Abstract

A range of enantiomerically pure protected side-chain-fluorinated amino acids has been prepared (13 examples) by treatment of protected amino acids containing unsaturated side chains with a combination of Fe(III)/NaBH4 and Selectfluor. The modification of the conditions by replacement of Selectfluor with NaN3 allowed the preparation of side-chain azido-substituted amino acids (five examples), which upon catalytic hydrogenation gave the corresponding amines, isolated as lactams (four examples). Radical hydration of the unsaturated side chains leading to side-chain-hydroxylated protected amino acids has also been demonstrated.

Introduction

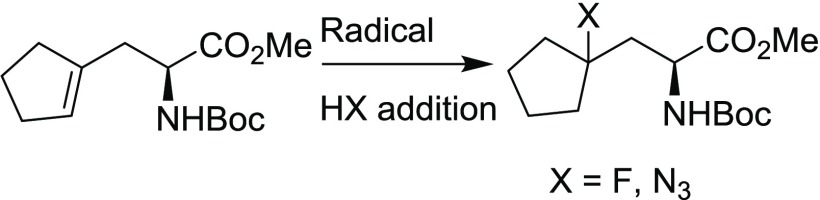

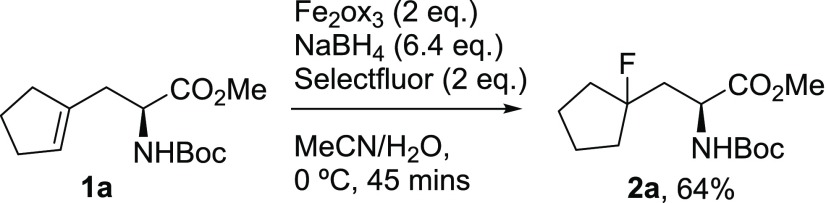

The synthesis of enantiomerically pure amino acids continues to attract substantial attention, and the development of new methods for the preparation of side-chain-functionalized amino acids is the focus of much effort.1 In particular, the synthesis of amino acids with side-chain fluorine substitution has been widely studied,2 specifically in the context of the preparation of (S)-γ-fluoroleucine, a component of the Merck Cathepsin K inhibitor odanacatib.3 An early approach to (S)-γ-fluoroleucine ethyl ester relied on the use of the Schöllkopf bis-lactim ether.4 The synthetic routes that have been developed more recently include the use of aspartic acid as a chiral pool starting material,5 a titanium-catalyzed asymmetric ene-reaction,6 use of glycine-Schiff base alkylation followed by enzymatic resolution,7 and more recently direct photochemical fluorination of leucine itself.8 This followed an earlier indirect method which employed photochemical bromination of leucine, followed by treatment with AgF.9 The latter two approaches rely on the selective radical cleavage of the tertiary C–H bond of leucine for their success. A complementary method makes use of AgF/tetra-n-butylammonium fluoride as the fluorine source, in conjunction with a manganese porphyrin catalyst.10 In previous work, we have reported a single example of the synthesis of the γ-fluorinated cyclopentylalanine derivative 2a using the ionic addition of hydrogen fluoride (HF) (using HF-pyridine) to an unsaturated amino acid 1a (Scheme 1).11 This compound was a key component of a Cathepsin S inhibitor. Although this synthetic approach was rather inefficient, largely due to the in situ tert-butoxycarbonyl (Boc)-deprotection of the substrate under the conditions of the reaction, it was nevertheless a very considerable improvement over the previous method used for making this protected amino acid.12

Scheme 1. Original Ionic Method for the Preparation of tert-Fluoride 2a.

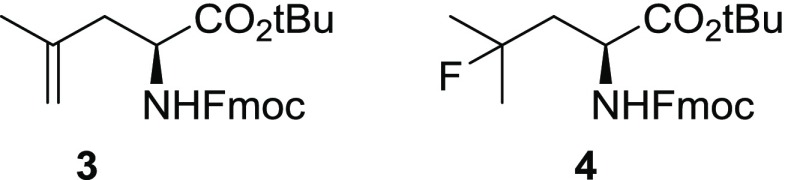

The report by Barker and Boger on the new radical addition

of HF

to unactivated alkenes, using Fe(III)/NaBH4, with Selectfluor

as the fluorine source,13 prompted us to

revisit our general strategy. Indeed, after we had completed the majority

of the work reported in this paper, another group reported the application

of the Barker and Boger method to the synthesis of Fmoc-(S)-γ-fluoroleucine 4 (in presumed 94% enantiomeric

excess (ee), based on the ee of the starting material), using the

2-propenylalanine derivative 3.14 We now report an in-depth study of this reaction, to assess its

generality and scope for the preparation of side-chain-fluorinated

amino acids as well as a possible extension by trapping the intermediate

alkyl radicals to allow the introduction of other functional groups

into the amino acid side chains, by exploring the use of subsequently

reported variants of the Boger process.15

Results and Discussion

Preparation of Unsaturated Amino Acids

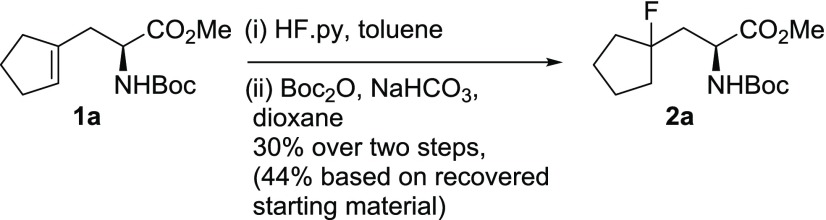

The initial goal was to prepare a representative selection of protected enantiomerically pure unsaturated amino acids, with double bonds at both the γ- and δ-positions. A range of cycloalkenylalanine derivatives was prepared by room-temperature Negishi cross-coupling of cycloalkenyl triflates (5a–d, 6, and 7) with the serine-derived zinc reagent 8, according to our previously reported methods from the protected iodoalanine derivative 9 (Scheme 2, Table 1).16 It was established that extending the reaction times for the cross-coupling generally resulted in higher isolated yields of the desired products (1a–d) than we had previously observed.11,16 In addition, two more functionalized vinyl triflates 6 and 7 were successfully coupled, giving the corresponding protected amino acids 10 and 11.

Scheme 2. Negishi Cross-Coupling with Cycloalkenyl Triflates.

Table 1. Negishi Coupling of Zinc Reagent 8 with Cycloalkenyl Triflates.

