Abstract

Calcium enriched herbal ice cream was developed using calcium gluconate (CG) as calcium source, Bacopa monniera whole plant extract (BME) is an herb containing saponins. Ice cream was prepared by incorporating CG and BME together. Preliminarily the range of CG and BME levels were fixed as 50–250 mg/100 mL and 10–50 mg/100 mL of ice cream mix respectively. Response surface methodology (RSM) was used to optimize the levels of two ingredients (CG and BME). Central Composite Rotatable Design using two variables and five responses comprising of sensory attributes was used for computation of optimized solution. All the responses fitted well into quadratic equation with R2 > 0.60. The optimum levels of CG and BME are 217.34 mg/100 mL and 10 mg/100 mL for preparation of experimental ice cream. RSM recommended with 87% acceptability for the optimum levels of CG and BME. Product is prepared with optimized solution and subjected to sensory evaluation.

Keywords: Calcium gluconate, Bacopa monniera extract, RSM, CCRD, Optimum levels, Sensory analysis

Introduction

In recent years, the people of all age groups are focusing on foods rich in neutraceuticles and functional properties. Ice cream is a frozen dairy food made by freezing pasteurized mix composed of milk fat, solid non fat (SNF), sugar, flavourings and stabilizer/emulsifier when agitated to incorporate air and to ensure uniformity in consistency. It is a good source of food energy having fat content three to four times and protein content of 12–16% more than that of milk (Marshall and Goff 2003). It is an enviable food for children and those who need weight gain, as it is a complete food with wholly digestible constituents (Marshall and Goff 2003). In India, annual turnover of ice cream industry was estimated to worth of 2000 crores of which 800 crores was shared by branded market (Kumar et al. 2013). Ice-cream production in India during 2014–2015 was 179,000 tonnes/annum and expected to increase 337,000/tonnes by 2020 (Anon 2015).The per capita consumption of ice cream is estimated to be 300 mL/annum in India compared to 22 L in USA or the world average of 2.3 L/annum (Anon 2015). With improving cold chain infrastructure in country coupled with increasing disposable income and changing lifestyle ice cream industry has great potential for growth.

Calcium, an important mineral component of human diet is available chiefly in milk, milk products, seafood, legumes and some vegetables. The major issues during fortification of calcium in liquid milk products are solubility, dissolution characteristics and stability of ingredients in solution (Gerstner 2003). Organic calcium salts such as CG, calcium lactate and calcium lactate gluconate exhibits high solubility with calcium content 9–13% (Flynn and Cashman 1999). As solubility is directly related to bioavailability, organic calcium salts exhibits higher bioavailability than inorganic calcium salts. Inorganic calcium salts like calcium chloride, calcium carbonate and calcium phosphate displays moderate solubility but their use is restricted due to its bitter and salty taste (Reddy et al. 1999). Calcium from dairy products is easily absorbed by intestine due to favourable effect of casein on calcium absorption by inhibiting calcium precipitation by phosphate in intestinal lumen through the action of phosphopeptides coming from enzymatic hydrolysis of casein (Kaushik et al. 2015). Due to the above fact calcium from dairy products has higher bioavailability than calcium in vegetables or cereals and further can be fortified with calcium salts in order to meet required daily intake or to reduce calcium deficiency diseases such as osteoporosis, osteomalacia, hypertension, colon cancer and obesity (Gerstner 2003). Flame Atomic Absorption Spectrometry (FAAS), Graphite Furnace Atomic Absorption Spectrometry (GF AAS), and Inductively Coupled Plasma Optical Emission Spectrometry (ICP OES) are the main techniques used for the determination of trace element contents in food analysis laboratories.

Bacopa monniera (BM) or Brahmi is an ayurvedic medicinal plant, clinically used for memory enhancing and as nerve tonic in Indian traditional medicine (Chopra et al. 1969). The activities of BM are believed to be associated with the polar fraction, mainly containing saponins as a complex mixture of bacosides (Bacoside-A and B), Bacopaside-I and Bacopaside-II (Rastogi et al. 1994). Effect of BME on human subjects had shown reduction in memory loss of newly gained information (Roodenrys et al. 2002) and improves cognitive performance in humans (Pase et al. 2011). Morgan and Stevens (2010) conducted a clinical trial in people above 55 years to assess the performance of BME (300 mg/day) as a memory enhancer for 12 weeks and reported that it aids in memory improvement for aged people. In the human body tissues, the concentration of calcium ions (Ca2+) outside cells is normally about 10,000-fold higher than the concentration inside cells. Embedded in the membrane of some cells are calcium channels. When these cells receive a certain signal, the channels open, letting calcium rush into the cell. Calcium channel blockers prevent or reduce the opening of these channels and thereby reduce blood pressure in patients with hypertension (Michaluk et al. 1998). Bacoside A possesses calcium channel inhibitory activity which has been found to potentiate opioid analgesia and delay tolerance onset without increasing respiratory depression (Dar and Channa, 1999). Herbs like B.monniera can be incorporated into ice cream for value addition and health benefits. Without saponins, the amount of calcium absorbed ranges from 5.8% in 15 min to 18% in 100 min. On addition of saponins the amount of calcium absorbtion increased 13% in 15 min and 36.5% in 100 min (Singh and Muthukumarappan 2008). High Performance Liquid Chromatography (HPLC) (Dowell et al. 2015) and methods based on UV detection have been developed for the determination of bacosides in BME (Shrikumar et al. 2004).

