Abstract

Pretreatment approaches are highly desirable to improve the commercial viability of nanocellulose production. In this study, we propose a new approach to mass produce nanocellulose using a hydrated choline chloride/oxalic acid dihydrate deep eutectic solvent (DES) combined with an ultrasonic process. The hydrogen bond acidity, polarizability, and solvation effect reflected by the Kamlet–Taft solvatochromic parameters did not decrease even after the addition of large amounts of water. Instead, the water facilitated the ionization of H+ and delocalization of Cl– ions, forming new Cl–H2O ionic hydrogen and oxalate–H2O hydrogen bonds, which are critical for improving the solvent characteristics. One pass of kraft pulp through the hydrated DESs (80 °C, 1 h) was sufficient to dissociate the kraft pulp into cellulose nanofibers or cellulose nanocrystals using an 800 W ultrasonic treatment. The present study represents an alternative route for the kraft pulp pretreatment and the large-scale production of nanocellulose.

Introduction

Nanocellulose has attracted widespread interest over the past decades.1,2 Owing to the nanoscale dimensions, large specific surface area, abundant reactive hydroxyl groups, and advantageous mechanical and thermal properties, nanocellulose has been utilized to construct a series of advanced materials/devices.3−6 Previous studies have confirmed that wood and agrowastes are important sources of nanocellulose production.7−10 Nanocellulose with various structures and surface chemical properties can be fabricated using various chemical and mechanical approaches.11−13

Nanocellulose is expected to be extracted in high yield with few steps and in an energy-efficient manner. However, the structural complexity of the biomass components in cell walls often results in recalcitrance, leading to the difficulty of individualizing the nanocellulose.14−16 Removing the matrix from the cellulose source is critical to reduce the energy requirement and improve the degree of nanofibrillation.17,18 Some of the existing chemical reagents, such as acidified sodium chlorite, carboxymethylated sulfite, hydrogen peroxide, and TEMPO, have been used to pretreat the lignocellulosic biomass and readily reduce the obstacles during mechanical processing.11,19−22 Despite the successful extraction of cellulose using these pretreatments, some practice issues remain, such as the long treatment time and environmental pollution. Among the new types of pretreatment protocols, organosolv pulping and ionic liquid pretreatments have been recognized as effective methods for fractionating lignocellulose components following the concepts of green chemistry.22−25 Although several inexpensive formulations of these solvents have been developed, they are still costly for industrial-scale production of nanocellulose.

Deep eutectic solvents (DESs) have emerged as a new generation of green solvents that fully agree with the 12 principles of green chemistry.26 A DES is usually synthesized by mixing a quaternary ammonium salt with a metal salt, a hydrated salt, or a simple hydrogen-bond donor (such as an alcohol, amine, or carboxylic acid).27 DESs are distinguished by their ease of preparation, biodegradability, and environmental friendliness.28 As DESs possess the unusual characteristics of a wide liquid range, negligible vapor pressure, high thermal stability, and nonflammability, they can be employed in chemical reactions at near-ambient conditions and in a variety of industrial applications.29 DESs have been used to pretreat biomass efficiently compared to some traditional solvents.30−32 Sirviö et al. reported that DESs can be used as hydrolytic media for lignocellulose and pulp pretreatment to produce cellulose nanofibers (CNFs) and cellulose nanocrystals (CNCs).33−37 In our previous studies, a choline chloride (ChCl)/oxalic acid DES was applied to cleave the lignin–carbohydrate complexes in wood and the strong hydrogen bonds in cotton to liquefy the noncellulosic components and extract the cellulose fibers to produce CNFs and CNCs.38,39 The significance of such studies was to demonstrate the positive role of DESs in providing a lignin-first biorefinery approach, while simultaneously maintaining the cellulose available to produce nanocellulose.

Although DESs are promising green solvents, there remains major challenges for using them to extensively produce nanocellulose. High viscosity and high cost are the most obvious problems, which lead to low mass concentration of dissolution and a slow solvent-transfer operation.40 Diluting DESs with water is an efficient way to decrease the viscosity and modify suitable DESs.41,42 A plausible reason is that water is a low-molecular-weight polar solvent that acts as a third type of constituent in the DES system. Using water also significantly reduces the viscosity and cost of a DES system. To the best of our knowledge, no specific studies have applied highly diluted DESs to refine kraft pulp and massively produce nanocellulose. There is still little understanding of the relevant mechanism.

Herein, hydrated DESs were synthesized to pretreat kraft pulp. The 10, 20, and 30% (v/v) DES solutions were prepared by mixing the ChCl/oxalic acid dihydrate constituents with the corresponding amount of water, respectively. A molecular dynamic simulation was employed for an in-depth understanding of the dynamic interactions between the DES constituents and water molecules and the supermolecular structures that were formed. The Kamlet–Taft solvatochromic parameters were measured to denote the solvent effects of the hydrated DESs. The kraft pulp was pretreated with these hydrated DESs, and comprehensive evaluations on the changes in chemical composition, degree of polymerization (DP), and cellulose accessibility were investigated. The pretreated pulp was fibrillated into CNFs and CNCs using ultrasonic treatment. The morphology, surface functional group charges, crystallinity, and physiochemical properties of the resulting CNFs and CNCs were comprehensively studied.

