Abstract

Distiller-dried grain solid (DDGS), a co-product of alcohol production, contains cereal grain residues, proteins, and yeast metabolites, which make it suitable in poultry feeding. However, high phytate content of DDGS limits its applicability in poultry feed. In this study, Plackett–Burman design was used to improve cell-bound phytase production by Williopsis saturnus NCIM 3298, and we achieved an enzyme activity of 269 IU/g of dry–wet biomass. The effect of this enhanced phytase-displaying yeast strain on hydrolysis of corn phytate and subsequently on ethanol production and DDGS quality was then investigated. Results of saccharification in the presence of phytase showed that reducing sugar content of liquefied mash increased by 11%, which subsequently improved the ethanol production by 18% (w/v) (p < 0.01) compared with the control. Notably, phytase treatment decreased the phytate content of corn by 70% (p < 0.01) compared with the control, thereby improving the availability of free phosphate in fermentation broth and DDGS. Thus, the results obtained suggest that the addition of W. saturnus NCIM 3298 strain has the potential of providing a new source of phytase that would be useful in the feed and ethanol industries.

Electronic supplementary material

The online version of this article (10.1007/s13205-019-1764-y) contains supplementary material, which is available to authorized users.

Keywords: Phytase, Williopsis saturnus NCIM 3298, Plackett–Burman design, Ethanol, DDGS

Introduction

Phosphorus (P) is an essential component of life and is needed for the survival of all living organisms. In the environment, P is usually stored in soil and rocks in the form of phosphate, while in plants it is stored in the seeds as phytic acid (phytate), which accounts for 60–90% of the total plant P (Konietzny and Greiner 2003; Reddy et al. 1982). In livestock cultivation, animals fulfil their P requirement through their plant-based diet. However, unlike ruminants, monogastric animals are unable to utilize the phytate-bound P, as they lack the intrinsic enzyme(s) that hydrolyse phytate (Mullaney et al. 2000; Bitar and Reinhold 1972). In addition, it is known that phytate is as an anti-nutrient, because it forms strong complexes with amino acids, proteins, starch, and nutritionally important metal ions such as calcium, zinc, magnesium, and iron, consequently decreasing their bioavailability (Greiner and Konietzny 2006; Schwarz and Hoppe 1992). Therefore, the high phytate content in the feed is a major concern, especially for nutritionists formulating feed specifications for monogastric animals. Inorganic phosphate supplementation in the feed could fulfil the P requirement for these animals. However, the addition of inorganic phosphate directly is disadvantageous, because it is expensive and its sources are non-renewable. Consequently, supplementing the feed with phytase, a phytic acid-degrading enzyme, has been suggested to increase the bioavailability of P along with other minerals. An added advantage of this approach is that it decreases P pollution in areas of intensive poultry, piggery farms, and ruminant production (de Souza et al. 2018; Vallejo-Hernández et al. 2019).

Yeasts are rich source of proteins, vitamins, and P (Querol and Fleet 2006), and hence, the use of cell-bound phytase-producing yeast as a feed/food additive may be expected to improve its nutritional value when compared with the use of conventional free phytase. Several yeast strains have been screened for their cell-bound and extracellular phytase production ability (Menezes et al. 2019; Savita et al. 2017; Nuobariene et al. 2011); however, because of low phytase productivities, very few of them have actually made it to the application level. Recently, Chen (2017) stated that phytase displayed on yeast surface can provide a beneficial novel platform for developing an environment friendly system for its industrial applications. We have earlier reported the cell-bound phytase production ability of the yeast strain, W. saturnus NCIM 3298 under submerged fermentation and its application in dephytinization of chickpea floor (Pable et al. 2014). The present work is directed towards the screening and selection of media components and their levels using Plackett–Burman Design (PBD), employing the yeast W. saturnus NCIM 3298 to improve its cell-bound phytase production.

Distiller-dried grain solid (DDGS) is a co-product of distillery grains after alcohol production. High levels of proteins, fibres, and minerals in DDGS make it a suitable diet source for the livestock industry (Wang et al. 2007). DDGS has been fed mainly to ruminants. However, with enormous rise in ethanol production and consequent increased availability of DDGS, it is also being used as feedstock for swine and poultry (Taheripour et al. 2010). Nonetheless, DDGS has limited value as poultry feed because of its high phytate content, which negatively affects the poultry production (Cowieson et al. 2006). Application of phytase in poultry feed formulation and its effect on DDGS phytate to make inorganic P available to non-ruminants have been studied previously (Almeida and Stein 2012). Recently, Mikulski et al. (2014) and Chen et al. (2016) studied the effect of phytase treatment on alcohol production and DDGS phytate content after treating corn with simultaneous saccharification and fermentation. Their observations showed that the addition of phytase during the alcohol production process improved the ethanol yield while providing DDGS with low phytate content. In this study, we have used W. saturnus as source of phytase. This yeast has been reported for its production of a killer toxin that inhibits the growth of food-spoiling microorganisms during ethanol fermentation and food processing (Liu and Tsao 2009; Lu et al. 2017). This suggests the applicability of W. saturnus in alcohol fermentation, food processing, and animal feed production. Therefore, in the present study, along with the aim of optimizing for efficient phytase production by W. saturnus NCIM 3298, we also studied its potential use in ethanol production using corn as a substrate. Obtaining encouraging results will have implications in both the feed as well as the fermentation industries.

