Abstract

The effect of sun-dried (SD), oven-dried (OD) and freeze-dried (FD) amla fruit powders on the mixing characteristic, objective color (ICI tristimulus L* a* b* values) and instrumental texture was investigated. The addition of differently dried amla powders did not affect the mixograms significantly. The color characteristics were affected by both the levels of addition as well as by the type of powder (SD, OD and FD) incorporated into the pan bread. The L*, a*, b* values were not significantly different for the crusts of all types of the breads at varying levels. However, incorporation of SD, OD and FD powder lowered L*and b* values significantly for the crumb, making it look lesser white but browner in color. The specific loaf volume of bread made with SD and OD amla fruit powders at lower levels of addition gave compression force values and specific loaf volumes very close to the bread made with 20 ppm of potassium bromate. But higher amounts (1–3%) of amla fruit powder resulted in harder bread texture, lower specific loaf volume and also a coarser crumb grain. Therefore, amla fruit being rich in ascorbic acid seems a good choice an alternative natural dough improver in place of potassium bromate which has been regarded as a potential carcinogen and now banned in many countries of the world.

Electronic supplementary material

The online version of this article (10.1007/s13197-019-03766-x) contains supplementary material, which is available to authorized users.

Keywords: Amla fruit powder, Ascorbic acid, Bread dough improver, Instrumental texture, Objective color

Introduction

Natural antioxidants being the focus of numerous research teams all over the world are being extensively investigated as information in this area is accumulating fast (Xu et al. 2019). The interest in natural antioxidants is determined by their action in various redox systems and consequently resulting in broad spectra of possible applications. Antioxidative phytochemicals are considered as functional ingredients for dietary supplements, functional foods and pharmaceuticals and various other uses. Herbs, spices, berries, seeds and other plant sources are an important source of natural antioxidants, however, their commercial application in the production of functional foods are restricted by several factors, particularly high production costs and stable availability of raw materials (Raudoniūtė et al. 2011). Amla fruit (Phyllanthus emblica L.), known as Indian Gooseberry, is widely cultivated in Pakistan, India, China, many East-Asian countries.

Fresh amla fruits have a short shelf-life and spoils easily during transportation and storage. Dehydration of amla during the main growing season is one of the fundamental methods of preservation that helps in reducing the post-harvest losses. Dried fruit products can be used as such after rehydration or can be used to develop value-added products during the off-season. Conventional air drying is the most frequently used dehydration process in the food industry, but it often results in the degradation of phytochemical compounds present in fruits and vegetables (Sidhu and Zafar 2012). To alleviate these problems, various drying techniques have been developed to improve the retention of phytochemicals, and this includes, infrared drying, vacuum drying, microwave drying and freeze drying (Ofor and Ibeawuchi 2010). Among all the techniques, freeze drying has been shown to achieve the highest retention of the phytochemical compounds with minimal decline in product quality (Kapoor et al. 2015).

Bread is a dietary staple of a large segment of the world’s population (Fardet et al. 2006). Bread products are well established worldwide because of their lower cost, ease of preparation, more variety, desirable sensory attributes and nutritional properties. Recently a number of studies have been reported on the milling and baking characteristics of Indian durum and bread wheats (Kaur et al. 2015; Singh et al. 2016; Katyal et al. 2017, 2018, 2019). In human nutrition, bread is not only a source of energy, but also a supplier of various nutrients, such as, proteins, dietary fiber, certain vitamins and minerals for the human body (Isserliyska et al. 2001). In bread making, oxidants play an important role in improving dough handling as well as finished product quality. Till recently, potassium bromate was commonly used as dough improver, but has come under suspicion lately (Emeje et al. 2015; Preethi 2016). Many of the European countries, Canada, Australia, and India have banned the use of potassium bromate in bread and a number of alternatives are being suggested (Ye et al. 2011). Microbial xylanases (Dahiya and Singh 2019; Tebben et al. 2018), ascorbic acid (Corrales et al. 1993), and many salts such as, ammonium persulfate, ammonium chloride, calcium peroxide, azodicarbonamide, potassium iodate (Bhide 2019) have been suggested as possible replacement for potassium bromate.

Keeping this in view the importance and need for using natural dough improvers, we have attempted to replace potassium bromate with differently dried amla fruit powders as a source of natural ascorbic acid for use in pan bread making. Secondly, amla fruit powder can serve not only as a safer substitute antioxidant/dough improver for potassium bromate in pan bread making, but also a source of many other health promoting phytochemicals. Thus, more importantly, the possibility of using dried amla fruit powders (SD, OD, and FD) for the production of white flour pan bread (WB) will improve the nutritional quality of this staple food.

