Abstract

Broken rice, a byproduct of the rice milling industry was utilized at different levels to evaluate unleavened flat bread (chapatti) making properties of whole wheat flour. Chapattis were prepared by replacing whole wheat flour with broken rice flour up to 50% level. Mixolab studies revealed that incorporation of rice flour lowered dough development time and dough stability of whole wheat flour up to 23.49% and 78.33%, respectively. Lower retrogradation was observed in whole wheat rice flour blends as revealed from soluble starch/amylose. A positive correlation of mixolab retrogradation was observed with soluble starch and soluble amylose. Whole wheat flour chapatti (fresh and retrograded) containing different level of rice flour were also evaluated for glycemic index (GI), rapidly digestible starch (RDS) and slowly digestible starch (SDS). Chapattis containing rice flour demonstrated higher GI and RDS but lower SDS. RDS correlated positively with GI. Chapattis from the whole wheat rice flour blends had good consumer acceptability.

Keywords: Broken rice flour, Mixolab, Starch digestibility, Retrogradation

Introduction

India is the second largest populated country in the world (World Bank 2017) but still a large section of the population remains undernourished. According to a report of FAO (2017), around 14% of the population is undernourished in India. The Indian government is facing a big challenge of ensuring food and nutritional security for its massive population. Therefore the Food and Public Distribution system (PDS) has been introduced by the Government of India as the most important medium to distribute essential commodities like rice and wheat at subsidized prices to the population below the poverty line (Kumar et al. 2016). However with the increasing population and adverse climatic conditions, it has become difficult to feed the growing population. Therefore, one of the effective means of preventing hunger and malnutrition could be to switch over to the underutilized byproducts of milling industry that could prove to be an efficient source of providing food and nutritional security.

India is also the second largest rice producing country with an annual rice production of 158.75 million metric tonnes (FAOSTAT 2017) and is considered as one of the major cereal crop that serve as a staple food for most of the world’s population, especially in Asian countries like India (Folorunso et al. 2016). Rice is also considered as an important source of energy because of its high concentration of starch and proteins (Deepa et al. 2010). During milling, the dehusking and polishing process leads to breakage of rice producing nearly 15% of broken rice or powder (Buggenhout et al. 2013). This broken rice is utilized primarily as a cattle feed (Setyawati et al. 2016), thickening agent, as brewing adjunct, in cosmetics and textile industries (Bhatnagar et al. 2014). Because of the low sodium content, bland taste, ease of digestibility, least allergenic and gluten free behavior, flour from broken rice has been used in many ready-to-eat breakfast cereals (Brennan et al. 2011; Folorunso et al. 2016). Besides due to lower price of rice brokens in the market, there is an incentive to utilize flour from the under-utilized broken rice in food products which could not only promote the effective utilization of broken rice grains but also reduce the losses that are normally incurred with the locally processed rice grains. Moreover, with the advantages of great availability and low cost, it will also prove to be a better alternative for gluten allergic patients (Okpala and Egwu 2015). However, the absence of gluten protein in rice makes the dough to be significantly less stretchable and poor in viscoelastic properties as compared to wheat flour dough. Thus, the rice flour dough lack good handling properties which lead to serious problems during preparation of rice dough based food products. Hence, it is desirable to partially substitute rice flour with wheat flour in different food products. Earlier studies have been conducted to make consumer acceptable products like bread and biscuits from the broken rice grains (Okpala and Egwu 2015; Mi et al. 1997).

Chapatti is unleavened flat bread commonly consumed in India and a huge population is dependent on it for calories in their daily diet (Sharma et al. 2017; Gujral and Pathak 2002; Gujral et al. 2018). Wheat is the most preferred cereal for chapatti making (Gujral and Pathak 2002; Kaur et al. 2018). However the utilization of flour from broken rice in chapatti making could be an effective and cheaper source of promoting the application of byproduct of rice milling industry in food product development that could further ensure food security.

Therefore the objective of present study was to investigate the suitability of a composite flour made by partially substituting wheat flour with broken rice flour for flat bread (chapatti) making and thereafter study the effect on starch digestibility, glycemic index and retrogradation behavior.

Materials and methods

Preparation of composite flour

Wheat cultivar HD 2967 was collected from Punjab Agricultural University, Ludhiana, India. The grains were cleaned manually and stored in PET (Polyethylene terephthalate) jars at 4 °C in a refrigerator till further use. The wheat grains were milled in a stone mill (Trimurti, Amar Industries, Amritsar, India) to obtain the whole wheat flour. During milling the gap between the two stones was adjusted such that 100% of the flour obtained could pass through 60 mesh sieve. Broken rice (kernels lower than 25% of grain length), from the cultivar PUSA 44 were procured from a local rice mill in Amritsar. The broken rice was similarly stone milled to pass through 60 mesh sieve. The whole wheat flour and broken rice flour were analyzed for protein, fat, starch and ash as per AACC (2000) methods; damaged starch and dietary fiber were analyzed enzymatically using Megazyme total dietary fiber and starch damage kit, respectively. The rice flour was then substituted to the whole wheat flour in the proportion of 10%, 20%, 30%, 40% and 50%, respectively. The prepared whole wheat rice flour blends were stored in airtight polypropylene bags at − 20 °C in a deep freezer.

Reagents

Sodium acetate and sodium hydroxide were provided by HiMedia Laboratories Pvt. Ltd. (Mumbai, India). Standard soluble starch and amylose were obtained from Sigma-Aldrich (Taufkirchen, Germany). Glucose (glucose oxidase peroxidase) kit was obtained from ERBA Diagnostics (Mannheim, Germany). The enzymes- Porcine amylase, Amyloglucosidase, Pancreatin and Pepsin were procured from Sigma-Aldrich (Taufkirchen, Germany). Starch Damage Assay Kit (K-SDAM) was obtained from Megazyme (Megazyme International Ireland Ltd., Wicklow, Ireland). All chemicals were analytical grade.

Mixolab properties

Mixolab 2 (Chopin Technologies, France) was used to determine the rheology of flour using the standard Chopin + protocol for a 1.11 Nm C1 torque; where “C” denotes consistency. The torque 1.11 Nm at C1 (consistency during first phase) was selected for the study because it is equivalent to the standard value for optimum dough consistency in farinograph i.e. 500 BU (Jeong et al. 2017). The dough was mixed for a total of 45 min. From the Mixolab curve various parameters like water absorption, dough development time, dough stability, protein weakening and retrogradation were obtained. The test was performed in triplicate.

Water absorption and preparation of chapatti

It is to be noted that the mixolab water absorption (WA) was insufficient and resulted in a stiff dough that was difficult to sheet. Hence the optimum water absorption required for a sheetable dough was evaluated subjectively by performing preliminary trials.