Results and Discussion

Molecular Dynamic Simulation of the Hydrated DESs

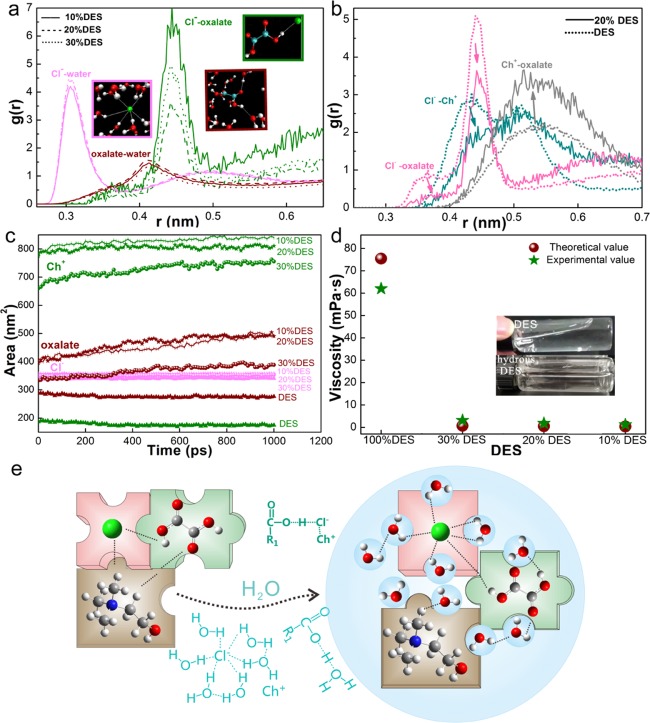

A molecular dynamic simulation was employed to reveal how water interacts with ChCl/oxalic acid DES at an atomic level and forms a co-solvent system.44,45 In the radial distribution function (RDF) graph of the hydrated DESs, the distance between Cl– and water molecules (Cl––H2O) was the nearest, followed by that of oxalate–H2O and Cl––H2O (Figures 1a and S3). The hydration number of Cl– was 6, which was larger than those of other hydration interactions (oxalate–H2O, Ch+–H2O) (Figure S4). These observations reveal that the Cl––H2O anionic hydrogen bond plays a dominant role in tuning the solvent properties. As neutral hydrogen bonds (oxalate–H2O) and ionic hydrogen bonds (Cl––H2O) coexisted, water presented higher hydrates of hydrogen ions (typically H13O6+), which facilitated the ionization and protonation of the co-solvent system. However, the RDFs of the hydrogen interactions in 20% DES were similar to those in DES (Figure 1b), indicating that a modest amount of water participates in establishing the hydrated hydrogen bonds rather than destroying the molecular interaction system within the DES. As shown in Figure 1c, adding water to the ChCl/oxalic acid dihydrate DES promoted the delocalization of molecules, and a great number of internal Ch+ and oxalates were readily released, whose accessible surface areas were enlarged. Accordingly, the fluidity of the hydrated DES was notably enhanced. The viscosity of pure DES and its hydrated DESs were studied through theoretical calculations and experimental testing. The viscosity decreased significantly as a large amount of water was added (Figure 1d). For example, after adding quadruple amount of water to the DES, the viscosity of the resulting 20% DES decreased from 62 to 1.8 mPa s, which is close to that of water. Such a low-viscosity DES is suitable for pulp pretreatment. From this analysis, we deduced that the “hydration factor” becomes another important interaction in the co-solvent system (Figure 1e). The promotional effect of molecular water can be regarded as the salvation-like effect and the water-mediated H-transfer effect.46

Figure 1.

(a) Radial distribution functions (RDFs, g(r)) of hydrated deep eutectic solvents (DESs) with respect to the center of mass of Cl–, oxalate, and water, respectively. (b) The RDFs of pure DES and 20% DES with respect to the center of mass of Cl–, oxalate, and Ch+. (c) Accessible surface area of the solvent constituents at different concentrations. (d) Theoretical and experimental viscosity values of the hydrated DESs. (e) Schematic illustration elucidating the hydration effect of water to a DES system.

Solvatochromic Parameters and NMR Spectra of the Hydrated DESs

The Kamlet–Taft solvatochromic parameters were used to estimate the properties of the hydrated DESs. The parameters α, β, and π* represent the hydrogen bond acidity, the hydrogen bond basicity, and the polarizability of the solvents, respectively. The α and β values of the ChCl/oxalic acid dihydrate DES were 1.90 and 0.41, respectively. The α value decreased slightly to 1.75 after adding water to the DES (Figure 2a). No obvious differences were found among the α values of the three hydrated DESs. The β values decreased from 0.41 to 0.2 after adding water. The decrease in the β values can be explained by Cl– being mostly sequestered by anionic hydrogen bonds. The π* values describe the ability to stabilize a neighboring charge or dipole, and it changed little due to a stable hydration effect between water and the DES.

Figure 2.

(a) Kamlet–Taft solvatochromic parameters of the hydrated deep eutectic solvents (DESs). (b) 1H NMR spectra of pure DES and the hydrated DESs.

The 1H NMR spectra of ChCl/oxalic acid dihydrate DES and the hydrated DESs are compared in Figure 2b. With the addition of water, the disappearance of the peak at 7.2 ppm in pure DES indicates that the group of COO–H in oxalic acid was delocalized, facilitating the ionization of H+. The resonance of peaks within 4.5–5.0 ppm originated from the hydrated hydrogen ions. The shifting of the resonance to a lower field was ascribed to the fact that water can diffuse faster into the DES and interact with ChCl/oxalic acid molecules. From these results, we confirmed that hydrated ions are important for improving the solvent properties.

Kraft Pulp Pretreated with Hydrated DESs

Poplar wood is comprised of 46.1% cellulose, 34.7% hemicellulose, and 19.1% lignin as raw materials.38 The lignin content of the bleached poplar kraft pulp from a sulfate pulping process dropped from 19.1 to 3.8%, and the hemicellulose content declined to 13.8% (Table 1). There was 3.8% lignin and 13.8% hemicellulose that remained in the kraft pulp. The lignin and hemicellulose in the pretreated pulp were further reduced after the kraft pulp was pretreated by one pass through the hydrated DESs, and the cellulose content in the pretreated pulp reached 90%. The DES treatment generated a hydrolytic influence on cellulose. The DP values of cellulose decreased from 1452 in the kraft pulp to half or one-third of that value (Table 1). The viscosity of cellulose also decreased significantly. The hydrolytic influence on cellulose by the hydrated DES was much less than that generated by 100% DES.

Table 1. Chemical Compositions of the Hydrated Deep Eutectic Solvents (DESs)-Pretreated Pulp.

| sample | lignin (%) | hemicellulose (%) | cellulose (%) | yield (%) | viscosity (mPa s) | DP |

|---|---|---|---|---|---|---|

| poplar wood | 19.1 ± 0.4 | 34.7 ± 0.2 | 46.1 ± 0.6 | |||

| bleached poplar kraft pulp | 3.8 ± 0.6 | 13.8 ± 1.1 | 82.6 ± 0.7 | 100 | 8.25 | 1452 |

| 10% DES-pretreated pulp | 1.9 ± 0.2 | 7.8 ± 0.7 | 90.2 ± 0.5 | 88.8 | 3.02 | 791 |

| 20% DES-pretreated pulp | 1.8 ± 0.3 | 6.8 ± 0.9 | 91.4 ± 0.6 | 85.8 | 3.35 | 595 |

| 30% DES-pretreated pulp | 1.2 ± 0.2 | 7.6 ± 0.8 | 91.2 ± 0.6 | 80.8 | 4.18 | 530 |

The hydrous DES can be reused to pretreat the kraft pulp. The efficacy of the hydrated DES can be maintained by supplying little of the DES constituents, and the viscosity of the DES can be adjusted by adding water. Furthermore, the DES can be recycled via distillation process.

