Abstract

Design for Environment (DfE) principles are helpful for integrating manufacturing-specific environmental sustainability considerations into product and process design. However, such principles are often overly general, static, and disconnected from production contexts. This paper proposes a visual analytics-based framework for generating DfE principles that are contextualized to specific production setups. These principles are generated through interactive visual exploration of design and process parameters as well as manufacturing process performance metrics corresponding to the production setup. We also develop a formal schema for aiding storage, updating, and reuse of the generated DfE principles. In this schema, each DfE principle is associated with corresponding product lifecycle data and the evidence that led to the generation of that principle. We demonstrate the proposed visual analytics framework using data from an industry-led experiment that compared dry ice based and oil based milling for a specific production setup.

1. INTRODUCTION

The rapid rise in digitization of manufacturing enterprises has the potential to significantly advance data-driven decision-making in product lifecycle management (PLM). To illustrate, a 2011 report by the McKinsey Global Institute [1] states that the manufacturing sector stores close to 2 Exabytes of new data. However, it is widely accepted that, the manufacturing world is far from effectively using this data and meeting its true potential in the digital age [2]. While research on distributed data collection, data storage, and process monitoring is needed, an important focus is creating data representation and analysis techniques that transform the gathered lifecycle data into actionable insights for decision-makers [3]. This is especially relevant for sustainable design and manufacturing due to the complexity and ambiguity of design representations, lack of information from downstream life cycle stages, and uncertainties in environmental assessment [4]. A potential solution to this challenge is creating visual analytics (VA) systems for sustainable lifecycle design that couple data-driven analyses with interactive data exploration [4]. In the current work, we detail one such VA system that supports sustainable manufacturing by enabling generation of Design for Environment (DfE) principles that are contextualized to specific production setups.

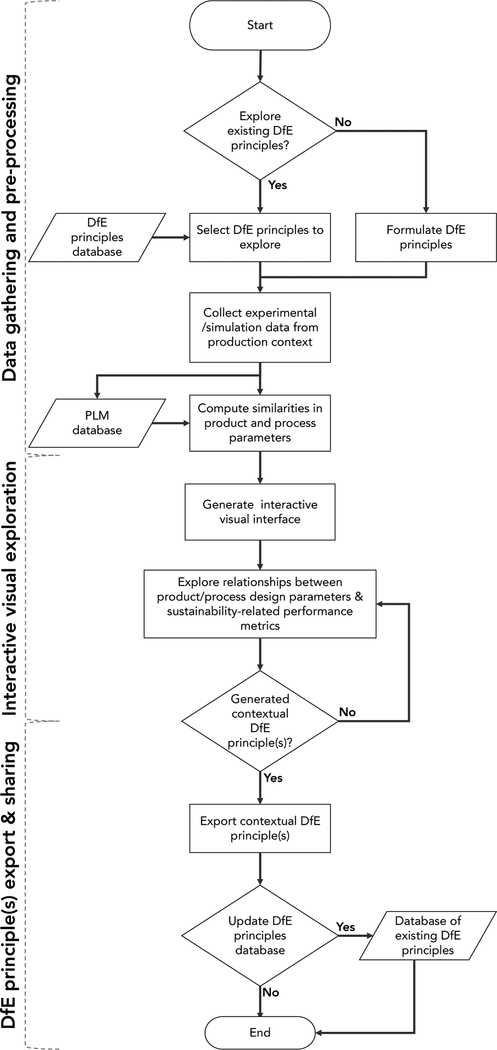

Figure 1 presents a conceptual overview of the approach proposed in this paper. As shown, existing DfE principles from a database can be used to define design and process parameters relevant to a production setup. The resulting process performance for the production setup is evaluated through simulations or real-world execution. A VA system is used to gather and interactively explore data generated from the specific production setup. Through this process, analysts can explore relationships between sustainability-related performance metrics and selected design and process parameters. This allows experts to distill rules-of-thumb specific to the production setup and generate contextual DfE principles. The generated principles are stored in the DfE principles database and can be updated or reused based on future production scenarios.

FIGURE 1.

Conceptual overview of the VA based approach for generating contextual DfE principles in sustainable manufacturing.

In the current paper, this approach is implemented using a VA system (titled VESPER: Visual Exploration of Similarity and PERformance metrics) that facilitates interactive visual exploration of similarity and performance metrics from computer-aided design (CAD) repositories. Our previous work [5] discussed the use of VESPER for sustainability-focused exploration in computer-aided design repositories as well as the exploration of tool wear and surface roughness in machined parts. The primary contributions of VESPER were, (i) the formalization of a data schema that enabled analysts to relate product lifecycle data with solid models and define custom similarity metrics and performance metrics, and (ii) the design and implementation of an interactive visual interface that facilitated exploration of similarity metrics, performance metrics, and lifecycle data. The current work extends these contributions by applying VESPER towards generating contextual DfE principles in sustainable manufacturing. The current work also extends VESPER’s data models by developing a formal schema for representing DfE principles.

The rest of the paper is organized as follows. Section 2 reviews methods for selecting DfE principles, their use in sustainable manufacturing, and VA-based tools for manufacturing-related decision-making. Section 3 discusses the methodology for generating contextual DfE principles using VESPER. It also details the data models used in VESPER and the proposed formal schema for representing DfE principles. Section 4 details a case study demonstrating the proposed approach for generating contextual DfE principles using VESPER. In this case study, a process engineer (PE) generated contextual DfE principles using VESPER. Data used in the case study was provided by an industry partner that had conducted experiments comparing the use of dry ice and an oil-based cutting fluid for face milling and plunge milling. Section 5 enumerates the limitations of our current work. Section 6 concludes the paper and presents directions for future work.

2. RELATED WORK

Recently, there has been an emphasis on tools and methodologies to make more environmentally efficient decisions through data-driven design and data-driven manufacturing [6]. To realize more sustainable production, considerable work has investigated the use of deep learning-based capabilities [7] as well as other machine learning techniques [8]. Another approach to deriving actionable insight with data is through VA interfaces. Though its exact definition is dependent on its context of use, VA can be broadly defined “the science of analytical reasoning facilitated by interactive visual interfaces” [9, p. 5]. The use of VA for improving the sustainability of products, processes, and systems remains in its infancy and requires additional research, development, and implementation [4]. In this paper, we develop a prototype VA interface to help analysts contextualize DfE principles in sustainable manufacturing. Thus, we contribute to the use of VA for sustainable decision-making.

2.1. Methods for selecting and refining DfE principles

DfE can be defined as the “explicit consideration of environmental concerns during the design of products and processes” [10]. Design-oriented textbooks and manuals have detailed the use of DfE principles in industrial practice [11–18]. Such principles are often used in the early design phase wherein limited information about the product’s lifecycle makes it challenging to perform a full-fledged environmental Life Cycle Assessment (LCA). DfE principles can provide guidance for designers to make more prudent decisions with respect to environmental performance [19]. DfE principles have found use in industrial engineering design practices as they focus on addressing environmental sustainability while maintaining a product’s design goals, such as cost, quality, and reliability. An example of a successful DfE program is the Xerox recovery program in the 1990s. After infusing DfE strategies throughout its design teams to improve disassembly and recovery practices, Xerox claimed a net savings of over $500 million while significantly minimizing the use of virgin materials in their products [10]. In general, DfE principles have served as helpful rules-of-thumb for instilling sustainable practices across enterprises [20].

