Abstract

Personal protective clothing (PPC) is mandatory in hazardous industrial workplaces, but can increase thermophysiological strain, causing fatigue, reduced productivity, illness and injury. We systematically reviewed the literature on PPC and heat stress, focusing on research relating to working conditions of high temperature and humidity. PPC must protect industrial workers from a wide variety of hazards, including sun damage, abrasion, chemical spills and electrical burns; these competing demands inevitably compromise thermal performance. Fiber type, textile material construction and treatment need to be considered alongside garment fit and construction to design functional PPC providing wearers with adequate protection and comfort. Several approaches to materials and PPC testing—objective benchtop evaluation, mathematical modelling, and physiological testing—can be combined to provide high-quality thermal and vapor performance data. Our review provides a foundation and directions for further research in low-level risk PPC, where current research in fabrics and clothing in this category is very limited, and will help designers and manufacturers create industrial workwear with improved thermal management characteristics.

Keywords: Protective clothing, Industrial workwear, Low-level risk protective clothing, Heat stress, Thermal comfort, Functional design

Introduction

Personal protective clothing (PPC) is primarily designed to protect workers from physical, mechanical, chemical and other hazards. However, the need to comply with safety and protection standards can impede the ergonomic performance of PPC1, 2). Most types of PPC involve increased bulk and weight that can raise the energy cost of work by up to 20%3, 4). Hence, working while wearing PPC, especially in hot and humid conditions, can cause significant physiological stresses on workers and can lead to cognitive impairment, discomfort, fatigue, reduced manual performance and injury1).

Human body temperature is regulated by heat exchange between the body and the thermal environment. When this mechanism cannot compensate for heat gain, core temperature can rise dangerously, causing heat stress5)—a major health and performance hazard in many industrial settings. Key risk factors linked to heat stress illness are the thermal environment, the physical exertion requirements and duration of activities, and clothing. Assessing heat stress necessitates an understanding of these elements and their underlying principles. Considerable research has been conducted on the functional properties of PPC6,7,8,9,10,11), as well as the comfort-related characteristics of garments, indicating the growing importance of wearer health when using PPC6, 11,12,13).

The effects of industrial PPC ensembles on heat stress are the focus of this review. Many industrial workplaces, such as mining, oil, gas, building and construction facilities are located in hot climatic regions, such as the Middle East, South America, South Africa and Australia14), where personnel are frequently required to work in very hot and humid outdoor conditions. Mining, oil, gas, building and construction workers are faced with many workplace hazards similar to workers from other industrial sectors that are exposed to thermal stress from machinery, equipment and the thermal environment15) and therefore are representative of a significant part of the outdoor workforce who are required to wear PPC.

However, whilst there is an extensive body of research into high risk PPC categories where multiple clothing layers are frequently used for protection, such as the firefighting, military, chemical, nuclear and biological sectors7, 13, 16,17,18,19), research of low-level risk category PPC, which is commonly only a single clothing layer, is much less extensive and warrants greater investigation.

This is highlighted by the frequent “off the shelf” purchase approach used by organizations that supply their workers with PPC20). As such the PPC is often not supplied with specific consideration of environmental conditions in which the PPC is worn20) with clothing suppliers offering limited evidence based PPC performance attributes, and infrequently propose new products20).

Further, the participation of women in these industrial sectors is now commonplace, yet female specific studies on PPC are limited, even though it has been found that women are at a comparative thermoregulatory disadvantage when wearing protective clothing and performing physical tasks in a hot environment21) and show different responses to men in hot/humid and hot/dry conditions22).

In addition, the impact of climate change will affect the thermal environments encountered by outdoor workers2), however, whilst heat stress has been widely studied, the extent of climate change effects requires greater research focus23).

We provide a comprehensive survey of PPC research, as well as research on clothing worn in sporting activities, particularly those involving hot conditions and prolonged physical exertion periods. This links to the emerging concept that physical workers and their metabolic outputs have some similarities to those of athletes and therefore their PPC should reflect the functional and performance requirements commonly underpinning functional sportswear design. For example, body-zoning of the garments using different materials at different body sites of the wearer’s body, and similar design concepts are quite common24,25,26). In addition, in sportswear some fibres and treatments are frequently marketed as being cooler, drier and more comfortable than others in the heat and during strenuous exercise27).

An understanding of existing knowledge about PPC performance and the factors that influence industrial worker safety and wellbeing are fundamental precursors for further research in this important segment of the apparel industry. This review provides a foundation for industrial apparel designers and material manufacturers to create apparel with improved comfort-related characteristics, better fit for purpose, for conditions of use and with enhanced ergonomic attributes, functionality and utility, especially for low-level risk PPC.

Methods

We systematically reviewed the existing evidence on PPC used in hot environmental conditions. To locate published studies, we searched relevant electronic databases—principally Scopus and Web of Science, but also Google Scholar and EBSCOhost (including Textile Technology Complete databases). The search strategy involved the keywords ‘personal protective clothing’, ‘safety apparel’, ‘protective clothing’, ‘workwear clothing’, ‘thermophysiological clothing comfort’, ‘thermoregulation and environment’, and ‘clothing’, combined with ‘environment’, ‘exercise’, ‘sport’, ‘work’, ‘ergonomics’, ‘comfort’ and ‘heat stress’. The literature search was initially performed during October 2014 and updated in May 2017. References in relevant publications were examined for additional research to review.

Two hundred and ninety retrieved studies were screened independently by the authors using document titles and abstracts. The search imposed no restriction on publication date, but only papers written in English were included. Selection criteria for studies included in this review were based on original works and/or specific focus on PPC used in hot environments; exercise or work activities in hot environments; physiological impacts of physical activity in hot environments along with thermophysiological clothing comfort. Once relevant studies were identified, the full publications were retrieved and reviewed to determine their suitability. One hundred forty nine studies and related standards and product performance articles were used in the development of this review. Any conflicts were resolved through further review by the first author. In addition, we examined secondary sources such as in-market research to identify commercial products relevant to workwear designed for hot environmental conditions, particularly PPC used in the mining, oil, gas, building and construction industries. All categories of PPC were included in literature search and review, both high and low risk PPC. Studies of high risk PPC were relevant to determination of the breadth of PPC research overall, and therefore to identification of the place the low-level risk PPC occupies in this knowledge domain and context. Any conflicts were resolved through further review by the first author. In addition, we examined secondary sources such as in-market research to identify commercial products relevant to workwear designed for hot environmental conditions, particularly PPC used in the mining, oil, gas, building and construction industries.

Results and Discussion

The results of our review are presented and discussed in seven sections: environmental and workplace conditions, properties of PPC, human thermal regulation and PPC, comfort and utility of PPC, methods for evaluating PPC, design of PPC, and textiles and treatments.

Personal protective clothing

PPC is required to protect wearers from external hazards when performing work tasks, with specially designed materials, accessories, treatments and their combinations commonly enabling this protection.

PPC is only one part of personal protective equipment (PPE), where six major categories of personal protective equipment are recognized28): eye and face protection, such as protective face masks and eyewear; head protection, such as helmets and head gear; foot and leg protection, such as protective footwear; hand and arm protection, such as protective gloves; and hearing protection, such as protective earmuffs; and earplugs with body protection, such as PPC being the most extensive part of PPE. PPC ensembles, the focus of the present review, can frequently cover 80–90% of the body surface area, providing an important protection barrier for workers and therefore being also a potential barrier to thermophysiological function of the wearer.

A non-exhaustive list of hazards in industrial workplaces and their effects on humans28, 29) includes physical hazards, such as explosions, rock falls, mobile equipment accidents and falls from a height, which can cause serious or fatal injury; thermal and electrical hazards, such as from arc flash and unprotected electrical cables, which can cause electrocution and burn injuries, and start fires that pose secondary risk; and chemical hazards from coal dust, diesel particulate matter, and various other substances (nickel compounds, arsenic, metal ores, cyanide), which are present in some mines, and mainly cause respiratory illnesses, such as chronic obstructive pulmonary disease and lung cancer. Respiratory illnesses can also result from biological hazards, primarily from contamination with legionella or other microorganisms in cooling towers. Noise hazards from drilling, blasting, cutting and other mining processes can seriously damage hearing; and radiation hazards, such as in uranium mining, can directly damage human tissue and are known to be carcinogenic. Finally, overexertion as a result of high-intensity or prolonged physical tasks can result in strain or sprain injuries30,31,32,33).