Response Surface Methodology (RSM) is a useful tool for optimizing the sensory quality of foods. Following appropriate statistical design i.e., Central Composite Rotatable Design (CCRD), the experimental data relate the variation in the consumer’s response to variations in selected factors (Arcia et al. 2011). If the proposed model is adequate, as revealed by the diagnostic checking provided by analysis of variance (ANOVA), the 3-D plots can be usefully employed to study the response surface and to locate the optimum values (Deepak et al. 2000). RSM was successfully used to identify the best combination of ingredients in newly developed products with health-promoting characteristics (Villegas et al. 2010). The main advantage of RSM is the reduced number of experimental runs needed to provide sufficient information for statistically acceptable results (Kim et al. 2002). Sheba (2015) endorsed the relevance of RSM in predicting the consumer acceptability of newly developed products. Although ice cream is rich in calories, it is poor in natural antioxidants and polyphenolic compounds. BM is one of the natural sources of neutraceutical and functional compounds mainly bacosides which aids in memory enhancing. Over the past years, economic burden of osteoporosis is increasing and the clinical implications of calcium deficiency are being better recognized. With increase in calcium level in ice cream mix it increases the viscosity of ice cream mix and lowers the overrun (Murari 2007). A reconsideration of dietary calcium intake through calcium fortified foods is needed. In the present study process is developed for manufacture of experimental ice cream incorporating CG and BME. The objective of this study was to optimize the levels of CG and BME and to evaluate acceptability of the product by using RSM.

Materials and methods

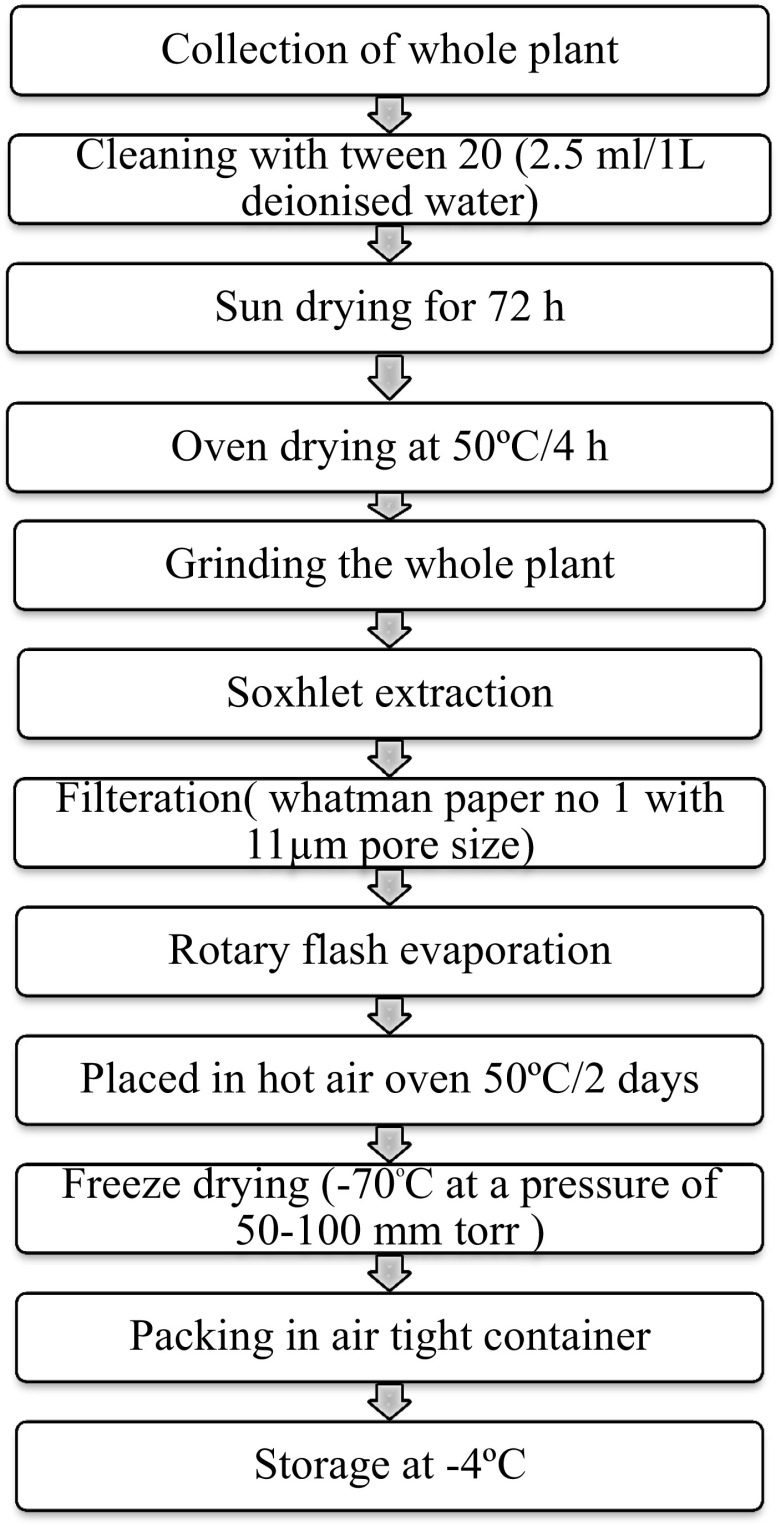

Extraction of saponins from BM whole plant was done using soxhlet extraction as follows.