Materials and methods

Materials

Fresh amla fruit

Fresh amla fruit imported from India, was obtained from the local Kuwaiti market. After washing the amla fruits thoroughly in running warm water to remove adhering dust and other impurities, were paper-towel dried, seeds removed, pulped in a blender. The pulped amla fruit was then taken for drying by three different methods, as explained in the following section.

Methods

Drying of amla fruit pulp

Fresh fruit pulp was spread thinly on aluminum foil, then sun-dried (~ 40 °C) in shaded corridor to achieve a moisture content of less than 10% (which took about four days). The product was weighed periodically to calculate the loss in weight. Constant drying rate was observed during the first day after which drying entered the falling rate period. The dried amla pulp was then powdered, labeled as sun-dried (SD) and stored at − 18 °C till further use. Kuwait has very hot summers so the temperature could reach as high as 50 °C even in the shaded areas. Fresh fruit was also dried in a hot air oven (Memmert, Germany) at 55 °C until the moisture content reached lower than 10%. Here the constant drying rate period was short (about five hours) and the falling rate drying rate period was observed for the next about 19 h. The dried pulp was then powdered, labeled as oven-dried (OD) and stored at − 18 °C till further use. Fresh fruit pulp was also freeze-dried (GAMMA 1-16 LSC, UK) until the moisture content reached lower than 2%. It was then powdered, labeled as freeze-dried (FD) and stored at − 18 °C till further use, as reported in earlier research publication (Alkndari et al. 2019).

Mixograph studies

Mixograms were obtained to study the effect adding differently dried amla powders at varying levels to the WF using a 10-g mixing bowl (National Mfg. Co. Lincoln, Nebraska, USA) as per the AACC method 54-40A (AACC 2000). Dough absorption water (at 14% mb) was estimated using the formula:

where X = % flour protein content (14% mb) and Y = % absorption water.

Mixograph was rum for 12 min, and the following measurements were obtained from the mixograms:

Time to maximum height or peak of minimum mobility.

Ascending and descending angles of the curve at the peak.

Instrumental texture measurement

After cooling the bread overnight at room temperature (22 ± 1 °C), one-inch thick slices (after discarding the edges) were obtained from each loaf. The bread texture was determined using TAXT2 texture analyzer (Make: Stable Micro System, UK). Each slice was placed in center of platform, and was compressed by 30%, using a 25 mm plunger at a speed of 1.00 mm/s with a 5 g trigger force (AlSaqer et al. 2000). For each bread sample, eight readings were obtained, and the mean ± SD has been reported. The hardness value indicating bread texture is a measure of the peak force that occurs during the first compression. The hardness does not need to occur at the point of deepest compression, although it typically does for most products. The hardness force required to compress a food between the molars is defined as force necessary to attain a given deformation.

Objective color measurement (CIE L*a*b* values)

The objective color of both the crust and crumb of these bread samples at 12 points on the samples in terms of CIE L* a*b* tristimulus values was measured using portable colorimeter (Make: Hunter Lab, Model: Mini Scan-EZ, USA). After discarding the two extreme values, the mean ± S.D. of the remaining 10 are reported. Similarly, the objective color of fresh crushed amla fruit as well as the differently dried amla powders was also measured in the same manner. Under this tristimulus color coordinate system, the L* values is a measure of lightness and ranges from 0 (black) to 100 (white); a* values ranges from − 100 (green) to + 100 (red), and the b* value ranges from − 100 (blue) to + 100 (yellow). As the values for a* and b* rise, the color becomes more saturated or chromatic, but these values approach zero for neutral colors (white, grey or black). The instrument settings were illuminant D50, display L*a*b*, observer angle 34° and the instrument was calibrated with a white primary tile (100) and with black primary tile (zero), supplied by the manufacturer.

