Abstract

Teff (Eragrostis tef) is an ancient cereal that is indigenous from Ethiopia. Nowadays, teff grain is becoming popular to many parts of the world. Teff is gluten-free in nature, has high iron and fiber content, and many other health benefits make this crop interesting to many consumers. Since no insect pests are attacking the teff grains, farmers do not apply pesticides on it, unlike maize and other grains. Nevertheless, residues of organochlorine pesticides have been detected at an alarming level that could pose a consumer risk. Teff is often consumed as injera which is a fermented flat pancake. The main aim of the present study is, therefore, to investigate the effect of household food processing (doughing and baking) on the reduction of pesticide residues from teff. Pesticide residues previously detected in teff grain such as permethrin, cypermethrin, deltamethrin, chlorpyrifos ethyl, p,p’-DDE, p,p’-DDD, o,p’-DDT, and p,p’-DDT were spiked and extracted followed by the subsequent household processing which are generally doughing (dough making followed by fermentation) and baking. From the findings of this study, doughing decrease the pesticide residues in the range of 59.9–86.4% and baking in the range of 63.2–90.2%. Kruskal−Wallis analysis indicates that the reduction of pesticide residues by baking is significantly different from doughing (p-value < 0.0001). There is also a significant difference between non-fermented and fermented dough (p-value = 0.012). The processing factor for doughing and baking was less than one (PF < 1 = reduction factor) which indicates the reduction of pesticides due to teff processing. The cumulative effect of these processing methods is important to evaluate the risks associated with the ingestion of pesticides, particularly in teff grain.

Keywords: Food science, Food safety, Chemistry

1. Introduction

Teff (Eragrostis tef) is an indigenous crop from Ethiopia. Currently, the world population showed a great interest to consume food products of teff due to its many health benefits. Teff is gluten-free and protein-rich staple food from Ethiopia that has received great attention recently. Due to its high content of different nutrients, rapid cooking time, and versatile applications, it makes it an ideal “superfood” for consumers from East Africa [1]. A very attractive nutritional profile of teff and gluten-free nature of the grain, making it a suitable substitute for wheat and other cereals in their food applications as well as foods for people with gluten intolerance or for people affected by celiac disease (Mekonnen M. Gebremariam, Zarnkow, & Becker, 2013; Mekonnen Melaku Gebremariam, Zarnkow, &Becker, 2014b). Teff is not only gluten-free but also naturally has higher content micronutrients such as calcium, iron, and fiber which make it a very good alternative in gluten-free products [2]. Because of its small size, teff is made into whole-grain flour (bran and germ included), due to this it has very high fiber content and useful to improve the hemoglobin level in the human body and helps to prevent malaria, the incidence of anemia and diabetes [3].

Teff grain flour is widely used in Ethiopia for making injera (staples for the majority of Ethiopian people) which is a fermented, pancake-like, soft, sour, circular flatbread), sweet unleavened bread, local beer (called Tella), porridges [4]. In addition, teff is the second most important cash crop next to coffee, which generates about 500 million USD per year for local farmers in Ethiopia [5]. This makes it an attractive export commodity to many European countries, the Middle East and North America. It is largely consumed crop, especially in urban and semi-urban Ethiopia with a national per capita consumption of 25.9 kg [6].

Unlike others, a grain of teff is not affected by insect pests as the result there is no direct application of pesticide during storage. According to [7], a small grain such as millet or fonio and teff are tolerant crop to many extreme environmental conditions including water-logging and resistant to storage pests such as insects. Nevertheless, previous studies indicate that different pesticide residues have been detected, mainly organochlorines and some pyrethroids due to environmental contamination from previous applications in the field [8]. Previous studies also indicate that environmental contamination due to persistent organochlorine pesticides is a major source of food contamination including drinking water sources [8, 9, 10, 11]. This makes foods and beverages to be unsafe for human consumption which eventually pose a health threat to consumers in the long term [12].

Food safety is a worldwide growing concern on account of its direct relation to human health where the major threats are arising from a wide application of harmful pesticides to control different pests. Therefore, it is important for consumers to know the different possibilities and steps on how to reduce pesticide intake together with their food. Food processing is the action of changing the food to a more edible form before the food is used for consumption. The household, as well as industrial food processing, can influence the level of the pesticide present in the raw agricultural commodity after it is harvested [13]. Different kinds of literature revealed that food processing such as baking, cooking, roasting, and others may reduce pesticide residue from raw food crops [14, 15]. In most of the cases, pesticide residue analyses are undertaken on raw agricultural crops such as cereals, vegetables, and fruits, animal products [8, 16, 17, 18, 19, 20]. However, to estimate consumer exposure to pesticides, it is important to investigate the pesticide residues at the point of consumption, mainly after food processing [21, 22]. Also, reports indicate that different household and industrial food processing's (such as washing with water, peeling of fruits and vegetables, cooking and baking) may reduce the pesticide residue in food to the acceptable level.

