Abstract

Biopolymer processing and handling is greatly facilitated by the use of ionic liquids, given the increased solubility, and in some cases, structural stability imparted to these molecules. Focussing on proteins, we highlight here not just the key drivers behind protein-ionic liquid interactions that facilitate these functionalities, but address relevant current and potential applications of protein-ionic liquid interactions, including areas of future interest.

Keywords: ionic liquids, enzymes, proteins, intermolecular interactions, reactions, molecular organization, physico-chemical relationships

Introduction

Proteins as both materials and catalysts have a number of practical features when considering global challenges such as developing a circular economy and minimization of environmental impacts. They are biodegradable and can be readily biosourced, are renewable, and can act as biocompatible scaffolds. Being polymeric materials consisting of combinations of around 20 main building blocks (amino acids), the range of materials properties that are accessible is substantial. The different amino acid functionalities lend these polymers to further post-processing, which can further extend the property scope. In addition to their catalytic properties as enzymes, proteins such as keratins, collagens, silks, and plant-fibers are strong, can be highly elastic, and possess many other desirable materials properties, including being suitable scaffolds for living cells. As such, these biopolymers have found significant use in the medical industries in particular, due to this biocompatibility and ability to replace or enhance existing tissues (Defrates et al., 2018).

Ionic liquids have firmly established themselves as useful industrial and laboratory solvents, reflected by substantial and ever-increasing literature in the area. Due to the reduced vapor pressure, arising from the strong electrostatic interactions of the constituent ions, they possess a number of useful properties, some of which underpin their “green” reputation. This includes minimal harmful vapor when handling, low flammability, and the lack of vaporization, which gives an opportunity to recycle these liquids across many cycles. The number of different ion combinations that can be considered leads to over 106 potential ionic liquids (Rogers and Seddon, 2003), before mixtures are even considered, each with different physical and chemical properties. Thus, in principle, tuning of the properties for a particular task can be achieved through judicious selection of ion combinations. They are especially good for the dissolution of recalcitrant materials, as the combination of electrostatic, hydrogen-bonding, π- and van der Waals interactions means that non-covalent (and sometimes covalent) interactions within these materials are more readily broken, with concomitant stabilization in the solution form.

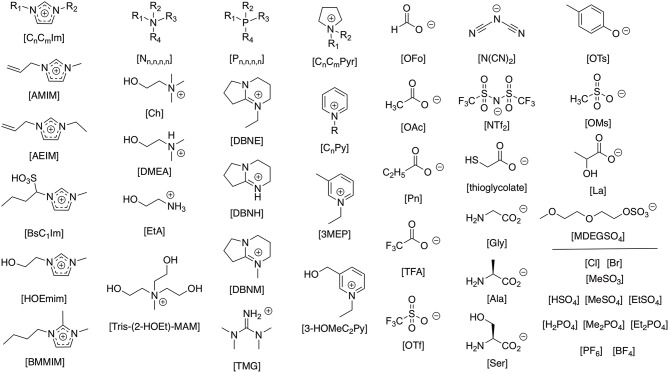

The interaction of ionic liquids with proteins adds a significant new landscape for the understanding of ionic-liquid solute interactions. With the vast range of cation and anion combinations available (see Figure 1 for those highlighted in this review) affording a differing balance of intermolecular interactions and thus interacting properties that can constitute an ionic liquid, not to mention mixtures of ions, the different anionic, cationic, hydrophobic, and polar interactions from each amino acid of a protein backbone becomes a many dimensional challenge.

Figure 1.

Representative ionic liquid cation and anion structures presented throughout the text.

Structural Proteins

Keratins

Keratins are proteins that can be sourced from the skin, hair, horns, nails, beaks, and teeth of different mammals, reptiles, birds, and fish (Mckittrick et al., 2012), and constitute a significant biowaste stream (Zoccola et al., 2009; Sharma and Gupta, 2016; Holkar et al., 2018). As a natural fiber, wool is widely used commercially in the textile industry (Lewis and Rippon, 2013), and has found many uses ranging from biomedical and cosmetic applications (Rouse and Van Dyke, 2010; Silva et al., 2014; Sharma and Gupta, 2016), (being documented in medical use at least since ancient Greek times) (Alves et al., 2013), to fertilizers and flame retardants (Sharma and Gupta, 2016).

Keratins can be categorized as either hard or soft, depending on their sulfur content, with hard keratins, like wool, having a high sulfur content, and therefore more covalent (disulfide) crosslinks (Simpson and Crawshaw, 2002; Zoccola et al., 2009; Mckittrick et al., 2012). Soft keratins can be found in the outer layer of the skin and have lower sulfur content and concomitantly fewer covalent (disulfide) crosslinks (Zoccola et al., 2009; Mckittrick et al., 2012). The disulfide bridges and strong inter- and intra-protein hydrogen-bonding of keratin proteins provide a significant processing challenge (Liu et al., 2018), often addressed through using mixtures of different solvents, with each solvent playing a key role in breaking covalent and/or non-covalent bonds (Xie et al., 2005). Volatility, corrosiveness, environmental impact, difficulty of recycling, and lack of renewability have all been highlighted as issues with these solvent regimes, in addition to the requirements for multi-step processes and resultant keratin degradation leading to regenerated keratin with a lower value (Hameed and Guo, 2009; Idris et al., 2013; Ji et al., 2014; Zheng et al., 2015; Liu et al., 2017; Zhang et al., 2017b). As such, there has been a growing demand to develop new solvents for keratin dissolution that are able to overcome the disadvantages associated with the traditional/existing solvents.

Ionic liquids have naturally been examined as solvents for the post-processing of keratin (Xie et al., 2005; Hameed and Guo, 2009; Sun et al., 2009; Zhao et al., 2010b; Lovejoy et al., 2012; Wang and Cao, 2012; Idris et al., 2013, 2014a,b; Li and Wang, 2013; Chen et al., 2014, 2015; Ghosh et al., 2014; Ji et al., 2014; Plowman et al., 2014; Wang et al., 2014, 2016; Zheng et al., 2015; Kammiovirta et al., 2016; Sharma and Gupta, 2016; Tran and Mututuvari, 2016; Liu et al., 2017, 2018; Zhang et al., 2017a;Zhang et al., 2017b). The dissolution process of keratin fiber starts with the swelling of the cuticle (outer layer) followed by the swelling and preferential dissolution of the cortex (inner layer). Of the two components, the cuticle generally takes longer to dissolve due to the high number of disulfide bonds present (Chen et al., 2014), however, selective swelling of the cuticle retaining the cortex intact is possible through careful control of conditions (Chen et al., 2015). According to Wang et al. (2014) for imidazolium cation and chloride anion-based ionic liquids, the combined effect of the anion and cation is responsible for breaking the covalent and non-covalent interactions in keratin, with each component participating through different interactions with the substrate (Ghosh et al., 2014).

An extensive array of ionic liquids has been tested with keratins (Table 1), reflecting the interest in reprocessing this protein. Early on, [C4C1Im][Cl] gained significant traction as the ionic liquid of choice for keratin dissolution (Xie et al., 2005; Hameed and Guo, 2009; Sun et al., 2009; Lovejoy et al., 2012; Idris et al., 2013; Li and Wang, 2013; Chen et al., 2014; Ghosh et al., 2014; Ji et al., 2014; Plowman et al., 2014; Wang et al., 2014; Zheng et al., 2015; Tran and Mututuvari, 2016; Zhang et al., 2017a; Liu et al., 2018), being effective for a broad range of keratin types, including human hair, hooves, goat and sheep wool, and duck, turkey and chicken feathers. Other small-cation imidazolium ionic liquids, primarily [AMIM], [C2C1Im] and [C4C1Im]-based derivatives have also been extensively trialed. It is the role of the anion, however, that appears to be key in the quality of regenerated keratin, with the nucleophilicity of chloride being suggested as the reason behind the degradation particularly of the disulfide bonds, and subsequent formation of cysteic acid (Ghosh et al., 2014). Acetate has also been strongly implicated in this process and was more effective than chloride, both for keratin and model systems (Zhang et al., 2017a). The differences between different cations with the same anion may potentially be attributed to the differences in ion-ion interactions providing a different effective availability of the corresponding anion. The wider ionic liquid organizational structure, combined with the specific structuring of the keratin, may also have implications for selectivity of different disulfides in the degradation process (Karimi et al., 2016).

Table 1.

Summary of keratin solubility in selected ionic liquids.

| Ionic liquid | Keratin type | Solubility | Dissolution conditions | References |

|---|---|---|---|---|

| [AMIM][Cl] | Wool keratin | 8 wt% | 130°C, N2, 10 h | Xie et al., 2005 |

| Turkey feathers | 50 wt% | 130°C, N2, 10 h | Idris et al., 2013 | |

| Wool keratin | 21 wt% | 130°C, 10.5 h | Li and Wang, 2013 | |

| Merino Wool | 200 mg/g | 130°C, N2, 10 h | Idris et al., 2014b | |

| Duck feather | 5 wt% | 120°C, 60 min | Ji et al., 2014 | |

| Human hair | 19 wt% | 130°C | Wang et al., 2014 | |

| Goat wool keratin | 9 wt% | 120°C, 30 min | Zhang et al., 2017a | |

| Wool keratin | 13 wt% | 120°C, 24 h | Liu et al., 2018 | |

| [AMIM][N(CN)2] | Merino Wool | 475 mg/g | 130°C, N2, 10 h | Idris et al., 2014b |

| [BsC1Im][HSO4] | Duck feather | 4 wt% | 120°C, 60 min | Ji et al., 2014 |

| [C1Im][OTf] | Duck feather | < 1 wt% | 120°C, 60 min | Ji et al., 2014 |

| [C2C1Im][OAc] | Wool keratin | 38 wt% | 120°C, 24 h | Liu et al., 2018 |

| Chicken Feathers | 5 wt% | 130°C, 2.5 h | Kammiovirta et al., 2016 | |

| Goat wool keratin | 9 wt% | 120°C, 30 min | Zhang et al., 2017a | |

| [C2C1Im][Cl] | Wool keratin | 14 wt% | 120°C, 24 h | Liu et al., 2018 |

| Goat wool keratin | 9 wt% | 120°C, 30 min | Zhang et al., 2017a | |

| [C2C1Im][Et2PO4] | Goat wool | 8 wt% | 120°C, 1.5 h | Liu et al., 2017 |

| Goat wool keratin | 9 wt% | 80-140°C,c 30–180 min | Zhang et al., 2017a | |

| Wool keratin | 22 wt% | 120°C | Liu et al., 2018 | |

| [C2C1Im][Me2PO4] | Wool keratin | 8 wt% | 130°C, 1.5 h | Zheng et al., 2015 |

| Wool keratin | 9 wt% | 130°C | Zhang et al., 2017b | |

| [C4C1Im][OAc] | Goat wool keratin | 9 wt% | 120°C, 30 min | Zhang et al., 2017a |