| entry | substrate | X | n | product | yield (%) |

|---|---|---|---|---|---|

| 1 | 5a | CH2 | 0 | 1a | 83 (70)a |

| 2 | 5b | CH2 | 1 | 1b | 92 (70)a |

| 3 | 5c | CH2 | 2 | 1c | 81 (62)a |

| 4 | 5d | CH2 | 3 | 1d | 61 (63)a |

| 5 | 6 | O | 1 | 10 | 52 |

| 6 | 7 | CF2 | 1 | 11 | 90 |

Yield obtained under previous conditions.11

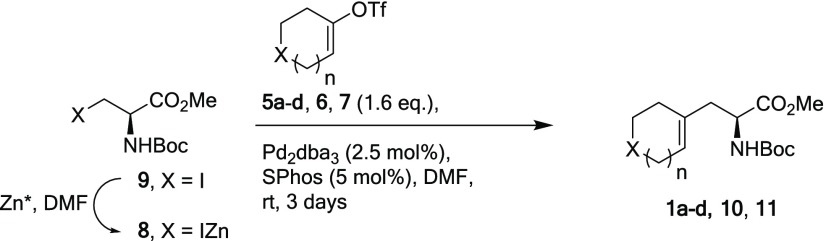

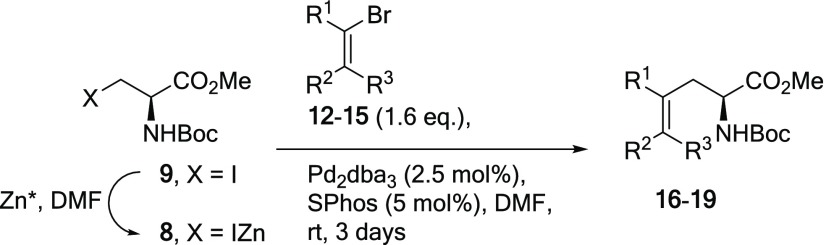

Although there is less precedent for the use of vinyl bromides in the Negishi cross-coupling with zinc reagent 8, a range of vinyl bromides (12–15) was successfully coupled under the same conditions that we had employed for coupling the vinyl triflates to give the expected unsaturated amino acids (16–19) (Scheme 3, Table 2). The cross-coupling reactions of (E)- and (Z)-2-bromo-2-butene with zinc reagent 8 were stereospecific, leading to the isomeric products (E)-18 and (Z)-18, respectively. Interestingly, the use of an excess of the commercially available isomeric mixture of 2-bromo-2-butene (E/Z, 1.9:1, as determined by 1H NMR, with both isomers used in excess relative to zinc reagent 8) in the cross-coupling resulted in the formation of a mixture of the products 18 that was substantially enriched in the (E)-isomer (E/Z, 7:1) (Table 2, entry 5), indicating that the Negishi cross-coupling of the zinc reagent 8 with (E)-2-bromo-2-butene (E)-14 was faster than with (Z)-isomer 2-bromo-2-butene (Z)-14 (by a factor of 3.5). This most likely reflects a faster rate of oxidative addition of the less hindered (E)-isomer of compound 14 to Pd. The most notable example was the successful cross-coupling of zinc reagent 8 with 1-bromocyclobutene 15 leading to the cyclobutenyl alanine derivative 19, which is a rare example of the use of 1-bromocyclobutene in the Negishi cross-coupling.

Scheme 3. Negishi Cross-Coupling with Vinyl Bromides.

Table 2. Negishi Coupling of Zinc Reagent 8 with Vinyl Bromides.

| entry | substrate | R1 | R2 | R3 | product | yield (%) |

|---|---|---|---|---|---|---|

| 1 | 12 | Me | H | H | 16 | 84 |

| 2 | 13 | H | Me | Me | 17 | 95 |

| 3 | (E)-14 | Me | Me | H | (E)-18 | 68 |

| 4 | (Z)-14 | Me | H | Me | (Z)-18 | 72 |

| 5 | (E,Z)-14 | Me | Me/H | (E,Z)-18 | 88 | |

| 6 | 15 | (CH2)2 | H | 19 | 79 | |

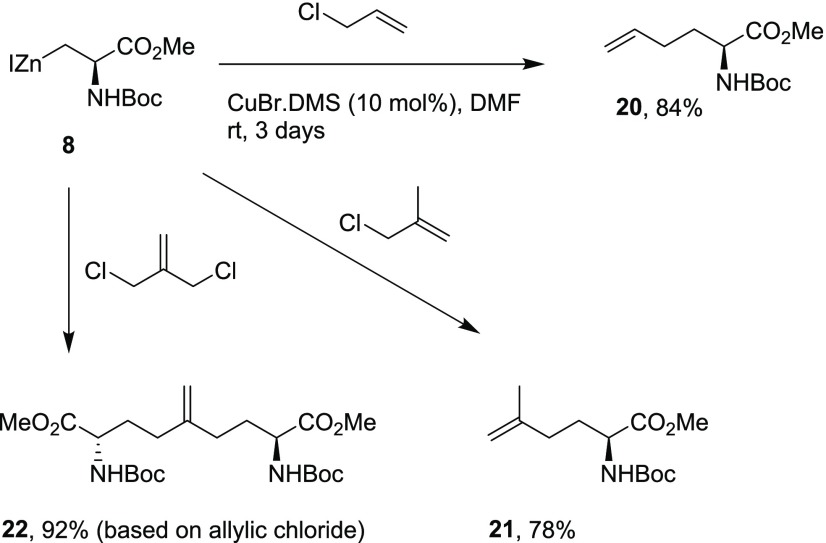

A small selection of unsaturated amino acid substrates 20–22 was prepared by our previously reported method using copper-catalyzed allylation of the zinc reagent 8 (Scheme 4).17 Again, we observed that extended reaction times at room temperature resulted, in most cases, in improved yields over those we had previously observed.

Scheme 4. Cu(I)-Catalyzed Allylation of Zinc Reagent 8.

Radical Addition of HF to Unsaturated Amino Acids

Barker and Boger’s original report contained examples of the radical HF-addition to terminal alkenes containing an ester or a protected amine as well as a dipeptide in which the terminal alkene was incorporated into a tyrosine residue.13 Therefore, it was reasonable that unsaturated amino acid substrates would also undergo the reaction. In the event, the application of the conditions reported by Barker and Boger to the cyclopentenylalanine derivative 1a resulted in the formation of 2a, identical to the material we had previously prepared,11 but in substantially higher yield (64%) and without unproductive protecting group removal and using less toxic reagents (Scheme 5). The structure of compound 2a was confirmed by X-ray analysis and showed a hydrogen bond from the carbamate N–H to the carbamate carbonyl of the neighboring molecule as well as a very distinct alignment of the C–F bond with the C–F bond of the closest neighbor.

Scheme 5. Radical Hydrofluorination of Cyclopentenylalanine 1a.

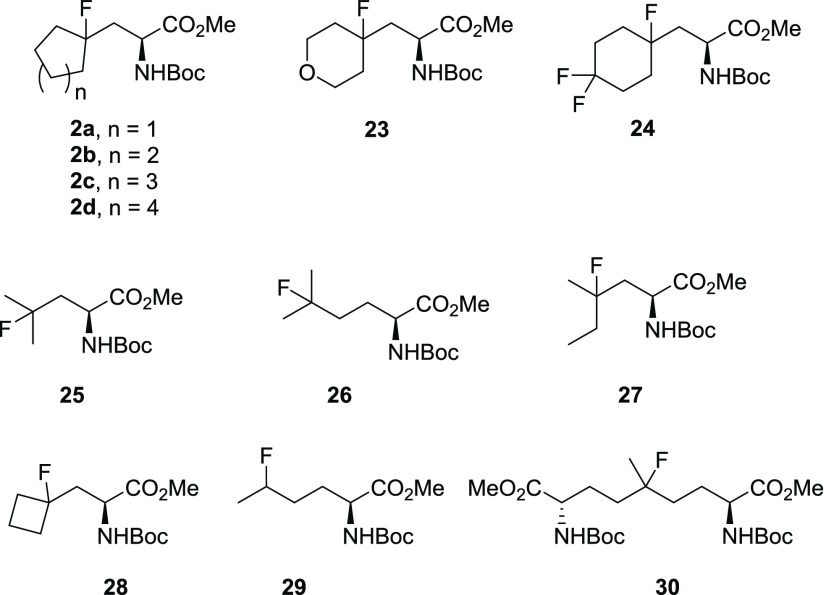

We were pleased to find that with the exception of the 4,4-difluorocyclohexen-1-yl alanine derivative 11 (vide infra), the procedure proved applicable to the other substrates that we had prepared, giving the desired HF-addition products in good to excellent yields (Table 3). To establish whether or not the reaction proceeded without racemization, both enantiomers of the 3-methyl-3-butenylglycine derivatives 16 and ent-16 were each separately subjected to the radical HF-addition conditions; the products 25 and ent-25 were obtained with high ee (99 and 98%, respectively, as determined by chiral phase high-performance liquid chromatography (HPLC)), thus establishing that the reaction did indeed proceed without racemization. When the two isomeric alkene substrates 17 and 21 were separately subjected to the radical HF-addition conditions, the same tert-fluoride 26 was obtained, with a slightly higher yield from the starting material 17 with the more substituted double bond (cf. entries 9 and 13, Table 3). When the radical HF-addition was attempted on the 4,4-difluorocyclohexen-1-yl alanine derivative 11, the conversion was incomplete and purification difficult. We, therefore, modified the procedure by increasing the amounts of Fe(III) and Selectfluor and by the dropwise addition of a solution of NaBH4 (in 0.1 M NaOH) over a period of 6 h, which resulted in the isolation of the desired product 24 in comparable yield to that obtained with the other substrates. This modified procedure may be successful with other more challenging substrates. The X-ray crystal structure of compound 24 was obtained, confirming the structure and showing similar intermolecular interactions in the solid state to those observed in the X-ray structure of 2a.