Chapattis were prepared by mixing the flour with optimum amount of water (Table 3) obtained from the preliminary trials in a laboratory pin mixer (National Manufacturing Company, NE, USA) according to the method discussed by Gujral et al. (2018). Chapatti parameters like bake loss (%) and shrinkage (%) were also recorded. The freshly prepared chapatti (0 h) was packaged immediately and stored at − 18 °C. Another batch of chapatti was packaged and kept at 25 °C for 48 h after which it was stored at − 18 °C till analysis. The preparation of chapatti was carried out in triplicate.

Table 3.

Effect of partially substituting whole wheat flour with broken rice flour on water absorption of dough, shrinkage, bake loss, soluble starch and soluble amylose content of chapatti

| Flour | WA (subjective) (%) | Shrinkage (%) | Bake loss (%) | Soluble starch (g/100 g) | Soluble amylose (g/100 g) | ||

|---|---|---|---|---|---|---|---|

| Fresh | Retrograded* | Fresh | Retrograded* | ||||

| Wheat flour | 80.00 ± 0.05b | 2.210 ± 1.156a | 22.300 ± 1.887c | 4.011 ± 0.061cq | 1.788 ± 0.005bp | 0.459 ± 0.018bq | 0.211 ± 0.023cp |

| 10% rice | 70.66 ± 0.04a | 1.814 ± 0.399a | 18.370 ± 1.516b | 3.325 ± 0.146bq | 1.303 ± 0.092ap | 0.398 ± 0.017aq | 0.135 ± 0.005ap |

| 20% rice | 68.66 ± 0.07a | 1.796 ± 0.630a | 15.385 ± 0.271a | 3.355 ± 0.075bq | 1.778 ± 0.047bp | 0.371 ± 0.007aq | 0.174 ± 0.001bp |

| 30% rice | 69.33 ± 0.02a | 3.210 ± 1.418a | 19.050 ± 0.346b | 3.212 ± 0.042aq | 2.024 ± 0.141cp | 0.375 ± 0.010aq | 0.237 ± 0.014dp |

| 40% rice | 68.00 ± 0.04a | 3.856 ± 1.165a | 18.900 ± 0.300b | 3.159 ± 0.099aq | 2.234 ± 0.005dp | 0.387 ± 0.023aq | 0.248 ± 0.025dp |

| 50% rice | 68.66 ± 0.06a | 4.838 ± 0.884a | 17.810 ± 0.890b | 3.368 ± 0.028bq | 2.087 ± 0.184cp | 0.370 ± 0.032aq | 0.240 ± 0.023dp |

WA water absorption (subjective) of dough for chapatti making

*Means with different superscript in the same row differ significantly (p < 0.05)

Means with different superscript in the same column differ significantly (p < 0.05)

Sensory characteristics of chapatti

A panel of twenty five members consisting of students and staff at the department evaluated the sensory characteristics of chapatti in terms of color, appearance, taste, aroma, texture and overall acceptability using a nine point Hedonic scale (Sharma et al. 2017). The panel members were regular consumers of chapatti and therefore were well aware of its quality attributes. The chapatti samples before evaluation were labeled with random three-digit codes to avoid bias.

Soluble starch and soluble amylose content

Soluble starch and soluble amylose content was determined following the method discussed by Sharma et al. (2017). The flour sample was extracted in water and the extract was then centrifuged (Eltek RC 4100 F Electrokraft Pvt Ltd, Mumbai, India) at 3300 rpm for 10 min. An aliquot of the supernatant was mixed with iodine solution which was then analyzed using a spectrophotometer (UV-1800 Shimadzu, Japan) at 590 nm for soluble starch and 620 nm for soluble amylose. The values reported are the mean of three determinations.

In-vitro starch digestibility and glycemic index

In-vitro digestibility of starch was determined as per the method discussed by Gujral et al. (2018). The digested starch was calculated as follows:

The digested starch was further divided into fractions such as rapidly digestible starch (RDS); slowly digestible starch (SDS), and resistant starch (RS) (Englyst et al. 1992).

The glycemic index (GI) was determined using the following equation given by Granfeldt et al. (1994). GI = 0.862 HI + 8.198, where HI is hydrolysis index.

Hydrolysis Index (HI) was calculated as the percent ratio between AUC (Area under curve) for digested sample and AUC of reference food (white bread) (Moza and Gujral 2016). The test was performed in triplicate.

Statistical analysis

Microsoft Excel software was used to carry out Analysis of variance (ANOVA) and Pearson correlation coefficients at a probability level of p < 0.05. Fisher’s least significant differences (LSD) test described means with 95% (p < 0.05) confidence.

Results and discussion

Composition

The whole wheat flour was characterized with 11.72% protein, 67.91% starch, 8.10% dietary fiber, 2.31% fat, 1.89% ash and 16.11% damaged starch content. The flour from broken rice demonstrated 6.81% protein, 85.49% starch, 0.11% dietary fiber, 0.29% fat, 0.11% ash and 21.41% damaged starch content.

