Bacillus subtilis utilizes different polysaccharides produced by plants. These carbohydrates are primarily degraded by extracellular hydrolases, and the resulting oligo-, di-, and monosaccharides are transported into the cytosol via phosphoenolpyruvate-dependent phosphotransferase systems (PTS), major facilitator superfamily, and ATP-binding cassette (ABC) transporters. In this study, a new carbohydrate utilization system of B. subtilis responsible for the utilization of α-galactosides of the raffinose family of oligosaccharides (RFOs) was investigated. RFOs are synthesized from sucrose in plants and are mainly found in the storage organs of plant leaves. Our results revealed the modus operandi of a new carbohydrate utilization system in B. subtilis.

KEYWORDS: α-galactosidase, α-galactosides, ABC transporter, carbohydrate, melibiase, melibiose, repressor, sugar-binding lipoprotein

ABSTRACT

Bacillus subtilis is a heterotrophic soil bacterium that hydrolyzes different polysaccharides mainly found in the decomposed plants. These carbohydrates are mainly cellulose, hemicellulose, and the raffinose family of oligosaccharides (RFOs). RFOs are soluble α-galactosides, such as raffinose, stachyose, and verbascose, that rank second only after sucrose in abundance. Genome sequencing and transcriptome analysis of B. subtilis indicated the presence of a putative α-galactosidase-encoding gene (melA) located in the msmRE-amyDC-melA operon. Characterization of the MelA protein showed that it is a strictly Mn2+- and NAD+-dependent α-galactosidase able to hydrolyze melibiose, raffinose, and stachyose. Transcription of the msmER-amyDC-melA operon is under control of a σA-type promoter located upstream of msmR (PmsmR), which is negatively regulated by MsmR. The activity of PmsmR was induced in the presence of melibiose and raffinose. MsmR is a transcriptional repressor that binds to two binding sites at PmsmR located upstream of the −35 box and downstream of the transcriptional start site. MsmEX-AmyCD forms an ATP-binding cassette (ABC) transporter that probably transports melibiose into the cell. Since msmRE-amyDC-melA is a melibiose utilization system, we renamed the operon melREDCA.

IMPORTANCE Bacillus subtilis utilizes different polysaccharides produced by plants. These carbohydrates are primarily degraded by extracellular hydrolases, and the resulting oligo-, di-, and monosaccharides are transported into the cytosol via phosphoenolpyruvate-dependent phosphotransferase systems (PTS), major facilitator superfamily, and ATP-binding cassette (ABC) transporters. In this study, a new carbohydrate utilization system of B. subtilis responsible for the utilization of α-galactosides of the raffinose family of oligosaccharides (RFOs) was investigated. RFOs are synthesized from sucrose in plants and are mainly found in the storage organs of plant leaves. Our results revealed the modus operandi of a new carbohydrate utilization system in B. subtilis.

INTRODUCTION

Bacillus subtilis is a soil bacterium found in the rhizosphere of many plants. Because of such a habitat, B. subtilis can utilize a variety of poly- and oligosaccharides present in the rhizosphere as a major carbon source and therefore has different systems for the utilization of poly-, oligo-, and monosaccharides synthesized by plants. The polysaccharides are primarily degraded to oligosaccharides with shorter chain lengths and to monosaccharides by extracellular enzymes such as α-amylase, pullulanase, or xylanase. The generated oligosaccharides and monosaccharides can be then taken up via the carbohydrate-specific transporters of the phosphoenolpyruvate-dependent phosphotransferase system (PTS), ATP-binding cassette (ABC) transporters, and the major facilitator superfamily (uniporters, symporters, and antiporters) (1, 2). Depending on the transport system, the carbohydrates are phosphorylated during (for PTS) and after (for non-PTS) the transport and usually converted to one of the intermediates of the glycolysis or pentose phosphate pathway (3, 4). Carbohydrate utilization genes can form operons consisting of genes encoding extracellular and/or intracellular degradation enzymes, the transporter components, and a specific regulator. The function of these specific regulators can be altered due to the binding of sugar ligands as seen in the ABC transport systems, such as it is in the maltodextrin and galactan utilization systems (5, 6), or as a result of the phosphorylation state of specific regulators in an interaction with the specific transporter as for the PTSs (5–7). All these systems are catabolically repressed in the presence of glucose (or other PTS sugars) via the global CcpA-dependent pathway (CcpA is the carbon catabolite protein) or via more specific pathways, such as inducer exclusion (8, 9).

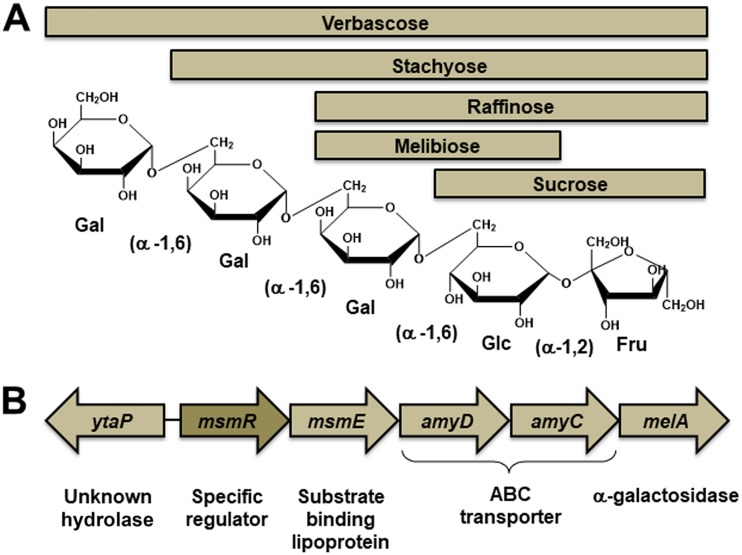

Among all carbohydrates, oligosaccharides of the raffinose family (RFOs) are ubiquitous among the plants. These soluble carbohydrates rank second in abundance, only after sucrose (10). RFOs, such as raffinose, stachyose, and verbascose (Fig. 1A), are in fact the α-galactosyl derivatives of sucrose (the major product of photosynthesis) and are synthesized in a reaction catalyzed by galactosyl transferase using sucrose and galactinol (galactose bound to myo-inositol) as the substrate (11). Therefore, RFOs and melibiose contain terminal α-galactosyl residues that are cleaved by α-galactosidases. Several bacteria, such as Escherichia coli (12, 13), Erwinia chrysanthemi (14), and different lactobacilli (15), are able to utilize RFOs or melibiose as their carbon source. The genome of B. subtilis also contains a gene for an α-d-galactoside galactohydrolase, also known as melibiase (16, 17), which is possibly involved in degradation of the RFOs, such as raffinose and melibiose (18). The melA gene is the last gene of the msmRE-amyDC-melA operon (or melibiose operon) (Fig. 1B) (19). In this study, we characterized the functions of the components of the melibiose utilization system of B. subtilis. MelA was shown to have α-galactosidase activity on the substrates transported by the ABC transport system. Also, the regulation of the system by a specific regulator (MsmR) was addressed, and the promoter region of the operon was characterized.

FIG 1.

(A) Chemical structure of melibiose and the raffinose family of oligosaccharides (RFOs). Galactose (Gal) moieties are α-1,6 linked to Gal or glucose (Glc). Sucrose consists of Glc that is α-1,2 linked to fructose (Fru). (B) The genetic map of the utilization system of melibiose and RFOs in B. subtilis.

RESULTS

MelA is an α-galactosidase able to hydrolyze melibiose and RFOs.