Significant challenges remain in implementing DfE principles in practice. Selecting the appropriate DfE guideline(s) for a specific situation is not trivial. Even after guideline selection, there often exists limited information on environmental performance of different design alternatives. In response, researchers have developed methodologies and tools to refine and re-purpose DfE guidelines. Telenko et al. [19] distilled 6 high-level DfE principles under which they classified 76 guidelines to clarify their scope for stakeholders. Ramanujan et al. [21] used a stochastic analytical hierarchy process to prioritize the most critical DfE strategies. Pigosso et al. [22] developed a classification hierarchy to systematically describe DfE strategies to help rate maturity levels of manufacturing companies’ ecodesign practices. Others have developed expert systems to help integrate DfE principles into design. Hernandez et al. [23] developed GREENESYS, a tool that recommends a set of DfE principles based on user-defined design parameters. Rombouts [24] developed the LEADS-II, a tool that aids product designers in ranking DfE strategies.

Researchers have also developed methodologies for refining DfE guidelines and making them more actionable. Rounds and Cooper [25] developed a methodology for refining DfE guidelines by traversing taxonomies classifying components of environmental issues and engineering systems. For each leaf node, e.g., “material acquisition and processing,” they list specific DfE principles, e.g., “avoid creating a new or expanded facility,” to guide the design process. They then leverage these refined guidelines to complete a House of Quality. Telenko and Seepersad [26] presented a methodology for updating and quantifying DfE guidelines based on product dissection and LCA. Luttropp and Lagerstedt [27] developed a list of “ten golden rules” to provide generic DfE principles to influence design. The methodology used these rules to suggest more refined DfE principles based on a specific application. The outcome is a focused checklist, where decision makers (e.g., designers) develop an action plan based on the refined rulesets. Oehlberg et al. [28] classified over 300 DfE principles based on how they influence different aspects of LCA in an effort to make them more tangible to quantitative methods.

2.2. DfE Principles in Sustainable Manufacturing

With regards to sustainable manufacturing, DfE principles have primarily been used for aiding material selection, process selection, and optimizing process parameters. While such principles are useful, they are often general and riddled with assumptions. In revisiting the basic concepts of DfE principles, Hauschild et al. [29] have suggested that using high-level DfE principles often leads to sub-optimal solutions from an environmental perspective since the DfE tool fixates on particular design activities. In response, they recommend creating DfE strategies should be a recursive and update-able process. As more information comes to light from downstream stages, DfE strategies should be updated. Similarly, Holt and Barnes [30] argue that the benefits realized by DfE (and design for X methods at large) should ideally be revisited throughout the entire product development cycle, including manufacturing operations.

There exists a disconnect between the complexities of real production systems and DfE principles that creates challenges for implementing DfE strategies in practice [31]. For example, to implement the DfE strategy of minimizing waste material, it would require substantial investigation in understanding how production parameters relate to waste generation. Methods for selecting and refining DfE principles that were discussed in the previous subsection have limited ability in addressing this challenge as they cannot associate DfE principles to specific process parameters or production setups. Building such associations is a challenging task as relationships between a specific DfE principle and process performance are often complex (e.g., increasing depth of cut might decrease total energy consumption in a milling operation but may increase the surface roughness of the machined part leading to increased material waste) and may require human expertise to identify and validate discovered relationships. Therefore, addressing this gap requires the use of novel methodologies such as VA, that can facilitate human-led exploration of these data.

2.3. Visual Analytics Tools in Manufacturing

The goal of VA tools is to support analysts’ insight generation processes and leverage their expertise in qualitative decision-making. A large number of VA tools used in industry are proprietary and developed specifically for internal use. Such tools are often developed for customized applications and rarely support decision-making through the entire life cycle. Reports detailing visualization tools in the industry (e.g., Bavarian Motor Works (BMW) [32]) indicate there are significant adoption challenges.

Below, we review manufacturing-related VA tools that have been published in academic literature. A majority of these tools focus on production management and supply chain decision-making. Mazumdar et al. [33] discuss a knowledge-based visualization dashboard that allows users to quickly identify problems on manufacturing floors by querying documents from multiple sources. ViDX [34] allows users to identify disruptions in the production facility, such as significant energy consumption of a single or set of processes. LiveGantt [35] aggregates and displays a large amount of streaming information of a production facility using horizon graphs [36]. ViSER [37] implements two mutually coordinated panes representing a supply chain tree and a product architecture graph. TISCSOFT [38] is a decision-support tool for optimizing transportation infrastructure in supply-chain networks. Other researchers have created dashboard-based tools using traditional key performance indicators for supply-chain decision-making [39, 40]. Techniques based on value stream mapping (VSM) have also gained prominence for visualizing supply chain performance [40].

Recently, commercial efforts have focused on creating visualizations that link product lifecycle management (PLM) data to CAD models. The SAP 3D Visual Enterprise [41] consists of a suite of applications for exploring PLM data. The Siemens NX HD3D Visual Reporting System [42] uses color-coding and interactive tagging to generate visual reports for PLM data. While such systems facilitate PLM-related decision-making (e.g., value analysis [43]), they do not explicitly support generation of DfE principles in sustainable manufacturing.

2.4. Research contributions

The primary contribution of the current research is the development of a systematic methodology that enables generation, storage, and reuse of DfE principles contextualized to specific processes and production setups. To the best of the authors’ knowledge, none of the reviewed methodologies can support such an approach. From a theoretical standpoint, the contributions from our work include the following.

a systematic three-step methodology for contextualizing DfE principles to specific manufacturing processes and production setups. A novel approach suggested within this methodology is the use of interactive visual analytics tools to aid this contextualization process.

a conceptual model for formally representing a DfE principle and lifecycle information relevant to that DfE principle. This enables linking a DfE principle to data from specific processes and real-world productions setups. Furthermore the lifecycle data associated with the DfE principle provides evidence for the guideline’s appropriateness in that production context.

From an implementation standpoint, this work demonstrates the application of the developed methodology and the DfE principles schema to a real-world case study. For this, we develop a prototype visual analytics tool that facilitates generation of contextual DfE principles in sustainable manufacturing through interactive visual exploration of product and process data. Furthermore, we have implemented the discussed DfE principle conceptual model as an extensible markup language (XML) schema definition (XSD). This is provided in the supplementary materials for the paper. We hope other researchers can adopt or extend the developed schema within their own methodologies and tools.

3. METHODOLOGY

A detailed overview of the methodology for generating contextual DfE principles in sustainable manufacturing using VESPER is shown in Fig. 2. The starting point for the proposed methodology is selecting the DfE principles to explore, either by modifying a set of existing principles, or by formulating new principles. Following this, product/process design data as well as manufacturing performance data are collected from a PLM database and if necessary, through performing manufacturing process simulations and real-world experiments. Next, these data are interactively explored in a visual interface that allows analysts to generate insights between relevant manufacturing performance metrics (e.g., tool life, energy consumption) and corresponding product and process parameters (e.g., part material, cutting speed). The analyst performing this exploration process could be a process engineering tasked with improving the environmental sustainability of the manufacturing process. Generating contextual DfE principles by exploring process and product data necessitates users to have prior knowledge of the specific process and the production setup as well as familiarity with DfE principles in sustainable manufacturing. If the analyst discovers insights relevant to the DfE principles being explored, they can contextualize these principles by adding new sub-principles that include information specific to the production setup, or by updating existing principles.

FIGURE 2.

Overview of the methodology for generating contextual DfE principles in sustainable manufacturing using VESPER. As shown, the tasks involved can be divided into three steps (i) data gathering and pre-processing, (ii) interactive visual exploration, and (iii) DfE principle(s) generation.

The sections below explain our methodology in further detail. The sections are divided based on the three steps in the methodology as shown in Fig. 2.