Table 3. Radical Hydrofluorination of Unsaturated Substrates.

| entry | substrate | product | yield (%) |

|---|---|---|---|

| 1 | 1a | 2a | 64 |

| 2 | 1b | 2b | 64 |

| 3 | 1c | 2c | 70 |

| 4 | 1d | 2d | 65 |

| 5 | 10 | 23 | 54 |

| 6 | 11 | 24 | 0 (64)a |

| 7 | 16 | 25 | 84 |

| 8 | ent-16 | ent-25 | 88 |

| 9 | 17 | 26 | 75 |

| 10 | 18 | 27 | 63 |

| 11 | 19 | 28 | 81 |

| 12 | 20 | 29 | 73 |

| 13 | 21 | 26 | 62 |

| 14 | 22 | 30 | 91 |

Reaction carried out by increasing the molar equivalents of Fe(III) and Selectfluor and by the dropwise addition of a solution of NaBH4 (in 0.1 M NaOH).

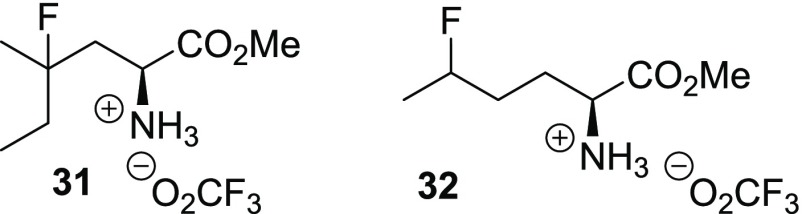

The addition of HF to the substrates 18 and 20 resulted in the formation of products 27 and 29 each with a new stereogenic center. In each case, the removal

of the Boc-protecting group with trifluoroacetic acid (TFA) to give

the corresponding trifluoroacetate salts, 31 and 32, followed by analysis by NMR methods established that,

in each case, the new stereogenic center had been formed with very

low diastereomeric excess (de) (specifically less than 5% de), entirely

consistent with the results of Barker and Boger.13

The addition of HF to the substrates 18 and 20 resulted in the formation of products 27 and 29 each with a new stereogenic center. In each case, the removal

of the Boc-protecting group with trifluoroacetic acid (TFA) to give

the corresponding trifluoroacetate salts, 31 and 32, followed by analysis by NMR methods established that,

in each case, the new stereogenic center had been formed with very

low diastereomeric excess (de) (specifically less than 5% de), entirely

consistent with the results of Barker and Boger.13

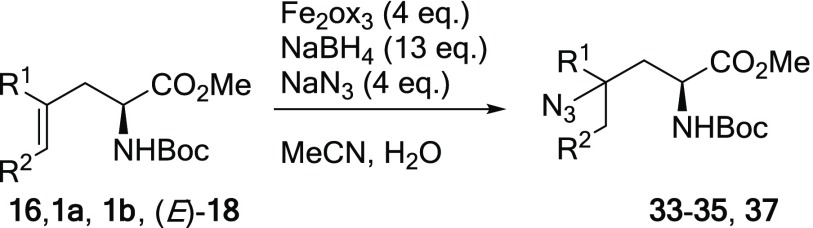

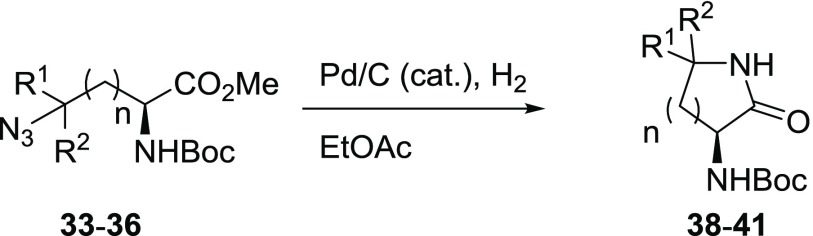

Radical Addition of HN3 to Unsaturated Amino Acids

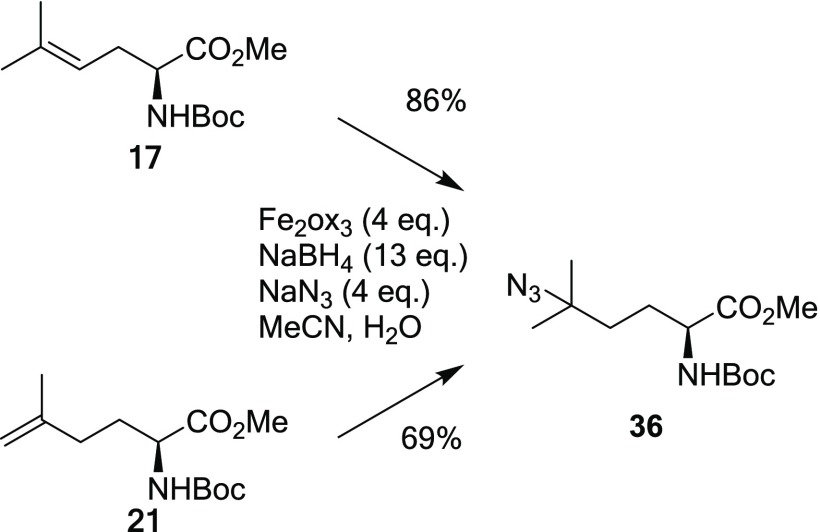

Given the efficiency of the radical addition of HF to unsaturated amino acids and the precedent from Leggans et al. that a combination of Fe(III)/NaBH4 and NaN3 as the azide source promoted the efficient radical addition of HN3 to alkenes,15 we have explored the application of this method to the functionalization of unsaturated amino acids. The formation of amino acids with side-chain nitrogen functionality is of interest, since the compounds are analogues of lysine. Direct application of the literature protocol for the hydroazidation of citronellol15 to unsaturated amino acid 16 resulted in the incomplete conversion of the starting materials. However, a minor modification, in which the excess of reagents was increased, resulted in a very efficient conversion of 16 to the corresponding tertiary azide 33. The application of this modified method to a representative selection of unsaturated amino acids resulted, in each case, in the formation of the expected tertiary azide in good to excellent yields (Scheme 6, Table 4). The two isomeric alkenes 17 and 21 gave the same tertiary azide 36, with a slightly higher yield being observed when using the more substituted alkene 17 (Scheme 7), as already observed during the HF-addition to the same substrates.

Scheme 6. Radical Hydroazidation of Unsaturated Substrates.

Table 4. Radical Hydroazidation of Unsaturated Substrates.

| entry | substrate | R1 | R2 | product | yield (%) |

|---|---|---|---|---|---|

| 1 | 16 | Me | H | 33 | 88 |

| 2 | 1a | (CH2)3 | 34 | 88 | |

| 3 | 1b | (CH2)4 | 35 | 71 | |

| 4 | (E)-18 | Me | Me | 37 | 63 |

Scheme 7. Alternative Approaches to Tertiary Azide 36.

Each of the azides 33–36 was reduced by catalytic hydrogenation to give the corresponding free amines, which underwent spontaneous cyclization to give the corresponding lactams 38–41, which were each isolated in high yields (Scheme 8, Table 5). The structure of the lactam 40 was confirmed by single-crystal X-ray structure analysis.

Scheme 8. Hydrogenation of Azido Amino Acids.

