Abstract

Objectives.

A systematic review of in vitro studies was conducted to assess the effect of thermal treatments on flexural strength or critical load to failure of porcelain-veneered zirconia (PVZ).

Sources.

Literature searches were performed up to June 2018 in PubMed/MEDLINE, Scopus and Web of Science databases, with no publication year or language limits.

Data.

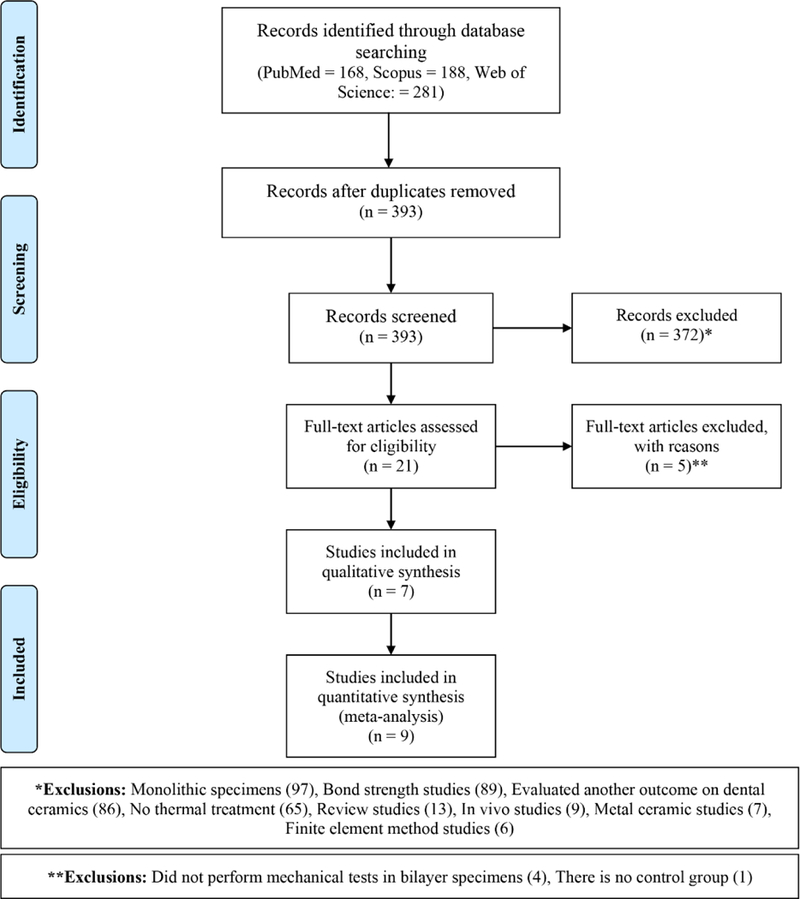

From 393 relevant studies, 21 were selected for full-text analysis, from which 7 failed to meet the inclusion criteria. The 14 remaining papers were included for the systematic review: 8 for meta-analysis and 6 restricted to descriptive analyses. Hand searching of reference lists resulted in no additional papers.

Study selection.

In vitro studies using PVZ specimens testing the influence of thermal treatments on the fracture resistance to monotonic or cyclic loading. Papers evaluating cooling rate were divided into those applying fast cooling from above the porcelain glass transition temperature (), or from below it. Meta-analyses were performed separately for flexural strength and critical load to failure, using random effects at a 5% significance level.

Conclusions.

Delaying furnace opening at a temperature below the porcelain is advised for PVZ restorations, in order to improve their fracture resistance. Additional information is required to confirm the apparently beneficial effect of self-glaze and repeated veneer firings on the mechanical properties of these restorations. Finally, in order to obtain conclusive and relevant evidence regarding thermal treatments and the fracture resistance of PVZs, future studies should concentrate on anatomically-correct crown specimens.

Keywords: porcelain-veneered zirconia, cooling protocols, glaze firings, repeated firings, heat treatment, mechanical properties

1. Introduction

Yttria-stabilized tetragonal zirconia polycrystal ceramic has been perceived as a superior restorative material due to its biocompatibility and mechanical properties.1 Porcelain-veneered zirconia restorations combine the strength of the zirconia framework with the excellent optical properties of the veneering porcelain.2 The clinical survival rates of these restorations range from 90% to 95% in 5 years.3–5 However, only about 70%,6–7 did not require any intervention for continued function. Veneer fracture has been the leading cause of the reduced success rates.6,7 These fractures may be repairable by polishing or filling with another restorative material (minor chipping) or not repairable (major chipping or catastrophic fractures), which lead to restoration replacement. Several factors have been associated to veneer failures, such as porcelain heterogeneous thickness,8,9 non-anatomical design of the framework,10–12 coefficient of thermal expansion (CTE) mismatch,13 elastic modulus14 and fracture toughness of porcelain,15 inadequate veneer firing,16 or residual thermal stresses.17, 18

Deleterious thermal stress gradients have been associated to the cooling rate after the last firing.19,20 When the bilayer restoration is fast cooled, meaning the restoration is exposed to a thermal shock in high temperatures by immediately opening the furnace once the firing schedule is done, the surface of the porcelain solidifies and contract earlier, while the inner region remains at higher temperature. When the inner temperature decreases, the already solid surface hinders the contraction of the inner porcelain upon cooling, and residual tensile stresses become locked into the material system.14,20 In contrary, when slow cooling is used, the restoration stays under controlled temperature reduction, thus, the whole structure of the restoration is expected to cool uniformly, effectively reducing residual thermal stresses.21 However, not all previous studies have shown difference in the strength of bilayer systems after fast or slow cooling.22–24 Various other thermal treatments have been proposed to overcome the chipping susceptibility and improve the fracture resistance of veneer ceramic, including glaze,25 number of veneer firings,26,27 and additional firing in different temperatures.28 Previous studies suggest that these thermal treatments may relief thermal stresses.29,30

Considering that veneer chipping is a current clinical problem and it is strongly associated to the thermal treatments experienced by the porcelain veneered restoration, a systematic compilation of the contradictory literature and pooled data analysis may provide clear conclusions. Thus, this systematic review sought to assess the available scientific literature, investigating the following research question: How do thermal treatments (glaze, number of veneer firings, annealing, and cooling rate) influence the flexural strength or critical load to failure of porcelain-veneered zirconia?