3.1. Step 1: Data Gathering and Pre-Processing

The starting point for generating contextual DfE principles is selecting and exploring existing principles. As discussed, previous works have compiled [13, 19, 22] an extensive set of DfE principles relevant for sustainable manufacturing. Table 1 illustrates a subset of DfE principles relevant to sustainable manufacturing. In the current methodology, such principles are selected and contextualized to specific production setups. If analysts choose, they can also formulate new DfE principles based on their experience and validate them using the proposed approach. In both cases, analysts store the DfE principles in a database linked to VESPER. In the following subsection, we explain the representation of a DfE principle and how it relates to VESPER’s data models.

TABLE 1.

Examples of DfE principles relevant for sustainable manufacturing. The heading for each column is the category for the DfE principles therein.

| Design for cleaner production [13] | Minimize scraps and discards [22] |

|---|---|

| Minimize material variety | Select processes that reduce scraps and discarded materials during production |

| Avoid waste material | Engage simulation systems to optimize transformation processes |

| Select low impact materials and processes | Use as much recyclable material in the process as possible |

| Optimize the reuse of scraps and discards during manufacturing |

3.1.1. Collecting information related to a production context:

Product and process data as well as manufacturing performance data relevant for exploring the selected DfE principles are collected from a PLM database and from simulation or experimental studies. These data are used in VESPER to facilitate similarity based exploration of product and process design parameters and manufacturing process performance metrics. If these data are stored in a proprietary PLM database, there is a need for creating translators or plugins that access and convert the data into a format that can be processed by VESPER. To address this issue, we define open data models for lifecycle information. Enabling integration of the proposed model with a specific PLM database will be a part of our future work. The final output from the data gathering and pre-processing step is the creation of an XML database that stores product and process data in the standard schemas detailed in the next paragraph. The generated XML database is accessed by the interactive visual interface and facilitates generation of contextual DfE principles to the exploration of these data.

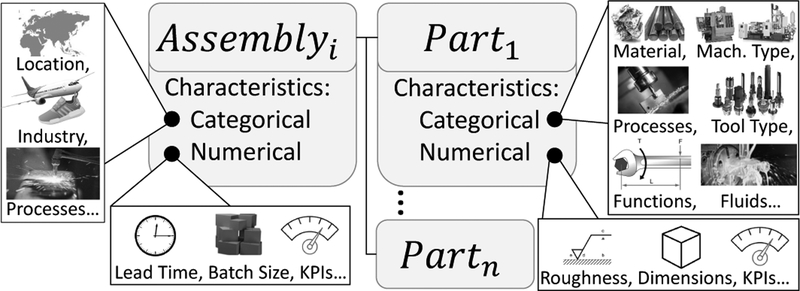

Herein, we describe three schemas, SolidModel, SimilarityMeasure, and Taxonomy, implemented in VESPER and detail their relationships to the DfePrinciple schema. Graphical representations of the former three schemas are available in our previous work [5]. As shown in Fig. 3, each assembly (Assemblyi) or part (Parti) in VESPER carries categorical and numerical characteristics representing information described through text and numerical values, respectively. For example, categorical characteristics can include geographical locations, industry categories, and manufacturing processes. Numerical characteristics can include batch sizes, lead times, and other key performance indicators (KPIs).

FIGURE 3.

Examples of categorical and numerical characteristics for both Assembly and Part elements. Key performance indicators (KPIs) refer to any performance characteristic.

SolidModel schema:

In the current work, we use a product-centric approach and model manufacturing data (e.g., process parameters, machine and tool information) as attributes of the product. Previous research [44] has shown the importance of machine tool attributes and the specific production setup in determining the real-world environmental impact of manufacturing. To capture this temporal variation within the definition of a DfE principle, the proposed schema associates the status of the production setup to the manufactured part. Using a product-centric approach also enables data from other downstream lifecycle stages to be directly linked to the developed schema (as they can be represented as additional product attributes).

To this end, entries in VESPER are denoted as SolidModel elements. To ensure traceability of the models, SolidModel includes an id, a parentID, and a version. It also includes other meta-information, i.e., name, timestamp, and description. These attributes form an attribute group, ModelAttributes, that is reused later in the schema. A SolidModel includes at least one Assembly and could include SupportingInformation. SupportingInformation can contain Hyperlink elements in the form of URIs or SupportingInformationDescription elements, which are stored as strings. The Assembly element also includes the attribute group, ModelAttributes. An Assembly includes at least one Part. Both Part and Assembly can include the elements, CategoricalCharacteristic, NumericalCharacteristic, and SupportingInformation. Note that it is possible for an assembly to only be comprised of one part.

CategoricalCharacteristic corresponds to all data associated with a Part or Assembly that is described as a string value. CategoricalCharacteristic contains three attributes, including its type, name, and from Taxonomy–a Boolean entry that specifies whether or not it is linked to a formal taxonomy.

NumericalCharacteristic corresponds to data associated with a Part or Assembly that can be described as a numerical value. A NumericalCharacteristic contains two attributes, its name and value. A NumericalCharacteristic also contains a UOMCode element for formally capturing measurement units. The code in a UOMCode should be selected among the trade codes proposed by the UN Centre for Trade Facilitation and E-business program at the United Nations Economic Commission for Europe [45]. If a code for a given unit is unavailable, a custom code is provided.

SimilarityMeasure schema:

Each SimilarityMeasure includes three attributes, name, description, and type, and contains at least one Score. SimilarityMeasure also can contain SupportingInformation, identical to the element described in the SolidModel schema of the same name. Each Score element includes one attribute, value, and two elements, Part1 and Part2. These elements refer to the respective parts for which the pairwise similarity Score is calculated. For example, if Part1 and Part2 have identical materials, then the Score element for material similarity between them is equal to one. Both Part1 and Part2 include two attributes, an id and a name. This schema provides elements and attributes to capture the results from the pairwise comparison of manufacturing processes and any supporting information to implement the same SimilarityMeasure in another context. An example application for this schema is encoding similarity values of categorical sets for manufacturing process capabilities, e.g., range of output shapes or achievable surface finish [46].

Taxonomy schema:

Each taxonomy is described by a Root element that contains two attributes, name and description as well as other SupportingInformation. A taxonomy should include at least two Child elements. Each Child element incorporates one attribute, name, and can contain other Child elements. For example, in our implementation, we encode the Allen and Todd taxonomy for manufacturing process [47] to enable taxonomic similarity evaluation. Note that the description of the Root element is used to match against the type attribute in the CategoricalCharacteristic element of the SolidModel schema.

DfePrinciple schema:

The representation of a DfE principle in VESPER is shown using a Unified Modeling Language (UML) conceptual diagram in Fig. 4. As shown in Fig. 4, we use the schemas described above to formally characterize a DfePrinciple in VESPER. Each DfePrinciple element contains four attributes, name, explorationStateId, description, and parent. The name attribute serves as an identifier for the DfePrinciple element. The explorationStateId allows the system to track the exploration process in the interactive visual interface that lead to the generation of a contextual DfePrinciple. Through the explorationStateId, a DfePrinciple is linked to production data (stored in a SolidModel) and the generated visual representation (stored in SimilarityMeasure). The description field allows analysts to add notes to the DfePrinciple element. Lastly, each DfePrinciple element stores a reference to its parent element, which enables them to be stored in a tree data structure in the DfE database.

FIGURE 4.

Unified Modeling Language (UML) conceptual diagram describing the formal schema for a DfE principles within VESPER.