| Goat wool | 8 wt% | 120°C, 2.5 h | Liu et al., 2017 | |

| Wool keratin | 8 wt% | 130°C, 10 min | Zheng et al., 2015 | |

| Wool | single fibers | 120°C, 3 min | Chen et al., 2014 | |

| Merino Wool | Cuticle removal | 75°C, 35 min | Chen et al., 2015 | |

| Goat wool keratin | 9 wt% | 120°C, 30 min | Zhang et al., 2017a | |

| [C4C1Im][BF4]† | Wool keratin | n/d | 130°C, N2, 24 h | Xie et al., 2005 |

| Human hair | insoluble | 130°C | Wang et al., 2014 | |

| [C4C1Im][Br] | Wool keratin | 2 wt% | 130°C, N2, 10 h | Xie et al., 2005 |

| Duck feather | 4 wt% | 120°C, 60 min | Ji et al., 2014 | |

| Human hair | 10 wt% | 130°C | Wang et al., 2014 | |

| [C4C1Im][Cl] | Wool keratin | 11 wt% | 130°C, N2, 10 h | Xie et al., 2005 |

| Wool | 5 wt% | 100°C | Hameed and Guo, 2009 | |

| Chicken feather | 23 wt% | 100°C, N2, 48 h | Sun et al., 2009 | |

| Pig hoof powder | 1 wt% | 130°C, 10 h | Lovejoy et al., 2012 | |

| Turkey feathers | 50 wt% | 130°C, N2, 10 h | Idris et al., 2013 | |

| Wool keratin | 15 wt% | 130°C, 9 h | Li and Wang, 2013 | |

| Duck feather | 5 wt% | 120°C, 60 min | Ji et al., 2014 | |

| Human hair | 13 wt% | 130°C | Wang et al., 2014 | |

| Wool | single fibers | 120°C, 90 min | Chen et al., 2014 | |

| Merino Wool | 5 wt% | 99°C, 18 h | Plowman et al., 2014 | |

| Merino Wool fabric | 14 wt% | 120, 150, and 180°C, 30 min | Ghosh et al., 2014 | |

| Merino Wool | 250 mg/g | 130°C, N2, 10 h | Idris et al., 2014b | |

| Wool keratin | 8 wt% | 130°C, 5 h | Zheng et al., 2015 | |

| Raw wool | 6 wt% | 125–130°C, 6–8 h | Tran et al., 2016 | |

| Goat wool keratin | 9 wt% | 120°C, 30 min | Zhang et al., 2017a | |

| Wool keratin | 35 wt% | 120°C, 24 h | Liu et al., 2018 | |

| [C4C1Im][Bu2PO4] | Wool | 5.0% a | 120°C, N2, 12 h | Wang et al., 2016 |

| [C4C1Im][N(CN)2] | Wool keratin | 1.5 wt% | 120°C, 24 h | Liu et al., 2018 |

| [C4C1Im][Me2PO4] | Wool keratin | 8 wt% | 130°C, 1.5 h | Zheng et al., 2015 |

| [C4C1Im][H2PO4] | Wool | 5.0% a | 120°C, N2, 10.5 h | Wang et al., 2016 |

| Wool | 5.0%a | 120°C, N2, 17 h | Wang et al., 2016 | |

| [C4C1Im][HSO4] | Wool | 5.0% a | 120°C, N2, 13.5 h | Wang et al., 2016 |

| [C4C1Im][NO3] | Duck feather | 4 wt% | 120°C, 60 min | Ji et al., 2014 |

| [C4C1Im][SCN] | Wool keratin | 8 wt% | 130°C, 15 h | Zheng et al., 2015 |

| Wool keratin | < 1 wt% | 120°C, 24 h | Liu et al., 2018 | |

| [C4C1Pyr][Cl] | Wool keratin | 40 wt% | 120°C, 24 h | Liu et al., 2018 |

| Pig hoof powder | 1 wt% | 130°C, 10 h | Lovejoy et al., 2012 | |

| [C4Py][Cl] | Wool keratin | 36 wt% | 120°C, 24 h | Liu et al., 2018 |

| [Ch][thioglycolate] | Turkey feathers | 45 wt% | 130°C, N2, 10 h | Idris et al., 2013 |

| Merino Wool | 225 mg/g | 130°C, N2, 10 h | Idris et al., 2014b | |

| Wool | single fibers | 120°C, 10 min | Chen et al., 2014 | |

| [Ch][Pn] | Wool | single fibers | 120°C, 45 min | Chen et al., 2014 |

| Merino Wool | Cuticle removal | 75°C, 35 min | Chen et al., 2015 | |

| [DBNE][Et2PO4] | Goat wool | 8 wt% | 120°C, 3 h | Liu et al., 2017 |

| [DBNH][OAc] | Goat wool | 8 wt% | 120°C, 20 min | Liu et al., 2017 |

| [DBNM][Me2PO4] | Goat wool | 8 wt% | 120°C, 3.5 h | Liu et al., 2017 |

| [DMEA][HCO2] | Turkey feathers | 150 mg/g | 100°C, 7 h | Idris et al., 2014a |

| [HOEmim][Cl] | Wool keratin | 3 wt% | 120°C, 24 h | Liu et al., 2018 |

| [HOEmim][NTf2] | Chicken feathers | 21.75%b | 80°C, 4 h | Wang and Cao, 2012 |

| [N2, 2, 2, 1][Me2PO4] | Wool keratin | 8 wt% | 130°C, 3 h | Zheng et al., 2015 |

| [P4, 4, 4, 4][Cl] | Pig hoof powder | 1 wt% | 130°C, 10 h | Lovejoy et al., 2012 |

| [TMG][Pn] | Wool | single fibers | 100°C, 6.5 h, partial dissolution | Chen et al., 2014 |

| Merino Wool | Cuticle removal | 75°C, 35 min | Chen et al., 2015 |

wool fiber/ionic liquid mass ratio.

extraction yield based on 1:45 mass ratio.

No dissolution reported below 110°C.

Bs, 1-sulfobutyl; Pn, propionate; OAc, acetate; DBNE, 1-Ethyl-1,5-diazabicyclo[4.3.0]-non-5-enium; DBNH, 1,5-diazabicyclo [4.3.0]non-5-enium; DBNM, 1-methyl-1,5-diazabicyclo[4.3.0]non-5-enium; DMEA, N,N-dimethylethanolammonium; TMG, 1,1,3,3-Tetramethylguanidinium.

Hydrolysable ionic liquid.

There has been a growing drive to expand the range of suitable solvents for keratin to those that have specific properties useful for larger-scale processing, and, as such, both distillable and protic ionic liquids have been utilized with good effect (Chen et al., 2014, 2015; Idris et al., 2014a), alongside those containing potentially more benign, bio-compatible (Lovejoy et al., 2012; Zheng et al., 2015) and bio-derived (Idris et al., 2013; Chen et al., 2014, 2015), cations. Ionic liquids that have been tested and were reported to show either very poor or no detectable solubility of keratins include: [C4C1Im][PF6] (Xie et al., 2005), [C1Im][Cl] (Zhang et al., 2017a), [C4Py][Cl] (Zheng et al., 2015; Zhang et al., 2017a), [C4C1Im][Br] (Zhang et al., 2017a), [C4C1Im][DBP] (Zhang et al., 2017a), [P4, 4, 4, 4][Cl] (Zheng et al., 2015; Zhang et al., 2017a), [N4, 4, 4, 4][Cl] (Zheng et al., 2015; Zhang et al., 2017a), [C4C1Im][H2PO4] (Zhang et al., 2017a), [C4C1Pyr][NTf2] (Lovejoy et al., 2012), [C4C1Im][OctSO4] (Lovejoy et al., 2012), [P6, 6, 6, 14][N(CN)2] (Lovejoy et al., 2012), [P1, sec−4, sec−4, sec−4][OTs] (Lovejoy et al., 2012), [C8C1Im][BF4] (Lovejoy et al., 2012), [P6, 6, 6, 14][Cl] (Lovejoy et al., 2012), [P6, 6, 6, 14][NTf2] (Lovejoy et al., 2012), [P6, 6, 6, 14][BF4] (Lovejoy et al., 2012), [C1Im][BF4] (Lovejoy et al., 2012), [C4C1Im][BF4] (Xie et al., 2005; Lovejoy et al., 2012) and [C4C1Im][FeCl4] (Zheng et al., 2015). The ionic liquids [DMEA][OAc] and [DMEA][Cl] were also identified as potential candidates for dissolution, but because they had poor processing parameters, have not been tested for solubility (Idris et al., 2014a).

Recently a more systematic approach to determining useful ionic liquids for keratin dissolution was successfully applied, exploiting computational prediction of ionic liquid properties (Keaveney et al., 2015), based on the parametrised COSMO-RS methodology, with subsequent experimental verification (Liu et al., 2018). Here the σ-potential, a measure indicating the hydrogen bond acceptor-donor interactions of the model substrate, was matched for each model to generate the logarithmic activity coefficient (ln γ, proportional to the ionicity of the solution; Marsh et al., 1955), calculated against ionic liquid ion pairs. By testing 621 ion pairs and ranking these by cation and anion, a strong reliance on the anion was identified with a much more subdued contribution from the cation. Cations with additional hydrogen bonding groups, such as hydroxyethyl-methylimidazolium, acted to improve solubility over that predicted, and highlighted the role of hydrogen bond disruption in solubilisation.

Collagens

Unlike the disulfide-reinforced, arginine/glutamate-rich keratins, collagens are predominantly glycine-rich proteins, featuring also proline and/or hydroxyproline. Collagens contribute a range of structural roles in skin, ligaments, cartilage and tendons, as well as in bones, teeth and the cornea (Chen et al., 2017). Three strands of collagen-protein are able to form stable triple-helicies, with macrostructural alignment further imparting specific mechanical properties (Chen et al., 2017), attractive for biomaterials development (Defrates et al., 2018). Since collagen has different hierarchical, ordered layers to keratin, it provides an alternative framework for understanding the interactions of different ionic liquids on peptide dissolution and stabilization.