2. Materials and methods

This systematic review was prepared and reported according to the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA).31 A non-registered protocol was elaborated prior to the literature search. The PICOS question was defined as follows: Population: porcelain-veneered zirconia (PVZ) specimens with any geometry; Intervention: slow cooling, more than two veneer firings, over- or self-glaze, or annealing; Comparison: fast cooling (from above or below transformation temperature () of the veneer porcelain), up to two veneer firings, no glaze, or no annealing; Outcomes: flexural strength or critical load to failure; Study design: in vitro studies.

2.1. Search Strategy

Literature search was carried out in PubMed/MEDLINE, Scopus and Web of Science databases to identify relevant articles up to June 2018. The search was conducted with no publication year or language limits. The studies were searched from PubMed/MEDLINE using the following strategy: ((zirconi*) OR (ytzp) OR (y-tzp)) AND ((dental porcelain*[MeSH Terms]) OR (porcelain) OR (veneer*) OR (bilayer) OR (veneered zirconia)) AND ((glaze*) OR (firing*) OR (fast cooling) OR (slow cooling) OR (cooling rate) OR (thermal treatment) OR (heat treatment) OR (annealing)) AND ((Compressive strength [MeSH Terms]) OR (strength) OR (flexural) OR (resistance) OR (load) OR (failure) OR (fatigue)). A sensitive search strategy was adapted for Scopus and Web of Sciences. The results of all databases searches were crosschecked to eliminate duplicates.

2.2. Selection of studies and eligibility criteria

Two reviewers (CSR and ILA) independently assessed the identified publications and selected them by title and abstract based on the following inclusion criteria: in vitro studies using PVZ specimens, which tested the influence of any thermal treatments on flexural strength or critical load to failure regardless the mechanical test configuration adopted (monotonic or cyclic loading).

The final decision about inclusion of a given study was made based on full-text evaluation of potentially relevant papers. Those which were not in accordance with the following criteria were excluded: 1) at least one intervention group subjected to more than two veneer firings, glaze firing, annealing, or slow cooling; 2) at least one comparison group subjected up to two veneer firings, no glaze, no annealing, or fast cooling, respectively; and 3) quantitative results reported as mean values and standard deviation (or equivalent central tendency and dispersion values) for flexural strength (MPa) or for critical load to failure (N), along with description of the sample sizes of each group. Reference lists of the included papers were also screened. When fatigue data was described in terms of reliability or number of cycles, authors were contacted and asked to provide the means and standard deviations of flexural strength or critical load to failure. Otherwise, these papers were not considered for meta-analyses. Any discrepancies between the reviewers were resolved through discussion and judgment by a third reviewer (LGM). The inter-examiner agreement (Kappa coefficient) was calculated for both phases (eligibility criteria: 0.86 and exclusion criteria: 0.95). Both reviewers also collected the data from the eligible studies independently, which were then compiled and discussed for consensus.

2.3. Risk of bias assessment

Quality of the studies was assessed by the two reviewers using the modified Consolidated Standards of Reporting Trials (CONSORT) checklist.32 The following items were evaluated in each paper: 1) Structured summary of trial design, methods, results and conclusions, 2a) Scientific background and explanation of rationale, 2b) Specific objectives and/or hypothesis, 3) The intervention of each group, including how and when it was performed, with sufficient detail to enable replication, 4) Completely defined, pre-specified primary and secondary measured of outcome, including how and when they were assessed, 5) How the sample size was determined, 6) Method used to generate the random allocation sequence, 7) Mechanism used to implement the random allocation sequence, 8) Who assigned the random allocation, 9) Who was blinded after assignment to the intervention, 10) Statistical methods used to compare groups, 11) Results for each group and estimated size of effect and its precision, 12) Trial limitations, addressing sources of potential bias, imprecision, and, if relevant multiplicity of analysis, 13) Sources of funding and other support, 14) Where the full trial protocol can be accessed. Each parameter was judged as reported (Yes) or not reported (No).

2.4. Data analyses

Data analyses were carried out using Review Manager software version 5.3 (Cochrane Collaboration). Papers evaluating cooling rate were categorized into those which used a fast cooling (furnace opening and samples immediately removed) from above or below the of the veneer porcelain. Distinct meta-analyses were performed using random effects for fast (above) versus slow cooling, fast (below) versus slow cooling, and for flexural strength or critical load to failure data. Forest plots were created and significance level was set at 5% (Z test). The heterogeneity among studies was evaluated by Cochrane Q test, where P<0.1 was considered statistically significant, and the inconsistency I2 test, where values higher than 50% were considered indicative of substantial heterogeneity. 33

Studies that could not be included in meta-analyses due to lack of data (mean and standard deviation values and sample size) and/or due to methodological differences that did not allow comparisons with other studies, were only descriptively analyzed.

3. Results

3.1. Study selection

Figure 1 depicts a flowchart summarizing the selection process for studies. The search strategy identified 393 potentially relevant records. The first screening, by title and abstract, resulted in 21 studies that remained for full-text reading. Finally, 14 papers were included in the systematic review: 8 for quantitative evaluation using meta-analyses and 6 restricted to descriptive analyses. Manual searching through the reference lists of included studies resulted in no additional papers. Table 1 describes the characteristics of included studies. The majority of studies evaluated cooling rate (10 studies),13,22–24,36–41 two evaluated number of veneer firings,26,27 one evaluated self-glaze,25 and one investigated alternative firings.28 The included studies used 9 different commercial brands of veneer porcelains, presenting a range of physical characteristics, such as elastic modulus (), coefficient of thermal expansion (CTE) and glass transition temperature (). These porcelains and their characteristics are described in Table 2.

Figure 1.

Selection of studies procedures according to PRISMA

Table 1.