Nowadays, the recognition of teff as a gluten-free food item has spurred global research interest by nutritionists and food scientists. Consequently, the number of studies on the nutritional composition of teff and its health benefits is increasing [3, 5, 7, 23] The application of pesticides for the production of teff is not common in Ethiopia; however, the grain may be contaminated from the previous applications through different routes of the environment. Recent studies done in southwestern Ethiopia detected cypermethrin, permethrin, deltamethrin, chlorpyrifos ethyl, and DDT and its metabolites in teff grains [8] which may be from environmental contamination. This reduces the global interest of importing teff from Ethiopia unless some mechanisms are proposed to reduce the presence of such contaminants. On top of that, consumers will be exposed to harmful chemicals while consuming teff products. Pesticide residues, which were present to a variable extent in the food commodities after harvesting is beyond the control of consumers. Hence, a pragmatic solution should be developed to tackle the problem of pesticide residues in teff where food processing could be one of the important solutions to reduce pesticide residues in different food items [13, 15, 24, 25, 26]. Therefore, the main purpose of the present study is to investigate the effect of household processing (doughing and baking) on the pesticide residues in teff as a means of risk reduction to consumers.

2. Materials and methods

2.1. Chemicals and reagents

Analytical grade acetonitrile (99.9% purity) was supplied by VWZ prolabo (UN1648, 00163 made in EC), high performance liquid chromatography grade n-hexane (98% purity) and acetone (98.9% purity) obtained from ALLthec company in Germany Thermo Fisher Scientific (Austin, TX, USA) supplied MgSO4 (98% purity), NaAc (99% purity), 50 mL centrifuge tube, 15 mL dispersive solid-phase extraction cleanup tube packed with Primary Secondary amine (PSA: 99% purity), Magnesium Sulphate (MgSO4: 98% purity) and Octadecyl (C18: 99% purity). The pesticides standards were obtained from Supelco (USA) and delivered by Sigma-Aldrich logistic analytical Gmbh company in Germany [8]. Pesticides studied with their purity and their physicochemical properties are shown as supplementary material.

2.2. Sampling of teff flour

A composite sample of 5 kg teff flour was bought from five shops (1 kg from each) local market in Jimma zone, southwestern Ethiopia. The samples were packed in polyethylene plastic bags, sealed and labeled properly. The samples were transported to the laboratory and stored at -20 °C until extraction was undertaken.

2.3. Treatment of the raw teff flour with pesticides understudy

A 5 g teff flour for each household processing method (doughing and backing) was spiked with eight pesticides including metabolites (DDT and its metabolites, cypermethrin, deltamethrin, permethrin, and chlorpyrifos ethyl), in three replicates to increase the reliability of results. The teff flour was stayed for 24 hours to increase the contact time between the pesticides and the matrix (teff flour). After one day the extraction, clean up and the processing methods were followed as stated below.

2.4. Extraction and cleanup of the samples

For the household processing of teff flour, we adopted the valid method for pesticide residue analysis in teff from a study done in Ethiopia by [8]. The limit of detection (LOD) for each pesticides in teff from the previous study were Chlorpyrifos ethyl (0.009 mg/kg), cypermethrin (0.062 mg/kg), permethrin (0.063 mg/kg), deltamethrin (0.015 mg/kg), p'p-DDE 0.016 mg/kg), p'p-DDD (0.023 mg/kg), o'p-DDT (0.036 mg/kg) and p'p-DDT (0.030 mg/kg) according to a study done in southwest, Ethiopia [8]. The quantitative determination of the pesticide residue in processed and unprocessed teff flour was done based on the external standard method. The calibration curves were obtained by injecting five different concentrations of the studied pesticide standards in a range of 0.005–1 mg/L. The coefficient of determination (R2) was >0.995 for all the pesticides under study indicated the acceptable linearity according to European document number Sanco [27]. Detection and quantification of the pesticides were done based on the retention time and peak area, respectively. The subsequent processing steps of the teff flour were done to correspond as close as possible to the actual traditional household teff processing in Ethiopia. Blank teff flour (non-spiked) was also analyzed together with the raw and processed teff. Blank teff flour (non-spiked) was analyzed by the same procedure as a control sample. The extraction and cleanup procedures were as follows.