Fabrication of Nanocellulose from Pretreated Pulp

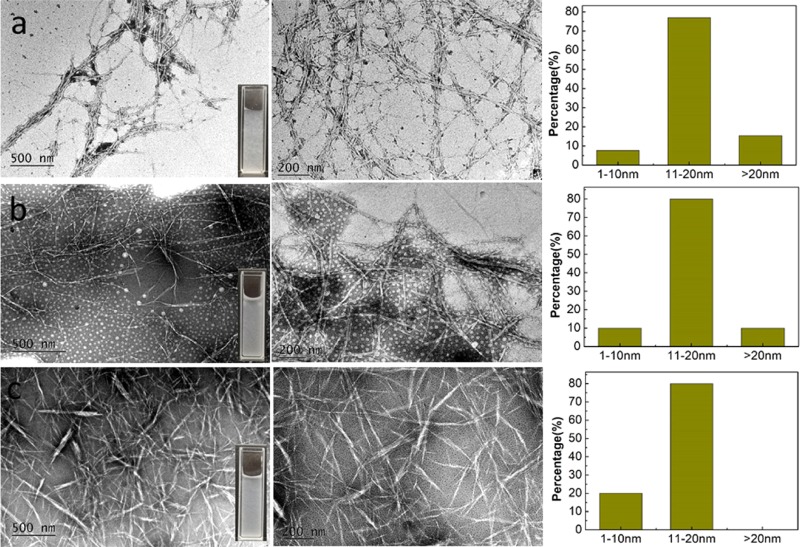

Ultrasonication is a frequently used approach in the liquid phase and in an open state. Ultrasonic treatment does not need a complicated setup or a high equipment investment. It is also suitable for industrial production. The drawback is its weaker nanofibrillation efficiency on the cellulose than that of other mechanical treatments, such as high-pressure homogenization. The kraft pulp was hardly fibrillated into homogeneous nanocellulose when directly subjected to an ultrasonic treatment (Figure S5). In conjunction with chemical pretreatments, the ultrasonic treatment has been demonstrated to effectively disintegrate the cellulose pulp into CNFs and CNCs.8,11,22,39 Here, the hydrated DES pretreatment improved accessibility of the cellulose pulp and facilitated the ultrasonic energy to disintegrate the pulp.47,48 The resulting nanocellulose suspensions appeared stable and showed no obvious precipitates. The transmission electron microscopy (TEM) images and size distributions of the nanocelluloses are shown in Figure 3. The 10% DES-pretreated pulp produced CNFs after ultrasonic processing. The percentage of the CNF diameters within 20 nm was 87%, and few recalcitrant thicker nanofibers remained. The lengths were usually within 300–2000 nm,40 which were longer than those produced from 100% DES-pretreated pulp (Figure S6).38,39 Increasing the DES concentration resulted in CNCs with a narrower diameter distribution. Little change in the diameter was observed between the CNCs pretreated with 20% DES and that treated with 30% DES, but the CNCs pretreated with 30% DES were shorter.

Figure 3.

Transmission electron microscopy images and diameter distribution histograms of the (a) 10% deep eutectic solvent (DES)-pretreated cellulose nanofibers (CNFs), (b) 20% DES-pretreated cellulose nanocrystals (CNCs), and (c) 30% DES-pretreated CNCs.

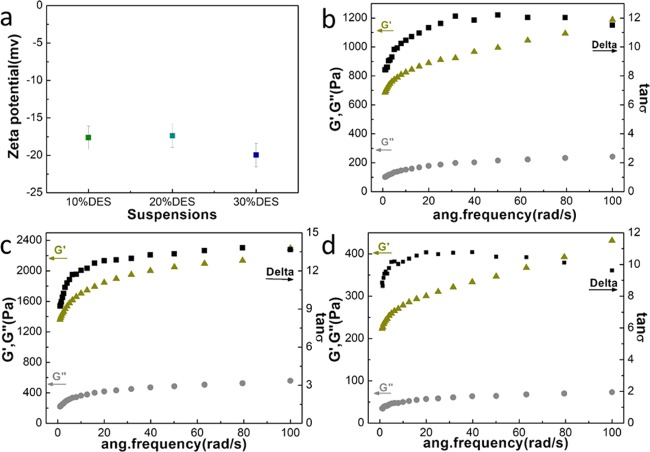

The ζ-potentials of the CNFs and CNCs were all negative at approximately 17–20 mV (Figure 4a). Such values were close to those of short-time acid hydrolysis but smaller than those of long-time acid hydrolysis.22,49 This result suggests that a slight DES-induced acidifying effect occurred on the hydroxyls and generated charge repulsive forces. The charge density of the resulting nanocellulose was determined by conductometric titration. The carboxyl content was 0.05–0.12 mmol g–1, suggesting that the hydrated DES pretreatment led to the generation of a small amount of negatively charged carboxyl moieties on the surfaces of the nanocelluloses.50 The charge densities obtained by this approach were far lower than those of the highly carboxylated CNFs obtained from TEMPO and periodate-chlorite oxidation.51

Figure 4.

(a) ζ-Potential plot of the nanocellulose suspensions. Storage and loss moduli (G′, G″) and loss tangent (tan δ) changes versus strain of the suspensions/gels composed by (b) 10% deep eutectic solvent (DES)-pretreated cellulose nanofibers (CNFs) and (c) 20% DES and (d) 30% DES-pretreated cellulose nanocrystals (CNCs).

The dynamic rheological behaviors of the suspensions/gels composed by the DES-pretreated nanocelluloses (0.5 wt %) are shown in Figure 4b–d. Both the storage modulus (G′) and the loss modulus (G″) values were frequency sensitive at low shear rates and became frequency independent as the shear rate continuously improved. The dynamic rheological results agreed with the shear-thinning behavior with a plateau region at the high shear rate interval. Although the G′ and G″ values were relatively low for the 10% DES-pretreated CNF suspension, they represent a highly viscous fluid behavior (Figure 4b). The 20% DES-pretreated CNC suspension showed the highest G′ values, which resulted from the optimal pretreatment of the pulp and adequate nanofibrillation (Figure 4c). Such a suspension presents a gel-like behavior generated from the dynamic stable network. The 30% DES-pretreated CNC suspension exhibited similar rheological behaviors, but gel strength was far lower than those of others, suggesting a low viscous fluid characteristic (Figure 4d).