Materials and methods

Chemicals

Phytic acid sodium salt was obtained from Sigma-Aldrich Chemical Co. (St. Louis, MO), USA. The α-amylase and glucoamylase were purchased from Himedia Laboratories Pvt. Ltd., Mumbai, India. All other chemicals and solvents used were of analytical grade.

Yeast strains and test sample

Phytase-producing yeast W. saturnus NCIM 3298 used in the present study was obtained from NCIM Resource Centre, CSIR-NCL, Pune, India. Corn and active dry yeast (Saccharomyces cerevisiae) were purchased from a local market.

Culture conditions and enzyme production

The stock culture was maintained on MGYP agar (malt extract 3 g/L, glucose 10 g/L, yeast extract 3 g/L, peptone 5 g/L, and agar 20 g/L) and stored at 4 °C. The culture was inoculated in yeast extract–glucose–peptone broth (glucose 10 g/L, yeast extract 3 g/L, and peptone 5 g/L) and incubated at 28 °C for 16 h. The optical density (O.D.) of the culture was measured at 660 nm and adjusted to 1.5, and then, the culture was used as inoculum for phytase production studies. Fermentation was carried out in 250 mL Erlenmeyer flasks containing 50 mL basal medium (glucose 20 g/L, yeast extract 3 g/L, NH4NO3 5 g/L, citric acid 5 g/L, and FeSO4 1 mM with pH 5.5). Media was sterilized at 121 °C for 15 min and then inoculated with 3% inoculum and incubated at 28 °C for 24 h on a rotary shaker at 160 rpm. The cells were harvested and washed thrice with distilled water to remove media ingredients and then used to determine cell-bound phytase activities. Media components screening tests were performed in triplicates in 250-mL flasks containing 50 mL medium at 160 rpm.

Screening of key media components by PBD

Two-level full-factorial design of PBD was employed for identification of key fermentation parameters (physical and chemical) that could most significantly influence the cell-bound phytase production by W. saturnus NCIM 3298. According to PBD, the screening was carried out in N+1 trials, where N = 11 (Plackett and Burman 1946). In the present study, seven independent variables, viz., glucose, NH4NO3, yeast extract, citric acid, incubation period, FeSO4, and pH were tested at two chosen levels (high and low) in a set of 12 trials. The PBD experimental design matrix with the variable name and the actual levels used is shown in Table 1. The matrix was constructed using the Design-Expert Software (DES) (version 7.1.2, Stat-Ease, Minneapolis, MN, USA). The experiments were carried out in triplicate and the average phytase production was taken as the response. The DES software calculates the standardized effect, sum of squares (SS), and evaluates the percentage contribution of each factor for a chosen mathematical model with the aim of identifying their individual significance. The percentage contribution is calculated by summing all the SS terms and then taking each individual SS and dividing by the total SS and multiplying by 100.

Table 1.

PBD screening variables to study cell-bound phytase activity by W. saturnus NCIM 3298 and identifying the key medium components for the chosen low and high levels

| Variable | Level 1 | Level 2 |

|---|---|---|

| Glucose (%) | 2.0 | 10 |

| NH4NO3 (%) | 0.2 | 2.0 |

| Yeast extract (%) | 0.1 | 0.5 |

| Citric acid (%) | 0.2 | 2.0 |

| Incubation period (h) | 16 | 36 |

| FeSO4 (mM) | 0.5 | 3.0 |

| pH | 5.0 | 7.0 |

Effect of phytase on ethanol production from corn

To study the effect of cell-bound phytase on ethanol production and DDGS phytate, we simultaneously studied the saccharification and fermentation of corn using a method described previously (Chen et al. 2016). Briefly, 30 g of corn was soaked in 200 mL of distilled water followed by the addition of W. saturnus NCIM 3298 cells corresponding to 3 U of phytase/g of corn. The mixture was incubated at 50 °C for 1 h. Phytase-treated mixture was then subjected to malting process by treating with α-amylase (1.5 U/g of corn) for 15 min at 55 °C (pH 5.5) followed by treatment with glucoamylase (1 U/g of corn) for 30 min at 60 °C (pH 4.8). The resultant liquefied mash was then subjected to ethanol fermentation by adding activated Baker’s yeast S. cerevisiae as the fermenting yeast and W. saturnus NCIM 3298 (1 U/g of corn) as the source of phytase (Treatment A). This second stage phytase treatment was carried out to increase the efficiency of phytate degradation during fermentation. Saccharification and fermentation without phytase treatment were used as a control (Treatment B). Fermentation was carried out for 72 h at 30 °C under static conditions. Fermented broth was centrifuged at 5000 rpm for 10 min. Broth supernatant and wet distiller’s grains solids (WDGS) were collected separately. Furthermore, WDGS was dried at 100 °C to get DDGS, which was subsequently analysed for phytate and free P content.

