Abstract

An 81-year-old woman presented with progressive groin pain after metal-on-polyethylene total hip arthroplasty with a modular neck stem and was found to have adverse local tissue reaction. As we report for the first time with this implant, we observed titanium neck-titanium stem taper corrosion intraoperatively. We also found head-neck taper corrosion. The patient underwent revision surgery to a modular fluted tapered stem with ceramic head and was asymptomatic at 3-year follow-up visit. In conclusion, consideration should be given to avoiding the routine use of this modular neck stem in total hip arthroplasty. Patients with this prosthesis should be closely monitored for adverse local tissue reaction.

Keywords: Total hip arthroplasty, Taper corrosion, Dual modular stem, Adverse local tissue reaction, Zimmer Kinectiv

Introduction

Early designs of femoral stems used in total hip arthroplasty (THA) were monolithic, without any modular junctions. Modularity of the femoral stem was developed to facilitate exposure during revision surgery, as well as for maintenance of adequate implant inventory. However, corrosion at stem modular junctions has been observed, resulting in adverse local tissue reaction (ALTR), a thick-walled collection of predominantly lymphocytic infiltrate that can be destructive to surrounding tissues [1].

ALTR secondary to head-neck taper corrosion in cobalt (Co)-chromium (Cr) alloy and titanium (Ti) alloy stems used in metal-on-polyethylene (MoP) THA has been reported [2]. The aforementioned stems are produced by various manufacturers and span various taper geometries. Modular neck femoral stems facilitate intraoperative restoration of patient anatomy. However, corrosion at the neck-stem junction of modular neck stems has also been observed. Patients with Co-Cr modular necks typically present with ALTR, while those with Ti necks more commonly present with neck fracture [3], [4]. This may be due to the greater strength and fatigue resistance of Co-Cr alloy than Ti alloy.

We report a case of ALTR associated with head-neck and neck-stem taper corrosion in a modular neck stem with Ti-alloy neck used in MoP THA. To our knowledge, we are the first to report corrosion at the neck-stem junction of this femoral stem.

The patient in this report is deceased, so her next of kin provided informed consent for publication of this manuscript.

Case history

This is the case of an 81-year-old woman's status after left THA, who presented to our institution with 6 months of left groin pain.

The history begins in 2008, when the patient underwent left THA. In 2013, the patient presented to our institution with left groin pain that was progressive over 6 months despite conservative measures. Her symptoms were exacerbated with activity and relieved with rest. The patient had no fever, wound drainage, thigh pain, or radiculopathy.

On physical examination, the patient displayed an antalgic gait. Her left hip incision was well healed without erythema. There was no pain with palpation of the greater trochanter. However, the patient did have left groin pain with extremes of motion of the hip. Left hip abductor strength was 5/5.