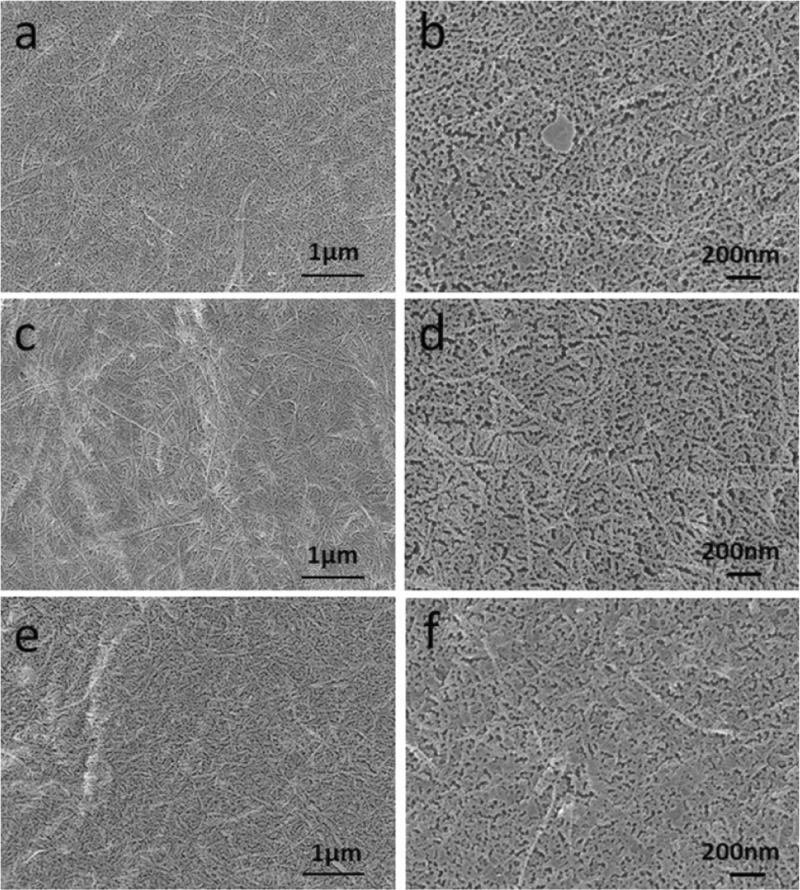

Figure 5 shows the scanning electron microscopy (SEM) images of the CNF and CNC mats produced by suction filtration and solvent evaporation drying. Although the widths of the CNFs and CNCs were mostly within 20 nm, they self-aggregated into long and thick nanofibers along the longitudinal direction during the drying process, owing to the formation of hydrogen bonds between the adjacent hydroxyl groups.52 The high-aspect-ratio nanofibers also formed web-like entangled structures, and massive nanometer-sized pores were observed throughout the entire mat.

Figure 5.

Scanning electron microscopy images of the fibrous mats composed by (a, b) 10% deep eutectic solvent (DES)-pretreated cellulose nanofibers (CNFs), (c, d) 20% DES-pretreated cellulose nanocrystals (CNCs), and (e, f) 30% DES-pretreated CNCs.

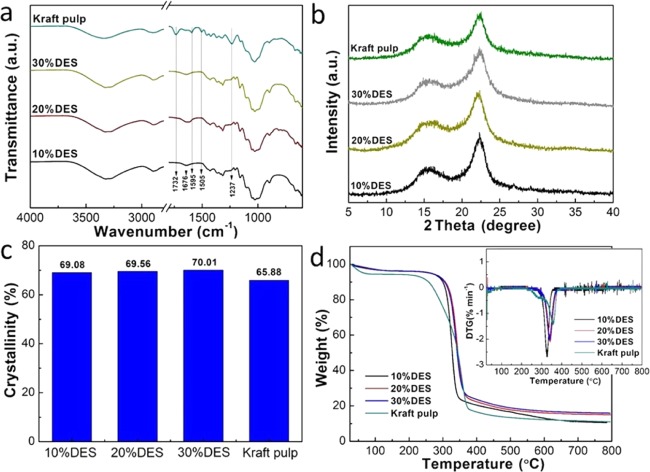

Fourier transform-infrared (FT-IR) spectra of the samples (Figure 6a) reveal the chemical transformation of the components.53 The disappearance of the absorbance peaks at 1590 and 1505 cm–1, representing the aromatic parts of lignin, was associated with complete removal of lignin. The decrease in the intensity of the prominent bands at 1732 and 1237 cm–1 (representing carboxyl groups and attributed either to the acetyl and uronic ester groups of the hemicellulose or to the ester linkage of the carboxyl groups of lignin and/or hemicellulose) indicated the dissolution/removal of hemicellulose. The stretching vibration characteristic peak of the C=O groups at 1676 cm–1 was enhanced, possibly corresponding to the presence of carboxyl and hemiacetal groups.54

Figure 6.

(a) Fourier transform-infrared spectra, (b) X-ray diffraction (XRD) patterns, (c) thermogravimetric curves, and (d) differential thermogravimetric curves of the kraft pulp and the hydrated deep eutectic solvent (DES)-pretreated nanocelluloses.

X-ray diffraction (XRD) was used to investigate the crystalline structure and the relative crystallinity of the nanocelluloses (Figure 6b). The kraft pulp, the hydrated DES-pretreated pulp, and the resulting nanocelluloses all exhibited typical diffraction peaks at approximately 2θ = 16.6 and 22.6°, which confirmed the type I crystal lattice structure of the native cellulose.55 These results reveal that the hydrated DES pretreatment did not change the crystalline structure of the cellulose. The crystallinity index (CrI) value of the kraft pulp was 65.88%, which increased to 69.08–70.01% after pretreatment with hydrated DES. The increase in the CrI value undoubtedly resulted from the removal of lignin and most of the hemicellulose.

The thermal degradation characteristics of the CNFs and CNCs were compared with those of kraft pulp. Similar initial decomposition temperatures of ∼280 °C were found among the resulting nanocelluloses, whereas the temperature of maximum degradation of the 10% DES-pretreated CNFs was slightly less than those of 20% DES-pretreated and 30% DES-pretreated CNCs (Figure 6d). The initial thermal degradation temperatures of the nanocelluloses obtained by this approach were apparently higher than those of the CNFs produced through the TEMPO treatment and those of the CNCs produced by strong acid hydrolysis.

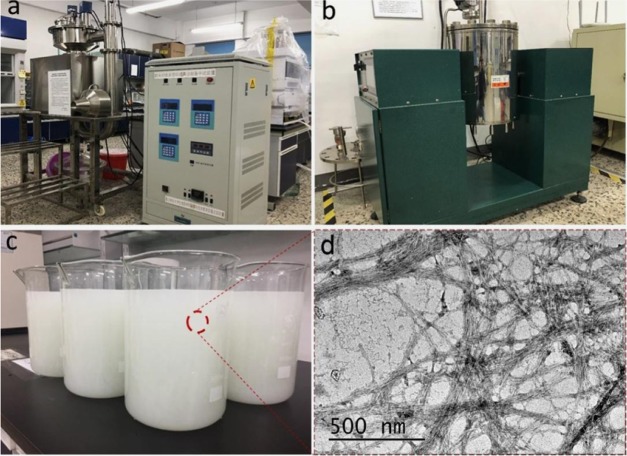

A pilot-scale test was conducted to produce CNFs and CNCs under optimized conditions. A portion of 0.5 kg (dry weight) pretreated pulp to 100 L water was added to a pilot-scale circulating ultrasonic apparatus (Figure 7a). The pilot-scale apparatus was equipped with three ultrasonic generators. During the working process, the output power for each ultrasonic generator was set to 800 W, and the processing time was 20 min. Therefore, approximately 100 L of CNF or CNC suspension (concentration: 0.5 wt %) can be processed by this apparatus every half hour. The resulting suspensions were uniform and stable in the macroscopic view (Figure 7c). However, the CNFs (or CNCs) were a bit longer and thicker than those produced on a laboratory scale (Figure 7d). The CNF/CNC diameters were almost within the range of 2–50 nm, and the lengths were usually larger than 500 nm.

Figure 7.

Combination of (a) pilot-scale circulated ultrasonic apparatus and (b) digester to massively produce nanocellulose suspension. (c) Photograph and (d) transmission electron microscopic image of the 10% deep eutectic solvent (DES)-pretreated and pilot-scale ultrasonicator-processed cellulose nanofiber (CNF) suspension.