The melibiose operon was predicted to encode the components of an α-galactosidic oligosaccharide utilization system in B. subtilis (1). Therefore, the first step toward understanding the utilization of α-galactosidic oligosaccharides by B. subtilis was to show the α-galactosidase activity of MelA. MelA belongs to the glycosyl hydrolase 4 (GH4) family, the members of which are known to require NAD+, Mn2+, and reducing agents for their optimal activity (20, 21). In order to measure the MelA activity, melA coding for a protein with an N-terminal Strep-tag was overexpressed by using the l-rhamnose-inducible promoter (rhaPBAD) in Escherichia coli (strain JM109/pHWG1118). The preliminary studies using 4-nitrophenyl-α-d-galactopyranoside (pNP-α-Gal) as the substrate indicated that the highest α-galactosidase activity was obtained with Mn2+ (3 mM), NAD+ (10 mM), and Tris(2-carboxyethyl)phosphine (TCEP) (1 mM) at pH 8 and 55°C (see Table S4 in the supplemental material). Under these optimal assay conditions, MelA was able to hydrolyze melibiose, raffinose, and stachyose (Table 1), whereas locust bean gum (a polymeric galactomannan) was not hydrolyzed (data not shown). Among all substrates, the highest specific activity of MelA was obtained with melibiose (Table 1). The Km values for the hydrolysis of melibiose and raffinose were 10 and 25 mM, respectively (Table 1). Altogether, this result confirmed the connection between the msmRE-amyDC-melA operon and α-galactoside utilization. To better understand this utilization system, the regulation of the operon was further studied.

TABLE 1.

α-Galactosidase activity of purified MelA with different substratesa

| Substrate | Sp act (U/mg) | Km (mM)b |

|---|---|---|

| pNP-αGal | 2.9 | ND |

| Melibiose | 4.8 | 10 |

| Raffinose | 3.3 | 25 |

| Stachyose | 1.5 | ND |

α-Galactosidase activity was measured in a buffer containing 0.1 M Tris-HCl (pH 8), 1 mM NAD+, 3 mM Mn2+, and 1 mM Tris(2-carboxyethyl)phosphine (TCEP). The reactions were carried out at 37°C and pH 8, as described in Materials and Methods.

ND, not determined.

MsmR represses the melibiose operon in the absence of melibiose or raffinose.

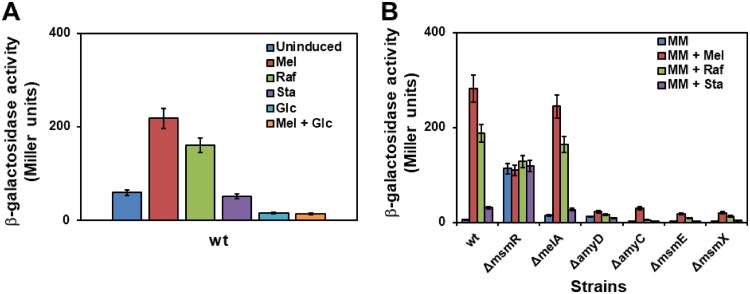

Transcriptome analysis of B. subtilis under different conditions (19) indicated that the melibiose operon has two transcription start sites, one located upstream of msmR (promoter PmsmR) and the other one located upstream of msmE (PmsmE). To verify the presence of two promoters controlling the expression of melibiose operon, the lacZ gene was used as a reporter. In detail, the PmsmR-lacZ and PmsmE-lacZ cassettes were constructed and integrated into the amyE locus of the wild-type B. subtilis KM0. The β-galactosidase activity of each strain was then measured in LB after the addition of melibiose, raffinose, and stachyose as the possible inducers. No or negligible β-galactosidase activity was detected with the PmsmE-lacZ fusion under all conditions (data not shown). This indicated that there is not a promoter in the intergenic region between msmR and msmE. This result contradicted the upshift of the msmE transcription reported by Nicolas et al. (19). Perhaps, another mechanism, such as mRNA endonucleolytic cleavage, as observed in the regulation of the cggR-gapA operon, is involved (22, 23). In contrast to PmsmE, melibiose and raffinose strongly induced PmsmR activity in the wild-type strain, while stachyose had no effect on PmsmR activity compared to the uninduced control (Fig. 2A). Likewise, the addition of glucose repressed the activity of PmsmR even in the presence of melibiose (Fig. 2A). This showed that the melibiose operon is transcribed under the control of PmsmR and subject to carbon catabolite repression.

FIG 2.

(A) Regulation of the melibiose operon in B. subtilis was measured by integration of the PmsmR-lacZ cassette (pKAM384) into the amyE locus of the wild-type strain (KM0). B. subtilis KM845 (wt) was cultured in LB, and the β-galactosidase activity was measured 1 h after the addition of carbohydrates (0.2%), melibiose (Mel), raffinose (Raf), stachyose (Sta), and glucose (Glc). (B) β-Galactosidase activity of B. subtilis strains KM845 (wt), KM861 (ΔmsmX), KM911 (ΔmsmR), KM912 (ΔamyD), KM913 (ΔamyC), and KM914 (ΔmelA) carrying the PmsmR-lacZ cassette was measured in minimal medium (MM) with succinate and glutamate as the basal carbon source. Melibiose, raffinose, and stachyose were added with a final concentration of 0.2% to the cultures, and the β-galactosidase activity was measured 4 h after the addition of carbohydrates.

