Abstract

Mayonnaise was prepared by replacing refined sunflower oil with physically refined rice bran oil (RBO), filtered sesame oil (SO) and blends of both RBO:SO. Emulsions were formulated using xanthan gum as a replacer for egg. The effect of replacing xanthan gum on varying oil blends (RBO:SO) on the physicochemical properties such as texture (consistency), stability, viscosity, and bioactives (oryzanol and sesamol content) were also studied. Significant differences were observed in the fat content of the emulsions prepared. Xanthan gum based mayonnaise’s had 63–65% fat, whereas control sample with egg had 78% fat. The spreadability ranged between 1.2 and 1.6 N and stability of these spreads was found to be better than that of control. Mayonnaise with the desired colour, optimum spreadability and excellent emulsion stability could be prepared using RBO, and blends of RBO:SO. Significant differences were seen in the instrumental consistency and rheological studies among the mayonnaises prepared. The present study focusses on the preparation of a healthy mayonnaise using rice bran and sesame oil and their blends which have beneficial health effects due to the presence of oryzanol and sesamol.

Keywords: Healthy mayonnaise, Rice bran oil, Sesame oil, Xanthan gum, Spreadability

Introduction

Mayonnaise, a semi-solid oil-in-water emulsion containing 70–80% fat is probably one of the oldest and most widely used sauces in the world today. It is traditionally prepared by carefully blending egg yolk, vinegar, oil, salt and spices (especially mustard). Among the ingredients in mayonnaise, egg yolk is most critical for its stability (Hasenhuettl 2008). Egg yolk is often used in foods as an emulsifier because it imparts desirable flavor, mouthfeel, and color (Bringe and Cheng 1995). A well-known fact of egg yolk is its high cholesterol content. Yet it is still the commonly used emulsifying agent, as it has high qualities for emulsifying, egg yolk is an emulsion itself, comprising of hydrophobic granules suspended in an aqueous phase containing most of the protein (Harrison and Cunningham 1986). The emulsifying capacity of egg yolk is a result of phospholipids, lipoproteins (LDL and HDL), and non-associated proteins (Livetin and phosvitin), with LDL being the most important contributor to these emulsifying properties (Kiosseoglou 1989). A problem associated with egg yolk is its high cholesterol content (1000–1200 mg/100 g), which has been implicated as a causative agent for heart disease. Several attempts have been made to develop low cholesterol sauces with characteristics similar to that of real mayonnaise. Largely influenced by health related concerns, there have been demands on the food industry to reduce the amount of fat, sugar, cholesterol, salt and certain additives in the diet (Liu et al. 2007).

Xanthan gum is an anionic heteropolysaccharide produced by the microorganism Xanthomonas campestris. The molecular weight of xanthan gum is approximately 2 million g/mol, it forms aggregates, and xanthan solutions are highly pseudoplastic and exhibit high viscosity. Xanthan gum is commonly added to oil-in-water emulsions to enhance viscosity. A few functional food formulations based on O/W emulsions, using whey proteins and xanthan gum have been tried by Caporaso et al (2016).

The demand for low fat and eggless mayonnaise has greatly increased in the recent years due to consumers’ concern about high fat diets and cholesterol content (Worrasinchai et al. 2006). High fat intake is associated with increased risk of obesity, some types of cancer, cardiovascular diseases, and hypertension (Liu et al 2007). The American Heart Association has suggested limiting fat consumption to less than 30% of the overall consumed calories. The adverse health effects of overconsumption of certain types of lipids have led to a trend within the food industry towards the development of healthy mayonnaises (Mun et al. 2009; Liu et al. 2007).

Traditional cooking oil used in India includes groundnut, coconut, sesame, mustard, safflower and sunflower oil, rice bran oil, palmolein and soybean oil. In mayonnaise, the oil percentage accounts to 75% or more of the total volume (Depree and Savage 2001). Normally synthetic antioxidants like BHT and TBHQ are used to depress rancidity of fats and oils. However the toxicity of synthetic antioxidants (Barlow 1990) and increasing consumer demand for natural products have directed our attention in using RBO and sesame oil which act as natural and safer antioxidants and also having hypocholesterolemic effect for use in mayonnaise.

Among vegetable oils, rice bran oil, (RBO) has been reported to have a hypocholesterlemic effect. Oryzanol, tocopherols and tocotrienols are present in RBO as unsaponifiable matter. Phytosterols are important minor components of RBO and their beneficial biological effects include cholesterol lowering, antiaging and antioxidants effects (Gopalakrishna et al. 2002). Micronutrients such as phytosterols, oryzanol, and tocotrienols present in rice bran oil are responsible for lowering plasma cholesterol. The cholesterol-lowering potential of phytosterols in humans is well established, and hence foods containing phytosterols can be used as a functional ingredients. Oryzanol is a group of sterol ferulate and is known to exert a hypocholesterolemic effect by decreasing cholesterol absorption and inhibiting hepatic cholesterol synthesis. Consumption of a diet enriched in rice bran oil, has advantages in terms of lowering plasma lipid levels or improving the cardiovascular risk profile (Raghuram and Rukmini 1995).

Sesame oil (SO) contains a class of unusual compounds known as lignans, comprising of sesamin, sesamolin, and a small amount of sesamol (Namiki 1995). They have multiple physiological functions, such as decreasing blood lipids (Hirata et al. 1996), increasing antioxidative ability (Hemalatha et al. 2004) and γ-tocopherol bioavailability providing anti-inflammatory function (Hsu et al. 2005) and estrogenic activity (Wu et al. 2006). Sesamol is a potent phenolic antioxidant present in sesame oil making it more resistant to oxidative deterioration. This oil was also used in our formulation along with rice bran oil to prepare mayonnaise like spread. In the present study, efforts were also made to substitute egg yolk with xanthan gum in the preparation of mayonnaise using blends of RBO and SO.

