Abstract

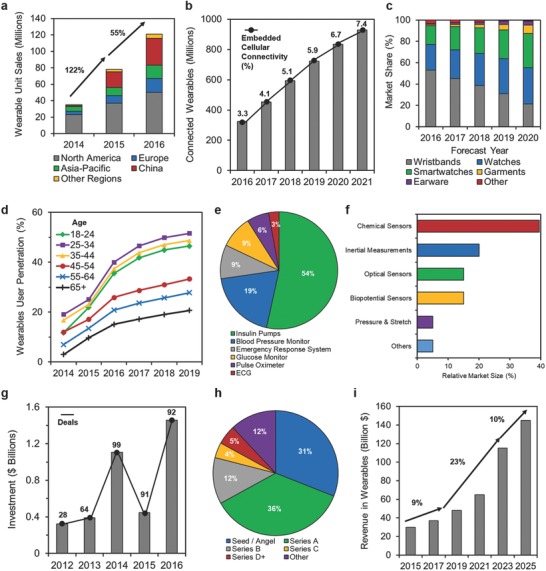

Wearables as medical technologies are becoming an integral part of personal analytics, measuring physical status, recording physiological parameters, or informing schedule for medication. These continuously evolving technology platforms do not only promise to help people pursue a healthier life style, but also provide continuous medical data for actively tracking metabolic status, diagnosis, and treatment. Advances in the miniaturization of flexible electronics, electrochemical biosensors, microfluidics, and artificial intelligence algorithms have led to wearable devices that can generate real‐time medical data within the Internet of things. These flexible devices can be configured to make conformal contact with epidermal, ocular, intracochlear, and dental interfaces to collect biochemical or electrophysiological signals. This article discusses consumer trends in wearable electronics, commercial and emerging devices, and fabrication methods. It also reviews real‐time monitoring of vital signs using biosensors, stimuli‐responsive materials for drug delivery, and closed‐loop theranostic systems. It covers future challenges in augmented, virtual, and mixed reality, communication modes, energy management, displays, conformity, and data safety. The development of patient‐oriented wearable technologies and their incorporation in randomized clinical trials will facilitate the design of safe and effective approaches.

Keywords: biosensors, diagnostics, drug delivery, personalized medicine, telemedicine

1. The Rise of Personalized Medicine

The “quantified self” movement is the driving force behind wearable technologies involving acquisition of data on daily activities, sport performance, and health status.1 In combination with value‐based healthcare systems through telehealth, wearable devices can enable monitoring at risk patients, intervening diseases at an earlier stage, and reducing healthcare expenditures by means of prediction and prevention of disease.2 These wearable technologies include smartwatches, wristbands, hearing aids, electronic/optical tattoos, head‐mounted displays, subcutaneous sensors, electronic footwear, and electronic textiles (Figure 1 a). They can be conformably placed on the epidermis, inserted through the skin or body orifices for measuring electrophysiological or biochemical signals, and delivering drugs.3 Such technologies when incorporated in garments, accessories, or epidermal surface to provide electronic alerts, sense physical and biochemical information, or deliver drugs are broadly called medical wearables.4, 5

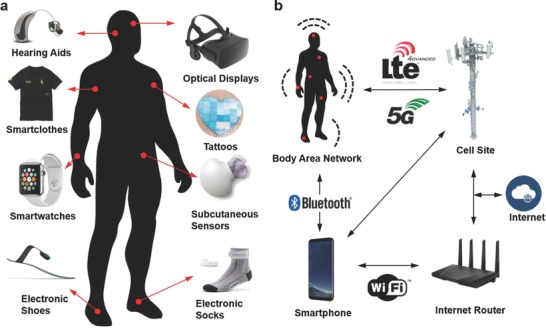

Figure 1.

Wearables devices for medical applications. a) Wearable devices (in vitro) have loose or conformal contact with the skin, or worn/inserted through body orifices. The most common interface is loose skin contact wearables, which measure electrophysiological signal via optics and electrodes. b) Information transfer from wearables. The data collected from wearable devices can be transmitted to the Internet or other devices via a body area network, Bluetooth, Wi‐Fi, LTE, 3G, 4G, or 5G connection. The medical data can be sent to a healthcare provider to receive therapeutic feedback or acted upon automatically by other devices in the network.

Wearable devices have the potential to offer features such as augmented, virtual, and mixed reality, artificial intelligence, and pattern recognition.6, 7, 8 These ubiquitous computing technologies typically contain microprocessors, sensors, and smartphone interfaces including wireless data communications to record medical data in real‐time and exchange information with other devices and/or centralized databases.9 Sensors integrated in wearable devices include inertial measurement units (gyroscopes, accelerometers, barometers, magnetometers), optical sensors (complementary metal–oxide–semiconductor (CMOS) sensors, spectrophotometers, cameras, photoplethysmogram), chemical probes, electrodes, temperature sensors, microphones, shock detectors, strain gauges, and pressure sensors.10 Multiple arrays of sensors enable obtaining data from multiple wearable devices and routing to a body area network.11 This body area network can transmit the medical data to the Internet through Bluetooth, Wi‐Fi LTE, 3G, 4G, or 5G connection for further analyses or feedback from a healthcare provider (Figure 1b). The capability of wearable devices, smartphones, and wireless communication devices to interoperate in a network infrastructure of connected devices constitutes Internet of things (IoT).12 Within this scheme, the medical data can be acted upon within the network or sent to emergency services, medical databases or physician's office to obtain therapeutic feedback about the health status.13 The diagnostic information collected from a sensor or an array of sensors can be connected, for example, to a drug delivery system to administer a precise dosage of a medication, or an assistive technology for impaired mobility.

1.1. Sensory Information in Wearables

Wearable devices integrated with electronic and optical biosensors can provide real‐time data about the electrophysiological or biochemical status of a patient at point‐of‐care settings or in the clinic. Such biosensors can be embedded in electronic tattoos/stamps, patches, prosthetics, textiles, wristbands, and contact lenses to form conformal contact with biological tissue or bodily fluids. These biosensors may be wirelessly powered or run via lightweight batteries that can be seamlessly integrated in wearable devices. Physical and biochemical data can be wirelessly transmitted to the patient or another wearable device for achieving closed‐loop therapeutic systems.

1.1.1. Close‐Contact Wearables

Conformable mounting of a wearable device on the human skin requires compatibility between the mechanical properties of the compliant wearable device substrate and the stiff surface. Understanding the mechanophysiology at the interface of the wearable device and epidermis is critical in wearable device design, which should adhere to strict design guidelines for the selection of materials and the geometry of the patterns to prevent device failure. The surface of the skin consists of features having 10–1000 µm height and it can be assumed to be a bilayer structure: the epidermis (thickness = 0.05–1.50 mm, Young's modulus = 140–600 kPa) and the dermis (thickness = 0.3–3.0 mm, Young's modulus = 2–80 kPa).14 This skin bilayer is linearly elastic for tensile strain values < 15% and enters plastic deformation above 30%. Hence, the mechanical properties of the device materials such as Young's modulus and bending stiffness must be compatible with the mechanical properties of the skin. Elastomers having low Young's modulus (50–100 kPa) are preferred in the fabrication of wearable devices. If the device contains standard electronic components having silicon (160 GPa) or gallium arsenide (90 GPa), the effective moduli can be within the range of 100–150 kPa.15 Wearable devices may have a bending stiffness within the range of 1–10 nN m. Low effective moduli and thin devices are ideal to prevent interfacial cracks and interface delamination from the skin. The effective modulus of a close‐contact wearable device can be calculated by approximating the substrate, sensing units, and interconnects. The effective modulus can be approximated as E eff = E connect (1 + L d L s −1), where E connect is the effective modulus of the interconnects, L d is the characteristic wearable device size, and L s is the distance between sensing units or components.15 These devices maybe mounted to the skin using a polyvinyl alcohol film support (thickness = 50 µm, Young's modulus ≈1.9 GPa).

Tattoo‐like films and patches placed over the skin have been utilized as temperature, electrophysiological, and strain sensors (Figure 2 a).15 Electrical components were constructed on a ≈30 µm gas permeable silicone sheet having low Young's modulus (≈60 kPa) similar to that of the human skin. The elements of the electronic tattoo consisted of conventional semiconductor materials including silicon, gallium arsenide, which were patterned as serpentine ribbons in microscale geometries. The wearable device was elastic under strain deformations having effective moduli of less than 150 kPa and bending stiffness of 1 nN m, thus allowing for it to be mounted on the skin via a temporary support polyvinyl alcohol film. Surface tension forces facilitated the adhesion of the wearable device to the skin having 20% areal contact of electronic components with the skin to establish an electrical interface. These tattoos could incorporate different components including capacitors, light‐emitting diodes (LEDs), transistors, radio frequency inductors, photodetectors, rectifying diodes, and oscillators. Moreover, electronic tattoo electrocardiograms (ECG) distinguished phases of heartbeats such as depolarization of the cardiac wave, and associated QRS waves in an ECG. Other uses of electronic tattoos are noninvasive electromyogram recording on the throat for recognized vocalization of different words.15

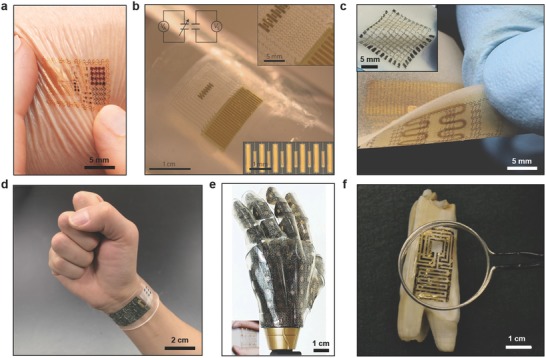

Figure 2.