Phytase activity

Phytase activity measurements were carried out at 50 °C using Na–phytate substrate in 0.1 M acetate buffer (pH 5.0), as described previously (Pable et al. 2014; Heinonen and Lahti 1981). One unit of phytase activity (IU) was expressed as the amount of enzyme that liberates 1 μM of inorganic P per min under standard assay conditions. Each experiment was carried out in triplicate and the values reported are mean of three such experiments. Negative controls were prepared from cells mixed with acetate buffer without Na–phytate. Cell associated phytase activities were expressed as IU/g of dry weight biomass (DWB).

Analytical methods

Corn phytate was extracted with 2.4% HCl as described earlier (Latta and Eskin 1980). Acid extracted samples were then passed through an AG-1-X8 anion exchange resin (200–400 mesh chloride form). Phytic acid and free phosphate content of raw corn, liquefied mash, and DDGS were determined using a spectrophotometer and the methods described earlier by Frühbeck et al. (1995) and Heinonen and Lahti (1981) respectively. Ethanol content in the fermented sample was estimated by titrimetric method using potassium dichromate, potassium iodide against sodium thiosulfate, and starch as indicator (Pilone 1985). Reducing sugar content of liquefied mash and fermented broth was estimated by DNSA method using glucose as standard (Miller 1959).

Statistical analysis

Design-Expert software (DES), version 7.1.2 (Stat-Ease, Minneapolis, MN, USA) was used for statistical and regression analysis of experimental data. The analysis of variance (ANOVA) was carried out to estimate the statistical parameters. Student’s t test for two variables was used to compare the results of phytase treatment on ethanol production with control as well as on DDGS phytate and free inorganic P content. A p value < 0.05 was considered to be statistically significant.

Results and discussion

Screening for significant media components using PBD

As mentioned in “Materials and methods”, a total of seven factors that are likely to affect phytase production were chosen for study by PBD of experiments. Table 2 shows the PBD matrix for selected variables along with the experimentally obtained values of the responses. The maximum phytase production (269 IU/g DWB) was obtained in trial number 4. The PBD experiments showed a wide range of response values with respect to phytase production (i.e., 10–269 U/g DWB). This large difference between low and high values of phytase production suggests that the response is strongly influenced by the components present in the medium, highlighting the importance of medium optimization studies.

Table 2.

Experimental design used in PBD study for the seven selected factors along with the experimentally obtained response values for cell-bound phytase production by W. saturnus NCIM 3298

| Run no. |

Factor | Phytase production (IU/g DWB) |

||||||

|---|---|---|---|---|---|---|---|---|

| Glucose (%) |

NH4NO3 (%) |

Yeast extract (%) |

Citric acid (%) |

Incubation period (h) |

FeSO4 (mM) |

PH | ||

| 1 | 10 | 0.2 | 0.5 | 2.0 | 16 | 3.0 | 7.0 | 45 ± 6.5 |

| 2 | 2.0 | 0.2 | 0.1 | 2.0 | 16 | 3.0 | 7.0 | 10 ± 1.3 |

| 3 | 10 | 0.2 | 0.1 | 0.2 | 36 | 0.5 | 7.0 | 211 ± 11.8 |

| 4 | 2.0 | 0.2 | 0.1 | 0.2 | 16 | 0.5 | 5.0 | 269 ± 6.4 |

| 5 | 10 | 2.0 | 0.1 | 0.2 | 16 | 3.0 | 5.0 | 219 ± 15.4 |

| 6 | 10 | 2.0 | 0.1 | 2.0 | 36 | 3.0 | 5.0 | 91 ± 4.8 |

| 7 | 2.0 | 2.0 | 0.5 | 2.0 | 16 | 0.5 | 5.0 | 72 ± 3.5 |

| 8 | 10 | 0.2 | 0.5 | 2.0 | 36 | 0.5 | 5.0 | 170 ± 4.0 |

| 9 | 2.0 | 2.0 | 0.5 | 0.2 | 36 | 3.0 | 7.0 | 116 ± 3.1 |

| 10 | 10 | 2.0 | 0.5 | 0.2 | 16 | 0.5 | 7.0 | 184 ± 12.1 |

| 11 | 2.0 | 0.2 | 0.5 | 0.2 | 36 | 3.0 | 5.0 | 123 ± 10.1 |

| 12 | 2.0 | 2.0 | 0.1 | 2.0 | 36 | 0.5 | 7.0 | 98 ± 6.5 |

The culture was grown at 30 °C as described in “Materials and methods”. The values given are the average of three independent experiments