2.4.1. Raw teff flour

A 50 g of teff flour was weighed on the analytical balance and spiked with 40 μl of 100 mg/L of each pesticide under study. After waiting for one day, the samples were extracted by the following procedures. A 10 mL of deionized water and 15 mL of acetonitrile was added and the sample was shaken for 30 seconds. Then 6 g MgSO4/1.5g NaAc was added and again shaken for 5min to prevent the formation of agglomerates with water. Then, the samples were centrifuged at 1957 g for 5 min. Then the upper organic layer was taken for cleanup to 15 mL dispersive solid-phase extraction tube (d-SPE) containing 300 mg PSA, 900 mg MgSO4 and 150 mg C18 and then shaken for 30 seconds and centrifuged. After centrifugation, 4 mL of the upper layer was transferred to 100 mL flat bottom flask and evaporated to dryness using a Rotary evaporator (N18673 Rotavapor; Buchi) at a temperature of 40 °C. The extract was reconstituted with 2 mL n-hexane/acetone (9:1 v/v) for a solvent exchange to make the sample more amenable for GC-ECD analysis. The blank teff flour was also extracted in a similar way together with the spiked teff samples. Then the extract was transferred to a vial for GC-ECD analysis [8]. The three replicate of each spiked samples of specific pesticides is separated by injecting n-hexane the extraction solvent to avoid cross-contamination.

2.4.2. Preparation of teff flour to dough and injera

For the treatment, 50 g teff flour was weighed on the analytical balance and then spiked with 400 μl of 100 mg/L of each pesticide understudy and stayed for one day. Depending on the need of the Ethiopian people, the dough was prepared for one, two and three-day fermentation and then final consumable injera was backed.

2.4.2.1. Dough preparation (one, two and three-day fermentation)

After waiting for 24 hours interaction of the pesticides spiked with matrix (50 g teff flour was taken), the teff flour was combined with 100 mL of water (equivalent to 100 g) and 0.5 g instant yeast to facilitate the fermentation process and a total of 150.5 g mixed thoroughly using wooden spoon until the coagulant disappears throughout the dough and to verify homogeneity. Then the prepared dough stayed for 24 (one day), 48 (two days) and 72 hours (three days) fermentations. Then 15 g of the dough was weighed on analytical balance using a 50 mL centrifuge tube and shake well by hand to keep the homogenous distribution of the pesticides spiked previously. Then the extraction and cleanup of the samples were done in a similar procedure with the raw teff flour and the concentration in the dough before baking injera was determined.

2.4.2.2. Backing injera

From each fermentation days, the remaining dough was used for baking injera. First, the dough was mixed thoroughly. Before backing, the pan was heated on the stove until it gets warmed followed by baking injera (traditional flatbread) resembling the traditional injera in Ethiopia. The pan was covered with a lid to protect injera from contamination and to control the loss of heat which is important to cook the baked injera. After waiting for 1 minute the injera was taken out and put on the flat plate until it gets cooled. The whole injera was ground and homogenized with a grinder (Fritel Quality grinder OZX48-6 cups). Then from the homogenous injera sample, 10 g of each was taken for analysis. The extraction and cleanup of the samples were done in a similar procedure with the raw teff flour. The remaining concentration of the studied pesticides after fermentation for the dough was determined in the injera.

2.5. Determination of processing factor (PF)

The effect of household processing on the level of pesticides often correlates with the physicochemical properties of the pesticides under study. To investigate whether the processing methods able to modify the properties of the pesticides and lead to reduce or concentrate their residue in one specific matrix, proper monitoring of the processing factor is important. The PF for all transformation steps was calculated by the ratio between the pesticide concentrations in the processed commodity (mg/kg) to the pesticide concentration in the raw commodity (mg/kg). According to [28], a PF less than one indicates that there is a reduction of pesticides by the processing method (PF < 1: reduction factor), while PF > 1 indicates the concentration factor. The processing factor is the proportional amount by which the residues change when food is processed. For this study PF was calculated by the formula below:

2.6. Analytical equipment

Quantitative determination and chromatographic separation of each pesticide were done by gas-chromatography with an electron capture detector (GC-ECD, Agilent Technologies 6890N) with an autosampler. Doughing and baking were undertaken on teff flour to see the effect of household processing on the pesticide residues previously detected in Ethiopian teff grain [8]. The chromatographic condition for the analysis of the pesticides was as follows: A HP-5 capillary column of 30 m × 0.25 mm i.d. x 0.25 μm film thickness was coated with 5% Phenyl Methyl siloxane (Model number Agilent 19091J-433) was used. The carrier gas was Helium (99.999%) purity at a flow rate of 0.9 mL/min. The oven temperature was maintained initially at 130 °C (1min), a rate of 30 °C min-1 to 280 °C (16min) and a rate of 50 °C min-1 to 325 °C (3min) and hold time was 22min. An aliquot of 1μl injected in split mode (Split ratio: 50:1) at an injection temperature of 280 °C. The pesticide residues were detected with Electron Capture Detector (ECD) operated at a temperature of 300 °C with a constant flow of nitrogen as makeup gas (60 mL/min)” [8]. For the detection of pesticides, each sample was injected in triplicate in the GC and the concentration of each pesticide was calculated from the average of the three analyses.