Another example of the broader impacts of workplace hazards is electrical arc burn injuries which are common in many industrial workplaces. Burn injuries can be fatal, but can also severely affect a survivor’s quality of life through poor ongoing health, finances, and other social factors. Typical effects of burn injuries are ongoing pain, permanent physical disfigurement, reduced movement of affected body parts, and diminished ability to participate in sporting and social activities34).

Frequent consequences of the external protection requirements are that PPC resists heat loss and has a low permeability to water vapour, reducing heat transfer and cooling and therefore increasing the risk of heat stress1, 10).

As already noted, hot and humid outdoor conditions create high potential for heat stress, dehydration, heat exhaustion and heat stroke, all of which can develop or be exacerbated through strenuous work activities35) with differing impacts on men and women21, 22). Heat stroke can be fatal29); dehydration can slow working speed and reduce productivity36). PPC restricts body heat exchange with the environment and its high bulk and weight increases the energy cost of work, raising the potential for harm from physical work in hot and humid conditions3).

Further, skin damage from prolonged exposure to solar radiation is also a common risk for outdoor workers. Melanoma is a well-known cancer risk and significant cause of illness and death in Australia and elsewhere37). PPC can protect outdoor workers from excessive sun exposure, but again, often at the cost of extra bulk and weight.

Environmental and workplace conditions

Thermal environmental conditions can affect the workplace significantly. The thermal environment takes account of environmental air, radiant and surface temperature; environmental vapour pressure; air speed; and clothing worn38,39,40).

The increasing presence of climate change has been cited as a key cause of high ambient temperature weather related mortality in many regions of the world23), with heat related illnesses commonly associated to prolonged exposure to high outdoor temperatures41).

Hot outdoor conditions can be broadly defined as those in which the air temperature and skin temperature are similar (31–33°C)40, 42), eliminating convective heat losses. Further, a humid environment can be classified as those levels of humidity where skin humidity and environmental vapour pressure minimizes heat dissipation through the evaporation of sweat40). The physiological impact on workers is closely associated with the thermal environment, but is also significantly influenced by the duration and intensity of work and exposure to thermal environment38, 40, 43).

Outdoor workers in some locations can be exposed to temperatures above 40°C, and can frequently encounter high relative humidity and solar radiation for extended periods of time. This is particularly relevant to mining, oil and gas industries, because many facilities are situated in hot climatic regions, such as the Middle East, South America, South Africa and Australia. For example, areas in the Middle East where outdoor industrial sites are located, such as oil and gas facilities in Kuwait and Saudi Arabia, have temperatures ranging from 29°C to 46°C at low humidity levels of 18–31%. Further, climates in South Africa can vary between 22°C and 42°C with high humidity—78% and above44).

A more detailed example of an extreme working environment is the oil and gas facility on Barrow Island, approximately 60 km off the north-western coast of Western Australia. Barrow Island’s climate is tropical, with high average temperatures and relative humidity, periods of high rainfall, and periods of high winds due to its offshore location. Between February 2015 and January 2016 temperatures ranged from 14.9°C to 40.3°C, relative humidity from 16% to 93%, and wind speed reached 128 km/h. Workers perform manual labor—moderately physical tasks such as electrical and equipment maintenance, and high-exertion activities such as hand excavation, lifting and rigging—in these conditions, often for long (12-h) shifts20). Such combinations of hot and humid ambient conditions and prolonged physical work tasks, such as lifting, rigging, hand excavation and use of powered equipment20), underscore the need to optimize PPC to reduce the potential for heat stress and related illnesses.

Standards for PPC

Numerous standards cover PPC and its performance in industrial workplaces. These include firefighting45), electrical work46,47,48,49), molten metal50) and chemical exposure, heat and flame51, 52), daylight and night time visibility53, 54), protection from ultra violet exposure55, 56), durability and during life care51) and other industrial workplace hazards. These standards cover a wide range of requirements for material performance in specified environments, such as for flame resistance, chemical protection and low light visibility; garment design, such as sleeve type and ventilation; and physical parameters such as tensile strength, durability with respect to industrial laundering, tear strength and abrasion.

A standard which covers a significant portion of the PPC used globally in the mining, oil and gas industries is the National Fire Protection Association (NFPA) (USA) standard48) for conditions for employees working with electricity and other hazards, such as flame resistance and low light visibility, encountered in many industrial sectors. It is explained here for illustration purposes to place PPC in the context of industrial workplace use and function.

NFPA 70E Standard for Hazard Risk Categories (HRC)48) covers several levels of electrical arc flash exposure and associated protection requirements for PPC. These HRC levels range from relatively low levels of arc exposure such as for mining, oil and gas workers (i.e., HRC level 1 and 2), to protection requirements for workers exposed to high-risk arc flash situations (i.e., levels 3 and 4), such as energized electrical conductors and circuit parts48).

In order to determine the requirements of PPC in any specific situation, the incident energy exposure of the worker is calculated and appropriate arc-rated clothing selected. An arc rating, expressed in incident energy density measured in calories/cm2, describes the performance of materials when exposed to an electrical arc discharge. It is derived from the arc thermal performance value (ATPV) or energy break-open threshold (EBT) (should a material system exhibit a break-open response below the ATPV value)48). The ATPV is the incident energy density associated with a 50% probability of transferring 1.2 cal/cm2 to a surface (i.e., a person) under the fabric. Many woven fabrics will resist heat transfer above 1.2 cal/cm2, but some materials or multilayer material systems ‘break open’ before the heat threshold has been surpassed. ‘Break open’ is defined as one or more holes at least 1.6 cm2 in area or 2.5 cm in length in each material layer. For these materials, the arc rating is equivalent to the EBT; that is, the incident energy density associated with a 50% probability of break-open occurring49). Arc rating is the lower of ATPV and EBT.

The performance rating of PPC to ATPV or EBT determines its compliance ranking. For example, compliance of PPC to HRC 1 requires a minimum rating of 4 cal/cm2 while HRC 2 requires a minimum rating of 8 cal/cm2. Fabric mass per unit area and/or density generally increase with higher protection categories.

In addition to the arc rating for each HRC, the Standard specifies the necessary types of PPC and PPE. For PPC, the Standard also gives a general description of garment styling as useful guidance for PPC designers and manufacturers. For example, for HRC level 1 and 2 protection, the Standard specifies clothing consisting of a long-sleeved shirt and trousers or coverall; face guard or hood, jacket, parka, rainwear, or hard hat liner; and safety glasses/goggles, hard hat, hearing protection (ear canal inserts), heavy-duty leather gloves, and leather work shoes. In addition, garments are required to be loose fitting and should be designed to provide the least hindrance to completion of work tasks48).

Thermoregulation and PPC

Six fundamental environmental variables influence the human body’s response to thermal environments: ambient factors—air temperature and movement, humidity, and radiation—and the body metabolic heat production, occurring during physical exercise57), and the clothing worn1,2,3, 40). Often assessment of these environmental variables is focused only on air temperature2), but all factors need to be considered when assessing the ability of the human body to maintain thermal homeostasis40).

The human thermoregulatory system strives to maintain a body core temperature within an acceptable range compatible with human survival, this being around 36 to 38°C. In general, to maintain this thermal equilibrium when at rest, humans require a skin/clothing microclimate temperature of 28–30°C58). The temperature and humidity of the microenvironment is influenced by the conditions of the ambient environment, movement, clothing permeability, clothing fit and design, and the metabolic heat produced during the physical activity58).

Health problems can occur if core body temperature drops below 36°C or exceeds 38°C, and become serious if temperature falls below 35°C or rises above 39°C2). High rates of heat loss or gain can be fatal very quickly.

The human body’s thermal homeostasis depends on the fine balance between heat production and heat dissipation. If heat inputs are greater than heat outputs internal temperature rises, and vice versa. The body autoregulates—adjusting skin blood flow, hormone levels and sweating—within a narrow thermal range. A net heat gain causes peripheral blood vessels to dilate, increasing skin temperature and enabling heat loss by convection and radiation. If this mechanism does not restore heat balance, further heat loss is achieved through sweating2).