Mixolab properties

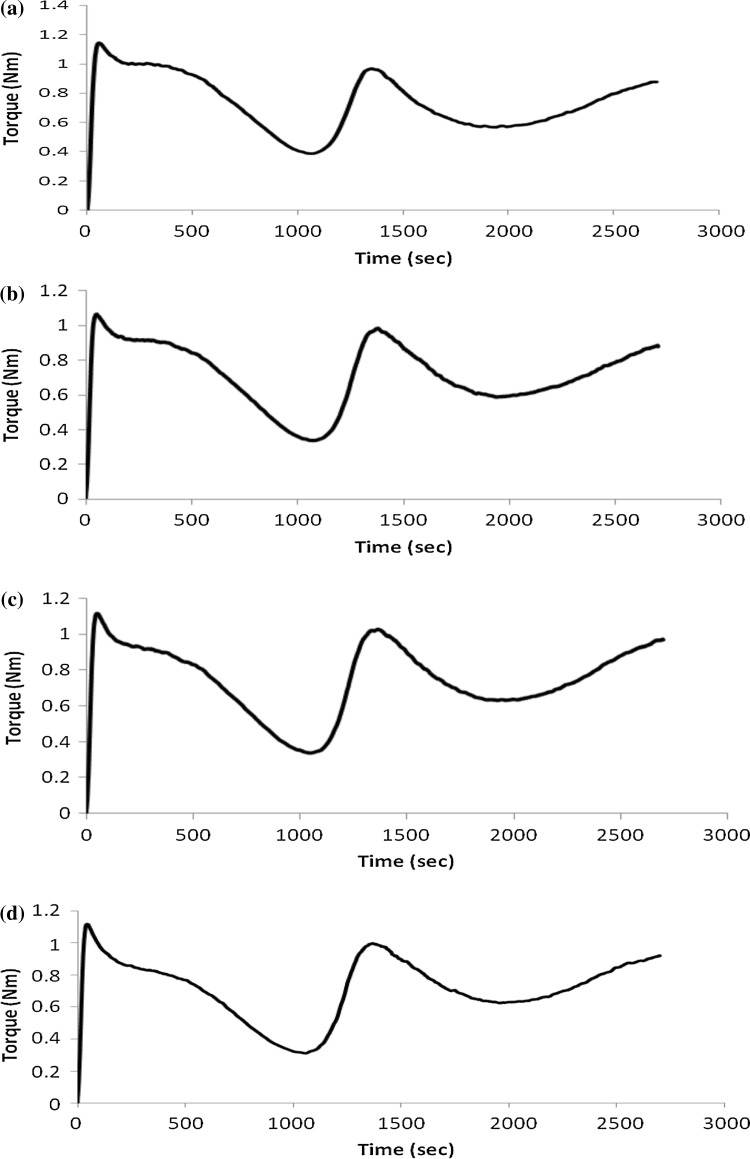

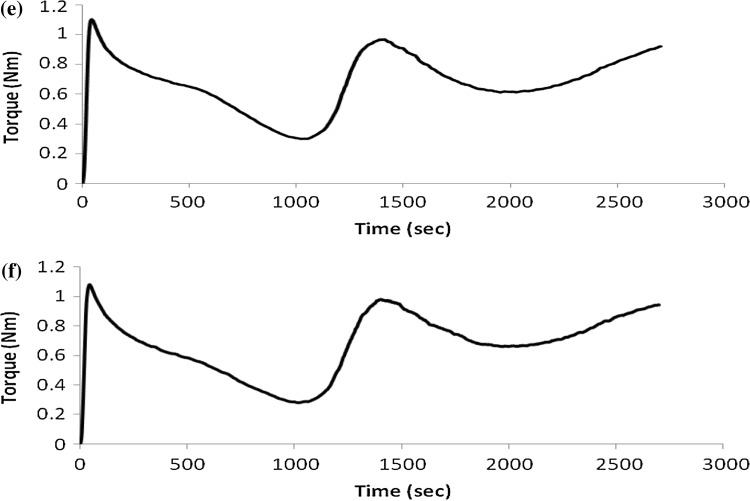

The effect of substituting whole wheat flour with rice flour at different levels on rheological properties is shown in Table 1 and Fig. 1(a–f). C1 (consistency during first phase) gives an account of the water absorption required to form dough that resulted in a torque of 1.11 Nm. The whole wheat flour required water content of 74.3% (14% moisture basis) to reach a torque of 1.11 Nm (Table 1). There was a decrease in water absorption upon incorporating broken rice flour at levels of 10 and 20% to whole wheat flour. The whole wheat flour showed more water absorption due to higher fiber content that contains non starchy polysaccharides which possess water binding capacity (Gujral et al. 2018). As the substitution level of rice flour increased a progressive increase in water absorption was observed (Table 1). The substitution of wheat flour with rice flour at 40 and 50% levels significantly led to water absorption increase to 75.5 and 76.6%, respectively to reach a torque of 1.11 Nm. This may be attributed to higher damaged starch content of broken rice flour.

Table 1.

Effect of partially substituting whole wheat flour with broken rice flour on the rheological characteristics of dough using Mixolab

| Flour | WA (%) | DDT (min) | Stability (min) | C2 (Nm) | Protein weakening (%) | C3 (Nm) | Speed of gelatinization (%) |

|---|---|---|---|---|---|---|---|

| Wheat flour | 74.30 ± 0.033b | 0.915 ± 0.021d | 5.215 ± 0.898d | 0.380 ± 0.012e | 58.911 ± 0.641c | 0.973 ± 0.004a | 60.994 ± 1.406a |

| 10% rice | 72.75 ± 0.028a | 0.855 ± 0.035c | 2.725 ± 0.064c | 0.339 ± 0.002d | 60.525 ± 0.280c | 0.978 ± 0.010b | 65.386 ± 0.567b |

| 20% rice | 73.50 ± 0.063a | 0.84 ± 0.014c | 2.100 ± 0.354b | 0.340 ± 0.002d | 59.870 ± 0.049c | 1.024 ± 0.008e | 66.828 ± 0.459c |

| 30% rice | 74.75 ± 0.007b | 0.75 ± 0.001b | 1.290 ± 0.057a | 0.308 ± 0.004c | 58.904 ± 2.463c | 0.987 ± 0.015d | 68.778 ± 0.040d |

| 40% rice | 75.50 ± 0.034c | 0.715 ± 0.021a | 1.130 ± 0.071a | 0.299 ± 0.003b | 54.629 ± 0.332b | 0.974 ± 0.023a | 68.653 ± 0.447d |

| 50% rice | 76.6 ± 0.072d | 0.7 ± 0.042a | 1.145 ± 0.035a | 0.282 ± 0.001a | 52.569 ± 0.050a | 0.982 ± 0.002c | 71.334 ± 0.072e |

WA—Mixolab water absorption, DDT—dough development time, protein weakening- (C1 at 8 min-C2), speed of gelatinization—(C3–C2%)

Means with different superscript in the same column differ significantly (p < 0.05)

Fig. 1.

Mixolab curves of a whole wheat flour b substitution of whole wheat flour with 10% rice flour c substitution of whole wheat flour with 20% rice flour d substitution of whole wheat flour with 30% rice flour e substitution of whole wheat flour with 40% rice flour f substitution of whole wheat flour with 50% rice flour

Dough development time (DDT) is the maximum time required to reach C1 torque. The maximum time required to reach C1 torque was 0.915 min for the whole wheat flour which decreased (p < 0.05) with the increase in the substitution level of rice flour. DDT ranged between 0.855 and 0.70 min (Table 1) for rice flour incorporation into whole wheat flour. The higher DDT for whole wheat flour indicated that dough took longer time to develop that may be due to higher gluten protein in wheat flour. Increasing levels of broken rice flour in wheat flour diluted the gluten protein leading to decrease in DDT. Pu et al. (2017) observed a similar decrease in DDT on substituting potato flour with wheat flour. Rosell et al. (2009) reported lowering of the DDT on substitution of wheat flour with quinoa flour.

