were reported to be in positive correlation with A-type granules and negative with B and C type granules (Singh et al. 2010). A-granules (large size) of size > 105 μm, possess a loose packing ability and occupy a relatively more volume than B and C type granules with > 55 to ≤ 105 μm and 0 to 55 μm size at same concentration. Kaur et al. (2016) and Shevkani et al. (2011) also reported a positive relation between paste properties and starch granule size. The rheology of starch was reported to be mainly affected by granule size distribution; the large granules tend to be become more viscous as compared to small size granules (Wong and Lelievre 1982). Starch suspensions with large proportions of A-type granules exhibited greater viscosity than suspensions of starch with higher proportions of B and C type granules (Singh et al. 2010, Shinde et al. 2008). The results clearly demonstrated that starches with higher A-type granules were less stable towards shearing. Katyal et al. (2019) also reported that MHW varieties starches had higher proportion of A-type granules and lower proportion of B and C-type granules while Ex-SW had more proportion of C-type granules. Time and temperature to C4 were negatively correlated to UnEx-MP. C5 is the torque that indicated retrogradation of starch. Ex-SW varieties were characterized with lower C5 indicating their lower tendency to retrograde as compared to MHW and HW varieties. C5 is located opposite to GHI (Fig. 2e), indicating lower for HW than MHW and EX-SW. C5 was negatively correlated to UnEx-PP and positively to UnEx-MP. Slopes α, β, γ were reported to be the indicators of protein weakening, speed of starch gelatinization and enzyme degradation speed, respectively. The minimum value of β was observed for Ex-SW varieties and the maximum was shown by MHW varieties. The results reflected that the rate of gelatinization varied with the damaged starch content. There were significant correlation of dough stability and C2 measured by Mixolab with sedimentation value and Alveograph values (Sharma et al. 2017). Alpha is a measure of the rate of protein weakening under the effect of heat and was associated to gluten as well as glutenin content. Flour with higher gluten and glutenin showed lower alpha value. Results reflected no direct relation between dough viscosity measured for dough system and paste system.

Table 1.

Mixolab parameters of flours from different HW, MHW and Ex-HW varieties

| Varieties | C1 (Nm) | DDT (min) | Stability | C2 (Nm) | Time to C2(min) | Temp at C2 (°C) | C3 (Nm) | Time to C3 (min) | Temp at C3 (°C) | C4 (Nm) | Time to C4 (min) | Temp at C4 (°C) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a | ||||||||||||

| K307 | 1.10 ± 0.04 | 2.96 ± 0.13 | 6.25 ± 0.10 | 0.44 ± 0.02 | 15.54 ± 0.37 | 48.20 ± 0.28 | 1.94 ± 0.02 | 23.00 ± 0.00 | 75.30 ± 0.28 | 2.09 ± 0.01 | 30.00 ± 0.00 | 83.95 ± 0.21 |

| DPW62150 | 1.12 ± 0.01 | 8.75 ± 0.11 | 10.98 ± 0.06 | 0.60 ± 0.00 | 16.81 ± 0.13 | 52.20 ± 0.42 | 2.10 ± 0.01 | 26.25 ± 0.82 | 80.00 ± 0.57 | 1.77 ± 0.01 | 29.00 ± 1.02 | 82.65 ± 0.35 |

| HD2932 | 1.06 ± 0.03 | 3.99 ± 0.13 | 8.80 ± 0.11 | 0.45 ± 0.01 | 16.64 ± 0.13 | 51.00 ± 0.28 | 2.07 ± 0.00 | 24.76 ± 0.48 | 77.70 ± 0.57 | 1.77 ± 0.00 | 26.85 ± 1.37 | 80.60 ± 1.27 |

| HD2733 | 1.11 ± 0.01 | 3.68 ± 0.18 | 6.19 ± 0.01 | 0.49 ± 0.01 | 16.08 ± 0.06 | 49.70 ± 0.42 | 1.84 ± 0.01 | 23.14 ± 0.02 | 74.70 ± 0.28 | 1.78 ± 0.02 | 29.97 ± 1.20 | 83.35 ± 0.64 |