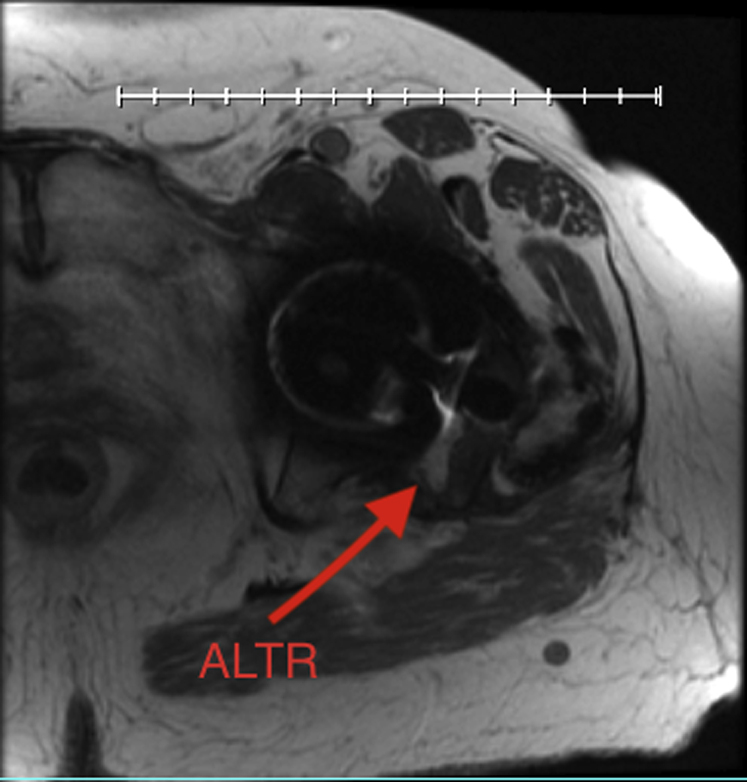

Plain films demonstrated well-fixed left THA without evidence of wear, osteolysis, or fracture (Fig. 1). Serum white blood cell count was 8.08 K/ul (reference range: 5.00-10.00 K/ul), erythrocyte sedimentation rate was 16 mm/h (reference range: 0-15 mm/h), and C-reactive protein level was <2.0 mg/L (reference range: 0-10 mg/L). Serum Co level was 4.8 ppb (reference range: 0.5-3.9 ppb) and Cr level was 1.0 ppb (reference range: ≤5.0 ppb). Ti level was undetectable. Left hip aspiration showed 61 white blood cells using a manual cell count. Cultures were negative. Given elevated Co level with increased Co-to-Cr ratio, metal artifact reduction sequence magnetic resonance imaging of the left hip was obtained, which demonstrated ALTR (Fig. 2). Operative records confirmed the presence of the following implants: size 11 Zimmer M/L Taper Kinectiv Ti-alloy (Ti6Al4V) femoral stem with 12/14 taper, size P straight Ti-alloy (Ti6Al4V) modular neck, 32 mm + 0 cobalt-chrome head, 50-mm Zimmer Trabecular Metal Modular cluster-hole acetabular shell, and 20-degree elevated rim longevity highly cross-linked polyethylene liner (Zimmer Biomet, Warsaw, IN).

Figure 1.

Anteroposterior left hip plain film demonstrating Zimmer M/L Taper Kinectiv modular neck stem.

Figure 2.

Left hip axial proton density weighted MRI demonstrating adverse local tissue reaction (ALTR) with Zimmer Kinectiv stem. MRI, magnetic resonance imaging.

The patient elected to proceed with left hip arthroplasty revision. Metal discoloration, but no purulence, was found intracapsularly with synovial thickening. Abductor and vastus lateralis integrity were preserved. There was no evidence of bone-implant or implant-implant impingement. Black corrosion and fretting products were observed at both the head-neck and neck-stem junctions (Fig. 3). One frozen section was negative for acute inflammation. The stem was revised to a modular fluted tapered stem. The acetabular component was revised to a more optimally positioned porous metal component. A BIOLOX delta (CeramTec, Plochingen, Germany) ceramic head and highly cross-linked polyethylene liner were implanted.

Figure 3.

Intraoperative image of Zimmer Kinectiv titanium modular neck demonstrating corrosion product at head-neck and neck-stem junctions.

The patient’s hospital course was unremarkable. Intraoperative cultures were negative. At the most recent 3-year follow-up visit in 2016, the patient denied any left hip pain, was ambulating without assistive device, and was participating in all her desired activities. However, the patient expired later the same year secondary to stage IV lung cancer.

Discussion

To our knowledge, we report the first case of neck-stem taper discoloration in this Ti-alloy stem with a Ti modular neck and only the third case of ALTR with this stem in MoP THA. Our findings are particularly interesting as the Ti neck-Ti stem junction of modular neck stems is not typically implicated in ALTR [5]. Plummer et al. and Canham et al. each previously identified 1 case of ALTR from corrosion at the head-neck junction of this modular neck stem in MoP THA but found no evidence of corrosion at the neck-stem junction [2], [5]. Consideration should be given to avoiding the routine use of this stem, particularly given its vulnerability to corrosion at all taper junctions.

Taper corrosion results from fretting, mechanical damage secondary to micromotion at the taper junction, and subsequent electrochemical reactions within the resulting crevices. These processes are collectively referred to as mechanically assisted crevice corrosion (MACC), which may present clinically as ALTR or even implant fracture [2], [3]. MACC is accelerated with smaller tapers or more flexible alloys [6]. Taper geometry may explain the frequency of MACC observed with the 12/14 head-neck taper of the stem in the current report, as well as other stems from the same manufacturer [7]. The 12/14 taper geometry has been shown to vary across manufacturers [8].

Head-neck taper corrosion is more likely with cobalt-chromium heads than with ceramic heads [6]. With greater prosthetic head diameter and length, the torque and moment arm on the stem neck increase, respectively, theoretically increasing the likelihood of fretting and thus corrosion at both the head-neck and neck-stem junctions of a modular neck stem. Interestingly, the 32 +0 mm cobalt-chromium head in this case was neither large in diameter nor long, suggesting the prosthetic head dimension may be less predictive of head-neck taper corrosion than head metallurgy or taper geometry.