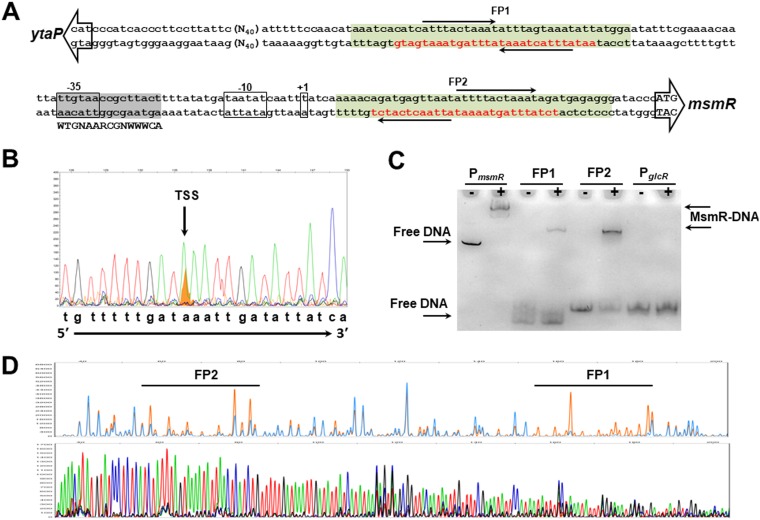

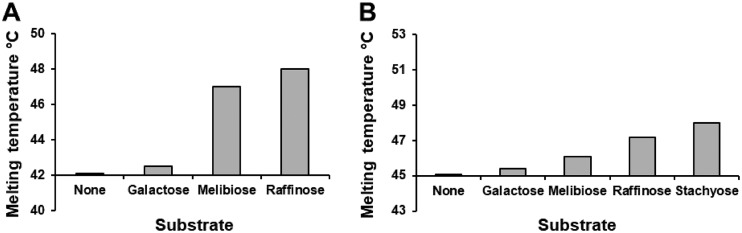

Given that melibiose and raffinose induced the activity of PmsmR, a specific regulation of PmsmR was further considered. The first gene of the melibiose operon encodes a putative transcriptional regulator, MsmR, which belongs to the LacI family of transcriptional regulators (24). The deletion of msmR in the wild-type strain resulted in KM911 and revealed a constitutive high activity of PmsmR under all conditions, showing that msmR had a negative regulatory effect on the expression of the melibiose operon (Fig. 2B). Next to the in vivo experiments with msmR-deficient strains, in vitro experiments were carried out with purified MsmR. In practice, the MsmR protein was produced by E. coli JM109 with plasmid pHWG1169, as described in Materials and Methods, and purified MsmR–Strep-tag protein was used for in vitro studies. In order to study the interaction between PmsmR and MsmR, the promoter elements of PmsmR were primarily identified (Fig. 3A). The transcription of msmR starts at a thymidine residue located 51 bp upstream of the start codon of MsmR (Fig. 3B). Accordingly, the −10 (TAATAT) and −35 (TTGTAA) boxes were found showing a σA-type (housekeeping sigma factor) promoter structure (Fig. 3A). Likewise, the presence of a catabolite responsive element (cre) site (25) within the spacer of PmsmR indicated the possibility of CcpA-dependent carbon catabolite repression of the melibiose operon similar to that in other carbohydrate utilization systems in B. subtilis (8, 26). The DNA fragment comprising the PmsmR region specifically interacted with purified MsmR compared to the control DNA fragment containing the PglcR region (Fig. 3C). DNase I footprinting revealed two MsmR binding sites at PmsmR (Fig. 3D) with the inverted repeat of ATTTACTAAAT (Fig. 3A). One of these MsmR binding sites is located upstream of the −35 box (FP1), whereas the other one was found downstream of the transcriptional start site (FP2) (Fig. 3A). An electrophoretic mobility shift assay confirmed the binding of MsmR to DNA fragments of the FP1 or FP2 inverted repeats (green boxes in Fig. 3C). To find the specific effector of MsmR, a thermal shift assay was carried out using purified MsmR and tested with different effectors, i.e., galactose, melibiose, and raffinose. The melting temperature of MsmR was elevated only in the presence of melibiose or raffinose (Fig. 4A). MsmR was, however, not dissociated from PmsmR DNA in the presence of raffinose or melibiose, as shown by the electrophoretic mobility shift assay (Fig. S1). This was similar to regulators such as MerR (27, 28) and GalR (29) in E. coli which remain bound to DNA even in the presence of their inducer. Altogether, these results indicated that MsmR represses the melibiose operon when there is no melibiose or raffinose as the inducer.

FIG 3.

Characterization of PmsmR. (A) The DNA sequence between msmR and ytaP start codons is shown. The open arrows show the start codons of ytaP and msmR. The core elements of PmsmR (−35 and −10 boxes) and the transcription start site of msmR are indicated with boxes. The protected regions of PmsmR DNA by MsmR from DNase I digestion (FP1 and FP2) are in red letters. The inverted repeats within the MsmR binding site are indicated by solid arrows. The putative cre site (gray highlighted) is also demonstrated. The green boxes show the DNA regions used for the electrophoretic mobility shift assay. (B) Identification of the transcription start site (TSS) of msmR was performed by primer extension. The migration of the generated cDNA fragment (orange) was compared with the sequencing reaction. (C) An electrophoretic mobility shift assay was carried out using 5′-end Cy5-labeled DNA fragments of PmsmR, the FP1 inverted repeat, and the FP2 inverted repeat. The amplified DNA fragment from the GlcR binding site was used as a negative control. The migration of the DNA fragment was investigated in the absence (−) or presence (+) of MsmR. (D) The chromatographs of the DNA footprinting and DNA sequencing reactions are separately shown. The 6-FAM-labeled PmsmR DNA was digested with DNase I in the absence (orange) or presence (blue) of 0.27 mM MsmR. The identified DNA footprints, FP1 and FP2, were then compared with the DNA sequencing reaction utilizing ddATP (green), ddGTP (black), ddCTP (blue), and ddTTP (red).

FIG 4.

Determination of substrate specificity of MsmR and MsmE by thermal shift assay. (A) Alteration of the melting temperature of purified MsmR–Strep-tag (concentration) in the absence of effectors was compared to the presence of galactose, melibiose, or raffinose with the final concentration of 10 mM. (B) Purified His6-MsmE was mixed with different effectors (10 mM), i.e., galactose, melibiose, raffinose, and stachyose, and its melting temperature was measured.

MsmEX-AmyCD forms the probable transporter of melibiose.

The melibiose operon encodes the components of a predicted ABC transport system, i.e., AmyC, AmyD, and MsmE, in addition to the intracellular α-galactosidase MelA. Among these proteins, MsmE was predicted to be a sugar-binding lipoprotein, which probably forms an ABC transporter together with the transmembrane proteins AmyC and AmyD (4). To confirm the function of these proteins, in vivo experiments with the different mutants of B. subtilis strains lacking msmE, amyC, or amyD were carried out, and β-galactosidase measurements were performed to investigate the inducibility of the PmsmR-lacZ cassette in the mutants lacking amyC, amyD, or msmE genes. The deletion of all these genes rendered PmsmR uninducible in the presence of melibiose and raffinose, confirming their probable function as an α-galactoside transport system (Fig. 2B). Nevertheless, an important missing piece of the melibiose transport puzzle was the nucleotide-binding domain. Previous studies of the carbohydrate transport systems showed that MsmX acts as the nucleotide binding domain of different carbohydrate ABC transporters (6, 30). Also here, the deletion of msmX resulted in the loss of inducibility of PmsmR by melibiose, showing that MsmX hydrolyzes ATP as the nucleotide binding domain for the transport of α-galactosides (Fig. 2B). The substrate specificity of the MsmEX-AmyCD transporter was also considered and investigated by in vitro experiments. Since the substrate specificity of ABC transporters depends on their substrate binding lipoprotein, MsmE was further studied in order to find its effector specificity. Analysis of the amino acid sequence of MsmE with the SignalP program (31) indicated a signal peptide motif with a possible cleavage site between amino acid positions 20 and 21. Therefore, the signal peptide sequence was replaced with the His6 tag, and the His6-msmE transcriptional fusion was overexpressed in E. coli (strain JM109/pHWG1149). The purified His6-MsmE (Fig. S2) was used for the thermal shift assay to examine galactose, melibiose, raffinose, and stachyose as the possible effectors for MsmE (Fig. 4B). Among these substrates, stachyose, raffinose, and melibiose were able to increase the melting temperature of MsmE. Surprisingly, only melibiose could support the growth of the B. subtilis cells in minimal medium as the main carbon source (Fig. S3). All strains lacking one of the components of the melibiose utilization system were unable to grow with melibiose (Fig. S3). Altogether, it seems that MsmE-AmyCD together with MsmX forms an ABC transporter for melibiose and, probably, raffinose and stachyose.

DISCUSSION

Most of the carbohydrates in the soil are released after decomposition of plant tissues and are rich in RFOs and α-galactosides. In this study, we showed that B. subtilis has an α-galactosidase, called MelA, that belongs to the rare GH4 family of α-galactosidase for the degradation of melibiose and RFOs. So far, there is little information on the enzymes of the GH4 family. By determination of the biochemical properties of MelA, another member of the rare GH4 family of α-galactosidase is now well known. MelA is a strictly Mn2+- and NAD+-dependent enzyme capable of hydrolyzing melibiose, raffinose, and stachyose, whereas it is unable to act on polymeric substrates, such as locust bean gum. Locust bean gum is a galactomannan consisting of a linear polymer of mannose with branching of an α-galactose after each fourth mannose. The substrate specificity and mode of action of MelA are highly similar to those of MelA of E. coli K-12 (32) and recombinant Mel4A (rMel4A) of Bacillus halodurans (33). Compared to MelA from E. coli and B. subtilis, recombinant Mrl4A (rMrl4A) has higher affinity toward raffinose than toward melibiose (33). Interestingly, B. halodurans has two extra putative α-galactosidase genes encoding enzymes of the glycoside hydrolase families GH27 and GH36 (33). In addition to melA, there is a putative intracellular hydrolase-encoding gene (ytaP) located upstream of melREDCA; however, the deletion of ytaP had no influence on the regulation of the melREDCA. Also, PytaP was not inducible with melibiose or raffinose (data not shown). Likewise, YtaP showed no hydrolase activity with sucrose as the substrate similar to an invertase (data not shown). Clearly, further studies are necessary to find the substrate specificity of YtaP hydrolase.

The melibiose utilization system of B. subtilis was inducible with both melibiose and raffinose. In. B. halodurans, however, the rMel4A activity was induced only after the addition of raffinose and not melibiose or stachyose (33). More-complex substrates, such as guar gum or locust bean gum, could not induce the system as observed in B. megaterium VHM1 (34). The regulator of the melibiose operon, MelR, is one of the 12 transcriptional regulators of the LacI family in B. subtilis, all of which are involved in carbon catabolic pathways. All of the well-studied LacI regulators in B. subtilis, including CcpA (25), AraR (35), GanR (36), KdgR (37), ExuR (38), and IolQ (39), recognize inverted repeats. The LacI family of regulators can have more than a single binding site leading to DNA bending or looping (40, 41). The presence of two binding sites at PmsmR may also result in bending of the DNA causing steric hindrance for the RNA polymerase. This mode of action is different from that of E. coli, in which MelR is a dual regulator, a transcriptional activator for melAB, and a repressor for melR that binds to five binding sites at the intergenic region of melR and melA in the absence of melibiose (42).