The main objectives of this study were, (1) Use of xanthan gum as an egg yolk replacer in mayonnaise. (2) Studying the texture (consistency), flow properties of mayonnaise prepared using different ratios of RBO and SO along with xanthan gum in terms of consistency index (K), flow index (n) and yield stress (3) studying the stability and sensory qualities of the prepared mayonnaise.

Materials and methods

Xanthan gum was obtained from Loba Chemie Pvt. Ltd. Mumbai, India. Rice bran and sesame oil were procured from the local market in Mysore. Double distilled water was used to hydrate the xanthan gum. All chemicals used were of reagent grade.

Preparation of mayonnaise

Experimental design used in this study for preparation of mayonnaise is given in Table 1. Emulsions were prepared by using Ultra Turrax T-50 (IKA, Instruments, Germany) equipped with a dispersing tool. Mayonnaise control was prepared using the formulation (Depree and Savage 2001) containing refined sunflower oil (70), egg yolk (19.1) salt (1), sugar (0.6), vinegar (7.2), mustard (1.8) and white pepper (0.3). For mayonnaise prepared with xanthan gum, 1 gm (dwb) of xanthan gum was hydrated in 20 ml of double distilled water and weighed in a bowl. Vinegar, sugar, salt, mustard and white pepper were weighed and mixed with the hydrated gum, and oil was trickled slowly and homogenized. Both time and temperature were kept constant. The mixture was stirred at 6000 rpm for 3.5 min, and at 2000 rpm for 3 min. Control sample and the formulation with xanthan gum was prepared with and refined sunflower oil. RBO, SO and blends of both RBO and SO were used to prepare mayonnaise according to the experimental design given in Table 1. Once prepared, emulsions were stored at 15 °C. All the samples prepared with individual oils and blends were prepared five times in order to establish the variability of the emulsification technique. In all the experimental samples prepared the amount of xanthan gum and other ingredients was kept constant only the oil blends were varied.

Table 1.

Experimental design and texture (consistency) of mayonnaises prepared with RBO and SO

| Sl no | Oil blends | Texture (N) | ||

|---|---|---|---|---|

| Refined sunflower oil | Rice bran oil (RBO) | Sesame oil (SO) | ||

| 1 | 100* | 0 | 0 | 1.44 ± 0.45cd |

| 2 | 100 | 0 | 0 | 1.62 ± 0.21d |

| 3 | – | 100 | 0 | 1.02 ± 0.36b |

| 4 | – | 90 | 10 | 1.61 ± 0.12d |

| 5 | – | 80 | 20 | 1.36 ± 0.44cd |

| 6 | – | 70 | 30 | 1.20 ± 0.52bc |

| 7 | – | 60 | 40 | 1.17 ± 0.38b |

| 8 | – | 50 | 50 | 1.10 ± 0.11b |

| 9 | – | 40 | 60 | 0.66 ± 0.27a |

| 10 | – | 30 | 70 | 0.62 ± 0.34a |

| 11 | – | 20 | 80 | 0.61 ± 0.33a |

| 12 | – | 10 | 90 | 0.58 ± 0.61a |

| 13 | – | 0 | 100 | 2.07 ± 0.14e |

*Contains egg, all the rest with xanthan gum, values in the same column with different superscripts differ significantly (p < 0.05)

The prepared mayonnaise’s were kept in glass jars and stored at 15 ± 1 °C. Samples were taken after 2 days, brought to room temperature (27 ± 1 °C) for further analyses.

pH and fat content

pH was measured at a temperature of 27 °C using a pH meter model EZDO 600 (HTA instruments, India) Three replicate readings (three different samples) were taken for each pH of mayonnaises.

Fat content was determined by Mistry and Hassan method (Mistry and Hassan 1992).

Colour parameters

The color of mayonnaise samples taken in a quartz cuvette was determined by employing a colorimeter (Model # LABSCAN XE, Hunter Associate Laboratory, Virginia, USA). The illuminant employed was D65 and view angle was 10°; the visible range of 400–700 nm was employed and the diameter of the measuring port was 10 mm. The color parameters like L* (lightness), a* and b* values were determined as per the Commission Internationale de’Eclairage (CIE) method. The total color difference (ΔE) was also calculated keeping the standard glazed white plate (supplied by the equipment manufacturer) as the reference for comparison.

Consistency measurement

TA-HDi plus Texture Analyser (Stable Microsystems Ltd., Surrey, England) was used to determine the spreadability of the emulsions prepared. The mayonnaise samples were carefully placed into cylindrical containers. Spreadability was measured using a spreadability rig (Stefan and Kocevski 2013). A 50-kg load cell was used at a crosshead speed of 5 mm/min. For each test, cone tests are set special place in already centered base of 25 mm. The male cone section ranges from the top down in a distance of 23 mm with speed of 3 mm/s, with penetration in tested mayonnaise, which is filled in the female cone. The force required for penetration of the male cone into the female cone, pushing the mayonnaise on the outside, is registered on the computer. Spreadability was measured using approximately 10 g of mayonnaise sample in Spreadability probe (perspex conical) with 45° angle at room temperature (25 ± 2 °C). The tests were performed in triplicate and the results were expressed as mean ± standard deviation.