Applications of wearable devices. a) Electronic tattoos conformally attached to the skin via van der Waals forces. Reproduced with permission.15 Copyright 2011, American Association for the Advancement of Science. b) A compliant modulus sensor comprising nanoribbons of lead zirconate titanate in arrays of mechanical actuators and sensors. The upper and lower insets show the interconnected array and actuator/sensing regions. Reproduced with permission.16 Copyright 2015, Nature Publishing Group. c) A wearable device that can monitor muscle activity, store data, and wirelessly communicate data closed‐loop therapy. The inset shows a wearable RAM array (10 × 10) on the patch. Reproduced with permission.19 Copyright 2014, Nature Publishing Group. d) A wearable wristband consisting of electrochemical sensors for the quantification of concentrations of glucose, lactate, electrolytes (Na+, K+ ions), and temperature for application in real‐time perspiration analysis. Reproduced with permission.28 Copyright 2016, Nature Publishing Group. e) Prosthetic skin featuring pressure, strain, humidity and temperature sensors, as well as electroresistive heaters for creating a skin‐like perception. The inset shows the prosthetic skin under ≈20% strain. Reproduced with permission.32 Copyright 2014, Nature Publishing Group. f) A antimicrobial peptide‐functionalized graphene sensor on a tooth for wireless detection of bacteria. Reproduced with permission.47 Copyright 2012, Nature Publishing Group.

Wearable piezoelectric tattoos have been fabricated to measure soft tissue viscoelasticity over epidermis (Figure 2b).16 A device was constructed from stretchable networks of mechanical actuators, and nanoribbon sensors containing lead zirconate titanate. The device incorporated capacitor‐type components including various piezoelectric layers, which were fabricated on elastomers (20 µm) to achieve stretchable mechanics. Lamination of the wearable piezoelectric actuator–sensor devices allowed for forming conformal contact with soft biological tissues via van der Waals forces, where the bending stiffness per sensor width was 4.5 × 10−8 N m. Cycles of stretching over 1000 times showed no delamination of the sensors from the substrate. Measurements of the localized skin properties over lesion sites showed higher modulus (≈6 mPa) than normal skin regions (≈5 mPa) in patients. The wearable device shaped as a protractor allowed quantitatively measuring viscoelastic moduli with spatial mapping for potential applications in the dermatological examination of basal ganglia carcinoma, fibroepithelial polyp, and histiocytoma.16 In another study, conformal epidermal sensors were designed for strain detection.17 The sensor consisted of LC resonators with capacitive electrodes that responded to variation in skin mechanics. Changes in the LC resonance frequencies were detected by monitoring the absorption of the coil electromagnetic energy, which was linked to an impedance detection device. The device had a resolution of 1.3% in strain detection. This sensor may allow monitoring the mechanical properties of the skin (e.g., lymphedema).17

Commercial integrated circuits and hardware can be incorporated in flexible polymer layers. Interconnected assemblies of chips have been created by microfluidic suspension in silicone elastomeric enclosures.18 In this assembly, each component was attached to the bottom surface of the enclosure through localized support posts. The electronic components were suspended in a surrounding dielectric fluid to isolate them mechanically. These components were joint to each other via serpentine‐shaped interconnects. The constructed system had the capability of acquisition, filtering, low‐noise amplification, and frequency‐modulated RF transmission of electrophysiological data. The resulting assembly could be stretched (≈30% uniaxial strain) and twisted (≈75%). The final device was laminated over the skin to create a sensory interface. Lamination of the device over the sternum enabled wireless collection of ECG (≈2.4 GHz) at distances up to 1 m. Q, R, and S waveforms were identified with low signal‐to‐noise values as compared to the commercial hardware.18

A wearable drug‐delivery device featuring silicon nanomembrane strain sensors, a temperature sensor, a resistive random access memory (RAM) array, and electroresistive heaters has been developed (Figure 2c).19 The RAM was formed by depositing TiO2 membranes within interstitial gold nanoparticle layers assembled via Langmuir–Blodgett process. A key concept of this wearable technology was energy‐efficient RAM due to the incorporation of gold nanoparticles to extend usage time. The constructed RAM operated at 100 µA, where the data was readable over 100 operations. The RAM did not have significant signal drift post 1000 stretching cycles at ≈30% strain. The sensors were used to monitor the tension and compression cycles on a wrist for potential application in detecting tremor frequencies in Parkinson's disease and epilepsy.19 The device was able to log data in different memory cells in every 10 s and the data was read in every 0.5 s. The capability to store data was used to trigger and control drug release. The drug delivery unit was created by forming m‐silica nanoparticles loaded with therapeutic compounds on a polymeric hydrocolloid membrane. An electroresistive heating unit was utilized to transdermally deliver drugs as well as serving as a temperature sensor. As the heat increased in the wearable device, the physical bonding between the nanoparticles and the drug degraded to diffuse the drug transdermally.19 This demonstrated wearable device was not wireless; hence, the integration of built‐in microprocessors, wireless communication, and energy transfer/storage units will lead to practical feedback‐based wearable devices.

Tattoo‐based wearables integrating optical sensors have been utilized as indicators for UV radiation exposure. Solar radiation is a risk factor for the major skin cancer forms including cutaneous melanoma and carcinomas (basal and squamous cells).20 Hence, the development of wearable sensors is highly desirable for determining the amount of UV exposure to develop awareness about the application of sun screens. La Roche‐Posay (L'Oreal) has recently commercialized a water‐resistant stretchable skin sensor to monitor UV exposure to the skin.21 Under the UV exposure, the photosensitive dyes within the 100 µm thick patch change color, which can be read with a smartphone camera.22 The patch is air‐permeable and can be worn up to 3 d.

A wearable tattoo‐based sensor was developed to monitor alcohol in sweat.23 The device had an iontophoretic‐biosensor along with a flexible electronics unit. Wearables could be a convenient technology to monitor alcohol intake to prevent unsafe drinking. Alcohol consumption results in 3.3 million deaths globally,24 and in the United States, ≈25 000 people die each year due to drunk driving.25 This device uses sweat secreted by the transdermal delivery of the pilocarpine via iontophoresis. Ethanol was amperometrically measured using a Prussian Blue electrode transducer comprising alcohol oxidase enzyme. The sensor detected blood alcohol concentration within the range of 0.001–0.062%. However, variation in skin permeability and sweat composition limits the practical use of this wearable device. Moreover, a startup company (BACtrack) has designed a wearable sensor that measures the blood alcohol content (BAC) from sweat.26 A lag time of ≈45 min was recorded for the alcohol to be present in sweat; hence, this wearable device measures a person's recent history of drinking habits. Another wearable device that can track alcohol is PROOF, which utilizes an enzymatic electrochemical sensor to measure perspired alcohol concentration.27 The cartridge of the sensor can be used for continuous measurements of alcohol over 12 h.

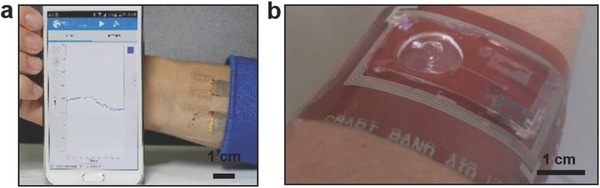

Noninvasively monitoring a patient's health status at the molecular level is the key in advancing the applications of wearables. A wearable device that can be worn on wrists or arms has been developed for application in wireless perspiration analysis (Figure 2d).28 The device comprised of multiplexed electrochemical sensors on a flexible circuit board for quantitatively monitoring electrolytes and metabolites in sweat. To realize the device, signal transduction, signal amplification, calibration, and wireless data transfer have been integrated within one chip. Glucose and lactate oxidase were immobilized within a chitosan substrate and Ag/AgCl conductor was used as reference counter electrodes. Amperometric detection was used as sensing units within a chitosan film. Prussian blue was used as a mediator to decrease the reduction potentials and activated the sensors without an external power source. Electrolytes were measured with ion‐selective electrochemical electrodes, where poly(3,4‐ethylenedioxythiophene)–poly(styrenesulfonate) performed as an ion‐to‐electron transducer, and CNTs were incorporated within the polyvinyl butyral reference membrane for continuous measurements.29 Furthermore, a microcontroller embedded in the wearable device calibrated and compensated the signal drift of the sensors. The data was communicated to a handheld device via on‐board wireless transceiver and Bluetooth connection. The concentrations of monovalent metal ions (Na+ and K+) as well as glucose and lactate were continuously monitored in a human subject while exercising with a constant load. Although the sweat concentrations of glucose, K+ ions and lactate decreased during exercise, sweat Na+ ion concentration increased.28 These changes might be attributed to the dilution of analyte concentrations. The wearable device was also utilized to determine dehydration status of a group of subjects during a prolonged outdoor running trial. Recently, a wearable patch that integrates biochemical analysis and electrophysiological signals has been fabricated.30 By incorporating a three‐electrode amperometric biosensor and a bipolar electrocardiogram sensor on a flexible polyester sheet, real‐time measurements of lactate and heart function was achieved. The wearable patch transferred the monitored signals to a mobile device by Bluetooth low‐energy. Additionally, epidermal patches that can measure pH have been developed for application in the assessment of the wound healing.31 Mesoporous microparticles have been functionalized with pH‐sensitive dyes. The electrostatic interactions between the mesoporous structure and the pH‐sensitive dye prevented dye leakage. These particles have been loaded to alginate microfibers via a microfluidic spinning system. The microfibers created conformal contact with the skin and they were able to measure pH within the range of 5.5–7.5.