Characteristics of included studies.

| Author (year) | Materials | Intervention | Comparison | Last firing | Testing set up | Veneer thickness (mm)* |

Sample size (n) |

|---|---|---|---|---|---|---|---|

| Ebadian et al (2018) | Vita PM9 (Vita) Vita In Ceram YZ (Vita) |

Slow cooling (furnace 30% open until 500˚C) | Fast cooling (Below Tg) | Veneering | Modified four-point bending | 6.5 | 10 |

| Passos et al (2017) | Vita VM9 (Vita) Lava Plus (3M ESPE) |

Slow cooling (furnace closed until 500˚C) | Fast cooling (Below Tg) | Veneering | Four-point bending | 0.5 | 20 |

| Tang et al (2017) | IPS e.max Ceram (Ivoclar) NaturZ (D-Max) |

Slow cooling (furnace closed until 500˚C) | Fast cooling (Above Tg) | Veneering | Load-to-failure (single crowns) | 1.0 or 2.0 | 10 |

| Meirelles et al (2016) | Vita VM9 (Vita) Ceramco PZF (Dentsply) Vita In Ceram YZ (Vita) |

Slow cooling (furnace closed until 50˚C below Tg/ 460˚C or 510 ˚C) | Fast cooling (Below Tg) | Veneering | Three-point-bending | 1.0 | 30 |

| Longhini et al (2016) | Vita VM9 (Vita) Vita PM9 (Vita) Vita In Ceram YZ (Vita) |

Slow cooling (furnace closed until room temperature) | Fast cooling (Above Tg) | Self-glaze | Piston-on-three-balls | 1.0 | 15 |

| Vichi et al (2015) | Initial Zr-Fs (GC Europe) Adva Zr (GC Europe) |

3 or 5 firing cycles | 1 firing cycle | Veneering | Three-point-bending | 1.2 | 15 |

| Paula et al (2015) | IPS e.max Ceram (Ivoclar) E.max ZirCAD (Ivoclar) |

Slow cooling (furnace closed until 50˚C) | Fast cooling (Above Tg) | Over-glaze | Fatigue test (single crowns) | 1.5 | 10 |

| Schmitter et al (2015) | Cercom Ceram press (DeguDent) Cercom base (DeguDent) |

Glaze | No glaze | Over-glaze | Three-point-bending Load-to-failure |

4.0 | 8 |

| Almeida Jr. et al (2013) | Vita VM9 (Vita) ZRHP (ProtMat) |

Slow cooling (furnace closed until room temperature) | Fast cooling (Above and Below Tg) | Veneering | Three-point-bending | 0.5 | 30 |

| Preis et al (2013) | Lava Ceram (3M ESPE) Lava (3M ESPE) |

Slow cooling (6 min of cooling before open the furnace) | Fast cooling (Above Tg) | Veneering | Load-to-failure (single crowns) | 2.0 | 6 |

| Lima et al (2013) | Vita VM9 (Vita) Vita PM9 (Vita) Vita In Ceram YZ (Vita) |

Slow cooling (furnace closed until 600˚C) | Fast cooling (Above Tg) | Self-glaze | Four-point-bending | 1.0 or 3.0 | 8 |

| Belli et al (2013) | Vita VM9 (Vita) Lava Ceram (3M ESPE) YZ Cubes (Vita) |

Slow cooling (furnace 10% opened until 200˚C) | Fast cooling (Above Tg) | Self-glaze | Load-to-failure (single crowns) | 1.4 | 16 |

| Lu et al (2012) | Vita VM9 (Vita) Kavo Zirconia (Kavo) |

4,6,or 8 firing cycles | 2 firing cycles | Veneering | Three-point-bending | 0.6 | 8 |

| Tan et al (2012) | Vita VM9 (Vita) Lava (3M ESPE) |

Slow cooling (furnace opened 30% until 500˚C) | Fast (Above Tg) | Self-glaze | Modified four-point-bending | 6.5 | 6 |

| Rues et al (2010) | Cercon Ceram Kiss (DeguDent) Cercon Ceram Love (DeguDent) Cercon Base (DeguDent) |

Slow cooling (6 min of cooling before open the furnace) | Fast cooling (Above Tg) | Self-glaze | Load-to-failure (single crowns) | 2.0 | 8 |

| Taskonak et al (2008) | Lava Ceram (3M ESPE) Lava (3M ESPE) |

Slow cooling (low cooling rate until room temperature) | Fast cooling (Above Tg) | Heat treatment | Ring-on-ring | 0.6 | 16 |

Occlusal thickness when specimens were crowns

Table 2.

Characteristics of the porcelain materials used in the included studies.

| Material/ Manufacturer |

Composition | Processing method |

Elastic module |

Coefficient of thermal expansion (CTE) |

Glass transition temperature (Tg) |

Cooling protocol suggested by the manufacturer |

|---|---|---|---|---|---|---|

| Vita VM9 (Vita) | Feldspathic ceramic | Hand-layered | 64.6 GPaa | 9.0 – 9.2 10−6K−1 (25 – 500 ˚C)* | 600˚C* | Furnace closed until 800˚C and 25% open until 600˚C |

| Vita PM9 (Vita) | Feldspathic ceramic | Heat-pressed | 70 GPab | 9.0 – 9.2 10−6K−1 (25 – 500 ˚C)* | 640˚Cb | Remove the investment ring from the furnace after the end of pressing and place it on a grid to cool it down to room temperature |

| IPS e.max Ceram (Ivoclar) | Fluorapatite ceramic | Hand-layered | 90 GPaa | 9.5 10−6K−1

(100 – 400˚C)* |

490˚C* | Glaze firing: furnace open after cooling down from 730˚C to 450˚C. No long-term cooling is indicated for sintering firings. |

| Ceramco PZF (Dentsply) | Feldspathic ceramic | Hand-layered | 75 GPac | 9.4 10−6K−1 d | 560˚Cc | 6 min cooling after maximum temperature (870˚C) for glaze firings. No long-term cooling is indicated for sintering firings |

| Lava Ceram (3M ESPE) | Feldspathic ceramic | Hand-layered | 80 GPa* | 10 10−6K−1

(25 – 500 ˚C)* |

565˚Cd | No long-term cooling is indicated |

| Cercon Ceram Kiss (DeguDent) | Feldspathic ceramic | Hand-layered | 75 GPaa | 9.2 10−6K−1

(25 – 500 ˚C)* |

- | 6 min cooling after maximum temperature (800˚C) for glaze firings. No long-term cooling is indicated for sintering firings |

| Cercon Ceram Love (DeguDent) | Feldspathic ceramic | Hand-layered | - | 9.2 10−6K−1

(25 – 500 ˚C)* |

- | 6 min cooling after maximum temperature (800˚C) for glaze firings. No long-term cooling is indicated for sintering firings |

| Cercon Ceram press (DeguDent) | Feldspathic ceramic | Heat-pressed | - | 10.5 10−6K−1

(25 – 500 ˚C)* |

- | No long-term cooling is indicated |

| Initial Zr-Fs (GC Europe) | Feldspathic ceramic | Hand-layered | - | 9.4 10−6K−1* | 550˚C* | No long-term cooling is indicated |

3.2. Risk of bias

Table 3 presents the estimated risk of bias of each included study. All included papers properly presented a structured summary, specific objectives, and statistical analyses. Some papers reported to have performed randomization,23,27,34,36,37 however, they have not reported how this procedure was carried out. Not one study clearly reported information about the mechanism used to implement the random allocation process, who performed it, and where the full trial protocol can be assessed. Background and rationale (6%), intervention description (19%), outcome description (12%), blinding (81%), limitations (56%), and funding resources (25%) were not always clearly reported.