In this context, the prime physiological objective of PPC is to support maintenance of body temperature within an acceptable thermal range. The clothing should permit the necessary heat transfer to occur or restrict heat gains and heat losses enough so that internal temperature does not vary beyond satisfactory limits2). As PPC represents a barrier to heat transfer and dissipation, optimisation of heat loss through PPC in hot environmental conditions is vital to thermal homeostasis.

Work tasks that require physical activity strongly influence metabolic energy production, which can fluctuate greatly depending on the required level and duration of muscular exertion. For example, the metabolic rate at rest is about 60 W/m2, but can vary from 100 W/m2 during light work to 250 W/m2 during heavy work59, 60). In some sporting activities, such as weight lifting and circuit training, and during firefighting rescue work it can be 300–500 W/m2 or even higher for periods (1–2 h)1, 60, 61). A study62) of energy expenditure for work tasks in various industries found that many tasks performed in industrial mining, oil and gas workplaces, such as drilling, fitting and shovelling, are within the moderate to heavy activity range (with metabolic rate ranges between 130 W/m2 and 300 W/m2) which can lead to significant core temperature increases63) unless thermoregulatory mechanisms are enabled64). This highlights the importance of thermal management attributes of PPC when workers are involved in tasks that require high metabolic energy production, especially in hot thermal environments.

As discussed earlier, it is recognised that wearing PPC impairs the loss of heat generated by metabolic energy production, and in addition, research shows that PPC itself contributes to increases in the metabolic energy produced when performing physical tasks3). Dorman3) demonstrated that various types of PPC significantly contributed to increases in metabolic rates through the restriction of range of movement and dexterity of the wearer and due to its mass and bulk imparted on the wearer. This demonstrates that it is important for designers to understand workplace tasks and assess movement needs of workers when considering the ergonomic attributes of PPC.

In addition, the increased bulk and mass of PPC can result in decreased mechanical efficiency in conducting tasks such as walking or performing high-intensity activities as physical exhaustion is approached65, 66). The onset of physical fatigue reduces the efficiency of body movement, resulting in excessive limb movements and body sway, further increasing metabolic energy expenditure67) with freedom of movement afforded by the PPC becoming even more critical. Exposure to hot environments exacerbates this situation. Therefore, minimising bulk and mass is an important consideration in PPC design, particularly for workers required to perform physical tasks for prolonged periods and in hot conditions.

An important mechanism for dissipation of heat produced by metabolic energy production is evaporation of sweat, which leads to body cooling due to the removal of latent heat through evaporation. In hot conditions more sweat is produced during physical activity as more intensive cooling is demanded by the body. Metabolic activity and sweating rates can vary considerably between genders68, 69) and individuals, as well as between different body sites of the same person when under physical exertion70). Further, it is known that females differ from males with delayed onset of sweating, reduced sweating sensitivity, and lower maximum sweat rates68, 69), however, these differences have been found to be minimal in some cases71).

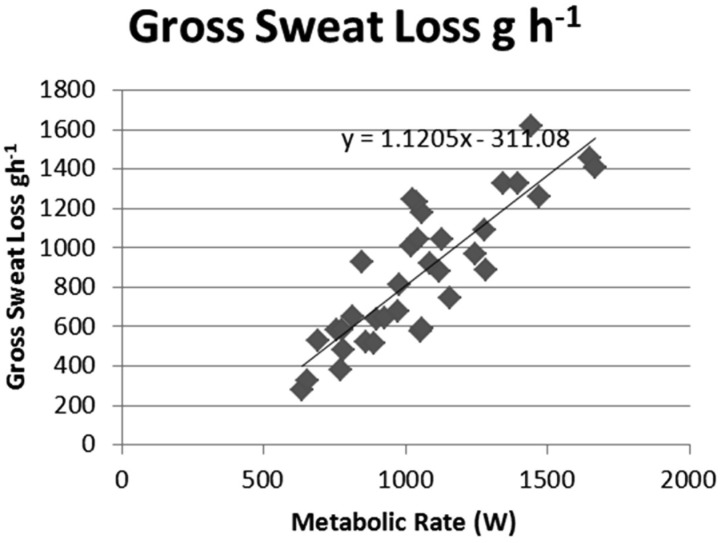

In healthy individuals, when physical activity intensity increases in static environmental conditions, gross sweat production, the total amount of sweat produced by the body on the surface of the body in grams/hour (gh−1), rises along with metabolic rate as demonstrated in Fig. 1.

Fig. 1.

Gross sweat loss versus metabolic rate.

Source: SMITH CJ and HAVENITH G (2011) Body mapping of sweating patterns in male athletes in mild exercise-induced hyperthermia. Eur J Appl Physiol, 111: 1391–1404.

When strenuous or prolonged tasks are undertaken in hot environmental conditions, gross sweat production increases further and can exceed 300 gh−1, and is exacerbated when PPC presents a barrier to evaporative heat dissipation.

When the thermal environment is humid the vapor pressure gradient between the skin and the external environment is diminished, therefore the ability of the body to evaporate sweat is reduced and heat stroke risk is increased72). Heat lost via sweating and the consequential loss of fluid (if not replenished) can lead to dehydration. Research shows that workers can experience sweating rates of >1 l/h in hot environments35, 73). Dehydration causes depleted blood volume and consequent cardiovascular strain; heart rate rises to compensate for the reduced blood by approximately 10 beats/min for every 1% of body weight lost36).

When reduced capacity to evaporate sweat is combined with dehydration (low body water content), core temperature in hot environment and presence of physical activity rapidly rises, leading to fatigue and greater threat of heat injury74, 75).

Research into heat illness in athletes shows that it is not uncommon to lose 2 or 3% of body weight during intermittent high-intensity activities, especially when the ambient conditions are hot42). These conditions and activity levels can be similar to those encountered by mining, oil and gas workers and therefore relevant in terms of levels of dehydration. A common result of dehydration is reduced worker productivity, such as from slower working pace, and lower effectiveness as a result of increased error frequency due to a decrease in mental function76).

Physical activity in hot conditions can also adversely impact cognitive function77) and reduce task performance and exercise efficiency78). Further, a hot thermal environment can impact on worker fatigue and productivity performance of tasks by increased heat gain from ambient radiation, convection and conduction. In a review of numerous field studies77) it was found that performance of more complex perceptual tasks, such as tasks requiring tracking and vigilance, deteriorated when workers were exposed to ambient temperatures above 30 °C even when exposed for 30 min or less. It is suggested that exposure to high temperatures and deterioration of task performance is consistent with the onset of human thermophysiological strain77).

To summarise, exertion while wearing PPC, particularly in hot conditions, carries a considerable physiological burden, unbalances thermal equilibrium and can rapidly exhaust workers1). This is due to the fact that PPC invariably increases thermal insulation and decreases dry heat loss and heat loss through evaporation of sweat. For example, PPC’s bulk and weight can increase the energy expended during work by up to 20%3); this is exacerbated in industrial workplaces, where physical tasks are typically of moderate to heavy intensity and result in high metabolic energy production. Therefore, the additional challenge for the designers and engineers of PPC is to create garments that optimize heat loss through the PPC to the thermal environment; and to prevent build-up of sweat on the skin surface.

Mechanisms of heat transfer in protective clothing

Heat can be transferred through clothing to the thermal environment in several ways: evaporation and moisture transfer, radiation heat exchange, convection, and conduction. Further, the ambient thermal environment contributes to heat gain or heat loss through conduction, radiation, convection and evaporation depending on the heat gradient between the body and the environment79). During physical activity in moderate ambient conditions, core body temperature is typically higher than skin temperature, allowing heat to be conducted from the muscles to the skin for dissipation. In addition, blood flow enables convective heat transfer from the core to the skin80). Then due to the temperature gradient between the skin and the thermal environment the heat is transferred to the environment and vice versa if ambient temperature is higher than skin temperature.