Choline salts have been examined in the context of collagen, because they provide potential for more biologically benign interaction agents suitable for biological implants. Cross-linking has been achieved in [Ch][lactate] and [Ch][levulinate] (Vijayaraghavan et al., 2010), along with the related, non-liquid, [Ch][tartrate] (Vijayaraghavan et al., 2010) and [Ch][H2PO4] (Vijayaraghavan et al., 2010; Mehta et al., 2015). The primary mechanism of the cross-linking is facilitated by the strong electrostatic interactions between the protein (Meng et al., 2012), postulated as from the arginine residues, and the ionic liquid, specifically the anion (Mehta et al., 2015). This was further explored both experimentally and theoretically with [Ch]2[SO4] (Tarannum et al., 2018a), and subsequently a selection of amino acid-based cholinium salts, [Ch][Ser], [Ch][Thr], [Ch][Lys], and [Ch]Phe] (Tarannum et al., 2018b). In all these cases, the cholinium-based ionic liquids showed some variation in their interaction with collagen, based on features such as increases in the thermal denaturation temperature, fibril morphology, and changes in FTIR spectra, with more destabilization of the structure indicated for the lysinate and phenylalanate anions.

This dominance of the anionic interaction in governing stabilization is, however, challenged by the observation that [P4, 4, 4, 1][Et2PO4], [P4, 4, 4, 1][MeSO3], and [HN2, 2, 1][MeSO3] can result in structural deformation (Tarannum et al., 2018b), with [C4C1Im][Me2PO4] resulting in collagen structural degradation (Tarannum et al., 2018a), rather than strengthening of the interactions. The implication is that both the nature of the anion is strongly important, and that the cation must also play a not insignificant role. Physicochemical impacts, including on thermal denaturation, were also observed for aqueous solutions of imidazolium chlorides [C2C1Im][Cl], [C4C1Im][Cl], and [C10C1Im][Cl] (Mehta et al., 2014).

Collagen fiber solution has been utilized extensively in a broader range of imidazolium ionic liquids. In addition to [C4C1Im][Cl] (Meng et al., 2012; Wang et al., 2013a; Mehta et al., 2014), where around 6 wt% collagen could be solubilised, [C2C1Im][OAc] (Hu et al., 2013; Zhang et al., 2014) showed temperature-dependant solubilisation ranging from 3.1 to 7.4 wt% going from 25 to 45°C, respectively, which was also impacted, and sometimes improved (up to ca. 10 wt%) by addition of sodium salts (Hu et al., 2013). This ionic liquid has been utilized in extracting collagen from waste fish scales (Muhammad et al., 2017). Aqueous mixtures of [C2C1Im][EtSO4] have been used with gelatin (partially hydrolysed collagen) to prepare nanoparticle-embedded ionogels with a variety of attractive properties. Other biomedical applications have included composite hydrogels for skin dressings (Iqbal et al., 2017), and composite hydrogels for bone applications (Iqbal et al., 2018a), prepared with collagen using the protic [C1Im][OAc] as a carrier. The protic, non-imidazolium [NH(CH2CH2OH)3][OAc] has similarly been used for preparation of bone filler composites (Iqbal et al., 2018b).

Similar to the work in keratin, COSMO has been utilized in the calculation of activity coefficients with ionic liquids and a collagen model (Muhammad et al., 2017). Here a range of imidazolium cations; [C2C1Im], [C4C1Im], [C6C1Im], [C8C1Im], [C10C1Im]; with a large selection of corresponding anions was trialed, with lowest ln γ values obtained consistently for the smallest cation, especially in combination with small organic acid anions (acetate, propionate, formate, butanoate and crotonate, respectively). This was followed by the chloride anion, which interestingly had the largest variation in effect with cation, with a dramatic difference in ln γ values on going from [C2C1Im] to [C4C1Im] and again to [C6C1Im], compared with other cation-anion combinations. Amino acid anions [Gly]−, [Arg]−, and [Glu]− afforded intermediate predictions, with more hydrophobic anions giving poor predictions for interaction, with high ln γ values. As a result, [C2C1Im][OAc] was selected in this study as extraction solvent of choice.

Plant Proteins

The use of ionic liquids with plant proteins is less extensive than for those proteins from animals. The huge scale of soybean production worldwide means that soy protein is readily accessible (Nishinari et al., 2014). In practice soy protein is a mixture of different proteins of different sizes and properties, with two dominant, multimeric constituents, β-conglycinin and glycinin. These proteins are particularly rich in glutamate and aspartate, as well as arginine, lysine, serine, and proline, with higher quantities of leucine and phenylalanine in more hydrophobic subunits (Riblett et al., 2001). Soy protein has been used in a wet spinning method through dissolution in [C4C1Im][Cl]/DMSO mixtures (Deng et al., 2014), and blend films of soy protein with cellulose have been prepared with [AMIM][Cl] as the solvent (Wu et al., 2009).

The poorly-soluble zein protein is obtained as a by-product of industrial corn processing, most recently through bioethanol production (Gupta et al., 2016), and comprises around 7–8 wt% of the corn kernel (Shukla and Cheryan, 2001). Although rich in glutamate, leucine, alanine, and proline, it is low in basic amino acids such as arginine and deficient in lysine and tryptophan, making it poor quality for human nutrition. In an attempt to improve accessibility to reaction, nearly 15 wt% of zein was shown to be soluble in [C4C1Im][Cl], with practical viscosities in the range of 10 wt% when dissolved at 120°C for 60 min, and benzoylation able to be demonstrated (Biswas et al., 2006). The ionic liquid [C4C1Im][N(CN)2] was reported to be similarly effective with solubilities of 10 wt%, whereas [Ch][Cl] deep eutectic mixtures were not effective at dissolving zein. With a focus on assessing green solvents, the imidazolium ionic liquids [C2C1Im][OAc] and [C2C1Im][Br] were compared with bioderived organic solvents. Here 1,4-dioxane and 2,3-butanediol were indicated as more promising for zein extraction applications (Gupta et al., 2016), although other ionic liquids may have performed better had they been assessed.

In 2014, Tomlinson et al. (2014) examined zein solubility in seven imidazolium ionic liquids; four non protic: ([C2C1Im][OAc], [C2C1Im][N(CN)2], [C4C1Im][OAc], and [C4C1Im][Cl]) and three protic: ([C1Im][OAc], [C1Im][OFo], and [C1Im][HSO4]), and related their results to the Linear Free Energy parameters α, β, and π* through multivariate regression. This model gave polarisability (π*) as the key contributor, increasing in importance at higher temperatures alongside the ET(30) polarity scale. They concluded that good solvents for zein would possess low hydrogen-bond accepting ability (β), low polarisability (π*) and weak hydrogen-bond donating ability (α), and that increases in water content within the ionic liquids had little impact on solubility. In line with this, they concluded that [C1Im][HSO4] was an extremely poor solvent and that [C1Im][OAc] and [C2C1Im][N(CN)2] were their preferred solvents for zein, with solubilities measured at ca. 25 wt% zein at 60°C. Other protic ionic liquids were also shown to be successful in solubilising zein with [NH3(CH2CH2OH)][OFo] and [NH3(CH2CH2OH)][OAc] producing highly viscous 70 wt% solutions (Choi and Kwon, 2011). More practical solutions of 20 wt% zein could be produced either by microwave heating, or by conventional heating at 120°C.

Silks

Silk from the larval form of the silk moth Bombyx mori is a material that has been used by humanity for thousands of years. Whilst predominantly used for its properties as a textile, it has desirable mechanical properties (Pérez-Rigueiro et al., 2000), as well as potential biomedical applications (Reviewed Altman et al., 2003; Kapoor and Kundu, 2016), and is attracting significant research therefore in identifying mechanisms for reprocessing. Similar to the complex, layered structures of keratins, silk fibers are formed of two monofilaments called brins that are spun by the spinneret of the silk moth larve into a single fiber (bave). Each brin consists of two different proteinaceous substances: the core consists of fibroins and these are coated by serecins. For the sake of clarity when discussing solubility in ionic liquids, “silk” here will refer to fibroin obtained from B. mori with the serecin removed, unless explicitly stated.

The superlative mechanical characteristics of silk derive from a glycine- and alanine-rich repeating motif of the hexapeptide GAGAGX (where X = S, Y, A), periodically broken up by a GAAS motif (Zhou et al., 2001). Within silk fibers, these repeat regions make up a β-sheet structure interspersed with less structured regions. Further examinations of silk structure with small angle electron diffraction have shown that the β-sheets are organized into crystallites with dimensions of 66 ± 34 nm and 10 ± 3 nm with the major axis being aligned with the fiber axis (Shen et al., 1998), and it is this macrostructuring from the secondary level upwards that provides the underpinning mechanical properties of silk.

Previous attempts at solubilisation have required harsh solvents such as either hexafluoroisopropanol (HFIP) (Park et al., 2006), or aqueous inorganic salts, most commonly lithium bromide (Iizuka and Yang, 1966), that require subsequent dialysis to remove them afterward. Other methods have been explored for the dissolution of silk including calcium chloride in formic acid as well as mixtures of inorganic salts, water and alcohols (Yue et al., 2014; Cheng et al., 2015). In 2004, Phillips et al. (2004) published the first communication on the use of ionic liquids for silk dissolution, demonstrating [C4C1Im] and [C2C1Im]-based ionic liquids as effective solvents. Ionic liquids have since proven great utility in dissolving B. mori silk for a range of applications (Phillips et al., 2004, 2005; Gupta et al., 2007; Mantz et al., 2007; Goujon et al., 2012, 2013; Silva et al., 2012, 2013; Wang et al., 2012, 2013b; Zhou et al., 2013; Yao et al., 2014a,b, 2018; Li et al., 2015; Lozano-Pérez et al., 2015; Zhang et al., 2016a; Susanin et al., 2017, 2018; Stanton et al., 2018; Table 2). Successful dissolution has been achieved with a range of 1-methyl-3-alkylimidazolium ionic liquids, particularly when partnered with chloride or carboxylate anions. In a similar fashion to other proteins, maximal solubility is achieved with the small methyl and ethyl alkyl groups on these cations. This trend for smaller side chains does not extend to the protic [C1Im][Cl], in which silk is insoluble. Alkylation at the 2-position of the imidazole ring also decreases silk solubility. As this is a known site of H-bonding within the imidazolium ionic liquids, it implies that cation H-bonding is also a critical interaction in stabilizing silk solutions.

Table 2.