Conclusions

In summary, green and low-cost hydrated DESs were developed by adding water to ChCl/oxalic acid dihydrate DES. The DES and the supermolecular structure of water possessed features of hydrated ionic and neutral hydrogen bonds, exhibiting high H+ ionization, ionic delocalization, and polarizability. The hydrated DESs were effective for pretreating kraft pulp to reduce pulp polymerization and increase its accessibility, thus making it feasible to fabricate CNFs and CNCs though an ultrasonic process. The 10% DES-pretreated pulp was nanofibrillated into CNFs using an 800 W ultrasonic treatment for 20 min, and the 20% DES (or 30% DES)-pretreated pulp was disintegrated into CNCs using the same ultrasonic treatment. The resulting CNFs and CNCs displayed a nano-order scale, high crystallinity, and good thermal stability. The entire pathway was simple and commercially competitive to produce nanocellulose on an industrial scale.

Experimental Section

Materials

The kraft pulp from poplar wood was used as the raw cellulose material. ChCl and oxalic acid dihydrate were purchased from Aladdin Reagent Co. Ltd. (Shanghai, China). Copper(II)–ethylenediamine complex (1 M, MW 121.6) for the DP test of cellulose was purchased from Guangfu Chemical Reagent Co., Ltd. (Tianjin, China).

Preparation of Hydrated DESs

The ChCl/oxalic acid dihydrate DES was synthesized at a molar ratio of 1:1 in a round-bottom flask. The binary mixtures were reacted under reduced pressure at 80 °C for 1 h until the mixtures became a clear liquid. Three hydrated DESs were synthesized by mixing the DES with water at the volume concentrations of 10, 20, and 30% and named 10% DES, 20% DES, and 30% DES, respectively.

Pulp Pretreatment with Hydrated DESs

The same amount of kraft pulp was added to each hydrated DES and heated at 80 °C for 1 h. The mass ratio of the kraft pulp to the hydrated DES was 5%. After the pretreatment, the pulp was filtered and washed with deionized water. The yield was calculated as the weight percentage of oven-dried pulp to that of raw kraft pulp.

Preparation of CNFs on a Laboratory Scale

The pretreated pulp was soaked in water at 0.5 wt % calculated content. The pulp was nanofibrillated in a common ultrasonic generator (JY99-IIDN, Scientz Biotechnology Co. Ltd., Ningbo, China) equipped with a cylindrical titanium alloy probe (25 mm in diameter). The ultrasonic frequency was 20 kHz, the output power was 800 W, and the processing time was 20 min.

Production of CNFs on a Pilot Scale

A 500 g portion of pretreated pulp and 100 L of water were added to the 105 L reactor chamber of a circulated ultrasonic apparatus (TGCXZ-100, Hongxianglong Biotechnology Co. Ltd., Beijing, China). The pilot-scale apparatus was equipped with three 25 mm cylindrical titanium alloy probes. The ultrasonic frequency was set to 20 kHz, the output power was 800 W for each ultrasonic generator, the mechanical stirring speed was 600 rpm, and the processing time was 20 min.

Characterizations

Molecular Dynamic Simulation

The rectangular periodic boxes contained 300 oxalate molecules and 300 ChCl molecules, and the number of water molecules was adjusted from 8945 to 34 503 to achieve the required concentrations of 30% DES, 20% DES, and 10% DES. The extended simple point charge model was used for the water molecules, and the force-field parameters were obtained from the GROMOS54a7 for ChCl, oxalate, and water. The periodic boundary condition was applied to all three dimensions. The particle mesh Ewald method was used to calculate the long-range electrostatic interaction with a real space cutoff of 1.0 nm. The short-range van der Waals cutoff was set to 1.0 nm. Simulations were performed in the NVT and NPT ensembles, with T = 353 K and P = 1 bar. Temperature and pressure were controlled using a V-Rescale thermostat and Parrinello–Rahman algorithm, respectively. The simulation temperatures were the same as those used for the experimental conditions. Minimization was performed using the steepest-descent algorithm for up to 50 000 steps or until the convergence tolerance was reached. All of the simulations were performed using the GROMACS 5.1 software suite. Radial distribution functions, hydrated hydrogen bonds, accessible surface area, and viscosity were computed using the GROMACS built-in analysis tools.

Viscosity of the Hydrated DESs

The viscosity of each sample was measured using a DVS+ digital viscosimeter (Brookfield Co., Ltd., Stoughton, MA) and five repeated tests.

Kamlet–Taft Solvatochromic Parameters of the Hydrated DESs

Nile red was used as a solvatochromic indicator to determine α, and 4-nitroaniline was used to determine β. N,N-Diethyl-4-nitroaniline was selected to determine π*.43 See Note S1 and Figure S1 in the Supporting Information for details.

NMR Analysis

A 300 μL aliquot of dimethyl sulfoxide and 300 μL DES sample were mixed together. The 1H NMR spectra were recorded with an Agilent Pro Pulse 500 MHz spectrometer (Agilent Technologies Inc., Santa Clara, CA) operating at 202.3 MHz using an inverse gated decoupling sequence. Relaxation delay was set to 5. Approximately 1000 transients were acquired to ensure a high signal/noise ratio.

Chemical Composition Analysis

The chemical compositions of the kraft pulp and the hydrated DES-pretreated samples were determined as described previously38 and expressed as wt % content of lignin, hemicellulose, and cellulose. A minimum of three tests were performed, and their average was calculated.

DP and Viscosity Measurement

The DP and viscosity of the kraft pulp and the hydrated DES-pretreated samples were measured using a 1835-4-0.80 Ubbelohde viscometer (Xinbiao Tengda Instruments, Beijing, China) and copper(II)–ethylenediamine as the solvent. See ISO 5351-2010 for details.

TEM Observation

TEM was used to observe the resulting nanocelluloses under a FEI Tecnai G2 microscope (FEI, Best, the Netherlands) at 80 kV. A 5 μL aliquot of the diluted slurry was dropped on a carbon-coated electron microscopy grid and was negatively stained with 1 wt % phosphotungstic acid to enhance the image contrast. The sizes of the nanocelluloses were measured from the TEM images using the TDY-V5.2 image analysis system (Tianhong Precision Instrument Co. Ltd., Beijing, China).

Conductometric Titration

The charge density of the nanocelluloses was determined through the conductometric titration with a DDS-11A conductivity meter (LEICI Instrument, Shanghai, China). A 100 mg portion of the nanocellulose was suspended in 10 mL of 0.01 M HCl by 4 h of sonication. The suspension was titrated with 0.01 M NaOH. A titration graph was fit to determine the charge density (Figure S2). The charge density was determined as mmol of RCOO– per g nanocellulose from the volume of NaOH used.

ζ-Potential Analysis

The surface charge of the aqueous nanocelluloses was measured using dynamic light scattering with a zetasizer (Nano ZS, Malvern, U.K.).