Table 5. Hydrogenation of Azides.

| entry | substrate | R1 | R2 | n | product | yield (%) |

|---|---|---|---|---|---|---|

| 1 | 33 | Me | Me | 1 | 38 | 99 |

| 2 | 34 | (CH2)4 | 1 | 39 | 93 | |

| 3 | 35 | (CH2)5 | 1 | 40 | 91 | |

| 4 | 36 | Me | Me | 2 | 41 | 98 |

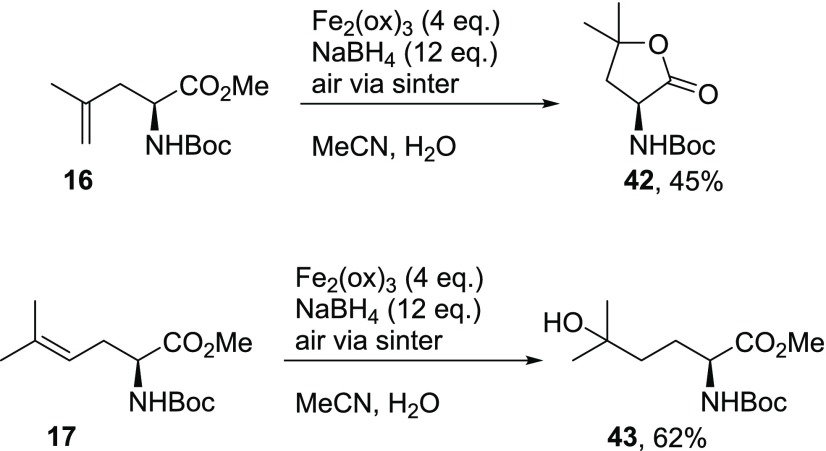

Radical Alkene Hydration

The final transformation that we briefly investigated was the radical hydration of unsaturated amino acids using the combination of Fe(III)/NaBH4 and air as a radical trap.15 Such a process would lead to amino acids with a side-chain hydroxyl group. The optimization of this particular radical addition process proved challenging and appeared to be critically dependent on the means by which the air was introduced into the reaction mixture. Most reliable results were obtained when the air was introduced using a sintered gas inlet, and in two cases (using 16 and 17 as substrates), moderate yields of the corresponding hydroxylated amino acids were obtained, albeit isolated as the corresponding lactone 42 in one case (Scheme 9).

Scheme 9. Radical Hydration of Unsaturated Amino Acids.

Conclusions

In conclusion, the generality and scope of the radical HF-addition to unsaturated amino acid substrates have been established, further demonstrating the functional group tolerance of the Boger radical hydrofluorination process. In combination with our previously reported methods for the preparation of unsaturated amino acids (extended to the Negishi cross-coupling with vinyl bromides in this paper), this constitutes an effective and direct method for the preparation of important side-chain-fluorinated amino acid derivatives. Furthermore, radical hydroazidation of unsaturated amino acid substrates has been demonstrated, allowing the synthesis of side-chain amino-substituted amino acids. Finally, radical hydration of unsaturated amino acid substrates has been demonstrated, but further work is required to establish the full scope of this transformation.

Experimental Section

High-resolution mass spectrometry (HRMS) measurements were carried out using electrospray (ES) ionization, with a time-of-flight mass analyzer. IR spectra were recorded as thin films or using attenuated total reflection. The synthesis of N-Boc-β-I-Ala-OMe was accomplished by the literature methods.18 For the preparation of zinc reagent 8 and general procedures A, B, and F, flame-dried glassware was used. Cycloalkenyl triflates 5a–d were prepared by general literature methods19 from the corresponding ketones and used without purification. Triflates 6,20721 and 1-cyclobutenyl bromide 15(22) were each prepared by literature methods.

Preparation of Zinc Reagent 8

Zinc powder (3 equiv) was suspended in dry dimethylformamide (DMF) (3 mL) under nitrogen, and iodine (nine crystals) was added immediately. A change in color from colorless to dark brown and colorless again was observed. N-Boc-β-I-Ala-OMe 9 (1 equiv) was added followed immediately by iodine (three crystals), the aforementioned color change was observed once more, and the insertion process was allowed to proceed for 30–60 min.

General Procedure A, Coupling of 8 to Vinyl Triflates and Halides

Immediately after the preparation of 8, Pd2(dba)3 (2.5 mol %) and SPhos (5.0 mol %) were added to the reaction vessel along with an excess vinyl halide/triflate (≈1.6 equiv), as indicated in the individual procedures below. The reaction mixture was stirred under a gentle flow of nitrogen for 72 h. The reaction mixture was then filtered through a silica plug eluting with EtOAc. The organic phase was washed with water (2 × 50 mL) and brine (50 mL). The organic phase was dried with Na2SO4, filtered, and the solvent removed under reduced pressure. Purification was carried out by flash column chromatography (EtOAc in petroleum ether (40–60) mixtures over silica).

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-3-(cyclopent-1-en-1-yl)propanoate 1a

Synthesis was achieved by general procedure A using zinc dust (0.217 g, 3.32 mmol), iodine (2 crystals, then 1 crystal), 9 (0.325 g, 0.99 mmol), Pd2(dba)3 (0.024 g, 0.03 mmol), SPhos (0.023 g, 0.06 mmol), and 5a (0.375 g, 1.73 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 1a as a light orange oil (0.220 g, 0.82 mmol, 83%); [α]D25 +17.0 (c 2.00, CHCl3), [lit. [α]D22 +13.9 (c 2.09, CHCl3)];16 νmax(ATR)/cm–1 3371, 2974, 2951, 2932, 2848, 1744, 1713, 1501, 1436, 1392, 1365, 1248, 1211, 1160, 1056, 1020, 860, 778, and 759; 1H NMR (CDCl3, 400 MHz) δH 5.47 (s, 1H), 4.98 (d, J = 7.8 Hz, 1H), 4.41 (m, 1H), 3.73 (s, 3H), 2.59 (dd, J = 14.2 Hz, 4.8 Hz, 1H), 2.49 (dd, J = 14.4 Hz, 7.5 Hz, 1H), 2.33–2.16 (m, 4H), 1.86 (apparent quin, J = 7.4 Hz, 2H), 1.44 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 173.2, 155.2, 139.0, 128.3, 79.8, 52.2, 52.1, 34.7, 34.2, 32.5, 28.3, 23.6; HRMS (ES) m/z: [M + Na]+ calcd for C14H23NO4Na 292.1519; found 292.1523.

The characterization data was consistent with that reported in the literature.16

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-3-(cyclohex-1-en-1-yl)propanoate 1b

Synthesis was achieved by general procedure A using zinc dust (0.606 g, 9.27 mmol), iodine (6 crystals, then 4 crystals), 9 (1.013 g, 3.08 mmol), Pd2(dba)3 (0.068 g, 0.07 mmol), SPhos (0.069 g, 0.17 mmol), and 5b (1.283 g, 5.57 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 1b as a light orange oil (0.798 g, 2.82 mmol, 92%); [α]D24 +14.1 (c 0.99, CHCl3), [lit. [α]D22 +14.5 (c 1.68, CHCl3)];16 νmax(ATR)/cm–1 3355, 2976, 2929, 2859, 2838, 1744, 1713, 1504, 1437, 1391, 1365, 1275, 1258, 1215, 1161, 1084, 1048, 1020, 920 and 863; 1H NMR (CDCl3, 400 MHz) δH 5.48 (s, 1H), 4.92 (d, J = 7.6 Hz, 1H), 4.39 (m, 1H), 3.74 (s, 3H), 2.43 (dd, J = 13.5 Hz, 5.2 Hz, 1H), 2.26 (dd, J = 13.5 Hz, 8.6 Hz, 1H), 2.00–1.88 (m, 4H), 1.68–1.52 (m, 4H), 1.45 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 173.4, 155.2, 132.7, 125.7, 79.8, 52.1, 51.9, 41.4, 28.3, 27.8, 25.3, 22.7, 22.1; HRMS (ES) m/z: [M + Na]+ calcd for C15H25NO4Na 306.1681; found 306.1676.