The best-fit linear model to the orthogonal PBD of experiments was found after performing regression analysis and the predicted response for cell wall-bound phytase activity (IU g/DWB) as follows:

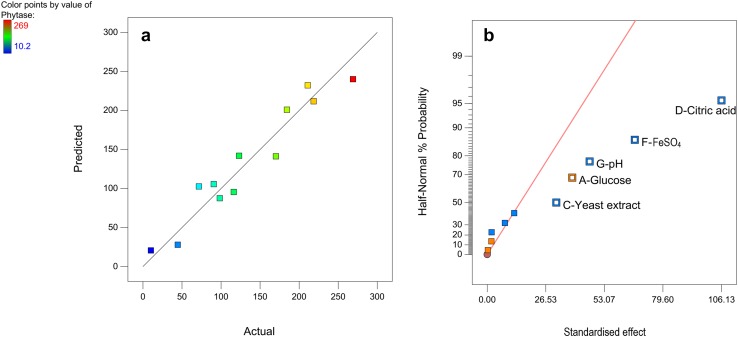

| 1 |

The coefficients of each variable represent the effect level, either positive or negative, of these variables on phytase production. A positive sign of the effect of the tested variable indicates its greater influence on phytase production at a high level and a negative effect indicates greater influence of the variable at a low level. ANOVA gave the sum of squares for the above individual factors (Table 3), respectively, and the coefficient estimate, effect, and percentage contribution of the individual terms (Table 4). The analysis of total SS and percentage contribution showed that glucose, citric acid, yeast extract, FeSO4, and pH influenced phytase production. ANOVA was further applied to test the acceptability of PBD model (Eq. 1). It gave a model F value of 14.86, implying that the selected model is significant and there is only a 0.25% chance that a model F value could occur due to noise (Table 4). The values of “Prob > F” less than 0.05 indicate that the model terms are significant. We obtained the coefficient of determination of R2 = 0.9253, which provides a measure of how much of the variability in the observed response values can be explained by the analysis. The predicted R2 value of 0.7012 is in reasonable agreement with the adjusted R2 value of 0.8630. Figure 1a represents the relationship between the actual phytase production values and the predicted values determined by the model (Eq. 1) with W. saturnus NCIM 3298. The points lie near the diagonal line, with an equal distribution of the points on both sides, suggesting that the model explains the experimentally determined observations. Figure 1b represents the half-normal plot for PBD and shows that the insignificant effects fall along a straight line in the region of the origin. The effects lying considerably to the right side of this line may be considered as statistically significant. Thus, the results clearly identify the factors glucose, pH, FeSO4, and citric acid to be statistically significant.

Table 3.

ANOVA analysis of PBD responses

| Source | Sum of squares | Mean square | F value |

p value (prob > F) |

|---|---|---|---|---|

| Model | 61,058.72 | 14529.91 | 14.86 | 0.0025 significant |

| Glucose | 4454.45 | 4454.45 | 5.42 | 0.0588 |

| Yeast extract | 2939.07 | 2939.07 | 3.58 | 0.1074 |

| Citric acid | 33,792.85 | 33,792.85 | 41.13 | 0.0007 |

| FeSO4 | 13,413.45 | 13,413.45 | 16.33 | 0.0068 |

| pH | 6458.88 | 6458.88 | 7.86 | 0.0310 |

| Residual | 4929.54 | 821.59 | ||

| Cor total | 65,988.25 |

Table 4.

Analysis of PBD for the % contribution of specified variable for cell-bound phytase production by W. saturnus NCIM 3298

| Variable | Sum of square | Coefficient estimate | Effect | Contribution (%) |

|---|---|---|---|---|

| Intercept | 134.03 | |||

| Glucose | 4454.45 | 19.27 | 38.53 | 6.75 |

| Yeast extract | 2939.07 | −15.65 | −31.3 | 4.45 |

| Citric acid | 33,792.85 | −53.07 | −106.133 | 51.21 |

| FeSO4 | 13,413.45 | −33.43 | −66.87 | 20.33 |

| pH | 6458.88 | −23.20 | −46.4 | 9.79 |

Fig. 1.

a Plot of model predicted vs. actual cell-bound phytase production. b Half-normal probability plot for cell-bound phytase production obtained from W. saturnus NCIM 3298 by PBD