Stability indicates the time for which the mixolab curve remains within 11% of the maximum consistency obtained during mixing phase and depicts dough strength. The stability for wheat flour was 5.215 min and substitution of wheat flour with rice flour caused a significant (p < 0.05) decrease in stability. The stability ranged between 1.145 and 2.725 min on progressive increase in the level of substitution of wheat flour with rice flour, indicating lower stability and strength of whole wheat rice flour blends (Table 1). This may be attributed to lowering of gluten content on substituting wheat flour with rice flour and also due to the physical hindrance of rice starch particles on the hydration and development of the gluten network. Pu et al. (2017) proposed that dough strength is related to the gluten protein. Ahmad et al. (2017) stated that the substitution of wheat flour with non-wheat flour causes the dilution of gluten protein that may disrupt the integrity of protein matrix.

Protein weakening (%)—The combined effect of heating and mechanical shear stress led to unfolding and destabilization of proteins inducing a decrease in dough consistency (C2 value) (Rosell et al. 2009) and the extent to which dough consistency decreases is an indication of protein quality and strength. C2 is also a measure of torque at the beginning of starch gelatinization. The whole wheat flour dough demonstrated significantly (p < 0.05) higher C2 whereas substituting wheat flour with rice flour up to 50% level caused lowering of C2 that ranged between 0.282 and 0.339 Nm for whole wheat rice flour blends. The percent protein weakening for whole wheat flour dough was 58.91% and on substituting whole wheat flour with rice flour a varied trend in protein weakening was observed that ranged from 52.56 to 60.53%. (Table 1). A lower value of C2 depicted more protein weakening due to unfolding of the protein matrix which could also be observed from a significant negative correlation (r = − 0.90, p < 0.05) between C2 and the percent protein weakening. The lowest C2 and hence the maximum protein weakening was observed on substitution of the wheat flour with rice flour at a level of 50%. This may be attributed to more disruption of the protein matrix as substituting whole wheat flour with rice flour decreased gluten protein content. The lack of gluten protein network in rice flour prevents the formation of a strong viscoelastic structure. However, interestingly it was noticed that the 30% substitution of wheat flour with rice flour had an insignificant (p < 0.05) effect on protein weakening whereas at higher levels the protein weakening decreased significantly (p < 0.05).

Peak viscosity (C3)—On heating, starch granules absorb water and swell leading to increase in viscosity and consequently causing a rise in torque. The C3 torque for whole wheat flour was 0.973 Nm whereas it increased on substitution of whole wheat flour with rice flour up to a level of 50% and ranged from 0.974 to 1.024 Nm (Table 1). The higher torque (C3)/peak viscosity on substitution of wheat flour with rice flour at different levels may be due to availability of more starch for gelatinization. The rice starch has undergone higher degree of swelling causing a rise in peak viscosity. Varavinit and Shobsngob (2000) reported a higher peak viscosity for rice flour as compared to wheat flour using Rapid-Visco Analyzer (RVA). The gelatinization and swelling properties including the speed of gelatinization and peak viscosity are governed by the starch granule architecture (crystalline to amorphous ratio), molecular structure of amylopectin, starch composition (amylose to amylopectin ratio), starch characteristics such as swelling potential, degree of gelatinization and re-association of amylose and amylopectin, upon subsequent cooling after the thermal treatment of starch (Kaur et al. 2016). The pasting properties are also known to be significantly affected by proteins. According to Singh et al. (2014) and Pu et al. (2017) proteins exert a suppressive effect on the swelling of starch granules consequently causing reduction in viscosity of the starch paste. Therefore, substituting whole wheat flour with rice flour up to a level of 50% decreased the gluten protein content in formulated dough consequently increasing the content of gelatinized rice starch. The speed of gelatinization was 60.99% for whole wheat flour whereas the progressive substitution of whole wheat flour with rice flour up to 50% led to a significant (p < 0.05) increase in the speed of gelatinization to 71.334% (Table 1). The higher gelatinization speed on substituting wheat flour with rice flour may be attributed to the increase in content of starch. The speed of gelatinization showed a positive correlation (r = 0.91, p < 0.05) with the starch content which signifies the role of starch components in pasting behavior. The peak temperature (dough temperature at C3) for whole wheat flour dough was 70.35 °C (Table 2). The substitution of wheat flour with rice flour caused an increase in peak temperature which could be attributed to higher pasting temperature of rice starch as compared to wheat starch. A higher peak temperature for rice starch as compared to wheat starch has been reported by Romano et al. (2016). Rai et al., (2012) reported higher gelatinization temperature and peak viscosity with increasing levels of rice flour incorporation in wheat flour. Yamauchi et al. (2004) reported that temperature obtained during the peak viscosity was higher for rice flour than the wheat flour.

Table 2.

Effect of partially substituting whole wheat flour with broken rice flour on peak temperature of dough, shear thinning and retrogradation behavior using Mixolab

| Flour | Dough temperature at C3 (peak, °C) | C4 (Nm) | Shear thinning (%) | C5 (Nm) | Retrogradation (%) |

|---|---|---|---|---|---|

| Wheat flour | 70.35 ± 0.636a | 0.558 ± 0.014a | 42.648 ± 1.704e | 0.878 ± 0.003a | 36.449 ± 1.406a |

| 10% rice | 69.60 ± 0.424a | 0.581 ± 0.008b | 40.594 ± 0.266d | 0.882 ± 0.004a | 34.124 ± 1.279a |

| 20% rice | 71.60 ± 0.424b | 0.630 ± 0.002d | 38.494 ± 0.260c | 0.974 ± 0.007b | 35.367 ± 0.687a |

| 30% rice | 71.60 ± 1.414b | 0.613 ± 0.016c | 37.866 ± 0.642c | 0.912 ± 0.011a | 32.754 ± 0.924a |

| 40% rice | 71.30 ± 0.778b | 0.614 ± 0.001c | 35.673 ± 1.600b | 0.889 ± 0.048a | 30.887 ± 3.818a |

| 50% rice | 71.45 ± 0.354b | 0.651 ± 0.016e | 33.758 ± 1.656a | 0.934 ± 0.013a | 30.321 ± 0.739a |

Means with different superscript in the same column differ significantly (p < 0.05)