Ionic liquid data for silk solubility found in the literature.

| IL | [Silk]/wt% | References |

|---|---|---|

| [AMIM][Cl] | 1–15 | Wang et al., 2012 |

| [C1Im][Cl] | Insoluble | Mantz et al., 2007 |

| [C2Im][Cl] | Insoluble | Lozano-Pérez et al., 2015 |

| [C1C1Im][Cl] | >12 | Lozano-Pérez et al., 2015 |

| [C1C1Im][NO3] | Insoluble | Mantz et al., 2007 |

| [C2C1Im][Cl] | 25 | Lozano-Pérez et al., 2015 |

| 23.3 | Mantz et al., 2007 | |

| [C2C1Im][NO3] | Insoluble | Mantz et al., 2007 |

| [C2C1Im][OAc] | 0.1–20 | Zhang et al., 2016a |

| [C2C1Im][SCN] | Insoluble | Mantz et al., 2007 |

| [C2C1Im][OTf] | Insoluble | Mantz et al., 2007 |

| Lozano-Pérez et al., 2015 | ||

| [C2C1Im][EtSO4] | Insoluble | Lozano-Pérez et al., 2015 |

| [C2C1Im][BF4] | Insoluble | Mantz et al., 2007 |

| [C2C1Im][AlCl4] | Insoluble | Mantz et al., 2007 |

| [C2C1Im][Gly] | 26.3 | Mantz et al., 2007 |

| [C2C1Im][Ala] | >20 | Mantz et al., 2007 |

| [C2C1Im][Ser] | >20 | Mantz et al., 2007 |

| [C3C1Im][Cl] | >15 | Lozano-Pérez et al., 2015 |

| [C4C1Im][Cl] | >12 | Lozano-Pérez et al., 2015 |

| 13.2 | Phillips et al., 2004; Mantz et al., 2007 | |

| [C4C1Im][Br] | 0.7 | Phillips et al., 2004; Mantz et al., 2007a |

| [C4C1Im][I] | 0.2 | Phillips et al., 2004; Mantz et al., 2007a |

| [C4C1Im][OAc] | 15 | Li et al., 2015; Susanin et al., 2018 |

| [C4C1Im][BF4]† | Insoluble | Phillips et al., 2004; Mantz et al., 2007a |

| [C4C1Im][PF6]† | Insoluble | Lozano-Pérez et al., 2015 |

| [C4C1Im][OctSO4] | Insoluble | Lozano-Pérez et al., 2015 |

| [C4C1Im][Cl] | 8.3 | Phillips et al., 2004; Mantz et al., 2007 |

| [C6C1Im][Cl] | >11 | Lozano-Pérez et al., 2015 |

| [C8C1Im][Cl] | Insoluble | Lozano-Pérez et al., 2015 |

| [C10C1Im][Cl] | Insoluble | Lozano-Pérez et al., 2015 |

| [3-MEP][EtSO4] | Insoluble | Lozano-Pérez et al., 2015 |

| EtAN | Insoluble | Lozano-Pérez et al., 2015 |

| [N4, 4, 4, 4][Gly] | Insoluble | Mantz et al., 2007 |

Solubility data obtained from whole cocoons including serecin.

3-MEP, 3-methyl ethylpyridinium; EtAN, Ethanolammonium nitrate.

Hydrolysable ionic liquid.

From the surveyed ionic liquids, only three classes of anion have shown good solubilising properties: chloride, acetate, and amino acid anions. Although halides have shown to be effective anions, a direct comparison regarding solubility in [Cl]-based ionic liquids is difficult, as the [C4C1Im][X] (X = Br−, I−) ionic liquids were tested on whole cocoons including the serecin. These ionic liquids, as well as the hydrolysable [C4C1Im][BF4] (Freire et al., 2010), are capable of dissolving serecin whilst displaying minimal to no fibroin solubility, a trend also confirmed in later work (Mantz et al., 2007). The imidazolium acetates have been utilized extensively in cellulose dissolution (Swatloski et al., 2002), but interestingly it was not until 2016 before [C2C1Im][OAc] was used on silk (Zhang et al., 2016a). Particular anions (, SCN−, TfO−, , , , , ) do not appear to sufficiently perturb the H-bonding of silk to act as useful solvents.

Amino acid-based ionic liquids, where the [C2C1Im] cation was paired with the carboxylate anion form of the 20 natural amino acids, were initially developed by Fukumoto et al. (2005) with a subset of these ionic liquids characterized for their silk dissolution capacity (Table 2; Mantz et al., 2007). These amino acid anion-based ionic liquids provide some of the highest dissolution capacities for silk, showing promise in the area for more biocompatible dissolution solvents. One consideration however is whether the marginal gains in dissolution capacity, coupled to enhanced biocompatibility, are sufficient to justify the added complexity of their synthesis.

Solubility characterization has a direct impact on mechanisms of processing to afford silk in a desired functional form, such as the non-exhaustive examples highlighted in Table 3, which include composite formation for biomedical use (Silva et al., 2012). Silk coagulation from solution, although unsuccessful, also provides information on the underlying multi-way interactions between solvent, silk and coagulant. In general, small alcohols have been the most popular choice of coagulant, due to their ability to reform the β-sheet network critical to the strength of the silk II polymorph (Asakura et al., 1985). Water too has been utilized with differing levels of success where a regenerated silk will either not form at all ([C4C1Im][Cl] and 9.51 wt% silk, consistent with amorphous silk being soluble in water) or form brittle films, unless both cellulose is used as an additive and the correct ionic liquid ([C2C1Im][OAc] or [AMIm][Cl]) is chosen. Typical antisolvent choices for polar systems seem to yield either no coagulation or a brittle film or fiber (Table 3; Phillips et al., 2005). These observations emphasize that both solvent choice and the choice of coagulant are of paramount importance, with dominant options well-explored in the literature.

Table 3.

A representative sample of methods by which silk is dissolved and subsequently reformed listing silk concentrations, additives, coagulants and processing methods.

| IL | [Silk] (wt%) | Additives | Coagulant | Processing method | RSF morphology | References |

|---|---|---|---|---|---|---|

| [C2C1Im][Cl] | 10.4 | 7% water | MeOH | Pipetted into coagulant bath, soaked for 24 h. | Fibers | Mantz et al., 2007 |

| 10.4 | 7% water | EtOH | Pipetted into coagulant bath, soaked for 24 h. | Precipitate | Mantz et al., 2007 | |

| 10.4 | 7% water | 0.1 M H3Ct−0.1 M NaH2Ct pH 2.96 | Pipetted into coagulant bath, soaked for 24 h. | - | Mantz et al., 2007 | |

| 10.4 | 7% water | 0.1 M NaH2Ct−0.1 M Na2HCt pH 4.29 | Pipetted into coagulant bath, soaked for 24 h. | Precipitate | Mantz et al., 2007 | |

| 10.4 | 7% water | 0.14 NaH2Ct−0.06M Na2HCt pH 4.05 | Pipetted into coagulant bath, soaked for 24 h. | Precipitate | Mantz et al., 2007 | |

| 10 | - | MeOH | Wet spinning. | Solid, clear fibers | Phillips et al., 2005 | |

| 10 | - | MeCN | Wet spinning. | Solid, white crusted, brittle fibers | Phillips et al., 2005 | |

| 10 | - | Water | Wet spinning. | Dissolved leaving small residual fiber | Phillips et al., 2005 | |

| 10 | - | Acetone | Wet spinning. | Formed immiscible droplets, no precipitation | Phillips et al., 2005 | |

| 10 | - | Ethyl Acetate | Wet spinning. | Formed immiscible droplets, no precipitation | Phillips et al., 2005 | |

| 10 | - | Hexanes | Wet spinning. | Formed immiscible droplets, no precipitation | Phillips et al., 2005 | |

| 1 | Cellulose 9 wt% | Water | Cast film between glass slides in coagulant bath. | Clear, solid film | Stanton et al., 2018 | |

| [C2C1Im][OAc] | 0.1–20 | - | Water | Gellation. | Gel | Zhang et al., 2016a |

| 5–10 | - | Water | Gellation. | Conductive Gel | Yao et al., 2018 | |

| 5–10 | - | Water/EtOH | Gellation. | Conductive Gel | Yao et al., 2018 | |

| 1 | Cellulose 9 wt% | Water | Cast film between glass slides in coagulant bath. | Clear, solid film | Stanton et al., 2018 | |

| [AMIM][Cl] | 1 | Cellulose 9 wt% | Water | Cast film between glass slides in coagulant bath. | Clear, solid film | Stanton et al., 2018 |

| [C4C1Im][Cl] | 9.51 | - | MeOH | Cast film in coagulant bath. | Transparent film, high crystallinity | Phillips et al., 2004, Mantz et al., 2007 |

| 9.51 | - | MeCN | Cast film in coagulant bath. | White film due to surface light scattering, low crystallinity | Phillips et al., 2004, Mantz et al., 2007 | |

| 9.51 | - | Water | Cast film in coagulant bath. | Dissolved | Phillips et al., 2004, Mantz et al., 2007 | |

| 5 | - | MeOH | Electrospun into coagulant bath with subsequent rinsing. | Fibers | Mantz et al., 2007 | |

| 1 | Cellulose 9 wt% | Water | Cast film between glass slides in coagulant bath. | Clear, solid film | Stanton et al., 2018 | |

| 10 | Water 25 wt% | MeOH | Spin Coating and immersion in coagulant. | Clear film | Gupta et al., 2007 | |

| 10 | - | MeOH Vapor | Cast film in vacuum oven with MeOH vapor, then water rinse and pressed between glass plates and dried under reduced pressure. | Clear film | Zhou et al., 2013 | |

| 7.5 | Cellulose 2.5 wt% | MeOH Vapor | Cast film in vacuum oven with MeOH vapor, then water rinse and pressed between glass plates and dried under reduced pressure. | Clear film | Zhou et al., 2013 | |

| 5 | Cellulose 5 wt% | MeOH Vapor | Cast film in vacuum oven with MeOH vapor, then water rinse and pressed between glass plates and dried under reduced pressure. | Clear film | Zhou et al., 2013 | |

| 2.5 | Cellulose 7.5 wt% | MeOH Vapor | Cast film in vacuum oven with MeOH vapor, then water rinse and pressed between glass plates and dried under reduced pressure. | Clear film | Zhou et al., 2013 | |

| 0 | Cellulose 10 wt% | MeOH Vapor | Cast film in vacuum oven with MeOH vapor, then water rinse and pressed between glass plates and dried under reduced pressure. | Clear film | Zhou et al., 2013 | |

| [C4C1Im][Br] | 1 | Cellulose 9 wt% | Water | Cast film between glass slides in coagulant bath. | Translucent, brittle film | Stanton et al., 2018 |

| [C4C1Im][OAc] | 5 | - | 80% TMG.La: 20% water | Injected silk solution into coagulant bath, left for 1 hr and then rinsed 3x with water. | Silk foam | Goujon et al., 2012 |

| 10 | - | EtOH | Molds immersed in EtOH for 24 h then Soxhlet extraction with EtOH for 5 days then into MeOH/water (80/20 vol%) to form beta sheets. | Cast hydrogel | Silva et al., 2013 | |

| 2.8 | Chitosan 1.2 wt% | EtOH | Molds immersed in EtOH for 24 h then Soxhlet extraction with EtOH for 3 days then into MeOH for 10 min to form beta sheets. | Cast hydrogel | Silva et al., 2012 | |

| 2 | Chitosan 2 wt% | EtOH | Molds immersed in EtOH for 24 h then Soxhlet extraction with EtOH for 3 days. | Cast hydrogel | Silva et al., 2012 | |

| 1.2 | Chitosan 2.8 wt% | EtOH | Molds immersed in EtOH for 24 h then Soxhlet extraction with EtOH for 3 days. | Cast hydrogel | Silva et al., 2012 | |

| 15 | - | EtOH | 1–2 h at 25°C 65% RH then into EtOH and finally into water. | Clear film | Li et al., 2015 | |

| [C4C1Im][MeSO3] | 1 | Cellulose 9 wt% | Water | Cast film between glass slides in coagulant bath. | Translucent, brittle film | Stanton et al., 2018 |