E. coli naturally takes up only melibiose via a melibiose:H+/Na+/Li+ symporter (MelB) (43), and raffinose can be transported via a plasmid-based system (44, 45), Unlike E. coli, RFOs and melibiose are mainly transported by the ABC transport systems in B. subtilis (1, 2). Interestingly, most of the carbohydrate ABC transporters, such as maltodextrin (5), galactan (6, 36, 46), and arabinan (47), optimally transport oligosaccharides with 3 to 4 degrees of polymerization. It seems that ABC transporters of B. subtilis are mainly involved in the uptake of oligosaccharides compared to the PTS transporters, which are mainly involved in the transport of mono- and disaccharides (48). Another missing piece of the α-galactoside ABC transport systems was the nucleotide binding domain. Interestingly, MsmX was shown to be the nucleotide binding domain of the MelECD ABC transporter, similar to the GanSPQ, AraNPQ, YtcQP-YteP, and MdxEFG ABC transporters (5, 6, 30). Despite the results from thermal shift assay and the inducibility of PmsmR with raffinose and melibiose, B. subtilis weakly grew only with melibiose. Such a weak growth could be due to weak promoter activity (approximately 250 Miller units) of PmsmR compared to other sugar-inducible promoters, such as PmtlA (49) or PmanP (50), or due to the low efficiency of the transport system. Indeed, further studies are necessary to clarify the transport efficiency of α-galactosides by the MelECD-MsmX transporter.

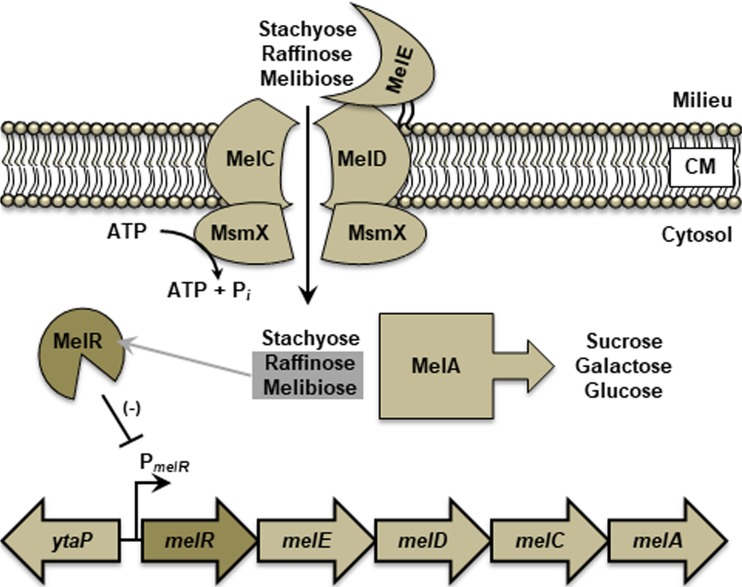

In conclusion, based on the results of this study, a model for the function of melibiose utilization system is demonstrated in Fig. 5 Briefly, B. subtilis takes up stachyose, raffinose, and melibiose via the MsmE-AmyCD-MsmX ABC transport system. These carbohydrates are then converted to glucose, galactose, and sucrose by the action of the α-galactosidase MelA. The melibiose operon is regulated by MsmR. MsmR acts as a transcriptional repressor for the melibiose operon by binding to FP1 and FP2 regions at PmsmR and inhibits the transcription of the mel operon.

FIG 5.

Model of the RFOs degradation by B. subtilis. After degradation of polysaccharide complexes produced by plants, the released α-galactosides are consumed by B. subtilis. MsmE as the substrate-binding lipoprotein binds melibiose, stachyose, and raffinose. The transport takes place via the channel formed by transmembrane proteins MelCD. The energy of the transport is provided by MsmX. Raffinose and melibiose induce the derepression of melibiose operon by interaction with MelR. The carbohydrates are then converted to glucose, galactose, and sucrose via the action of the α-galactosidase activity of MelA. Raffinose and melibiose are the effectors of MsmR. CM, cytoplasmic membrane.

MATERIALS AND METHODS

Strains, media, and growth conditions.

All strains used in this study are listed in Table S1 in the supplemental material. To propagate plasmids or express the desired genes, Escherichia coli JM109 was used as a host. The transformants of E. coli were selected on LB agar supplemented with ampicillin (100 μg/ml) or spectinomycin (100 μg/ml), depending on the plasmid selection marker. To overexpress the desired gene, E. coli JM109 carrying the expression plasmid was inoculated into LB medium with ampicillin (100 μg/ml) with a starting optical density at 600 nm (OD600) of 0.05. After 2 h of incubation at 37°C with 200 rpm shaking intensity, l-rhamnose (0.2% [wt/vol]) was added to the bacterial culture, and the cells were harvested by centrifugation after 4 h of incubation at 30°C. The harvested cell pellet was kept at −20°C for further analysis.

Bacillus subtilis KM0, a tryptophan prototroph derivative of strain 168, was used as the wild-type strain in this study. B. subtilis knockout erythromycin (BKE) strains (51) were also obtained from the Bacillus Genetic Stock Center (BGSC, OH). B. subtilis transformants were selected on LB plates containing spectinomycin (100 μg/ml) or erythromycin (5 μg/ml). The tryptophan auxotroph BKE strains were cultured in Spizizen’s minimal medium (52) supplemented with tryptophan (50 μg/ml). To find the inducer of the melibiose utilization system, LB medium was inoculated with the desired strains with a starting OD600 of 0.05. After 2 h of incubation at 37°C with 200 rpm shaking intensity, raffinose, melibiose, stachyose, or glucose was added to the bacterial cultures at a final concentration of 0.2% (wt/vol). Each bacterial culture was harvested after 1 h to measure the β-galactosidase activity.

To study the regulation of the melibiose utilization genes and isolation of total RNA, B. subtilis wild-type and mutant strains were cultured in Spizizen’s minimal medium [(NH4)2SO4 (2 g/liter), K2HPO4 (14 g/liter), KH2PO4 (6 g/liter), Na3 citrate·2H2O (1 g/liter), MgSO4·7H2O (0.2 g/liter)] supplemented with 0.6% (wt/vol) succinate, 0.8% (wt/vol) glutamate, trace elements (CaCl2·2H2O [0.5 mg/liter], FeCl3·6H2O [16.7 mg/liter], Na2-EDTA [20.1 mg/liter], ZnSO4·7H2O [0.18 mg/liter], MnSO4·H2O [0.1 mg/liter], CuSO4·5H2O [0.16 mg/liter], CoCl2·6H2O [0.18 mg/liter]), and 0.02% (wt/vol) Casamino Acids. Fifty milliliters of the minimal medium was inoculated with a starting OD600 of 0.1 and incubated at 37°C with 200 rpm shaking intensity. After 3 h and 45 min of incubation, 0.2% (wt/vol) of raffinose, melibiose, or stachyose was added to the 8-ml aliquots of bacterial culture. After 4 h of incubation, the bacterial culture was harvested and used for the measurement of β-galactosidase activity. All experiments were repeated twice, and the mean values were used for further analysis.

DNA manipulation and plasmid construction.