Table 3.

Risk of bias of included studies.

| Author (year) | 1 | 2a | 2b | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ebadian et al (2018) | Yes | Yes | Yes | Yes | Yes | No | No | No | No | Yes | Yes | Yes | Yes | Yes | No |

| Passos et al (2017) | Yes | Yes | Yes | Yes | Yes | No | No | No | No | No | Yes | Yes | No | Yes | No |

| Tang et al (2017) | Yes | Yes | Yes | Yes | Yes | No | No | No | No | No | Yes | Yes | Yes | Yes | No |

| Meirelles et al (2016) | Yes | Yes | Yes | Yes | Yes | No | No | No | No | Yes | Yes | Yes | No | Yes | No |

| Longhini et al (2016) | Yes | Yes | Yes | Yes | Yes | No | No | No | No | No | Yes | Yes | Yes | No | No |

| Vichi et al (2015) | Yes | Yes | Yes | Yes | Yes | No | No | No | No | No | Yes | Yes | Yes | No | No |

| Paula et al (2015) | Yes | Yes | Yes | Yes | Yes | No | No | No | No | No | Yes | Yes | No | Yes | No |

| Schmitter et al (2015) | Yes | Yes | Yes | Yes | Yes | No | No | No | No | No | Yes | Yes | Yes | Yes | No |

| Almeida Jr. et al (2013) | Yes | Yes | Yes | Yes | Yes | No | No | No | No | No | Yes | Yes | Yes | No | No |

| Preis et al (2013) | Yes | Yes | Yes | No | Yes | No | No | No | No | No | Yes | Yes | No | Yes | No |

| Lima et al (2013) | Yes | Yes | Yes | Yes | Yes | No | No | No | No | No | Yes | Yes | No | Yes | No |

| Belli et al (2013) | Yes | Yes | Yes | Yes | Yes | No | No | No | No | No | Yes | Yes | No | Yes | No |

| Lu et al (2012) | Yes | No | Yes | Yes | No | No | No | No | No | No | Yes | Yes | No | No | No |

| Tan et al (2012) | Yes | Yes | Yes | Yes | No | No | No | No | No | Yes | Yes | No | No | Yes | No |

| Rues et al (2010) | Yes | Yes | Yes | No | Yes | No | No | No | No | No | Yes | Yes | Yes | Yes | No |

| Taskonak et al (2008) | Yes | Yes | Yes | No | Yes | No | No | No | No | No | Yes | Yes | No | Yes | No |

1) Structured summary of trial design, methods, results and conclusions, 2a) Scientific background and explanation of rationale, 2b) Specific objectives and/or hypothesis, 3) The intervention of each group, including how and when it was administered, with sufficient detail to enable replication, 4) Completely defined, pre-specified primary and secondary measured of outcome, including how and when they were assessed, 5) How the sample size was determined, 6) Method used to generate the random allocation sequence, 7) Mechanism used to implement the random allocation sequence, 8) who generated the random allocation, 9) Who was blinded after assignment to intervention, 10) Statistical methods used to compare groups, 11) Results for each group and estimated size of effect and its precision, 12) Trial limitations, addressing sources of potential bias, imprecision, and, if relevant multiplicity of analysis, 13) Sources of funding and other support, 14) Where to full trial protocol can be accessed.31

3.3. Data analyses

Data analyses were performed qualitatively (descriptive summary) and quantitatively (meta-analyses), when appropriate, for each of the following treatments topics.

3.3.1. Cooling rate

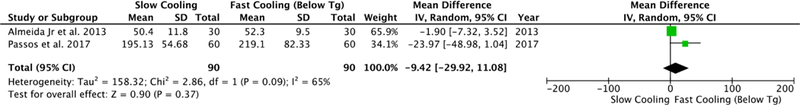

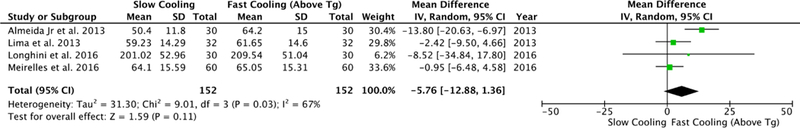

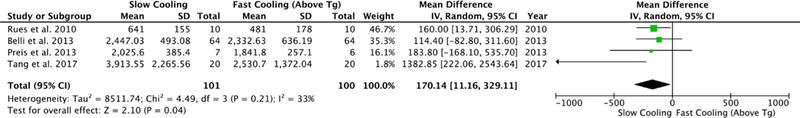

Figure 1 shows the forest plot of the meta-analysis comprising 2 studies 34,37 with high heterogeneity (65%), comparing the fast cooling from below versus slow cooling effect on PVZ flexural strength. As a result, no statistical difference was observed (P = 0.37) between cooling rates. A meta-analysis assessing the influence of fast cooling from above versus slow cooling on flexural strength was carried out including 3 studies (Figure 2).22,23,37 Heterogeneity was also considered high (61%) and no statistical difference was detected (P = 0.08). However, when the fast cooling from above versus slow cooling effect on critical load to failure of PVZ crowns was investigated, the results of the meta-analysis involving 4 studies with low heterogeneity (33%)13,35,38,39 showed that slow cooling yielded higher values of critical load to failure (P = 0.04) (Figure 3).

Figure 2.

Forest plot for flexural strength analysis of fast cooling (below Tg) versus slow cooling.

Figure 3.

Forest plot for flexural strength analysis of fast cooling (above Tg) versus slow cooling.

Paula et al.36 investigated the influence of cooling rates on mechanical behavior of bilayer systems reporting only the number of cycles until failure. Thus, could not be included in meta-analyses, being only descriptively analyzed. The authors investigated the influence of fast cooling from above and slow cooling rates on the survival of crown-shaped PVZ specimens. Their results showed that none of the fast cooled crowns survived 106 cycles, whereas all slow cooled crowns survived until the end of the test (106 cycles).