In contrast to water or alcohols as the coagulant for the regeneration of silk from solution, the tunability of ionic liquids offers an alternative approach to regeneration, and highlights the potential of these solvents. Protic ionic liquids (pILs) have been used to develop an all ionic liquid process for the dissolution and regeneration of silk (Goujon et al., 2012). Initially 5% w/w silk solutions in HFIP were regenerated using pILs based around the triethylammonium (TEA+) cation with differing anions: lactate (La−), triflate (OTf−), mesylate (OMs−) and dihydrogenphosphate (), each of which was in an 80%:20% w/w ratio of pIL to water. Fourier self-deconvolution of the FTIR spectrum was used to determine the secondary structure content of the silk foams regenerated with each of these coagulant solutions. The different anions were able to generate silk foams with very different structures. SEM showed a much more open and porous morphology for silk in [TEA][OMs] and a major peak at 22° shown in the XRD spectrum. Conversely, [TEA][H2PO4] showed a much tighter foam-like morphology and a single peak at 18.5° in the XRD spectrum, which is possibly a native-like structure (16.5°) but with a greater intersheet spacing. Focussing on the underlying secondary structure, [TEA][H2PO4] yielded the most native-like secondary structure with 55% β-sheet content (1,621–1,630 cm−1) and no α-helices (1,655–1,662 cm−1) whereas [TEA][OMs] yielded a silk foam with a large amount of α-helical structure (45%) as well as a large β-sheet content (50%).

Previous work with the amyloid peptide Aβ(1-40), best known for its implied role in Alzheimer's disease, foreshadowed the helix-inducing properties of [TEA][OMs] (Debeljuh et al., 2011). Through CD spectroscopy the secondary structure of Aβ(1-40) was monitored under varying [TEA][OMs] content. From 0 to 50% w/w [TEA][OMs] in water, the Aβ(1-40) retained its β-sheet secondary structure and ability to form fibrils. At 50–90% w/w the Aβ(1-40) changed to an α-helix secondary structure and no fibrils were formed. Finally at 90–100% w/w the Aβ(1-40) adopted the random coil conformation. Two potential hypotheses have been given for the mechanism by which pILs drive these conformational changes: the first is that the unique H-bonding network that pILs exhibit may drive proteins to preferentially form intermolecular bonds over intramolecular bonds. Alternatively, the microheterogeneity of pILs could be providing a membrane-like environment where a helical structure is preferred. Both of these hypotheses could help explain the preferential formation of α-helices by silk in [TEA][OMs].

For [TMG][La] (1,1,3,3-tetramethylguanidinium lactate) the general trend was that as water content increased, the β-sheet content fell, and the propensity for a microsphere morphology increased. Changes in the H-bonding network, alongside changes to the surface tension could drive the microsphere morphology. Yields decreased and coagulation time increased with increasing water content, consistent with amorphous silk being soluble in water. With this in mind an 80%:20% w/w [TMG][La]:water composition was used to coagulate silk from a 5% w/w solution in [C4C1Im][OAc]. The choice of both coagulant and solvent affects both morphology and secondary structure content. When HFIP was used to dissolve silk, a much finer foam structure was formed compared to [C4C1Im][OAc], containing larger, disordered voids. The secondary structure differed also with HFIP showing 55% β-sheet, 14% silk I structure, 12% α-helix and 9% β-turns, whereas using [C4C1Im][OAc] there was 64% β-sheet, 6% silk I, 27% α-helices and 2% β-turns. The demonstrated capability of pILs to alter protein conformation in a tunable sense is a compelling phenomenon and could provide good potential for generating precise morphology for future protein formulations.

Enzymes

Potential applications for ionic liquids in the biotech-industry are numerous and an exhaustive list is not possible here. However, the limiting biocompatibility of these electrolytes has led to the emergence of very specific fields of implementation, whereby the advantage in overcoming issues of common chemical synthesis by deploying a reaction-selective biocatalyst outweighs the challenges of finding a suitable ionic liquid system. In this regard, the solubility of either the substrate or product can be identified as the primary driver that indicates use of an ionic liquid solvent may be valuable. The major focus areas of published research concerning biocatalysis in ionic liquids over the last decade have been in biofuel production, followed by the use as biosensors, and the production of enantiomerically-pure compounds (reviewed in Itoh, 2017b; Meyer et al., 2018). Protein stability in ionic liquids has been examined (Kumar and Venkatesu, 2014; Zhao, 2016), and provides part of the story, but cannot always accurately predict activity. A more thorough understanding of salt and enzyme interactions, including a classification of the impact of different anions and cations on enzyme activity, will enable applications that lie outside these dominating research fields, and is one of the rising areas of interest in the ionic liquid field. Some recent highlights for specific systems are provided here.

Cellulases

Cellulases and their use in aqueous ionic liquids have one major, documented application: the saccharification of cellulose from various lignocellulose biomass sources for the production of biofuels. The treatment of the biomass with ionic liquids and the saccharification by the enzymes can be performed simultaneously, limited by the stability of the biocatalyst in such media. Pretreatment can be established through alkali, steam, acid or aqueous ammonia soaking, used for different substrates and exhibiting different yields (Ruiz et al., 2008; Cho et al., 2013; Govumoni et al., 2013; Maurelli et al., 2013). Pretreatment with ionic liquids dissolves lignin and hemicellulose by disruption of the hydrogen bonds of the cellulose to reduce crystallinity, thereby facilitating access for the hydrolytic enzymes (Tan and Macfarlane, 2010).

There is not a great variety of ionic liquids used for this process, as they need to have the ability to effectively compete with existing intermolecular H-bond interactions to separate the polymer chains (Table 4; Pinkert et al., 2010). The most usual cations are [C4C1Im] and [C2C1Im], and occasionally [AMIM] or [HEMA] (tris-(2-hydroxyethyl)-methylammonium). Similar to the situation with proteins, increasing the chain length of the imidazolium cation also leads to a decrease in dissolution of the cellulose (Kosan et al., 2007; Vitz et al., 2009; Cao et al., 2017). The anions [Cl], [OAc] and [BF4] have been most commonly investigated, followed by [Et2PO4] or [Me2PO4] and [MeSO4]. The hydrophobic [NTf2] ion is not capable of interacting strongly with the hydroxyl groups of the polymer chains. The H-bond acceptor ability and size of the anions primarily determine the ionic liquid dissolution ability (Pinkert et al., 2009), with a loose ranking of [SCN] < [Br] < dialkylphosphates < [OFo] ~ [OAc] ~ [Cl].

Table 4.

Summary of selected cellulase reactions in ionic liquids.

| Ionic Liquid | Organism | Concentration range | Experimental outcome | References |

|---|---|---|---|---|

| [AMIM][Cl] | Hu-CBH1 | 20–40% (v/v) aq, 2 M NaCl | ~100–5% relative activity, respectively | Zhang et al., 2011 |

| Celluclast T. reesei | 10% (v/v) aq | ~ 25% relative residual activity (30 min) | Engel et al., 2010 | |

| Cel5A from T. tengcongensis | 2 M | 50% relative residual activity after 5 h at room temperature | Liang et al., 2011 | |

| [AMIM][Me2PO4] | T. reesei | 20, 50, and 100% (v/v) aq | 34.36, 0.3, and 0% conversion, respectively, with ultrasonic heating pretreatment | Yang et al., 2010 |

| [AEIM][Et2PO4] | T. reesei | 20, 50, and 100% (v/v) aq | 11.00, 0, and 0% conversion, respectively, with ultrasonic heating pretreatment | Yang et al., 2010 |

| [C1C1Im][Me2PO4] | T. reesei | 20, 50, 100% (v/v) aq | 53.18, 1, and 0.3% conversion, respectively, with ultrasonic heating pretreatment | Yang et al., 2010 |

| Celluclast T. reesei | 10% (v/v) aq | 40% relative residual activity after 11 days | Engel et al., 2010 | |

| [C1C1Im][MeSO4] | α-galactosidase Thermatoga maritimia | 0, 9, 27, and 45% (v/v) | 42.7, 33, 6.2, 5.8 kcat/Km s−1mM−1 respectively to the concentrations | Ferdjani et al., 2011 |

| [C1C1MIm][MeSO4] | α-galactosidase T. maritimia | 0-33% (v/v) | Similar activity profile to [C1C1Im][MeSO4] but less soluble | Ferdjani et al., 2011 |

| [C2C1Im][Br] | Pseudoalteromonas sp. cellulase | 1–20% (v/v) aq | 115% relative activity at 5% (v/v) | Trivedi et al., 2013 |

| [C2C1Im][CF3CO] | CelA2 | 30% (v/v) aq | 506 mU/mg | Ilmberger et al., 2012, 2013 |

| [C2C1Im][Cl] | TmBgl1A | 200, 500 mM | 1.32 × 103 kcat/Km (s−1 mM−1) at 200 mM | Kudou et al., 2014 |

| S. cerevisiae MT8-1 | 50–1000 mM | 0.7 g/l ethanol production after 200 h | Nakashima et al., 2011 | |

| Hu-CBH1 | 20% (v/v) aq 2 M NaCl | ~120% relative activity | Zhang et al., 2011 | |

| [C2C1Im][Et2PO4] | S. cerevisiae MT8-1 | 50–1,000 mM | 1.4 g/l ethanol produced after 200 h | Nakashima et al., 2011 |

| T. reesei | ≤ 40% (v/v) aq | In situ one pot synthesis | Kamiya et al., 2008 | |

| T. reesei | 20, 50, and 100% (v/v) aq | 2.18, 0, and 0% conversion at respective concentrations in ultrasonic heating pretreatment | Yang et al., 2010 | |