The characterization data was consistent with that reported in the literature.16

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-3-(cyclohept-1-en-1-yl)propanoate 1c

Synthesis was achieved by general procedure A using zinc dust (0.791 g, 12.10 mmol), iodine (12 crystals, then 5 crystals), 9 (1.330 g, 4.04 mmol), Pd2(dba)3 (0.094 g, 0.10 mmol), SPhos (0.112 g, 0.27 mmol), and 5c (1.609 g, 6.59 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 1c as a light orange oil (0.981 g, 3.30 mmol, 82%); [α]D24 +8.4 (c 1.08, CHCl3), [lit. [α]D22 +7.8 (c 1.15, CHCl3)];16 νmax(ATR)/cm–1 3367, 2975, 2919, 2846, 1744, 1712, 1498, 1438, 1389, 1365, 1248, 1212, 1159, 1050, 1022, 994 and 852; 1H NMR (CDCl3, 400 MHz) δH 5.62 (t, J = 6.2 Hz, 1H), 4.93 (d, J = 7.1 Hz, 1H), 4.34 (m, 1H), 3.73 (s, 3H), 2.46 (dd, J = 13.2 Hz, 5.6 Hz, 1H), 2.27 (dd, J = 13.3 Hz, 8.3 Hz, 1H), 2.14–2.06 (m, 4H), 1.76–1.70 (m, 2H), 1.44–1.35 (m, 13H); 13C NMR (CDCl3, 100 MHz), δC 173.4, 155.2, 139.3, 131.0, 79.8, 52.1, 52.0, 43.4, 32.4, 32.3, 28.5, 28.3, 27.0, 26.5; HRMS (ES) m/z: [M + Na]+ calcd for C16H27NO4Na 320.1838; found 320.1833.

The characterization data was consistent with that reported in the literature.16

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-3-(cyclooct-1-en-1-yl)propanoate 1d

Synthesis was achieved by general procedure A using zinc dust (0.596 g, 9.11 mmol), iodine (9 crystals, then 5 crystals), 9 (0.990 g, 3.01 mmol), Pd2(dba)3 (0.074 g, 0.08 mmol), SPhos (0.066 g, 0.16 mmol), and 5d (1.311 g, 5.08 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 1d as a light orange oil (0.572 g, 1.84 mmol, 61%); [α]D24 +7.8 (c 1.15, CHCl3), [lit. [α]D22 +9.5 (c 0.53, CHCl3)];16 νmax(ATR)/cm–1 3365, 2977, 2923, 2851, 1745, 1714, 1501, 1469, 1436, 1391, 1365, 1248, 1216, 1160, 1057, 1023, 894, and 861; 1H NMR (CDCl3, 400 MHz) δH 5.42 (t, J = 8.0 Hz, 1H), 4.90 (d, J = 7.2 Hz, 1H), 4.35 (m, 1H), 3.73 (s, 3H), 2.50 (dd, J = 13.8 Hz, 4.9 Hz, 1H), 2.26 (dd, J = 13.7 Hz, 9.1 Hz, 1H), 2.15–2.08 (m, 4H), 1.54–1.47 (m, 8H), 1.44 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 173.4, 155.2, 135.6, 128.7, 79.8, 52.1, 52.0, 40.3, 29.7, 28.5, 28.3, 26.4, 26.3, 26.2; HRMS (ES) m/z: [M + H]+ calcd for C17H30NO4 312.2175; found 312.2183.

The characterization data was consistent with that reported in the literature,16 with the exception of the 13C NMR shifts. In the previous report, a signal at δC 22.8 was assigned to the compound, but this was not observed in our purified sample, and is, therefore, due to an impurity; heteronuclear single quantum coherence analysis established that the true signal was, in fact, obscured by the tert-butyl methyl signal.

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-3-(3,6-dihydro-2H-pyran-4-yl)propanoate 10

Synthesis was achieved by general procedure A using zinc dust (1.484 g, 22.69 mmol), iodine (12 crystals, then 6 crystals), 9 (2.507 g, 7.62 mmol), Pd2(dba)3 (0.168 g, 0.18 mmol), SPhos (0.153 g, 0.37 mmol), and 6 (2.620 g, 11.28 mmol). Purification by flash column chromatography (25% EtOAc in petroleum ether (40–60), over silica) gave 10 as a colorless oil (1.132 g, 3.97 mmol, 52%); [α]D25 +18.6 (c 1.02, CHCl3); νmax(ATR)/cm–1 3340, 3003, 2977, 2930, 2853, 1743, 1709, 1511, 1436, 1391, 1365, 1249, 1215, 1160, 1126, 1054, 1024, 1000, 849 and 752; 1H NMR (CDCl3, 400 MHz) δH 5.52 (m, 1H), 5.00 (d, J = 7.7 Hz, 1H), 4.42 (m, 1H), 4.11 (m, 2H), 3.77 (m, 5H), 2.50 (dd, J = 13.9 Hz, 4.6 Hz, 1H), 2.32 (dd, J = 14 Hz, 8.5 Hz, 1H), 2.08 (m, 2H), 1.44 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 173.1, 155.2, 130.9, 124.1, 80.0, 65.4, 64.3, 52.3, 51.7, 40.44, 28.3, 27.9; HRMS (ES) m/z: [M + Na]+ calcd for C14H23NO5Na 308.1474; found 308.1485.

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-3-(4,4-difluorocyclohex-1-en-1-yl)propanoate 11

Synthesis was achieved by general procedure A using zinc dust (0.615 g, 9.41 mmol), iodine (10 crystals, then 3 crystals), 9 (1.046 g, 3.18 mmol), Pd2(dba)3 (0.066 g, 0.07 mmol), SPhos (0.075 g, 0.18 mmol), and 7 (1.313 g, 4.93 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 11 as a colorless oil (0.914 g, 2.86 mmol, 90%); [α]D24 +25.6 (c 1.02, CHCl3); νmax(ATR)/cm–1 3353, 2980, 1744, 1711, 1504, 1437, 1365, 1264, 1250, 1216, 1160, 1108, 1069, 1014, 971, 889, 860, and 777; 1H NMR (CDCl3, 400 MHz) δH 5.36 (m, 1H), 4.97 (br d, J = 7.9 Hz, 1H), 4.46 (m, 1H), 3.75 (s, 3H), 2.51 (m, 3H), 2.38–2.25 (m, 3H), 2.09–1.98 (m, 2H), 1.45 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 172.9, 155.1, 132.7, 122.7 (t, J = 240 Hz), 120.4, 80.0, 52.3, 51.8, 40.6, 34.7 (t, J = 27 Hz), 30.3 (t, J = 24 Hz), 28.3, 26.1 (t, J = 5 Hz); 19F{1H} NMR (CDCl3, 377 MHz) δF −95.7 (d, J = 235 Hz, 1 F), −97.3 (d, J = 235 Hz, 1 F); HRMS (ES) m/z: [M + H]+ calcd for C15H24F2NO4 320.1673; found 320.1679.

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-4-methylpent-4-enoate 16

Synthesis was achieved by general procedure A using zinc dust (1.966 g, 30.07 mmol), iodine (15 crystals, then 6 crystals), 9 (3.292 g, 10.00 mmol), Pd2(dba)3 (0.229 g, 0.25 mmol), SPhos (0.211 g, 0.51 mmol), and 2-bromopropene 12 (0.9 mL, 1.226 g, 10.13 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 16 as a light orange oil (2.051 g, 8.43 mmol, 84%); [α]D24 +10.5 (c 1.05, CHCl3); νmax(ATR)/cm–1 3379, 2977, 2956, 2932, 1744, 1713, 1500, 1437, 1365, 1247, 1215, 1160, 1046, 1020, 895, 861, 779 and 759; 1H NMR (CDCl3, 400 MHz) δH 4.96 (d, J = 6.6 Hz, 1H), 4.86 (s, 1H), 4.76 (s, 1H), 4.41 (m, 1H), 3.73 (s, 3H), 2.52 (dd, J = 13.8 Hz, 5.4 Hz, 1H), 2.37 (dd, J = 13.8 Hz, 8.3 Hz, 1H), 1.74 (s, 3H), 1.44 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 173.1, 155.3, 140.5, 114.5, 79.9, 52.2, 51.8, 40.7, 28.3, 21.8; HRMS (ES) m/z: [M + Na]+ calcd for C12H21NO4Na 266.1363; found 266.1365.