When the difference between ambient and skin temperatures becomes negligible the contributions of conduction, convection and radiation to the transfer of heat become increasingly insignificant, with the majority of heat transfer occurring through evaporation by vapor and sweating81). The ability of the body to transfer heat by evaporation of vapor and liquid moisture from the skin provides an opportunity for large amounts of heat to dissipate82). Therefore, considering that the PPC is worn against the skin, creating a barrier between the skin and the environment, the primary ways for increasing heat loss through PPC in hot environments are to reduce its thermal and evaporative resistance83).

The key attributes of the PPC that influence heat exchange between the wearer of PPC and the ambient environment require further discussion to determine their impact on the wearer in hot conditions.

Dry thermal resistance

Thermal resistance refers to the ability of the PPC to resist the transfer of dry heat to the external environment. Conduction, radiation, and convection all promote dry heat exchange. This resistance to dry heat exchange characterizes the thermal insulation properties of the PPC. Clothing acts as a barrier and reduces heat loss within the environment thereby increasing insulation, but convective air currents can significantly reduce its insulation performance80).

Some key determinants of thermal resistance of protective clothing are the characteristics of the material, such as thickness, density, composition, and construction; the thickness of the air layers (when present) trapped between the skin and materials and the number of material layers82). Accordingly, the lateral resultant thickness of the clothing ensemble constitutes a reasonable approximate measure of thermal insulation1). In addition, other factors such as ventilation of the protective clothing ensemble82, 84), as well as compression of materials and their assemblies can be important in hot conditions.

Vapour and liquid moisture resistance

Evaporative resistance of materials is the resistance to the transfer of moisture in form of vapour. Heat is transferred when the water in sweat evaporates at the skin surface6); low evaporative resistance permits this process.

Evaporation of water from the skin and respiratory tract is the main mechanism of cooling, particularly during exercise74); it accounts for only 10–20% of total heat loss at rest, but can account for 80% during exercise in low humidity conditions where the vapour pressure gradient between the skin and the environment is significant74). Further, hot and dry ambient conditions can result in up to 98% of heat transfer by evaporation85), but this is not the case in hot and humid environments. Therefore, low vapour resistance of PPC is paramount. In addition, the clothing system must allow moisture to be efficiently transported away from the skin to facilitate heat loss through evaporation86). This is a challenge, however, for workwear designers and manufacturers, as mandatory protective compliance requirements often restrict these attributes and must be balanced with wearer physiological and biomechanical comfort (which has safety benefits of its own).

In general, the most important properties of clothing with respect to evaporative resistance are the thickness of the air layers through which moisture must travel and the pore size of the material. The thicker the air layers and the smaller the pores, the less water vapor and hence heat will be transferred1). In addition, fabric composition can influence evaporative resistance. The moisture absorption capacity of the fabric can support transfer of water and vapor assisting in evaporative transfer.

Evaporative resistance is also affected by the air gap between the garment and the body. The evaporative resistance increases with the size of the air gap until the latter reaches a threshold value; for larger air gaps, evaporative resistance decreases86). The same could be said about the air gaps between the clothing layers.

The microclimate is the environment created between clothing and human skin; it refers to factors such as the air temperature and the water vapor pressure. Clearly, the attributes of PPC affect the microclimate. For example, if the clothing is impermeable to water vapor, then water vapor pressure will gradually rise, eventually reaching saturation pressure (100% relative humidity).

In addition, low air permeability constrains the movement of water vapour through clothing and affects its evaporative resistance, which is directly associated with the rate of evaporative cooling and determines its evaporative cooling potential5). Ventilation defines the volume of air movement through and around clothing, also affecting rates of evaporation and convection. In the case of PPC, ventilation through garment openings is often an important means of reducing next to skin water vapor pressure and increasing heat exchange, since the protective fabric itself may restrict the heat transfer24).

Heat exchange at the surface of the clothing

The body surface area of the average man is approximately 1.8 m2 (ISO8996). Clothing is commonly made with positive fit where its size is larger than the body size, creating a larger surface area for heat from the body to disperse from the clothing to the surrounding environment1).

In uniform environments radiant temperature is equal to the air temperature, but sizeable hot or cold surfaces or sources of radiation such as the sun in hot outdoor environments can substantially alter radiant temperature1). In the case of solar heat load, radiation intensity increases with sun elevation, peaking at 90°, but generates maximum exposure to the body at 30–40° above the horizon1). Heat will be exchanged by radiation when the body’s surface temperature and the temperature of the surfaces in the environment differ82). For workers wearing PPC in hot environmental conditions with high solar radiation, such as when radiant heat and air temperatures are greater than the surface temperature of the PPC (e.g., 40°C), the radiative heat can greatly affect heat load imposed on the wearer exacerbating thermal strain and endurance capacity1, 87). Minimizing the body surface area which is exposed to the source of radiant heat, especially uncovered, will reduce the environmental thermal load.

One study demonstrated that black, matte fabrics are better at absorbing the energy in the visible spectrum of the sunshine than white and reflective fabrics1), and can therefore negatively impact the level of radiant heat load on the wearer88). In another study89), it was found that radiant heat gain from the environment was influenced by the reflective characteristics of the ensemble with a negative dark color effect apparent in the solar spectrum but not in the infrared spectrum, This is particularly relevant to PPC, where dark-colored fabrics are frequently used to mask the appearance of unsightly soiling of the clothing during work activities.

Convective heat exchange occurs when heat is lost due to the movement of air around clothing or human body, due to the presence of wind and human movement, and can reduce the thermal insulation82, 90) due to so called pumping effects. When the air is cooler than the skin, or the clothing surface, it flows along their surface dissipating heat by convection82).

Convection can also occur as air moves through clothing openings and vents. The greater the movement of air around and through clothing, the more heat is exchanged via convection. For example, when wind and body motion facilitates convection through the clothing ensemble it can reduce its total insulation by around 30%. Similarly, wind speeds of 10–15 m/s can decrease insulation by up to 90% for an ensemble made of air-permeable fabrics by influence of convection91). This has major implications for PPC design and fit, although mandatory compliance requirements obviously restrict design elements such as vents and openings, which assist in facilitation of convection through the ensemble.

Conduction is a basic mechanism of heat flow in static substances. It occurs as free electrons in solids and molecules interact in liquids and gases, causing transfer from higher to lower temperatures82). Conduction requires direct physical contact between the interacting objects, and is directly proportional to the temperature difference between them. For example, conductive heat loss occurs when a warmer surface is in direct contact with a colder surface. In normal conditions, only a minor percentage of body heat loss is due to conduction82); however, when clothing is wet, conductive heat loss can increase fivefold.

Comfort and utility of personal protective clothing

The thermal sensations associated with microclimate effects are an important element of clothing comfort. They tell humans about their thermal states, both internal and external, which are vital for body temperature regulation and therefore to personal survival. For example, as relative humidity increases in the microclimate, perceived comfort decreases92).

In addition, garment size and fit of PPC are important considerations for comfort and utility, particularly when they restrict range of movement and dexterity93).

All of these factors influence the comfort of the wearer and his or her workplace productivity, and are important to consider in the design and manufacture of PPC. Comfort and functional fit are explored in more detail below.

Comfort

Clothing comfort is a complex and amorphous concept. It has been defined as ‘a pleasant state of physiological, psychological and physical harmony between a human being and the environment’94) and ‘a state of satisfaction indicating physiological, psychological and physical balance among the person, his/her clothing and his/her environment’95). Comfort has physiological, physical and psychological aspects and is regarded as critical for clothing assessment94, 96).

The physiological aspect of comfort can be divided into two phases. Firstly, a human body in normal conditions continuously generates insensible perspiration. Steady-state heat and moisture vapor fluxes are created and must be gradually dissipated for thermoregulation and thermal comfort maintenance. Secondly, people exposed intermittently to work activities and/or environmental conditions that generate sweating must manage removal of sensible perspiration and liquid sweat via their clothing11). It is under these transient conditions that PPC performance requires much greater study in order to generate designs that will improve worker comfort and wellbeing.

The physical aspects of clothing comfort relate to clothing characteristics such as heat conductivity, water vapour resistance, air permeability, and moisture regain. In addition, touch characteristics (such as softness, stiffness, handle and drape) are part of physical comfort.