3.1.2. Computing similarities in product and process data:

In VESPER, similarities in product and process parameters as well as relevant manufacturing performance parameters are computed from CategoricalCharacteristic, and/or NumericalCharacteristic present in the SolidModel. With regards to manufacturing performance, both product-specific (e.g., emissions rate, energy efficiency) and process-specific metrics (e.g., consumables reuse) can be stored in a SolidModel. Product and process metrics relevant for sustainable manufacturing can be formulated by analysts or chosen from existing literature [48].

Analysts can specify custom similarity metrics using the SimilarityMeasure schema for computing pair-wise similarities between corresponding attributes. For numerical parameters, the similarity metric takes the corresponding NumericalCharacteristic from two SolidModel elements as input and outputs a similarity score element as defined in the SimilarityMeasure schema. For categorical parameters, the similarity metric is defined on the taxonomy corresponding to the CategoricalCharacteristic. Further details related to similarity computation in VESPER are detailed in our previous work [5]. We would also like to note that computing a similarity measure for product and process parameters is one potential approach for exploring them. Other approaches could include creating charts for quantitative data as-is or generating lists or other textual visualizations for qualitative data. Our previous research [4] notes the benefits of similarity-based exploration of product and process data, especially if it involves multi-dimensional exploration of large-scale data.

3.2. Step 2: Interactive Visual Exploration

Figure 5 illustrates the system architecture for facilitating interactive visual exploration in VESPER. It contains elements for managing visualization, interaction, and exporting of data.

FIGURE 5.

Analysts interact with the visual interface by exploring part data, similarity and performance metrics, as well as the selected DfE principles. Contextual DfE principles are generated by the analysts by exploring these data. The visual interface also facilities export of the generated DfE principles and analysts’ interaction data. The dotted line in the figure represent analysts’ interactions with the tool while the solid lines represent automated operations.

A visual interface enables analysts to interactively explore manufacturing process performance, and product and process similarities for contextualizing selected DfE principles. The visual interface connects to an XML database that stores information about (i) part metadata, (ii) similarity and performance metrics, and (iii) selected DfE principles, using the data models described in Section 3.1.1. The proposed methodology does not prescribe a specific design for the visual interface, as it can depend on the data being explored and the analyst’s preferences. To illustrate the use of interactive visual exploration for generating contextual DfE principles, the current work implements a visual interface amenable to data of the case study.

This visual interface also consists of a reporting module that can export data and interaction history from the visual interface for reporting or further analysis. The module implemented for the case study allows analysts to export (i) a log file of their interactions with the interface (logFile), (ii) metadata, similarity metrics, and performance metrics of selected items for further external validation (selParts), (iii) history of saved exploration states (stateHistory), and (iv) contextualized DfE principles created during the exploration process.

As shown in Fig. 5, contextual DfE principles are generated by analysts through the exploration of similarities in product and process data (see Section 3.1.2), as well as manufacturing process performance data (e.g., maximum cutting force, surface roughness of the workpiece). Exploring these data allows analysts to reason about the underlying interrelationships in these data and associate them to top-level or generic DfE principles.

For example, as discussed in the case study section, the general DfE principle of “avoid toxic cutting fluids” was explored by an analyst in order to reduce the environmental impact of plunge milling and face milling operations. Using the visual interface developed for the case study, the analyst explored the resulting surface finish quality of the workpiece across a range of materials, cutting speeds, feeds, and depth of cuts, for two types of cutting fluids–dry ice and conventional oil-based cutting fluid. From their exploration, the analyst observed and validated the fact that using dry ice in plunge milling or face milling finishing operations did not deteriorate surface finish quality. Therefore, the top-level DfE principle of “avoid toxic cutting fluids” was contextualized to “in plunge milling or face milling finishing operations avoid conventional oil-based cutting fluids as using dry ice resulted in comparable performance” by the analyst. Thus, by supporting analysts to interactively explore process-related data from specific production setups, VESPER aids analysts in formulating such contextual guidelines.

3.3. Step 3: DfE Principles Export and Sharing

DfE principles exported from the visual interface are represented using the DfePrinciple element described in Section 3.1.1. Exported DfE principles can be added to an XML database wherein each DfE principle is modeled as a node element in a tree structure. The root element in a tree is a general DfE principle that is not associated to any specific production setup (e.g., minimize energy consumption in manufacturing). The tree structure allows analysts to add child DfE principles contextualized to a production setups under the more general parent DfE principle. This allows reuse of DfE principles at different levels of specificity.

If no prior information is available related to a production setup, a very general DfE principle can be used. For known production setups, DfE principles contextualized to that specific production setup should be used. For example, as shown in Fig. 5, in order to fulfill the DfE principle of minimizing material waste in a machining scenario, the operator could use dry ice (DI) instead of flooding the cutting surface with mineral oil. In such a case, “Use of DI does not contribute to waste” is captured as a child node of its parent “Minimize material waste.” Furthermore, the tree-based representation also allows analysts to extend the DfE principles across similar production setups (e.g., across machine tools for the same manufacturing process).

A variety of open source database engines are available to query, visualize, and maintain XML databases (e.g., BaseX1, eX-istdb2). This makes it possible to add, remove, and maintain DfE principles outside VESPER. Additionally, to aid access and sharing of DfE principles, they can be exported to a comma separated value (CSV) file from VESPER’s visual interface.

4. CASE STUDY

This section discusses a case study that demonstrates the application of VESPER for generating contextual DfE principles in sustainable manufacturing. Section 4.1 provides an overview of the case study, including the testing procedure. Sections 4.2 and 4.3 describe an implementation of the VA system based on case study data. Data used in the case study was provided by an industry partner that had previously performed experiments comparing the use of dry ice and an oil-based cutting fluid for face milling and plunge milling. Details of the experiment setup, including the machine tool used, type of tool, and specific process parameters, are omitted from this paper due to confidentiality requirements from the industry partner. Section 4.4 steps through the contextual DfE principles generated by a PE from industry.

The goal of this test was to explore VESPER’s use by analysts (such as the PE) to explore production data and generate contextual DfE principles specific to these data. Section 4.5 describes feedback from the PE after using VESPER. We would like to reiterate the point that the goal of the case study is demonstrating the use of VESPER for generating contextual DfE principles with real production data. The current work does not discuss the usability of the visual interface or the measure the quantity or quality of DfE principles that can be formulated by an analyst. Nonetheless, this case study highlights the ability for generating and storing DfE principles in a real scenario using the DfePrinciple schema and the VA approach developed in this paper. Demonstrating the ability to create and update DfE principles contextualized to real, existing production data presents a novel contribution, that has not been previously explored to the best of our knowledge.

4.1. Testing Methodology

4.1.1. Testing goals:

To demonstrate the use of VESPER for generating contextual DfE principles, we tested the system with a PE who was employed with the industry partner. The PE had four years of work experience in a manufacturing setting and had previously completed a graduate degree in mechanical engineering. The PE had also worked on other projects relevant to sustainable manufacturing, including minimizing energy losses in milling due to tool chatter and reducing manufacturing waste by improving milling tool performance.

As discussed earlier, the focus of our test was limited to demonstrating the use of VESPER for generating contextual DfE principles. The test did not evaluate the usability of the prototype visual interface or the the merits of choosing one type of visualization (e.g., scatterplot matrices) over another.

4.1.2. Testing procedure:

The test was conducted remotely using video conferencing and lasted for a total of 90 minutes. The test consisted of three tasks, (i) introduction to VESPER, (ii) using VESPER to generate contextual DfE principles, and (iii) feedback on the developed methodology and VESPER.