Emulsion stability test

The emulsion stability of mayonnaise was measured following the method developed by Chun and Song (1995). 15 g of mayonnaise samples (F1) were taken in centrifuge tubes. The tubes were tightly sealed with plastic caps and then centrifuged for 30 min at 5000 rpm. The weight of the precipitated fraction (F1) was noted and stability of emulsion or stability ratio (SR) was calculated as (%) = (F1/F2) × 100 (Mun et al. 2009). Furthermore, to measure the heat stability of mayonnaise samples, they were stored at 80 °C for 30 min. After that, emulsions were placed in centrifuge tubes and processed for 30 min at 5000 rpm. Heat stability was characterized using the above equation.

Oryzanol estimation

Oryzanol content was estimated as per the method of Seetharamaiah and Prabakar (1986). Accurately weighed oil samples (about 10 mg each) in replicates were dissolved in hexane, and made up to 10 ml. O.D. of the solution was recorded in a 10 mm cell at 314 nm in a Shimadzu UV-240 double beam recording spectrophotometer (solutions having OD more than 1.2 were further diluted before recording). The oryzanol content in the oil was calculated using the formula,

Sesamol estimation

0.01 g of sample was dissolved in 10 ml of hexane + chloroform mixture (7:3, v/v) and the absorbance was measured at 288 nm using spectrophotometer (UV-1601, UV–VIS spectrophotometer, Shimadzu Corporation). The sesamol content was calculated by using the formula (Shukla and Singh 2005).

where A = absorbance; W = weight of the sample in gram/100 ml; 230.1 = extinction coefficient value.

Rheological properties

A controlled stress rheometer with coaxial cylinder (Z41) attachment (Model # RS6000 Haake RheoWin, Thermo Scientific, Karlsruhe, Germany) was used to determine the flow behavior of the mayonnaise samples. All rheological measurements were conducted at 25 °C on triplicate samples by employing a circulating water bath for control of temperature by ± 0.1 °C (Bhattacharya 1999). Special care was taken to minimize the effect of the work softening when the mayonnaise sample was initially loaded on the plate each time (Kokini and Dickie 1981). The mayonnaise sample was removed in one stroke from the container using a plastic spatula and was subsequently deposited onto the plate. The sample filled up the whole gap by lowering the upper plate down to the designed preset gap. The extra sample around the edge of the plate was removed with the plastic spatula. In this study, all samples were allowed to rest for 60 s after loading to allow sample relaxation and temperature equilibration. The samples were initially pre-sheared at a shear-rate of 10 s−1 for 30 s followed by a gradual increase of shear-rate up to 500 s−1 in 60 s. Apparent viscosity was taken as the ratio of shear-stress and shear-rate when the latter was taken as 100 s−1. Yield stress was determined by shearing at 5 s−1 for 30 s followed by stopping the spindle, and allowing the sample to relax for 120 s. However, no detectable yield stress was observed for the samples. Hence, shear-stress and shear-rate data were fitted to the commonly employed power law model (Eq. 1), and model parameters (k and n) were calculated by using the software provided by the instrument manufacturer. In the power law model (Eq. 1), σ was the shear-stress (Pa), was the shear-rate (s−1), k was the consistency index (Pa sn) and n was the flow behavior index (dimensionless). The suitability of the power law model was examined by determining the variance (χ2) and correlation coefficient (r); the significance of r-values was judged at p ≤ 0.01.

| 1 |

Sensory analysis

Quantitative descriptive analysis (QDA) was used to evaluate perceived textural attributes. Twelve trained panelists evaluated the mayonnaise samples. Approximately 15 ml samples of each mayonnaise were served on porcelain plates and transferred to the mouth with a plastic spoon. The panelists rinsed their mouths with warm water after evaluating each sample. All samples were served in randomized order and the panelists evaluated each sample in duplicate. Sensory scores was recorded with higher intensity was on the right end and low intensity on the left end of the scale.

Statistical analysis

All measurements were carried out in triplicates (unless specifically mentioned), and data were expressed as arithmetic mean ± standard deviations (SD). Duncan’s Multiple Range Test (DMRT) was applied to determine the existence of significant difference at p ≤ 0.05 (Duncan 1955).

Results and discussion

pH and fat content

pH of all the mayonnaise samples ranged between 3.9–4.0 and was not affected by varying oil blends. Fat content in traditional mayonnaise prepared with egg was 78% whereas in all the other samples prepared using xanthan gum it ranged between 63–65%.

Colour parameters

Visual colour

Control mayonnaise was light yellow in colour, due to the presence of egg yolk which imparts a natural yellowness with refined sunflower oil. On replacing egg yolk with gum the mayonnaise was light cream to white in colour. Addition of RBO and sesame oil darkened the product slightly due to the natural pigments of the oils but were not yellow. Gopalakrishna et al. (2005), showed that the natural pigments of the oil imparts a slight colour to product.

Instrumental color

L* values for control sample with egg was 72.86 while that prepared with gum was 79.9. The total colour difference showed a value of 17.77 the least among all the variation studied indicating it to be the lightest. In terms of colour the product prepared using 90:10 (RBO:SO) blend was similar to that of the control sample with egg. Although the lightness values varied slightly no significant differences were observed in L* values among the blends. b* or yellowness index increased significantly with an increase in sesame oil. The total colour difference ΔE showed higher values (Table 2) for mayonnaise prepared with 40% and above ratios of sesame oil. This was also due to the fact that natural pigments present in oil lowered emulsion stability and some amount of oil separation could be observed in samples wherein sesame oil was above 40% (Table 1) where stability ratio’s decreased from 88.03 to 53.69% in the blends.

Table 2.