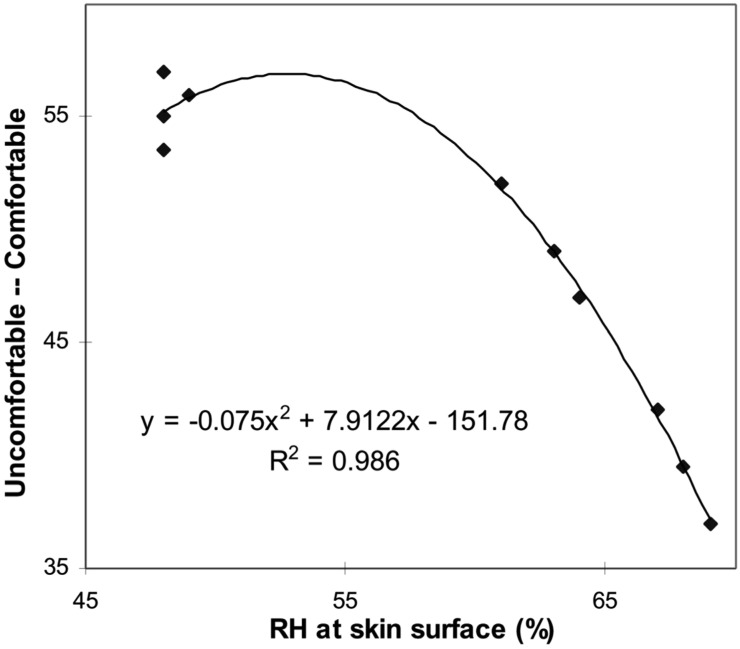

Moisture in clothing contributes to wearer discomfort92). Li92) assessed subjective measures of comfort and compared them to the relative humidity in the microclimate of the clothing; as relative humidity increased, wearer perceptions of comfort decreased. Li92) concluded that comfort is positively related to perceived warmth and negatively to perceived dampness (Fig. 2). Raccuglia et al.97) also found a strong relationship between increased wetness perception and reduced thermal comfort. Further, Winslow et al.98) and Fukazawa and Havenith99) found that when humans are in warm ambient conditions or are conducting strenuous activities, skin wettedness is more strongly related to perceived thermal comfort than to the skin surface temperature. In addition, Raccuglia et al.100) found that wetness perceptions increased with smoother fabric surface texture, which may be caused by a greater number of skin contact points and resultant skin deformation.

Fig. 2.

Perception of comfort and clothing microclimate humidity.

Source: Li, Y. (2005) Perceptions of temperature, moisture and comfort in clothing during environmental transients. Ergonomics, 48: 234–248.

Other aspects of physical comfort were studied by Chan101), who surveyed three groups—construction workers, horticultural and cleaning workers, and airport apron service workers—about the comfort attributes of cooling vests. They measured 17 subjective attributes, and found that three aspects significantly affected workers’ comfort.

Firstly, Chan and colleagues assessed thermal comfort, including moisture. Men were more influenced by this comfort factor than women, and the authors identified five important elements of thermal comfort: clammy vs. dry, airtight vs. breathable, damp vs. dry, sticky vs. non-adhesive, and hot vs. cool.

Secondly, participant evaluation of tactile comfort of the garments showed that women were more affected by this attribute than men101). Three elements were tested and found to be important: prickly vs. non-prickly, itchy vs. non-itchy, and scratchy vs. non-scratchy.

In another study, Yoo and Barker12) measured the perceived comfort of garments and its relationship to fabric properties. They found that tactile comfort was related to surface geometric roughness, the number of contact points, and the bending and shear rigidities of the fabric. In addition, Yoo and Barker found that subjective feelings of non-absorbency, clinginess, and clamminess were related to objective fabric measurements such as vapor buffering index and liquid moisture management properties102) such as the level of absorbency, the initial rate of absorption, the wet cling index, and the apparent water ratio (which can be assessed by a modified demand wettability test). Additionally, Raccuglia et al.103) concluded that fabric mass and the fit of clothing can affect fabric-to-skin pressure, which may result in a tactile stimulus affecting the perceived comfort of the wearer. These studies demonstrate that consideration of tactile and aesthetic factors when designing PPC is important in order to optimize comfort, and that consideration of gender is essential in PPC design approach.

The psychological properties of clothing relate to the subjective perceptions of an individual to the aesthetic design and feel of the clothing such as the clothing’s cultural acceptability104), personal status105) and design for modesty of the wearer105), which can be based on the clothing’s color, cut, drape and fabric handle101). Measurement of psychological comfort can be difficult to assess as individuals will have differing perceptions of the comfort of clothing, even if they are assessed wearing the same clothing in identical conditions106). For example, whilst one person may have a perception of wettedness another may feel dry.

Finally, in another study, participants were asked to assess the aesthetic feel of the garments, related to fabric handle. This attribute affected women more than men. Three elements were identified as important: stiff vs. pliable, heavy vs. light, and rough vs. smooth101).

Functional fit and mobility factors

As discussed earlier, functional fit and freedom of movement are critical to PPC enabling work rather than hindering it3, 104) with the construction of the garment and the degree to which the garment is created to follow the body shape of the wearer being paramount. For example, the PPC should fit and allow freedom of movement in multiple positions, such as bending, kneeling or reaching. The garment ease—the amount of fabric added to facilitate body movement to overcome inadequate stretch—can influence mobility. In addition, fabric stretch to aid in posture movement and symmetry of garment balance when being worn were deemed important for optimized fit and mobility104).

The fit of everyday garments is commonly based on a stationary standing position, which is insufficient for functional clothing that requires a range of movement and dynamic motion104) found that improved functional fit can be achieved by assessing the body dimensions of the wearer in key anatomical positions and the amount of ease necessary to perform the required movements. In addition, characteristics that can limit the functional ease of PPC garments include heavy and stiff fabric with little or no stretch; multiple layers in the ensemble which do not move or stretch similarly; styles or sizes that do not fit correctly, and work tasks or body shapes being poorly understood or considered in the design process104).

As described earlier, a study of the effect of protective coverall size and fit found that improperly fitted garments significantly impaired wearer dexterity and movement, causing discomfort and reduced worker performance93). In extreme cases, when PPC is not worn or incorrectly worn due to discomfort-related factors such as excessive thermal burden or restricted motion, risk of injury is increased93); for example, a study of high level risk female fire fighters clothing proposed that ill-fitting trousers can reduce comfort and contribute to greater physical strain and risk of injury107, 108). An individually tailored fit can be achieved by customization of the protective clothing to each wearer, but this approach is costly and therefore not offered in low-level risk PPC.

Chan et al.101) found that usability was the characteristic most strongly correlated with the cooling vest preference he investigated, for both male and female workers, although gender-specific factors such as tactile comfort and aesthetic feel were also important. This shows that whilst some characteristics of PPC are genderless, others should be considered in PPC design and construction for men and women, particularly as it is evident that research focus to date on women’s PPC requirements is limited.

In order to design PPC for maximum freedom of movement, the work activities performed by the wearers must be understood, alongside thermoregulatory needs, to help designers to optimize PPC’s fitness for purpose.

Methods for evaluation of personal protective clothing

Numerous methods exist for evaluating PPC ensembles and their constituent materials in relation to their thermal performance and ergonomic function. These can be divided into three categories: objective benchtop evaluation, mathematical modelling, and human physiological and sensorial testing9).

Objective benchtop evaluation

Objective benchtop evaluation of PPC and the components is twofold. Firstly, two-dimensional evaluation is conducted on materials, which includes the use of guarded hotplates, liquid moisture management and air permeability instruments. The guarded hotplate method is used to simulate heat exchange between the skin and clothing, and through the clothing material to the ambient environment. It is used to determine insulation and permeability values by measuring the thermal and vapor characteristics of materials109). These can be measured for a single layer or multiple layers.

The guarded hotplate method permits initial evaluation of thermal and vapor characteristics of materials prior to manufacturing garments for testing. Similarly, liquid moisture management and air permeability methods offer only materials characterization. These methods can only measure in flat or two-dimensional form, therefore the measurements are inapplicable to PPC garments which are three dimensional and have all seams and other construction elements included.