Challenges exist in the material selection to maintain the conformal contact with the skin. For example, dead cell efflux through the skin may interfere with the measurement data. Another challenge that limits the adoption of electronic tattoos is that long time‐wear over the skin may cause ‘irritant' dermatitis. One potential direction in the development of electronic tattoos is the use of surgical‐grade stainless steel and its alloys that can provide high hypoallergenic features.

1.1.2. Wearables over the Body

The development of electronic prosthetics can allow for sensor‐laden bionic systems having spatiotemporal resolution. An electronic prosthetic skin has been created to incorporate single crystalline silicon nanoribbon pressure, strain, temperature, humidity sensors, and electroresistive heating units for nerve stimulation (Figure 2e).32 The sensors were organized in isolated layers and the device mechanically coupled on curvilinear surfaces. This three‐layer artificial skin had localized perception in response to external stimuli to act as a peripheral nervous system interface. The bottom layer of the electronic skin had electroresistive filamentary heating units on a polydimethylsiloxane (PDMS) substrate. The middle layer had temperature, pressure, and strain sensors organized in linear and serpentine patterns. The top layer contained a humidity sensor array comprising coplanar capacitors. Each layer had interconnections to an external microprocessor. The capability of the device to function as a prosthetic skin was tested in different scenarios. For example, the prosthetic skin can map spatiotemporal strain, detect temperature changes (0–65 °C), and measure the humidity level of an object. Additionally, the signals from the prosthetic skin were transmitted to the corresponding peripheral nervous system in a rat model. To create a skin‐nerve interface, multielectrode arrays were coated with platinum nanowires, where ceria nanoparticles were adsorbed to scavenge reactive oxygen species to potentially prevent inflammation. Electrophysiological signals originating from the ventral posterolateral nucleus revealed that the pressure sensor response resulted in synchronized spikes, showing electrical signal transmission to the central nervous system.32 A limitation of this system includes the entrance of fractured platinum nanoparticles into the bloodstream and the role of ceria nanoparticles in the inflammation suppression was unclear. Recently, tactile pressure sensors have been developed in the form of active‐matrix arrays consisting of pressure‐sensitive graphene transistors with air–dielectric layers.33 These tactile sensors allowed detecting a broad pressure range from 250 Pa to 3 MPa.

1.1.3. Textile‐Based Wearables

Sensors have been incorporated into fabrics to create textile‐based diagnostic devices. The electrodes were sawn into textiles using a computerized embroidery machine in customized geometries.34 These embroidered electrochemical sensors have been used for quantitative analysis in biofluids. Glucose and lactate oxidase were immobilized on conductive Ag/AgCl‐coated treads to create these flexible sensors on textiles. As the concentration of glucose was increased from zero to 40 mmol L−1 in blood, the current through the embroidered electrodes shifted 0.9 mA.34 Additionally, lactate oxidase electrodes that underwent 100 cycles of bending (90°) showed negligible difference in the sensor readouts. In another study, polyurethane‐based ion‐selective membranes were integrated with textile‐based potentiometric sensors to create stretchable diagnostic devices.35 The polyurethane membrane and carbon nanotube (CNT) ink was combined with a platinum‐catalyzed silicone film having Ag/AgCl ink and a reference electrode for the quantification Na+ and K+ ions. A wireless high‐input impedance voltmeter was used to transfer real‐time measurement data to a tablet computer with an iOS application. Na+ and K+ ion selective electrodes showed a limit of detection of ≈10−5 m.35 Other sensors integrated within textiles have been utilized for physiological monitoring such as respiration,36 heart rate,37 and temperature measurements.38

1.1.4. Electronic Footwear

The analysis of human walking patterns is required to correct abnormal gaits. An electronic shoe‐based gait monitoring device has been developed to monitor patients with walking problems.39 To measure ground contact forces, continuous pressure transducers were utilized with a fuzzy logic algorithm. This algorithm allows the detection of abnormal foot pressure patterns that do not follow natural sequence of gait phases. In another study, electronic shoes have been designed to monitor human motion and body posture.40 A mobile 3D motion capture in combination with inertial sensors and electronic shoes was devised to enable diagnosis and analysis of abnormal postures. The measurements of ground reaction forces obtained from the electronic shoes are converted to quaternion in order to prevent gimbal lock. These electronic devices can be configured to harvest energy to power a Bluetooth step counter system.41 Such a system may consist of a magnetoinductive transducer for power conditioning to utilize the energy recovery as the shoe impacted on the ground. The energy harvester in the shoe involved exploiting pulse width modulation for performing transducer output ratification and emulating optimal load impedance and charging a storage capacitor. In a typical foot step, the mean energy recovery was 644 µJ. In another study, electronic shoes have been utilized to assess the walking ability of elderly patients with lumbar spinal stenosis.42 The electronic shoes had an array of sensors to measure lateral plantar pressure, heel‐strike, and toe pressure with spatiotemporal resolution. These sensors acquired real‐time data at 80 Hz and transmitted this information to a computer via the IEEE 802.15.4 standard. The Oswestry disability index was estimated in a 10 min self‐paced walking test and machine learning algorithms were employed.

Electronic socks have also been developed to monitor vital functions in the body. In one such study, piezoresistive pressure sensors were knitted in a sock to wirelessly measure gate and plantar pressure up to 500 kPa.43 The data allowed evaluating running and walking modes of asymptomatic and flat foot. In another study, electronic socks were utilized to prevent pressure‐induced foot ulcers in diabetic patients.44 The socks consisted of cotton, polyamide, silver‐coated cotton, and piezoresistive fibers. Silver‐coated fibers knitted to piezoresistive fibers collected and transmitted an electrical signal, which was correlated with pressure values. The real‐time data was stored in a centralized serial memory and sent to a computer wirelessly via Bluetooth. In another study, foot motion was monitored with electronic socks comprising flexible conductive polymers on an elastic textile.45 When the socks were subject to strain, the resistance of the conductive polymers were changed. These sensors were utilized to measure foot motion patterns at joint locations. Dynamic input strain was tracked up to 4 Hz. The sensors allowed distinguishing motion around metatarsophalangeal and ankle joints during dorsiflexion. Recently, an electronic shoe consisting of textile sensors connected to a low energy local area Bluetooth beacon has been used to improve athletic performance by optimizing the biomechanics of running.46

1.1.5. In Vivo Interface Wearables

Wearable electronic films have been incorporated over the surface of tooth enamel (Figure 2f).47 A graphene layer was printed onto water soluble silk allowing for self‐assembly of antimicrobial peptides for bacteria detection in saliva. The device also featured a resonant coil for wireless detection of H. pylori, which causes 90% of stomach cancers and duodenal ulcers.48 The wireless query operation was achieved by a parallel resonant circuit having a gold‐coated meander line inductor as well as capacitive electrodes. The resistance change was wirelessly monitored as a function of the concentration of bacteria present in saliva. The in vitro studies showed a correlation between bacteria concentration logarithm and variation in resistance showing a detection limit of ≈100 cells.47

Ocular diagnostic devices have undergone rapid development over the last decade.49 Intraocular pressure can be monitored though measuring the forces acting on the contact lenses to manage glaucoma. To measure intraocular pressure, capacitive,50 piezo‐resistive,51 mechanical strain gauge,52 and microinductor53 sensors have been developed. Sensimed AG has introduced a contact lens sensor (Triggerfish) that holds Class IIa CE approval.54 The sensor comprised Pt–Ti strain gauges for measuring the dimensional changes over corneoscleral junction for estimating intraocular pressure. An external wearable device attached to the waist of the patient wirelessly powered the Triggerfish contact lens while it received wireless readouts. This contact lens sensor provided readouts up to 288 measurements within 24 h. However, wearing Triggerfish contact lenses produces physiological irregularities as compared to conventional contact lenses, resulting in low oxygen transmissibility to the cornea and altering intraocular pressure measurements.55 Another limitation of Triggerfish is that the readouts are in arbitrary units, hence the clinical interpretation of the results are challenging.56