Interestingly, among the various tested factors, citric acid was found to have an added influence on phytase production and its contributory effect was more than 50% in PBD. Previously, (Spier et al. 2008) reported the use of citrate pulp as an agro-industrial waste for phytase production by fungal isolates using solid-state fermentation. This study is the first report on the use of citric acid in medium to enhance the phytase production using yeast system. Surprisingly, phytase activity, in the absence of citric acid, declined drastically after 24 h of incubation (Supplementary Fig. 1). On the other hand, in the presence of citric acid, phytase production continued even after 24 h of fermentation, with only a small decrease in activity (Supplementary Fig. 2). Moreover, the pH remained same in citric acid-containing medium at the initially adjusted value (pH 4.5), while, without citric acid, the medium pH decreased from 5.5 to 2.5 within 24 h of incubation. It is likely that the buffering capacity of citrate prevented the change in pH during fermentation and thus could be responsible for the observed phytase production even after 24 h of fermentation. Furthermore, it has been shown that low pH of the medium has negative influence on phytase production (Vats and Banerjee 2002). Another potential mechanism to explain citric acid-mediated enhanced phytase production could be its P-chelating ability. It has been known that a depleted P or low P medium enhances the phytase production (Quan et al. 2001; Shieh and Ware 1968). It may be noted that percentage contribution of pH and FeSO4 on phytase production was significant to the extent of 9.8 and 20.3%, respectively. It is known that Fe2+ influences the phytase production by yeast in a positive way (Vohra and Satyanarayana 2001) and this observation is corroborated in our study.

The selected media components (glucose 2 g/L, HN4NO3 0.2 g/L, yeast extract 0.1 g/L, citric acid 0.2 g/L, FeSO4 0.5 mM and pH 5), predicted by PBD gave phytase production of 269 IU/DWB, whereas the basal medium (glucose 40 g/L, NH4NO3 5 g/L, citric acid 5 g/L, yeast extract 3 g/L, and FeSO4 1 mM with pH 5.5) showed a phytase production of 46 IU/g DWB. Thus, an approximately 5.8-fold enhancement in phytase production was achieved by the present screening based on PBD of experiments. A time-course experiment was carried out and it validated the PBD model obtained from the experimental data (Supplementary Fig. 2). It may be noted that optimization using central composite design in the case of P. anomala gave a phytase activity of only 120 IU/g using glucose, beef extract, and Fe2+ (Kaur and Satyanarayana 2005), while our study reports a notable improvement with phytase production of 269 IU/g DWB. The identification of the significant variables with optimization by PBD suggests that more studies using Response Surface methodologies may be worthwhile.

Effect of phytase on ethanol production and DDGS phytate content

The effect of cell-bound phytase of W. saturnus NCIM 3298 on ethanol production from corn was studied by applying the W. saturnus NCIM 3298 cells during saccharification and fermentation. Furthermore, DDGS, the co-product of ethanol production, was analysed for its phytate and free P content. Our study showed that after phytase treatment, the ethanol production significantly increased, while the phytate content of DDGS decreased drastically when compared with the control (i.e., without phytase treatment). Table 5 shows the quantitative analysis of treatments A and B. The reducing sugar content of phytase-treated liquefied mash (Treatment A) was 79.9 g/L, which was significantly higher than the control (Treatment B; 72.67 g/L; p < 0.05) (Table 5). The higher value of reducing sugar in phytase-treated samples is in good agreement with the underlying assumption that phytic acid forms insoluble complexes with polysaccharides and Ca2+, a factor required for amylase activity, and this limits the phytic acid availability for enzyme hydrolysis (Mikulski et al. 2014). Furthermore, Treatment A resulted in production of 12.4 g of ethanol/L, which was higher than ethanol production by the control (10.47 g/L; p < 0.05) (Table 5). Thus, overall ~ 18% increase in ethanol yield was achieved with cell-bound phytase treatment during simultaneous saccharification and fermentation when compared with control. Earlier, Chen et al. (2016) reported a 6.2% increase in ethanol production with the treatment of cell surface-displayed phytase in S. cerevisiae. The addition of exogenous phytase during the E-Mill dry grind corn process for bioethanol production resulted in an increased final ethanol concentration by 0.9% v/v (Khullar et al. 2011).

Table 5.