2.7. Statistical analysis

All the treatments of the processing methods (doughing and baking) were done in three replicates. Statistical significance was checked using the non-parametric Kruskal-Wallis test to see if there is a significant difference in pesticide residues between the processing methods (raw teff flour, doughing and baking) where each processing had triplicate values and also to check the difference between pesticides under study. Kruskal-Wallis test is applied when there are small data sets and the data is not normally distributed [29]. Since our data sets had few data points Kruskal-Wallis is an appropriate and robust statistical test. The differences at p-value < 0.05 were considered as significant.

3. Results and discussion

3.1. Effect of fermentation on pesticide residues during dough preparation

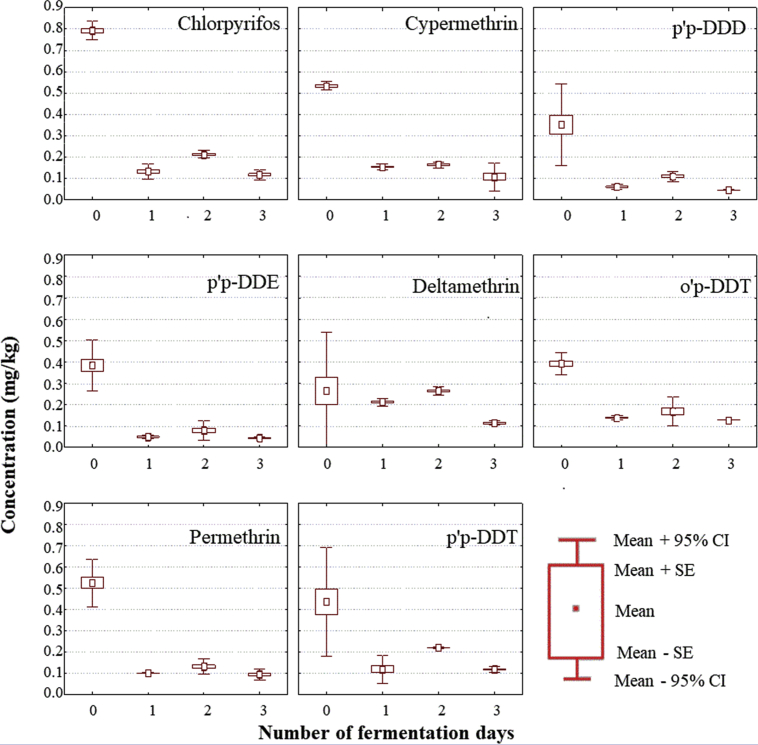

Before baking injera for final consumption the teff flour is mixed with water in the presence of yeast and fermented for one, two or three days based on the need of the people and commonly used in Ethiopian tradition. As indicated in Fig. 1 the fermentation process or the household dough processing has a great effect on the level of the studied pesticides. Kruskal-Wallis test indicated that there is a significant difference in concentration of the pesticides among the days of fermentation (p-value = 0.012) compared with non-fermented teff dough. There is a significant difference between day one and day three fermentation (p-value = 0.0056). From the box-whiskers plot, there is a decrement of the pesticide residues from raw teff flour (zero fermentation) to three days of fermentation. This indicated that fermentation during dough preparation has a significant effect to decrease the pesticide residues which is important from consumer's health point of view. Even though there is a difference in the reduction of the concentration of pesticides during fermentation, there is no statistically significant (p-value = 0.488) difference between pesticides under study. This indicates that household processing has a more or less similar effect on the reduction of the concentration of studied pesticides. Different studies also indicate that fermentation is a process that leads to a large reduction in pesticide residues from the original amount [30]. Sharma et al. ([31] also report that fermentation facilitates the reduction of pesticides in food products.

Fig. 1.

Effect of fermentation on pesticide residue in teff during the household dough processing. CI = Confidence Interval, SE = Standard Error.