CG of food grade was procured (Nice chemicals pvt.ltd, India). The level of these two additional ingredients (CG and BME) in the product was optimized by CCRD. The experimental ice cream was developed with ingredients of cream, skim milk, sugar, stabilizer/emulsifier plus CG and BME. The five responses or sensory characteristics (colour, flavour, body and texture, melting property and overall acceptability) of the product were analysed.

Preliminary trials for selecting minimum and maximum levels of two ingredients

The minimum and maximum levels of acceptability should be known to perform RSM for optimization. CG was added at the rate of 0 (T1), 50 (T2), 100 (T3), 150 (T4), 200 (T5), 250 (T6), 300 (T7) mg per 100 mL of mix. The aged ice cream mix was frozen, packed and hardened. The chosen sensory parameters as responses for optimization of levels of two ingredients were analysed. The levels of ingredients were selected based on sensory scores of five responses by panel comprising of five experienced judges and the scores obtained for each of the attributes was analyzed using Friedman’s test and post hoc analysis was done by Wilcoxon Signed Rank Test. Same was followed for BME added at the rate of 0 (T1), 10 (T2), 20 (T3), 30 (T4), 40 (T5), 50 (T6), 60 (T7) mg per 100 mL ice cream mix.

Experimental design

The RSM (Design expert® software version 9.0.4.1) was used to design the experiment based on CCRD for the optimization of different levels of two factors (CG and BME) in the formulation of experimental ice cream. Thirteen sets of experiments were obtained by presenting minimum and maximum levels to RSM which consisted of eight factorial points, six axial points and six replicates of the central point. The optimization of the level of factors was carried out based on the sensory characteristics as mentioned above.

Optimization of levels of factors in experimental ice cream by RSM

Based on preliminary trials, two factors with their ranges were selected for the optimization. The coded and actual values of two factors at five levels in the CCRD was obtained. The centre point experiment was repeated six times to calculate reproducibility of the method. A second order mathematical model was fitted to all response data.

where β0, βi, βii, βij, are regression coefficients Xi and Xj are independent variables in coded form, k is the number of independent variables and Y is the response.

Optimization procedure and verification of results

Optimization of the two factors and multiple responses was carried out using numerical optimization technique. The desired goals for each factor and responses were given based on data obtained from sensory analysis of thirteen sets of combinations and responses were recorded (Table 1). From that data minimum and maximum levels of two factors and scores of responses were taken. After fixing the desired goals, eleven sets of solutions (final combination of two ingredients) generated by RSM was taken. The solution having highest desirability was chosen for preparation of product. Verification of results was done by replicating prepared product to five times. It was subjected to sensory analysis and scores were noted. The scores given initially for generating final solutions (predicted value) and the scores obtained after sensory analysis of five replicated samples (observed value) were taken.

Table 1.

Central composite design matrix for two ingredients (CG and BME)

| Standard order | Factor 1 | Factor 2 | Response 1 | Response 2 | Response 3 | Response 4 | Response 5 |

|---|---|---|---|---|---|---|---|

| A:BME (mg/100 mL) | B:CG (mg/100 mL) | Colour | Flavour | Body and texture | Melting property | Overall acceptability | |

| 1 | 30 | 140.29 | 8.3 | 8.3 | 7.4 | 7.8 | 7.8 |

| 2 | 58.28 | 140.29 | 7.3 | 7.5 | 7.6 | 7.2 | 7.5 |

| 3 | 1.71 | 140.29 | 8.3 | 8.5 | 8.1 | 8.3 | 8.5 |

| 4 | 30 | 140.29 | 7.1 | 7.8 | 7.1 | 7.5 | 7.3 |

| 5 | 30 | 140.29 | 7.1 | 7.9 | 7.5 | 7.4 | 7.2 |

| 6 | 10 | 224.55 | 8.5 | 8.7 | 8.7 | 8.4 | 8.7 |

| 7 | 50 | 224.55 | 6.5 | 7.0 | 6.5 | 6.3 | 6.5 |

| 8 | 30 | 140.29 | 7.1 | 7.5 | 7.2 | 7.0 | 7.0 |

| 9 | 50 | 56.03 | 6.7 | 6.2 | 6.5 | 6.4 | 6.3 |

| 10 | 30 | 259.45 | 6.8 | 6.4 | 6.2 | 6.6 | 6.4 |

| 11 | 30 | 21.12 | 6.3 | 6.3 | 6.3 | 6.5 | 6.3 |

| 12 | 10 | 56.03 | 6.6 | 6.6 | 6.3 | 6.5 | 6.4 |

| 13 | 30 | 140.29 | 7.1 | 6.8 | 6.5 | 6.6 | 6.6 |

Diagnostic check of the quadratic model

The sensory responses obtained as a result of proposed experimental design were subjected to regression analysis in order to assess the effect of levels of two ingredients. Multiple linear regression analysis was used for each of the response variables to fit the model. The linear, quadratic and interaction effects were calculated for each model.