At the next level, three-dimensional evaluation is conducted on PPC ensembles using thermal manikins. To objectively evaluate dry thermal resistance and vapor resistance of PPC, a sweating thermal manikin is used. These manikins have articulated joints and can simulate simple human movement (and consequent air movement through the ensemble) in a controlled thermal environment, which can regulate temperature, humidity and air velocity. By measuring the thermal and vapour resistance of the clothing ensemble and the effect of air movement, this method allows assessment of the impact of the ergonomics such as sizing, fit, construction and design of the PPC as well as the performance of the constituent material110). Moreover, manikins can be dynamically controlled, permitting simulation of metabolic heat production of workers involved in physical activities and/or in hot ambient conditions111).

Modelling

Modelling has been utilized for several decades112, 113) and is commonly used to imitate human thermal regulation and estimate physiological strain, such as temperature and sweating114). Mathematical models can be used over a variety of environmental and metabolic conditions115) to provide useful estimation of thermoregulatory stresses in workplace situations. They are an alternative to testing with human participants as they are cost-effective and do not have the same ethical restrictions116). Mathematical modelling of physiological processes consists of two types: empirical and rational models9) and have been progressing with greater levels of precision and sophistication to better mimic human thermoregulation processes coupled with heat and mass transfer from the body, through the clothing to the environment116). These include multi-segmented models114, 117) and a 65-node thermoregulation model118) which simulate convective heat losses; radiant heat exchange with environment and the amount of radiation exposure of particular areas of the body dependent on posture116).

Empirical models are formulated to fit experimental data. An example is the US Army Research Institute of Environmental Medicine Heat Strain Decision Aid (HSDA), based on the physiological results from many human subject experiments119). HSDA development involved measuring the physiological reactions of fit male soldiers who performed duties that required various levels of metabolic activity, such as marching and operation of military equipment, in a range of environmental conditions. Whilst the tasks were military, they relate to domains such as high-intensity exercise and manual labor9).

Rational models are developed from recognized physiological principles, and can cope with variability in physical attributes, fitness levels, and responses to heat stress9). The Six Cylinder Thermal Model uses six cylinders to represent the human torso, head and all limbs and simulates changes in blood flow around the body120). This human/clothing model produces reliable results under a range of conditions, such as heat, cold and physical activity120).

Further, models are coupled with the thermal manikin instruments in research to predict and measure the thermoregulatory burden and impact of clothing. These multi zoned manikins’ measure thermal and evaporative resistance of clothing ensembles, and directly quantify the impact of PPC on environmental heat exchange116). One example of a commercial thermo-physiological model is the ManikinPC thermoregulatory model marketed by Thermetrics121). This model enables control of the manikin across different activity levels to imitate the human metabolism when the body is involved in activities such as sporting exercises, and sleeping. The model can measure the rate of heat loss from each zone of the manikin and at each surface segment to provide real data to the physiological software model121).

Another example of an earlier model is (SCENARIO) which models perceived heat strain expected to be experienced during activities such as those associated with armed services, industrial and sporting pursuits122). The model takes account of different clothing ensembles; fitness levels; varying ambient environments and aspects associated with fatigue such as dehydration; and models human physiological responses such as body temperature and circulatory changes122).

Human physiological testing

Testing the physiological and sensorial impacts of PPC on live human subjects produces real-life data and gives a powerful understanding of how PPC influences thermal stress123). Human studies can be conducted in controlled environments (i.e., laboratories) or in the field. Human physiological and sensorial testing can involve tests of heat and cold stress and measurement of parameters such as metabolic rate, fluid intake, core temperature, skin temperature, heart rate (this can reflect the metabolic rate as well as cardiac strain due to thermal stress), sweat rate, and the subject’s perceptions124).

In addition to assessment of these physiological aspects, the ergonomics of ensembles can be considered in human studies. Subjective evaluation of the ergonomics of design, construction, material, sizing, fit, and utility of ensemble features for performance of workplace tasks are best assessed using the entire ensemble110). In these assessments the ensembles are evaluated in field where workers are undertaking tasks, for example fire-fighting, and military activities, and ensembles are assessed for freedom of movement and ergonomic design as tasks are completed110).

Human testing has several drawbacks. Firstly, it is expensive, due to the cost of staff needed for safety monitoring, collecting data and administration, as well as participant reimbursement and transporting equipment for field studies. Ethical guidelines for studies involving human participants add further cost due to increased complexity and time. Secondly, differences in participant fitness, body size and shape, dietary regimes, work environments and so on, can bias data, so strict protocols are needed. Thirdly, suitable environmental conditions have to be engineered to be able to discriminate between clothing ensembles. Finally, the cost of trials may make significant results difficult to obtain due to low numbers of subjects125).

Nevertheless, laboratory testing in environmental chambers allows control over temperature, humidity and wind to create the same conditions for repeated experiments and reduce confounding. Repeated measures designs are frequently used, involving the same subject performing trials with each experimental PPC and the control in a random or balanced order. This removes variability due to individual characteristics and makes differences due to the PPC easier to detect.

Human testing in field situations means relinquishing control over environmental conditions; control over volunteer activity can also be difficult in a field environment. However, field experiments are closest to real-world conditions and therefore valuable for evaluation.

The different approaches for testing PPC all provide useful data. Objective testing provides direct comparisons and is efficient and cost effective in many cases. The use of two-dimensional testing, such as with a guarded hotplate, enables useful first-tier establishment of fabric performance12). Testing with thermal manikins creates an objective view126, 127) of PPC performance and can generate better measures for predictive mathematical models9). However, all objective methods can be enhanced with the use of human testing, in which subjective evaluations of PPC are quantified in wear trials1). The combination of objective and subjective evaluation provides designers and researchers with the most comprehensive understanding of PPC functional performance.

Design of personal protective clothing

Simultaneously achieving effective function and optimal comfort is challenging128), and is exacerbated when gender is considered. Whilst there are no all-inclusive specifications for PPC, numerous guides and recommendations apply to PPC design compliance48, 129). These cover various aspects of PPC design and can be summarized by garment design and construction.

With respect to design, garments should provide protection from the torso to the neck, arms to wrists, and legs to ankles; fully cover the worker’s body in the range and extent of expected positions, for example, bending, reaching and kneeling; maximise the worker’s freedom of movement; be compatible with other PPE worn for the tasks; and be easily cleaned in either domestic or industrial washing cycles.

The requirements with respect to garment construction involve numerous elements. Seams should meet the performance requirements of the relevant standard and expected work tasks. Pockets should be manufactured using the same textile as the main body fabric of the garments, including the internal pocket linings. Vents and garments openings should not compromise the protective properties of the garment. Further, zippers should be protected at top and bottom, and fasteners and draw tags should not protrude from the protective textile of the garment. Retro-reflective trims should be flame retardant, including attachment threads. Finally, labels and trims should not reduce the protective performance of the garment48).

Whilst these guidelines broadly encompass PPC design and elements, optimal design must balance thermal management and comfort. As Rossi125) noted, these requirements are conflicting and very challenging, and explain why commercial research and development of protective clothing products is ongoing, but is not extensive in low-level risk categories; and minimal for female PPC130).

Fabric selection is important in PPC design, as it must cope with sometimes competing issues of protective performance, such as in fire or electric arc standards, and comfort performance, such as thermal and evaporative resistance, air permeability and moisture transfer. In addition, the mechanical properties of fabrics, such as stiffness, stretch and recovery, and drapability affect utility and ergonomic performance131). However, research into fabrics in low-level risk categories is limited, and requires greater focus on PPC.

Another important factor in PPC design is fit—the closeness between the skin and the garment, a function of the required ease. Fit relates to wearer preference or the activity for which the garment is worn132); for example, compression sportswear fits closely to reduce muscle oscillation during strenuous exercise. Fit also takes account of the wearer’s body shape and size, and can also include posture and movement and their influence on performance in ergonomic and comfort terms133). For example, the size and type of air layers between the wearer’s body and the boundary air layer of the garment influence comfort134). However, in many instances, PPC designs are established based on static standing postures and standard body proportions135) and do not take account of the practical uses of the outdoor industrial PPC in completion of daily tasks20).