The prospect to use contact lenses to quantify tear fluid composition through smartphones or a wearable device has generated interest from Verily, Microsoft, and Novartis.49 Blood and tear fluid have a compositional difference due to the blood–tear barrier; however, the concentrations of analytes in both fluids have a relationship as a result of plasma leakage.57 Their correlation allows using tears as a surrogate for the continuous measurements of blood chemistry.58 Contact lenses have been functionalized with electronics and photonic crystals to report on the concentrations of analytes in tear fluid.59 Detection approaches including electrochemical, fluorescence, and photonic crystal probes have been integrated in contact lenses for the continuous monitoring of analytes in tears. Miniaturized electrochemical sensors featuring 3‐electrode systems were coupled with enzymatic reactions for the quantitative measurements in contact lenses.60 Such contact lens sensors could be powered by near‐field inductive coupling.61 An electrochemical sensor incorporating glucose oxidase enzyme was tested in rabbits.62 The contact lens sensor tracked the tear fluid glucose concentration ((0.03–5.00) × 10−3 m), which had a 10 min delay time depending on blood glucose. The utilization of gold electrodes featuring 3D pillars increased the surface area (300%) as compared to 2D geometries to achieve a sensitivity of 40 × 10−6 m in vivo.63 Electronic contact lenses may be configured to provide quantitative or semiquantitative readouts wirelessly or using an LED display. For example, based on the concentration of the glucose, the intensity of an LED embedded in the contact lens can change, where the light output can be quantified using a smartphone camera. Similarly, for semiquantitative applications, for example, when the glucose concentration in tears decreases below 0.9 mmol L−1 (threshold value), and the LED in the contact lens can be turned on or off.64 Other electrochemical sensors embedded in contact lenses were utilized to quantify lactate concentration in 35 s with 53 µA mm −1 resolution.65

Optical sensors including fluorescence probes have been also investigated. Glucose concentration in tear fluid was measured by hydrogel‐coated nanospheres comprising tetramethylrhodamine isothiocyanate concanavalin A and fluorescein isothiocyanate dextran in contact lenses.66 These fluorescence probes allowed monitoring tear glucose concentration in a diabetic human patient over 3 h. A photofluorometer via a telemetry transmitter was utilized to send the readouts to an insulin pump.67 Additionally, crystalline colloidal arrays and holographic sensors have been incorporated into contact lenses to continuously sense glucose using phenylboronic acid derivatives in hydrogels.68 These sensors can be fabricated by exposing a photosensitized hydrogel matrix to laser light interference in Denisyuk holography mode, or self‐assembly of highly charged monodispersed spheres that form close‐packed crystalline arrays in hydrogels via electrostatic repulsion.69 Phenylboronic acids form reversible covalent bonds with glucose molecules.70 As the concentration of the glucose increases, the phenylboronic acid functionalized hydrogel swells due to Donnan osmotic pressure changes.71 Hence, changes in the hydrogel volume results in diffracted Bragg peak shifts, which can be used as an optical transducer to report on glucose concentration in tears.72 These reversible optical sensors can quantify a wide range of analytes including pH,73 metal ions,74 carbohydrates,75 and alcohol,76 as well as temperature.77 Such photonic devices may be also printed in 2.5D format on flexible substrates to sense humidity and glycerol.78 Bioinspired optical nanostructures may be also incorporated in contact lenses for application in real‐time sensing.79

Microfluidic contact lenses have been fabricated by laser ablation and fiber templating. A microlithography method has been developed to create microconcavities and microchannels in contact lenses.80 The microfluidic channel diameters ranged from 100 to 150 µm and their stability properties were evaluated by flow testing of artificial fluid. Microfluidic contact lenses were also functionalized with fluorophores to demonstrate their optical emission capabilities in the visible spectrum. Microfluidic contact lenses may allow sampling tear fluid for multiplexed sensing in vivo and they may simultaneously deliver drugs to the eye.80

The capability to monitor glucose concentration in interstitial fluid as a surrogate for blood chemistry allows preventing hypoglycemic episodes and tightly controlling the glucose concentration throughout the day.81 Real‐time monitoring of glucose in conjunction with automated insulin pumps lowers the glycated hemoglobin (HbA1c) level, which is an indicator for glycemic control.82 Continuous glucose monitoring systems utilize minimally invasive subcutaneous sensors to measure glucose concentration in interstitial fluid via electrochemistry.83 Such glucose sensors can communicate with insulin pumps to create a closed‐loop feedback to control the concentration of the glucose in blood (normal: 4.2–6.4 mmol L−1, diabetics: >7.0 mmol L−1). Commercial continuous glucose monitoring systems include Guardian REAL‐Time (Medtronic), SEVEN Plus/G4 (Dexcom), FreeStyle Navigator (Abbott), HG1‐c (C8 Medisensors), and GlucoTrackT (GlucoTrack). The electrochemical sensor probes (length = 9–14 mm) are subcutaneously inserted into the interstitial fluid at 45° from skin normal. Recently, new interfaces and connectivity options have been introduced to continuous glucose monitoring systems. For example, G5 Mobile CGM System (Dexcom) offers real‐time glucose monitoring that can be monitored through a smartphone, tablet computer, or smartwatch via Bluetooth. The smartphone application sends audio alerts to the patient when the concentration of the glucose in interstitial fluid is low or high. The information can also be displayed on Apple Watch and Fitbit smartwatch. The development of smartwatch applications triggered open‐source projects (e.g., NightScout movement), in which patients develop their own medical applications to access their continuous glucose measurement data using AndroidWear.84 The readout data can be monitored by others or shared with healthcare professionals. Apple health kit, for example, was developed in response to these requirements of connecting devices for gathering medical data in a secure environment, and under complete transparency for healthcare professionals and regulatory authorities; and used in wearable glucose monitoring trials.85

1.2. Limitations in Existing Sensing Technologies

Electrochemical sensors degrade in vivo due to biofouling, which requires replacement every 3–4 d.86 These electrochemical sensors, typically used for the management of diabetes, are intrinsically prone to drift in vivo; hence they require frequent calibration with finger prick blood tests. The measurement of glucose concentration in interstitial fluid is associated with a lag time as compared to blood glucose. Limitations of these wearable glucose sensors apply to all types of electrochemical sensors and include (i) frequent calibration of the sensor, (ii) sensor readout drift due to biofouling, (iii) biweekly sensor replacement, and (iv) relatively high cost. Other well‐known sensors in wearables include heart rate monitors, thermometers, and accelerometers. These types of sensors have been fully characterized and work seamlessly; however, the amount of signal processing and data processing required to for healthcare applications is large and requires continuous operation and energy supply.

1.3. Next Generation Sensors

Power‐efficient sensors are increasingly gaining significance in wearables. Recently, a low‐power temperature sensor was developed based on complementary temperature dependencies of n‐ and p‐type metal‐oxide‐semiconductor field effect transistors in the subthreshold region.87 Tunneling currents and a capacitive charging‐time‐to‐digital feedback allowed digitizing the temperature at 113 pW, operating from 10 to 60 °C.87 Such individual sensors can be interconnected within wearable body area networks.88