Rheological Measurement

The rheological measurements on the nanocellulose gels were carried out using a rotational rheometer (AR 2000, TA Instruments, New Castle, DE). The strain amplitude value was set to 0.25 to ensure dynamic oscillatory deformation within the linear viscoelastic region.

SEM Observation

The microstructure of the nanocellulose mats in a dry state was observed using a field emission scanning electron microscope (Sirion 200, FEI) at 10–15 kV. The samples were coated with platinum using a vacuum sputter coater before the observations.

FT-IR Spectroscopy

The FT-IR spectra were measured using a Nicolet Magna 560 FT-IR instrument (Thermo Fisher Co., Waltham, MA). The spectra were measured in the ATR mode, and the data were recorded over the range from 650 to 4000 cm–1, with a resolution of 4 cm–1.

XRD Analysis

The XRD curves were obtained using an X-ray diffractometer (D/max 2200, Rigaku, Tokyo, Japan) with Ni-filtered Cu Kα radiation (λ = 0.154 nm) at 40 kV and 30 mA. The diffraction data were collected from 2θ = 5 to 40° at a scanning rate of 4° min–1. The crystallinity index (CrI) was estimated using the Segal method.

Thermogravimetric (TG) Analysis

The TG analysis was performed using a TG analyzer (Pyris 6, PerkinElmer, Waltham, MA) at a heating rate of 10 °C min–1 in a nitrogen atmosphere.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos. 31670583 and 31622016), the Natural Science Foundation of Heilongjiang Province of China (Grant No. JC2016002).

Supporting Information Available

The Supporting Information is available free of charge on the ACS Publications website at DOI: 10.1021/acsomega.9b00519.

Experimental details for the measurement of Kamlet–Taft solvatochromic parameters, conductometric titration of carboxyl groups, and related figures for additional characterizations (PDF)

Author Contributions

† Y.M. and Q.X. contributed equally to this work.

The authors declare no competing financial interest.

Supplementary Material

References

- Klemm D.; Kramer F.; Moritz S.; Lindström T.; Ankerfors M.; Gray D.; et al. Nanocelluloses: A New Family of Naturebased Materials. Angew. Chem., Int. Ed. 2011, 50, 5438–5466. 10.1002/anie.201001273. [DOI] [PubMed] [Google Scholar]

- Ling S.; Chen W.; Fan Y.; Zheng K.; Jin K.; Yu H.; et al. Biopolymer Nanofibrils: Structure, Modeling, Preparation, and Applications. Prog. Polym. Sci. 2018, 85, 1–56. 10.1016/j.progpolymsci.2018.06.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kontturi E.; Laaksonen P.; Linder M. B.; Nonappa; Gröschel A. H.; Rojas O. J.; Ikkala O. Advanced Materials through Assembly of Nanocelluloses. Adv. Mater. 2018, 30, 1703779 10.1002/adma.201703779. [DOI] [PubMed] [Google Scholar]

- Nascimento D. M.; Nunes Y. L.; Figueirêdo M. C.; de Azeredo H. M.; Aouada F. A.; Feitosa J. P.; et al. Nanocellulose Nanocomposite Hydrogels: Technological and Environmental Issues. Green Chem. 2018, 20, 2428–2448. 10.1039/C8GC00205C. [DOI] [Google Scholar]

- Kaushik M.; Moores A. Review: Nanocelluloses as Versatile Supports for Metal Nanoparticles and Their Applications in Catalysis. Green Chem. 2016, 18, 622–637. 10.1039/C5GC02500A. [DOI] [Google Scholar]

- Chen W.; Yu H.; Lee S.-Y.; Wei T.; Li J.; Fan Z. Nanocellulose: A Promising Nanomaterial for Advanced Electrochemical Energy Storage. Chem. Soc. Rev. 2018, 47, 2837–2872. 10.1039/C7CS00790F. [DOI] [PubMed] [Google Scholar]

- Abe K.; Iwamoto S.; Yano H. Obtaining Cellulose Nanofibers with A Uniform Width of 15 nm from Wood. Biomacromolecules 2007, 8, 3276–3278. 10.1021/bm700624p. [DOI] [PubMed] [Google Scholar]

- Chen W.; Yu H.; Liu Y.; Hai Y.; Zhang M.; Chen P. Isolation and Characterization of Cellulose Nanofibers from Four Plant Cellulose Fibers using A Chemical-Ultrasonic Process. Cellulose 2011, 18, 433–442. 10.1007/s10570-011-9497-z. [DOI] [Google Scholar]

- Chen W.; Yu H.; Liu Y. Preparation of Millimeter-Long Cellulose I Nanofibers with Diameters of 30–80 nm from Bamboo Fibers. Carbohydr. Polym. 2011, 86, 453–461. 10.1016/j.carbpol.2011.04.061. [DOI] [Google Scholar]

- Deepa B.; Abraham E.; Cordeiro N.; Mozetic M.; Mathew A. P.; Oksman K.; et al. Utilization of Various Lignocellulosic Biomass for the Production of Nanocellulose: A Comparative Study. Cellulose 2015, 22, 1075–1090. 10.1007/s10570-015-0554-x. [DOI] [Google Scholar]

- Chen W.; Yu H.; Liu Y.; Chen P.; Zhang M.; Hai Y. Individualization of Cellulose Nanofibers from Wood using High-Intensity Ultrasonication Combined with Chemical Pretreatments. Carbohydr. Polym. 2011, 83, 1804–1811. 10.1016/j.carbpol.2010.10.040. [DOI] [Google Scholar]

- Khalil H. P. S. A.; Davoudpour Y.; Nazrul Islam M.; Mustapha A.; Sudesh K.; Dungani R.; et al. Production and Modification of Nanofibrillated Cellulose using Various Mechanical Processes: A Review. Carbohydr. Polym. 2014, 99, 649–665. 10.1016/j.carbpol.2013.08.069. [DOI] [PubMed] [Google Scholar]

- Jiang F.; Hsieh Y.-L. Chemically and Mechanically Isolated Nanocellulose and Their Self-Assembled Structures. Carbohydr. Polym. 2013, 95, 32–40. 10.1016/j.carbpol.2013.02.022. [DOI] [PubMed] [Google Scholar]

- Meng X.; Pu Y.; Yoo C. G.; Li M.; Bali G.; Park D. Y.; et al. An In-Depth Understanding of Biomass Recalcitrance using Natural Poplar Variants as the Feedstock. ChemSusChem 2017, 10, 39–150. 10.1002/cssc.201601303. [DOI] [PubMed] [Google Scholar]

- Li N.; Li Y.; Yoo C. G.; Yang X.; Lin X.; Ralph J.; et al. An Uncondensed Lignin Depolymerized in the Solid State and Isolated from Lignocellulosic Biomass: A Mechanistic Study. Green Chem. 2018, 20, 4224–4235. 10.1039/C8GC00953H. [DOI] [Google Scholar]