Effect of phytase treatment during saccharification and fermentation on ethanol production and on DDGS phytate and free phosphate content

| Treatmenta | Reducing sugar concentration of liquefied mash (g/L) | Ethanol production (g/L) | Phytate content (mg/100 g) |

Free phosphate content (mg/100 g) |

|||

|---|---|---|---|---|---|---|---|

| Liquefied mash | Fermentation broth | Liquefied mash | DDGS | Liquefied mash | DDGS | ||

| Raw corn | 1074 ± 10.7 | 37.48 ± 1.9 | |||||

| A | 79.9 ± 1.1 | 12.8 ± 0.6 | 12.4 ± 0.1 | 357.7 ± 29.5 | 284.3 ± 16.7 | 314.4 ± 4.1 | 320.5 ± 8.9 |

| B | 72.7 ± 1.5 | 13.1 ± 0.2 | 10.5 ± 0.2 | 863.0 ± 10.8 | 816.7 ± 15.8 | 40.2 ± 1.2 | 54.4 ± 1.9 |

aSaccharification carried out in presence of A) Amylases + W. saturnus NCIM 3298 and B) Amylases only. Fermentation carried out using A) S. cerevisiae + W. saturnus NCIM 3298 and B) S. cerevisiae. p value < 0.05 (one-tailed t test); the values given are the average of three independent experiments

Phytate and free P content of raw corn were analysed following the procedure mentioned in “Analytical methods” and the values obtained were 1074 and 37.48 mg, respectively, per 100 g of raw corn (Table 5). The obtained phytate content in raw corn is comparable with that of the previously reported value (Hídvégi and Lásztity 2002). In the presence of cell-bound phytase, phytate content was reduced to 357.7 mg/100 g corn and 284.3 mg/100 g corn for liquefied mash and DDGS, respectively. In case of control, the phytate content reduced to 863 mg/100 g corn and 816.7 mg/100 g corn for liquefied mash and DDGS, respectively (Table 5). With two-step phytase treatment, we observed 67% phytate degradation during saccharification and 7% phytate degradation during fermentation. This indicates an overall decrease of 74% in phytate content in DDGS with phytase treatment, compared with the raw corn. Furthermore, phytase treatment resulted in 45% greater reduction in corn phytate as compared to control treatment, indicating that the use of DDGS might be favourable in poultry feed.

The application of cell-bound phytase during saccharification and fermentation resulted in an increased concentration of free P. Thus, it increased by 274.2 mg/100 g and 266.1 mg/100 g in liquefied mash and DDGS, respectively, as compared with the control with a free P content of 40.2 mg/100 g and 54.4 mg/100 g for liquefied mash and DDGS, respectively (Table 5). Thus, approximately six times more inorganic P was liberated in phytase-treated DDGS as compared with the control strain. This increased level of free P in DDGS with phytase treatment will minimize the addition of external P in poultry feed, which in turn can reduce the P burden in water bodies. Moreover, it also suggests that the inefficiency of the used S. cerevisiae strain for phytate degradation during the fermentation resulted in a low level of ethanol yield and inorganic P in DDGS. Fujita et al. (2001) reported that the inorganic P content in the medium influences the yeast growth and ethanol production. This could be the one of the reason for higher ethanol production in the phytase-containing treatment as compared with the control. Improved free P concentration in DDGS due to the phytase treatment of substrate has been demonstrated previously (Mikulski et al. 2014; Chen et al. 2016; Makolomakwa et al. 2017).

Conclusion

The present study describes media optimization using PBD for improved phytase production by W. saturnus NCIM 3298 and application of this phytase in ethanol production and animal feed. To the best of our knowledge, it is the first study on phytase production using citric acid-containing medium, which drastically improved the phytase production. Assessment of the phytase performance in the simultaneous saccharification and fermentation process demonstrated that phytase-displaying wild strain of yeast could be useful as a phytic acid-degrading agent in the processes of ethanol production by S. cerevisiae. An increase in phosphate concentration in the DDGS, which is brought about by hydrolysis of phytate during saccharification and fermentation, improved the feed quality of the DDGS. Importantly, the result obtained here suggests that cell-bound phytase of W. saturnus NCIM 3298 has the potential for improving ethanol production and DDGS quality by decreasing phytate content.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgements

This work was financially supported by Board of College and University Development (BCUD) Grant, Savitribai Phule Pune University (OSD/BCUD/360/14). Anupama Pable is thankful to the Department of Science and Technology, New Delhi, India for providing financial support for equipment facility at Department of Microbiology (under DST-PURSE program).

Compliance with ethical standards

Conflict of interest

The authors declare that they have no conflict of interest.

Contributor Information

Anupama A. Pable, Phone: + 91 020 25690643, Email: anupamapable@unipune.ac.in

V. Ravi Kumar, Email: v.ravikumar@ncl.res.in, https://www.researchgate.net/profile/V_Ravi_Kumar_Kumar

Jayant M. Khire, Email: jm.khire@ncl.res.in, https://www.researchgate.net/profile/Jayant_Khire

References

- Almeida FN, Stein HH. Effects of graded levels of microbial phytase on the standardized total tract digestibility of phosphorus in corn and corn coproducts fed to pigs. J Anim Sci. 2012;90:1262–1269. doi: 10.2527/jas.2011-4144. [DOI] [PubMed] [Google Scholar]

- Bitar K, Reinhold JG. Phytase and alkaline phosphatase activities in intestinal mucosae of rat, chicken, calf, and man. BBA-Enzymol. 1972;268:442–452. doi: 10.1016/0005-2744(72)90340-3. [DOI] [PubMed] [Google Scholar]