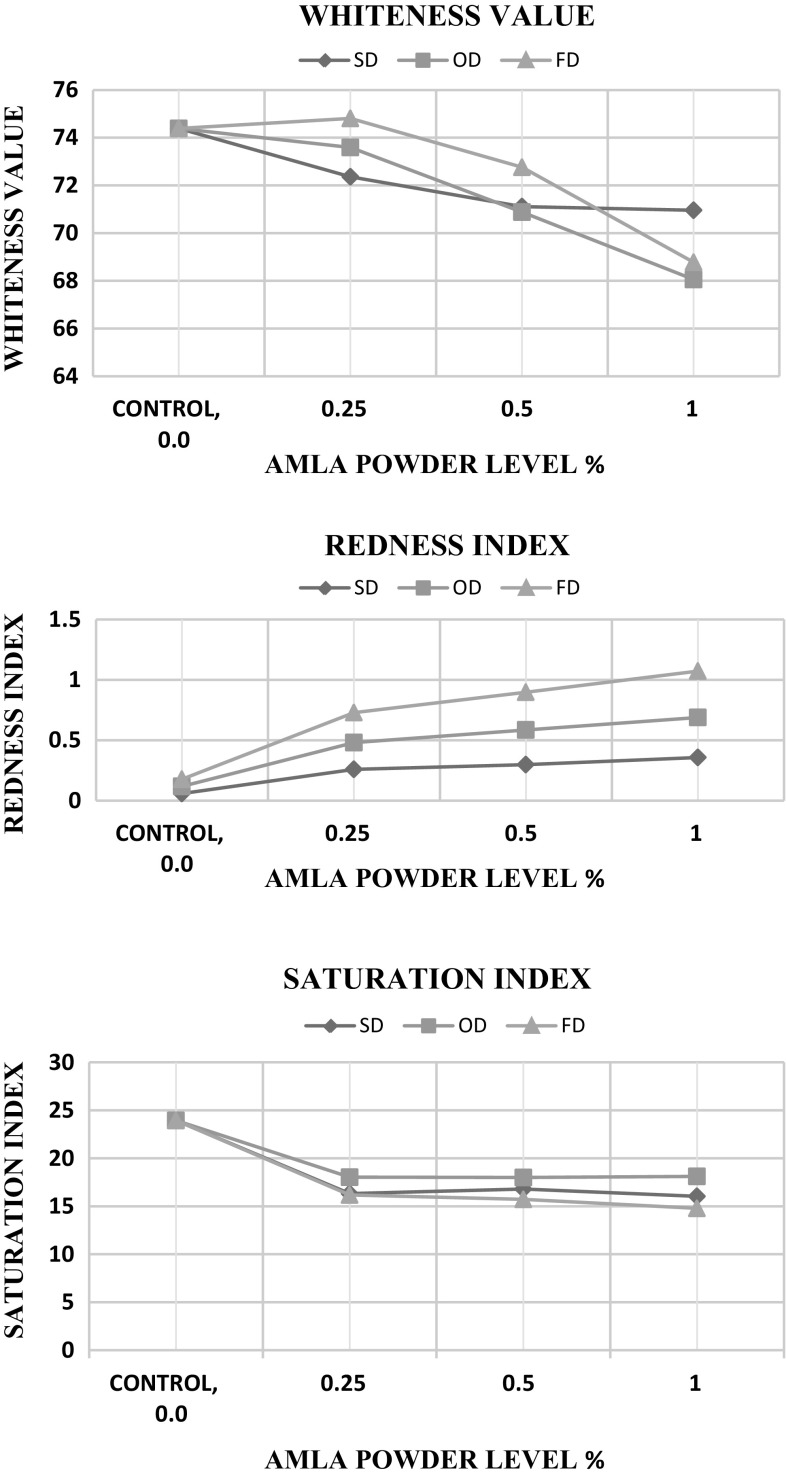

Additional attributes, such as, whiteness value, redness index (RI), and saturation index (SI), were also calculated as explained earlier (Al-Hooti et al. 2000). Whiteness was calculated by the equation: 100 − [(100 − L*)2 + a*2 + b*2]1/2. The a*/b* ratio was taken as an index of apparent change in redness index (RI); the saturation index representing the color purity or color intensity of a sample, was calculated by the equation: (a*2 + b*2)1/2.

Statistical analysis

All of the research data were statistically analyzed using the software: IBM SPSS statistics (Version 21 software Inc. Chicago, USA). Significant differences between the mean values were evaluated with one-way analysis of variance (ANOVA) followed by Tukey’s posthoc multiple comparisons test. A value of alpha level at P < 0.05 was considered to be statistically significant. Results are presented as Mean ± SD (Danianni et al. 2013).

Results and discussion

Fresh amla fruit procured from the local market was dried by three different techniques, fresh amla as well as dried amla powders were analyzed for proximate composition, antioxidant capacity, white flour bread was made with amla powders and then analyzed for proximate composition, TEAC, TPC, baking quality and sensory characteristics, which have been presented in an earlier publication (Alkndari et al. 2019). The data related to specific loaf volume and baking loss in bread samples is presented in supplementary Table 1s. It is not possible to completely eliminate the browning reactions during sun or oven drying operations without the use of potassium metabisulfite (whose use we avoided). Only the freeze drying was effective in preventing browning reactions during drying operation. The research data related to the effect of amla powders addition on the mixograms characteristics, objective color and instrumental texture of pan bread are presented and discussed in the following sections.