Shear thinning—(C3–C4)%, retrogradation—(C5–C4)%

Breakdown/shear thinning (C4)—The holding of dough at 90 °C cause the swollen starch granules to disintegrate due to the shearing action of the instrument and the viscosity decreases to a trough viscosity (also called breakdown) resulting in lowering of the torque. The whole wheat flour dough displayed a C4 value of 0.558 Nm (Table 2) whereas substitution of whole wheat flour with rice flour significantly (p < 0.05) improved the breakdown characteristics of the hot starch paste (Table 2). Higher C4 torque/viscosity indicated lesser breakdown/shear thinning. It is also related to the cooking stability of the hot gel/paste. On cooking, the amylopectin double helices are disrupted and amylose leaches out of the starch granule. The results of the present study indicated that the substitution of whole wheat flour with rice flour caused lesser breakdown of the hot starch paste. The percent breakdown or shear thinning (C3–C4) in whole wheat flour dough was 42.65% whereas the substitution of whole wheat flour with rice flour up to a level of 50% demonstrated significantly (p < 0.05) lower breakdown (Table 2). The lower breakdown of the hot starch paste may be due to the increased affinity of proteins to interact with starch thereby attaining a stable protein-gelatinized starch matrix that tends to lower starch disintegration/breakdown. In contrast, the increase in breakdown is generally caused by the weakening and disruption of the protein-starch matrix. Similar observation has been reported by Saleh and Meullenet (2015). The higher breakdown in the whole wheat flour dough could be attributed to the dilution of gluten fraction on substitution with rice flour up to a level of 50%. Also whole wheat flour contained all the bran that is a source of endogeneous alpha-amylase enzyme causing hydrolysis of starch while substitution of wheat flour with rice flour reduced the content of enzymes that led to lesser breakdown. Rai et al. (2012) reported lesser breakdown on increasing the level of rice flour to wheat flour. Kaur et al. (2018) reported that higher breakdown value is an indication of lower stability on heating and shear stress during the process of cooking. Therefore the blends formulated by substituting wheat flour with rice flour were considered to be stable to shear stress and heating process.

Retrogradation (C5)—As the hot pastes begin to cool, they become more elastic and develop distinct solid properties, i.e. gelation occurs which is related to the reordering and recrystallization of the starch molecules, also known as retrogradation and there is an increase in torque, also referred to as setback (Rosell et al. 2009). A lower setback viscosity indicates higher resistance to retrogradation. The increase in viscosity during the cooling period indicates a tendency of various constituents present in the hot paste (swollen granules) to associate or retrograde as the temperature of the paste decreases. The percent increase in torque from C4 to C5 indicated percent retrogradation (C5–C4%) which was 36.45% in whole wheat flour whereas the substitution of whole wheat flour with rice flour at different levels (up to 50%) decreased retrogradation to 30.32% (Table 2). During heating lipids have been reported to form complexes with amylose which decreases the susceptibility of the starches to degradation (Kraithong et al. 2018). Since the progressive substitution of whole wheat flour with broken rice flour led to reduction of oil content in the formulated blends, leading to lower amounts of amylose lipid complexes and therefore lower tendency of the cooked dough to retrograde. A lower setback or retrogradation for rice flour bread has been reported by Yamauchi et al. (2004).

Chapatti evaluation

Water absorption for chapatti making (subjective)

The water absorption (WA) (subjective, Table 3) for whole wheat flour was 80% whereas substitution of whole wheat flour with broken rice flour led to a decrease in WA that ranged between 68 and 70.66%. This decrease in WA of whole wheat flour on rice flour substitution could be attributed to the decreased amount of gluten content and less availability of polar amino acids on addition of rice flour. The formation of amylose–lipid/amylose-protein complexes cause reduction of the polar and charged molecules resulting in hindering of the hydration properties (Falade and Christopher 2015). Moreover the whole wheat flour was characterized with higher WA due to higher levels of gluten proteins and the presence of bran fraction (seed coat and embryo) that is known to have water absorbing arabinoxylans which results in high hydration capacity of the whole wheat flour. Derycke et al. (2005) stated that the proteins present in rice act as barrier to penetration of water. Sozer (2009) described that the wheat gluten proteins have a capacity to absorb and hold water twice its own weight by forming a complex aggregate matrix structure. Even though rice flour has low capacity to absorb water, it is one of the most suitable cereal flour used in gluten-free products, because it is hypoallergenic and colourless with bland taste. Also less force was required to sheet chapattis on incorporating rice flour into wheat flour as rice flour made the dough less elastic.

Shrinkage

The reduction in diameter of chapatti after baking is reported as shrinkage. It is caused due to the contraction of gluten on baking. The percent shrinkage in whole wheat flour chapatti was 2.21% whereas the chapattis prepared on substitution of whole wheat flour with rice flour at different levels showed shrinkage in chapattis ranging from 1.81 to 4.84% (Table 3). The chapattis prepared on substitution of wheat flour with rice flour at 10 and 20% levels had lower shrinkage than the whole wheat flour chapatti. Further increase in the substitution level of rice flour into wheat flour up to 50% caused an increase in shrinkage of chapattis. This variation in shrinkage behavior could be attributed to the change in protein-starch type in formulated blends.

Bake loss

Bake loss is an indicator of the amount of water lost from the chapatti during baking and it was 22.3% for whole wheat flour chapatti. The progressive substitution of whole wheat flour with rice flour up to a level of 50% showed a significantly (p < 0.05) lower bake loss in chapattis that ranged from 15.38 to 19.05% (Table 3). It was also noticed that the baking time of chapatti prepared from whole wheat flour was 80 s while substituting whole wheat flour with rice flour significantly changed the baking time of chapattis that ranged between 60 and 75 s. The higher baking time of whole wheat flour chapatti could be a probable reason for higher bake loss. A positive correlation (r = 0.81, p < 0.05) exhibited between the subjective water absorption for dough making and the bake loss. Higher moisture content in baked goods has also been associated with lower staling rate (Moza and Gujral 2016), hence the chapattis prepared from whole wheat rice flour blends retained more moisture during baking leading to lower staling.

Sensory characteristics of chapatti

The chapattis prepared by substitution of wheat flour with rice flour at different levels received lower sensory scores in terms of color and taste parameters as compared to whole wheat flour chapatti. This could be attributed to the increased whitish color and non-wheatish taste of chapattis on progressive substitution of wheat flour with rice flour up to a level of 50%. The chapattis with 10% and 20% substitution of rice flour into whole wheat flour had best overall acceptability whereas it decreased insignificantly (p < 0.05) on further substitution of rice flour into wheat flour (Table 4). The whole wheat flour chapatti received lower scores for aroma while substitution of whole wheat flour with rice flour at different levels led to an increase in the aroma of chapattis. Moreover, the substitution of whole wheat flour with rice flour up to 50% led to softer texture of chapattis. The reason for the softer texture on incorporating rice flour into whole wheat flour could be lower bake loss in whole wheat rice flour blend chapattis. It has been reported by Sharma et al. (2017) that lower bake loss resulted in more soft and pliable chapattis due to retention of higher moisture content. Yamauchi et al. (2004) reported a reduction in the quality characteristics of the bread on 50% incorporation of rice flour to wheat flour.

Table 4.