Methyl (2R)-2-{[(tert-Butoxy)carbonyl]amino}-4-methylpent-4-enoate ent-16

Synthesis was achieved by general procedure A using zinc dust (0.607 g, 9.28 mmol), iodine (9 crystals, then 3 crystals), (S)-N-Boc-β-I-Ala-OMe ent-9 (1.027 g, 3.12 mmol), Pd2(dba)3 (0.076 g, 0.08 mmol), SPhos (0.067 g, 0.16 mmol), and 2-bromopropene 12 (0.45 mL, 0.613 g, 5.07 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave ent-16 as a light orange oil (0.729 g, 3.00 mmol, 96%); [α]D24 −10.1 (c 1.48, CHCl3).

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-5-methylhex-4-enoate 17

Synthesis was achieved by general procedure A using zinc dust (0.594 g, 9.08 mmol), iodine (6 crystals, then 3 crystals), 9 (1.006 g, 3.06 mmol), Pd2(dba)3 (0.070 g, 0.08 mmol), SPhos (0.065 g, 0.16 mmol), and 1-bromo-2-methyl-1-propene 13 (0.614 g, 4.55 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 17 as a light orange oil (0.748 g, 2.91 mmol, 95%); [α]D24 +28.6 (c 1.05, CHCl3); νmax(ATR)/cm–1 3358, 2976, 2918, 1744, 1702, 1498, 1437, 1366, 1352, 1273, 1248, 1208, 1162, 1111, 1059, 1023, 860 and 754; 1H NMR (CDCl3, 400 MHz) δH 5.02 (m, 2H), 4.34 (m, 1H), 3.72 (s, 3H), 2.53 (m, 1H), 2.41 (m, 1H), 1.70 (d, J = 0.8 Hz, 3H), 1.6 (s, 3H), 1.43 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 172.9, 155.3, 136.3, 117.6, 79.8, 53.3, 52.2, 30.9, 28.3, 25.9, 17.8; HRMS (ES) m/z: [M + Na]+ calcd for C13H23NO4Na 280.1519; found 280.1524.

This reaction was also carried out on a larger scale using 9 (3.292 g, 10.00 mmol) and analogous equivalents of reagents, giving 17 (2.310 g, 8.98 mmol, 90%).

Methyl (2S,4E)-2-{[(tert-Butoxy)carbonyl]amino}-4-methylhex-4-enoate (E)-18

Synthesis was achieved by general procedure A using zinc dust (0.233 g, 3.56 mmol), iodine (4 crystals, then 2 crystals), 9 (0.339 g, 1.03 mmol), Pd2(dba)3 (0.026 g, 0.03 mmol), SPhos (0.023 g, 0.06 mmol), and (E)-2-bromo-2-butene 14 (0.12 mL, 0.159 g, 1.18 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave (E)-18 as a light orange oil (0.181 g, 0.70 mmol, 68%); [α]D24 +10.0 (c 1.20, CHCl3); νmax(thin film, NaCl plates)/cm–1 3443, 3372, 2978, 2930, 2862, 1747, 1718, 1503, 1438, 1366, 1250, 1218, 1170, 1060 and 1019; 1H NMR (CDCl3, 400 MHz) δH 5.26 (q, J = 6.0 Hz, 1H), 4.91 (d, J = 7.4 Hz, 1H), 4.34 (m, 1H), 3.70 (s, 3H), 2.45 (dd, J = 13.4 Hz, 5.3 Hz, 1H), 2.27 (dd, J = 13.4 Hz, 8.5 Hz, 1H), 1.6 (m, 3H), 1.57 (d, J = 6.7 Hz, 3H), 1.41 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 173.3, 155.2, 130.7, 123.2, 79.7, 52.1, 52.0, 42.7, 28.3, 15.3, 13.5; HRMS (ES) m/z: [M + Na]+ calcd for C13H23NO4Na 280.1519; found 280.1521.

Methyl (2S,4E)-2-{[(tert-Butoxy)carbonyl]amino}-4-methylhex-4-enoate (Z)-18

Synthesis was achieved by general procedure A using zinc dust (0.623 g, 9.53 mmol), iodine (10 crystals, then 3 crystals), 9 (1.000 g, 3.04 mmol), Pd2(dba)3 (0.072 g, 0.08 mmol), SPhos (0.068 g, 0.17 mmol), and (Z)-2-bromo-2-butene 14 (0.50 mL, 0.666 g, 4.93 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave (Z)-18 as a light orange oil (0.564 g, 2.19 mmol, 72%); [α]D23 +13.7 (c 1.38, CHCl3); νmax(thin film, NaCl plates)/cm–1 3445, 3373, 2977, 2930, 2865, 1747, 1717, 1505, 1453, 1438, 1367, 1278, 1251, 1208, 1169, 1086, 1052, 1021, 861 and 779; 1H NMR (CDCl3, 400 MHz) δH 5.39 (q, J = 6.6 Hz, 1H), 4.97 (d, J = 7.7 Hz, 1H), 4.40 (m, 1H), 3.72 (s, 3H), 2.52 (dd, J = 13.6 Hz, 6.2 Hz, 1H), 2.42 (dd, J = 13.2 Hz, 7.8 Hz, 1H), 1.68 (m, 3H), 1.56 (d, J = 6.6 Hz, 3H), 1.42 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 173.3, 155.2, 130.5, 123.5, 79.8, 52.2, 52.0, 34.3, 28.3, 23.3, 13.4; HRMS (ES) m/z: [M + Na]+ calcd for C13H23NO4Na 280.1519; found 280.1520.

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-3-(cyclobut-1-en-1-yl)propanoate 19

Synthesis was achieved by general procedure A using zinc dust (0.592 g, 9.06 mmol), iodine (9 crystals, then 6 crystals), 9 (0.988 g, 3.00 mmol), Pd2(dba)3 (0.070 g, 0.08 mmol), SPhos (0.063 g, 0.17 mmol), and 1-bromo-1-cyclobutene 15 (2.6 M in tetrahydrofuran, 0.38 mL, 0.99 mmol). Purification by flash column chromatography (8% EtOAc in petroleum ether (40–60), over silica) initially gave the product and N-Boc-Ala-OMe as a mixture. Further purification by flash column chromatography (CH2Cl2, over silica) gave 19 as a colorless oil (0.201 g, 0.79 mmol, 80%); [α]D24 +20.2 (c 1.19, CHCl3); νmax(thin film, NaCl plates)/cm–1 3362, 2978, 2953, 2929, 1745, 1716, 1512, 1438, 1392, 1367, 1250, 1219, 1166, 1052, 1024, and 858; 1H NMR (CDCl3, 400 MHz) δH 5.82 (s, 1H), 5.08 (d, J = 7.8 Hz, 1H), 4.42 (m, 1H), 3.75 (s, 3H), 2.54–2.36 (br, m, 6H), 1.45 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 172.9, 155.2, 144.5, 131.6, 79.9, 52.3, 51.9, 34.0, 31.5, 28.3, 27.1; HRMS (ES) m/z: [M + Na]+ calcd for C13H21NO4Na 278.1363; found 278.1363.

General Procedure B, Reaction of 8 with Allyl Chlorides

A flask containing CuBr·DMS (10 mol %) was placed under vacuum and heated vigorously until the gray CuBr·DMS became light green/yellow. The flask was then placed under a flow of nitrogen and allowed to cool to room temperature. This was repeated once more, and the flask was allowed to cool to room temperature. A prepared solution of 8 in DMF was transferred to the flask containing CuBr·DMS. Allylic chloride (1.5 equiv) was added, and the reaction stirred for 72 h at room temperature. The reaction mixture was then filtered through a silica plug eluting with EtOAc. The organic phase was washed with water (2 × 50 mL) and brine (50 mL). The organic phase was dried with Na2SO4, filtered, and the solvent removed under reduced pressure. The product was purified by flash column chromatography (EtOAc in petroleum ether (40–60) over silica).