Product preparation

Calcium added to milk reacts with soluble phosphate and results in precipitation of colloidal calcium phosphate, an increase in ionized calcium, a decrease in the concentration of soluble phosphate and finally decreases pH. The pH is restored back to the original value (6.3) with the addition of 10% (w/v) solution of sodium hydrogen phosphate (Na2HPO4). BME has impact of its strong flavour on addition to ice cream mix. Vanilla No. 1 (Bush Boake Alien (India) Ltd, Chennai) was used in this study to mask the flavour of BME.

Acceptability of ice cream

Sensory attributes play a major role in determining the acceptability of a food product as well as ultimate purchase decision of consumers. Freshly prepared experimental and control ice cream was evaluated for its sensory characteristics by triangle test. Two batches of experimental ice cream (A and B) with same compositions and control ice cream (C) was prepared. Samples were given to sensory panel consisting of five judges and scores were taken based on 9-point Hedonic scale (Amerine and Pangborn 1965).

Results and discussion

Preliminary trials for selecting minimum and maximum levels of two ingredients (CG and BME)

From the results (Table 2) in case of CG, it can be inferred that T7 (300 mg/100 mL mix) significantly differs from T1 (CG zero mg/100 mL mix). No significant difference (p > 0.05) was found among T4 (150 mg/100 mL), T5 (200 mg/100 mL) and T6 (250 mg/100 mL) when they compared to T1, while T2 (50 mg/100 mL), T3 (100 mg/100 mL) had significantly lower scores when compared with T1 due to presence of lower CG which has potential to impart sweeter taste as it is organic in nature. Average mean scores increased from T2 to T6 after which got reduced due to the fact that increase in CG increased the overall acceptability by means of flavour, taste, melting point and body and texture but after 250 mg/100 mL and increased the viscosity of product drastically which effected the overall acceptability. Pinto (2006) also noted that calcium imparts smooth texture to the product thereby resulting in enhanced glossiness of the ice cream. As the objective was to select minimum and maximum levels of CG, levels were selected as T2 (50 mg/100 mL) and T6 (250 mg/100 mL) because T1 had shown lower available calcium content, while T7 had shown increased viscosity and coagulation effect on ice cream mix. Singh and Muthukumarappan (2008) has reported that there is no difference in the control yoghurt and CG enriched fruit yogurt up to 260 mg/100 mL when compared to four different characteristics viz., flavour, body and texture, appearance and overall acceptability. In case of BME (Table 3) it can be inferred that T7 (60 mg/100 mL mix) significantly differ from T1 (Zero mg/100 mL mix). But, no significant difference (p > 0.05) was found among T3 (20 mg/100 mL), T4 (30 mg/100 mL), T5 (40 mg/100 mL) and T6 (50 mg/100 mL) when compared to T1. T2 (10 mg/100 mL) had significantly lower scores when compared with T1 as BME contains phenolics which imparted bitter taste to and light green colour to product. Average mean scores decreased from T2 to T6 because increase in BME concentration had significantly reduced overall acceptability, affected the sweetness of the product because of the increased perceived bitterness and astringency owing to the presence of phenolics in the extract. Phenolics have been known to mask the sweetness or increase the threshold for sweetness. T7 had imparted dark greenish colour to product and taste was unacceptable. As the objective was to select minimum and maximum levels of BME addition in ice cream, the levels were selected as 10 mg/100 m L and 50 mg/100 mL respectively. Similar findings reported by Russo and Borrelli (2005) that Increasing the BME adversely affected the flavour of the product because of the presence of phenolics, which are bitter in taste and thereby decrease the overall acceptability.

Table 2.

Effect of addition of CG on the sensory scores of ice cream

| Treatments | Parameter | ||||

|---|---|---|---|---|---|

| Colour | Flavour | Body and texture | Melting property | Overall property | |

| T1 | 8.54 ± 0.22ac | 8.44 ± 0.16a | 8.50 ± 0.10ac | 8.42 ± 0.15a | 8.36 ± 0.09a |

| T2 | 6.40 ± 0.18b | 6.60 ± 0.24b | 6.38 ± 0.27bc | 6.20 ± 0.12b | 6.60 ± 0.10b |

| T3 | 7.34 ± 0.26bc | 7.30 ± 0.12ab | 7.38 ± 0.22bc | 7.34 ± 0.14ac | 7.38 ± 0.22ac |

| T4 | 7.40 ± 0.35ac | 7.32 ± 0.25ac | 7.40 ± 0.18ac | 7.46 ± 0.24ac | 7.48 ± 0.25ac |

| T5 | 7.96 ± 0.06ac | 8.12 ± 0.10a | 7.94 ± 0.15a | 7.98 ± 0.18ac | 7.96 ± 0.11ac |

| T6 | 8.44 ± 0.19a | 8.60 ± 0.06a | 8.64 ± 0.06a | 8.62 ± 0.04a | 8.66 ± 0.05a |

| T7 | 6.48 ± 0.21b | 6.28 ± 0.13bc | 6.12 ± 0.13b | 6.36 ± 0.12b | 6.46 ± 0.27bc |

| Chi square value | 22.75** | 27.03** | 27.56** | 26.55** | 26.25** |

Figures are mean ± standard error of sensory scores by five judges in three replications

a–cFigures in a row bearing different superscript differ significantly (p < 0.01)

**Significant at 1% level (p < 0.01)

Table 3.