Stability test and colour measurement of mayonnaise prepared with RBO and SO

| Sl no | Refined oil | Rice bran oil (RBO) | Sesame oil (SO) | Stability ratio (%) | Instrumental colour measurement | ||||

|---|---|---|---|---|---|---|---|---|---|

| 27 °C | 80 °C | L* | a* | b* | ΔE | ||||

| 1 | 100* | – | – | 96.48 ± 0.02d | 90.21 ± 0.14f | 72.86 ± 0.11d | 1.96 ± 0.02g | 21.98 ± 2.15b | 28.63 ± 2.14d |

| 2 | 100 | – | – | 98.89 ± 0.12e | 95.48 ± 0.11h | 79.92 ± 0.13f | 0.54 ± 0.12b | 10.85 ± 1.18a | 17.77 ± 2.31a |

| 3 | – | 100 | 99.53 ± 0.04f | 94.12 ± 0.27g | 77.28 ± 0.24e | 0.71 ± 0.01c | 22.54 ± 2.91b | 25.05 ± 2.39c | |

| 4 | – | 90 | 10 | 98.65 ± 0.11e | 97.13 ± 0.13j | 73.39 ± 0.31d | 0.12 ± 0.01a | 25.46 ± 2.34d | 23.64 ± 2.01b |

| 5 | – | 80 | 20 | 98.49 ± 0.37e | 96.12 ± 0.15i | 73.75 ± 0.12d | 0.93 ± 0.01d | 21.19 ± 1.63b | 23.27 ± 2.18b |

| 6 | – | 70 | 30 | 97.27 ± 0.13d | 95.39 ± 017h | 73.19 ± 0.19d | 1.05 ± 0.03d | 22.15 ± 1.58b | 23.83 ± 1.98b |

| 7 | – | 60 | 40 | 92.1 ± 0.27c | 88.03 ± 0.41e | 70.13 ± 0.34c | 1.74 ± 0.21f | 23.66 ± 1.78c | 36.41 ± 1.64e |

| 8 | – | 50 | 50 | 89.18 ± 0.32b | 75.94 ± 0.22d | 69.87 ± 0.28bc | 1.32 ± 0.14e | 23.94 ± 2.31c | 36.77 ± 1.18e |

| 9 | – | 40 | 60 | 54.22 ± 0.22a | 58.16 ± 0.37c | 69.72 ± 0.15bc | 1.79 ± 0.02f | 23.11 ± 2.09c | 36.37 ± 1.42e |

| 10 | – | 30 | 70 | 54.99 ± 0.31a | 55.65 ± 0.39b | 68.23 ± 0.17ab | 1.29 ± 0.17e | 23.36 ± 2.11c | 28.79 ± 3.01d |

| 11 | – | 20 | 80 | 54.56 ± 0.18a | 55.44 ± 0.11b | 67.88 ± 0.21a | 2.04 ± 0.14g | 23.31 ± 2.96c | 37.92 ± 2.52e |

| 12 | – | 10 | 90 | 54.93 ± 0.14a | 53.69 ± 0.15a | 68.54 ± 0.11ab | 2.35 ± 0.02h | 22.39 ± 2.35b | 36.86 ± 2.63e |

| 13 | – | 0 | 100 | 54.82 ± 0.28a | 53.18 ± 0.19a | 72.61 ± 0.18d | 1.66 ± 0.13f | 21.38 ± 2.14b | 24.42 ± 2.18b |

*Contains egg, all the rest with xanthan gum, values in the same column with different superscripts differ significantly (p < 0.05)

Texture/consistency measurement

Visual observations

Control mayonnaise had smell of raw oil and the formulation was spoonable. Mayonnaise with RBO (100%) was smooth, thicker in consistency than that of control sample but without the characteristic smell of RBO. As the level of sesame oil increased the emulsion became thinner and pourable, the characteristic nature of the emulsion declined and it appeared to be slimy. Also the strong flavour of sesame became more dominant. The products at 50:50, 40:60, 30:70 and 20:80 levels of the blended oils of RBO and SO showed slight to moderate oil separation and were unacceptable sensorily. Samples with RBO:SO ratio’s 100:0, 90:10, 80:20 and control were considered for sensory analyses.

Instrumental consistency

A spreadability rig was used to assess the spreadability of table fats by Glibowski et al. (2008). The control sample prepared with egg and refined oil showed a reading of 1.44 N and the product was thick spoonable, and did not flow (Table 1). Mayonnaise prepared using xanthan gum and refined oil (100%) was closer to that of control sample (egg formulation, 1.44 N) but the texture measurement was 1.62 N. Mayonnaise prepared using SO (100%) was thin, slippery and slimy, however oil separation was observed after an hour of preparation. Mayonnaise was prepared from the blends of RBO and SO (90:10. 80:20, 70:30, 60:40 and 50:50). 50:50 blends was found to be suitable for mayonnaise. A good emulsion with desirable spreadability was observed at 1.44 N in the control sample prepared with egg. The sample with 80:20 ratio of RBO:SO was found to be closest to that of the control sample in terms of textural (consistency) parameters (1.362 N). Texture values in the range of 1.2–1.6 N indicated acceptable consistency and spreadability. Spreads with values lower than 1.0 N were thinner in consistency and those having less than 0.6 N were flowy. Liu et al. (2007) have reported the application of whey protein isolate and low-methoxy pectin-based fat mimetics in mayonnaise, in terms of texture, their formulation with pectin weak-gel as fat mimetic showed similar texture values as those of the full fat sample.