- Chen X. Yeast cell surface display: an efficient strategy for improvement of bioethanol fermentation performance. Bioengineered. 2017;8:115–119. doi: 10.1080/21655979.2016.1212135. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chen X, Xiao Y, Shen W, et al. Display of phytase on the cell surface of Saccharomyces cerevisiae to degrade phytate phosphorus and improve bioethanol production. Appl Microbiol Biotechnol. 2016;100:2449–2458. doi: 10.1007/s00253-015-7170-4. [DOI] [PubMed] [Google Scholar]

- Cowieson AJ, Hruby M, Pierson EEM. Evolving enzyme technology: impact on commercial poultry nutrition. Nutr Res Rev. 2006;19:90. doi: 10.1079/NRR2006121. [DOI] [PubMed] [Google Scholar]

- de Souza TPP, da Mariano SRM, Vieira MS, et al. Biofactories for the Production of recombinant phytases and their application in the animal feed industry. Recent Pat Biotechnol. 2018 doi: 10.2174/1872208311666170915161848. [DOI] [PubMed] [Google Scholar]

- Frühbeck G, Alonso R, Marzo F, Santidrián S. A modified method for the indirect quantitative analysis of phytate in foodstuffs. Anal Biochem. 1995;225:206–212. doi: 10.1006/abio.1995.1145. [DOI] [PubMed] [Google Scholar]

- Fujita J, Fukuda H, Yamane YI, Kizaki Y, Shigeta S, Ono K, Suzuki O, Wakabayashi S. Critical importance of phytase for yeast growth and alcohol fermentation in Japanese sake brewing. Biotechnol Lett. 2001;23:867–871. doi: 10.1023/A:1010599307395. [DOI] [Google Scholar]

- Greiner R, Konietzny U. Phytase for food application. Food Technol. Biotechnol. 2006;44:125–140. [Google Scholar]

- Heinonen JK, Lahti RJ. A new and convenient colorimetric determination of inorganic orthophosphate and its application to the assay of inorganic pyrophosphatase. Anal Biochem. 1981;113:313–317. doi: 10.1016/0003-2697(81)90082-8. [DOI] [PubMed] [Google Scholar]

- Hídvégi M, Lásztity R. Phytic acid content of cereals and legumes and interaction with proteins. Period Polytech Chem Eng. 2002;46:59–64. [Google Scholar]

- Kaur P, Satyanarayana T. Production of cell-bound phytase by Pichia anomala in an economical cane molasses medium: optimization using statistical tools. Process Biochem. 2005;40:3095–3102. doi: 10.1016/j.procbio.2005.03.059. [DOI] [Google Scholar]

- Khullar E, Shetty JK, Rausch KD, et al. Use of phytases in ethanol production from E-mill corn processing. Cereal Chem. 2011;88:223–227. doi: 10.1094/CCHEM-04-10-0058. [DOI] [Google Scholar]

- Konietzny U, Greiner R. Phytic acid: nutritional impact. In: Caballero B, Trugo L, Finglas P, editors. Encyclopaedia of food science and nutrition. 2. London: Elsevier; 2003. pp. 4555–4563. [Google Scholar]

- Latta M, Eskin M. A simple and rapid colorimetric method for phytate determination. J Agric Food Chem. 1980;28:1313–1315. doi: 10.1021/jf60232a049. [DOI] [Google Scholar]

- Liu SQ, Tsao M. Inhibition of spoilage yeasts in cheese by killer yeast W. saturnus var. saturnus. Int J Food Microbiol. 2009;131:280–282. doi: 10.1016/j.ijfoodmicro.2009.03.009. [DOI] [PubMed] [Google Scholar]

- Lu Y, Peh JCH, Lee PR, Liu SQ. Modulation of grape wine flavor via the sequential inoculation of W. saturnus and S. cerevisiae. Food Biotechnol. 2017;31:245–263. doi: 10.1080/08905436.2017.1369434. [DOI] [Google Scholar]

- Makolomakwa M, Puri AK, Permaul K, Singh S. Thermo-acid-stable phytase-mediated enhancement of bioethanol production using Colocasia esculenta. Bioresour Technol. 2017;235:396–404. doi: 10.1016/j.biortech.2017.03.157. [DOI] [PubMed] [Google Scholar]

- Menezes AGT, Ramos CL, Cenzi G, et al. Probiotic potential, antioxidant activity, and phytase production of indigenous yeasts isolated from indigenous fermented foods. Probiotics Antimicrob Proteins. 2019 doi: 10.1007/s12602-019-9518-z. [DOI] [PubMed] [Google Scholar]