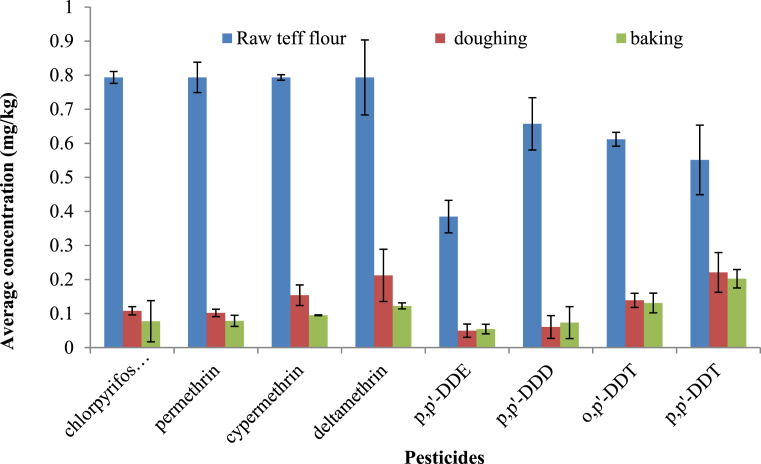

3.2. The influence of the two household teff flour processing (doughing and baking) on pesticide residues

Fig. 2. Presents the effect of doughing and baking on pesticide residues in teff. The preparation of dough decreases the pesticide residues in teff in the range of 59.9–86.4%, while baking decreases the pesticide residues in the range of 63.2–90.2%. This indicates that household processing has an effect on the reduction of the level of pesticides in teff and which will be helpful for consumers' safety. From the finding of the present study, the baking process decreases the residues in particular chlorpyrifos ethyl up to 90.2%. Kruskal−Wallis analysis also indicates that the reduction of pesticide residues by baking is significantly different from doughing (p-value < 0.0001). This indicates that baking of injera is the most effective to decrease the residues of the pesticides. This may be due to the application of heat during the baking process. According to [32], baking decreases the residue of chlorpyrifos up to 98% in winter squash and up to 70% in sweet potato. The preparation of dough and baking has a lower removal effect on p,p’-DDT (major isomer). The residue of p,p’-DDT reduced only up to 59.9% and 63.3% during doughing and baking, respectively. This may be due to p,p-DDT is highly resistant to thermal treatment as well as degradation by fermenting bacteria. The cumulative effect of these household processing methods (doughing and backing) is important to reduce consumers' exposure to pesticides in teff grain.

Fig. 2.

The average concentration of pesticides in raw and processed teff flour (n = 12), Error bar indicates standard deviation.

3.3. Processing factor

From the findings of the present study, the processing factors for both doughing and baking were less than one, for all the pesticides under study (Table 1). This indicates that there is a reduction of the pesticide residue due to the household processing of the teff flour and the result is supported by other studies [13, 33, 34].

Table 1.

The processing factor for dough preparation and baking teff injera from the raw teff flour (n = 12).

| Pesticide | Concentration in raw teff flour (mg/kg) | PF doughing | PF baking |

|---|---|---|---|

| Chlorpyrifos ethyl | 0.793 | 0.136 | 0.098 |

| Permethrin | 0.793 | 0.129 | 0.099 |

| Cypermethrin | 0.793 | 0.194 | 0.120 |

| Deltamethrin | 0.793 | 0.267 | 0.154 |

| p,p’-DDE | 0.385 | 0.130 | 0.142 |

| p,p’-DDD | 0.657 | 0.092 | 0.112 |

| o,p’-DDT | 0.612 | 0.227 | 0.214 |

| p,p’-DDT | 0.551 | 0.401 | 0.367 |

PF = Processing factor.

From Table 2 the present study shows us a better reduction of the pesticide residues from teff grain compared to some other studies. Our study results show fermentation has a better reduction of pesticide residues compared to the reduction of pyrethroid bifenthrin in wheat [35]. This may be due to the variation in the fermentation process and may be due to the behavior of pesticide in different matrixes. From the present study, there is a 90.2% reduction of chlorpyrifos ethyl during the baking process. This may be due to the application of heat in the baking process and the volatile properties of chlorpyrifos [13]. While washing of wheat and maize reduce chlorpyrifos up to 100%. This may be due to the varying composition and properties of food commodities as well as the difference in the chemical properties of pesticides. The rate at which pesticides are dissipated from the different food commodities is closely related to their physicochemical properties and the su [39] rounding environmental conditions [33].

Table 2.

Comparison of the present study with some studies undertaken on the effect of processing on the level of pesticides (decimal values are rounded).

| Food commodity | Pesticides | Processing | Pesticide residue reduction (%) | Reference |

|---|---|---|---|---|

| Wheat | Bifenthrin | Fermentation | 19–63 | [35] |

| Sterilization | 17–18 | |||

| Wheat | Chlorpyrifos, Endosulfan α, and β, Deltamethrin | Storage | 60–72 | [13] |

| Wheat | Malathion | Milling to flour | 90 | [36] |

| Soya bean | Captain | Ozone treatment | 12 | [37] |

| Rice and maize | Chlorpyrifos | Washing | 59–100 | [38] |

| Teff | Permethrin, Cypermethrin, Deltamethrin, Chlorpyrifos ethyl, p,p'-DDE, p,p'-DDD, o,p'-DDT, and p,p'-DDT | Doughing | 60–86 | The present study |

| Baking | 63–90 |

In general, to avoid food safety issues related to pesticides, organic farming is being propagated in the world. However, organic farming is not well-practiced in most developing countries for several reasons, such as the increasing population size, the effect of pests may decrease agricultural production, low awareness of the pesticide users on organic practices and wrong perception of pesticide users particularly farmers. Most farmers in Ethiopia considering pesticides are the best option to increase agricultural production. In addition to this, there are critics that organic farming use more land compared to conventional agriculture [40]. Therefore, it is still important to look for other solutions to tackle food safety problems related to pesticide residues in agricultural crops.