All plasmids used in this study are listed in Table S2. Standard molecular techniques were carried out as described by Sambrook and Russell (53). DNA fragments were amplified by PCR using Phusion high-fidelity (HF) DNA polymerase (catalog no. M530S; New England BioLabs, Frankfurt am Main, Germany) on a LifeECO thermal cycler (Hangzhou Bioer Technology Co. Ltd., China). Unless otherwise specified, the chromosomal DNA of B. subtilis KM0 was used as the template in all PCRs. Chromosomal DNA of B. subtilis was isolated using the innuPREP bacterial DNA kit (Analytik Jena AG, Jena, Germany), according to the manufacturer’s instructions. All oligonucleotides used were synthesized by Eurofins MWG Operons (Ebersberg, Germany) (Table S3). Restriction enzymes purchased from New England BioLabs were used for the digestion of DNA fragments. PCR or digested DNA fragments cut from agarose gel were isolated using the NucleoSpin gel and PCR cleanup kit (Macherey-Nagel GmbH, Düren, Germany). Ligation of the desired DNA fragments was catalyzed by T4 DNA ligase (Thermo Fisher Scientific, Inc., Karlsruhe, Germany). The innuPREP plasmid minikit (Analytik Jena AG) was purchased for plasmid extraction. All newly constructed plasmids were sequenced by GATC Biotech AG (Constance, Germany). The construction of each plasmid is thoroughly explained in Table S2.

Construction of the B. subtilis strains.

Natural transformation of B. subtilis strains was performed according to the Paris method (54). All of the mutants used in this study were derivatives of the Bacillus knockout erythromycin (BKE) strains constructed by Koo et al. (51). To remove the erythromycin resistance gene, each strain was transformed with the unstable plasmid pJOE6732.1 (6) expressing Cre recombinase. After selection on LB with spectinomycin, a single colony was further cultured in LB for 24 h at 37°C, and a 10−6 dilution was plated on LB. Approximately 50 colonies were checked for the loss of spectinomycin and erythromycin. Finally, each deletion was verified with appropriate oligonucleotides in a PCR. Since all BKE strains and their derivatives were tryptophan auxotrophs, the trpC2 mutation was repaired using plasmid pKAM041 (55). After transformation of the strains, selection was performed on minimal medium without tryptophan. To investigate the regulation of the promoter regions, the derivatives of pKAM263 (48), i.e., pKAM384 (PmsmR) and pKAM385 (PmsmE), containing the promoter-lacZ fusion were integrated into the amyE locus of the desired strain. The transformants were selected on LB containing spectinomycin, and the sensitivity to erythromycin (single-crossover integration) and loss of α-amylase activity (LB containing 1% starch) verified the integration of the promoter-lacZ via double crossover.

Gene expression and protein purification.

For expression in E. coli, the coding regions of melA, msmE, and msmR were amplified by PCR, with genomic DNA from Bacillus subtilis 168 serving as the template. The specific primers additionally introduced the restriction sites necessary for the cloning of the desired genes (see Table S2) and resulted in the expression plasmids pHWG1118 for the Strep-tag–melA transcriptional fusion, pHWG1149 for the His6-msmE transcriptional fusion, and pHWG1169 for the msmR–Strep-tag transcriptional fusion, respectively. The growth conditions of the strains for overproduction of proteins have previously been described. The cell pellet of E. coli strain JM109/pHWG1118 (Strep-tag–MelA) was dissolved in 12 ml of 0.1 M Tris-HCl (pH 8.0), while JM109/pHWG1169 (for MsmR–Strep-tag) was dissolved in 12 ml of 0.1 M Tris-HCl (pH 8.0), 0.3 MnSO4, and 1 mM Tris(2-carboxylethyl)phosphine (TCEP). The cells were disrupted by passing the cell suspension through pouring into the ice-cooled chamber of an EmulsiFlex-C5 high-pressure homogenizer (Avestin, Mannheim, Germany) at 15,000 lb/in2. The bacterial suspension was completely ruptured after 2 to 3 min. The bacterial lysate was centrifuged for 30 min at 12,000 × g. The cleared bacterial lysate was then passed through 1 ml of Strep-Tactin resin for the purification of streptavidin-tagged proteins. The purification steps were carried out according to the manufacturer’s instructions. Purification of MsmE without its signal peptide was performed using strain JM109/pHWG1149. The cell disruption steps were accomplished as mentioned above, and the cleared cell lysate was passed through 1 ml of Talon metal affinity resin (Clontech Laboratories, Inc., Mountain View, CA) to purify His6-tagged MsmE.

DNA sequencing.

The sequencing reaction of pKAM0138 carrying the msmR promoter region was performed with 5′,6-carboxyfluorescein (5′,6-FAM)-labeled oligonucleotide s12050 using the Thermo Sequenase cycle sequencing kit (Affymetrix, High Wycombe, UK). The master mix for sequencing was prepared by mixing 2 μl of pKAM0138 (30 fmol/μl) with 2 μl of the reaction buffer, 1 μl of the desired oligonucleotide (4 pmol/μl), 1 μl dimethyl sulfoxide (DMSO), 2 μl DNA polymerase, and 9.5 μl double-distilled water (ddH2O). Four microliters of the sequencing master mix was then added to 4-μl aliquots of ddGTP, ddATP, ddTTP, and ddCTP. The sequencing reaction was accomplished in a LifeECO thermal cycler (Hangzhou Bioer Technology Co. Ltd., China). The amplification program included initial denaturation for 2 min at 95°C, 30 cycles of 95°C for 30 s, 56°C for 30 s, and 72°C for 1 min, and a final extension for 1 min at 72°C. Finally, amplified DNA in each reaction mixture was precipitated with 3 M sodium acetate (pH 6.3) and isopropanol. The DNA was then dissolved in 6 μl ddH2O and 34 μl Hi-Di formamide (catalog no. 4401457; Applied Biosystems by Thermo Fisher Scientific, USA). After the addition of 0.5 μl GeneScan 600 LIZ size standard v2.0 from the GeneScan installation kit DS-33 (catalog no. 4376911; Applied Biosystems by Thermo Fisher Scientific, USA), the samples were run on a SeqStudio genetic analyzer (Applied Biosystems by Thermo Fisher Scientific), and the results were analyzed using the GeneMapper software 5 (Applied Biosystems by Thermo Fisher Scientific).

Primer extension.

To find the transcription start site (TSS) of msmR, strain KM845 containing the integrated PmsmR-lacZ cassette was used. Strain KM845 was inoculated to 20 ml minimal medium containing 0.2% melibiose and incubated overnight at 37°C. The total mRNA was isolated using the Qiagen RNeasy minikit (Hilden, Germany), as instructed by the manufacturer. Approximately 30 μg of total RNA was precipitated using 3 M sodium acetate (pH 6.3) and ethanol. The precipitated RNA was dissolved in 5 μl of RNase-free ddH2O and 0.5 μl of RNasin RNase inhibitor (40 U/μl; Promega, Mannheim, Germany). After incubation at 65°C for 3 min, 0.5 μl of the 5′,6-FAM-labeled s11996 or s12048 oligonucleotide (10 pmol/μl) and 2 μl of 5× avian myeloblastosis virus reverse transcriptase (AMV-RT) reaction buffer (New England BioLabs GmbH, Frankfurt am Main, Germany) were added. The mixture was incubated for 20 min at 51°C, followed by incubation for 5 min at room temperature. Afterwards, 1 μl dinucleoside triphosphate (dNTP) (10 mM) and 1 μl AMV-RT (20 U/μl; New England BioLabs GmbH) were added to start the reverse transcription, and the reaction mixture was incubated for 1 h at 42°C. Finally, the generated cDNA was purified using DNA Clean & Concentrator-5 kit (Zymo Research GmbH, Freiburg, Germany) and eluted in 6 μl ddH2O. After the addition of 34 μl Hi-Di formamide (catalog no. 4401457; Applied Biosystems by Thermo Fisher Scientific, USA) and of 0.5 μl GeneScan 600 LIZ size standard v2.0 from the GeneScan installation kit DS-33 with 600 LIZ size standard v2.0 (catalog no. 4376911; Applied Biosystems by Thermo Fisher Scientific), the samples were run on a SeqStudio genetic analyzer (Applied Biosystems by Thermo Fisher Scientific). The GeneMapper software 5 (Applied Biosystems by Thermo Fisher Scientific) was used to compare the primer extension peak with the DNA sequencing results of pKAM384 (using the same oligonucleotides) to find the TSS.

Electrophoretic mobility shift assay.