Emulsion stability

Mayonnaise stability was determined by monitoring oil separation and texture attributes. The stability ratio (SR) of the prepared emulsions was carried out at 27 °C and 80 °C. It was observed that at 27 °C for control sample the SR was 96.48, while the highest SR was observed in mayonnaise prepared with 100% RBO, followed by 100% refined oil and blends of RBO:SO (90:10, and 80:20). In general xanthan gum has been reported to increase the stability of mayonnaise and emulsions as well as its structure by the formation of aggregates of larger size (Yilmazer and Kokini 1992). It was observed that the SR decreased with an increase in the level of sesame oil. No significant differences were observed among mayonnaise samples containing sesame oil above 60% with respect to SR. Samples containing sesame oil above 60% were thinner in consistency, pourable and a thin layer of oil separation could be observed. It can be concluded that above 40% sesame oil the stability ration declined. Mayonnaise instability is caused due to convergence of oil droplets. An effective way of coalescence is to avoid oil droplets from getting too close together, e.g. generating sufficiently strong repulsive between droplets.

In mayonnaise, oil accounts for 75% or more of the total volume. This means that the oil droplets become distorted from their normal, spherical shape. The close packing of the droplets allows them to interact very strongly with one another. It is this combination of factors that gives mayonnaise its characteristic high viscosity. The strength of the interactions between oil droplets depends on the van der Waals attractions. The quality of the emulsion depends on the right balance between these forces: too strong an attraction will pull the droplets together causing the aqueous phase to be squeezed out and promoting coalescence of the droplets. Too strong a repulsion will allow the droplets to slip easily past one another. This was observed when sesame oil was higher than 40%, where the emulsion had low viscosity and was prone to ‘creaming’ as the oil droplets settled into their minimum volume allowing the water to drain out. Similar results have been reported by Kiosseoglou and Sherman (1983).

Oryzanol and sesamol content

Table 3 shows the percentage of oryzanol and sesamol content in the mayonnaise prepared with individual and blends of both the oils. It can be seen that the percentage of oryzanol decreased with a decrease in the RBO oil in the blends. The consistency of 90:10 and 80:20 blends were comparatively closer to that of the control mayonnaise, and these had 0.813 and 0.71. 1% of oryzanol and 0.088 and 0.176% of sesamol contents respectively. 0.5% of oryzanol is known to have hypocholesterolemic effect in humans. Both oryzanol and sesamol are known natural antioxidants and together they provide synergistic health benefits. Lichtenstein et al. (1994) in his study has concluded that consumption of a diet enriched in rice bran oil had comparable advantages in terms of lowering plasma lipid levels or reduce the cardiovascular risk profile.

Table 3.

Oryzanol and Sesamol content of mayonnaise prepared with RBO and SO

| Sl no | Oil blend (%) | Oryzanol % | Sesamol % | |

|---|---|---|---|---|

| RBO | SO | |||

| 1 | 100 | – | 0.91 ± 0.01i | – |

| 2 | 90 | 10 | 0.81 ± 0.21h | 0.08 ± 0.01a |

| 3 | 80 | 20 | 0.71 ± 0.14g | 0.17 ± 0.01a |

| 4 | 70 | 30 | 0.60 ± 0.38f | 0.26 ± 0.02b |

| 5 | 60 | 40 | 0.50 ± 0.17e | 0.35 ± 0.01c |

| 6 | 50 | 50 | 0.40 ± 0.05d | 0.44 ± 0.10d |

| 7 | 40 | 60 | 0.30 ± 0.01c | 0.52 ± 0.14e |

| 8 | 30 | 70 | 0.20 ± 0.05b | 0.61 ± 0.09f |

| 9 | 20 | 80 | 0.10 ± 0.02a | 0.70 ± 0.11g |

| 10 | 10 | 90 | 0.09 ± 0.01a | 0.85 ± 0.08h |

| 11 | – | 100 | – | 0.88 ± 0.13i |

Values in the same column with different superscripts differ significantly (p < 0.05)

Rheological properties

A significantly higher viscosity was obtained from the control formulation. This result indicates that the highest viscosity was obtained for mayonnaise formulated with egg yolk and this could not be achieved using xanthan gum. Similar results have been reported by Ghoush et al (2008). Table 4 shows the rheological data of mayonnaise samples formulated by using various blends of oils.

Table 4.

Rheological data for mayonnaise with prepared with RBO and SO

| Sample | Oil blend | Yield stress (mPa) | Apparent viscosity | Flow behaviour index | Consistency index (mPa sn) | Correlation coefficient (r) | ||

|---|---|---|---|---|---|---|---|---|

| Refined oil | Rice bran oil (RBO) | Sesame oil (SO) | ||||||

| 1 | 100* | – | – | 6.10 ± 0.23c | 3.09 ± 0.13f | 0.29 ± 0.02b | 47.49 ± 1.00i | 0.98 ± 0.01 |

| 2 | 100 | – | – | 11.43 ± 0.85f | 1.90 ± 0.03de | 0.23 ± 0.01a | 33.36 ± 1.81g | 0.98 ± 0.01 |

| 3 | – | 100 | – | 14.41 ± 0.27g | 2.17 ± 0.08e | 0.23 ± 0.01a | 37.76 ± 0.87h | 0.99 ± 0.00 |

| 4 | – | 90 | 10 | 9.70 ± 0.27e | 1.72 ± 0.18d | 0.24 ± 0.02a | 29.51 ± 1.27f | 0.98 ± 0.01 |

| 5 | – | 80 | 20 | 8.17 ± 0.42d | 1.47 ± 0.04c | 0.25 ± 0.01a | 23.81 ± 1.30e | 0.99 ± 0.00 |

| 6 | – | 70 | 30 | 7.57 ± 0.17d | 1.53 ± 0.04c | 0.29 ± 0.00b | 22.15 ± 0.77e | 0.99 ± 0.00 |