| [C2C1Im][EtSO4] | C. rugosa lipase | 20% wt | Simulation revealed, that effect of altering enzyme charge is confined to short range (<1 nm) ordering of the IL | Burney et al., 2015 |

| [C2C1Im][Me2PO4] | T. reesei | 20, 50, and 100% (v/v) aq | 48.14, 0.7, and 0% conversion at respective concentrations in ultrasonic heating pretreatment | Yang et al., 2010 |

| [C2C1Im][MeSO3] | Pseudoalteromonas sp. cellulase | 1–20% (v/v) aq | 98% relative activity at 5% (v/v) | Trivedi et al., 2013 |

| [C2C1Im][OAc] | T. maritimia endogluconase | 5, 10, 15, and 20% (v/v) aq | 52% decrease in specific activity at 15% (v/v) | Datta et al., 2010 |

| T. viride celullase | 5, 10, 15, and 20% (v/v) aq | 100% decrease in specific activity at 15% (v/v) | Datta et al., 2010 | |

| Pyrococcus horikoshii endogluconase | 5, 10, 15, and 20% (v/v) aq | 5% decrease in specific activity at 15% (v/v) | Datta et al., 2010 | |

| Cellulases from A. terreus | 5, 10, 15, and 20% (v/v) aq | 100% relative activity at 10% (v/v) | Gunny et al., 2014 | |

| TmBgl1A | 200 and 500 mM | 3.15 × 103 kcat/Km (s−1 mM−1) at 200 mM | Kudou et al., 2014 | |

| S. cerevisiae MT8-1 | 50–1,000 mM | 1 g/l ethanol production after 200 h | Nakashima et al., 2011 | |

| Paenibacillus tarimensis | 20% (v/v) aq | 90 and 80% relative activity at 80 and 50°C, respectively | Raddadi et al., 2013 | |

| Pseudoalteromonas sp. cellulase | 1–20% (v/v) aq | 105% relative activity at 5% (v/v) | Trivedi et al., 2013 | |

| β-glucosidase T. reesei | 15 and 20% (w/v) | 77 and 65% relative activity, respectively | Wang et al., 2011 | |

| Hu-CBH1 | 20% (v/v) aq, 2 M NaCl | ~ 100% relative activity | Zhang et al., 2011 | |

| [C2C1Im][OTf] | CelA2 | 30% (v/v) aq | 54% relative activity | Ilmberger et al., 2012, 2013 |

| CelA3 | 30% (v/v) aq | 68% relative activity | Ilmberger et al., 2012, 2013 | |

| CelA Thermatoga maritimia | 60% (v/v) aq | 115% relative residual activity after 4 days | Ilmberger et al., 2012, 2013 | |

| [C2C2Im][Et2PO4] | T. reesei | 20, 50, 100% (v/v) aq | 18.55, 0.1, and 0% conversion at respective concentrations in ultrasonic heating pretreatment | Yang et al., 2010 |

| [C4C1Im][BF4] | Humicola insolens | IL:Buffer 1:1 | 1.5 γc (g/l) after 6 h | Paljevac et al., 2006 |

| [C4C1Im][Cl] | Cellulases from A. terreus | 5, 10, 15, and 20% (v/v) aq | 60% relative activity at 10% (v/v) | Gunny et al., 2014 |

| Cel5A from T. tengcongensis | 40% (v/v) aq | 80% relative residual activity after 5 h | Liang et al., 2011 | |

| TmBgl1A | 200 and 500 mM | 1.89 × 103 kcat/Km (s−1 mM−1) at 200 mM | Kudou et al., 2014 | |

| T. reesei engineered | 0–5% (v/v) aq | ~ 33, 18, and 16% conversion of 0.25 wt% lignin by succinylated, acetylated and wt enzyme, respectively | Nordwald et al., 2014 | |

| H. insolens | IL:Buffer 1:1 | 0.3 γc (g/l) after 6 h | Paljevac et al., 2006 | |

| Paenibacillus tarimensis | 40% (v/v) aq | 40 and 45% relative activity at 80 and 50°C, respectively | Raddadi et al., 2013 | |

| P. tarimensis | 20% (v/v) aq | 75 and 70% relative activity at 80 and 50°C, respectively | Raddadi et al., 2013 | |

| Hu-CBH1 | 20% (v/v) aq, 2 M NaCl | ~105% relative activity | Zhang et al., 2011 | |

| Pseudoalteromonas sp. cellulase | 1–20% (v/v) aq | 102% relative activity at 5% (v/v) | Trivedi et al., 2013 | |

| [C4C1Im][OAc] | Cellulases from A. terreus | 5, 10, 15, and 20% (v/v) aq | 60% relative activity at 10% (v/v) | Gunny et al., 2014 |

| TmBgl1A | 200 and 500 mM | ~23 U/mg at 200 mM (80°C) | Kudou et al., 2014 | |

| [C4C1Im][OTf] | 89C12 | 30% (v/v) aq | 111 mU/mg | Ilmberger et al., 2012, 2013 |

| Pseudoalteromonas sp. cellulase | 1–20% (v/v) aq | 94% relative activity at 5% (v/v) | Trivedi et al., 2013 | |

| [C4C1Im][PF6] | H. insolens | IL:Buffer 1:1 | 1.8 γc (g/l) after 6 h | Paljevac et al., 2006 |

| [BMMIM][Cl] | CelA2 | 30% (v/v) aq | 181 mU/mg | Ilmberger et al., 2012, 2013 |

| CelA3 | 60% (v/v) aq | 79% relative residual activity after 4 days | Ilmberger et al., 2012, 2013 | |

| [C4C1Pyr][OTf] | CelA2 | 60% (v/v) aq | 11% relative residual activity after 5 days | Ilmberger et al., 2012, 2013 |

| CelA84 | 30% (v/v) aq | 8% relative activity | Ilmberger et al., 2012, 2013 | |

| CelA84 | 60% (v/v) aq | 81% relative residual activity after 4 days | Ilmberger et al., 2012, 2013 | |

| CelA10 | 30% (v/v) aq | 74% relative activity, 0.8% relative residual activity after 17 h | Pottkämper et al., 2009 | |

| CelA24 | 30% (v/v) aq | 2% relative activity | Pottkämper et al., 2009 | |

| Pseudoalteromonas sp. cellulase | 1–20% (v/v) aq | 93% relative activity at 5% (v/v) | Trivedi et al., 2013 | |

| [Tris-(2-HOEt)-MAM][MeSO4] | A. niger endo-1,4-β-D-glucanase | 0, 10, 50, and 99% (v/v) aq | Higher than average thermal stability; up to 140% relative activity at 75°C | Bose et al., 2012 |

A comprehensive overview of reports on enzymatic lignocellulose treatment is given in a publication by Wahlstroem and Suurnaeki (Wahlström and Suurnäkki, 2015). Early publications investigated Trichoderma reesei cellulase effectiveness in ionic liquids (Turner et al., 2003; Kamiya et al., 2008), and found very low enzymatic activity and stability. Following this, very interesting results were obtained by a study from Datta et al. (2010) on three structurally similar family-5-celullases obtained from the three different domains of life (Eukarya, Bacteria and Archaea; Trichoderma viride and thermophilic cellulases from Thermogata maritime and Pyrococcus horikoshii, respectively), which showed dramatically different activities in [C2C1Im][OAc] over a concentration range of 0–50% (v/v) (Datta et al., 2010). Relative specific activity was vastly different between all three. While T. viride cellulase activity had already declined to a third at 5% (v/v) IL, a linear trend of decreasing activity was observed for the cellulase from T. maritima, with about a third of the activity remaining at 20% (v/v). Activity stayed almost constant and equally high in comparison to the absence of ionic liquid for P. horikoshii cellulase in up to 20% (v/v) ionic liquid. However, by 50% (v/v) [C2C1Im][OAc], activity had completely declined for all enzymes, with only that from P. horikoshii showing the slightest activity.

Picking up on these differences Jaeger et al. (2015) conducted a MD study on those very same systems and found the impact of the ionic liquid derived in each case from individual local structural disturbances (Jaeger et al., 2015). Simulating a concentration of 0, 15, and 50%, they found that for P. horikoshii and T. viride only a few unstructured loops were displaced at both concentrations, while the secondary structure of the T. maritima cellulase is intensely disrupted. Moreover, results suggest that the secondary structure is more heavily disrupted at low to medium concentrations of around 15% and some kind of refolding or “reassuming of a prime-similar structure” occurs at 50%. The observation of refolding also held true for both of the other enzymes. RMSD values for these two enzymes indicated an even higher stability in 50% ionic liquid, compared to the buffer system. Their reported trajectories for the positively charged surface of T. maritima suggest that key salt bridges within the protein are broken and enable large structural changes. The RMSD values at 15% (v/v) suggest higher conformational stability, most likely due to the trapping of the enzyme in a less favorable conformation, reflected in the gradual decrease of activity in the study by Datta et al. (2010) For T. viride they suggest a likely competitive inhibition for substrate binding. Indeed, a recently published enzyme kinetic analysis of a commercially available cellulase cocktail finds competitive inhibition by [C4C1Im][Cl] is highly likely (Nemestóthy et al., 2017). In the case of the halophilic P. horikoshii cellulase, a possible deactivation at 50% (v/v) due to aggregation is suggested, because no major structural changes occur in the simulation (Jaeger et al., 2015).

Although many enzymes of other classes do not display their best activities in ionic liquids comprising chloride ions, a great number of cellulases seem to be particularly affected by [Cl] (Paljevac et al., 2006; Salvador et al., 2010; Ilmberger et al., 2013; Yoshimoto et al., 2013; Jaeger et al., 2015). For the highly positively surface-charged T. maritima celullase, which is also particularly enriched in α-helices, an investigative comparison between [C4C1Im] and [C2C1Im], in combination with [Cl] and [OAc], revealed that although conformational stability in low concentrations (0.2 M) of [C4C1Im][Cl] was extremely similar to the aqueous system with 10 mM phosphate buffer, a considerably decreased conformational stability in 0.2–0.5 M [C4C1Im][OAc] correlated with a considerably higher relative activity than for the other solvent systems, including the aqueous environment (Kudou et al., 2014). This relative activity was found to be highly temperature dependent and had an optimum at 80°C, which is unsurprising given it is a hyperthermophile-derived cellulase. Conformational restriction in [C2C1Im][OAc] manifested as an increased stability but to the point where the lowest activity was observed, as the active site could no longer be accessed effectively. These results imply that, as long as either catalytic residues are not displaced or the active center is not inhibited, a decreased conformational stability is rather preferable to a “rock-solid” conformation, where the active center is not flexible enough. The kcat/Km values were also found to be considerably increased for [C4C1Im][OAc], indicating higher enzyme-substrate affinity (Kudou et al., 2014). These findings complement the observations by Jaeger et al. (2015) and Datta et al. (2010).