Effect of different levels of B. monniera on sensory scores of ice cream

| Treatments | Parameter | ||||

|---|---|---|---|---|---|

| Colour | Flavour | Body and texture | Melting property | Overall property | |

| T1 | 8.54 ± 0.22ac | 8.68 ± 0.09a | 8.40 ± 0.10ac | 8.52 ± 0.15a | 8.66 ± 0.09a |

| T2 | 7.50 ± 0.11b | 7.36 ± 0.16b | 7.44 ± 0.12bc | 7.38 ± 0.12b | 7.38 ± 0.11b |

| T3 | 7.40 ± 0.07bc | 7.24 ± 0.09ab | 7.48 ± 0.08bc | 7.52 ± 0.08ac | 7.32 ± 0.07ac |

| T4 | 7.56 ± 0.05ac | 7.18 ± 0.07ac | 7.42 ± 0.08ac | 7.34 ± 0.16ac | 7.22 ± 0.16ac |

| T5 | 7.58 ± 0.10ac | 7.10 ± 0.07a | 7.34 ± 0.08a | 7.26 ± 0.09ac | 7.25 ± 0.11ac |

| T6 | 7.28 ± 0.03a | 7.14 ± 0.05a | 7.22 ± 0.05a | 7.16 ± 0.05a | 7.18 ± 0.07a |

| T7 | 6.58 ± 0.25b | 6.50 ± 0.04bc | 6.48 ± 0.14b | 6.56 ± 0.05b | 6.40 ± 0.09bc |

| Chi square value | 24.04** | 28.27** | 27.53** | 25.26** | 26.19** |

Figures are mean ± standard error of sensory scores by five judges in three replications

a–cFigures in a row bearing different superscript differ significantly (p < 0.01)

**Significant at 1% level (p < 0.01)

Diagnostic check of quadratic model

The regression analysis of the responses produced the quadratic models for each response. The coefficient of determination (R2) ranged from 59 to 68%. The model F-value of the fitted quadratic model for all the responses was found to be significant. Regression models developed from the experimental data had shown significant difference with the observed p-values. The sufficient accuracy for predicting all response variables of experimental ice cream prepared from any combinations of variables within the range evaluated was indicated by non significant lack of test and confirms the obtained quadratic model fitted the data strongly. Adequate Precision Value (APV) for a well fitted model always should be higher than 4. This measure also completes for the obtained mode with APV values ranging from 7.2 to 9.17. All these results firmly recommended that the model could be used to cruise the design.

The final equation obtained by RSM in terms of actual factors for predicting the effect of different variables on overall acceptability of experimental ice cream as follows:

The coefficient of determination (R2) of 0.65 with adequate precision of 8.39 strongly recommends the use of this response viz. overall acceptability to navigate the design. The response values of overall acceptability for the experimental ice cream were observed in range from 6.3 to 8.7. The partial coefficients of overall acceptability in terms of linear order, second order and interaction of both the two independent parameters are also given in the regression analysis data. BME had significant effect (p < 0.05) on the overall acceptability of the experimental ice cream in linear terms. The effect of CG on overall acceptability profile was not significant (p > 0.05) in linear terms and the effect of interaction of these variables was found to be non significant effect (p > 0.05). At quadratic level BME had no significant effect (p > 0.05) and CG had significant (p < 0.05) effect on overall acceptability.