| 7 | – | 60 | 40 | 5.58 ± 0.11c | 1.25 ± 0.02c | 0.32 ± 0.00a | 16.28 ± 0.01d | 0.99 ± 0.00 |

| 8 | – | 50 | 50 | 3.42 ± 0.17b | 0.67 ± 0.01b | 0.31 ± 0.02a | 9.00 ± 0.44c | 0.98 ± 0.00 |

| 9 | – | 40 | 60 | 1.03 ± 0.04a | 0.30 ± 0.03a | 0.49 ± 0.09cd | 2.20 ± 0.55b | 0.96 ± 0.02 |

| 10 | – | 30 | 70 | 0.78 ± 0.06a | 0.27 ± 0.03a | 0.56 ± 0.08d | 1.48 ± 0.34a | 0.98 ± 0.00 |

| 11 | – | 20 | 80 | 0.85 ± 0.11a | 0.26 ± 0.01a | 0.38 ± 0.02b | 2.82 ± 0.10b | 0.98 ± 0.01 |

| 12 | – | 10 | 90 | 0.77 ± 0.08a | 0.26 ± 0.03a | 0.45 ± 0.04c | 2.21 ± 0.63b | 0.98 ± 0.00 |

| 13 | – | 0 | 100 | 2.97 ± 0.18b | 0.64 ± 0.02b | 0.29 ± 0.01b | 9.19 ± 0.90c | 0.98 ± 0.00 |

*Contains egg, all the rest with xanthan gum, values in the same column with different superscripts differ significantly (p < 0.05)

For all mayonnaise samples, shear stress and shear rate data showed nonlinear relationship. Thus, non-Newtonian flow characteristic was observed and the flow behavior index (n) was found to be less than unity. The power law model was used to explain the relationship between shear rate and apparent viscosity and all samples were found to fit the model with high determination coefficients (0.969–0.995). Power law, Herschel Bulkley and Casson models have been widely used to describe the flow properties of mayonnaise and salad dressings (Ma and Barbosa-Canovas 1995).

Flow behavior index (n) values of samples were in the range of 0.23–0.56 (Table 2), and showed that all the samples were shear thinning and the apparent viscosity decreased with increasing shear rate. In a concentrated emulsion, flocculation leads to the formation of a three-dimensional network of aggregated droplets. Increasing the shear rate causes progressive deformation and disruption of the aggregated particles, which in turn decreases emulsion resistance to flow and reduces its apparent viscosity (Mun et al. 2009).

The apparent viscosity (µ) of the control mayonnaise prepared with egg was 3.09 Pa s which is the highest among all the samples prepared. Mayonnaise prepared with RBO alone was found to be closest to the control egg formulation with an apparent viscosity of 2.17 Pa s. All the other samples were less viscous. It was observed that increasing the amount of sesame oil decreased the apparent viscosity of the mayonnaise. A similar trend can be observed in the instrumental texture (consistency) values (Table 1) which shows lower values for emulsions prepared with sesame oil.

The consistency index (κ) Table 4, was the highest at 47.49 mPa sn for the control sample. Lee et al. (2013) have reported that the consistency index for commercial mayonnaise ranged between 20.60 and 64.82 mPa sn. In our studies the consistency index of the samples made with RBO:SO blends of 90:10, 80:20, and 70:30 ranged between 22.15 and 37.76 mPa sn. Mayonnaise prepared using 100% RBO had highest consistency index values at 37.76, which is significantly lower than that of the control. Incorporating xanthan gum along with dietary fibre increased flour paste viscosities and batter viscoelasticity in eggless gluten-free muffins as reported by Singh et al (2016). Low consistency index and high flow behaviour index (Table 4) was observed in mayonnaise with higher amounts of sesame oil. In other words these emulsions were of pourable consistency and with decreased stability ratios as shown in Table 2. According to a study by Rahbari et al. (2014), the rheological results of low cholesterol mayonnaise containing wheat germ protein isolate and xanthan gum as egg substitutes showed similar characteristics to those of a typical mayonnaise made using egg yolk.

Sensory quality/product acceptability

Preliminary sensory analysis was carried out for all the 13 products (Table 1) prepared the panelists felt that samples 6–13 were not meeting the sensory quality required for a mayonnaise, hence they were not considered for QDA analysis.