In the introduction task, the methodology behind VESPER and the goal of the experiment was explained. Next, the various visualizations, interaction elements, and features of the visualization tool were demonstrated. No time limit was set for the introduction task and it took a total of 20 minutes for the PE to feel ready to proceed to the second task.

In the usage task, we asked the PE to generate contextual DfE principles starting from the top-level DfE principles discussed earlier. Since the test was conducted over video-conferencing the PE could not directly control the visual interface. One of the authors, serving as the test administrator, translated requirements posed by the PE into operations on the visual interface. For example, the PE indicated, “I want to see the surface roughness values for all other workpieces with material similarity = 1.” The administrator drew a brush in the results viewer window selecting workpieces with material similarity = 1.0 and switched the performance metrics bar chart to display surface roughness values for the selected workpieces. Note that the PE was solely responsible for guiding the exploration process, discovering insights in the data, and formulating contextual DfE principles. The PE used the entire 60 minutes that was allocated for the usage task.

Lastly, the PE was asked to provide feedback regarding the use of VESPER for generating contextual DfE principles. We also asked the PE to reflect on the potential need, use cases, and challenges in using such a system within their organization. The feedback session was open-ended as the focus was on eliciting benefits and challenges in this process and not on evaluating or benchmarking its performance. The PE discussed these points with the author for a total of 10 minutes. The results and details from the usage and feedback tasks are discussed below.

4.2. Step 1: Data Gathering and Pre-processing

The top-level DfE principles explored in the case study are listed below. As can be seen, these DfE principles are general and are not associated with any specific process or product data.

avoid toxic cutting fluids

minimize machining energy consumption

reduce machining consumables

minimize material waste

These DfE principles were explored in the context of real-world experimental data that compared machining using dry ice (DI) and an oil-based cutting fluid. Three types of machining processes were evaluated: (i) face milling–roughing, (ii) face milling–finishing, and (iii) plunge milling. For each machining process, workpieces were machined using DI and the oil-based cutting fluid while maintaining the same cutting speed, feed rate, depth of cut, and milling tool. Five different work-pieces were evaluated and their material types are shown in Table 2. Thus, the total number of experiments were 3 (#processes) × 5 (#workpieces) × 2 (#cutting f luid) = 30. Figure 6 illustrates the process plan (including toolpaths) for the machined geometries. In both cases, face milling proceeds in a spiral path starting from the outer perimeter and continuing towards the center of the workpiece. The orange lines shown in Fig. 6 illustrate the trajectories followed for machining grooves using plunge milling. The milling depth along the Z-axis for each operation was the same for both geometries.

TABLE 2.

Geometry, material, and dimensions of workpieces used in the experiment comparing DI and oil-based cutting fluid.

| Geometry | Material | Dimensions (mm) |

|---|---|---|

| Cylinder | Austenitic Stainless Steel | ϕ 150 × 100 |

| Cube | Aluminum Alloy 7075 | 180 × 180 × 100 |

| Cylinder | Low Alloy Cr Ni Steel | ϕ 150 × 100 |

| Cylinder | Tool Steel | ϕ 150 × 100 |

| Cube | Structural Steel | 180 × 180 × 100 |

FIGURE 6.

Process plans for the cylinder and cube geometry. The machining depth for each operation (shown in the Z axis) was the same for both geometries.

To explore these data, similarities in cutting speed (n), feed rate (f), depth of cut (d), and material (m) were calculated. Since the first three quantities are numerical characteristics, similarity between the ith workpiece and the reference workpiece (simref,i) was encoded using the normalized absolute difference between their respective parameter values [46].

| (1) |

Here, the subscript ‘re f ‘ stands for the reference workpiece used for pair-wise similarity computation. Thus, Eq. 1 computes the pair-wise similarity between parameters (n, f, d) by re-scaling the numerical difference to the range [0,1].

Similarity in material is computed based on material taxonomy in Ashby & Cebon [49]. Given two materials (m1,m2) from this taxonomy, their similarity given by sim(m1,m2) = 1 − D(m1,m2). Here D(m1,m2) represents distance between the two materials on the taxonomy and is computed using Eq. 2. Thus, material similarity is also expressed as a dimensionless quantities bounded in the range [0,1]. Interested readers are directed to our previous publication [50] that offers a more detailed explanation of this computation.

| (2) |

where,

= Nearest corresponding ancestor nodes for a1 and a2 such that tree-depth of tree-depth .

= Depth of the lowest common ancestor of node and node from the root. Note that the depth of the root node is equal to zero.

= Length of traversed path (number of hops) to reach node from node .

The machining performance metrics measured in for each experiment, included:

surface roughness of the machined surface, measured as the mean deviation of the profile

total time spent in cut

tool wear

Workpiece data, similarity, and performance measures from these experiments were represented using the data model discussed in Section 3 to enable interactive visual exploration. Note that since the experimental data were not stored in a PLM database, they were translated to the corresponding schema by the authors using MATLAB® scripts.

4.3. Step 2: Interactive Visual Exploration

For the case study, the visualization and reporting module was implemented using JAVA3 and Processing4. Figure 8 (see Appendix) illustrates the prototype visual interface that was implemented for this case study. A brief description of the elements in each window is discussed below.

1. Results viewer:

The results viewer window displays a two dimensional scatterplot matrix based visualization (SPLOM) of data on input similarity dimensions (Fig. 8–a in Appendix). Thus for N similarity metrics, the SPLOM generates an N × N array of scatterplots. Scatterplots below the diagonal are not shown as they are the mirror images of plots above. On each scatterplot, two dimensions of similarity are measured on a normalized scale spanning from [0,0] to [1,1]. Therefore, on a scatterplot, an item identical to the reference item (in the corresponding similarity dimensions) is displayed as a data point at the top-right corner [1,1]. On the other hand, an item that is entirely dissimilar to the reference item will be displayed as a data point in the bottom-left corner of the scatterplot [0,0]. For analyzing the data in the case study, the similarity dimensions chosen were material similarity, cutting speed similarity, and depth of cut similarity. Each point in a scatterplot represents a single experimental run using a specific workpiece. The color of the point indicates the type of cutting fluid used. Our implementation of the SPLOM also consists of interactive elements such as single selection of a data point, group-based selection using brushing (area selection), and linking of data points across multiple scatterplots. The selected data point is also simultaneously highlighted (in black) in all scatterplots. Furthermore, a label with metadata pertaining to the item is displayed (Fig. 8–b).

2. Control panel:

The control panel window consists of graphical user interface elements for interactions such as loading data, changing plot controls, and saving history states. The brushed list (Fig. 8–c) populates item names for data points selected by the analyst though a brushing operation on the SPLOM. The DfE principles list (Fig. 8–d) displays top-level principles initially selected by the analyst for further exploration. The control panel also contains form elements for changing the reference part for similarity computation (Fig. 8–e), editing drawn brushes (Fig. 8–f), and adding contextual DfE principles (Fig. 8–g). The bar charts (Fig. 8–h) display performance metrics for the selected workpiece and are colored based on the cutting fluid used. The performance metric displayed can be switched using the radio buttons above them. From left to right, the button panel (Fig. 8–i) consists of buttons for the following actions, (i) delete brush, (ii) undo operation, (iii) export interaction history, (iv) export DfE principles to a CSV spreadsheet, and (v) take a snapshot of the current exploration state and add it to the history tree.

3. History browser:

The history browser window displays analysts’ exploration history using a tree-based visualization (Fig. 8–j). It also allows analysts to select and jump back to any previous exploration state. A node is added each time the analyst clicks on the snapshot button in the control panel window.

4. Object browser:

The object browser window visualizes a 3D model of a selected workpiece (Fig. 8–k). The 3D model is loaded from the associated STL file linked in the XML repository. A label on the top left corner of this window displays the name and volumetric properties.