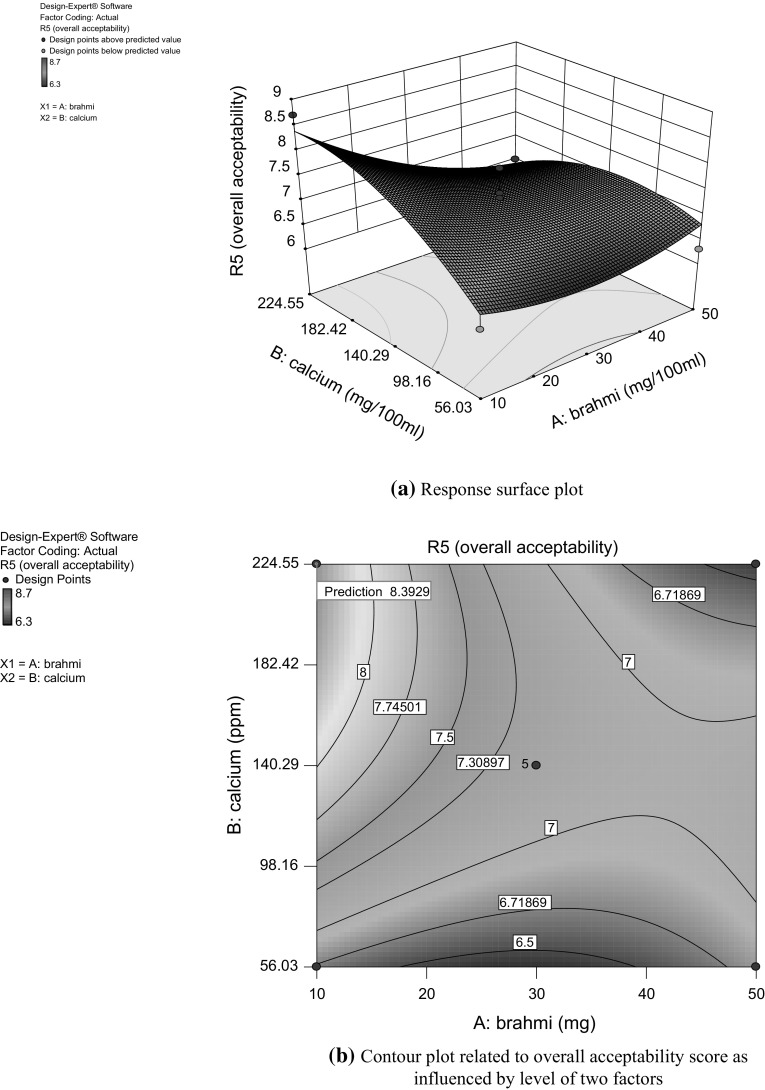

Representation of the interaction among the two different variables and their effect on overall acceptability of the experimental ice cream are depicted in three dimensional surface plots (Fig. 1). From Fig. 1, when inoculation rate of BME was kept constant (10 mg/100 mL) the addition of CG showed improved overall acceptability to a level of (224.55 mg/100 mL) and beyond that level reduction of scores was observed. Addition of BME by keeping CG constant (224.55 mg/100 mL) followed reduction in overall acceptability. In general, the addition of BME and CG significantly increased the overall acceptability of the experimental ice cream. Increase in addition of CG levels by keeping level of BME constant (10 mg/100 mL) has found to improved the overall acceptability. This could be because of the ability of CG to improve the sensory characters mainly imparts sweetness to product. The similar effect of calcium addition in dairy foods earlier also reported by Singh and Muthukumarappan (2008) that calcium shown no affect on organoleptic properties in the study of calcium fortified yoghurt and had more overall acceptability to control sample. The interactive effect of BME and CG was found to have no effect on overall acceptability.

Fig. 1.

a Response surface plot and b contour plot related to overall acceptability score as influenced by level of two factors

Verification of the optimum formulations

It was observed that the values were no significant different (p > 0.05) from the predicted values with respect to all attributes. The sensory scores have got in line with predicted scores given by RSM (Table 4).

Table 4.

Verification of the predicted value

| Attributes | Predicted value | Observed value | t-value |

|---|---|---|---|

| Colour | 8.30 | 8.17 ± 0.09 | 0.19ns |

| Flavour | 8.28 | 8.13 ± 0.1 | 0.17ns |

| Body and texture | 8.08 | 7.99 ± 0.06 | 0.21ns |

| Melting point | 8.24 | 8.12 ± 0.07 | 0.17ns |

| Overall acceptability | 8.39 | 8.28 ± 0.06 | 0.12ns |

Figures are the mean ± standard error of six replications

ns non-significant (p > 0.05)

Acceptability of calcium enriched herbal ice cream

Phytates and oxalates are the anti-nutrients normally present in all plant materials. Oxalates has affinity to bind calcium and forms calcium oxalates stones and they are rich in rhubarb, spinach, beetroot, parsley, okra, soya beans and many soya products, yams, wheat bran, nuts, peanut butter, sesame seeds, black pepper, chocolate, chocolate drinks and tea. Phytates also exhibit a high affinity toward important for human body micro- and macroelements but they are considerably low in herbal plants. Normally BME contains phytates and oxalates in the range of 41–48 and 1–3 mg/100 g (Filipiak-Szok et al. 2016). Experimental ice cream is having total bacoside content 0.36 mg/100 ml in which Bacoside A is 0.19 mg/100 ml and Bacopaside II is 0.17 mg/100 ml. In this study 10 mg of BME is added to 100 mL ice cream mix that contributes very low amount of both phytates and oxalates in the final product. The daily intake of calcium recommended by Indian council of medical research (ICMR) for children and adults are 600 and 1000 mg/day. Calcium content in ice cream was estimated by using Atomic Absorption Spectroscopy (Perkin Elmer, Model-PinAAcle 900H) according to (IS: 12760:2012). CG salt (217 mg) of having 138.3 mg of free calcium is added to 100 mL ice cream mix. Calcium in control ice cream was 155 mg/100 g while in experimental ice cream was 293 mg/100 g. Hence consumption of 100 g of this ice-cream will meet the 30% RDA of calcium. Experimental ice creams (A & B) significantly differ from control sample but there was no significant difference between experimental samples. The developed experimental ice cream has shown overall acceptability of 8.25 which is good indicative of the higher organoleptic quality for frozen products. The sensory scores of the experimental ice cream on a 9 point hedonic scale had shown in Table 5. From the results, prepared experimental ice cream was shown significant difference (p < 0.01) in the mean score and had higher overall acceptability from normal traditional ice cream. In order to make a good source of calcium the finished product must ideally contain 10–19% daily value (DV) or 100–190 mg calcium per serving. Standard ice-cream contains 80 mg of calcium per serving or per 60 g (Kaushik et al. 2015).Though BME had imparted bitter taste, CG had imparted sweet taste which improved the overall acceptability of product. Similar results reported by Yonis et al. (2013) that CG fortified banana stirred yogurt shown highest mean values for over all acceptability at 1% level. The chronic toxicity test was conducted in accordance with World Health Organization (2000) and Organisation of Economic Co-operation and Development (1891) guidelines. According to WHO/OECD guidelines acceptable daily intake of BME in food supplements is 300 mg/day or 5 mg/kg body weight/day.