Effect of partially substituting whole wheat flour with broken rice flour on sensory characteristics of chapatti

| Flour | Appearance | Color | Taste | Texture | Aroma | Overall acceptability |

|---|---|---|---|---|---|---|

| Wheat flour | 8.50 ± 0.50a | 8.00 ± 0.47a | 8.50 ± 0.50c | 6.75 ± 0.35a | 6.00 ± 1.00a | 8.75 ± 0.35b |

| 10% rice | 8.17 ± 0.29a | 7.67 ± 0.35a | 7.67 ± 0.57b | 8.25 ± 0.44b | 7.66 ± 0.58a | 8.50 ± 0.47b |

| 20% rice | 7.83 ± 0.28a | 7.24 ± 0.47a | 7.83 ± 0.29b | 8.25 ± 0.35b | 7.50 ± 0.50a | 8.50 ± 0.64b |

| 30% rice | 7.50 ± 0.45a | 7.00 ± 0.64a | 7.33 ± 0.57b | 7.10 ± 0.14a | 7.33 ± 0.58a | 7.00 ± 1.20a |

| 40% rice | 7.67 ± 0.57a | 6.50 ± 0.31a | 7.67 ± 0.66b | 7.35 ± 0.49a | 6.33 ± 1.53a | 6.75 ± 0.78a |

| 50% rice | 7.33 ± 1.15a | 6.33 ± 0.42a | 5.67 ± 0.85a | 7.15 ± 0.21a | 6.33 ± 1.99a | 6.00 ± 0.35a |

Means with different superscript in the same column differ significantly (p < 0.05); (n = 25)

Soluble starch and soluble amylose content

The changes in soluble starch and soluble amylose contents are related to the retrogradation behavior of heat processed starchy foods due to reorganization of the crystalline structure of the starch molecules (Karim et al. 2000). Whole wheat flour chapatti (fresh) showed soluble starch content of 4.011 g/100 g whereas on substitution of wheat flour with rice flour at levels up to 50% it ranged from 3.159 to 3.368 g/100 g (fresh) (Table 3). The percent decrease in solubility of starch for whole wheat flour chapattis after 48 h storage was 55.43% whereas substitution of whole wheat flour with rice flour up to 50% caused a decrease to 29.89% in soluble starch content of chapattis. During retrogradation the amylose chains form double helix structure while amylopectin crystallization occurs by reassociation of the outermost short chains (Deepa et al. 2010). The percent decrease in soluble amylose content after 48 h storage was 54.08% for whole wheat flour chapatti while rice flour substitution into whole wheat flour caused a decrease to 35.18% in the soluble amylose content of chapattis. This decrease in soluble amylose on storage could be attributed to the retrogradation process as the leaching of amylose after retrogradation reduces (Karim et al. 2000). Retrogradation of amylose is a more rapid process that occurs immediately on cooling but amylopectin requires longer time and hence storage conditions are important factors affecting retrogradation. Minimum decrease in solubility of starch and amylose on storage indicated that retrogradation was less in the chapattis prepared on substituting rice flour into whole wheat flour. Moreover it was noticed that the retrogradation percent shown by mixolab correlated positively with the percent decrease in soluble starch (r = 0.77, p < 0.05) and soluble amylose (r = 0.75, p < 0.05) on storage.

In-vitro starch digestibility and glycemic index

Rapidly digestible starch (RDS)—The wheat flour chapatti (fresh) showed a RDS content of 34.04 g/100 g flour whereas it increased on substituting wheat flour with rice flour at different levels that ranged between 37.70 and 47.87 g/100 g flour (Table 5). The results suggest that the rice starch is rapidly digestible than the wheat starch. Similar results stating higher digestibility of rice starch has been reported by Frei et al. (2003). Romano et al. (2016) reported that the starch digestibility of rice is higher as compared to wheat due to the small size of rice granules as the digestibility properties are affected by the particle size. The smaller the particle, more is the surface area for enzyme activity thus higher the digestibility of starch. On storage for 48 h, the RDS content decreased significantly (p < 0.05) for both the whole wheat flour and whole wheat rice flour blend chapattis. The percent decrease in RDS content of whole wheat flour chapatti after 48 h storage was 8.81%. Substitution of whole wheat flour with rice flour up to 50% cause a decrease in RDS content to 5.67%. It has been reported by Frei et al. (2003) that the retrogradation process lowers digestibility of starch because the resistance of starch to digestive enzymes is increased.

Table 5.

Effect of partially substituting whole wheat flour with broken rice flour on the starch digestibility and glycemic index of chapatti

| Flour | RDS (g/100 g) | SDS (g/100 g) | RS (g/100 g) | GI | ||||

|---|---|---|---|---|---|---|---|---|

| Fresh | Retrograded* | Fresh | Retrograded* | Fresh | Retrograded* | Fresh | Retrograded* | |

| Wheat flour | 34.04 ± 0.354aq | 31.04 ± 0.495ap | 33.61 ± 0.212bp | 35.95 ± 0.778aq | 0.30 ± 0.141ap | 0.96 ± 0.124aq | 74.65 ± 0.460aq | 71.78 ± 0.933ap |

| 10% rice | 37.70 ± 0.905bq | 34.88 ± 0.841bp | 30.97 ± 0.827ap | 33.63 ± 0.849aq | 0.21 ± 0.078ap | 0.36 ± 0.011aq | 77.24 ± 0.354bp | 77.09 ± 0.537bp |

| 20% rice | 40.53 ± 0.191cq | 37.72 ± 0.438cp | 29.68 ± 0.438ap | 32.21 ± 0.297aq | 0.45 ± 0.247ap | 0.73 ± 0.139bq | 80.76 ± 0.453cq | 78.72 ± 0.665bp |

| 30% rice | 43.32 ± 0.898dq | 40.86 ± 1.082cp | 28.30 ± 0.990ap | 30.37 ± 0.919aq | 0.42 ± 0.092ap | 0.81 ± 0.163bq | 81.41 ± 0.792cp | 80.59 ± 0.877cp |

| 40% rice | 46.67 ± 2.963eq | 37.65 ± 3.104cp | 27.76 ± 2.906ap | 36.49 ± 3.444aq | 0.46 ± 0.057ap | 0.75 ± 0.339bp | 83.02 ± 0.933dq | 77.70 ± 0.834ap |

| 50% rice | 47.87 ± 1.259eq | 39.83 ± 1.633cp | 27.09 ± 1.147ap | 34.78 ± 1.167aq | 0.91 ± 0.112bp | 1.27 ± 0.467cp | 84.16 ± 0.651eq | 78.05 ± 0.651bp |

RDS rapidly digestible starch, SDS slowly digestible starch, RS resistant starch, GI glycemic index

*Means with different superscript in the same row differ significantly (p < 0.05)

Means with different superscript in the same column differ significantly (p < 0.05)

Slowly digestible starch (SDS) is the amount of glucose released between 20 and 120 min of in vitro starch digestion producing a lower glycemic response (Englyst et al. 1992). The whole wheat flour chapatti was characterized with higher SDS content which was observed to be 33.61 g/100 g flour. Substituting up to 50% rice flour in wheat flour led to decrease in SDS that was found to be up to 19.40% for fresh chapatti (Table 5). However after storage SDS content increased. The whole wheat flour chapatti showed an increase of 6.51% in the SDS content on storage while chapattis prepared by substitution of rice flour into whole wheat flour at different levels caused the SDS content to increase by 23.93%. Chung et al. (2006) also reported an increase in SDS content of waxy rice flour on retrogradation.