Another included study that was only descriptively analyzed was Meirelles et al.24, which evaluated the effect of cooling regiments on flexural strength of different porcelains on bilayer samples. The slow cooling protocol adopted in this study is actually identical to the fast cooling from below, in which the samples were immediately removed from the furnace once the firing cycle ended. The comparison group was fast cooling from above. The authors observed that the cooling protocols had no influence on flexural strength of the bar-shaped PVZ specimens.

3.3.2. Number of firings

As only two methodologically distinct studies evaluated number of veneer firings, no meta-analyses could be performed. Vichi et al (2015)27 observed that 2 and 5 veneering firings led to higher values of flexural strength [78 (13) MPa, and 78 (12) MPa, respectively] than only one firing cycle [52 (9) MPa], when tested with the porcelain veneer in tension. Lu et al (2011)26 tested 2, 4, 6, 8 firing cycles and did not find any statistical difference among flexural strength means [996 (145) MPa, 999 (120) MPa, 1019 (51) MPa, and 1008 (103) MPa, respectively], tested with the zirconia layer in tension.

3.3.3. Glaze and annealing

Only one included study compared groups with or without glaze firing.25 The authors described that the load to failure of the polished and glazed group (389 ±202 N) was significantly greater than the polished-only group (301 ±199 N).

No included study evaluated annealing treatments, however Taskonak et al.28 tested extended firing cycles comprising a 60 min holding time stage in different temperatures around the, followed by slow or fast cooling. The authors reported that the treatments at or above the followed by fast cooling resulted in higher flexural strength, compared to extended slow cooling to room temperature.

4. Discussion

The results of this systematic review showed that thermal treatments can influence flexural strength and critical load to failure of PVZ restorations. Most of included studies evaluated cooling protocols, which allowed us to perform three meta-analyses. For complex geometry samples (crowns), the cooling protocol significantly affected the critical load to failure of PVZ. However, when simple geometry samples (bars or discs) were used, no difference in fracture resistance was detected between different cooling regimens. Self-glaze and repeated veneer firings appeared to increase the mechanical strength of veneered systems based on the few studies available. However, this effect could only be descriptively analyzed, thus any inferences should be taken with caution.

A critical aspect regarding pooling data from various or multiple cooling rate studies is that there is no clear definition of what is considered slow cooling, since a large variety of protocols were used among the included studies (Table 1). Similarly, fast cooling regimens also vary among studies. Studies were classified into those where specimens were fast cooled from a temperature above the porcelain or from below, considering that the veneer porcelain behave completely different on each stage.40 Glassy materials are viscous liquids above, and fast cooling them from above this point means that structural contraction may lead to residual stress locked inside the material during the process.13 In contrast, retarding fast cooling of PVZ restorations from temperatures below the may impede the deleterious temperature gradients. Thus, avoiding the development of transient and residual stresses, which could weaken the ceramic material.21 These observations are in agreement with the results of our meta-analysis, indicating that flexural strength is not affected by cooling rate when the rapid cooling stage is performed from below. One should notice, though, that this meta-analysis pooled data from studies that used simple geometry specimens for the precise calculation of flexural strength. Finite element analysis (FEA) studies reported that cooling down restorations from 50˚C below is enough to decrease residual stresses and avoid thermal gradients;42 and that an overextended cooling protocol (closed furnace until 25˚C at 2˚C/min), besides time consuming, added more tensile and compressive residual stresses throughout the porcelain layer, compared to a more reasonable slow cooling regimen (closed furnace until 450˚C). 41

Our two meta-analyses comparing fast cooling from above versus slow cooling, for flexural strength (Fig. 2) and critical load to failure (Fig. 3), presented contradictory results. The studies evaluating flexural strength use simple geometry specimens, in which case no differences between the two cooling rates were observed. Nonetheless, when crown-shaped specimens were used and the critical load to failure was recorded, slow cooling yielded superior results. In addition to the geometric differences, bar and disc specimens (in the flexural strength analysis) had porcelain veneer thickness of 0.5 – 1.0 mm; while, the crown specimens (in the critical load to failure analysis) had 1.5 – 2.0 mm thick porcelain veneers. Benetti et al.21, using FEA, observed that when porcelain layer increases from 1 to 2 mm, thermal stresses gradients increase throughout the veneer. The authors also observed that the fast cooling (furnace opening at 800˚C – above) led to high levels of transient tensions, which were associated to internal microcracks and, consequently, early failures. Moreover, previous studies have observed distinct residual stresses in curved areas of PVZ crowns,41–43 especially when fast cooling was applied.43 Thus, it is plausible that the difference in residual stress distributions due to different geometries and thicknesses led to the contradictory meta-analyses results regarding flexural strength and critical load to failure.

The only two included studies that evaluated number of firings in PVZ indicate that two veneer firings may improve the flexural strength of the bilayer specimens, while no further improvement is seen when more than two firings are applied. However, these results must be interpreted with cautions, since one test was performed with porcelain in tension27 and the other one with zirconia in tension.26 Such contrast resulted in extremely different flexural strength values between the two papers, since the mechanical properties of the specimens are determined by the material under tension.44 The study of Tang et al.46, which is not included in this systematic review, also did not observe differences in the flexural strength of most monolithic veneering ceramics when fired for 2 up to 10 times. Nonetheless, other studies evaluating monolithic porcelain specimens, observed that increasing number of firings can improve hardness, density, and decrease porosity.45,46

Among the included studies, only one evaluated the effect of glaze firing on bilayer specimens.25 The experimental groups included one that was just polished and another polished and self-glazed, which presented higher flexural strength. Self-glaze is technically convenient since it does not require the application of additional glazing material. This heat treatment aims to expose a glass-based material to temperatures at or above the for 1 – 2 min in order to promote a superficial melting, improving gloss and healing surface deffects.47 Previous literature is controversial, showing that self-glaze can either improve48 or decrease49 the flexural strength of monolithic porcelains, showing a lack of evidence regarding the effect of self- or over- glaze in mechanical properties of porcelains for bilayer systems.