Table 5.

Sensory characteristics of ice cream samples

| Sensory attributes | Type of ice cream | Chi square value | ||

|---|---|---|---|---|

| Control ice cream (C) | A | B | ||

| Colour | 7.8 ± 0.08b | 8.31 ± 0.06a | 8.25 ± 0.04a | 9.25** |

| Flavour | 7.75 ± 0.08bc | 8.3 ± 0.06a | 8.2 ± 0.06ac | 9.40** |

| Body and texture | 7.62 ± 0.07b | 8.33 ± 0.07a | 8.40 ± 0.06a | 9.38** |

| Melting property | 7.6 ± 0.06bc | 8.48 ± 0.07a | 8.43 ± 0.06ac | 9.10** |

| Overall acceptability | 7.6 ± 0.07bc | 8.25 ± 0.06ac | 8.28 ± 0.07a | 10.30** |

Figures are mean ± standard error of three replications

ns non-significant (p > 0.05)

**Significant at 1% level (p < 0.01)

a,bMean scores with same super script within rows did not differ from each other, A and B—experimental ice cream

Conclusion

RSM has been successfully applied for optimizing CG and BME at (217.38 mg/100 mL and 10 mg/100 mL) which shown no affect on overall acceptability of ice cream. The concentration of CG beyond above mentioned value had shown coagulation effect due to alterations in salt balance i.e., calcium and phosphorous ratio mix while BME imparted a bitter taste due to the presence of phenolics. The additional calcium fortification was done to meet the 30% RDA of calcium and reduce the chances of calcium deficiency diseases. In this newly developed product RSM became a useful tool for optimization of additional ingredients.

Acknowledgements

The authors thank the “College of Dairy Science and Technology” (CDST, Kerala, India) for the financial support to carryout research and “Department of Veterinary Pharmacology and Toxicology” (COVAS, Kerala) for their support in extraction of bacosides from BM plant.

Abbreviations

- CG

Calcium gluconate

- BM

Bacopa monniera

- BME

Bacopa monniera whole plant extract

- RSM

Response surface methodology

- CCRD

Central composite rotary design

- SNF

Solid non fat

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

M. Davuddin Baig, Email: davuddinmohammed@gmail.com.

A. Malik, Email: ashumalik925@gmail.com

M. Dharani Kumar, Email: kumar.dharani1@gmail.com.

M. Bumbadiya, Email: mitulbumbadiya@gmail.com

S. N. Rajakumar, Email: nageshrajakumar@yahoo.co.in

A. K. Beena, Email: akbeena@kvasu.ac.in

References

- Amerine MA, Pangborn RM. Food science and technology monographs. In: Roessler EB, editor. Principles of sensory evaluation of food. 2. New York: Academic Press; 1965. pp. 338–339. [Google Scholar]

- Anon P (2015) Ice cream industry In: Gupta PR (ed) Dairy India 2015, 7th edn. Baba Barkha Nath Printers and Publishers, New Delhi

- Arcia PL, Costell E, Tárrega A. Inulin blend as prebiotic and fat replacer in dairy desserts: optimization by response surface methodology. J Dairy Sci. 2011;94:2192–2200. doi: 10.3168/jds.2010-3873. [DOI] [PubMed] [Google Scholar]

- Chopra RN, Chopra IC, Verma BS. Glossary of Indian medicinal plants. New Delhi: CSIR; 1969. p. 10p. [Google Scholar]

- Dar A, Channa S. Calcium antagonistic activity of Bacopa monniera on vascular and intestinal smooth muscles of rabbit and guinea-pig. J Ethnopharmacol. 1999;66(2):167–174. doi: 10.1016/S0378-8741(98)00240-2. [DOI] [PubMed] [Google Scholar]

- Deepak S, Garg R, Kumar P, Saxena DC, Mathur GN. Optimization studies of blend composition and ageing parameters for making LDPE/HDPE/LLDPE films by response surface methodology. Macromol Mater Eng. 2000;283:81–87. doi: 10.1002/1439-2054(20001101)283:1<81::AID-MAME81>3.0.CO;2-S. [DOI] [Google Scholar]