Mixograph studies

The effect of adding amla powder on the mixing characteristics of white flour were studied using the standard AACC method (AACC 2000) and the results are summarized in Table 1. No significant differences were observed in any of the mixogram characteristics among the three different types of amla powders. Typical mixograms obtained in this study have been shown in Supplementary Fig. 1s. According Schroeder and Hoseney (1978), some of the ascorbic acid is utilized as an oxidizing agent when it is converted to dehydroascorbic acid by the enzyme ascorbic acid oxidase in the presence of oxygen available in the dough. As suggested by them, the higher oxidant levels are known to strengthen the gluten proteins which are weakened by the tripeptide glutathione present in wheat flour and is known for its strong reducing properties (Sidhu et al. 2001; Meredith and Bushuk 1962). In some of the studies, significant variations in the mixograms characteristics and quality traits among different Indian durum and breadmaking wheat varieties have been reported by a number of workers (Kaur et al. 2015; Singh et al. 2016; Katyal et al. 2017, 2019). Katyal et al. (2018) have recently investigated the diversity in protein profiling, and various rheological parameters of meals obtained a wide range of durum wheat accessions. Higher levels of amla powder, thus, was found to minimize the deleterious effects of glutathione on dough quality. However, when lower levels of amla powder were used, there weren’t any significant differences on the mixogram characteristics, but with the higher amounts of amla powder, some differences in dough strengthening effect was observed, as indicated by the lower values of descending angle (Supplementary Table 2s).

Table 1.

Effect of amla powder addition on the ascending and descending angles of mixograms

| Level of amla powder addition, % | Ascending angle | Descending angle | ||||

|---|---|---|---|---|---|---|

| SD | OD | FD | SD | OD | FD | |

| Control | 21.5 ± 3.5 | 21.5 ± 3.5 | 21.5 ± 3.5 | 6.0 ± 0.0 | 6.0 ± 0.0 | 6.0 ± 0.0 |

| 0.25 | 20.5 ± 2.1 | 18.0 ± 0.0 | 20.5 ± 3.5 | 4.5 ± 0.7 | 5.0 ± 0.0 | 5.0 ± 0.2 |

| 0.50 | 21.0 ± 1.4 | 21.5 ± 3.5 | 19.0 ± 1.4 | 4.0 ± 0.0 | 3.5 ± 0.1 | 4.1 ± 0.4 |

| 1.0 | 16.0 ± 4.2 | 18.5 ± 0.7 | 21.0 ± 0.0 | 3.5 ± 0.1 | 3.0 ± 0.1 | 3.5 ± 0.3 |

No significant differences between the ascending angle and descending angle values in rows and columns were detected by the mixograph at P < 0.05

SD Sun dried, OD oven dried, FD freeze dried

Objective color measurement of amla powders and pan bread

The objective color of crushed fresh amla fruit as well as the differently dried amla powders in terms of CIE L*a*b* values was measured at 12 different points using Hunter Lab mini scan as explained earlier. After discarding the two outlying values, mean and standard deviations of L* a* b* values are presented in Table 2.

Table 2.

CIE L*a*b* color values of fresh amla fruit and differently dried amla fruit powders

| Type of amla fruit | Tristimulus color values | ||

|---|---|---|---|

| L* | a* | b* | |

| FA | 82.6 ± 0.7a | − 1.3 ± 0.08c | 21.6 ± 0.4g |

| SD | 82.8 ± 0.4a | 4.2 ± 0.08d | 14.9 ± 0.3h |

| OD | 83.3 ± 0.5a | 7.5 ± 0.2e | 10.8 ± 0.2i |

| FD | 92.4 ± 0.5b | − 0.9 ± 0.06f | 18.3 ± 0.2h |

Mean values with different superscripts differ significantly (P < 0.05) in a column

Fresh amla fruit originally possessed a light lime green color but after drying there was an appreciable and varied change in the color of finished powders. Depending upon the temperature used during drying, different methods are known to bring about noticeable changes in the color of finished powders. The FD powder had significantly higher Lightness (L*) values, indicating lighter color. The redness (a*) values differed significantly amongst the powders compared with the FA. OD powder had the highest redness value (7.5) indicating more browning. The fresh amla pulp and the FD amla powder possessed green color as indicated by negative a* values (− 0.9 and − 1.3), obviously due to the presence of certain amount of chlorophyll pigment. After drying process, the green pigment got destroyed and due to browning reactions, it turned towards red color in SD and OD amla powders giving positive a* values (+ 4.2 and + 7.5). Though significantly different, the redness (a*) and yellowness (b*) values of FD amla powder was the closest to the FA, indicating a minimum amount of browning during freeze-drying process. Obviously, the OD powder had the darkest color among the three powders. This may be due to the higher temperature reached in case of OD powder that led to more browning resulting in darker color of finished powder, possibly due to caramelization of sugars, the Maillard reactions, enzymatic degradation and pigment loss, as has also been suggested by Arslan and Özcan (2010).