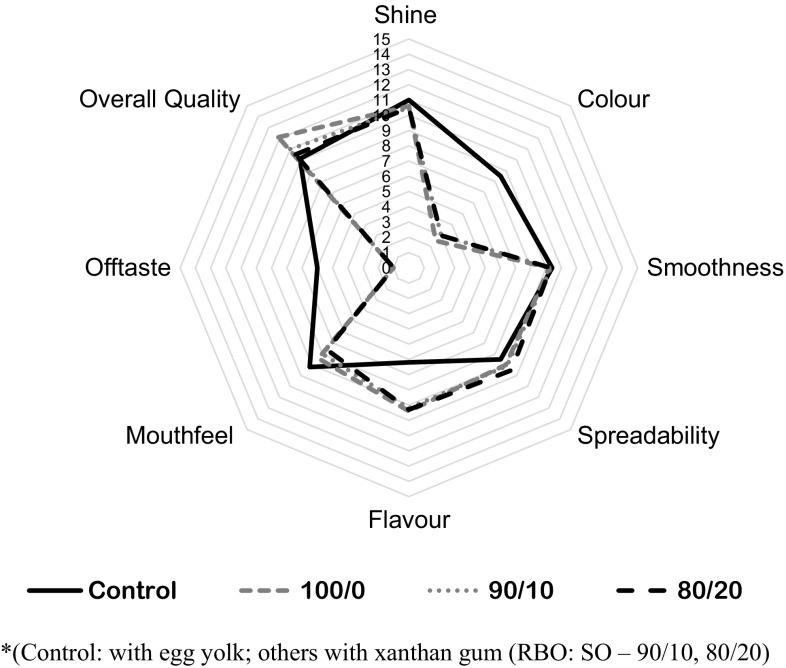

Sensory analyses carried out for control mayonnaise with egg, RBO (100%) and RBO:SO blends (90/10 and 80/20) are shown in Fig. 1. The shine and smoothness attributes of the product showed no significant differences among the samples. However the colour of control product was light yellow due to egg yolk, while mayonnaise prepared RBO alone and blends were cream to white in colour. Only marginal variations were observed in spreadability, but significant difference was observed in flavour, the control which contained egg yolk had a strong egg flavour and this was absent in other samples. The overall quality scores were highest for 100% RBO mayonnaise followed by 90/10. RBO:SO (80/20) was closer to that of control only due to the low scores of flavour profile (egg smell) and not due to the other attributes of mayonnaise.

Fig. 1.

Sensory analysis of mayonnaise with rice bran oil and sesame oil. *(Control: with egg yolk; others with xanthan gum (RBO:SO—90/10, 80/20)

Conclusion

Rice bran oil (100%) or a blend of rice bran and sesame oils (90:10, 80:20) were used as major ingredients in preparation of a mayonnaise in which xanthan gum was used as an egg yolk substitute. Added advantages of the new formulation are the health benefits provided by the presence of nutraceuticals mainly oryzanol and sesamol in rice bran and sesame oils. The mayonnaise with added health benefits associated with RBO and SO was much preferred than control, as these products had high sensory overall acceptability scores. Thus a healthy mayonnaise was formulated and standardized.

Acknowledgement

The authors express their thanks to the Director, CSIR-Central Food Technological Research Institute, Mysore. The authors also wish to thank CSIR-CFTRI for the financial assistance under MLP projects.

Compliance with ethical standards

Conflict of interest

The authors declare that they have no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Barlow SM. Toxicological aspects of antioxidants used as food additives. In: Hudson BJF, editor. Food antioxidants. London: Elsevier; 1990. pp. 253–307. [Google Scholar]

- Bhattacharya S. Yield stress and time-dependent rheological properties of mango pulp. J Food Sci. 1999;64:1029–1033. doi: 10.1111/j.1365-2621.1999.tb12275.x. [DOI] [Google Scholar]

- Bringe NA, Cheng J. Low-fat, low-cholesterol egg yolk in food applications. Food Technol. 1995;49:94–106. [Google Scholar]

- Caporaso N, Genovese A, Burke R, Ryan CB, Sacchia R. Effect of olive mill wastewater phenolic extract, whey protein isolate and xanthan gum on the behaviour of olive O/W emulsions using response surface methodology. Food Hydrocoll. 2016;61:66–76. doi: 10.1016/j.foodhyd.2016.04.040. [DOI] [Google Scholar]

- Chun JA, Song ES. Sensory and physical properties of low-fat mayonnaise made with starch-based fat replacers. Korean J Food Sci Technol. 1995;27:839–844. [Google Scholar]

- Depree JA, Savage GP. Physical and flavour stability of mayonnaise. Trends Food Sci Technol. 2001;12:157–163. doi: 10.1016/S0924-2244(01)00079-6. [DOI] [Google Scholar]

- Duncan DB. Multiple range and multiple F tests. Biometrics. 1955;11:1–42. doi: 10.2307/3001478. [DOI] [Google Scholar]

- Ghoush MA, Samhouri M, Al-Holy M, Herald T. Formulation and fuzzy modeling of emulsion stability and viscosity of a gum–protein emulsifier in a model mayonnaise system. J Food Eng. 2008;84(2):348–357. doi: 10.1016/j.jfoodeng.2007.05.025. [DOI] [Google Scholar]

- Glibowski P, Zarzycki P, Krzepkowska M. The rheological and instrumental textural properties of selected table fats. Int J Food Prop. 2008;11:678–686. doi: 10.1080/10942910701622599. [DOI] [Google Scholar]

- Gopalakrishna AG, Khatoon S, Shiela PM, Sarmandal CV, Indira TN, Mishra A. Effect of refining of crude rice bran oil on the retention of oryzanol in the refined oil. J Am Oil Chem Soc. 2002;78:127–131. [Google Scholar]

- Gopalakrishna AG, Khatoon S, Babylatha R. Frying performance of rice bran oils. J Food Lipids. 2005;12:1–11. doi: 10.1111/j.1745-4522.2005.00001.x. [DOI] [Google Scholar]

- Harrison FE, Cunningham LJ. Influence of salt on properties of liquid yolk andfunctionality in Mayonnaise. Poult Sci. 1986;65:915–921. doi: 10.3382/ps.0650915. [DOI] [Google Scholar]

- Hasenhuettl GL. Overview of food emulsifiers. In: Hasenhuettl GL, Hartel RW, editors. Food emulsifiers and their applications. New York: Springer; 2008. pp. 1–7. [Google Scholar]

- Hemalatha S, Raghunath M, Ghafoorunissa Dietary sesame oils inhibits iron-induced oxidative stress in rats. Br J Nutr. 2004;92:581–587. doi: 10.1079/BJN20041239. [DOI] [PubMed] [Google Scholar]

- Hirata F, Fujita K, Ishikura Y, Hosoda K, Ishikawa T, Nakamura H. Hypocholesterolemic effect of sesame lignan in humans. Atherosclerosis. 1996;122:135–136. doi: 10.1016/0021-9150(95)05769-2. [DOI] [PubMed] [Google Scholar]