One advantage for consumers is that food processing minimizes pesticide residues in food which had been shown in this work. Food processing such as washing, peeling, cooking, blanching, and baking can decrease pesticide residue in food [41]. As a result, food processing at household and industrial can reduce the exposure of consumers to pesticides [14].

In the present study, household processing of teff flour reduces pesticide residues from the raw commodity including the high thermal resistant DDT and its metabolites, particularly during the baking process. The PFs for both household processing methods (doughing and baking) were found to be less than one, which is an indication of a reduction of pesticide residues compared to the raw teff grain. The percent reduction varies from processing to processing. As indicated in table one the physicochemical properties of pesticides are different and which may have an effect on the level of reduction during household processing. The effects of food processing are influenced by the physicochemical properties of pesticides such as the solubility, thermal degradation, octanol-water partition coefficient (KOW) and volatility [14, 42, 43].

4. Conclusions

Pesticides are one of the major chemical hazards that contaminate food items. Different scientific investigations are important to reduce pesticide residues among different food items to safeguard consumers' safety. Our study has indicated the importance of household food processing of teff flour in reducing pesticide residue where effective reduction is registered. Among the two household processing methods, baking is the most effective to reduce the residues than fermentation. Based on the PF value, the household processing methods (doughing and baking) were the cause of residue reduction. Such reduction is important in evaluating the risks associated with the ingestion of pesticides, specifically from the consumption of teff grain. The household processing of teff has a paramount effect on the reduction of pesticide residues as well as consumers’ exposure and this initiates to work on the effect of different household processing methods on other cereals and pesticides.

Declarations

Author contribution statement

Seblework Mekonen: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Argaw Ambelu: Analyzed and interpreted the data; Wrote the paper.

Pieter Spanoghe: Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This work was supported by BOF (Special Research Fund) at Ghent University and Jimma Universities.

Competing interest statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Appendix A. Supplementary data

The following is the supplementary data related to this article:

References

- 1.Mellen P.B., Walsh T.F., Herrington D.M. Whole grain intake and cardiovascular disease: a meta-analysis. Nutr. Metabol. Cardiovasc. Dis. 2008;18:283–290. doi: 10.1016/j.numecd.2006.12.008. [DOI] [PubMed] [Google Scholar]

- 2.Kenney E.S., Butler C., Moore C., Bhaduri S., Ghatak R., Navder K.P. The effect of substituting teff flour in gluten-free sugar cookies and peanut butter cookies. J. Am. Diet. Assoc. 2011;111:A63. [Google Scholar]

- 3.Gebremariam M.M., Zarnkow M., Becker T. Teff (Eragrostis tef) as a raw material for malting, brewing, and manufacturing of gluten-free foods and beverages: a review. J. Food Sci. Technol. 2014;51:2881–2895. doi: 10.1007/s13197-012-0745-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Yetneberk S., Rooney L.W., Taylor J.R. Improving the quality of sorghum injera by decortication and compositing with tef. J. Sci. Food Agric. 2005;85:1252–1258. [Google Scholar]

- 5.Minten B., Tamru S., Engida E., Kuma T. 2013. Ethiopia’s Value Chains on the Move: the Case of Teff.http://www.ifpri.org/sites/default/files/publications/esspwp52.pdf [Google Scholar]

- 6.Berhane G., Paulos Z., Tafere K., Tamru S. 2011. Foodgrain Consumption and Calorie Intake Patterns in Ethiopia, ESSP II Working Paper No. 23.http://www.ifpri.org/sites/default/files/publications/esspwp23.pdf [Google Scholar]

- 7.de Oliveira do Nascimento K., do Nascimento Dias Paes S., Reis de Oliveira I., Pereira Reis I., Maria Augusta I. Teff: suitability for different food applications and as a raw material of gluten-free, a literature review. J. Food Nutr. Res. 2018;6:74–81. [Google Scholar]

- 8.Mekonen S., Ambelu A., Spanoghe P. Pesticide residue evaluation in major staple food items of Ethiopia using the QuEChERS method: a case study from the Jimma Zone: pesticide residues in food items. Environ. Toxicol. Chem. 2014;33:1294–1302. doi: 10.1002/etc.2554. [DOI] [PubMed] [Google Scholar]