| Average (HW) | 1.0975 | 4.845 | 8.055 | 0.495 | 16.2675 | 50.275 | 1.9875 | 24.2875 | 76.925 | 1.8525 | 28.955 | 82.6375 |

| HD2967 | 1.18 ± 0.03 | 5.68 ± 0.14 | 9.74 ± 0.30 | 0.60 ± 0.01 | 16.54 ± 0.05 | 50.65 ± 0.07 | 2.14 ± 0.03 | 23.00 ± 0.00 | 73.95 ± 0.07 | 2.26 ± 0.02 | 30.00 ± 0.00 | 83.50 ± 0.14 |

| HI977 | 1.14 ± 0.03 | 1.50 ± 0.18 | 10.50 ± 0.18 | 0.62 ± 0.01 | 16.08 ± 0.15 | 50.10 ± 0.99 | 2.17 ± 0.01 | 22.16 ± 0.08 | 73.00 ± 0.28 | 1.72 ± 0.00 | 29.00 ± 0.54 | 82.95 ± 0.21 |

| UP2672 | 1.11 ± 0.03 | 4.95 ± 0.18 | 8.70 ± 0.04 | 0.56 ± 0.01 | 16.21 ± 0.01 | 49.30 ± 0.57 | 1.96 ± 0.01 | 22.09 ± 0.51 | 71.10 ± 1.98 | 1.89 ± 0.01 | 29.04 ± 0.48 | 82.30 ± 0.28 |

| DBW39 | 1.10 ± 0.06 | 5.44 ± 0.34 | 8.59 ± 0.45 | 0.51 ± 0.02 | 16.27 ± 0.09 | 49.85 ± 0.35 | 1.87 ± 0.03 | 22.99 ± 0.02 | 73.90 ± 0.28 | 1.97 ± 0.26 | 29.00 ± 1.41 | 82.45 ± 1.34 |

| Average (MHW) | 1.1325 | 4.3925 | 9.3825 | 0.5725 | 16.275 | 49.975 | 2.035 | 22.56 | 72.9875 | 1.96 | 29.26 | 82.8 |

| QBP12 9 | 1.09 ± 0.01 | 5.25 ± 0.32 | 6.91 ± 0.11 | 0.52 ± 0.09 | 15.60 ± 0.39 | 47.74 ± 0.34 | 2.39 ± 0.01 | 23.56 ± 0.05 | 76.59 ± 0.30 | 1.97 ± 0.03 | 29.45 ± 0.07 | 83.93 ± 0.18 |

| QBP1210 | 1.06 ± 0.00 | 5.41 ± 0.33 | 7.05 ± 0.11 | 0.42 ± 0.00 | 16.37 ± 0.05 | 48.20 ± 0.85 | 2.29 ± 0.02 | 24.41 ± 0.30 | 75.80 ± 1.41 | 1.90 ± 0.00 | 30.03 ± 0.74 | 82.80 ± 0.14 |

| QBP 12 8 | 1.07 ± 0.00 | 1.70 ± 0.10 | 9.94 ± 0.37 | 0.46 ± 0.00 | 16.79 ± 0.08 | 51.35 ± 1.20 | 2.42 ± 0.01 | 23.38 ± 0.08 | 74.55 ± 0.92 | 1.97 ± 0.03 | 31.25 ± 0.18 | 83.90 ± 0.42 |

| QBP1211 | 1.07 ± 0.01 | 6.48 ± 0.06 | 9.81 ± 0.23 | 0.52 ± 0.00 | 16.50 ± 0.21 | 49.65 ± 1.34 | 2.43 ± 0.04 | 28.13 ± 3.96 | 81.65 ± 2.19 | 2.11 ± 0.09 | 31.33 ± 1.06 | 83.75 ± 1.20 |