- Hsu DZ, Su SB, Chien SP, Chiang PJ, Li YH, Lo YJ. Effect of sesame oil on oxidative-stress-associated renal injury in endotoxemic rats: involvement of nitric oxide and pro inflammatory cytokines. Shock. 2005;24:276–280. doi: 10.1097/01.shk.0000172366.73881.c7. [DOI] [PubMed] [Google Scholar]

- Kiosseoglou VD. Egg yolk. In: Charalambous G, Doxastakis G, editors. Food emulsifiers: chemistry, technology, functional properties and applications. London: Elsevier; 1989. pp. 63–85. [Google Scholar]

- Kiosseoglou VD, Sherman P. Influence of egg yolk lipoproteins on the rheology and stability of oil/water emulsions and mayonnaise 1. Viscoelasticity of groundnut oil-in-water emulsions and mayonnaise. J Texture Stud. 1983;14:397–417. doi: 10.1111/j.1745-4603.1983.tb00358.x. [DOI] [Google Scholar]

- Kokini JL, Dickie A. An attempt to identify and model transient viscoelastic flow in foods. J Texture Stud. 1981;12:539–557. doi: 10.1111/j.1745-4603.1981.tb00266.x. [DOI] [Google Scholar]

- Lee I, Lee S, Lee N, Ko S. Reduced-fat mayonnaise formulated with gelatinized rice starch and xanthan gum. Cereal Chem. 2013;90(1):29–34. doi: 10.1094/CCHEM-03-12-0027-R. [DOI] [Google Scholar]

- Lichtenstein AH, Ausman LM, Carrasco W, Gualtieri LJ, Jenner JL, Ordovas JM, Nicolosi RJ, Goldin BR, Schaefer EJ. Rice bran oil consumption and plasma lipid levels in moderately hypercholesterolemic humans. Arterioscler Thromb Vasc Biol. 1994;14:549–556. doi: 10.1161/01.ATV.14.4.549. [DOI] [PubMed] [Google Scholar]

- Liu H, Xu XM, Guo SD. Rheological, texture and sensory properties of low-fat mayonnaise with different fat mimetics. LWT Food Sci Technol. 2007;40:946–954. doi: 10.1016/j.lwt.2006.11.007. [DOI] [Google Scholar]

- Ma L, Barbosa-Canovas GV. Rheological characterization of mayonnaise. Part II: flow and viscoelastic properties at different oil and xanthan gum concentration. J Food Eng. 1995;25:409–425. doi: 10.1016/0260-8774(94)00010-7. [DOI] [Google Scholar]

- Mistry VV, Hassan HN. Manufacture of nonfat yogurt from a high milk protein powder. J Dairy Sci. 1992;75:947–957. doi: 10.3168/jds.S0022-0302(92)77835-7. [DOI] [PubMed] [Google Scholar]

- Mun S, Kim YL, Kang CG, Park KH, Shim JY, Kim YR. Development of reduced-fat mayonnaise using 4αGTase-modified rice starch and xanthan gum. Int J Biol Macromol. 2009;44(5):400–407. doi: 10.1016/j.ijbiomac.2009.02.008. [DOI] [PubMed] [Google Scholar]

- Namiki M. The chemistry and physiological functions of sesame. Food Rev Int. 1995;11:281–329. doi: 10.1080/87559129509541043. [DOI] [Google Scholar]

- Raghuram TC, Rukmini C. Nutritional significance of rice bran oil. Indian J Med Res. 1995;10:241–244. [PubMed] [Google Scholar]

- Rahbari M, Aalami M, Kashaninejad M, Maghsoudlou Y. Effect of wheat germ protein isolate and xanthan gum as egg substitutes on the rheological properties of mayonnaise. J Food Sci Technol. 2014;12(46):106–118. [Google Scholar]

- Seetharamaiah GS, Prabakar JV. Oryzanol content of Indian rice bran oil and its extraction from soap stock. J Food Sci Technol. 1986;23:270–274. [Google Scholar]

- Shukla AK, Singh RP. Detection of sesame oil in other oils and fats. J Oleo Sci. 2005;54(10):543–544. doi: 10.5650/jos.54.543. [DOI] [Google Scholar]

- Singh JP, Kaur A, Singh N. Development of eggless gluten-free rice muffins utilizing black carrot dietary fibre concentrate and xanthan gum. J Food Sci Technol. 2016;53(2):1269–1278. doi: 10.1007/s13197-015-2103-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stefan K, Kocevski D. Determination of the rheological properties of mayonnaise. Int J Eng Appl Sci. 2013;4(6):36–40. [Google Scholar]

- Worrasinchai S, Suphantharika M, Pinjai S, Jamnong P. β-glucan prepared from spent brewer’s yeast as a fat replacer in mayonnaise. Food Hydrocoll. 2006;20:68–78. doi: 10.1016/j.foodhyd.2005.03.005. [DOI] [Google Scholar]

- Wu WH, Kang YP, Wang NH, Jou HJ, Wang TA. Sesame ingestion affects sex hormones, antioxidant status and blood lipids in postmenopausal women. J Nutr. 2006;136:1270–1275. doi: 10.1093/jn/136.5.1270. [DOI] [PubMed] [Google Scholar]

- Yilmazer G, Kokini JL. Effect of salt on the stability of propylene glycol alginate/xanthan gum/polysorbate-60 stabilized oil-in-water emulsions. J Texture Stud. 1992;23:195–213. doi: 10.1111/j.1745-4603.1992.tb00520.x. [DOI] [Google Scholar]