5′-end Cy5-labeled oligonucleotides were used to create Cy5-labeled DNA fragments by PCR or hybridization. The Cy5-PmsmR DNA fragment was amplified from pKAM384 using the s11321 and s5960 oligonucleotides. The footprinting regions at PmsmR, i.e., FP1 and FP2, were also labeled by DNA hybridization of the s12280 and s12281 oligonucleotides for FP1 and the s12282 and s12283 oligonucleotides for FP2. As the negative control, the DNA fragment containing the GlcR binding site of PglcR was labeled after hybridization of s12284 and s12285. All electrophoretic mobility shift assays were carried out in a total volume of 20 μl containing 2 μl of Cy5-labeled DNA fragment (50 fmol/μl) and 4 μl of 5× shift buffer (50 mM Tris-HCl [pH 7.5], 250 mM KCl, 10 mM dithiothreitol [DTT], 25% [vol/vol] glycerol, 250 μg/ml bovine serum albumin [BSA], 25 μg/ml herring sperm DNA). Fourteen microliters of purified MsmR–Strep-tag (0.015 mg/ml) was added to the reaction mixture, and the reaction mixture was incubated on ice for at least 15 min. Finally, 10 μl of the reaction mixture was loaded onto a 6% (wt/vol) native polyacrylamide gel to separate the free DNA and DNA-protein complexes. The migration of the bands of free DNA and the DNA-protein complexes was visualized using the Storm 860 PhosphorImager (Molecular Dynamics).

DNase I footprinting.

Fluorescence labeling of the noncoding strand of PmsmR DNA was carried out by PCR using T7 and 5′,6-FAM-labeled s12050 oligonucleotide from pKAM0138. DNase I digestion was performed by mixing of 20 μl of the 6-FAM-labeled PmsmR DNA fragment (50 fmol/μl) with 48 μl of 5× shift buffer containing 50 mM Tris-HCl (pH 7.5), 250 mM KCl, 10 mM DTT, 25% (vol/vol) glycerol, 250 μg/ml BSA, and 25 μg/ml herring sperm DNA to prepare the master mix. Seventeen microliters of the master mix was then mixed with 43 μl of purified MsmR–Strep-tag (0.015 mg/ml). As the negative control, purified MsmR was similarly added to the master mix after denaturation by incubation for 10 min at 99°C. After 15 min of incubation on ice, the DNA-protein mixture was preheated for 1 min at 25°C. Next, 10 μl of the DNase I master mix containing 7 μl of 10× DNase I buffer, 2.75 μl ddH2O, and 0.25 μl DNase I (2,000 U/ml; New England BioLabs GmbH) was added. The reaction was stopped after 1 min of incubation at 25°C with the addition of stop solution (50 mM EDTA [pH 8.0], 15 μg/ml calf thymus DNA). Phenol-chloroform-isoamyl alcohol (25:24:1 [vol/vol/vol]) extraction, followed by washing of the DNA with ethanol, was carried out to remove the protein. The DNA was then dissolved in 6 μl ddH2O and 34 μl Hi-Di formamide (catalog no. 4401457; Applied Biosystems by Thermo Fisher Scientific, USA). After the addition of 0.5 μl GeneScan 600 LIZ size standard v2.0 from the GeneScan installation kit DS-33 with 600 LIZ size standard v2.0 (catalog no. 4376911; Applied Biosystems by Thermo Fisher Scientific), the samples were run on a SeqStudio genetic analyzer (Applied Biosystems by Thermo Fisher Scientific), and the results were analyzed using the GeneMapper software 5 (Applied Biosystems by Thermo Fisher Scientific).

Thermal shift assay.

To find the possible effectors of MsmR and MsmE, a thermal shift assay (also known as differential scanning fluorimetry) was performed with a Mastercycler ep realplex (Eppendorf, Hamburg, Germany) utilizing the melting capability. Each reaction was carried out in a total volume of 50 μl by mixing purified MsmR–Strep-tag (12 μg), purified His6-MsmE (20 μg) with or without the effectors, galactose, melibiose, raffinose, and stachyose at a final concentration of 1 mM, with SYPRO Orange (5 μl of the 50× stock solution in DMSO; Sigma, Munich, Germany). The fluorescence intensity profile (or melting curve) of the SYPRO Orange-protein complex was measured at 520 nm with intervals of 0.2°C from 20°C to 90°C. The thermal stability (melting temperature) was recorded from the formula Δfluorescence/Δtemperature.

Measurement of α-galactosidase activity.

The α-galactosidase activity was determined by measuring the rate of para-nitrophenyl-α-galactopyranoside (pNPG) hydrolysis, as described previously (56), in 0.1 M Tris-HCl (pH 8.0) at 37°C. The effects of Mn2+ (3 mM), NAD+ (1 to 10 mM), and the reducing agents, such as mercaptoethanol (100 mM) and Tris(2-carboxylethyl)phosphine (TCEP) (1 mM), were studied in a 50-μl reaction mixture. The standard melibiase activity test was performed in the presence of 3 mM MnCl2, 10 mM NAD+, and 1 mM TCEP. One unit of the enzyme activity was defined as the amount of enzyme required to hydrolyze 1 μM pNPG per minute. The protein concentration was determined by the method of Bradford (57) using bovine serum albumin (BSA) as a standard.

The rate of melibiose hydrolysis was determined by assessing the amount of released glucose, which was determined by a glucose-hexokinase test (DiaSys GmbH, Holzheim, Germany) and quantified according to a glucose standard curve. The rates of raffinose and stachyose hydrolysis were measured by assessing the release of galactose after separation of the reaction mixture by high-performance liquid chromatography (HPLC), as described before (56). The hydrolysis of the mentioned sugars was measured from a final concentration of 100 mM under standard assay conditions. Kinetic parameters (apparent Michaelis constant [Km] were determined for the substrates (melibiose and raffinose) and were obtained by curve fitting analysis using the KaleidaGraph software (Synergy Software, USA).

Measurement of β-galactosidase activity.

The β-galactosidase activity was measured using p-nitrophenyl-β-d-galactopyranoside (pNP-β-Gal), according to the Miller assay (58).

Supplementary Material

ACKNOWLEDGMENTS

We thank Gisela Wajant, Gisela Kwiatkowski, Silke Weber, and Annette Schneck for their technical assistance during this study.

Footnotes

Supplemental material for this article may be found at https://doi.org/10.1128/JB.00109-19.

REFERENCES

- 1.Deutscher J, Galinier A, Martin-Verstraete I. 2002. Carbohydrate uptake and metabolism, p 129–150. In Sonenshein AL, Hoch JA, Losick R (ed), Bacillus subtilis and its closest relatives: from genes to cells. ASM Press, Washington, DC. [Google Scholar]

- 2.Stülke JS, Hillen W. 2000. Regulation of carbon catabolism in Bacillus species. Annu Rev Microbiol 54:849–880. doi: 10.1146/annurev.micro.54.1.849. [DOI] [PubMed] [Google Scholar]

- 3.Deutscher J, Francke C, Postma PW. 2006. How phosphotransferase system-related protein phosphorylation regulates carbohydrate metabolism in bacteria. Microbiol Mol Biol Rev 70:939–1031. doi: 10.1128/MMBR.00024-06. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Quentin Y, Fichant G, Denizot F. 1999. Inventory, assembly and analysis of Bacillus subtilis ABC transport systems. J Mol Biol 287:467–484. doi: 10.1006/jmbi.1999.2624. [DOI] [PubMed] [Google Scholar]