Resistant starch (RS) is the starch fraction that escapes enzymatic digestion in small intestine and undergoes fermentation in large intestine by microbial flora (Sharma et al. 2017). RS was found to be 0.3 g/100 g flour in whole wheat flour chapattis (fresh). However substitution of whole wheat flour with rice flour caused an increase in the RS content of chapattis that ranged from 0.21 to 0.91 g/100 g flour (Table 5). The higher content of RS on substitution of whole wheat flour with rice flour may be attributed to the lesser formation of amylose lipid complex as the content of lipid decreased on substitution of whole wheat flour with rice flour. It has been reported by Deepa et al. (2010) that lipid-amylose complex decreases the amount of amylose available to interact with the external chains of amylopectin to form RS. The RS is known to impart beneficial effects by preventing several intestinal disorders. However upon storage of chapattis for 48 h, the RS content increased. The whole wheat flour chapatti demonstrated an increase in RS content by 68.8% and chapattis prepared by substituting whole wheat flour with rice flour at levels up to 50% showed an increase in RS content up to 48.1% on storage. According to Deepa et al. (2010) RS formation is influenced by amylose-amylopectin ratio. The retrogradation process of starch may affect the bioavailability of starch in the gastro-intestinal tract, and recrystallised starch constitutes a starch fraction which may be delivered to the large bowel.

Glycemic index (GI)—The whole wheat flour chapatti showed a GI of 74.65. However substitution of whole wheat flour with rice flour at different levels caused an increase in GI that was found to range between 77.24 and 84.16 (Table 5). The increase in GI upon substitution of whole wheat flour with rice flour could be due to the rapidly digestible nature of rice starch. This could also be observed from a positive correlation of GI with RDS (r = 0.98, p < 0.05) indicating a positive and significant influence of RDS on GI. Higher RDS fraction in starch is generally related to higher extent of starch digestion and consequently a higher GI is produced (Englyst et al. 1992). GI is related to nutritional quality of food and a product with a low GI is preferable for individuals having diabetes.

Conclusion

Due to the absence of gluten protein in rice flour, substitution of wheat flour with broken rice flour diluted the gluten protein that weakened the gluten network for whole wheat rice flour system. As a result, the formulated dough indicated decrease in DDT, dough stability and increase in destabilization of the gluten dough matrix and peak viscosity. Chapatti WA lowered on substituting whole wheat flour with broken rice flour up to a level of 50%. According to the sensory analysis, substitution of whole wheat flour with rice flour up to 20% produced the acceptable chapatti whereas further increase in the substitution level lowered the sensory scores. With increase in the substitution level of whole wheat flour with rice flour, the digestibility of starch increased. As a result the GI also increased. The results of the present study suggest the potential for encouraging the utilization of broken rice flour by substitution into wheat flour to prepare an economically viable composite flour for chapatti making.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AACC . Approved methods of the AACC. St. Paul: American Association of Cereal Chemists; 2000. [Google Scholar]

- Ahmad U, Alfaro L, Awudzi MY, Kyereh E, Dzandu B, Bonilla F, Chouljenko A, Sathivel S. Influence of milling intensity and storage temperature on the quality of Catahoula rice (Oryza sativa L.) LWT - Food Sci Technol. 2017;75:386–392. doi: 10.1016/j.lwt.2016.09.014. [DOI] [Google Scholar]

- Bhatnagar AS, Prabhakar DS, Kumar PK, RajaRajan RG, Krishna GA. Processing of commercial rice bran for the production of fat and nutraceutical rich rice brokens, rice germ and pure bran. LWT Food Sci Technol. 2014;58:306–311. doi: 10.1016/j.lwt.2014.03.011. [DOI] [Google Scholar]

- Brennan C, Brennan M, Derbyshire E, Tiwari BK. Effects of extrusion on the polyphenols, vitamins and antioxidant activity of foods. Trends Food Sci Technol. 2011;22:570–575. doi: 10.1016/j.tifs.2011.05.007. [DOI] [Google Scholar]

- Buggenhout J, Brijs K, Celus I, Delcour JA. The breakage susceptibility of raw and parboiled rice: a review. J Food Eng. 2013;117:304–315. doi: 10.1016/j.jfoodeng.2013.03.009. [DOI] [Google Scholar]

- Chung HJ, Lim HS, Lim ST. Effect of partial gelatinization and retrogradation on the enzymatic digestion of waxy rice starch. J Cereal Sci. 2006;43:353–359. doi: 10.1016/j.jcs.2005.12.001. [DOI] [Google Scholar]

- Deepa G, Singh V, Naidu KA. A comparative study on starch digestibility, glycemic index and resistant starch of pigmented (‘Njavara’ and ‘Jyothi’) and a non-pigmented (‘IR 64’) rice varieties. J Food Sci Technol. 2010;47:644–649. doi: 10.1007/s13197-010-0106-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Derycke V, Veraverbeke W, Vandeputte G, De Man W, Hoseney R, Delcour J. Impact of proteins on pasting and cooking properties of nonparboiled and parboiled rice. Cereal Chem. 2005;82:468–474. doi: 10.1094/CC-82-0468. [DOI] [Google Scholar]

- Englyst HN, Kingman SM, Cummings JH. Classification and measurement of nutritionally important starch fractions. Eur J Clin Nutr. 1992;46:S33–S50. [PubMed] [Google Scholar]

- Falade KO, Christopher AS. Physical, functional, pasting and thermal properties of flours and starches of six Nigerian rice cultivars. Food Hydrocoll. 2015;44:478–490. doi: 10.1016/j.foodhyd.2014.10.005. [DOI] [Google Scholar]

- FAO . The state of food security and nutrition in the world: building resilience for peace and food security. Rome: Food and Agricultural Organisation of the United Nations; 2017. [Google Scholar]

- FAOSTAT (2017) Database of food and agricultural organisation. http://www.fao.org/faostat/en#data/QC Accessed 3 Mar 2018

- Folorunso AA, Omoniyi SA, Habeeb AS. Proximate composition and sensory acceptability of snacks produced from broken rice (Oryza sativa) flour. Am J Food Nutr. 2016;6:39–43. [Google Scholar]