Halophilic cellulases appear to be promising biocatalysts and a recent patent out of the research on Halorhabdus utahensis cellulase Hu-CBH1 highlights this. This particular cellulase was found to display the same activity at 20% (v/v) [C2C1Im][OAc] and [AMIM][Cl] as in 2 M NaCl-buffer and activity was even slightly improved at 20% (v/v) [C2C1Im][Cl] (Zhang et al., 2011). The molecular basis for this improvement was postulated as due to the highly elevated negative surface charge brought about by a high proportions of Glu and Asp residues. There has been increasing interest in the investigation of halophilic celullases since Zhang's pioneering study (Ilmberger et al., 2012; Raddadi et al., 2013; Gunny et al., 2014; Nordwald et al., 2014). Ilmberger et al. (2012) used a concentration of 30% (v/v) of [C4C1Im][Cl] and [BMMIM][Cl] (1-butyl-2,3- diemthylimidazolium), which yielded moderate specific activities from newly isolated, moderately thermophilic and halotolerant enzymes CelA2 and CelA3 from a biogas plant.

Raddadi et al. (2013) assayed a crude lysate of Paenibacillus tarimensis and demonstrated a clear correlation between temperature and salt concentration, which was also found in other studies regarding halophilic enzymes (Zhang et al., 2011; Gunny et al., 2014). While an increase of salt concentration in aqueous buffer systems leads, at low-moderate temperatures, to a decrease in activity, at high temperatures the opposite is found. However, this does not apply to ionic liquid concentrations. Mixtures of aqueous solution of 20 and 40% (v/v) [C4C1Im][Cl] without NaCl in the buffer showed lower activity for the higher concentration at higher temperatures (Raddadi et al., 2013). Interestingly, if the buffer-ionic liquid solution contained an additional 5 M NaCl, a slight increase in activity at higher temperatures was effected at 20% (v/v) [C4C1Im][Cl] and [C2C1Im][OAc]. The sodium ions are likely the essential mitigators, coordinating to the negatively charged surface residues. Systems with [C2C1Im][OAc] displayed overall the highest activity with ~90% relative activity. Optimum activity for an Aspergillus terreus-derived cellulase was reached in low to medium concentrations of 10% (v/v) [C2C1Im][OAc] with almost the same relative activity compared to the buffer system (Gunny et al., 2014). This study also found a similar salt-mitigating temperature dependence as per the Raddadi study.

Finally, another study examining T. reesei cellulase once more, modified the enzyme surface charge by succinylation and acylation, finding a moderate improvement for succinylation and a slight negative effect for acylation in [C4C1Im][Cl] (Nordwald et al., 2014). This adverse effect of acylation in comparison to natively, negatively-charged enzymes could be explained by, and at the same time verify, the theory that negatively-charged surface residues are not randomly placed, but rather “strategically” favorable (Madern et al., 2000). This placement acts either to have these residues repel and lend the protein more flexibility; or to coordinate positively charged ions to secondary structural regions of interest, e.g., to α-helices, which seem to be more affected by salt than β-sheets; or a combination of both.

In conclusion, the studies of cellulases in ionic liquids have demonstrated that small positively charged ions (Na+, K+) seem to be essential for structural integrity, at least to enzymes that possess a negatively-charged surface. If the surface charge is positive, symmetrical, smallish, negatively-charged ions (Cl−) are attracted to the surface and disrupt the secondary structure substantially, with the coordinating strength of the anion to the surface depending on its H-bond acceptor ability. This disruption does not automatically lead to a major disturbance of the active center, unless inhibition by the ionic liquid ions occurs. Upon increasing ionic liquid concentrations, overall enzyme structure can get trapped by the charged molecules; this applies already at low to moderate concentrations for mesophilic proteins and at higher concentrations of ionic liquid for halophilic proteins. In the latter case, the negatively charged surface residues most likely repel the negatively charged ions of the solution.

Alcohol Dehydrogenases

Alcohol dehydrogenases (ADHs) are valuable biocatalysts due to their enantioselective reactions with prochiral ketones and alcohols. Productivity for a broad range of substrates, however, is limited by the incompatibility of the solubility of the required redox cofactor NAD(P)H in non-aqueous media and sparingly water-soluble ketone substrates. This makes ionic liquids an attractive medium for reaction, where compatibility with the enzyme can be established.

A range of ionic liquids, primarily based on either imidazolium or ammonium cations (Table 5), have been employed with ADHs. The mechanism of impact of ionic liquids on ADH can be interpreted through the prism of three ionic liquid classifications: (a) hydrophilic ionic liquids (b) water-immiscible ionic liquids, which drive the partition coefficients of substrates and products in favor of the enzyme without direct interaction and (c) water-miscible, amphiphilic ionic liquids, which provide H-bonding through the hydrophilic part and substrate solubility within their alkyl-tail-pockets.

Table 5.

Summary of ADH reactions in selected ionic liquids.

| Ionic Liquid | Enzyme | Concentration ranges | Experimental outcomes | References |

|---|---|---|---|---|

| [C4C1Im][PF6] | YADH | IL:EtOH:H2O | Catalytic activities between 0.7 and 11 mol L−1 min−1 recorded, depending on (up to 0.55 IL) | Zhang et al., 2011 |

| YADH | IL:H2O:TritonX-100 | Catalytic activity 51 mol L−1 min−1 with ratios 0.1:0.3:0.6, respectively. | Zhang et al., 2011 | |

| HL-ADH | 0.025–0.4 g/ml | Enhanced activity (up to 145% at 0.025 g/ml) dropping to 95% and then < 50% at 0.075 and 0.15 g/ml and above, respectively. Half-life 1.6 h with residual activity at 50 h. | Shi et al., 2006 | |

| RE-ADH | 10% v/v (aq) | Conversion rate 98.5%; Activity 28% Half-life 135 h. | Hussain et al., 2008 | |

| R. ruber ADH-A | 20, 50, and 80% v/v (aq) | Conversion rates ~30, 20, and 15%, respectively | De Gonzalo et al., 2007 | |

| [C4C1Im][NTf2] | LB-ADH | Biphasic with 50 mM phosphate buffer | 88% conversion; 61% conversion in MTBE/buffer | Eckstein et al., 2004 |

| W110A TE-ADH | 50% v/v (aq) | Conversion 52% - >99% with a selection of substrates | Musa et al., 2008 | |

| R. ruber ADH-A | 20, 50, and 80% v/v (aq) | Conversion rates ~25, 10, 5%, respectively | De Gonzalo et al., 2007 | |

| [C4C1Im][Cl] | HL-ADH | 0.025–0.4 g/ml | Enhanced activity (up to 155% at 0.05 g/ml) dropping to 90% and then < 50% at 0.2 and 0.4 g/ml, respectively. Half-life 14.5 h with residual activity at 50 h. | Shi et al., 2006 |

| YADH | 0.01–0.6 M | 98–20%, respectively; enzyme parameters. | Dabirmanesh et al., 2011, 2012 | |

| [C4C1Im][Br] | HL-ADH | 0.025–0.4 g/ml | Enhanced activity (up to 185% at 0.05 g/ml) dropping to 90% and then < 50% at 0.15 and 0.4 g/ml, respectively. Half-life 5.3 h with residual activity at 50 h. | Shi et al., 2006 |

| [C4C1Im][BF4] | HL-ADH | 0.025–0.4 g/ml | Activity ~30% at 0.025 g/ml dropping to ~0% at 0.075 g/ml. Half-life < 0.5 h. | Shi et al., 2006 |

| RE-ADH | 10% v/v (aq) | Conversion rate 99.5%; Activity 38% Half-life 82 h. | Hussain et al., 2008 | |

| W110A TE-ADH | 50% v/v (aq) | Conversion 40–96% with a selection of substrates | Musa et al., 2008 | |

| YADH | 0.01–0.4 M | 95–20%, respectively; enzyme parameters. | Dabirmanesh et al., 2011, 2012 | |

| [C4C1Im][OAc] | R. ruber ADH-A | 20, 50, and 80% v/v (aq) | Conversion rates ~40, 10, and 0%, respectively | De Gonzalo et al., 2007 |

| [C4C1Im][OTf] | HL-ADH | 0.025–0.4 g/ml | Activity ~25% between 0.025 and 0.1 g/ml dropping to ~0% at 0.15 g/ml. Half-life 1.5 h. | Shi et al., 2006 |

| [C2C1Im][OAc] | R. ruber ADH-A | 20, 50, and 80% v/v (aq) | Conversion rates ~ 45, 2, and 0%, respectively | De Gonzalo et al., 2007 |

| [C2C1Im][Cl] | HL-ADH | 0.025–0.4 g/ml | Enhanced activity (up to 155% at 0.025 g/ml) dropping to 95% and then < 50% at 0.075 and 0.4 g/ml, respectively. | Shi et al., 2006 |

| [C2C1Im][Et2PO4] | LB-ADH | 10% v/v (aq) | Activity ~ 5% | Kohlmann et al., 2011 |

| [C2C1Im][Me2PO4] | LB-ADH | 10% v/v (aq) | Activity ~ 80% | Kohlmann et al., 2011 |

| [C2C1Im][EtSO4] | RE-ADH | 10% v/v (aq) | Half-life 147 h. | Hussain et al., 2008 |

| [C2C1Im][MeSO3] | R. ruber ADH-A | 20, 50, and 80% v/v (aq) | Conversion rates ~5, 0, and 0%, respectively | De Gonzalo et al., 2007 |

| LB-ADH | 10% v/v (aq) | Activity ~ 105% | Kohlmann et al., 2011 | |

| [C2C1Im][MDEGSO4] | RE-ADH | 10% v/v (aq) | Half-life 22 h. | Hussain et al., 2008 |

| LB-ADH | 10% v/v (aq) | Activity ~ 70% | Kohlmann et al., 2011 | |

| [C2C1Im][OTs] | RE-ADH | 10% v/v (aq) | Conversion rate 89%; Activity 51% Half-life 45 h. | Hussain et al., 2008 |

| [C1C1Im][Me2PO4] | RE-ADH | 10% v/v (aq) | Conversion rate 38.5%; Activity 66% Half-life 182 h. | Hussain et al., 2008 |

| [C1Im][BF4] | YADH | 0.01–0.6 M | 85–0%, respectively with zero activity from 0.4 M; enzyme parameters. | Dabirmanesh et al., 2011, 2012 |

| [C1Im][Cl] | YADH | 0.01–0.2 M | 80–0%, respectively; enzyme parameters. | Dabirmanesh et al., 2011, 2012 |

| [3-HOMeC2Py][EtSO4] | RE-ADH | 10% v/v (aq) | Conversion rate 100%; Half-life 266 h. | Hussain et al., 2008 |

| [C4C1Pyr][NTf2] | RE-ADH | 10% v/v (aq) | Activity 43%; Half-life 144 h. | Hussain et al., 2008 |