5. DfE principles browser:

The DfE principles browser displays the DfE principles being explored and allows analysts to add contextual DfE principles into the DfE database (Fig. 8–l). To add a sub-principle to the tree, the parent node is selected from the corresponding DfE principle tree and the details of the sub-principle are entered using the form elements (Fig. 8–g) in the control panel window.

4.4. Step 3: DfE Principles Export and Sharing

Contextual DfE principles (P#.#) generated by the PE were organized under the corresponding top-level DfE principle (P#). The name of the principles along with the insight that led to their discovery is summarized below. Figure 7 illustrates the tree structure for sub-principles added under the DfE principle of “minimize material waste”.

FIGURE 7.

Contextual DfE sub-principles added by the PE under the “minimize material waste” DfE principle.

P1 - Avoid toxic cutting fluids:

P1.1 - Use DI for Stainless Steel: For Stainless Steel work-pieces, DI machining showed improved performance than conventional (oil-based) cutting fluid with regards to cutting forces and tool wear.

P1.2 - Avoid conventional (oil-based) cutting fluid: In plunge milling or face milling–finishing avoid the use of conventional (oil-based) cutting fluid as DI showed comparable performance with regards to obtained surface finish quality.

P2 - Minimize machining energy consumption:

P2.1 - Use DI for Stainless Steel: Use of DI machining for Stainless Steel workpieces did not significantly increase cutting forces. The surface finish performance did not reduce significantly.

P2.2 - Avoid DI for face machining-roughing: In all materials except Stainless Steel, using DI for face machining-roughing increased cutting forces significantly.

P3 - Reduce machining consumables:

P3.1 - Reduce cutting speed for Tool Steel: With conventional (oil-based) cutting fluid, reduce cutting speed for Tool Steel workpieces as rapid wear of the tool was observed for the cutting speeds used in the experiment.

P4 - Minimize material waste:

P4.1 - Use of DI does not contribute to waste: Even though cutting forces increases for some milling operations, it was observed that increased cutting force did not result in degradation of surface finish.

P4.2 - Use DI for face milling–roughing: Data from experiments show that using DI while machining Structural Steel, Low alloy Cr Ni Steel, Tool Steel, and Aluminum alloy 7075 increased finish quality during face milling-roughing.

P4.2.1 - Use either DI or conventional (oil-based) cutting fluid for face milling–finishing: Data from experiments show choice of DI or conventional (oil-based) cutting fluid does not contribute to a significant difference in finished quality and, thus, not to material waste either.

While generating these principles, the PE identified a pair of contradicting DfE sub-principles that were generated. For face milling-roughing, the PE added “avoid DI for face machining–roughing” under “minimize machining energy consumption” and “use DI for face milling–roughing” under “minimize material waste”. The PE reported this was a result from DI increasing the finish quality while also increasing cutting forces significantly. The PE concluded that additional experiments or analysis would be needed to refine these sub-principles further.

Figure 9–a in the Appendix illustrates the DfE principles XML database containing the contextual DfE principles generated in the case study. As shown, these DfE principles can be explored, maintained, or updated outside VESPER using existing XML database management software. Furthermore, the CreationDate attribute of the DfePrincple references a specific exploration state in VESPER along with the corresponding Solid-Model and the SimilarityMeasure elements. This enables other analysts to load the specific exploration state in VESPER and view or update the DfE principle as necessary. Figure 9–b illustrates a spreadsheet exported from VESPER containing DfE principles generated in the case study under the root principle of “minimize material waste”. As shown, such spreadsheets allow simpler exchange of contextual DfE principles among analysts in an organization.

Thus, results from the case study demonstrate the application of the developed methodology (see Fig. 2) and the DfePrinciple schema (see Fig. 4) for contextualizing DfE principles in sustainable manufacturing. By supporting analysts (such as the PE) generate, export, and update DfE principles, our work addresses the previously discussed limitations of using high-level DfE principles in sustainable manufacturing.

4.5. Feedback from PE

After using VESPER, the PE provided feedback about the overall approach as well as the visual interface. The PE was satisfied by the number of contextual DfE principles that were generated and the quality of analysis they performed. The PE reported the ability to create dynamic, contextual DfE principles was very relevant as production situations and the performance criteria continually change. The PE also reported the ability to relate DfE principles to the data helped identify confirmatory evidence, plan future experiments, and translate findings across manufacturing contexts. The PE mentioned that there were other teams working on promoting sustainable manufacturing through alternative strategies such as liquid nitrogen based cryogenic machining as well as air-cooled machining. The ability to synthesize such efforts using a shared DfE database would be valuable. The PE suggested that standardizing data using the schema used in VESPER could be a challenge, as there was no current standard for defining product or process parameters at their facility.

The PE reported that while beneficial, using a novel visualization-driven system like VESPER across the organization would require allocation of significant resources towards training personnel. Therefore, the PE envisioned such a system to be used by a limited group, while data exported from the system (in the form of spreadsheets or a database) could be shared across the organization. The PE mentioned generating contextual DfE principles by linking it with data made VESPER useful in evidence-based presentation and reporting. The PE also mentioned the need for additional features in the visual interface to identify anomalies in manufacturing performance data and directly importing experimental data from existing spreadsheets.

5. LIMITATIONS

The case study demonstrated the use of VESPER for generating contextual DfE principles using one industry provided dataset. To improve generalizability, further testing with additional datasets is required. Additionally, the case study data pertained to well-known manufacturing processes and therefore DfE principles generated from these data may not necessarily represent novel insights. Even so, the case study demonstrated the ability to relate DfE principles to a specific production setup. Such relationships when maintained in a database and updated over time have the ability to present insights unique to that specific context. Longitudinal case studies conducted within the industry can help explore these aspects in the future. Furthermore, we did not evaluate the usability or the performance of the interface in the case study. Therefore, the quality or quantity of DfE principles generated may have been a product of the chosen interface design. The lack of standardization in collecting and representing lifecycle information presents a challenge for integrating VESPER within existing industry practices. Development and adoption of relevant standards for lifecycle information representation [51–53], communication (e.g. MTconnect5), and formal models for representing lifecycle information [54] can help address such limitations.

6. CONCLUSIONS & FUTURE WORK

This paper presented VESPER, a visual analytics system for generating contextual DfE principles in sustainable manufacturing through the exploration of product and process parameters in design and manufacturing as well as manufacturing process performance. We also presented a formal schema for linking generated DfE principles to corresponding lifecycle information as well as the evidence that led to their discovery. We demonstrated the use of VESPER for generating contextual DfE principles using an industry-provided dataset that compared DI-based and oil-based machining for face milling and plunge milling. Results show that the PE using VESPER was able to generate contextual DfE principles based on the experimental data and discover need for further testing. Feedback provided by the PE outline the potential for visual analytics systems, like VESPER, to improve existing practices for implementing DfE principles in sustainable manufacturing.

Our future work will focus on improving the usefulness of VESPER by targeting the generalizability of the data models used to define life cycle information. One idea is to link formal rulesets that characterize best practices in manufacturing operations. Predictive Modeling Markup Language (PMML)6 provides a data model to capture such rulesets in a formal and consistent manner. Leveraging the existing PMML data model offers potential for the efficient capture and exchange of highly detailed DfE principles. Another potential direction is augmenting the interactive exploration process in VESPER using machine learning based approaches than automatically detect underlying correlations in data and suggest contextual DfE principles. We will also explore the use of statistical techniques for automated pattern and anomaly detection.