- 5.Schönert S, Seitz S, Krafft H, Feuerbaum E-A, Andernach I, Witz G, Dahl MK. 2006. Maltose and maltodextrin utilization by Bacillus subtilis. J Bacteriol 188:3911–3922. doi: 10.1128/JB.00213-06. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Watzlawick H, Morabbi Heravi K, Altenbuchner J. 2016. Role of the ganSPQAB operon in degradation of galactan by Bacillus subtilis. J Bacteriol 198:2887–2896. doi: 10.1128/JB.00468-16. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Deutscher J, Ake FM, Derkaoui M, Zebre AC, Cao TN, Bouraoui H, Kentache T, Mokhtari A, Milohanic E, Joyet P. 2014. The bacterial phosphoenolpyruvate:carbohydrate phosphotransferase system: regulation by protein phosphorylation and phosphorylation-dependent protein-protein interactions. Microbiol Mol Biol Rev 78:231–256. doi: 10.1128/MMBR.00001-14. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Fujita Y. 2009. Carbon catabolite control of the metabolic network in Bacillus subtilis. Biosci Biotechnol Biochem 73:245–259. doi: 10.1271/bbb.80479. [DOI] [PubMed] [Google Scholar]

- 9.Görke B, Stülke J. 2008. Carbon catabolite repression in bacteria: many ways to make the most out of nutrients. Nat Rev Microbiol 6:613–624. doi: 10.1038/nrmicro1932. [DOI] [PubMed] [Google Scholar]

- 10.French D. 1954. The raffinose family of oligosaccharides. Adv Carbohydr Chem 9:149–184. [DOI] [PubMed] [Google Scholar]

- 11.Martínez-Villaluenga C, Frias J, Vidal-Valverde C. 2008. Alpha-galactosides: antinutritional factors or functional ingredients? Crit Rev Food Sci Nutr 48:301–316. doi: 10.1080/10408390701326243. [DOI] [PubMed] [Google Scholar]

- 12.Webster C, Kempsell K, Booth L, Busby S. 1987. Organisation of the regulatory region of the Escherichia coli melibiose operon. Gene 59:253–263. doi: 10.1016/0378-1119(87)90333-7. [DOI] [PubMed] [Google Scholar]

- 13.Aslanidis C, Schmid K, Schmitt R. 1989. Nucleotide sequences and operon structure of plasmid-borne genes mediating uptake and utilization of raffinose in Escherichia coli. J Bacteriol 171:6753–6763. doi: 10.1128/jb.171.12.6753-6763.1989. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Hugouvieux-Cotte-Pattat N, Charaoui-Boukerzaza S. 2009. Catabolism of raffinose, sucrose, and melibiose in Erwinia chrysanthemi 3937. J Bacteriol 191:6960–6967. doi: 10.1128/JB.00594-09. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Gänzle MG, Follador R. 2012. Metabolism of oligosaccharides and starch in lactobacilli: a review. Front Microbiol 3:340. doi: 10.3389/fmicb.2012.00340. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Kunst F, Ogasawara N, Moszer I, Albertini AM, Alloni G, Azevedo V, Bertero MG, Bessières P, Bolotin A, Borchert S, Borriss R, Boursier L, Brans A, Braun M, Brignell SC, Bron S, Brouillet S, Bruschi CV, Caldwell B, Capuano V, Carter NM, Choi S-K, Codani J-J, Connerton IF, Cummings NJ, Daniel RA, Denizot F, Devine KM, Düsterhöft A, Ehrlich SD, Emmerson PT, Entian KD, Errington J, Fabret C, Ferrari E, Foulger D, Fritz C, Fujita M, Fujita Y, Fuma S, Galizzi A, Galleron N, Ghim S-Y, Glaser P, Goffeau A, Golightly EJ, Grandi G, Guiseppi G, Guy BJ, Haga K, et al. 1997. The complete genome sequence of the Gram-positive bacterium Bacillus subtilis. Nature 390:249. doi: 10.1038/36786. [DOI] [PubMed] [Google Scholar]

- 17.Barbe V, Cruveiller S, Kunst F, Lenoble P, Meurice G, Sekowska A, Vallenet D, Wang T, Moszer I, Médigue C, Danchin A. 2009. From a consortium sequence to a unified sequence: the Bacillus subtilis 168 reference genome a decade later. Microbiology 155:1758–1775. doi: 10.1099/mic.0.027839-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Lapidus A, Galleron N, Sorokin A, Ehrlich SD. 1997. Sequencing and functional annotation of the Bacillus subtilis genes in the 200 kb rrnB-dnaB region. Microbiology 143:3431–3441. doi: 10.1099/00221287-143-11-3431. [DOI] [PubMed] [Google Scholar]

- 19.Nicolas P, Mäder U, Dervyn E, Rochat T, Leduc A, Pigeonneau N, Bidnenko E, Marchadier E, Hoebeke M, Aymerich S, Becher D, Bisicchia P, Botella E, Delumeau O, Doherty G, Denham EL, Fogg MJ, Fromion V, Goelzer A, Hansen A, Härtig E, Harwood CR, Homuth G, Jarmer H, Jules M, Klipp E, Le Chat L, Lecointe F, Lewis P, Liebermeister W, March A, Mars RAT, Nannapaneni P, Noone D, Pohl S, Rinn B, Rügheimer F, Sappa PK, Samson F, Schaffer M, Schwikowski B, Steil L, Stülke J, Wiegert T, Devine KM, Wilkinson AJ, van Dijl JM, Hecker M, Völker U, Bessières P, et al. 2012. Condition-dependent transcriptome reveals high-level regulatory architecture in Bacillus subtilis. Science 335:1103–1106. doi: 10.1126/science.1206848. [DOI] [PubMed] [Google Scholar]

- 20.Thompson J, Hess S, Pikis A. 2004. Genes malH and pagl of Clostridium acetobutylicum ATCC 824 encode NAD+- and Mn2+-dependent phospho-a-glucosidase(s). J Biol Chem 279:1553–1561. doi: 10.1074/jbc.M310733200. [DOI] [PubMed] [Google Scholar]

- 21.Yip VL, Withers SG. 2006. Mechanistic analysis of the unusual redox-elimination sequence employed by Thermotoga maritima BglT: a 6-phospho-β-glucosidase from glycoside hydrolase family 4. Biochemistry 45:571–580. doi: 10.1021/bi052054x. [DOI] [PubMed] [Google Scholar]

- 22.DeLoughery A, Lalanne JB, Losick R, Li GW. 2018. Maturation of polycistronic mRNAs by the endoribonuclease RNase Y and its associated Y-complex in Bacillus subtilis. Proc Natl Acad Sci U S A 115:E5585–E5594. doi: 10.1073/pnas.1803283115. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Ludwig H, Homuth G, Schmalisch M, Dyka FM, Hecker M, Stülke J. 2001. Transcription of glycolytic genes and operons in Bacillus subtilis: evidence for the presence of multiple levels of control of the gapA operon. Mol Microbiol 41:409–422. doi: 10.1046/j.1365-2958.2001.02523.x. [DOI] [PubMed] [Google Scholar]

- 24.Finn RD, Coggill P, Eberhardt RY, Eddy SR, Mistry J, Mitchell AL, Potter SC, Punta M, Qureshi M, Sangrador-Vegas A, Salazar GA, Tate J, Bateman A. 2016. The Pfam protein families database: towards a more sustainable future. Nucleic Acids Res 44:D279–D285. doi: 10.1093/nar/gkv1344. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Miwa Y, Nakata A, Ogiwara A, Yamamoto M, Fujita Y. 2000. Evaluation and characterization of catabolite-responsive elements (cre) of Bacillus subtilis. Nucleic Acids Res 28:1206–1210. doi: 10.1093/nar/28.5.1206. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Marciniak BC, Pabijaniak M, de Jong A, Dűhring R, Seidel G, Hillen W, Kuipers OP. 2012. High- and low-affinity cre boxes for CcpA binding in Bacillus subtilis revealed by genome-wide analysis. BMC Genomics 13:401. doi: 10.1186/1471-2164-13-401. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Summers AO. 1992. Untwist and shout: a heavy metal-responsive transcriptional regulator. J Bacteriol 174:3097–3101. doi: 10.1128/jb.174.10.3097-3101.1992. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Ansari AZ, Bradner JE, O’Halloran TV. 1995. DNA-bend modulation in a repressor-to-activator switching mechanism. Nature 374:371–375. doi: 10.1038/374370a0. [DOI] [PubMed] [Google Scholar]