The metallic composition of the neck and that of the stem in this implant were identical (Ti6Al4V), suggesting there was no galvanic component to the neck-stem taper corrosion observed. The modular neck was not long, so it is doubtful that there was excessive torque at the neck-stem junction resulting in increased fretting. As a result, taper geometry likely contributed most to the neck-stem taper corrosion observed.

The aforementioned case illustrates several hallmarks of ALTR secondary to taper corrosion. Diagnostically, serum Co-to-Cr ratio was greater than the normal value of 1 due to head-neck taper corrosion [2]. Metal artifact reduction sequence magnetic resonance imaging demonstrated ALTR, characterized by a thick-walled fluid collection and/or increased synovial thickness and volume [9]. The neck-stem taper corrosion observed in this case was possibly associated with in ALTR, not neck fracture, as is more commonly observed with Ti-alloy necks [3]. However, it is possible that symptomatic ALTR prompted early recognition of an impending neck fracture. Of note with the undetectable Ti levels, it is very possible that the ALTR was solely due to the fretting corrosion at the head-neck junction that was also present in this case.

When corrosion occurs at the stem taper junction in a modular neck stem, the stem should be revised. Neck exchange does nothing to eliminate the etiology of taper corrosion and may result in accelerated fretting corrosion or mechanical failure due to the already damaged female stem taper. Stem revision was performed with a modular fluted tapered stem with no reports of ALTR due to taper corrosion at its modular junctions, high rate of distal ingrowth, and excellent survival [10]. A ceramic head was implanted to minimize the risk of head-neck taper corrosion.

Summary

To our knowledge, we are the first to observe neck-stem taper corrosion in this modular neck femoral stem. Close surveillance for ALTR should be considered in patients with this prosthesis, particularly in those with a cobalt alloy head. Surgeons should be cautious with regard to the use of modular neck stems due to the risk of MACC and ALTR. Future identification of characteristics unique to the head-neck and neck-stem tapers of this stem that increase the likelihood of taper corrosion may guide implant design.

Footnotes

One or more of the authors of this article have disclosed potential or pertinent conflicts of interest, which may include receipt of payment, either direct or indirect, institutional support, or association with an entity in the biomedical field which may be perceived to have potential conflict of interest with this work. For full disclosure statements refer to https://doi.org/10.1016/j.artd.2019.04.009.

Appendix A. Supplementary data

References

- 1.Lindgren J.U., Brismar B.H., Wikstrom A.C. Adverse reaction to metal release from a modular metal-on-polyethylene hip prosthesis. J Bone Joint Surg Br. 2011;93(10):1427. doi: 10.1302/0301-620X.93B10.27645. [DOI] [PubMed] [Google Scholar]; Lindgren JU, Brismar BH, Wikstrom AC: Adverse reaction to metal release from a modular metal-on-polyethylene hip prosthesis. J Bone Joint Surg Br 2011;93(10):1427-1430. [DOI] [PubMed]

- 2.Plummer D.R., Berger R.A., Paprosky W.G., Sporer S.M., Jacobs J.J., Della Valle C.J. Diagnosis and management of adverse local tissue reactions secondary to corrosion at the head-neck junction in patients with metal on polyethylene bearings. J Arthroplasty. 2016;31(1):264. doi: 10.1016/j.arth.2015.07.039. [DOI] [PubMed] [Google Scholar]; Plummer DR, Berger RA, Paprosky WG, Sporer SM, Jacobs JJ, Della Valle CJ. Diagnosis and management of adverse local tissue reactions secondary to corrosion at the head-neck junction in patients with metal on polyethylene bearings. J Arthroplasty 2016; 31(1): 264-268. [DOI] [PubMed]

- 3.Atwood S.A., Patten E.W., Bozic K.J., Pruitt L.A., Ries M.D. Corrosion-induced fracture of a double-modular hip prosthesis: a case report. J Bone Joint Surg Am. 2010;92(6):1522. doi: 10.2106/JBJS.I.00980. [DOI] [PubMed] [Google Scholar]; Atwood SA, Patten EW, Bozic KJ, Pruitt LA, Ries MD: Corrosion-induced fracture of a double-modular hip prosthesis: a case report. J Bone Joint Surg Am 2010;92(6):1522-1525. [DOI] [PubMed]