| Average (Ex-SW) | 1.0725 | 4.71 | 8.4275 | 0.48 | 16.315 | 49.235 | 2.3825 | 24.87 | 77.1475 | 1.9875 | 30.515 | 83.595 |

| Varieties | C5 (Nm) | Time at C5 (min) | Temp at C5 (°C) | Amplitude | Alpha | Beta | Gamma | Absorption | Mixing | Gluten+ | Viscosity | Amylase | Retrogradation |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| b | |||||||||||||

| K307 | 3.36 ± 0.18 | 45.01 ± 0.01 | 60.60 ± 0.00 | 0.06 ± 0.00 | − 0.07 ± 0.00 | 0.61 ± 0.01 | − 0.022 ± 0.017 | 1 ± 0 | 2.5 ± 0.71 | 4.5 ± 0.71 | 7 ± 0 | 8.5 ± 0.71 | 8 ± 0 |

| DPW62150 | 3.32 ± 0.13 | 45.01 ± 0.01 | 59.85 ± 0.35 | 0.06 ± 0.01 | − 0.12 ± 0.01 | 0.07 ± 0.06 | − 0.117 ± 0.103 | 2 ± 0 | 5 ± 0 | 7.5 ± 0.71 | 8 ± 0 | 5 ± 1.41 | 8 ± 0 |

| HD2932 | 3.23 ± 0.07 | 45.01 ± 0.01 | 58.70 ± 0.28 | 0.05 ± 0.00 | − 0.09 ± 0.00 | 0.31 ± 0.05 | − 0.123 ± 0.132 | 2 ± 0 | 3.5 ± 0.71 | 3.5 ± 0.71 | 8 ± 0 | 5.5 ± 2.12 | 8 ± 0 |

| HD2733 | 2.67 ± 0.02 | 45.01 ± 0.01 | 59.65 ± 1.06 | 0.07 ± 0.01 | − 0.06 ± 0.02 | 0.53 ± 0.01 | − 0.013 ± 0.004 | 0.5 ± 0.71 | 2 ± 0 | 6 ± 0 | 6.5 ± 0.71 | 8 ± 0 | 7 ± 0 |

| Average (HW) | 3.145 | 45.01 | 59.7 | 0.06 | − 0.085 | 0.38 | − 0.06875 | 1.375 | 3.25 | 5.375 | 7.375 | 6.75 | 7.75 |

| HD2967 | 3.37 ± 0.08 | 45.02 ± 0.00 | 60.65 ± 0.07 | 0.09 ± 0.01 | − 0.11 ± 0.01 | 0.48 ± 0.05 | − 0.028 ± 0.011 | 2 ± 0 | 5.5 ± 0.71 | 5.5 ± 0.71 | 8 ± 0 | 7 ± 0.71 | 8 ± 0 |

| HI977 | 3.00 ± 0.01 | 45.00 ± 0.00 | 59.70 ± 0.57 | 0.06 ± 0.01 | − 0.09 ± 0.01 | 0.52 ± 0.04 | − 0.165 ± 0.061 | 3.5 ± 0.71 | 5 ± 0 | 8 ± 0 | 8 ± 0 | 4 ± 0 | 8 ± 0 |

| UP2672 | 2.87 ± 0.07 | 45.01 ± 0.01 | 59.95 ± 0.21 | 0.07 ± 0.01 | − 0.07 ± 0.01 | 0.62 ± 0.03 | − 0.003 ± 0.001 | 5.5 ± 0.71 | 4.5 ± 0 | 5.5 ± 0.71 | 7.5 ± 0.71 | 8 ± 0 | 7 ± 0 |

| DBW39 | 3.44 ± 0.24 | 45.01 ± 0.01 | 59.65 ± 0.64 | 0.07 ± 0.00 | − 0.08 ± 0.01 | 0.63 ± 0.03 | − 0.008 ± 0.008 | 2.5 ± 0.71 | 5 ± 0 | 4.5 ± 0.71 | 7 ± 0 | 8.5 ± 0.71 | 8 ± 0 |