Further, the fit of PPC can affect its thermal and moisture vapor resistance. This is in part due to the air gap thickness between the body and the garment. Chen et al.86) showed that thermal insulation rises as the air gap increases, but when the air gap exceeds a threshold its thermal insulation and moisture vapor resistance start to decline. This phenomenon is mediated by fabric properties, garment fit and wind conditions.

In one study136), it was found that when garments worn by overweight people become tightly fitted the insulation values can be 6–31% lower than when the same style of garments are worn by lean people and are therefore more loosely fitted to the body. It was concluded that the difference is highest when sitting, and decreases when wind is present.

In addition, the body shape of male and female workers requires consideration; for example, research of thermal management utilizing three-dimensional body scanners to understand where heat is trapped and moved within garment ensembles for female fire fighters has resulted in improved design features137, 138). This approach can also be applied for industrial PPC where heat stress is a concern. However, whilst some manufacturers are now designing specific styles to account for the body shape differences of female workers139), there is a lag in evidence-based research into the gender specific requirements for females. This highlights the importance of understanding the morphology profile of the target workforce to enable more effective garment fit—particularly significant when activities involve high metabolic rates and hot and humid conditions.

Garment size refers to a pre-established regime of garment dimensions specified by the manufacturer which significantly affect the fit of the garment on the wearer. These size dimensions are normally loosely categorized as small, medium, large, or sizes 8, 10, 12 (etc.), although size specifications can vary widely from one manufacturer to another. Workers required to wear PPC are frequently issued with garments that fit poorly due to limited sizing and styles, potentially compromising thermal and moisture vapor resistance128). Compromises in sizes can be related to cost, but a potential flow-on effect of improper size is reduced productivity.

Textile materials and treatments

As discussed earlier, textile materials and textile treatments play an important role in PPC performance from a safety and health perspective, yet are not adequately researched in low-level risk PPC categories. Selection of fiber type and composition, fabric construction, fabric density and textile treatments are vital determinants of resultant PPC performance.

An array of fabric compositions and constructions is commercially available for PPC. Fiber compositions are generally categorised into two groups:

• inherently fire-retardant (FR) textile materials, such as aramid fibers and modacrylic, in which the polymers are fire retardant. This group can be further divided into synthetic fibers and synthetic natural fiber blends; and

• non-inherently FR textiles, such as FR-treated cotton textiles, to which the FR characteristic is added as part of the textile processing method.

Both categories of FR textiles are widely used in PPC. Synthetic fiber textiles are sometimes criticized for imparting greater thermal load to wearers, as a result of the relatively poor ability of synthetic fibers to absorb the vapor or liquid sweat of the wearer when compared with natural fibers. Typically, synthetic fibers, such as nylon, acrylic and polyester, absorb less than 7% of their weight in moisture140), whereas natural fibers such as cotton and wool can absorb 30% or more140). This is important, as PPC that can efficiently move moisture from the body by absorption and/or transportation create a more comfortable wearer experience, particularly in hot and humid environments.

Despite the limitations of synthetics described above, natural fibers are not universally superior. Yoo and Barker11) studied a range of synthetic and natural fiber fabric alternatives for their thermal management and sensorial properties in varying user conditions. They observed that the 100% cotton fabric had the longest drying time, and was inferior to the other fabrics tested in terms of heat transmission and thermal and vapor resistance properties in changing conditions. They also found that fiber composition and construction are important in heat and water vapor dissipation from the microclimate to the ambient environment, and hence in the physiological comfort of PPC.

The use of synthetic materials in PPC has been widespread for many years. These materials typically provide inherent FR protection but sub-optimal thermal resistance and evaporative resistance performance in hot environments. Artificial natural fibers can address these deficiencies; a notable example is Lenzing FR®141)—wood pulp fiber with an FR additive included in the polymerization prior to final extrusion. According to the manufacturer, this cellulose fiber, produced from beechwood, offers permanent protection against heat and flame in many applications. It is claimed that Lenzing FR® fiber greatly reduces the thermal load imposed by PPC in hot environments due to the moisture management properties of the viscose fiber141).

Textile fabrics manufactured for PPC are typically woven, with plain weave and twill weave constructions being most common. Textile mass per unit area ranges from 180 gsm to over 300 gsm, depending on HRC and PPC style and application. For example, fabrics used in shirting are usually lighter than those used in trousers.

Further, with ongoing improvements and development of manufacturing technologies there is a trend toward textile fabrics that functional attributes, but with reduced mass142). This trend is of interest for protective textiles used in hot environments due to the potential of lighter weight fabrics for improved dry thermal resistance and vapor and liquid resistance.

Fabric construction variables, such as fiber content, yarn property, weave type and functional finishes, contribute to comfort in dynamic and realistic wearing conditions and are therefore integral to optimizing wearer comfort. Consequently, the relationships between these fabric design elements, the perceived comfort of protective garments and their dependence on the specific conditions of end use are extremely important research targets11).

Kwon et al.143) investigated the physiological impacts of hydrophobic and hydrophilic fabrics during physical activity as well as during rest in hot ambient conditions, and concluded that their use reduces heat strain, especially in windy conditions. Subjects wearing fabrics with the highest moisture regain (wool/cotton blend) demonstrated lower microclimate humidity and temperature and lower skin temperature than participants wearing less hydrophilic fabrics.

In recent decades fabric surface treatment technologies have emerged that are designed to enhance the performance characteristics of fabrics, in some cases without compromising their aesthetic properties. The functions of the treatments include ultraviolet protection enhancement, soil or water repellence, improved hydrophilic function, temperature control, and bacterial inhibition. They can impart functional flexibility and durability; many have minimal surface modification impact, and some are highly cost effective.

Yoo and Barker11) found that treating textiles with hydrophilic finishes enhanced wettability, reducing wetting time and increasing absorption rates. However, although rates of absorption rose, the absorption capacity of the synthetic fiber fabrics they tested did not change, reiterating the importance of fiber selection in PPC design. In a further study, Yoo and Barker12) measured subjects’ perceptions of the dampness of garments. Those treated with hydrophilic finishes rated higher on comfort than the same fabrics left untreated.

To mitigate solar radiation and prolonged sun exposure described earlier, some fabric treatments can reduce ultraviolet (UV) penetration of the PPC, and some are purported to reflect UV. One such product is coldblack®, a UVA and UVB protection textile treatment from Schoeller Technologies AG144), which is claimed to reduce the absorption of sunlight and therefore heat build-up. In addition, it is said to provide improved protection from UV rays144). This type of treatment can be applied to numerous fiber types and fabric constructions so would be suitable across a range of PPC types.

Many textile treatment products are designed to be applied to synthetic or natural fiber textiles to improve functional temperature control. An example is ADAPTIVE®, manufactured by HeiQ Materials AG145). According to HeiQ, this treatment changes properties in response to temperature. At low temperatures, the polymer binds moisture in its structure, keeping the wearer drier; as temperature rises, the polymer releases the stored moisture to the ambient environment145). However, to our knowledge, there is no scientific research that evidences this claimed performance.

Materials that store, release or absorb heat as they transition between solid and liquid form are known as phase change materials (PCM). These materials react to falling temperatures by releasing heat as they change to a solid state and conversely, absorbing it as they return to liquid when temperatures rise. Some PCM products change phase within a temperature range that is just above and just below human skin temperature. They can be used in fabric and foam to store body heat and then release it when needed, and are being added to textile materials—coated on or encapsulated or incorporated into the fabric—to enhance temperature control within the skin/clothing microclimate146). They are found in clothing developed for extremely hot or cold environments or for activities that require very high metabolic energy output147).

However, some PCM products have been found to affect other functional properties of materials. Shin et al.146) studied polyester knit fabrics treated with PCM microcapsules by a pad-dry-cure method, finding that the treatment changed the fabric’s surface morphology and increased its thickness, leading to decreased air and moisture vapor permeability. This could decrease the thermal comfort of a garment, creating greater risk of heat stress.

In another study, cooling vests treated with PCM were shown to add extra insulation and restrict sweat evaporation148). The vests were effective in high heat and humidity, but not in a high-heat low-humidity environment. The cost effectiveness and operational usage of these types of vests remains to be determined.