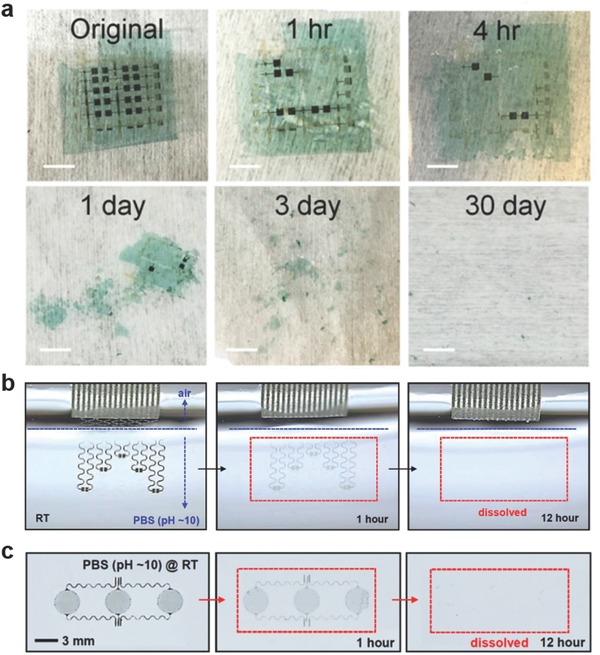

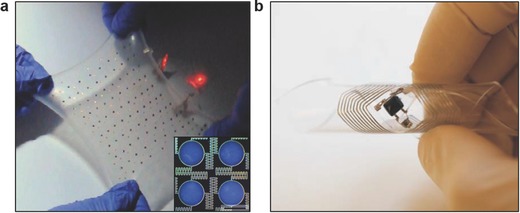

Transient technology is an emerging field and it refers to a group of devices that dissolve over a period of operation.89 This may allow practical disposability properties at point‐of‐care settings. After the exposure of the transient device to a stimulus, the functionality of the device is controllably terminated in a specific period of time. The applications of these transient devices have been realized in bioelectronics, environmental monitoring, and energy harvesting. The transient behavior of such devices can be initiated primarily by aqueous solutions, but also at a lesser extent with light, temperature, or mechanical forces. The main substrate building blocks may consist of water‐soluble polymers such as polyvinylpyrrolidone (PVP), poly(vinyl alcohol), polylactic acid, polylacticcoglycolic acid (PLGA), and polycaprolactone (PCL). In transient electronic devices, magnesium (Mg), zinc (Zn), iron (Fe), tungsten (W), and molybdenum (Mo) have been explored as degradable conductive materials. Recently, a transient material based pseudo‐CMOS was demonstrated.90 The 800 nm thin device consisted of a degradable cellulose substrate and iron electrodes with thermal and chemical stability to achieve and operating voltage of 4 V (Figure 3 a). In a recent study, transient materials have been developed for pH and electrophysiological sensing (Figure 3b,c).91 A capacitive electrophysiological sensor was connected to a preamplifier having low‐input capacitance and high‐input impedance. Near‐unity gain was achieved in the preamplifier enabling electrophysiological measurements via a SiO2 insulation layer. The amplifier and filter units of this transient device provided tunable gain from 60 to 80 dB for electrocardiogram and electromyogram measurements, where the results were comparable to conventional gel‐based electrodes.

Figure 3.

Transient electronics. a) Disintegrable electronics comprising iron as electrodes at various stages of disintegration in a pH 4.6 buffer solution (scale bars = 5 mm). Reproduced with permission.90 Copyright 2017, United States National Academy of Sciences. b) A biodegradable pH sensor based on doped silicon nanoribbons (Si NRs) at different stages of dissolution while submerged in PBS (pH 10) at 24 °C. Reproduced with permission.91 Copyright 2015, United States National Academy of Sciences. c) Capacitive biodegradable electrophysiological sensors and their dissolution in PBS (pH 10) at 24 °C. Reproduced with permission.91 Copyright 2015, United States National Academy of Sciences.

A biodegradable electronic patch integrated with flexible heaters was developed to deliver drugs on demand.92 This thermally‐controllable patch allowed administering antibiotics. A blend of poly(glycerol sebacate)‐PCL was synthesized and electrospun to create elastic sheets (tensile modulus = 4–8 MPa), where the fiber diameters ranged from 350 to 1100 nm. A metallic heater was deposited on the elastic sheet, which released antibiotics upon thermal stimulation. In vitro studies showed that the patch successfully released cefazolin in agar plates inoculated with Staphylococcus aureus and E. coli. Wound patches (1.5 cm in diameter) having heaters resulted in a zone of inhibition up to 1.0 cm over 24 h as compared to control samples without a heater.92

2. Utilization of Wearables Sensory Data

2.1. Management of Wearables Data

2.1.1. Data Storage and Communication

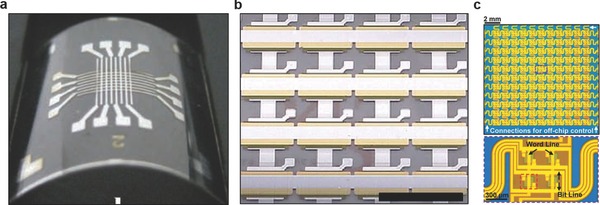

Commercial solid‐state, nonvolatile flash memories are based on rigid silicon data storage units. In this scheme, the data is first converted into a charge level and stored in floating gates.93 Recent advances in the memory development focused on improving flexibility and stretchability, which are required in medical wearables. Flexible NOR type resistive random‐access memories having one transistor–one memristor (1T–1M) structure have been developed.94 These memory cells were created by integrating single crystal silicon transistors with an amorphous α‐TiO2 memristor on a flexible substrate. Word, bit, and source lines allowed interconnecting the 1T–1M RRAM unit cells in the 8 × 8 NOR‐type array to achieve independent cell control. Microcontact printing has been utilized to fabricate a flash memory based on a high‐density Ag nanoparticle charge trapping layer on a flexible polyethylene terephthalate (PET) substrate.95 A close‐packed Ag nanoparticle monolayer was embedded at the interface of a blocking layer (200 nm) and a 10 nm atomic layer‐deposited Al2O3 (tunneling layer) to fabricate a data storage unit controlled by external gate bias. As compared to memory devices featuring a floating gate, a memory window of 16.5 V and retention time of 105 s was achieved. The produced devices had high‐density storage sites and low lateral change leakage, as well as offering high endurance over 1000 cycles and robust mechanical stability over 500 bending cycles.95 Another study involved the development of flexible transistor organic memory devices consisting of (spin‐coated) crosslinked PVP films and organic pentacene thin‐film transistors (TFTs) on flexible matrices, in which Au NPs were utilized as charge trapping elements.96 The produced TFT‐based nonvolatile floating gate device had a memory windows of 10 V and sustained operation over 1000 bending cycles times. Such organic memories can also be fabricated from polyimide (PI) and 6‐phenyl‐C61 butyric acid methyl ester (PCBM) on flexible PET substrates (Figure 4 a).97 Furthermore, flexible all organic vertically‐stacked 64‐bit memory cell arrays consisting of one diode‐one resistor system without crosstalk have been developed (Figure 4b).98 The memories components comprised of poly(3‐hexylthiophene) (P3HT) diodes and a combination of polystyrene (PS) and PCBM on polyethylene naphthalate (PEN) substrates. A photocrosslinker (bis‐perfluorobenzoazide:bis‐FB‐N3) was utilized to covalently bind the P3HT and PS side chains by nitrene‐based N‐H insertion. The memory cell arrays were stable (I ON/I OFF ratio ≈103) and had retention time of 104 s, displaying an endurance cycle of 102.98 In a recent study, stretchable silicon nanomembranes circuits incorporate silicon nonvolatile memory arrays with nanocrystal floating gates in a wearable device (Figure 4c).99 Other emerging data storage technologies include piezoelectricity and inverse magnetostriction.100 These nonvolatile memories operate at low energy schemes with storage densities up to 0.2 µm2. Recently, ferroelectric based nonvolatile flip flop memories (1.6 µs for 10‐year data retention, and 170 ns for 10 h data retention) were developed to reduce power dissipation for heart rate data storage.101

Figure 4.

Advances in flexible data storage and memory units. a) Photograph of a flexible 8 × 8 array‐type Ti/Au/Al/PI:PCBM/Al organic memory device. Reproduced with permission.97 Copyright 2010, Wiley‐VCH Verlag GmbH & Co. KGaA, Weinheim. b) A flexible 1D‐1R organic resistive memory cell array on a flexible PEN substrate. Scale bar = 5 mm. Reproduced with permission.98 Copyright 2013, Nature Publishing Group. c) Photograph of a 22 × 22 multiplexed charge trap floating gate memory array (top) and a magnified image (bottom) illustrating four memory pixels interconnected with word and bit lines. Reproduced with permission.99 Copyright 2016, American Association for the Advancement of Science.

Standard communication protocols for electronic devices include Bluetooth classic,102 Zigbee,103 and Wi‐Fi.104 However, these protocols have not been designed to be power‐efficient. Hence, early wearable device designs included proprietary protocols to reduce energy consumption, but this approach restricted the use of interoperability in a personalized network area or IoT.105 To address these issues, Bluetooth low energy (BLE) was developed to achieve power efficiency for short‐range communication while operating within industrial, scientific, and medical (ISM) radio band (2.4 GHz) with a bandwidth of 1 Mbps.106 This protocol allows transferring state information in small blocks of data at regular intervals, where the processor operates in a low power mode.107 It also supports Adaptive Frequency Hopping with a 32‐bit cyclic redundancy check,108 and the beaconing (advertising mode) in the BLE standard allows short, unsolicited messages at flexible update rates.109 Thus, it provides a low power high‐rate always connected transfer of data. Always‐connected devices such as smartphones and IoT networks can serve as hosts for BLE‐enabled wearables.110 A recent advance in such enabling technologies is Bluetooth 5, which offers quadruple data communication range with increased transmission power, and double the data speed (2 Mbps) as compared to Bluetooth 4.x.111

Body area wireless networks are currently being standardized.112 For example, the “400 MHz” band comprising Medical Implant Communication Serive band and ISM band are standardized under IEEE 802.15.6 for close‐to‐body wearables, also for low‐power system‐on‐chip architectures.113 An emerging problem with sensor networks is the interference with existing Wi‐Fi systems that require more power.114 Standards such as IEEE 802.11ah on other bands are adopted for “DeepSleep” power saving mode and energy harvesting.115 BLE, ZigBee, the standard 2.4 GHz personal area network radios will still be used for independent sensor connectivity with healthcare platforms and the IoT.116 Such interconnected sensors will require safety measures to protect the personal information and patient data.