| Average (MHW) | 3.17 | 45.01 | 59.9875 | 0.0725 | − 0.0875 | 0.5625 | − 0.051 | 3.375 | 5 | 5.875 | 7.625 | 6.875 | 7.75 |

| QBP12 9 | 3.69 ± 0.01 | 45.00 ± 0.01 | 58.80 ± 0.15 | 0.06 ± 0.01 | − 0.08 ± 0.00 | 0.37 ± 0.08 | − 0.004 ± 0.003 | 0.5 ± 0.71 | 3.5 ± 0.71 | 4.5 ± 0.71 | 7.5 ± 0.71 | 4.5 ± 0.71 | 7.5 ± 0.7 |

| QBP1210 | 3.60 ± 0.02 | 45.01 ± 0.00 | 59.55 ± 0.49 | 0.07 ± 0.01 | − 0.07 ± 0.01 | 0.20 ± 0.07 | − 0.089 ± 0.024 | 0 ± 0 | 3.5 ± 0.71 | 4 ± 0 | 9 ± 0 | 5 ± 0 | 8 ± 0 |

| QBP 12 8 | 3.67 ± 0.09 | 45.00 ± 0.01 | 60.20 ± 0.42 | 0.05 ± 0.01 | − 0.10 ± 0.00 | 0.48 ± 0.03 | − 0.030 ± 0.014 | 1 ± 0 | 3.5 ± 0.71 | 5 ± 0 | 9 ± 0 | 6.5 ± 2.12 | 8 ± 0 |

| QBP1211 | 4.15 ± 0.03 | 45.00 ± 0.00 | 59.15 ± 1.06 | 0.05 ± 0.01 | − 0.09 ± 0.01 | 0.06 ± 0.03 | − 0.474 ± 0.082 | 1 ± 0 | 5.5 ± 0.71 | 5 ± 0 | 8.5 ± 0.71 | 8 ± 0 | 8 ± 0 |

| Average (Ex-SW) | 3.7775 | 45.0025 | 59.425 | 0.0575 | − 0.085 | 0.2775 | − 0.14925 | 0.625 | 4 | 4.625 | 8.5 | 6 | 7.875 |

Data represented as mean value ± SD

Fig. 1.

a Mixolab curve of flour milled from different HW, MHW and Ex-SW varieties. b Mixolab curve of flour milled from different HW varieties. c Mixolab curve of flour milled from different MHW varieties. d Mixolab curve of flour milled from different Ex-SW varieties

Table 2.

Damaged starch content and Mixolab parameters of flours from different HW, MHW and Ex-HW varieties

| Varieties | Damaged starch (%) | C3–C4 | C5–C4 |

|---|---|---|---|

| K307 | 9.98 ± 0.198 | − 0.15 | 1.27 |

| DPW62150 | 9.53 ± 0.226 | 0.33 | 1.55 |

| HD2932 | 9.23 ± 0.212 | 0.3 | 1.46 |

| HD2733 | 9.20 ± 0.078 | 0.06 | 0.89 |

| Average (HW) | 9.485 | 0.135 | 1.2925 |

| HD2967 | 6.98 ± 0.122 | − 0.12 | 1.11 |

| HI977 | 7.02 ± 0.311 | 0.45 | 1.28 |

| UP2672 | 7.88 ± 0.071 | 0.07 | 0.98 |

| DBW39 | 8.45 ± 0.141 | − 0.1 | 1.47 |

| Average (MHW) | 7.5825 | 0.075 | 1.21 |

| QBP 12-9 | 2.02 ± 0.170 | 0.42 | 1.72 |

| QBP 12-10 | 2.47 ± 0.027 | 0.39 | 1.7 |

| QBP 12-8 | 2.94 ± 0.042 | 0.45 | 1.7 |

| QBP 12-11 | 2.31 ± 0.103 | 0.32 | 2.04 |

| Average (Ex-SW) | 2.435 | 0.395 | 1.79 |

Fig. 2.