- Mikulski D, Kłosowski G, Rolbiecka A. Effect of phytase application during high gravity (HG) maize mashes preparation on the availability of starch and yield of the ethanol fermentation Process. Appl Biochem Biotechnol. 2014;174:1455–1470. doi: 10.1007/s12010-014-1139-0. [DOI] [PubMed] [Google Scholar]

- Miller GL. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem. 1959;31:426–428. doi: 10.1021/ac60147a030. [DOI] [Google Scholar]

- Mullaney EJ, Daly CB, Ullah AH. Advances in phytase research. Adv Appl Microbiol. 2000;47:157–199. doi: 10.1016/S0065-2164(00)47004-8. [DOI] [PubMed] [Google Scholar]

- Nuobariene L, Hansen AS, Jespersen L, Arneborg N. Phytase-active yeasts from grain-based food and beer. J Appl Microbiol. 2011;110:1370–1380. doi: 10.1111/j.1365-2672.2011.04988.x. [DOI] [PubMed] [Google Scholar]

- Pable A, Gujar P, Khire JM. Selection of phytase producing yeast strains for improved mineral mobilization and dephytinization of chickpea flour. J Food Biochem. 2014;38:18–27. doi: 10.1111/jfbc.12020. [DOI] [Google Scholar]

- Pilone GJ. Determination of ethanol in wine by titrimetric and spectrophotometric dichromate methods: collaborative study. J Assoc Off Anal Chem. 1985;68:188–190. [PubMed] [Google Scholar]

- Plackett RL, Burman JP. The design of optimum multifactorial experiments. Biometrika. 1946;33:305. doi: 10.2307/2332195. [DOI] [Google Scholar]

- Quan C, Zhang L, Wang Y, Ohta Y. Production of phytase in a low phosphate medium by a novel yeast Candida krusei. J Biosci Bioeng. 2001;92:154–160. doi: 10.1263/jbb.92.154. [DOI] [PubMed] [Google Scholar]

- Querol Amparo, Fleet Graham., editors. Yeasts in Food and Beverages. Berlin, Heidelberg: Springer Berlin Heidelberg; 2006. [Google Scholar]

- Reddy NR, Sathe SK, Salunkhe DK. Phytates in legumes and cereals. Adv Food Res. 1982;28:1–92. doi: 10.1016/S0065-2628(08)60110-X. [DOI] [PubMed] [Google Scholar]

- Savita PD, Suvarna VC, Annu T, Balakrishna AN, Kanchanashri B, Yallappa M. Characterization and identification of phytate solubilizing yeasts isolated from food grains. Int J Curr Microbiol Appl Sci. 2017;6:1184–1192. doi: 10.20546/ijcmas.2017.604.145. [DOI] [Google Scholar]

- Schwarz G, Hoppe PP. Phytase enzyme to curb pollution from pigs and poultry. Feed Magazine. 1992;1:22–26. [Google Scholar]

- Shieh TR, Ware JH. Survey of microorganism for the production of extracellular phytase. Appl Microbiol. 1968;16:1348–1351. doi: 10.1128/am.16.9.1348-1351.1968. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Spier MR, Greiner R, Rodriguez-León JA, Woiciechowski AL, Pandey A, Soccol VT, Soccol CR. Phytase production using citric pulp in SSF. Food Technol Biotechnol. 2008;46:178–182. [Google Scholar]

- Taheripour F, Hertel TW, Tyner WE, et al. Biofuels and their by-products: global economic and environmental implications. Biomass Bioenerg. 2010;34:278–289. doi: 10.1016/j.biombioe.2009.10.017. [DOI] [Google Scholar]

- Vallejo-Hernández Laura Haydée, Rodríguez German Buendia, Elghandour Mona Mohamed Mohamed Yasseen, Greiner Ralf, Salem Abdelfattah Zeidan Mohamed, Adegbeye Moyosore Joseph. Influence of phytase enzyme on ruminal biogas production and fermentative digestion towards reducing environmental contamination. Environmental Science and Pollution Research. 2019;26(10):9992–9999. doi: 10.1007/s11356-019-04400-1. [DOI] [PubMed] [Google Scholar]

- Vats P, Banerjee UC. Studies on the production of phytase by a newly isolated strain of Aspergillus niger var teigham obtained from rotten wood-logs. Process Biochem. 2002;38:211–217. doi: 10.1016/S0032-9592(02)00079-1. [DOI] [Google Scholar]

- Vohra A, Satyanarayana T. Phytase production by the yeast, Pichia anomala. Biotechnol Lett. 2001;23:551–554. doi: 10.1023/A:1010314114053. [DOI] [Google Scholar]

- Wang Z, Cerrate S, Coto C, et al. Use of constant or increasing levels of distillers dried grains with solubles (DDGS) in broiler diets. Int J Poult Sci. 2007;6:501–507. doi: 10.3923/ijps.2007.501.507. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.