The crust and crumb color of pan bread made by adding varying levels of amla fruit powders, was measured for L* a* b* values as explained earlier, and the results are summarized in Table 3. The observed differences in the crust color of pan bread made by adding varying levels of amla fruit powders were statistically nonsignificant, and the data are presented in supplementary Table 3s. However, the addition of every amla fruit powder significantly affected the crumb color of pan bread samples. As the level of amla powder addition increased from 0 to 1%, the crumb color became darker as indicated by the lower L* values. No significant difference in lightness (L*) values was observed among the bread samples made with differently dried amla powders. The redness values (positive a*) of bread crumb were found to increase significantly (P < 0.05) with the increasing levels of supplementation with amla powders, and the increase was found to be more in OD, followed by SD and was the lowest in the FD samples. Interestingly, compared with the control (no amla powder added), the addition of amla fruit powders reduced the yellow color of bread crumb as evident from the lower b* values. The positive b* values that indicates yellowness of bread crumb decreased with the increasing levels of supplementation with each amla powder. The natural cream color of bread crumb is attributed to the caroteinoid pigments present in wheat flour (Ram et al. 2002), but this color gets overshadowed by the red color being contributed by added the amla powder that had attained brown color during the drying process. Moreover, the ascorbic acid is also known to undergo nonenzymatic browning reactions during heating (Tatum et al. 1969). As amla powder is rich in ascorbic acid, it may undergo browning reaction reading to the observed increase in a* values of bread crumb of these samples. Reduction in b* values may also signify the increase in blueness value of the samples (Altan et al. 2008). The crumb grain structure of pan breads made with SD and OD amla fruit powders is shown in Fig. 1.

Table 3.

CIE L*a*b* values for crumb color of pan bread made with differently dried amla fruit powders

| Level of dried amla, % | L* values | a* values | b* values | ||||||

|---|---|---|---|---|---|---|---|---|---|

| SD | OD | FD | SD | OD | FD | SD | OD | FD | |

| Control | 90.9 ± 0.4a | 90.9 ± 0.4e | 90.9 ± 0.4j | 1.4 ± 0.2a | 1.4 ± 0.2e | 1.4 ± 0.2 k | 23.9 ± 0.1a | 23.9 ± 0.1d | 23.9 ± 0.1f |

| 0.25 | 77.7 ± 0.3b | 80.7 ± 0.6f | 79.0 ± 0.4 k | 4.1 ± 0.1b | 3.9 ± 0.1f | 3.9 ± 0.1 m | 15.8 ± 0.3b | 17.6 ± 0.2e | 15.7 ± 0.2 g |

| 0.50 | 76.5 ± 0.6c | 77.2 ± 0.7 g | 78.0 ± 0.4 k | 4.8 ± 0.1c | 5.0 ± 0.1 h | 4.7 ± 0.1n | 16.1 ± 0.4b | 17.4 ± 0.2e | 15.0 ± 0.2 g |

| 1.0 | 75.8 ± 0.8d | 73.7 ± 0.4 h | 72.5 ± 0.6 m | 5.4 ± 0.1d | 5.7 ± 0.1j | 5.3 ± 0.1p | 15.1 ± 0.1c | 17.2 ± 0.3e | 13.8 ± 0.3 h |

Mean values with different superscripts differ significantly (P < 0.05) in rows for each L* a* b* values between SD, OD, and FD pan bread samples

Mean values with different subscripts differ significantly (P < 0.05) in columns for each L* a* b* values between different alma powder levels used in pan bread samples

Fig. 1.

Crumb grain appearance of Amla fruit powder breads

Based on the L*, a*, b* values, whiteness value, redness index, and saturation index were calculated for crumb of all the pan bread samples made with the addition of amla powders (0–1% level) and the results are presented in Fig. 2. Compared with control, the whiteness values of crumb showed a significant reduction in all three amla powders with increasing level of amla powder addition, meaning the color becoming darker. In case of all the amla powder addition, the redness index of bread crumbs showed insignificant increase at all levels of addition. This may be explained due to the development of brown pigments in amla powders during drying operations which may be responsible for the higher redness index of bread crumb. Compared with the control bread, the purity (saturation index) of crumb color decreased significantly even at a staring level of 0.25% of amla powder addition. It can be concluded that the addition of dried amla powders significantly affected the various color properties, and the tristimulus system can effectively be utilized in evaluating the crumb color of these bread samples. In another study using green tea extracts, Wang et al. (2007) have also shown that addition of tea tannins reduced the bread crumb brightness and sweetness.