Regarding annealing, not one study evaluating this heat treatment on PVZ met the inclusion criteria of this systematic review. Previous investigations have shown that annealing can promote crack healing50 and improve flexural strength51 of glassy ceramics. Nevertheless, annealing is very time consuming, firstly, the glassy material is heated and kept at a temperature above for a given time, usually 10 h, to allow for atomic rearrangement; then, the material is slowly cooled in order to prevent new residual stresses.40 The time issue is a practical disadvantage of annealing, which seems to discourage researchers to evaluate its effects on bilayer systems. Nonetheless, Taskonak et al.28 studied extended firings at different temperatures around the as an alternative thermal treatment. The authors tested four different additional firing cycles at temperatures below, at, and above porcelain, followed by slow or fast cooling. They observed higher flexural strength for the groups treated at or above then fast cooled. This may be associated with an atomic rearrangement, which only happens in temperatures above, when the glass viscosity decreases.40 Nonetheless, one should note that the authors compared fast cooling with an overextended slow cooling regimen (down to room temperature, taking around 600 min). An aforementioned FEA study41 showed that overextended slow cooling below is deleterious even for flat specimens.

Most papers in the literature do not clearly report the details of their methodological approaches. Similar shortcomings were also observed in the included studies (Table 3). Similarly, previous systematic reviews of in vitro studies also found only a few papers with low risk of bias,52,53 which demonstrates that poor methodological report is a common problem.54 Furthermore, most of the included studies tested cooling rates, while only very few, if any, investigated other thermal treatments. Thus, it was not possible to reach substantial conclusions on other treatments, such as glazing, annealing, and number of veneer firings. Another limitation relies on the heterogeneity of included studies, specially the lack of consensus about what is a slow or a fast cooling protocol. Interestingly, some manufacturers already recommend, for all firing cycles, that the furnace should only be opened below the porcelain, which is in agreement with the findings of our systematic review. However, other manufacturers still disregard the deleterious effects of residual thermal stresses and recommend fast cooling from sintering temperature or any other firings (Table 2). In all included studies, compatible porcelains were used to veneer zirconia substructures, as recommended by the dental ceramic manufacturers (Table 2). Nonetheless, it is known that even small mismatches in CTE, along with the elastic properties of the porcelain, can affect the magnitude, location and type of residual stresses.14 Moreover, other variables such as porcelain/zirconia thickness ratio23,35 and the indenter used for load application55,56 may also affect the results. Therefore, the high heterogeneity observed in our meta-analyses, may also be explained by the pooling of data including distinct porcelain/zirconia combinations and test configurations.

Despite all the methodological differences among the studies (Table 1), our results showed that fast cooling PVZ from temperatures above the porcelain has deleterious effect on its critical load to failure for complex geometries -- crowns. However, delaying furnace opening to temperatures below the, seems to be enough to preserve the material’s mechanical behavior. In addition, the geometry of specimens for in vitro investigations of thermal stresses should be considered, since it seems to affect the mechanical response of veneered zirconia systems.

5. Conclusions

The systematic investigation of the literature has led to the recommendation to delay the furnace opening at a temperature below the porcelain glass transition temperature for porcelain-veneered zirconia restorations. This procedure improves the fracture resistance of the restoration, while fast cooling from temperatures above the porcelain glass transition temperature leads to a decrease in their critical load to failure. More studies are required to confirm the seemingly positive effect of self-glaze and repeated firings on the mechanical properties of these restorations. Nonetheless, future studies should concentrate on anatomically-correct crown specimens in order to obtain conclusive and relevant evidence regarding thermal treatments and the fracture resistance of PVZs.

Figure 4.

Forest plot for critical load to failure analysis of fast cooling (above Tg) versus slow cooling.

6. Acknowledgments

The authors are thankful to the Federal Agency for Support and Evaluation of Graduate Education (CAPES) (finance code 001) by the PhD scholarship.

References

- 1.Manicone PF, Rossi Iommetti P, Raffaelli L. An overview of zirconia ceramics: basic properties and clinical applications. J Dent. 2007. November;35(11):819–26. [DOI] [PubMed] [Google Scholar]

- 2.Larsson C, Wennerberg A. The clinical success of zirconia-based crowns: a systematic review. Int J Prosthodont. 2014. Jan-Feb;27(1):33–43. [DOI] [PubMed] [Google Scholar]

- 3.Chaar MS, Kern M. Five-year clinical outcome of posterior zirconia ceramic inlay-retained FDPs with a modified design. J Dent. 2015. December;43(12):1411–5. [DOI] [PubMed] [Google Scholar]

- 4.Raigrodski AJ, Yu A, Chiche GJ, Hochstedler JL, Mancl LA, Mohamed SE. Clinical efficacy of veneered zirconium dioxide-based posterior partial fixed dental prostheses: five-year results. J Prosthet Dent. 2012. October;108(4):214–22. [DOI] [PubMed] [Google Scholar]

- 5.Dhima M, Paulusova V, Carr AB, Rieck KL, Lohse C, Salinas TJ. Practice-based clinical evaluation of ceramic single crowns after at least five years. Prosthet Dent. 2014. February;111(2):124–30. [DOI] [PubMed] [Google Scholar]

- 6.Gherlone E, Mandelli F, Capparè P, Pantaleo G, Traini T, Ferrini F. A 3 years retrospective study of survival for zirconia-based single crowns fabricated from intraoral digital impressions. J Dent. 2014. September;42(9):1151–5. [DOI] [PubMed] [Google Scholar]

- 7.Nicolaisen MH, Bahrami G, Schropp L, Isidor F. Comparison of Metal-Ceramic and All-Ceramic Three-Unit Posterior Fixed Dental Prostheses: A 3-Year Randomized Clinical Trial. Int J Prosthodont. 2016. May-Jun;29(3):259–64. [DOI] [PubMed] [Google Scholar]

- 8.Benetti P, Pelogia F, Valandro LF, Bottino MA, Della Bona A. The effect of porcelain thickness and surface liner application on the fracture behavior of a ceramic system. Dent Mater. 2011. September;27(9):948–53. [DOI] [PubMed] [Google Scholar]

- 9.Swain MV . Unstable cracking (chipping) of veneering porcelain on all-ceramic dental crowns and fixed partial dentures. Acta Biomater. 2009. June;5(5):1668–77. [DOI] [PubMed] [Google Scholar]

- 10.Kokubo Y, Tsumita M, Kano T, Fukushima S. The influence of zirconia coping designs on the fracture load of all-ceramic molar crowns. Dent Mater J. 2011;30(3):281–5. [DOI] [PubMed] [Google Scholar]

- 11.Bonfante EA, Rafferty B, Zavanelli RA, Silva NR, Rekow ED, Thompson VP, Coelho PG. Thermal/mechanical simulation and laboratory fatigue testing of an alternative yttria tetragonal zirconia polycrystal core-veneer all-ceramic layered crown design. Eur J Oral Sci. 2010. April;118(2):202–9. [DOI] [PubMed] [Google Scholar]