- Naderi A.; Lindström T.; Sundström J. Repeated Homogenization, A Route for Decreasing the Energy Consumption in the Manufacturing Process of Carboxymethylated Nanofibrillated Cellulose?. Cellulose 2015, 22, 1147–1157. 10.1007/s10570-015-0576-4. [DOI] [Google Scholar]

- Meng X.; Parikh A.; Seemala B.; Kumar R.; Pu Y.; Wyman C. E.; et al. Characterization of Fractional Cuts of Co-Solvent Enhanced Lignocellulosic Fractionation Lignin Isolated by Sequential Precipitation. Bioresour. Technol. 2018, 272, 202–208. 10.1016/j.biortech.2018.09.130. [DOI] [PubMed] [Google Scholar]

- Lee M.; Heo M. H.; Lee H.; Lee H. H.; Jeong H.; Kim Y. W.; et al. Facile and Eco-Friendly Extraction of Cellulose Nanocrystals via Electron Beam Irradiation Followed by High-Pressure Homogenization. Green Chem. 2018, 20, 2596–2610. 10.1039/C8GC00577J. [DOI] [Google Scholar]

- Siró I.; Plackett D. Microfibrillated Cellulose and New Nanocomposite Materials: A Review. Cellulose 2010, 17, 459–494. 10.1007/s10570-010-9405-y. [DOI] [Google Scholar]

- Patankar S. C.; Renneckar S. Greener Synthesis of Nanofibrillated Cellulose using Magnetically Separable TEMPO Nanocatalyst. Green Chem. 2017, 19, 4792–4797. 10.1039/C7GC02383A. [DOI] [Google Scholar]

- Saito T.; Nishiyama Y.; Putaux J. L.; Vignon M.; Isogai A. Homogeneous Suspensions of Individualized Microfibrils from TEMPO-Catalyzed Oxidation of Native Cellulose. Biomacromolecules 2006, 7, 1687–1691. 10.1021/bm060154s. [DOI] [PubMed] [Google Scholar]

- Li Y.; Liu Y.; Chen W.; Wang Q.; Liu Y.; Li J.; et al. Facile Extraction of Cellulose Nanocrystals from Wood using Ethanol and Peroxide Solvothermal Pretreatment Followed by Ultrasonic Nanofibrillation. Green Chem. 2016, 18, 1010–1018. 10.1039/C5GC02576A. [DOI] [Google Scholar]

- Zhang Z.; Song J.; Han B. Catalytic Transformation of Lignocellulose into Chemicals and Fuel Products in Ionic Liquids. Chem. Rev. 2017, 117, 6834–6880. 10.1021/acs.chemrev.6b00457. [DOI] [PubMed] [Google Scholar]

- Tang L.; Huang B.; Yang N.; Li T.; Lu Q.; Lin W.; et al. Organic Solvent-Free and Efficient Manufacture of Functionalized Cellulose Nanocrystals via One-Pot Tandem Reactions. Green Chem. 2013, 15, 2369–2373. 10.1039/c3gc40965a. [DOI] [Google Scholar]

- Shen X.; Wang B.; Huang P.; Wen J.; Sun R. C. Effects of Aluminum Chloride-Catalyzed Hydrothermal Pretreatment on the Structural Characteristics of Lignin and Enzymatic Hydrolysis. Bioresour. Technol. 2016, 206, 57–64. 10.1016/j.biortech.2016.01.031. [DOI] [PubMed] [Google Scholar]

- Erythropel H. C.; Zimmerman J. B.; de Winter T. M.; Petitjean L.; Melnikov F.; Lam C. H.; et al. The Green ChemisTREE: 20 Years after Taking Root with the 12 Principles. Green Chem. 2018, 20, 1929–1961. 10.1039/C8GC00482J. [DOI] [Google Scholar]

- Abbott A. P.; Boothby D.; Capper G.; Davies D. L.; Rasheed R. K. Deep Eutectic Solvents Formed between Choline Chloride and Carboxylic Acids: Versatile Alternatives to Ionic Liquids. J. Am. Chem. Soc. 2004, 126, 9142–9147. 10.1021/ja048266j. [DOI] [PubMed] [Google Scholar]

- Smith E. L.; Abbott A. P.; Ryder K. S. Deep Eutectic Solvents (DESs) and Their Applications. Chem. Rev. 2014, 114, 11060–11082. 10.1021/cr300162p. [DOI] [PubMed] [Google Scholar]

- Carriazo D.; Serrano M. C.; Gutiérrez M. C.; Ferrer M. L.; del Monte F. Deep-Eutectic Solvents Playing Multiple Roles in the Synthesis of Polymers and Related Materials. Chem. Soc. Rev. 2012, 41, 4996–5014. 10.1039/c2cs15353j. [DOI] [PubMed] [Google Scholar]

- Satlewal A.; Agrawal R.; Bhagia S.; Sangoro J.; Ragauskas A. J. Natural Deep Eutectic Solvents for Lignocellulosic Biomass Pretreatment: Recent Developments, Challenges and Novel Opportunities. Biotechnol. Adv. 2018, 36, 2032–2050. 10.1016/j.biotechadv.2018.08.009. [DOI] [PubMed] [Google Scholar]

- Vigier K. D. O.; Chatel G.; Jérôme F. Contribution of Deep Eutectic Solvents for Biomass Processing: Opportunities, Challenges, and Limitations. ChemCatChem 2015, 7, 1250–1260. 10.1002/cctc.201500134. [DOI] [Google Scholar]

- Tang X.; Zuo M.; Li Z.; Liu H.; Xiong C.; Zeng X.; et al. Green Processing of Lignocellulosic Biomass and Its Derivatives in Deep Eutectic Solvents. ChemSusChem 2017, 10, 2696–2706. 10.1002/cssc.201700457. [DOI] [PubMed] [Google Scholar]

- Sirviö J. A.; Visanko M. Anionic Wood Nanofibers Produced from Unbleached Mechanical Pulp by Highly Efficient Chemical Modification. J. Mater. Chem. A 2017, 5, 21828–21835. 10.1039/C7TA05668K. [DOI] [Google Scholar]

- Sirviö J. A.; Visanko M.; Liimatainen H. Deep Eutectic Solvent System Based on Choline Chloride-Urea as A Pre-Treatment for Nanofibrillation of Wood Cellulose. Green Chem. 2015, 17, 3401–3406. 10.1039/C5GC00398A. [DOI] [Google Scholar]

- Sirviö J. A.; Visanko M.; Liimatainen H. Acidic Deep Eutectic Solvents as Hydrolytic Media for Cellulose Nanocrystal Production. Biomacromolecules 2016, 17, 3025–3032. 10.1021/acs.biomac.6b00910. [DOI] [PubMed] [Google Scholar]

- Suopajärvi T.; Sirviö J. A.; Liimatainen H. Nanofibrillation of Deep Eutectic Solvent-Treated Paper and Board Cellulose Pulps. Carbohydr. Polym. 2017, 169, 167–175. 10.1016/j.carbpol.2017.04.009. [DOI] [PubMed] [Google Scholar]