- 9.Abiye A., Hadera G. EPA/SEG; Addis Ababa: 2005. A Report on POPs and Other Pesticides Inventory in Ethiopia; POPs/NIP Project. [Google Scholar]

- 10.Ahmed N., Zaki E.M.S. Detection of some organochlorine pesticides in raw milk in giza governorate. J. Appl. Sci. Res. 2009;5:2520–2523. [Google Scholar]

- 11.Aktar W., Sengupta D., Chowdhury A. Impact of pesticides use in agriculture: their benefits and hazards. Interdiscip. Toxicol. 2009;2:1–12. doi: 10.2478/v10102-009-0001-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Mekonen S., Lachat C., Ambelu A., Steurbaut W., Kolsteren P., Jacxsens L., Wondafrash M., Houbraken M., Spanoghe P. Risk of DDT residue in maize consumed by infants as complementary diet in southwest Ethiopia. Sci. Total Environ. 2015;511:454–460. doi: 10.1016/j.scitotenv.2014.12.087. [DOI] [PubMed] [Google Scholar]

- 13.Pal Pranoy, Sahah P.G. Effect of storage and processing on dissipation of five insecticides on wheat. Pestic. Res. J. 2008;20:253–258. [Google Scholar]

- 14.Kaushik G., Satya S., Naik S.N. Food processing a tool to pesticide residue dissipation – a review. Food Res. Int. 2009;42:26–40. [Google Scholar]

- 15.Mekonen S., Ambelu A., Spanoghe P. Effect of household coffee processing on pesticide residues as a means of ensuring consumers’ safety. J. Agric. Food Chem. 2015;63:8568–8573. doi: 10.1021/acs.jafc.5b03327. [DOI] [PubMed] [Google Scholar]

- 16.Fadaei A., Dehghani M.H., Nasseri S., Mahvi A.H., Rastkari N., Shayeghi M. Organophosphorous pesticides in surface water of Iran. Bull. Environ. Contam. Toxicol. 2012;88:867–869. doi: 10.1007/s00128-012-0568-0. [DOI] [PubMed] [Google Scholar]

- 17.Yoshida S., Murata H., Imaida M. Distribution of pesticide residues in vegetables and fruits and removal by washing. J. Agric. Chem. Soc. Jpn. 1992;66:1007–1011. [Google Scholar]

- 18.Bempah C.K., Asomaning1 J., Boateng J. Market basket survey for some pesticide residues in fruits and vegetables from Ghana. J. Microbiol. Biotechnol. Food Sci. 2012;2:850–871. [Google Scholar]

- 19.Hamilton D., Ambrus A., Dieterle R., Felsot A., Harris C., Petersen B., Racke K., Wong S.-S., Gonzalez R., Tanaka K., Earl M., Roberts G., Bhula R. Advisory committee on crop protection chemistry, division of chemistry and the environment, of the international union of pure and applied chemistry, pesticide residues in food--acute dietary exposure. Pest Manag. Sci. 2004;60:311–339. doi: 10.1002/ps.865. [DOI] [PubMed] [Google Scholar]

- 20.Keikotlhaile B.M., Spanoghe P. Pesticide residues in fruits and vegetables. In: Stoytcheva M., editor. Pestic. Formul. Eff. FATE. InTech; Rijeka, Croatia: 2011. p. 808.http://rileypestmanagement.net/custom-1/Pesticides-Formulations-Effects-Fate.pdf [Google Scholar]

- 21.Damalas C.A., Eleftherohorinos I.G. Pesticide exposure, safety issues, and risk assessment indicators. Int. J. Environ. Res. Public Health. 2011;8:1402–1419. doi: 10.3390/ijerph8051402. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Keikotlhaile B.M. Ghent University; Belgium: 2011. Influence of the Processing Factors on Pesticide Residues in Fruits and Vegetables and its Application in Consumer Risk Assessment. PhD Thesis. Ghent University, Belgium. [Google Scholar]

- 23.Hrušková M. Composite flours-characteristics of wheat/hemp and wheat/teff models. Food Nutr. Sci. 2012;03:1484–1490. [Google Scholar]

- 24.Ahmed A., Randhawa M.A., Yusuf M.V., Khalid N. Effect of processing on pesticide residues in food crops-Ariview. J. Agric. Res. 2011;49 [Google Scholar]

- 25.Keikotlhaile B.M., Spanoghe P., Steurbaut W. Ghent University; Belgium: 2011. Influence of the Processing Factors on Pesticide Residue in Fruits and Vegetables and its Application in Consumer Risk Assessment.https://biblio.ugent.be/publication/1943291/file/1944016 [Google Scholar]