- 12.Shirakura A, Lee H, Geminiani A, Ercoli C, Feng C. The influence of veneering porcelain thickness of all-ceramic and metal ceramic crowns on failure resistance after cyclic loading. J Prosthet Dent. 2009. February;101(2):119–27. [DOI] [PubMed] [Google Scholar]

- 13.Belli R, Frankenberger R, Appelt A, Schmitt J, Baratieri LN, Greil P, Lohbauer U. Thermal-induced residual stresses affect the lifetime of zirconia-veneer crowns. Dent Mater. 2013. February;29(2):181–90. [DOI] [PubMed] [Google Scholar]

- 14.Kim J, Dhital S, Zhivago P, Kaizer MR, Zhang Y. Viscoelastic finite element analysis of residual stresses in porcelain-veneered zirconia dental crowns. J Mech Behav Biomed Mater. 2018. June;82:202–209. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Quinn JB, Quinn GD, Sundar V. Fracture Toughness of Veneering Ceramics for Fused to Metal (PFM) and Zirconia Dental Restorative Materials. J Res Natl Inst Stand Technol. 2010. Sep-Oct;115(5):343–352. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Cheung KC, Darvell BW. Sintering of dental porcelain: effect of time and temperature on appearance and porosity. Dent Mater. 2002. March;18(2):163–73. [DOI] [PubMed] [Google Scholar]

- 17.Mainjot AK, Schajer GS, Vanheusden AJ, Sadoun MJ. Residual stress measurement in veneering ceramic by hole-drilling. Dent Mater. 2011. May;27(5):439–44. [DOI] [PubMed] [Google Scholar]

- 18.Baldassarri M1, Stappert CF, Wolff MS, Thompson VP, Zhang Y Residual stresses in porcelain-veneered zirconia prostheses. Dent Mater. 2012. August;28(8):873–9. doi: 10.1016/j.dental.2012.04.019. Epub 2012 May 11. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Tholey MJ1, Swain MV, Thiel N Thermal gradients and residual stresses in veneered Y-TZP frameworks. Dent Mater. 2011. November;27(11):1102–10. [DOI] [PubMed] [Google Scholar]

- 20.Wendler M, Belli R, Petschelt A, Lohbauer U. Characterization of residual stresses in zirconia veneered bilayers assessed via sharp and blunt indentation. Dent Mater. 2015. August;31(8):948–57. [DOI] [PubMed] [Google Scholar]

- 21.Benetti P, Kelly JR, Sanchez M, Della Bona A. Influence of thermal gradients on stress state of veneered restorations. Dent Mater. 2014. May;30(5):554–63. [DOI] [PubMed] [Google Scholar]

- 22.Longhini D, Rocha CO, Medeiros IS, Fonseca RG, Adabo GL. Effect of Glaze Cooling Rate on Mechanical Properties of Conventional and Pressed Porcelain on Zirconia. Braz Dent J. 2016. Sep-Oct;27(5):524–531. [DOI] [PubMed] [Google Scholar]

- 23.Lima JM, Souza AC, Anami LC, Bottino MA, Melo RM, Souza RO. Effects of thickness, processing technique, and cooling rate protocol on the flexural strength of a bilayer ceramic system. Dent Mater. 2013. October;29(10):1063–72. [DOI] [PubMed] [Google Scholar]

- 24.Meirelles PD, Spigolon YO, Borba M, Benetti P. Leucite and cooling rate effect on porcelain-zirconia mechanical behavior. Dent Mater. 2016. December;32(12):e382–e388. [DOI] [PubMed] [Google Scholar]

- 25.Schmitter M, Lotze G, Bömicke W, Rues S. Influence of surface treatment on the in-vitro fracture resistance of zirconia-based all-ceramic anterior crowns. Dent Mater. 2015. December;31(12):1552–60. [DOI] [PubMed] [Google Scholar]

- 26.Lu RJ, Ma TT, Yi YF, Shao LQ, Tian JM, Hou KL, Wen N, Deng B. Influence of Multiple Firing on the Bending Strength of Zirconia/Porcelain Bilayered Dental Ceramics. Key Engineering Materials. 2012. September;492(9):24–29. [Google Scholar]

- 27.Vichi A, Sedda M, Bonadeo G, Bosco M, Barbiera A, Tsintsadze N, Carrabba M, Ferrari M. Effect of repeated firings on flexural strength of veneered zirconia. Dent Mater. 2015. August;31(8):e151–6. [DOI] [PubMed] [Google Scholar]

- 28.Taskonak B, Borges GA, Mecholsky JJ Jr, Anusavice KJ, Moore BK, Yan J. The effects of viscoelastic parameters on residual stress development in a zirconia/glass bilayer dental ceramic. Dent Mater. 2008. September;24(9):1149–55. [DOI] [PubMed] [Google Scholar]

- 29.Queiroz JR, Benetti P, Massi M, Junior LN, Della Bona A. Effect of multiple firing and silica deposition on the zirconia-porcelain interfacial bond strength. Dent Mater. 2012. July;28(7):763–8. [DOI] [PubMed] [Google Scholar]

- 30.Griggs JA, Thompson JY, Anusavice KJ. Effects of flaw size and auto-glaze treatment on porcelain strength. J Dent Res. 1996. June;75(6):1414–7. [DOI] [PubMed] [Google Scholar]

- 31.Moher D, Liberati A, Tetzlaff J, Altman DG, Prisma T. Preferred reporting items for systematic reviews and meta-analyses: the PRISMA statement. Int J Surg 2010;8:336–41. [DOI] [PubMed] [Google Scholar]

- 32.Faggion CM Jr. Guidelines for reporting pre-clinical in vitro studies on dental materials. Evid Based Dent Pract. 2012. December;12(4):182–9. [DOI] [PubMed] [Google Scholar]

- 33.Higgins J, Green S, eds. Cochrane handbook for systematic reviews of interventions version 5.1.0 [updated March 2011]. The Cochrane Collaboration, 2011. Available at: http://handbook.cochrane.org. Accessed August 10, 2017. [Google Scholar]

- 34.Passos SP, Linke B, Major PW, Nychka JA. Improving the compatibility of an Y-TZP/porcelain system using a new composite interlayer composition. J Mech Behav Biomed Mater. 2017. January;65:11–19. [DOI] [PubMed] [Google Scholar]