Wearable devices need to be able to function with an independent operating system offering low power consumption and user friendliness without being paired to smartphones. Android Wear 2.0 (Google) features new functions such as Google Fit and enhanced Google assistant, as well as Android pay via NFC and Smart Reply.117 For example, Samsung Gear S offers a micro SIM card option, run applications, and able connect to Wi‐Fi; however, it is only compatible with Samsung smartphones.118 In combination with upcoming 5G connectivity, that could enable laptops or IoT devices as connecting hubs, power‐efficient medical wearables could access these connected nodes inside homes, clinics, or transportation systems.119

2.1.2. Data Processing and Interpretation

Real‐time data acquisition in wearables requires continuous processor operation, which demands power consumption and thus low power domain sensors. Node processors for sensor signal acquisition offer low power consumption and energy management.120 Fine‐grained power management can be achieved via clock gating, which eliminates switches in the processor to improve power efficiency.121 Having multiple CPUs for different applications or parts of the feature‐OS together with processors with low leakage can provide power‐efficient wearable devices.122 Within such systems, low internal clock speeds and input/output signal processes can be minimized to reduce the overall power consumption. Chip architectures are also being designed to operate at power down modes and adapt high‐speed logic.123 For example, Snapdragon Wear 1200 is a low‐power, global navigation satellite system‐enabled processor (Qualcomm) that supports LTE Cat‐M1 (eMTC) and NB‐1 (NB‐IoT) for application in wearables.124

2.1.3. Data Safety

The protection of the personal information and patient data in wearables is a significant concern. The ownership of the data from wearable devices is debatable. Currently some wearable device service providers limit their users' access the access to the collected and stored data. These service providers charge their users' fees to access their row data, which is also acquired by third‐party companies. These third party companies also sell patient information (age, sex, height, weight, location, contact details) and global positioning‐tracked activities.125 While some manufacturers claim to anonymize patient data by removing identifying features, these protective approaches are inadequate to prevent identity fraud. Advanced algorithms have the capability of crossreference biometric information collected with wearable devices based on users' behavior (activity time, location) to reveal the patient's identity.126 For example, digital traces of patient information can be collected by social media to predict identity.127 Furthermore, wearable device can be hacked by accessing the communication channel between the wearable device and smartphones.128 Such security vulnerabilities have been previously observed in pacemakers and glucose pumps.129

Wearable device manufacturers and IT infrastructure should protect medically relevant data by providing tamper protection, authentication, data encryption, or end‐to‐end data integrity. Tamper‐resistant authentication protocols should be lightweight to be integrated into wearables.130 Digital cryptography requires computing power and is not available in wearable device applications. Physical cryptography offers an alternative strategy by using physical unclonable functions.130 Moreover, authentication protocols can be extended to multiple party interactions, for example, user‐device, device‐network, and user‐network systems.131 Body signals may also be used to authenticate and create secure communications.132 Additionally, lightweight on‐chip loadable data encryption protocols have been designed for wearable devices.133 Preservation of data integrity from end‐to‐end user can be compromised by multiple encryption methodologies that can cause data loss.134

2.2. Aided Living and Treatment with Wearables

Wearable devices have application in aiding patients with disabilities and metabolic disorders. These applications range from aiding hearing to drug delivery. Wearables can be configured to deliver drugs through skin, eye, or ear interfaces. Their simple formats can actuate the release of therapeutics via mechanical stress or strain. These so called passive wearable devices consist of drug reservoirs directly embedded in the polymer matrixes or microneedle depots. When contacted with the body surface, drugs can be delivered by means of passive diffusion or electronic actuation. Such mechanisms can be triggered by heating, pH, or other chemical means to actuate a drug‐impregnated medium or mechanically opening the depots to initiate drug diffusion. These wearable devices can be integrated with biosensors to create closed‐loop systems, in which the drug dosage can be controlled and wirelessly communicated to the user, and further connected to body area networks for tracking and monitoring.

2.2.1. Aided Living

Hearing impairment is the major reason of disability among old patients.135 One of the early examples of the use of wearable devices in medicine was to treat hearing loss. Electroacoustic devices amplify sound and conformably fit behind auricle and/or in the ear canal for the correction of impaired hearing. These devices amplify quiet sounds audible, but a threshold mechanism prevents the amplification of loud sounds. Such devices consist of an earmold, which may contain an electronic circuit, a microphone, a loudspeaker, and a battery (zinc–air, 1.35–1.45 V). However, recent miniaturized models offer devices that can be inserted in the outer ear bowl or the ear canal. Hearing aids can be wirelessly connected to smartphones or tablet computers to directly tune the volume or the bass of the sound.136 These wireless hearing aids can communicate with one another to adjust the audio properties simultaneous. Such devices offer FM listening devices with wireless microphones that can be used by a partner. These devices are examples of how wearables can interconnect. Additionally, these devices can connect to the mobile phones, audio sources, and TV streamliners via Bluetooth (2.4 GHz).137

2.2.2. Drug Delivery

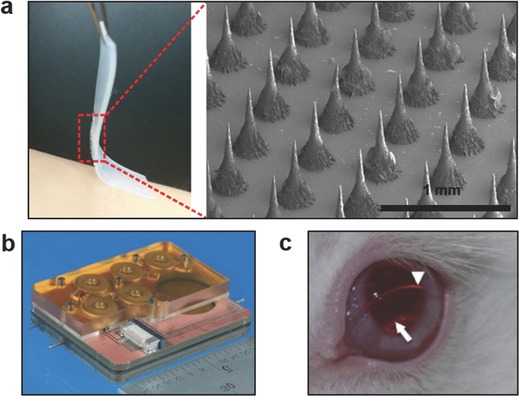

Therapeutic agents can be released from wearable elastomer films by applying mechanical forces. A wearable device containing a microgel depot has been developed to release drug loaded nanoparticles based on tensile strain triggering of an elastomer membrane (Figure 5 a).138 When tensile strain was applied to the elastomer film, the drug was released due to the Poisson's ratio‐induced compression of the microgel depot and the enlarged diffusion surface area. The wearable device could be configured to release antineoplastic and antibacterial agents based on routine body motions, or pulsatile release by patient‐controlled administration. The effectiveness of the doxorubicin‐eluting film was demonstrated by inhibiting tumor spheroid, showing two times more reduction in tumor size as compared to passive drug release. Furthermore, ciprofloxacin was incorporated into the elastomer film treating local infection on a finger joint. The amount of ciprofloxacin released after 100 and 1000 finger movements was 9.2 and 56.6 µg mL−1. Additionally, crosslinked hyaluronic acid microneedles were integrated within the wearable device to transdermally deliver insulin to control the concentration of blood glucose in type 1 diabetic mice. After 10 cycles of stretching at a strain of 50%, the concentration of the blood glucose, which was at a hyperglycemic state (550 mg dL−1), decreased to the normal glycemic state (<200 mg dL−1) within 30 min.138 To refill this drug delivery system, the microgel depot layer may be replaced while retaining the microneedles in situ.

Figure 5.

Applications of wearable devices in drug delivery. a) Stretch‐actuated drug delivery from elastomer films comprising microgel depots containing therapeutic nanoparticles for diabetes, anticancer, and antibacterial treatments. The device comprises a microneedle array (SEM image) for stretch‐mediated control of insulin delivery. Reproduced with permission.138 Copyright 2015, The American Chemical Society. b) A microfluidic reciprocating pump and electromagnetic actuators for intracochlear drug delivery. Reproduced with permission.148 Copyright 2016, The Royal Society of Chemistry. c) Latanoprost‐eluting contact lenses on the surface of a rabbit's eye for glaucoma treatment. The arrowhead illustrates the lens edge and the arrow show inner diameter of drug‐polymer film. Reproduced with permission.149 Copyright 2014, Elsevier.

Engineering biocompatible and flexible microneedles will minimize the risks of immune reaction and breakage after skin penetration. Microneedles made of high Young's modulus materials such as silicon, nickel lack biocompatibility. However, microneedles created from polymers have low mechanical strength limiting their application in drug‐eluting patches. The microneedles could be configured to dissolve in vivo. For example, microneedles have been utilized to deliver influenza virus vaccine and dissolve in the skin within minutes.139 Recently, a wearable patch comprising a bendable microneedle array was developed.140 Each microneedle consisted of four bendable PDMS pillar bases and a rigid SU‐8 or maltose sharp tip. The array tolerated the deformation associated with buckling and lateral movement forces during skin penetration and daily wear without needle breakage. The concentration of blood glucose in rats treated with the insulin‐eluting microneedle array decreased from over 5.5 h, where the dose was controlled from 50 to 183 µL by varying the pressing force.140 This drug delivery system was integrated with a refillable microfluidic drug reservoir that was assembled at the backside of the microneedle patch.