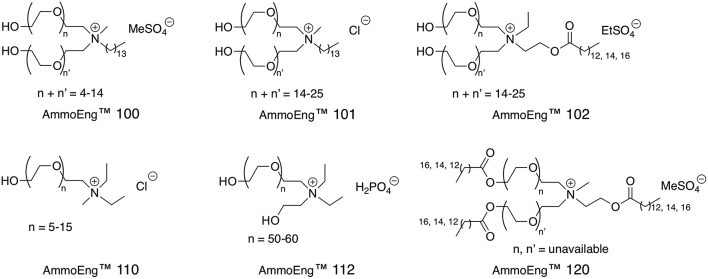

| AmmoEng™ 100* | R. ruber ADH-A | 70, 80, and 90% | Conversion rates 77.5, 73.1, and 27.0%, respectively | De Gonzalo et al., 2007 |

| LB-ADH | 10% v/v (aq) | Activity ~ 150% | Kohlmann et al., 2011 | |

| AmmoEng™ 101* | R. ruber ADH-A | 70, 80, and 90% | Conversion rates 78.2, 77.4, and 28.3%, respectively | De Gonzalo et al., 2007 |

| LB-ADH | 10% v/v (aq) | Activity ~ 180% | Kohlmann et al., 2011 | |

| AmmoEng™ 102* | RE-ADH | 10% v/v (aq) | Conversion rate 100%; Activity 9.4%; Half-life 12 h. | Hussain et al., 2008 |

| R. ruber ADH-A | 70, 80, and 90% | Conversion rates 69.7, 67.1, and 7.5%, respectively | De Gonzalo et al., 2007 | |

| LB-ADH | 10% v/v (aq) | Activity ~ 110% | Kohlmann et al., 2011 | |

| AmmoEng™ 110* | RE-ADH | 10% v/v (aq) | Half-life 77 h. | Hussain et al., 2008 |

| AmmoEng™ 112* | LB-ADH | 10% v/v (aq) | Activity ~ 100% | Kohlmann et al., 2011 |

| AmmoEng™ 120 | RE-ADH | 10% v/v (aq) | Half-life 40 h. | Hussain et al., 2008 |

| AmmoEng™ 140 | LB-ADH | 10% v/v (aq) | Activity ~ 90% | Kohlmann et al., 2011 |

| [N8, 8, 8, 1][NTf2] | R. ruber ADH-A | 20, 50, and 80% v/v (aq) | Conversion rates ~40, 20, and 10%, respectively | De Gonzalo et al., 2007 |

| [Tris-(2-HOEt)-MAM][MeSO4] | LB-ADH | 10% v/v (aq) | Activity ~ 120% | Kohlmann et al., 2011 |

| R. ruber ADH-A | 70, 80, and 90% | Conversion rates 79, 76.4, and 65.3%, respectively | De Gonzalo et al., 2007 |

MDEGSO4, 2-(2-methoxyethoxy)ethylsulfate;

REACH registered.

-

Hydrophilic ionic liquids

-

Ion effects

The impact of hydrophilic ions, such as Me4N, choline, and imidazolium cations, and Cl, Br, BF4, PF6, OTf, Me2PO4, Et2PO4, MeSO3 anions, has been examined for a number of ADH systems, with the caveat that PF6 or BF4 ions can be hydrolysed in aqueous solutions. While PF6 hydrolysis is mainly promoted only under acidic conditions so that the PF6 ion can be suitable for use at moderate temperatures in aqueous solutions, activity in BF4 might not be fully attributed to the biocatalyst, as it is not stable in water and will hydrolyse readily (Freire et al., 2010). The ionic liquids [C2C1Im][Cl], [C4C1Im][PF6], [C4C1Im][Cl] and [C4C1Im][Br] were able to enhance activity of HlADH at low concentrations between 0.05 and 0.075 M, when compared to pure buffer systems (Shi et al., 2006). This finding may hold true for many more small-molecule ions, but unfortunately not many ADH studies in ionic liquids apply alternatives to imidazolium cations or examine such low concentrations (see Table 5). Comparability of results in this field is also challenging as reported results vary between conversion rates, yields and residual activity. Regardless, conversion rates and half-life of enzymes seem to show considerable improvements upon addition of aqueous ionic liquids, relative to buffer solutions at low to moderate concentrations. In particular, improvements have been seen for [C4C1Im][OAc] and [C2C1Im][OAc] at 20% (v/v) (De Gonzalo et al., 2007), for [C2C1Im][MDEGSO4], [C2C1Im][MeSO3], and [C1C1Im][Me2PO4] at 10% (v/v) with respect to conversion rates (Kohlmann et al., 2011), and for [EMP][ES], [C4C1Im][BF4], and [C2C1Im][OTs] at 10% (v/v) with respect to half-life stability (Hussain et al., 2008). In contrast, imidazole and imidazolium derivatives, because of their similarity in structure to parts of the cofactor NADP+ (Dabirmanesh et al., 2012), have been reported as exhibiting competitive inhibition of the active center of ADHs (Zhang et al., 2008), and with smaller alkyl chains lengths for these imidazolium-based ionic liquids the inhibitory effect increases (Dabirmanesh et al., 2012).

Chloride-ion based ionic liquids do not act as a challenge to ADH-systems. YADH assayed in [C4C1Im][Cl] lead to a slight decrease in activity (~95%) at very low concentrations (~0.01 M), but activity (~20% remaining) was maintained up to a concentration of ~0.6 M ionic liquid, while for [C1C1Im][Cl] only 80% remaining activity was observed at 0.01 M and activity had completely declined at ~ 0.2 M (Dabirmanesh et al., 2011). For HlADH assayed in [C4C1Im][Cl] a maximum relative activity of 150% was observed at 0.075 M and decreased slowly to 25% at 0.4 M ionic liquid concentration. Use of [C2C1Im][Cl] lead to a maximum relative activity of 150% at 0.05 M, but activity values were ~50% less on average at higher concentrations (0.1–0.3 M) than for [C4C1Im][Cl] (Shi et al., 2006). However, activity ended up being about the same at 0.4 M in both ionic liquids, which was the highest concentration assayed. Of the other hydrophilic ionic liquid systems that have been assayed, [C2C1Im][Et2PO4] is strikingly detrimental to the enzymatic activity of L. brevis ADH with only 5% relative activity left at 10% (v/v) for the reduction of 2-octanone. This contrasts with [C1C1Im][Me2PO4], with 85% relative activity, and is comparable to the activity of YADH found for [C1C1Im][Cl] (above), and [C2C1Im][MeSO3] with 105% relative activity (Kohlmann et al., 2011).

Simulation studies have been able to shed light on the specific interactions that may be at play in controlling activity. Ionic liquid ions with low charge density (most cations) do not tend to exhibit any preference of vicinity on the protein surface, since coulombic forces for these ions are less dominant due to delocalisation and are competitive with the van der Waals interactions of the alkyl chains. Thus, these ions tend to be more mobile on the protein surface, than those ions with high charge density (most anions) (Tomé et al., 2012; Lim and Klähn, 2018), and this gives a rationale for the relatively more significant impact ascribed ionic-liquid anions. At all concentrations, the cations with their alkyl chains are able to contact like-charged-ions, but at low concentrations, since there are only a few about, they will, as single ions or small clusters, be able to closely associate to the protein surface.

The shorter the alkyl chain, the smaller are the polar domains that can interact with other species meaning, [C1C1Im] or [C2C1Im] can associate more closely and individually onto the surface of the protein and more easily into the binding pocket, than, for example C4C1Im. The peak in activity at very low concentrations of ionic liquid, and the consequent decrease in activity at increasing concentrations of ionic liquid may be attributed to the different numbers of cations being able to aggregate on the protein surface. As the cations continue to coordinate to the protein surface at increasing concentrations (Lim and Klähn, 2018), the ions form ever bigger patches, that are still small enough to amass onto the protein surface, but with the increasing patch-size an increased rigidity of the protein is conferred. The discrepancy of ~50% less activity between [C4C1Im] and [C2C1Im] at medium range concentrations (0.1–0.3) underlines the different interactions of the ions with the protein surface, as [C2C1Im] having shorter chains will be able to associate more closely overall. This close association allows an optimum effect on the flexibility (and activity) of the protein at a slightly lower concentration (0.05 M), than [C4C1Im] with 0.075 M, and at the same time having a much higher impact on constraining the protein flexibility at medium concentrations. At low ionic strength, the ring and tail of the imidazolium ions are equally often in contact with the protein surface, whereby the tail mainly has a steric interaction (fitting into clefts on the surface) and the ring has a mostly charged interaction, which becomes more pronounced and dominant at higher ionic strengths (Haberler et al., 2011). In comparison, high-charge density ions, if located on the surface, preferentially reside at positions with oppositely charged amino acids and hardly associate with like-ions. At low ionic liquid concentrations the number of low charge density ions populating the protein surface is far greater than the number of high charge density ions, which prefer the hydration of water molecules in the bulk phase (Haberler et al., 2011), leading to asymmetric influence at different concentrations on the protein.

Anions with high charge density, being dispersed in bulk water at low concentrations, may strip off a small number of tightly bound, structuring water molecules from the protein surface, leading to an increase in entropy and hence more flexibility and activity of the enzyme, up to the maximum point, upon thereafter the disruption of the secondary structure and subsequent rigidity of the protein (as seen for cellulases) becomes detrimental. This can affect the binding pocket significantly, as was proposed by the study on the enantioselectivity of Thermoanaerobacter ethanolicus ADH (Musa et al., 2008). In aqueous solution, the binding pocket of T. ethanolicus ADH includes a bound, ordered water molecule, which is displaced when a bulky (R)-substrate binds, yielding a substantial entropy increase (Heiss et al., 2001). For smaller substrates there is no enantioselective conversion in aqueous solution because they are unable to displace the water molecule. Addition of ~50% (v/v) of the hydrolysable ionic liquid [C4C1Im][BF4] was able to facilitate the asymmetric reduction of small phenyl-ring containing ketones, with this result suggested as indicating the expulsion of the tightly bound, structured water molecule by the ionic liquid (Musa et al., 2008). A similar result was obtained using ~50% (v/v) of the water immiscible [C4C1Im][NTf2], where the lower concentration of substrate in the aqueous phase was used to account for the increase in enantioselectivity, highlighting that a more microscopic view of the reaction may be required to fully interpret the role of the ions.

-

Water-effects