- 26.Satpathy G., Tyagi Y.K., Gupta R.K. Removal of organophosphorus (OP) pesticide residues from vegetables using washing solutions and boiling. J. Agric. Sci. 2012;4 [Google Scholar]

- 27.Valverde A. 2015. EU Guidelines on Method Validation and Quality Control Procedures for Pesticide Residues Analysis in Food and Feed, Unpublished. [Google Scholar]

- 28.Bonnechere A., Hanot V., Jolie R., Hendrickx M., Bragard C., Bedoret T., Van Loco J. Processing factors of several pesticides and degradation products in carrots by household and industrial processing. J. Food Res. 2012;1 doi: 10.1080/19440049.2012.672339. [DOI] [PubMed] [Google Scholar]

- 29.McDonald J. third ed. Sparky House Publishing; Baltimore, Maryland: 2014. Handbook of Biological Statistics.http://www.biostathandbook.com/kruskalwallis.html [Google Scholar]

- 30.Regueiro J., López-Fernández O., Rial-Otero R., Cancho-Grande B., Simal-Gándara J. A review on the fermentation of foods and the residues of pesticides—biotransformation of pesticides and effects on fermentation and food quality. Crit. Rev. Food Sci. Nutr. 2015;55:839–863. doi: 10.1080/10408398.2012.677872. [DOI] [PubMed] [Google Scholar]

- 31.Sharma J., Satya S., Kumar V., Tewary D.K. Dissipation of pesticides during bread-making. Chem. Health Saf. 2005;12:17–22. [Google Scholar]

- 32.Byrne S.L., Pinkerton S.L. The effect of cooking on chlorpyrifos and 3,5,6-trichloro-2-pyridinol levels in chlorpyrifos-fortified produce for use in refining dietary exposure. J. Agric. Food Chem. 2004;52:7567–7573. doi: 10.1021/jf049212w. [DOI] [PubMed] [Google Scholar]

- 33.Bajwa U., Sandhu K.S. Effect of handling and processing on pesticide residues in food- a review. J. Food Sci. Technol. 2014;51:201–220. doi: 10.1007/s13197-011-0499-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Hasmukh J., Neha T., Praful J. Effect of household processing on reduction of pesticide residues in Cauliflower (Brassica oleraceae var. botrytis) Eur. J. Exp. Biol. 2012;2:1639–1645. [Google Scholar]

- 35.Đorđević T.M., Šiler-Marinković S.S., Đurović R.D., Dimitrijević-Branković S.I., Gajić Umiljendić J.S. Stability of the pyrethroid pesticide bifenthrin in milled wheat during thermal processing, yeast, and lactic acid fermentation, and storage: stability of bifenthrin in wheat. J. Sci. Food Agric. 2013;93:3377–3383. doi: 10.1002/jsfa.6188. [DOI] [PubMed] [Google Scholar]

- 36.Uygun U., Senoz B., Öztürk S., Koksel H. Degradation of organophosphorus pesticides in wheat during cookie processing. Food Chem. 2009;117:261–264. doi: 10.1016/j.foodchem.2007.12.048. [DOI] [PubMed] [Google Scholar]

- 37.Zhanggui Q., Xiaoping Y., Xia W. Trials of ozone reducing pesticide residues in grain. Grain Storage. 2003;32:10–13. [Google Scholar]

- 38.A. Tejada, S. Calumpang, N. Gambalan, Effect of processing on residues of Chlorpyriphos in stored corn and rice, Phillipine Agric.. 73 (n.d.) 375–385.

- 39.Akalu G., Taffesse S., Gunaratna N.S., De Groote H. The effectiveness of quality protein maize in improving the nutritional status of young children in the Ethiopian highlands. Food Nutr. Bull. 2010;31:418–430. doi: 10.1177/156482651003100304. [DOI] [PubMed] [Google Scholar]

- 40.Seufert V., Ramankutty N., Foley J.A. Comparing the yields of organic and conventional agriculture. Nature. 2012;485:229–232. doi: 10.1038/nature11069. [DOI] [PubMed] [Google Scholar]

- 41.Elkins E.R. Effect of commercial processing on pesticide residues in selected fruits and vegetables. J. – Assoc. Off. Anal. Chem. 1989;72:533–535. [PubMed] [Google Scholar]

- 42.Holland P.T., Hamilton D., Ohlin B., Skidmore M.W. 1994. Effects of Storage and Processing on Pesticide Residues in Plant Products, Applied Chemistry Devisio Commision on Agrochemicals.http://www.iupac.org/publications/pac/1994/pdf/6602x0335.pdf [Google Scholar]

- 43.Gebremariam M.M., Zarnkow M., Becker T. Thermal stability of starch degrading enzymes of teff (Eragrostis tef) malt during isothermal mashing. Process Biochem. 2013;48:1928–1932. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.