A microneedle‐based immunopatch has been created for melanin‐mediated cancer treatment.141 Polymeric microneedles consisted of B16F10 whole tumor lysate containing melanin. The microneedles released lysate upon insertion into the skin in a controlled manner. Excitation of the melanin with near‐infrared light increased the local temperature that promoted tumor‐antigen uptake by dendritic cells to improved antitumor vaccination. This patch provided spatiotemporal immunotherapy that enhanced infiltration of polarized T cells and local cytokine release. Studies in mice showed increase in survival after tumor challenge targeting established primary tumors as well as distant tumors.141

Transdermal drug delivery has been achieved through iontophoresis in graphene‐based wearable devices.142 A thermally controlled transfer printing approach has been developed to produce patterned graphene layers on an elastic stamp. Graphene‐based iontophoresis electrodes was used a heating unit (22–44 °C) to actuate the thermal transdermal drug delivery. Iontophoresis electrodes were laminated on the skin of a nude mouse and doxorubicin was loaded on the graphene electrodes and electric field was applied. The penetration of the depth of doxorubicin was proportional to the applied heat to graphene and the concentration of iontophoresis stimuli.142 Such wearable devices may also consist of nanofibers that can be designed in stretchable formats.143 These devices many reach sheet resistance of ≈1.3 Ω sq−1 having a power efficiency of 0.65 W cm−2 and an optical transmittance of ≈90%.

A textile dressing has been developed for temporal and dosage‐controlled drug delivery.144 The wound dressing consisted of composite fibers having a core electrical heater, which was coated with an alginate (Alg)/poly(ethylene glycol) diacrylate (PEGDA) film to deliver a drug. The wound dressing allows releasing antibiotics and vascular endothelial growth factors (VEGF) to reduce bacterial infection and induce angiogenesis in vivo. To construct the fibers, a cotton thread was coated with a carbon ink. For example, a conductive tread having a diameter of 1.2 mm showed 5 Ω cm−1. The temperature of the fibers could be controlled between 25 and 45 °C as the applied voltage was increased up to 4.5 V. p(NIPAM/PEGDA) hybrid particles containing cefazolin and vancomycin have been synthesized. For example, a 5 cm long thread released 30 µg cefazolin over an hour, whereas four threads released 130 µm cefazolin. In a diabetic mouse model, fabricated fibers were used to deliver VEGF to skin wounds of the animals to evaluate wound healing rate. Threefold increase in the granulation of the tissue deposition across the wound bed was measured as compared to the control group without VEGF.144 These textile dressings may be integrated with hydrogel optical fibers and photonic nanomaterials for photodynamic therapy.145

Microfluidic systems have been developed to deliver drugs to inner ear fluid.146 A microfluidic device has been fabricated to infuse and withdraw sub‐microliter drug solutions to and from inner ear fluid to achieve a liquid transfer with zero net volume.147 The drug delivery system consisted of a polymer reciprocating pump and an electromagnetic actuator for application in head‐mounted wearables. The mass transport of the drug molecules to the cochlea was achieved through diffusion and mixing. The programmable pump created a reciprocating flow and a reservoir to control the drug concentration in the infused bolus. The efficacy of the drug delivery device was evaluated by delivering 6,7‐dinitroquinoxaline‐2,3‐dione to the cochlea of guinea pigs. After the implantation of the cannula by the 24 kHz region at the cochlea base, auditory nerve compound action potentials were monitored. As the reciprocating pump drove the drug at 0.64–1.18 µL infuse‐withdraw in 3–4 min intervals, compound action potential thresholds increased for 1 h and returned to normal levels.147 A recent iteration of the device included an embedded drug reservoir and all fluidic components in the microfluidic architecture (Figure 5b).148 This intracochlear drug delivery system operated at 6 s drug loading, 16 s infusion, and 10 min idle stages, where the energy consumption was 20.9 J. This device allowed for running 157 cycles on a 3.8 V 240 mAh power source corresponding to 27.3 h run time. This miniaturized system may also allow for replacing the drug reservoir cartridge for long‐term use.

A contact lens has been created to deliver latanoprost to the eye for the treatment of glaucoma.149 The contact lens formulation consisted of latanoprost‐PLGA films encapsulated by methafilcon, which is a co‐polymer of poly(2‐hydroxyethyl methacrylate) (pHEMA) and methacrylic acid. The contact lens (dry thickness = 300 µm, wet outer diameter = 15 mm, wet central aperture = 4 mm) was fabricated by a combination of spincoating, and UV‐initiated free radical polymerization, and lathing the material into a curved geometry. The amount of the drug (89–178 µg) encapsulated in the contact lenses was controlled by varying the concentration of the latanoprost during UV polymerization. The drug was released by an early burst followed by sustained release over a month. 50–90% of the drug amount was released in vitro over 3 d depending on the thickness of the contact lens. The efficacy of the drug‐eluting contact lens in the treatment of glaucoma was assessed by in vivo studies in rabbit eyes (Figure 5c). The concentration of the latanoprost released from 3‐d preconditioned contact lenses decreased from 100 to 10 ng mL−1 over 3 d, followed by a sustained release over a month.149 Recently, enzyme‐cleavable contact lenses were developed.150 These lenses comprised nanodiamonds that released timolol maleate in the presence of lysozyme for sustained glaucoma treatment. The nanodiamonds were coated with polyethyleneimine and crosslinked with an enzyme‐cleavable chitosan to encapsulate timolol maleate. The nanodiamond drug reservoirs were embedded in a pHEMA matrix and casted to obtain a contact lens. In the presence of lysozyme, the contact lenses released 9.41 µg timolol maleate over a day.150 This approach allowed for wet storage of the contact lenses prior to use. Additionally, ciprofloxacin‐eluting contact lenses inhibited S. aureus for extended zero‐order release.151 These antimicrobial PLGA‐pHEMA contact lenses completely inhibited 105 S. aureus cells as the cumulative mass release of ciprofloxacin was 4.5 mg over 28 d. In another study, econazole‐eluting PLGA‐pHEMA contact lenses have been fabricated for the treatment of fungal ocular infections.152 The antifungal drug‐release kinetics of the contact lenses was tested in an assay against Candida albicans. The contact lenses comprising 16 mg econazole killed 100% of the Candida (0.5–1.0 × 107 cells) over 8–10 d.

2.2.3. Behavior Therapy

With the emergence of optical headsets such as Google Glass 2, Oculus Rift and Magic Leap, HoloLens for application in video games and entertainment, reality simulation platforms have also found use in medical research, diagnostics, and treatment.153 These simulated reality platforms provide imaginary environment, sounds, vibrations, and other sensations to observe and interact with the imaginary surroundings and items.7, 154 They can facilitate the management of mental and anxiety disorders including autism, posttraumatic stress disorder (PTSD), persecutory delusions, and phobias.155 Enabling patients to evaluate these mental challenges in a virtual reality social environment can allow the management of safety‐seeking or anxiety behaviors. Other applications of reality simulation programs include ocular treatment, rehabilitation, pain management, and surgical training.

Brain power system for autism is a customized head‐mounted display that provides personalized coaching experiences via a gamified augmented‐reality application incorporating artificial intelligence modes.6 This application aids the patient to establish emotion recognition, eye contact, face‐directed gaze, and behavioral self‐regulation. The head‐mounted display integrating the brain power system was utilized to coach two children with clinically diagnosed Autism spectrum disorder. 24 h postintervention, these patients demonstrated decreased disorder symptoms based on the aberrant behavior checklist.156 In another study, head‐mount displays were utilized to automatically recognize facial expressions.157 The headset behaviorally aided children with Autism spectrum disorder by providing real‐time social cues and minimizing distractions. This system displayed facial expressions and records social responses including eye contact time and using an eye tracker. A trial involving 38 children with Autism spectrum disorder and typically developing children showed correct emotion recognition rates within the range of 85–95%. While significant real‐time physiological and behavioral data can be collected from mentally ill patients, the connection between the data and the emotions of the patient is unclear to draw definite diagnosis conclusions. Hence, the interpretation of the results for actionable treatment is a challenge. In another study, a randomized, double‐blind, placebo‐controlled study of virtual reality exposure therapy was designed to treat PTSD due to military trauma in veterans (n = 156).158 Virtual reality exposure therapy was introduced to patients in six sessions to decrease the PTSD symptoms in combination with psychiatric medications, d‐cycloserine (50 mg) and alprazolam (0.25 mg), and compared to the placebo effect. The virtual reality therapy augmented in reducing PTSD symptoms, and these reduced symptoms were maintained at 3–12 months of treatment.158

In a recent study, clinically diagnosed patients with persecutory delusions (n = 30) were enrolled to virtual reality cognitive therapy sessions in order to decrease in delusional conviction and real‐world distress.159 Virtual reality cognitive therapy reduced delusional conviction by 22% and real‐world stress by 19.6% as compared with virtual reality exposure group.159 In another study, VR was also used in treating glossophobia (fear of public speaking) by exposing subjects to a VR public speaking scene over 5 weeks.160 Questionnaires such as attitude toward public speaking and subjective units of disturbance, as well as heart rate monitoring showed significant improvements in public speaking fear as compared to a control group.