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}hex-5-enoate 20

Synthesis was achieved by general procedure B using zinc dust (0.993 g, 15.19 mmol), iodine (11 crystals, then 5 crystals), 9 (1.665 g, 5.06 mmol), CuBr·DMS (0.064 g, 0.31 mmol), and allyl chloride (0.5 mL, 0.470 g, 6.14 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 20 as a colorless oil (1.030 g, 4.23 mmol, 84%); [α]D24 +20.0 (c 1.05, CHCl3); νmax(ATR)/cm–1 3352, 2978, 2953, 2930, 1742, 1697, 1504, 1437, 1392, 1366, 1247, 1214, 1159, 1049, 1023, 994, 913, 858 and 778; 1H NMR (CDCl3, 400 MHz) δH 5.80 (m, 1H), 5.04 (m, 3H), 4.34 (m, 1H), 3.75 (s, 3H), 2.12 (m, 2H), 1.92 (m, 1H), 1.73 (m, 1H), 1.45 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 173.3, 155.3, 136.9, 115.7, 79.9, 53.0, 52.3, 32.0, 29.5, 28.3; HRMS (ES) m/z: [M + Na]+ calcd for C12H21NO4Na 266.1363; found 266.1369.

This characterization data is consistent with that previously reported.23

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-5-methylhex-5-enoate 21

Synthesis was achieved by general procedure B using zinc dust (1.033 g, 15.80 mmol), iodine (15 crystals, then 6 crystals), 9 (1.648 g, 5.00 mmol), CuBr·DMS (0.105 g, 0.51 mmol), and 3-chloro-2-methyl-1-propene (1.038 g, 11.46 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 21 as a colorless oil (1.009 g, 3.92 mmol, 78%); [α]D24 +21.6 (c 1.11, CHCl3); νmax(ATR)/cm–1 3358, 2978, 2160, 1978, 1743, 1713, 1506, 1450, 1365, 1276, 1258, 1212, 1163, 1051, 1023 and 888; 1H NMR (CDCl3, 400 MHz) δH 5.07 (d, J = 7.9 Hz, 1H), 4.75 (br s, 1H), 4.70 (br s, 1H), 4.33 (m, 1H), 3.75 (s, 3H), 2.09–1.88 (br m, 3H), 1.79–1.72 (br m, 4H), 1.45 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 173.3, 155.3, 144.3, 110.7, 79.9, 53.2, 52.2, 33.3, 30.7, 28.3, 22.5; HRMS (ES) m/z: [M + H]+ calcd for C13H24NO4 258.1705; found 258.1710.

1,9-Dimethyl (2S,8S)-2,8-Bis({[(tert-butoxy)carbonyl]amino})-5-methylidenenonanedioate 22

Synthesis was achieved by general procedure B using zinc dust (0.495 g, 7.57 mmol), iodine (10 crystals, then 5 crystals), 9 (0.828 g, 2.52 mmol), CuBr·DMS (0.058 g, 0.28 mmol), and 3-chloro-2-chloromethyl-1-propene (0.125 mL, 0.116 g, 0.93 mmol). Purification by flash column chromatography (25% EtOAc in petroleum ether (40–60), over silica) gave 22 as a colorless oil (0.393 g, 0.86 mmol, 92%); [α]D22 +27.5 (c 1.09, CHCl3); νmax(ATR)/cm–1 3358, 2976, 2933, 1739, 1694, 1647, 1513, 1452, 1437, 1392, 1365, 1273, 1248, 1213, 1160, 1049, 1025, 892, and 864; 1H NMR (CDCl3, 400 MHz) δH 5.08 (d, J = 8.0, 2H), 4.77 (s, 2H), 4.31–4.26 (m, 2H), 3.72 (s, 6H), 2.07–1.90 (m, 6H), 1.76–1.67 (m, 2H), 1.43 (s, 18H); 13C NMR (CDCl3, 100 MHz), δC 173.2, 155.3, 146.5, 110.6, 79.9, 53.1, 52.2, 31.6, 30.8, 28.3; HRMS (ES) m/z: [M + H]+ calcd for C22H39N2O8 459.2706; found 459.2690.

General Procedure C, Radical Fluorination

The protected amino acid (1 equiv) was dissolved in MeCN (20 mL) and placed under nitrogen. The solution was cooled to 0 °C. Fe2(ox)3 (15 wt % solution) and deionized water (18 mL) were added. Selectfluor was then added followed by NaBH4, which was added in two portions with ≈2 min between each addition. The reaction was stirred for 45 min at 0 °C. Conc. NH4OH solution (4 mL) was added. The reaction mixture was stirred for 1 min. The aqueous layer was extracted with CH2Cl2 (3 × 50 mL), the combined organic layers were dried with Na2SO4, filtered, and the solvent removed under reduced pressure. The product was isolated by column chromatography (EtOAc in petroleum ether (40–60) mixtures over silica).

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-3-(1-fluorocyclopentyl)propanoate 2a

Synthesis was achieved by general procedure C using 1a (0.128 g, 0.48 mmol), Fe2(ox)3·6H2O (15 wt % solution) (3.283 g, 1.02 mmol), Selectfluor (0.367 g, 1.04 mmol), and NaBH4 (0.069 g, 1.82 mmol; 0.066 g, 1.74 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 2a as a colorless oil (0.088 g, 0.30 mmol, 63%); crystals were obtained by dissolving in hot pentane and leaving the solution to slowly evaporate; mp 43–46 °C; [α]D23 +5.0 (c 1.20, CHCl3); νmax(ATR)/cm–1 3355, 2972, 1752, 1685, 1531, 1438, 1391, 1366, 1337, 1318, 1289, 1205, 1161, 1130, 1055, 1028, 996, 960, 866, 792, 778, and 761; 1H NMR (CDCl3, 400 MHz) δH 5.26 (d, J = 6.0 Hz, 1H), 4.44 (m, 1H), 3.73 (s, 3H), 2.32–1.96 (br m, 4H), 1.79 (m, 2H), 1.69–1.52 (br m, 4H), 1.43 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 173.1, 155.2, 105.9 (d, J = 173 Hz), 79.9, 52.3, 51.3, 39.9 (d, J = 23 Hz), 37.8 (d, J = 24 Hz), 37.7 (d, J = 24 Hz), 28.3, 23.6, 23.5; 19F{1H} NMR (CDCl3, 377 MHz) δF −142.8 (s); HRMS (ES) m/z: [M + Na]+ calcd for C14H24FNO4Na 312.1582; found 312.1573.

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-3-(1-fluorocyclohexyl)propanoate 2b

Synthesis was achieved by general procedure C using 1b (0.155 g, 0.55 mmol), Fe2(ox)3·6H2O (15 wt % solution) (3.318 g, 1.03 mmol), Selectfluor (0.365 g, 1.03 mmol), and NaBH4 (0.066 g, 1.74 mmol; 0.070 g, 1.85 mmol). Purification by flash column chromatography (8% EtOAc in petroleum ether (40–60), over silica) gave 2b as a colorless oil (0.107 g, 0.35 mmol, 64%); [α]D24 +2.0 (c 1.13, CHCl3); νmax(ATR)/cm–1 3367, 2936, 2866, 1746, 1710, 1504, 1437, 1392, 1366, 1276, 1257, 1212, 1160, 1114, 1049, 1023, 965, 946, 917, 865, and 827; 1H NMR (CDCl3, 400 MHz) δH 5.20 (d, J = 4.6 Hz, 1H), 4.43 (m, 1H), 3.74 (s, 3H), 2.16–1.87 (br m, 4H), 1.64–1.24 (m, 17H); 13C NMR (CDCl3, 100 MHz), δC 173.3, 155.3, 95.7 (d, J = 170 Hz), 79.9, 52.4, 50.2, 41.4 (d, J = 22 Hz), 35.6 (d, J = 22 Hz), 34.7 (d, J = 22 Hz), 28.3, 25.1, 21.8; 19F NMR (CDCl3, 377 MHz) δF −153.7 (br s); HRMS (ES) m/z: [M + Na]+ calcd for C15H26FNO4Na 326.1744; found 326.1736.