- 35.Tang YL, Kim JH, Shim JS, Kim S. The effect of different cooling rates and coping thicknesses on the failure load of zirconia-ceramic crowns after fatigue loading. J Adv Prosthodont. 2017. June;9(3):152–158. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Paula VG, Lorenzoni FC, Bonfante EA, Silva NR, Thompson VP, Bonfante G. Slow cooling protocol improves fatigue life of zirconia crowns. 2015 Dent Mater. 2015. February;31(2):77–87. [DOI] [PubMed] [Google Scholar]

- 37.Almeida Junior AA, Longhini D, Domingues NB, Santos C, Adabo GL. Effects of extreme cooling methods on mechanical properties and shear bond strength of bilayered porcelain/3Y-TZP specimens. J Dent. 2013. April;41(4):356–62. [DOI] [PubMed] [Google Scholar]

- 38.Preis V, Letsch C, Handel G, Behr M, Schneider-Feyrer S, Rosentritt M. Influence of substructure design, veneer application technique, and firing regime on the in vitro performance of molar zirconia crowns. Dent Mater. 2013. July;29(7):e113–21. [DOI] [PubMed] [Google Scholar]

- 39.Rues S, Kröger E, Müller D, Schmitter M. Effect of firing protocols on cohesive failure of all-ceramic crowns. Dent. 2010. December;38(12):987–94. [DOI] [PubMed] [Google Scholar]

- 40.Callister WD, Rethwisch DG. Materials science and engineering: an introduction. 8th ed New Jersey: John Wiley and Son, 2009. [Google Scholar]

- 41.Tanaka CB, Harisha H, Baldassarri M, Wolff MS, Tong H, Meira JB, Zhang Y. Experimental and finite element study of residual thermal stresses in veneered Y-TZP structures. Ceram Int. 2016. May 15;42(7):9214–9221. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Belli R, Monteiro S Jr, Baratieri LN, Katte H, Petschelt A, Lohbauer U. A photoelastic assessment of residual stresses in zirconia-veneer crowns. J Dent Res. 2012. March;91(3):316–20. [DOI] [PubMed] [Google Scholar]

- 43.Meira JB, Reis BR, Tanaka CB, Ballester RY, Cesar PF, Versluis A, Swain MV. Residual stresses in Y-TZP crowns due to changes in the thermal contraction coefficient of veneers. Dent Mater. 2013. May;29(5):594–601. [DOI] [PubMed] [Google Scholar]

- 44.Borba M, de Araújo MD, de Lima E, Yoshimura HN, Cesar PF, Griggs JA, Della Bona A. Flexural strength and failure modes of layered ceramic structures. Dent Mater. 2011. December;27(12):1259–66. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 45.Alkurt M, Yeşil Duymus Z, Gundogdu M. Effects of multiple firings on the microstructure of zirconia and veneering ceramics. Dent Mater J. 2016;35(5):776–781 [DOI] [PubMed] [Google Scholar]

- 46.Tang X, Nakamura T, Usami H, Wakabayashi K, Yatani H. Effects of multiple firings on the mechanical properties and microstructure of veneering ceramics for zirconia frameworks. J Dent. 2012. May;40(5):372–80. [DOI] [PubMed] [Google Scholar]

- 47.Yilmaz K, Ozkan P. The methods for the generation of smoothness in dental ceramics. Compend Contin Educ Dent. 2010. Jan-Feb;31(1):30–41. [PubMed] [Google Scholar]

- 48.De Jager N, Feilzer AJ, Davidson CL. The influence of surface roughness on porcelain strength. Dent Mater. 2000. November;16(6):381–8. [DOI] [PubMed] [Google Scholar]

- 49.Fairhurst CW, Lockwood PE, Ringle RD, Thompson WO. The effect of glaze on porcelain strength. Dent Mater. 1992. May;8(3):203–7. [DOI] [PubMed] [Google Scholar]

- 50.Denry IL1, Holloway JA, Tarr LA. Effect of heat treatment on microcrack healing behavior of a machinable dental ceramic. J Biomed Mater Res. 1999;48(6):791–6. [DOI] [PubMed] [Google Scholar]

- 51.Fischer H, Hemelik M, Telle R, Marx R. Influence of annealing temperature on the strength of dental glass ceramic materials. Dent Mater. 2005. July;21(7):671–7. [DOI] [PubMed] [Google Scholar]

- 52.Marchionatti AME, Aurélio IL, May LG. Does veneering technique affect the flexural strength or load-to-failure of bilayer Y-TZP? A systematic review and meta-analysis. J Prosthet Dent. 2018 [DOI] [PubMed] [Google Scholar]

- 53.Aurélio IL, Marchionatti AM, Montagner AF, May LG, Soares FZ. Does air particle abrasion affect the flexural strength and phase transformation of Y-TZP? A systematic review and meta-analysis.Dent Mater. 2016. June;32(6):827–45. [DOI] [PubMed] [Google Scholar]

- 54.Dechartres A, Trinquart L, Atal I, Moher D, Dickersin K, Boutron I, et al. Evolution of poor reporting and inadequate methods over time in 20920 randomised controlled trials included in Cochrane reviews: research on research study. BMJ 2017;357:j2490. [DOI] [PubMed] [Google Scholar]

- 55.Yi YJ, Kelly JR. Effect of occlusal contact size on interfacial stresses and failure of a bonded ceramic: FEA and monotonic loading analyses. Dent Mater. 2008. March;24(3):403–9. [DOI] [PubMed] [Google Scholar]

- 56.Kelly JR. Clinically relevant approach to failure testing of all-ceramic restorations. J Prosthet Dent. 1999. June;81(6):652–61. [DOI] [PubMed] [Google Scholar]

- 57.Sawada T, Schille C, Wagner V, Spintzyk S, Schweizer E, Geis-Gerstorfer J. Biaxial flexural strength of the bilayered disk composed of ceria-stabilized zirconia/alumina nanocomposite (Ce-TZP/A) and veneering porcelain. Dent Mater. 2018;34(8):1199–1210. doi: 10.1016/j.dental.2018.05.003. [DOI] [PubMed] [Google Scholar]

- 58.Choi JE, Waddell JN, Torr B, Swain MV. Pressed ceramics onto zirconia. Part 1: Comparison of crystalline phases present, adhesion to a zirconia system and flexural strength. Dent Mater. 2011;27(12):1204–12. doi: 10.1016/j.dental.2011.08.006. [DOI] [PubMed] [Google Scholar]