Virtual reality head‐mounted displays were utilized to treat patients with amblyopia.161 Human subjects (n = 17) with clinically‐diagnosed anisometropic amblyopia were enrolled in a 8‐session dichoptic game‐based training program (diplopia, vivid vision), which was operated on a Oculus Rift OC DK2 display. The game involved flying a spaceship through a rings system, where the simulated system was in a 3D dichoptic virtual reality setup (Figure 6 a). The virtual vehicle was only observed with the dominant eye and all the objects in the game were seen with the amblyopic eye to force the brain to cooperatively use both eyes. After the treatment, the corrected visual acuity of the patients significantly improved from 0.58 ± 0.35 (LogMAR) to 0.43 ± 0.38 (p < 0.01), while mean stereoacuity shifted from 263.3 to 176.7 of arc, showing potential for the treatment of sight disorders.161

Figure 6.

Applications of virtual reality in medicine. a) Dichoptic training game seen through a head‐mounted optical display in virtual reality. The amblyopic eye views the left side of the image to fly the spaceship through the blue gates. Spaceship is only seen with the dominant eye (right side). Reproduced with permission.161 Copyright 2017, Springer. b) The RAPAEL Smart Glove system tracks the posture and the motion of a user's distal limb. Reproduced with permission.138, 162 Copyright 2016, BioMed Central Ltd. c) The use of head‐mounted optical displays with virtual reality in a pediatric burn patient during motion exercises. Reproduced with permission.163 Copyright 2014, Mary Ann Liebert, Inc.

The rehabilitation effects of VR therapy were demonstrated on the distal extremity function of stroke survivors (n = 46) in a single‐blinded randomized controlled trial.162 Patients were divided into two groups consisting of electronic glove group and conventional intervention group (control) to assess changes in health‐related quality of life indicators. The electronic glove (RAPAEL, Neofect) provided feedback by tracking the posture and the motion of the user's distal limb (Figure 6b). The glove incorporated inertial and bending sensors that measure 3D position of the distal limb and the degree of finger bending. It had the capability to recognize the forearm pronation, ulnar deviation, wrist movement, and finger flexion. The software application then displayed a virtual hand and objects in real time. Fugl–Meyer assessment scores, Purdue pegboard test, Jebsen–Taylor hand function test, and Stroke Impact Scale indicated improvements in the rehabilitation outcomes as compared the control group.

VR reality has been utilized as a pain distraction technology for wound care and physical therapy procedures of burn patients, where pain medications are inadequate.163 In a case study, Oculus Rift VR goggles were used to immerse the 3rd degree burn patient into a virtual environment during occupational therapy (Figure 6c). The patient had one occupational therapy session (no VR) on day 1, a VR‐supported occupational therapy session on day 2, followed by a final occupational therapy session with no VR on day 3. Subjective rating of pain intensity results decreased from severely painful to moderately painful when VR was employed. These results were consistent with functional magnetic resonance imaging studies that showed pain‐related brain activity decrease during VR induced pain distraction.164

2.3. Limitations of Wearable Treatment Approaches

Challenges remain in the development of theranostic systems that enable closed‐loop dynamics and respond correctly to physiological and pathological conditions. The main drawbacks of these technologies for application in point‐of‐care settings arise from the limited integration and miniaturization. Early approaches to treatment of disease by wearables lacked the patient improvement feedback; however, under professional supervision they proved effective, for example, to mitigate Parkinson's disease.165 Others have operated under the assumption that the function of the wearable is continuously required, this has proven to be effective for renal failure patients.166 Issues with wearables for treatment include low biocompatibility, insufficient conformal contact, inefficient energy consumption, and short lifetime. These factors limit the development of automated systems that can sense physiological stimulus and respond with an accurate therapeutic dosage to create real closed‐loop systems worn long‐term.

2.4. Building the Next Generation Wearables

Several efforts have been made to solve the limitation of closed‐loop wearables, nevertheless, wearable technologies are still in development. As an example, a promising wearable device featuring a graphene layer doped with gold, and integrated with a serpentine layer of gold mesh for electrochemical monitoring of glucose in sweat was developed (Figure 7 a).167 The device consisted of a humidity detector, a heater and temperature sensor combined with polyvinyl pyrrolidone microneedles for thermally activated transcutaneous drug delivery. After the patch was laminated on the human skin, the device was activated upon sweat generation in ≈15 min. After reaching 80% relative humidity, the concentration of the glucose and pH was measured in sweat. The microneedles were coated with tridecanoic acid having a transition temperature of 41 °C. As the sensors detected hyperglycemia, the microneedles were thermally activated by melting the tridecanoic acid coating to release N,N‐dimethylimidodicarbonimidic diamide (Metformin). Experiments on diabetic mice showed suppression of blood glucose concentration by the Metformin‐eluting array as compared to the control group (P < 0.05).167 However, this system was not suitable for long term delivery of Metformin as the microneedle system consisted of bioresorbable tridecanoic acid coating.

Figure 7.

Closed‐loop wearables. a) A wearable device for glucose monitoring and drug‐delivery that can wirelessly communicates with smartphones via Bluetooth. Reproduced with permission.167 Copyright 2016, Nature Publishing Group. b) A microfluidic bandage on the arm. The wearable device consists of a capacitive touch detector, a temperature sensor, and a drug delivery pump. Reproduced with permission.168 Copyright 2014, Wiley‐VCH Verlag GmbH & Co. KGaA, Weinheim.

Another challenge is the design of energy efficient theranostic wearable technologies, as the energy requirements tend to be higher as their diagnostic or therapeutic wearable counterparts, nevertheless several examples of energy efficient devices exist.19 Recently, a wearable microfluidic bandage incorporating sensors and a drug delivery system was developed (Figure 7b).168 This bandage featured sensors, a microfluidic drug delivery pump, a wireless signal transmittance unit, and a microelectoromechanical system on a flexible substrate. The sensing units were fabricated by screen and shadow mask printing techniques in combination with laser cutting. A wireless coil, a capacitive touch sensor, and a temperature sensor were fabricated by patterning silver ink, conductive poly(3,4‐ethylenedioxythiophene)–poly(styrenesulfonate) and a CNT mixture. The drug delivery pump was created by forming PDMS patterns via soft lithography as a semisphere fluid reservoir (0.2 mL). The temperature sensor operated from 20 to 50 °C at a sensitivity of 0.61 °C and functioned at a curvature radius up to 3.6 mm. The threshold pressure to eject a fluid was 3.3 kPa at a rate of 35 nL kPa−1, where the bending radius up to 6 mm did not alter the reservoir volume.168 The wearable device was used to measure the temperature changes on human arm over time; nevertheless, the drug delivery capability was not tested and the transistors were not integrated within the device, showing limited translation to potential clinical settings.

In creating closed‐loop automated systems for disease monitoring and drug release, the use of sensitive polymers such as chitosan, poly(methacrylicacid), modified poly(acrylamide), sulfonated polystyrenes, and ethylenevinylacetate have enabled the development of systems that interact directly with the tissue microenvironment. These materials can release drugs and modify its physical chemistry based on sensing physiological responses such as temperature, pH, light, electric fields and ultrasound waves.169 Nevertheless, challenges remain in accurately controlling the release of the desired drug dosage based on the physiological needs; however studies so far have been limited to characterizing the response of the stimuli‐responsive material. In pathological conditions, the response of materials can be modeled to adjust their release kinetics via the development of several physicochemical formulations. Nevertheless, to develop materials for clinical applications, the development should move from stimuli‐responsive materials to physiologically sensitive materials that act and deliver drug dosages based in organic needs. The ideal material would have to adapt to several circumstances and respond to them in a personalized manner, as most of the current materials present a nonflexible behavior difficult to modulate after its fabrication. This part is fundamental to translate closed‐loop technologies from the laboratory to the clinic as pathological states are fast‐evolving physiological treats that need personalized interventions.

Wearable devices require hardware and software to acquire real‐time data from the user. The data retrieved from sensors are processed, analyzed, displayed, or interpreted to produce actionable information. Hence, hardware and software interactions need to be optimized for each wearable device. An overarching system architecture can be created for wearables, from which particular applications can be derived. As wearables are not user interface centric, plug and play architectures can be conceived when programing or specific data input is required. The application scenarios in disease diagnosis and drug delivery are determining factors for sensor types and processor types in signal analysis and device architecture. Nevertheless, certain components are usually included in all wearable device configurations. The wearables system architecture requirements are driven not only by the continuous data acquisition, but also by the need for a seamless user experience. In healthcare applications, long‐term wear is paramount, also continuous communication to the user for self‐monitoring, and data transfer to a health professional.170 As a rule of thumb, system architecture requirements are: (i) long battery life or capability to wirelessly receive power in conjunction with low power consumption, (ii) continuous synchronization within IoT or local networks, (iii) robust sensors with low signal‐to‐noise ratio, (iv) high‐performance data processing, (v) secure or encrypted data transfer, (vii) conformability, comfortability, thin geometry, and (vi) amenable to mass manufacturing at low cost.

2.4.1. Sensor Signal Acquisition, Processing, and Artificial Intelligence Algorithms