Fig. 2.

CIE L* a* b* color values for crumb of pan bread made with differently dried amla fruit powders

Instrumental texture

The data related to the effect of adding varying levels of amla powder addition on the objective texture of pan bread samples are presented in Table 4. Compared with control (no amla powder, no potassium bromate), the compression force values for the pan bread were found to decrease as the level of amla powder was increased from 0.25 to 1%, whereas at the higher level (3%), it increased across all the three types of amla powders, indicating a harder texture of bread, especially at 3% amla powder addition. The bread texture were found to be similar to bromate containing sample with the use of SD and OD amla powders up to a level of 0.50%, but with FD amla powder, the bread texture became significantly harder at and beyond 0.25% level of amla powder. Compression force values of WB supplemented with all the amla powders were found to be the higher as the level of amla powders were increased beyond 1% level, thus indicating a harder texture. Phenolic compounds have been shown to interact with disulfide groups, thus weakening the gluten network, which resulted in reduced loaf volume (Han and Koh 2011; Nicks et al. 2013). Free radicals of the phenolics present in plants products have been shown to break the disulfide bonds of gluten proteins thus leading to the weakening of the dough (Han and Koh 2011), which could be one of the technological problem for the bakers to address appropriately. Otherwise, the pan bread will have compact structure giving lower loaf volume and harder texture. In a similar study, Nicks et al. (2013) have shown that the addition of ferulic acid (a phenolic compound) to dough accelerated the dough breakdown and reduction in loaf volume.

Table 4.

Compression force (g) values for amla fruit powder pan bread

| Amla powder level, % | Compression force, g | ||

|---|---|---|---|

| SD | OD | FD | |

| Control (no amla, no bromate) | 282.3 ± 17.6a | 282.3 ± 17.6a | 282.3 ± 17.6a |

| Pot. bromate, 20 ppm | 160.8 ± 5.9b | 160.8 ± 5.9b | 160.80 ± 5.90b |

| 0.25 | 145.1 ± 11.9cg | 157.8 ± 13.3bg | 166.00 ± 9.05bg |

| 0.50 | 173.0 ± 12.6dh | 174.3 ± 14.8ch | 198.30 ± 21.60cj |

| 1.0 | 220.0 ± 27.2ek | 207.1 ± 22.4dk | 238.86 ± 29.07am |

| 2.0 | 268.5 ± 26.6an | 234.7 ± 38.7ap | 359.97 ± 53.48dq |

| 3.0 | 409.2 ± 38.9fr | 327.9 ± 37.6as | 379.36 ± 45.56er |

Mean values for compression force values with different superscripts differ significantly (P < 0.05) in a column for a level of addition for different types of dried powder

Mean values for compression force values with different subscripts differ significantly (P < 0.05) in a row for a level of addition for different types of dried powder

The use of SD and OD amla powders up to a level of 0.50% significantly increased the specific volume of pan breads, however, the FD amla powder gave lower specific loaf volume beyond 0.25% level of addition. The lower specific loaf volume gave compact bread structure resulting in higher compression force values (Table 4). At higher levels of dried amla powders addition (beyond 1% level), the specific loaf volume values were significantly reduced in all three types of dried amla powders. The bread crumb grain became coarser and darker in all these bread samples having higher levels (beyond 1%) of dried amla powders (Supplementary data Table 1). The instrumental texture data have clearly shown that by using 0.25% of FD amla powder or up to 0.50% of SD and OD amla powders, use of potassium bromate as flour oxidant can successfully be replaced with a natural additive, an ascorbic acid and antioxidants-rich amla fruit powder.

Conclusion

The effect of adding amla powders on the mixogram characteristics was found to be non-significant. The L*, a*, b* values were not significantly different for crusts of all types of the breads baked using varying levels of these dried amla powders. However, incorporation of SD, OD and FD powder lowered L*and b* values significantly for the crumb color. Use of 0.25% FD and up to 0.50% of SD and OD amla powders were found to replace potassium bromate as a dough improver in bread making, thus suggesting the use of a safer natural amla fruit powder that is known to be rich not only in ascorbic acid but also in various other phytochemicals. Further studies on the role of amla fruit phenolics in the reduction of carcinogenic acrylamide formation, starch gelatinization & retrogradation, antimicrobial properties, their influence on the shelf life of bread are suggested. The health benefits of amla fruit powder supplemented breads, and the bioavailability of phenolics in baked goods need further study.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AACC . Approved methods. 10. St. Paul: American Association of Cereal Chemists; 2000. [Google Scholar]