We also plan on performing additional case studies to explore the application of VESPER in different production contexts relevant to sustainable manufacturing. Such studies could improve the external validity of the proposed approach and point to improved approaches for exploring similarities in product and process data as well as manufacturing performance. We will also explore the need for creating a web-based version of the VESPER system to improve dissemination.

In closing, the case study presented demonstrates the utility of VESPER in a real-world production context. This presents potential for (i) training users with limited hands-on experience in sustainable manufacturing, and (ii) handing-off insight from experts to novices through the formal exchange of contextual DfE principles. Without formal and reproducible approaches for data capture and exchange, tacit knowledge embedded in the most experienced employees is not easily transferable to novices. According to a 2015 Deloitte report [55], in the next decade, 3.5 million manufacturing jobs are likely needed to be filled, while the skills gap in US manufacturing is expected to result in 2 million of those jobs unfilled, further motivating the criticality of efficiently handing-off manufacturing data and analyses from experienced employees to less-experienced newcomers. Our future work, as described above, will continue to leverage VESPER to close the skills gap. Providing a means for interactive visual exploration of complex relationships between input parameters (e.g., design, process, and resource information) with manufacturing-oriented outcomes (e.g., tool wear, energy consumption, and scrap rate) facilitate the creation of more refined mental models. We believe this process is essential for bringing newcomers up-to-speed quickly.

Supplementary Material

ACKNOWLEDGEMENTS

We thank the process engineer who participated in the case study. Our thanks to Moneer Helu, John Michaloski, and Saadia Razvi for providing feedback on the paper. This work was partly supported by the Department of Engineering, Aarhus University.

NOMENCLATURE

- CAD

Computer-Aided Design

- CSV

Comma Seperated Value

- DfE

Design for Environment

- DI

Dry Ice

- PE

Process Engineer

- PLM

Product Lifecycle Management

- KPI

Key Performance Indicator

- LCA

Life Cycle Assessment

- PMML

Predictive Modeling Markup Language

- SPLOM

Scatterplot Matrix

- VA

Visual Analytics

- VESPER

Visual Exploration of Similarity and Performance Metrics

- UML

Unified Modeling Language

- XML

Extensible Markup Language

- XSD

XML Schema Definition

APPENDIX

FIGURE 8.

Screen capture of the prototype visual interface implemented for the case study. Please note data related to process and performance parameters are boxed out due to confidentiality requirements. Elements present in the interface are detailed in Section 4.3.

FIGURE 9.

(a) DfE database populated with contextual DfE principles generated in the case study. (b) DfE principles exported to a spreadsheet.

Footnotes

Publisher's Disclaimer: DISCLAIMER

No approval or endorsement of any commercial product by NIST is intended or implied. Certain commercial equipment, instruments or materials are identified in this report to facilitate better understanding. Such identification does not imply recommendations or endorsement by NIST nor does it imply the materials identified are necessarily the best available for the purpose.

SUPPLEMENTARY MATERIALS

An XSD file of the DfePrinciple schema implementation (shown in Figure 4) can be downloaded from the following link: https://tinyurl.com/MANU-18-1302-SUPPMATL

REFERENCES

- [1].Manyika Chui, B. B. D. R. B., 2011. Big data: The next frontier for innovation, competition, and productivity Tech. rep, McKinsey Global Institute. [Google Scholar]

- [2].Lee J, Lapira E, Bagheri B, and Kao H. a., 2013. “Recent advances and trends in predictive manufacturing systems in big data environment”. Manufacturing Letters, 1(1), pp. 38–41. [Google Scholar]

- [3].Barnaghi P, Sheth A, and Henson C, 2013. “From data to actionable knowledge: Big data challenges in the web of things [guest editors’ introduction]”. IEEE Intell Syst, 28(6), pp. 6–11. [Google Scholar]

- [4].Ramanujan D, Bernstein WZ, Chandrasegaran SK, and Ramani K, 2017. “Visual analytics tools for sustainable lifecycle design: Current status, challenges, and future opportunities”. Journal of Mechanical Design, 139(11), p. 111415. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [5].Ramanujan D, and Bernstein WZ, 2018. “VESPER: Visual exploration of similarity and performance metrics for computer-aided design repositories”. In ASME 2018 Manufacturing Science and Engineering Conference, American Society of Mechanical Engineers. [Google Scholar]

- [6].Kim HHM, Liu Y, Wang CC, and Wang Y, 2017. “Special issue: Data-driven design (d3)”. Journal of Mechanical Design, 139(11), p. 110301. [Google Scholar]

- [7].Wang J, Ma Y, Zhang L, Gao RX, and Wu D, 2018. “Deep learning for smart manufacturing: Methods and applications”. Journal of Manufacturing Systems. [Google Scholar]

- [8].Wuest T, Weimer D, Irgens C, and Thoben K-D, 2016. “Machine learning in manufacturing: advantages, challenges, and applications”. Production & Manufacturing Research, 4(1), pp. 23–45. [Google Scholar]

- [9].Thomas JJ, 2005. Illuminating the Path: the Research and Development Agenda for Visual Analytics. IEEE Computer Society. [Google Scholar]

- [10].Lenox M, King A, and Ehrenfeld J, 2000. “An assessment of design-for-environment practices in leading US electronics firms”. Interfaces, 30(3), pp. 83–94. [Google Scholar]

- [11].Keoleian GA, Menerey D, et al. , 1993. “Life cycle design guidance manual: Environmental requirements and the product system”. In Life cycle design guidance manual: environmental requirements and the product system. EPA. [Google Scholar]

- [12].Graedel TE, and Allenby BR, 1996. Design for Environment. Prentice Hall. [Google Scholar]

- [13].Brezet H, 1997. “Ecodesign, a promising approach to sustainable production and consumption”. United Nations Environmental Program (UNEP). [Google Scholar]

- [14].Gungor A, and Gupta SM, 1999. “Issues in environmentally conscious manufacturing and product recovery: a survey”. Computers & Industrial Engineering, 36(4), pp. 811–853. [Google Scholar]

- [15].Gutowski TG, Murphy CF, Allen DT, Bauer DJ, Bras B, Piwonka TS, Sheng PS, Sutherland JW, Thurston DL, and Wolff EE, 2001. Environmentally benign manufacturing Tech. rep, International Technology Research Institute, World Technology (WTEC) Division, Baltimore, MD. [Google Scholar]

- [16].Giudice F, La Rosa G, and Risitano A, 2006. Product design for the environment: a life cycle approach. CRC press. [Google Scholar]

- [17].Vezzoli C, and Manzini E, 2008. Design for environmental sustainability. Springer. [Google Scholar]

- [18].Fiksel J, 2009. Design for environment: a guide to sustainable product development. McGraw Hill Professional. [Google Scholar]

- [19].Telenko C, O’Rourke JM, Seepersad CC, and Webber ME, 2016. “A compilation of design for environment guidelines”. Journal of Mechanical Design, 138(3), p. 031102. [Google Scholar]

- [20].Ehrenfeld J, and Lenox MJ, 1997. “The development and implementation of dfe programmes”. Journal of Sustainable Product Design, 1(1), pp. 17–27. [Google Scholar]

- [21].Ramanujan D, Bernstein WZ, Choi J-K, Koho M, Zhao F, and Ramani K, 2014. “Prioritizing design for environment strategies using a stochastic analytic hierarchy process”. Journal of mechanical design, 136(7), p. 071002. [Google Scholar]

- [22].Pigosso DCA, McAloone TC, and Rozenfeld H, 2014. “Systematization of best practices for ecodesign implementation”. In DS 77: Proceedings of the DESIGN 2014 13th International Design Conference. [Google Scholar]