- Dowell A, Davidson G, Ghosh D. Validation of quantitative HPLC method for bacosides in keenmind. Evid-Based Complement Altern Med. 2015;14(3):145–160. doi: 10.1155/2015/696172. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Filipiak-Szok A, Kurzawa M, Szłyk E. Simultaneous determination of selected anti-nutritional components in Asiatic plants using ion chromatography. Eur Food Res Technol. 2016;242(9):1515–1521. doi: 10.1007/s00217-016-2652-x. [DOI] [Google Scholar]

- Flynn A, Cashman K. Calcium. In: Hurrel R, editor. The mineral fortification of foods. England: Leatherhead International Ltd, Surrey; 1999. [Google Scholar]

- Gerstner G. Dairy products: the calcium challenge. Int Food Ingred. 2003;3:45–48. [Google Scholar]

- Kaushik R, Sachdeva B, Arora S. Heat stability and thermal properties of calcium fortified milk. CyTA J Food. 2015;13(2):305–311. doi: 10.1080/19476337.2014.971346. [DOI] [Google Scholar]

- Kim P, Meyer D, Jellema RH. Inulins improve sensoric and textural properties of low-fat yoghurts. Int Dairy J. 2002;16:1098–1103. [Google Scholar]

- Kumar S, Rai DC, Singh D. Role of herbal ice cream in human health: a review. Trends Biosci. 2013;6(2):130–132. [Google Scholar]

- Marshall TR, Goff HD (2003) Composition andproperties. In: Hartel RW (ed) Ice cream, 6th edn. Springer, New York

- Michaluk J, Karolewicz B, Antkiewicz-Michaluk L, Vetulani J. Effects of various Ca2+ channel antagonists on morphine analgesia, tolerance and dependence, and on blood pressure in the rat. Eur J Pharmacol. 1998;352(2–3):189–197. doi: 10.1016/S0014-2999(98)00373-2. [DOI] [PubMed] [Google Scholar]

- Morgan A, Stevens J. Does Bacopa monnieri improve memory performance in older persons results of a randomized, placebocontrolled, double-blind trial. J Altern Complement Med. 2010;16(7):753–759. doi: 10.1089/acm.2009.0342. [DOI] [PubMed] [Google Scholar]

- Murari SP (2007) Development of an ice-cream formulation with enhanced health attributes. Doctoral dissertation, NDRI, Karnal

- Organization of Economic Co-operation and Development (1981) The OECD guideline for testing of chemical: chronic toxicity studies. France

- Pase MP, Kean J, Sarris J, Neale C, Scholey AB, Stough C. The cognitive enhancing effects of Bacopa monniera: a systematic review of randomized, controlled human clinical trials. J Altern Complement Med. 2011;18(7):647–652. doi: 10.1089/acm.2011.0367. [DOI] [PubMed] [Google Scholar]

- Pinto SV (2006) Development of technology for manufacture of dietetic frozen dessert. Doctoral dissertation, Anand Agricultural University; Anand

- Rastogi S, Pal R, Kulshreshtha DK. Bacoside A3-a triterpenoid saponin from Bacopa monniera. Phytochem. 1994;36:133–137. doi: 10.1016/S0031-9422(00)97026-2. [DOI] [PubMed] [Google Scholar]

- Reddy S, Sher A, Vadehra VD, Wredal ER (1999) Calcium complex and a process of making a food fortified with calcium. US Patent 5,928,691

- Roodenrys S, Booth D, Bulzomi S, Phipps A, Micallef C, Smoker J. Chronic Effects of Brahmi (Bacopa monniera) on Human Memory. Neuropsychopharmacology. 2002;27:279–281. doi: 10.1016/S0893-133X(01)00419-5. [DOI] [PubMed] [Google Scholar]

- Russo A, Borrelli F. Bacopa monniera, a reputed nootropic plant: an overview. Phytomedicine. 2005;12(3):305–317. doi: 10.1016/j.phymed.2003.12.008. [DOI] [PubMed] [Google Scholar]

- Sheba S (2015) Development of a ready-to-reconstitute probiotic drink using indigenous lactic acid bacteria. M.Tech. thesis, Kerala Veterinary and Animal Sciences University, Pookode

- Singh G, Muthukumarappan K. Influence of calcium fortification on sensory, physical and rheological characteristics of yoghurt. Food Sci Technol. 2008;41:1145–1152. [Google Scholar]

- Shrikumar S, Ravi TK, Umamaheshwari M. A HPTLC determination and fingerprinting of bacoside A in Bacopa monnieri and its formulation. Indian J Pharm Sci. 2004;66(1):132–140. [Google Scholar]

- Villegas B, Tárrega A, Carbonell I, Costell E. Optimising acceptability of new prebiotic low-fat milk beverages. Food Qual Prefer. 2010;21:234–242. doi: 10.1016/j.foodqual.2009.03.001. [DOI] [Google Scholar]

- World Health Organization (2000) General guidelines for methodologies on research and evaluation of traditional medicine, Switzerland

- Yonis A, Elzamzamy AM, Shimaa FM, Elmorsi A. Fortification of banana stirred yogurt with calcium. J Food Dairy Sci. 2013;4(5):183–192. [Google Scholar]