- Al-Hooti SN, Sidhu JS, Al-Saqer JM. Utility of CIE tristimulus system in measuring the objective crumb color of high-fiber toast bread formulations. J Food Quality. 2000;23(1):103–116. doi: 10.1111/j.1745-4557.2000.tb00199.x. [DOI] [Google Scholar]

- Alkndari D, Sarfraz H, Sidhu JS. Development of a functional food (pan bread) using amla fruit powder. J Food Sci Technol. 2019 doi: 10.1007/s13197-019-03718-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- AlSaqer JM, Sidhu JS, AlHooti SN. Instrumental texture and baking quality of high fiber toast bread as affected by added wheat mill fractions. J Food Process Preserv. 2000;24(1):1–16. doi: 10.1111/j.1745-4549.2000.tb00402.x. [DOI] [Google Scholar]

- Altan A, McCarthy KL, Maskan M. Evaluation of snack foods from barley- tomato pomace blends by extrusion processing. J Food Eng. 2008;84(2):231–242. doi: 10.1016/j.jfoodeng.2007.05.014. [DOI] [Google Scholar]

- Arslan D, Özcan MM. Dehydration of red bell-pepper (Capsicum annuum L.): change in drying behavior, color and antioxidant content. Food Bioprod Process. 2010;89:504–513. doi: 10.1016/j.fbp.2010.09.009. [DOI] [Google Scholar]

- Bhide R (2019) Substitute to potassium bromate and their cost implications. Trademill Technol Pvt. Ltd, India.www.chemarc.com/content/article/substitute-to-potassium-bromate-and- their-cost-implications/58786d117eb5593bf5d22bb2. Accessed 10 Feb 2019

- Corrales X, Guerra M, Granito M, Ferris J. Substitution of ascorbic acid for potassium bromate in making of French bread. Arch Latinoam Nutr. 1993;43(3):234–240. [PubMed] [Google Scholar]

- Dahiya S, Singh B. Microbial xylanases in bread making. Reference module in food science. Encycl Food Chem. 2019;2:140–149. doi: 10.1016/B978-0-08-100596-5.21644-2. [DOI] [Google Scholar]

- Danianni MZ, Karolline MS, Sylvain G, Alessandro N. Phenolic profile and antioxidant capacity of the principal apples produced in Brazil. Int J Food Sci Nutr. 2013;64(5):611–620. doi: 10.3109/09637486.2013.763909. [DOI] [PubMed] [Google Scholar]

- Emeje OM, Ifiora BL, Ezenyi CL, Ofoefule SP. Assessment of bread safety in Nigeria: one decade after the ban on the use of potassium bromate. J Food Process Technol. 2015;6:1–4. [Google Scholar]

- Fardet A, Leenhardt F, Lioger D, Scalbert A, Remesy C. Parameters controlling the glycemic response to breads. Nutr Res Rev. 2006;19:18–25. doi: 10.1079/NRR2006118. [DOI] [PubMed] [Google Scholar]

- Han HM, Koh BK. Effect of phenolic acids on the rheological properties and proteins of hard wheat flour dough and bread. J Sci Food Agric. 2011;91(13):2495–2499. doi: 10.1002/jsfa.4499. [DOI] [PubMed] [Google Scholar]

- Isserliyska D, Karadjov G, Angelov A. Mineral composition of Bulgarian wheat bread. Eur Food Res Technol. 2001;213:244–245. doi: 10.1007/s002170100331. [DOI] [Google Scholar]

- Kapoor S, Ranote PS, Sharma S. Bioactive components and quality assessment of Jamun (Syzygium cumini L.) powder Supplemented Chapatti. Indian J Sci Technol. 2015;8(3):287–295. doi: 10.17485/ijst/2015/v8i3/59863. [DOI] [Google Scholar]

- Katyal M, Singh N, Virdi AS, Kaur A, Chopra N, Ahlawat AK, Singh AM. Extraordinarily soft, medium-hard and hard Indian wheat varieties: composition, protein profile, dough and baking properties. Food Res Int. 2017;100:306–317. doi: 10.1016/j.foodres.2017.08.050. [DOI] [PubMed] [Google Scholar]