- Frei M, Siddhuraju P, Becker K. Studies on the in vitro starch digestibility and the glycemic index of six different indigenous rice cultivars from the Philippines. Food Chem. 2003;83:395–402. doi: 10.1016/S0308-8146(03)00101-8. [DOI] [Google Scholar]

- Granfeldt Y, Liljeberg H, Drews A, Newman R, Bjorck I. Glucose and insulin responses to barley products: influence of food structure and amylose amylopectin ratio. Am J Clin Nutr. 1994;59:1075–1082. doi: 10.1093/ajcn/59.5.1075. [DOI] [PubMed] [Google Scholar]

- Gujral HS, Pathak A. Effect of composite flours and additives on the texture of chapatti. J Food Eng. 2002;55:173–179. doi: 10.1016/S0260-8774(02)00061-4. [DOI] [Google Scholar]

- Gujral HS, Sharma B, Khatri M. Influence of replacing wheat bran with barley bran on dough rheology, digestibility and retrogradation behavior of chapatti. Food Chem. 2018;240:1154–1160. doi: 10.1016/j.foodchem.2017.08.042. [DOI] [PubMed] [Google Scholar]

- Jeong S, Kim HW, Lee S. Rheological and secondary structural characterization of rice flour-zein composites for noodles slit from gluten-free sheeted dough. Food Chem. 2017;221:1539–1545. doi: 10.1016/j.foodchem.2016.10.139. [DOI] [PubMed] [Google Scholar]

- Karim AA, Norziah MH, Seow CC. Methods for the study of starch retrogradation. Food Chem. 2000;71:9–36. doi: 10.1016/S0308-8146(00)00130-8. [DOI] [Google Scholar]

- Kaur A, Shevkani K, Katyal M, Singh N, Ahlawat AK, Singh AM. Physicochemical and rheological properties of starch and flour from different durum wheat varieties and their relationships with noodle quality. J Food Sci Technol. 2016;53:2127–2138. doi: 10.1007/s13197-016-2202-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kaur P, Singh N, Pal P, Kaur A. Traditional and improved paddy varieties: Composition, protein, pasting, and gluten-free chapati making properties. Cereal Chem. 2018;95:666–678. doi: 10.1002/cche.10080. [DOI] [Google Scholar]

- Kraithong S, Lee S, Rawdkuen S. Physicochemical and functional properties of Thai organic rice flour. J Cereal Sci. 2018;79:259–266. doi: 10.1016/j.jcs.2017.10.015. [DOI] [Google Scholar]

- Kumar A, Parappurathu S, Babu S, Betne R. Public distribution system in Bihar, India: implications for food security. J Agric Food Inf. 2016;17:300–315. doi: 10.1080/10496505.2016.1206018. [DOI] [Google Scholar]

- Mi YK, Yeong HC, Hae CC. Effects of gums, fats and glutens adding on the processing and quality of milled rice bread. J Korean Soc Food Sci Nutr. 1997;29:700–704. [Google Scholar]

- Moza J, Gujral HS. Starch digestibility and bioactivity of high altitude hulless barley. Food Chem. 2016;149:1–30. doi: 10.1016/j.foodchem.2015.07.149. [DOI] [PubMed] [Google Scholar]

- Okpala LC, Egwu PN. Utilisation of broken rice and cocoyam flour blends in the production of biscuits. Niger Food J. 2015;33:1–8. doi: 10.1016/j.nifoj.2015.04.002. [DOI] [Google Scholar]

- Pu H, Wei J, Wang L, Huang J, Chen X, Luo C, Liu S, Zhang H. Effects of potato/wheat flours ratio on mixing properties of dough and quality of noodles. J Cereal Sci. 2017;76:236–242. doi: 10.1016/j.jcs.2017.06.020. [DOI] [Google Scholar]

- Rai S, Kaur A, Singh B, Minhas KS. Quality characteristics of bread produced from wheat, rice and maize flours. J Food Sci Technol. 2012;49:786–789. doi: 10.1007/s13197-011-0548-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Romano A, Mackie A, Farina F, Aponte M, Sarghini F, Masi P. Characterisation, in vitro digestibility and expected glycemic index of commercial starches as uncooked ingredients. J Food Sci Technol. 2016;53:4126–4134. doi: 10.1007/s13197-016-2375-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rosell CM, Cortez G, Repo-Carrasco R. Breadmaking use of Andean crops quinoa, kaniwa, kiwicha, and tarwi. Cereal Chem. 2009;86:386–392. doi: 10.1094/CCHEM-86-4-0386. [DOI] [Google Scholar]

- Saleh M, Meullenet JF. Cooked rice texture and rice flour pasting properties; impacted by rice temperature during milling. J Food Sci Technol. 2015;52:1602–1609. doi: 10.1007/s13197-013-1180-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Setyawati YD, Ahsan SF, Ong LK, Soetaredjo FE, Ismadji S, Ju YH. Production of glutinous rice flour from broken rice via ultrasonic assisted extraction of amylose. Food Chem. 2016;203:158–164. doi: 10.1016/j.foodchem.2016.02.068. [DOI] [PubMed] [Google Scholar]

- Sharma B, Gujral HS, Solah V. Effect of incorporating finger millet in wheat flour on mixolab behavior, chapatti quality and starch digestibility. Food Chem. 2017;231:156–164. doi: 10.1016/j.foodchem.2017.03.118. [DOI] [PubMed] [Google Scholar]

- Singh N, Shevkani K, Kaur A, Thakur S, Parmar N, Virdi AS. Characteristics of starch obtained at different stages of purification during commercial wet milling of maize. Starch-Starke. 2014;66:668–677. doi: 10.1002/star.201300261. [DOI] [Google Scholar]

- Sozer N. Rheological properties of rice pasta dough supplemented with proteins and gums. Food Hydrocoll. 2009;23:849–855. doi: 10.1016/j.foodhyd.2008.03.016. [DOI] [Google Scholar]

- Varavinit S, Shobsngob S. Comparative properties of cakes prepared from rice flour and wheat flour. Eur Food Res Technol. 2000;211:117–120. doi: 10.1007/s002179900124. [DOI] [Google Scholar]

- World Bank (2017) DataBank world-development indicators. http://www.databank.worldbank.org/data//reports.aspx?source=2&country=IND&series=&period. Accessed 3 Mar 2018

- Yamauchi V, Noda T, Matsuura-Endo C, Takigawa S, Saito K, Oda Y, Funatsuki W, Iriki N, Hashimot N. Bread-making quality of wheat/rice flour blends. Food Sci Technol Res. 2004;10:247–253. doi: 10.3136/fstr.10.247. [DOI] [Google Scholar]