a Loading plot indicating the relationship of mixographic properties with Mixolab properties of flour obtained from different HW, MHW and Ex-SW varieties (MPT, mixograph peak time; MPW, mixograph peak width; LPV, left peak value; LPW, left peak width; RPV, right peak value; RPW, right peak width; WS). b Loading plot indicating the relationship of pasting properties with Mixolab properties of flour obtained from different HW, MHW and Ex-SW varieties (PT, pasting temperature; PV, peak viscosity; BDV, breakdown viscosity; FV, final viscosity; SBV, setback viscosity). c Loading plot indicating the relationship of farinographic properties with Mixolab properties of flour obtained from different HW, MHW and Ex-SW varieties(WA, water absorption; DDT, dough development time; DS, dough stability; DOS, degree of softening). d Loading plot indicating the relationship of particle size and protein characteristics with Mixolab properties of flour obtained from different HW, MHW and Ex-SW varieties (Ex-PP, Extractable Polymeric protein; Ex-MP, Extractable Monomeric protein; UnEx-PP, UnExtractable Polymeric Protein; UnEx-MP, UnExtractable Monomeric Protein; LSP, Large size particles; MSP, Medium size particles; SSP, Small size particles). e Loading plot indicating the relationship of grain hardness and solvent retention capacity with mixographic parameters with Mixolab properties of flour obtained from different HW, MHW and Ex-SW varieties (GHI, Grain hardness index; SRC, solvent retention capacity; NaSRC, sodium carbonate SRC; SuSRC, sucrose SRC; LASRC, lactic acid SRC; WSRC, water SRC)

Conclusion

Mixolab properties of Ex-SW, MHW and HW wheat varieties were related to damaged starch content, particle size distribution, pasting, empirical and dynamic rheology. Higher damaged starch led to more WA in HW varieties. MHW varieties showed less protein weakening, the varieties with lower C2 value showed more weakening of gluten protein network on simultaneous mixing and heating. C2, an indicator of start of pasting of dough was closely associated with gluten content and LASRC. Both the viscous (G’) and elastic modulus (G’’) was correlated with C2. The maximum value of torque during heating phase (C3) was significantly higher for flours with lower NaSRC and SuSRC. C3, an indicator of peak viscosity, was higher for Ex-SW varieties as compared to HW varieties. The lowest peak temperature was observed for MHW varieties among all three wheat varieties. Starches with higher A-type granules had lower stablity toward the shearing than those containing more of B and C type granules. Ex-SW varieties were characterized with higher C5 indicating more of retrogradation as compared to MHW and HW varieties. The starch gelatinization rate was lower for Ex-SW varieties than MHW and HW varieties.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgements

NS acknowledges CSIR, New Delhi for providing funds in the form of a research project. Also acknowledges Dr. Anju Mahendru Singh, Division of Genetics, Indian Agricultural Research Institute, New Delhi 110012, India for providing the material.

Abbreviations

- DDT

Dough development time

- DS

Dough stability

- Ex-MP

Extractable Monomeric protein

- Ex-PP

Extractable Polymeric protein

- GHI

Grain hardness index

- LASRC

Lactic acid SRC

- NaSRC

Sodium carbonate SRC

- PCA

Principal component analysis

- SRC

Solvent retention capacity

- SuSRC

Sucrose SRC

- UnEx-MP

UnExtractable Monomeric Protein

- UnEx-PP

UnExtractable Polymeric Protein

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Banu I, Stoenescu G, Ionescu V, Aprodu I. Estimation of the baking quality of wheat flours based on rheological parameters of the Mixolab curve. Czech J Food Sci. 2011;29:35–44. doi: 10.17221/40/2009-CJFS. [DOI] [Google Scholar]