- Katyal M, Virdi AS, Singh N, Kaur A, Rana JC, Kumari J. Diversity in protein profiling, pasting, empirical and dynamic dough rheological properties of meal from different durum wheat accessions. J Food Sci Technol. 2018;55(4):1256–1269. doi: 10.1007/s13197-018-3036-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Katyal M, Singh N, Singh H. Effects of incorporation of groundnut oil and hydrogenated fat on pasting and dough rheological properties of flours from wheat varieties. J Food Sci Technol. 2019;56(2):1056–1065. doi: 10.1007/s13197-019-03633-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kaur A, Singh N, Kaur S, Katyal M, Virdi AS, Kaur D, Ahlawat AK, Singh AM. Relationship of various properties with noodle making characteristics among durum wheat varieties. Food Chem. 2015;188:517–526. doi: 10.1016/j.foodchem.2015.05.009. [DOI] [PubMed] [Google Scholar]

- Meredith P, Bushuk W. The effects of iodate, N-ethylmaleimide, and oxygen on the mixing tolerance of dough. Cereal Chem. 1962;39:411–416. [Google Scholar]

- Nicks F, Richel A, Dubrowski T, Wathelet B, Wathelet JP, Blecker C, Paquot M. Effect of new synthetic PEGylated ferulic acids in comparison with ferulic acid and commercial surfactants on the properties of wheat flour dough and bread: effect of ferulic acid on flour dough and bread. J Sci Food Agric. 2013;93(10):2415–2420. doi: 10.1002/jsfa.6047. [DOI] [PubMed] [Google Scholar]

- Ofor MO, Ibeawuchi II. Sun-drying—a low cost technology for reducing postharvest losses. Academia Arena. 2010;2(1):56–59. [Google Scholar]

- Preethi GG. Use of potassium bromate in baking industry: a perspective. J Food Dairy Technol. 2016;4(3):1–7. [Google Scholar]

- Ram S, Boyko E, Giroux MJ, Gill BS. Null mutation in puroindoline A is prevalent in Indian wheats: puroindoline genes are located in the distal part of 5DS. J Plant Biochem Biotechnol. 2002;11:79–83. doi: 10.1007/BF03263140. [DOI] [Google Scholar]

- Raudoniūtė I, Rovira J, Venskutonis PR, Damašius J, Rivero-Pérez MD, González- SanJosé ML. Antioxidant properties of garden strawberry leaf extract and its effect on fish oil oxidation. Int J Food Sci Technol. 2011;46:935–943. doi: 10.1111/j.1365-2621.2011.02582.x. [DOI] [Google Scholar]

- Schroeder LF, Hoseney RC. Mixograph studies. II. Effect of activated double-bond compounds on dough mixing properties. Cereal Chem. 1978;55:348–350. [Google Scholar]

- Sidhu JS, Zafar TA. Super fruits: pomegranate, wolfberry, aronia (chokeberry), acai, noni, and amla. In: Sinha NK, Sidhu JS, Barta J, Wu JSB, Cano MP, editors. Handbook of fruits and fruit processing. 2. Oxford: Wiley-Blackwell; 2012. pp. 667–671. [Google Scholar]

- Sidhu JS, AlHooti SN, AlSaqer JM, Alothman A. Studies on the development of pan bread using raw wheat germ. J Food Qual. 2001;24(3):235–248. doi: 10.1111/j.1745-4557.2001.tb00605.x. [DOI] [Google Scholar]

- Singh N, Kaur A, Katyal M, Bhinder S, Ahlawat AK, Singh AM. Diversity in quality traits amongst Indian wheat varieties II: paste, dough and muffin making properties. Food Chem. 2016;197:316–324. doi: 10.1016/j.foodchem.2015.10.035. [DOI] [PubMed] [Google Scholar]

- Tatum JH, Shaw PE, Berry RE. Degradation products from ascorbic acid. J Agric Food Chem. 1969;17:38–40. doi: 10.1021/jf60161a008. [DOI] [Google Scholar]

- Tebben L, Shen Y, Li Y. Improvers and functional ingredients in whole wheat bread: a review of their effects on dough properties and bread quality. Trends Food Sci Technol. 2018;81:10–24. doi: 10.1016/j.tifs.2018.08.015. [DOI] [Google Scholar]

- Wang R, Zhou W, Isabelle M. Comparison study of the effect of green tea extract (GTE) on the quality of bread by instrumental analysis and sensory evaluation. Food Res Intl. 2007;40(4):470–479. doi: 10.1016/j.foodres.2006.07.007. [DOI] [Google Scholar]

- Xu J, Wang W, Li Y. Dough properties, bread quality, and associated interactions with added phenolic compounds: a review. J Funct Foods. 2019;52:629–639. doi: 10.1016/j.jff.2018.11.052. [DOI] [Google Scholar]

- Ye J, Wang X, Sang Y, Liu Q. Assessment of the determination of azodicarbonamide and its decomposition product semicarbazide: investigation of variation in flour and flour products. J Agril Food Chem. 2011;59:9313–9318. doi: 10.1021/jf201819x. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.