- [23].Hernandez NV, Kremer GO, Schmidt LC, and Herrera PA, 2012. “Development of an expert system to aid engineers in the selection of design for environment methods and tools”. Expert Systems with Applications, 39(10), pp. 9543–9553. [Google Scholar]

- [24].Rombouts JP, 1998. “LEADS-II. a knowledge-based system for ranking dfe-options”. In Electronics and the Environment, 1998. ISEE-1998. Proceedings of the 1998 IEEE International Symposium on, IEEE, pp. 287–291. [Google Scholar]

- [25].Rounds KS, and Cooper JS, 2002. “Development of product design requirements using taxonomies of environmental issues”. Research in Engineering Design, 13(2), pp. 94–108. [Google Scholar]

- [26].Telenko C, and Seepersad CC, 2010. “A methodology for identifying environmentally conscious guidelines for product design”. Journal of Mechanical Design, 132(9), p. 091009. [Google Scholar]

- [27].Luttropp C, and Lagerstedt J, 2006. “Ecodesign and the ten golden rules: generic advice for merging environmental aspects into product development”. Journal of Cleaner Production, 14(15–16), pp. 1396–1408. [Google Scholar]

- [28].Oehlberg L, Bayley C, Hartman C, and Agogino A, 2012. “Mapping the life cycle analysis and sustainability impact of design for environment principles”. In Leveraging Technology for a Sustainable World. Springer, pp. 221–226. [Google Scholar]

- [29].Hauschild MZ, Jeswiet J, and Alting L, 2004. “Design for environmentdo we get the focus right?”. CIRP Annals-Manufacturing Technology, 53(1), pp. 1–4. [Google Scholar]

- [30].Holt R, and Barnes C, 2010. “Towards an integrated approach to design for x: an agenda for decision-based dfx research”. Research in Engineering Design, 21(2), pp. 123–136. [Google Scholar]

- [31].Ramani K, Ramanujan D, Bernstein WZ, Zhao F, Sutherland J, Handwerker C, Choi J-K, Kim H, and Thurston D, 2010. “Integrated sustainable life cycle design: a review”. Journal of Mechanical Design, 132(9), p. 091004. [Google Scholar]

- [32].Sedlmair M, Isenberg P, Baur D, and Butz A, 2011. “Information visualization evaluation in large companies: Challenges, experiences and recommendations”. Inf Vis, 10(3), pp. 248–266. [Google Scholar]

- [33].Mazumdar S, Varga A, Lanfranchi V, Petrelli D, and Ciravegna F, 2011. “A knowledge dashboard for manufacturing industries”. In Extended Semantic Web Conference, Springer, pp. 112–124. [Google Scholar]

- [34].Xu P, Mei H, Ren L, and Chen W, 2016. “ViDX: Visual diagnostics of assembly line performance in smart factories”. In Proc. of the IEEE Conference on Visual Analytics Science and Technology, p. 10. [DOI] [PubMed] [Google Scholar]

- [35].Jo J, Huh J, Park J, Kim B, and Seo J, 2014. “Livegantt: Interactively visualizing a large manufacturing schedule”. IEEE Trans Vis Comput Graph, 20(12), pp. 2329–2338. [DOI] [PubMed] [Google Scholar]

- [36].Reijner H, 2008. “The development of the horizon graph”. In Proceedings of Workshop on from Theory to Practice: Design, Vision and Visualization. [Google Scholar]

- [37].Bernstein WZ, Ramanujan D, Elmqvist N, Zhao F, and Ramani K, 2014. “ViSER: Visualizing supply chains for eco-conscious redesign”. In Proc. of the ASME 2014 IDETC & CIE, ASME, p. V004T06A049. [Google Scholar]

- [38].Kamath M, Srivathsan S, Ingalls RG, Shen G, and Pulat PS, 2011. “Tiscsoft: A decision support system for transportation infrastructure and supply chain system planning”. In Proc. of the 44th Hawaii Internal Conference on System Sciences (HICSS), IEEE, pp. 1–9. [Google Scholar]

- [39].Hesse S, Spehr M, Gumhold S, and Groh R, 2014. “Visualizing time-dependent key performance indicator in a graph-based analysis”. In Proc. of the IEEE ETFA, IEEE, pp. 1–7. [Google Scholar]

- [40].Childerhouse P, and Towill DR, 2002. “Analysis of the factors affecting real-world value stream performance”. INT J PROD RES, 40(15), pp. 3499–3518. [Google Scholar]

- [41].SAP 3D Visual Enterprise. https://www.sap.com/products/product-visualization.html. Accessed: 2017–11–01.

- [42].Siemens NX HD3D Visual Reporting System. https://www.plm.automation.siemens.com/en/products/nx/for-design/visual-analytics/reporting.shtml. Accessed: 2017–11–01.

- [43].Bertoni M, Bertoni A, Broeze H, Dubourg G, and Sandhurst C, 2014. “Using 3d cad models for value visualization: An approach with siemens nx hd3d visual reporting”. Comput Aided Des Appl, 11(3), pp. 284–294. [Google Scholar]

- [44].Gutowski T, Dahmus J, and Thiriez A, 2006. “Electrical energy requirements for manufacturing processes”. In 13th CIRP international conference on life cycle engineering, Vol. 31, CIRP International Leuven, Belgium, pp. 623–638. [Google Scholar]

- [45].UNECE, 2005. Codes for units of measure used in international trade.

- [46].Li K, and Bernstein WZ, 2017. “Developing a capability-based similarity metric for manufacturing processes”. In Proceedings of the ASME 2017 12th International Manufacturing Science and Engineering Conference, ASME, p. V003T04A015. [Google Scholar]

- [47].Todd R, Allen D, and Alting L, 1994. Manufacturing processes reference guide. Industrial Press Inc. [Google Scholar]

- [48].Lu T, Gupta A, Jayal A, Badurdeen F, Feng SC, Dillon O Jr, and Jawahir I, 2011. “A framework of product and process metrics for sustainable manufacturing”. In Advances in Sustainable Manufacturing. Springer, pp. 333–338. [Google Scholar]

- [49].Ashby M, and Cebon D, 1993. “Materials selection in mechanical design”. Le Journal de Physique IV, 3(C7 1–10). [Google Scholar]

- [50].Ramanujan D, Bernstein WZ, Benjamin W, Ramani K, Elmqvist N, Kulkarni D, and Tew J, 2015. “A framework for visualization-driven eco-conscious design exploration”. J COMPUT INF SCI ENG, 15(4), p. 041010. [Google Scholar]

- [51].ISO 10303–1:1994, 1994. Industrial automation systems and integration – Product data representation and exchange – Part 1: Overview and fundamental principles. ISO. [Google Scholar]

- [52].ISO 14040:2006, 2006. Environmental management – Life cycle assessment – Principles and framework. ISO. [Google Scholar]

- [53].ASTM E3012–16, 2016. Standard Guide for Characterizing Environmental Aspects of Manufacturing Processes. ASTM International. [Google Scholar]

- [54].Barbau R, Krima S, Rachuri S, Narayanan A, Fiorentini X, Foufou S, and Sriram RD, 2012. “Ontostep: Enriching product model data using ontologies”. Comput Aided Des, 44(6), pp. 575–590. [Google Scholar]

- [55].Giffi C, McNelly J, Dollar B, Carrick G, Drew M, and Gangula B, 2015. The skills gap in U.S. manufacturing: 2015 and beyond Tech. rep, Deloitte Development LLC. Report co-sponsored by the Manufacturing Institute and Deloitte. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.