Conclusions

PPC is an important component of worker safety. Whilst the primary function of PPC is the protection of wearers from external workplace hazards, the thermal burden imposed by PPC, particularly in hot and humid environments, can adversely affect worker health and efficient performance of workplace tasks. This is particularly salient with the increasing impact of climate change on conditions faced by outdoor workers.

Investigation of low-level risk category PPC is rare, which is highlighted by the frequent “off the shelf” purchase approach used by organizations that supply their workers with PPC. As this category covers industries that employ a significant number of outdoor workers, low-level risk category PPC warrants greater research and new product design and development focus.

Further, with the participation of women in these industrial sectors now routine, greater research attention is required into female specific PPC, particularly with the physiological distinctions between genders and resultant differences in thermophysiological responses.

The optimization of PPC for thermal regulation in the workplace creates competing challenges for designers and manufacturers, who must ensure that the PPC affords the mandatory protection for wearers and minimizes thermal burden. The identified trend toward functional fabrics with reduced mass provides manufacturers and designers with opportunities to develop lighter weight fabrics with the potential for improved dry thermal, vapor and liquid resistance attributes. Fiber type, textile material construction and treatment need to be considered alongside garment fit and design to give PPC wearers high protection and comfort.

This review provides a comprehensive overview of the requirements of PPC and its impact on physiological function during physical exertion—in particular, the considerable strain that PPC can exert in conditions of high heat and humidity. This information represents a useful comprehensive source for designers and manufacturers seeking to develop PPC that optimizes wearer comfort in hot and humid environments. More research in this domain will inform designers and manufacturers and allow them to address these differences in requirements in product design and function.

Disclosure Statement

The authors have no financial interest in and receive no benefit from the direct applications of their research.

Acknowledgments

This work was supported and partially funded by Chevron Australia Pty. Ltd., under Grant number 334096.

References

- 1.Holmér I. (2006) Protective clothing in hot environments. Ind Health 44, 404–13. [DOI] [PubMed] [Google Scholar]

- 2.Parsons K .(2014) Human thermal environments: the effects of hot, moderate, and cold environments on human health, comfort, and performance. CRC Press, London. [Google Scholar]

- 3.Dorman LE, Havenith G .(2005) The effects of protective clothing on metabolic rate. In: Proceedings of 11th International Conference on Environmental Ergonomics, Holmér I, Kuklane K and Gao C (Eds.) 82–85, Ystad.

- 4.Dorman LE, Havenith G. (2009) The effects of protective clothing on energy consumption during different activities. Eur J Appl Physiol 105, 463–70. [DOI] [PubMed] [Google Scholar]

- 5.Pease AL .(2010) Heat stress evaluation of protective clothing ensembles. University of South Florida, Tampa. [Google Scholar]

- 6.Holmér I. (1995) Protective clothing and heat stress. Ergonomics 38, 166–82. [DOI] [PubMed] [Google Scholar]

- 7.Song G, Paskaluk S, Sati R, Crown EM, Doug Dale J, Ackerman M. (2011) Thermal protective performance of protective clothing used for low radiant heat protection. Text Res J 81, 311–23. [Google Scholar]

- 8.Fu M, Weng WG, Yuan HY. (2014) Quantitative assessment of the relationship between radiant heat exposure and protective performance of multilayer thermal protective clothing during dry and wet conditions. J Hazard Mater 276, 383–92. [DOI] [PubMed] [Google Scholar]

- 9.O’Brien C, Blanchard LA, Cadarette BS, Endrusick TL, Xu X, Berglund LG, Sawka MN, Hoyt RW. (2011) Methods of evaluating protective clothing relative to heat and cold stress: thermal manikin, biomedical modeling, and human testing. J Occup Environ Hyg 8, 588–99. [DOI] [PubMed] [Google Scholar]

- 10.Kofler P, Herten A, Heinrich D, Bottoni G, Hasler M, Faulhaber M, Bechtold T, Nachbauer W, Burtscher M. (2013) Viscose as an alternative to aramid in workwear: influence on endurance performance, cooling, and comfort. Text Res J 83, 2085–92. [Google Scholar]

- 11.Yoo S, Barker RL. (2005) Comfort properties of heat-resistant protective workwear in varying conditions of physical activity and environment. Part I: Thermophysical and sensorial properties of fabrics. Text Res J 75, 523–30. [Google Scholar]

- 12.Yoo S, Barker RL. (2005) Comfort properties of heat resistant protective workwear in varying conditions of physical activity and environment. Part II: Perceived comfort response to garments and its relationship to fabric properties. Text Res J 75, 531–9. [Google Scholar]

- 13.Levine L, Sawka MN, Gonzalez RR. (1998) Evaluation of clothing systems to determine heat strain. Am Ind Hyg Assoc J 59, 557–62. [DOI] [PubMed] [Google Scholar]

- 14.Li G .(2011) World atlas of oil and gas basins. John Wiley & Sons, Oxford. [Google Scholar]

- 15.Crown EM, Dale JD .(2005) Protection for workers in the oil and gas industries. In: Scott RA (Ed.), Textiles for protection, 699–713, Woodhead Publishing, Sawston. [Google Scholar]

- 16.Carter BJ, Cammermeyer M. (1985) Biopsychological responses of medical unit personnel wearing chemical defense ensemble in a simulated chemical warfare environment. Mil Med 150, 239–49. [PubMed] [Google Scholar]

- 17.Goldman RF. (1963) Tolerance time for work in the heat when wearing CBR protective clothing. Mil Med 128, 776–86. [PubMed] [Google Scholar]

- 18.Crown EM, Ackerman MY, Dale JD, Tan YB. (1998) Design and evaluation of thermal protective flightsuits. Part II: instrumented mannequin evaluation. Cloth Text Res J 16, 79–87. [Google Scholar]

- 19.Taylor NA, Lewis MC, Notley SR, Peoples GE. (2012) A fractionation of the physiological burden of the personal protective equipment worn by firefighters. Eur J Appl Physiol 112, 2913–21. [DOI] [PubMed] [Google Scholar]

- 20.Mannion T, Nichevich A .(2013) Ergonomic safety apparel: Research & development project brief. 1–8, Chevron Australia, Perth. [Google Scholar]

- 21.McLellan TM. (1998) Sex-related differences in thermoregulatory responses while wearing protective clothing. Eur J Appl Physiol Occup Physiol 78, 28–37. [DOI] [PubMed] [Google Scholar]

- 22.Shapiro Y, Pandolf KB, Avellini BA, Pimental NA, Goldman RF. (1980) Physiological responses of men and women to humid and dry heat. J Appl Physiol 49, 1–8. [DOI] [PubMed] [Google Scholar]

- 23.Lundgren K, Kuklane K, Gao C, Holmér I. (2013) Effects of heat stress on working populations when facing climate change. Ind Health 51, 3–15. [DOI] [PubMed] [Google Scholar]

- 24.Zhao M, Gao C, Wang F, Kuklane K, Holmér I, Li J. (2013) A study on local cooling of garments with ventilation fans and openings placed at different torso sites. Int J Ind Ergon 43, 232–7. [Google Scholar]

- 25.CW-X “Ventilator.” (2018) https://cw-x.com/technology/exo-web-technology-bottoms/, 2018.

- 26.2XU Pty Ltd: “COMPRESSION L/S TOP.” (2018) https://www.2xu.com/au/p/compression-l%2Fs-top/WA2270a.html?dwvar_WA2270a_color=BLACK_BLACK&lang=en_AU#prefn1=restrictedProduct&sz=24&start=25&prefv1=no&lang=en_AU.

- 27.Davis JK, Bishop PA. (2013) Impact of clothing on exercise in the heat. Sports Med 43, 695–706. [DOI] [PubMed] [Google Scholar]

- 28.Dolez PI, Vu-Khanh T. (2009) Recent developments and needs in materials used for personal protective equipment and their testing. Int J Occup Saf Ergon 15, 347–62. [DOI] [PubMed] [Google Scholar]

- 29.Donoghue AM. (2004) Occupational health hazards in mining: an overview. Occup Med (Lond) 54, 283–9. [DOI] [PubMed] [Google Scholar]