- Codina GG, Mironeasa S, Bordei D, Leahu A. Mixolab versus alveograph and falling number. Czech J Food Sci. 2010;28:185–191. doi: 10.17221/169/2008-CJFS. [DOI] [Google Scholar]

- Dubat A. A new AACC International approved method to measure rheological properties of a dough sample. Cereal Food World. 2010;55:150–153. [Google Scholar]

- Gaines CS. Collaborative study of methods for solvent retention capacity profiles (AACC method 56-11) Cereal Food World. 2000;45:303–306. [Google Scholar]

- Gujral HS, Sharma B, Khatri M. Influence of replacing wheat bran with barley bran on dough rheology, digestibility and retrogradation behavior of chapatti. Food Chem. 2018;240:1154–1160. doi: 10.1016/j.foodchem.2017.08.042. [DOI] [PubMed] [Google Scholar]

- Heo S, Lee SM, Shim JH, Yoo SH, Lee S. Effect of dry-and wet-milled rice flours on the quality attributes of gluten-free dough and noodles. J Food Eng. 2013;116:213–217. doi: 10.1016/j.jfoodeng.2012.11.017. [DOI] [Google Scholar]

- Hrušková M, Švec I, Jurinová I. Changes in baking quality of composite wheat/hemp flour detected by means of Mixolab. Cereal Res Commun. 2013;41:150–159. doi: 10.1556/CRC.2012.0033. [DOI] [Google Scholar]

- Katyal M, Virdi AS, Kaur A, Singh N, Kaur S, Ahlawat AK, Singh AM. Diversity in quality traits amongst Indian wheat varieties I: flour and protein characteristics. Food Chem. 2016;194:337–344. doi: 10.1016/j.foodchem.2015.07.125. [DOI] [PubMed] [Google Scholar]

- Katyal M, Singh N, Virdi AS, Kaur A, Chopra N, Ahlawat AK, Singh AM. Extraordinarily soft, medium-hard and hard Indian wheat varieties: composition, protein profile, dough and baking properties. Food Res Int. 2017;100:306–317. doi: 10.1016/j.foodres.2017.08.050. [DOI] [PubMed] [Google Scholar]

- Katyal M, Singh N, Chopra N, Kaur A. Hard, medium-hard and extraordinarily soft wheat varieties: comparison and relationship between various starch properties. Int J Biol Macromol. 2019;23:1143–1149. doi: 10.1016/j.ijbiomac.2018.11.192. [DOI] [PubMed] [Google Scholar]

- Kaur A, Shevkani K, Katyal M, Singh N, Ahlawat AK, Singh AM. Physicochemical and rheological properties of starch and flour from different durum wheat varieties and their relationships with noodle quality. J Food Sci Technol. 2016;53:2127–2138. doi: 10.1007/s13197-016-2202-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Koksel H, Kahraman K, Sanal T, Ozay DS, Dubat A. Potential utilization of Mixolab for quality evaluation of bread wheat genotypes. Cereal Chem. 2009;86:522–526. doi: 10.1094/CCHEM-86-5-0522. [DOI] [Google Scholar]

- Mironeasa S, Codina GG, Mironeasa C. The effect of wheat flour substitution with grape seed flour on the rheological parameters of the dough assessed by Mixolab. J Texture Stud. 2012;43:40–48. doi: 10.1111/j.1745-4603.2011.00315.x. [DOI] [Google Scholar]

- Morris VJ. Starch gelation and retrogradation. Trends Food Sci Technol. 1990;1:2–6. doi: 10.1016/0924-2244(90)90002-G. [DOI] [Google Scholar]

- Moza J, Gujral HS. Mixolab, retrogradation and digestibility behavior of chapatti made from hulless barley flours. J Cereal Sci. 2018;79:383–389. doi: 10.1016/j.jcs.2017.11.003. [DOI] [Google Scholar]