- 4.Walsh C.P., Hubbard J.C., Nessler J.P., Markel D.C. Revision of recalled modular neck rejuvenate and ABG femoral implants. J Arthroplasty. 2015;30(5):822. doi: 10.1016/j.arth.2014.12.002. [DOI] [PubMed] [Google Scholar]; Walsh CP, Hubbard JC, Nessler JP, Markel DC. Revision of Recalled Modular Neck Rejuvenate and ABG Femoral Implants. J Arthroplasty 2015; 30(5): 822-826. [DOI] [PubMed]

- 5.Canham C.D., Muradov P.I., Simpson J.B., Incavo S.J. Corrosion and adverse local tissue reaction after total hip arthroplasty with a modular titanium alloy femoral neck. Arthroplast Today. 2017;3(4):211. doi: 10.1016/j.artd.2017.03.003. [DOI] [PMC free article] [PubMed] [Google Scholar]; Canham CD, Muradov PI, Simpson JB, Incavo SJ. Corrosion and adverse local tissue reaction after total hip arthroplasty with a modular titanium alloy femoral neck. Arthroplast Today 2017; 3(4): 211-214. [DOI] [PMC free article] [PubMed]

- 6.Tan S.C., Lau A.C., Del Balso C., Howard J.L., Lanting B.A., Teeter M.G. Tribocorrosion: ceramic and oxidized zirconium vs cobalt-chromium heads in total hip arthroplasty. J Arthroplasty. 2016;31:2067. doi: 10.1016/j.arth.2016.02.027. [DOI] [PubMed] [Google Scholar]; Tan SC, Lau AC, Del Balso C, Howard JL, Lanting BA, Teeter MG: Tribocorrosion: ceramic and oxidized zirconium vs cobalt-chromium heads in total hip arthroplasty. J Arthroplasty 2016 [DOI] [PubMed]

- 7.McGrory B.J., MacKenzie J., Babikian G. A high prevalence of corrosion at the head-neck taper with contemporary Zimmer non-cemented femoral hip components. J Arthroplasty. 2015;30(7):1265. doi: 10.1016/j.arth.2015.02.019. [DOI] [PubMed] [Google Scholar]; McGrory BJ, MacKenzie J, Babikian G. A High Prevalence of Corrosion at the Head-Neck Taper with Contemporary Zimmer Non-Cemented Femoral Hip Components. J Arthroplasty 2015; 30(7):1265-1268. [DOI] [PubMed]

- 8.Mueller U., Braun S., Schroeder S., Sonntag R., Kretzer J.P. Same same but different? 12/14 stem and head tapers in total hip arthroplasty. J Arthroplasty. 2017;32(10):3191. doi: 10.1016/j.arth.2017.04.027. [DOI] [PubMed] [Google Scholar]; Mueller U, Braun S, Schroeder S, Sonntag R, Kretzer JP. Same Same but Different? 12/14 Stem and Head Tapers in Total Hip Arthroplasty. J Arthroplasty 2017; 32(10):3191-3199. [DOI] [PubMed]

- 9.Nawabi D.H., Gold S., Lyman S., Fields K., Padgett D.E., Potter H.G. MRI Predicts ALVAL and tissue damage in metal-on-metal hip arthroplasty. Clin Orthop Relat Res. 2014;472(2):471. doi: 10.1007/s11999-013-2788-y. [DOI] [PMC free article] [PubMed] [Google Scholar]; Nawabi DH, Gold S, Lyman S, Fields K, Padgett DE, Potter HG: MRI Predicts ALVAL and tissue damage in metal-on-metal hip arthroplasty. Clin Orthop Relat Res 2014;472(2):471-481. [DOI] [PMC free article] [PubMed]

- 10.Restrepo C., Mashadi M., Parvizi J., Austin M.S., Hozac W.J. Modular femoral stems for revision total hip arthroplasty. Clin Orthop Relat Res. 2011;469(2):476. doi: 10.1007/s11999-010-1561-8. [DOI] [PMC free article] [PubMed] [Google Scholar]; Restrepo C, Mashadi M, Parvizi J, Austin MS, Hozac WJ. Modular femoral stems for revision total hip arthroplasty. Clin Orthop Relat Res 2011; 469(2):476-482. [DOI] [PMC free article] [PubMed]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.