- 29.Chatterjee S, Zhou YN, Roy S, Adhya S. 1997. Interaction of Gal repressor with inducer and operator: induction of gal transcription from repressor-bound DNA. Proc Natl Acad Sci U S A 94:2957–2962. doi: 10.1073/pnas.94.7.2957. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Ferreira MJ, Mendes AL, de Sá-Nogueira I. 2017. The MsmX ATPase plays a crucial role in pectin mobilization by Bacillus subtilis. PLoS One 12:e0189483. doi: 10.1371/journal.pone.0189483. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Petersen TN, Brunak S, von Heijne G, Nielsen H. 2011. SignalP 4.0: discriminating signal peptides from transmembrane regions. Nat Methods 8:785. doi: 10.1038/nmeth.1701. [DOI] [PubMed] [Google Scholar]

- 32.Burstein C, Kepes A. 1971. The α-galactosidase from Escherichia coli K-12. Biochim Biophys Acta 230:52–63. doi: 10.1016/0304-4165(71)90053-5. [DOI] [PubMed] [Google Scholar]

- 33.Anggraeni AA, Sakka M, Kimura T, Ratanakhaokchai K, Kitaoka M, Sakka K. 2008. Characterization of Bacillus halodurans α-galactosidase Mel4A encoded by the mel4A gene (BH2228). Biosci Biotechnol Biochem 72:2459–2462. doi: 10.1271/bbb.80242. [DOI] [PubMed] [Google Scholar]

- 34.Patil AG, K PK, Mulimani VH, Veeranagouda Y, Lee K. 2010. α-Galactosidase from Bacillus megaterium VHM1 and its application in removal of flatulence-causing factors from soymilk. J Microbiol Biotechnol 20:1546–1554. doi: 10.4014/jmb.0912.12012. [DOI] [PubMed] [Google Scholar]

- 35.Mota LJ, Tavares P, Sa-Nogueira I. 1999. Mode of action of AraR, the key regulator of l-arabinose metabolism in Bacillus subtilis. Mol Microbiol 33:476–489. doi: 10.1046/j.1365-2958.1999.01484.x. [DOI] [PubMed] [Google Scholar]

- 36.Habib C, Yu Y, Gozzi K, Ching C, Shemesh M, Chai Y. 2017. Characterization of the regulation of a plant polysaccharide utilization operon and its role in biofilm formation in Bacillus subtilis. PLoS One 12:e0179761. doi: 10.1371/journal.pone.0179761. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Pujic P, Dervyn R, Sorokin A, Ehrlich SD. 1998. The kdgRKAT operon of Bacillus subtilis: detection of the transcript and regulation by the kdgR and ccpA genes. Microbiology 144:3111–3118. doi: 10.1099/00221287-144-11-3111. [DOI] [PubMed] [Google Scholar]

- 38.Mekjian KR, Bryan EM, Beall BW, Moran CP. 1999. Regulation of hexuronate utilization in Bacillus subtilis. J Bacteriol 181:426–433. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Kang DM, Michon C, Morinaga T, Tanaka K, Takenaka S, Ishikawa S, Yoshida KI. 2017. Bacillus subtilis IolQ (DegA) is a transcriptional repressor of iolX encoding NAD+-dependent scyllo-inositol dehydrogenase. BMC Microbiol 17:154. doi: 10.1186/s12866-017-1065-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Becker NA, Peters JP, Maher LJ III, Lionberger TA. 2013. Mechanism of promoter repression by Lac repressor-DNA loops. Nucleic Acids Res 41:156–166. doi: 10.1093/nar/gks1011. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Oehler S, Eismann ER, Krämer H, Müller-Hill B. 1990. The three operators of the lac operon cooperate in repression. EMBO J 9:973–979. doi: 10.1002/j.1460-2075.1990.tb08199.x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Williams J, Michan C, Webster C, Busby S. 1994. Interactions between the Escherichia coli MelR transcription activator protein and operator sequences at the melAB promoter. Biochem J 300:757–763. doi: 10.1042/bj3000757. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 43.Bassilana M, Pourcher T, Leblanc G. 1987. Facilitated diffusion properties of melibiose permease in Escherichia coli membrane vesicles. Release of co-substrates is rate limiting for permease cycling. J Biol Chem 262:16865–16870. [PubMed] [Google Scholar]

- 44.Schmid K, Schmitt R. 1976. Raffinose metabolism in Escherichia coli K-12. Eur J Biochem 67:95–104. doi: 10.1111/j.1432-1033.1976.tb10637.x. [DOI] [PubMed] [Google Scholar]

- 45.Ulmke C, Lengeler JW, Schmid K. 1997. Identification of a new porin, RafY, encoded by raffinose plasmid pRSD2 of Escherichia coli. J Bacteriol 179:5783–5788. doi: 10.1128/jb.179.18.5783-5788.1997. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 46.Chai Y, Beauregard PB, Vlamakis H, Losick R, Kolter R. 2012. Galactose metabolism plays a crucial role in biofilm formation by Bacillus subtilis. mBio 3:e00184-12. doi: 10.1128/mBio.00184-12. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Inacio JM, de Sa-Nogueira I. 2008. Characterization of abn2 (yxiA), encoding a Bacillus subtilis GH43 arabinanase, Abn2, and its role in arabino-polysaccharide degradation. J Bacteriol 190:4272–4280. doi: 10.1128/JB.00162-08. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Morabbi Heravi K, Altenbuchner J. 2018. Cross talk among transporters of the phosphoenolpyruvate-dependent phosphotransferase system in Bacillus subtilis. J Bacteriol 200:e00213-18. doi: 10.1128/JB.00213-18. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 49.Heravi KM, Altenbuchner J. 2014. Regulation of the Bacillus subtilis mannitol utilization genes: promoter structure and transcriptional activation by the wild-type regulator (MtlR) and its mutants. Microbiology 160:91–101. doi: 10.1099/mic.0.071233-0. [DOI] [PubMed] [Google Scholar]

- 50.Wenzel M, Altenbuchner J. 2013. The Bacillus subtilis mannose regulator, ManR, a DNA-binding protein regulated by HPr and its cognate PTS transporter ManP. Mol Microbiol 88:562–576. doi: 10.1111/mmi.12209. [DOI] [PubMed] [Google Scholar]

- 51.Koo BM, Kritikos G, Farelli JD, Todor H, Tong K, Kimsey H, Wapinski I, Galardini M, Cabal A, Peters JM, Hachmann AB, Rudner DZ, Allen KN, Typas A, Gross CA. 2017. Construction and analysis of two genome-scale deletion libraries for Bacillus subtilis. Cell Syst 4:291–305.e7. doi: 10.1016/j.cels.2016.12.013. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 52.Anagnostopoulos C, Spizizen J. 1961. Requirements for transformation in Bacillus subtilis. J Bacteriol 81:741–746. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.Sambrook J, Russell DW. 2001. Molecular cloning: a laboratory manual, 3rd ed. Cold Spring Harbor Laboratory Press, Cold Spring Harbor, NY. [Google Scholar]

- 54.Harwood CR, Cutting SM. 1990. Molecular biological methods for Bacillus. Wiley, Chichester, NY. [Google Scholar]

- 55.Rahmer R, Morabbi Heravi K, Altenbuchner J. 2015. Construction of a super-competent Bacillus subtilis 168 using the PmtlA-comKS inducible cassette. Front Microbiol 6:1431. doi: 10.3389/fmicb.2015.01431. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 56.Foucault M, Watzlawick H, Mattes R, Haser R, Gouet P. 2006. Crystallization and preliminary X-ray diffraction studies of two thermostable alpha-galactosidases from glycoside hydrolase family 36. Acta Crystallogr Sect F Struct Biol Cryst Commun 62:100–103. doi: 10.1107/S1744309105042582. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 57.Bradford MM. 1976. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254. doi: 10.1016/0003-2697(76)90527-3. [DOI] [PubMed] [Google Scholar]

- 58.Miller JH. 1972. Experiments in molecular genetics. Cold Spring Harbor Laboratory Press, Cold Spring Harbor, NY. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.