- Papouskova L, Capouchova I, Kostelanska M, Skeríkova A, Prokinova E, Hajslova J, et al. Changes in baking quality of winter wheat with different intensity of Fusarium spp. contamination detected by means of new rheological system Mixolab. Czech J Food Sci. 2011;29:420–429. doi: 10.17221/426/2010-CJFS. [DOI] [Google Scholar]

- Rosell CM, Marco C, García-Alvarez J, Salazar J. Rheological properties of rice-soybean protein composite flours assessed by Mixolab and ultrasound. J Food Process Eng. 2011;34:1838–1859. doi: 10.1111/j.1745-4530.2009.00501.x. [DOI] [Google Scholar]

- Rosell CM, Altamirano-Fortoul R, Don C, Dubat A. Thermomechanically induced protein aggregation and starch structural changes in wheat flour dough. Cereal Chem. 2013;90:89–100. doi: 10.1094/CCHEM-05-12-0056-R. [DOI] [Google Scholar]

- Sandhu RS, Singh N, Kaler RSS, Kaur A, Shevkani K. Effect of degree of milling on physicochemical, structural, pasting and cooking properties of short and long grain Indica rice cultivars. Food Chem. 2018;260:231–238. doi: 10.1016/j.foodchem.2018.03.092. [DOI] [PubMed] [Google Scholar]

- Sandhyarani MR, Bhattacharaya KR. Rheology of rice-flour pastes. Effect of variety, concentration and temperature and time of cooking. J Texture Stud. 1989;20:127–137. doi: 10.1111/j.1745-4603.1989.tb00427.x. [DOI] [Google Scholar]

- Sharma B, Gujral HS, Solah V. Effect of incorporating finger millet in wheat flour on Mixolab behavior, chapatti quality and starch digestibility. Food Chem. 2017;231:156–164. doi: 10.1016/j.foodchem.2017.03.118. [DOI] [PubMed] [Google Scholar]

- Shevkani K, Singh N, Singh S, Ahlawat AK, Singh AM. Relationship between physicochemical and rheological properties of starches from Indian wheat lines. Int J Food Sci Technol. 2011;46:2584–2590. doi: 10.1111/j.1365-2621.2011.02787.x. [DOI] [Google Scholar]

- Shinde SV, Nelson JE, Huber KC. Soft wheat starch pasting behaviour in relation to A- and B-type granule content and composition. Cereal Chem. 2008;80:91–98. doi: 10.1094/CCHEM.2003.80.1.91. [DOI] [Google Scholar]

- Singh S, Singh N, Isono N, Noda T. Relationship of granule size distribution and amylopectin structure with pasting, thermal and retrogradation properties in wheat starches. J Agric Food Chem. 2010;58:1180–1188. doi: 10.1021/jf902753f. [DOI] [PubMed] [Google Scholar]

- Singh N, Kaur A, Katyal M, Singh AM, Ahlawat AK, Bhinder S. Diversity in quality traits amongst Indian wheat varieties II: paste, dough and muffin making properties. Food Chem. 2016;197:316–324. doi: 10.1016/j.foodchem.2015.10.035. [DOI] [PubMed] [Google Scholar]

- Torbica A, Draskovic M, Tomic J, Dodig D, Boskovic J, Zecevic V. Utilization of Mixolab for assessment of durum wheat quality dependent on climatic factors. J Cereal Sci. 2016;69:344–350. doi: 10.1016/j.jcs.2016.04.012. [DOI] [Google Scholar]

- Wong RBK, Lelievre J. Rheological characteristics of wheat starch measured under steady shear conditions. J Appl Polym Sci. 1982;27:1433–1440. doi: 10.1002/app.1982.070270502. [DOI] [Google Scholar]

- Xiao ZS, Park SH, Chung OK, Caley MS. Solvent retention capacity values in relation to hard winter wheat and flour properties and straight-dough bread making quality. Cereal Chem. 2006;83:465–471. doi: 10.1094/CC-83-0465. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.