- Li P.; Sirviö J. A.; Haapala A.; Liimatainen H. Cellulose Nanofibrils from Nonderivatizing Urea-Based Deep Eutectic Solvent Pretreatments. ACS Appl. Mater. Interfaces 2017, 9, 2846–2855. 10.1021/acsami.6b13625. [DOI] [PubMed] [Google Scholar]

- Liu Y.; Chen W.; Xia Q.; Guo B.; Wang Q.; Liu S.; et al. Efficient Cleavage of Lignin–Carbohydrate Complexes and Ultrafast Extraction of Lignin Oligomers from Wood Biomass by Microwave-Assisted Treatment with Deep Eutectic Solvent. ChemSusChem 2017, 10, 1692–1700. 10.1002/cssc.201601795. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liu Y.; Guo B.; Xia Q.; Meng J.; Chen W.; Liu S.; et al. Efficient Cleavage of Strong Hydrogen Bonds in Cotton by Deep Eutectic Solvents and Facile Fabrication of Cellulose Nanocrystals in High Yields. ACS Sustainable Chem. Eng. 2017, 5, 7623–7631. 10.1021/acssuschemeng.7b00954. [DOI] [Google Scholar]

- Chen W.; Li Q.; Cao J.; Liu Y.; Li J.; Zhang J.; et al. Revealing the Structures of Cellulose Nanofiber Bundles Obtained by Mechanical Nanofibrillation via TEM Observation. Carbohydr. Polym. 2015, 117, 950–956. 10.1016/j.carbpol.2014.10.024. [DOI] [PubMed] [Google Scholar]

- Dai Y.; Witkamp G. J.; Verpoorte R.; Choi Y. H. Tailoring Properties of Natural Deep Eutectic Solvents with Water to Facilitate Their Applications. Food Chem. 2015, 187, 14–19. 10.1016/j.foodchem.2015.03.123. [DOI] [PubMed] [Google Scholar]

- Xie Y.; Dong H.; Zhang S.; Lu X.; Ji X. Effect of Water on the Density, Viscosity, and CO2 Solubility in Choline Chloride/Urea. J. Chem. Eng. Data 2014, 59, 3344–3352. 10.1021/je500320c. [DOI] [Google Scholar]

- Xia Q.; Liu Y.; Meng J.; Cheng W.; Chen W.; Liu S.; et al. Multiple Hydrogen Bond Coordination in Three-Constituent Deep Eutectic Solvents Enhances Lignin Fractionation from Biomass. Green Chem. 2018, 20, 2711–2721. 10.1039/C8GC00900G. [DOI] [Google Scholar]

- Wagle D. V.; Deakyne C. A.; Baker G. A. Quantum Chemical Insight into the Interactions and Thermodynamics Present in Choline Chloride Based Deep Eutectic Solvents. J. Phys. Chem. B 2016, 120, 6739–6746. 10.1021/acs.jpcb.6b04750. [DOI] [PubMed] [Google Scholar]

- Smith M. D.; Mostofian B.; Cheng X.; Petridis L.; Cai C. M.; Wyman C. E.; et al. Cosolvent Pretreatment in Cellulosic Biofuel Production: Effect of Tetrahydrofuran-Water on Lignin Structure and Dynamics. Green Chem. 2016, 18, 1268–1277. 10.1039/C5GC01952D. [DOI] [Google Scholar]

- Chang C. R.; Huang Z. Q.; Li J. The Promotional Role of Water in Heterogeneous Catalysis: Mechanism Insights from Computational Modeling. Wiley Interdiscip. Rev.: Comput. Mol. Sci. 2016, 6, 679–693. 10.1002/wcms.1272. [DOI] [Google Scholar]

- Xu G. C.; Ding J. C.; Han R. Z.; Dong J. J.; Ni Y. Enhancing Cellulose Accessibility of Corn Stover by Deep Eutectic Solvent Pretreatment for Butanol Fermentation. Bioresour. Technol. 2016, 203, 364–369. 10.1016/j.biortech.2015.11.002. [DOI] [PubMed] [Google Scholar]

- Lu Q.; Cai Z.; Lin F.; Tang L.; Wang S.; Huang B. Extraction of Cellulose Nanocrystals with A High Yield of 88% by Simultaneous Mechanochemical Activation and Phosphotungstic Acid Hydrolysis. ACS Sustainable Chem. Eng. 2016, 4, 2165–2172. 10.1021/acssuschemeng.5b01620. [DOI] [Google Scholar]

- Lu P.; Hsieh Y. L. Preparation and Characterization of Cellulose Nanocrystals from Rice Straw. Carbohydr. Polym. 2012, 87, 564–573. 10.1016/j.carbpol.2011.08.022. [DOI] [PubMed] [Google Scholar]

- Sirviö J. A. Cationization of Lignocellulosic Fibers with Betaine in Deep Eutectic Solvent: Facile Route to Charge Stabilized Cellulose and Wood Nanofibers. Carbohydr. Polym. 2018, 198, 34–40. 10.1016/j.carbpol.2018.06.051. [DOI] [PubMed] [Google Scholar]

- Jiang F.; Hsieh Y. L. Self-Assembling of TEMPO Oxidized Cellulose Nanofibrils as Affected by Protonation of Surface Carboxyls and Drying Methods. ACS Sustainable Chem. Eng. 2016, 4, 1041–1049. 10.1021/acssuschemeng.5b01123. [DOI] [Google Scholar]

- Chen W.; Li Q.; Wang Y.; Yi X.; Zeng J.; Yu H.; et al. Comparative Study of Aerogels Obtained from Differently Prepared Nanocellulose Fibers. ChemSusChem 2014, 7, 154–161. 10.1002/cssc.201300950. [DOI] [PubMed] [Google Scholar]

- Ding Q.; Xu X.; Yue Y.; Mei C.; Huang C.; Jiang S.; et al. Nanocellulose-Mediated Electroconductive Self-Healing Hydrogels with High Strength, Plasticity, Viscoelasticity, Stretchability, and Biocompatibility toward Multifunctional Applications. ACS Appl. Mater. Interfaces 2018, 10, 27987–28002. 10.1021/acsami.8b09656. [DOI] [PubMed] [Google Scholar]

- Lu T.; Li Q.; Chen W.; Yu H. Composite Aerogels Based on Dialdehyde Nanocellulose and Collagen for Potential Applications as Wound Dressing and Tissue Engineering Scaffold. Compos. Sci. Technol. 2014, 94, 132–138. 10.1016/j.compscitech.2014.01.020. [DOI] [Google Scholar]

- Li Q.; Chen W.; Li Y.; Guo X.; Song S.; Wang Q.; et al. Comparative Study of the Structure, Mechanical and Thermomechanical Properties of Cellulose Nanopapers with Different Thickness. Cellulose 2016, 23, 1375–1382. 10.1007/s10570-016-0857-6. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.