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-3-(1-fluorocycloheptyl)propanoate 2c

Synthesis was achieved by general procedure C using 1c (0.148 g, 0.50 mmol), Fe2(ox)3·6H2O (15 wt % solution) (3.236 g, 1.00 mmol), Selectfluor (0.368 g, 1.04 mmol), and NaBH4 (0.061 g, 1.61 mmol; 0.063 g, 1.67 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 2c as a colorless oil (0.112 g, 0.35 mmol, 70%); [α]D24 +1.8 (c 1.14, CHCl3); νmax(ATR)/cm–1 3362, 2931, 2858, 1744, 1712, 1502, 1458, 1438, 1389, 1365, 1252, 1204, 1159, 1050, 1022, 961, 861, and 836; 1H NMR (CDCl3, 400 MHz) δH 5.21 (m, 1H), 4.41 (m, 1H), 3.75 (s, 3H), 1.72 (br m, 23H); 13C NMR (CDCl3, 100 MHz), δC 173.3, 155.3, 100.1 (d, J = 169 Hz), 80.0, 52.4, 50.6, 42.4 (d, J = 22 Hz), 39.2 (d, J = 24 Hz), 38.0 (d, J = 24 Hz), 29.55, 29.51, 28.3, 22.1 (d, J = 7 Hz), 22.0 (d, J = 5 Hz); 19F{1H} NMR (CDCl3, 377 MHz) δF −137.7; HRMS (ES) m/z: [M + Na]+ calcd for C16H28FNO4Na 340.1900; found 340.1913.

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-3-(1-fluorocyclooctyl)propanoate 2d

Synthesis was achieved by general procedure C using 1d (0.171 g, 0.55 mmol), Fe2(ox)3·6H2O (15 wt % solution) (3.320 g, 1.03 mmol), Selectfluor (0.367 g, 1.04 mmol), and NaBH4 (0.070 g, 1.85 mmol; 0.065 g, 1.72 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 2d as a colorless oil (0.120 g, 0.36 mmol, 65%); [α]D25 +3.8 (c 1.58, CHCl3); νmax(ATR)/cm–1 3363, 2921, 2857, 1747, 1713, 1504, 1475, 1436, 1391, 1366, 1276, 1248, 1213, 1160, 1048, 1026, 917, 864, and 829; 1H NMR (CDCl3, 400 MHz) δH 5.24 (d, J = 4.2 Hz, 1H), 4.40 (m, 1H), 3.74 (s, 3H), 1.71 (br m, 25H); 13C NMR (CDCl3, 100 MHz), δC 173.3, 155.3, 99.8 (d, J = 167 Hz), 79.9, 52.4, 50.6, 40.3 (d, J = 21 Hz), 34.7 (d, J = 24 Hz), 33.2 (d, J = 24 Hz), 28.3, 28.0, 27.8, 24.9, 21.9 (d, J = 8 Hz), 21.8 (d, J = 8 Hz); 19F{1H} NMR (CDCl3, 377 MHz) δF −137.2; HRMS (ES) m/z: [M + Na]+ calcd for C17H30FNO4Na 354.2057; found 354.2067.

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-3-(4-fluorooxan-4-yl)propanoate 23

Synthesis was achieved by general procedure C using 10 (0.144 g, 0.50 mmol), Fe2(ox)3·6H2O (15 wt % solution) (3.247 g, 1.01 mmol), Selectfluor (0.355 g, 1.00 mmol), and NaBH4 (0.061 g, 1.61 mmol; 0.067 g, 1.77 mmol). Purification by flash column chromatography (15–25% EtOAc in petroleum ether (40–60), over silica) gave 23 as a colorless oil (0.090 g, 0.29 mmol, 58%); [α]D24 +7.0 (c 1.42, CHCl3); νmax(ATR)/cm–1 3347, 2958, 2930, 2867, 1747, 1710, 1513, 1436, 1392, 1366, 1280, 1249, 1214, 1160, 1102, 1048, 1014, 985, 838, 780, and 758; 1H NMR (CDCl3, 400 MHz) δH 5.17 (d, J = 6.7 Hz, 1H), 4.50 (m, 1H), 3.65–3.69 (m, 7H), 2.23–1.62 (m, 6H), 1.46 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 173.0, 155.2, 92.7 (d, J = 172 Hz), 80.1, 63.4, 52.5, 49.7, 41.9 (d, J = 21 Hz), 35.6 (d, J = 22 Hz), 35.1 (d, J = 22 Hz), 28.3; 19F{1H} NMR (CDCl3, 377 MHz) δF −159.8; HRMS (ES) m/z: [M + Na]+ calcd for C14H24FNO5Na 328.1536; found 328.1551.

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-3-(1,4,4-trifluorocyclohexyl)propanoate 24

Synthesis was achieved by general procedure C with the modifications discussed in the Results and Discussion section using 11 (0.161 g, 0.50 mmol), Fe2(ox)3·6H2O (15 wt % solution) (3.289 g, 1.02 mmol), Selectfluor (0.905 g, 2.55 mmol), and NaBH4 (0.305 g, 8.06 mmol) in 0.1 M NaOH solution (30 mL) added over 6 h. Purification by flash column chromatography (13% EtOAc in petroleum ether (40–60), over silica) gave the product as a colorless oil that solidified on standing to give 24 as a white solid. Recrystallized from hot pentane (0.110 g, 0.32 mmol, 64%); mp 67–69 °C; [α]D24 +1.9 (c 1.03, CHCl3); νmax(ATR)/cm–1 3378, 3010, 2970, 2936, 2862, 2339, 1763, 1689, 1530, 1442, 1389, 1367, 1343, 1316, 1270, 1256, 1221, 1162, 1122, 1095, 1053, 1022, 992, 963, 913, 893, 865, and 844; 1H NMR (CDCl3, 400 MHz) δH 5.16 (d, J = 7.5 Hz, 1H), 4.48 (m, 1H), 3.76 (s, 3H), 2.20–2.00 (br m, 8H), 1.82–1.65 (br m, 2H), 1.45 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 172.9, 155.2, 122.6 (dd, J = 243 Hz, 238 Hz), 93.5 (d, J = 173 Hz), 80.2, 52.6, 50.1, 41.3 (d, J = 21 Hz), 31.8 (dd, J = 10 Hz, 10 Hz), 31.5 (dd, J = 10 Hz, 10 Hz), 29.2 (apparent t, J = 25 Hz), 28.3; 19F{1H} NMR (CDCl3, 377 MHz) δF −93.4 (d, J = 238 Hz, 1 F), −105.0 (d, J = 238 Hz, 1 F), −162.6 (s, 1 F); HRMS (ES) m/z: [M + Na]+ calcd for C15H24F3NO4Na 362.1555; found 362.1541.

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-4-fluoro-4-methylpentanoate 25

Synthesis was achieved by general procedure C using 16 (0.119 g, 0.49 mmol), Fe2(ox)3·6H2O (15 wt % solution) (3.247 g, 1.01 mmol), Selectfluor (0.357 g, 1.01 mmol), and NaBH4 (0.066 g, 1.74 mmol; 0.059 g, 1.56 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 25 as a colorless oil, which solidified on standing (0.107 g, 0.41 mmol, 84%); mp 37–40 °C; [α]D24 −2.5 (c 1.18, CHCl3); νmax(ATR)/cm–1 3373, 2980, 2957, 2917, 2849, 1746, 1712, 1505, 1438, 1390, 1366, 1249, 1206, 1161, 1049, 1027, 990, 889, 866, 849, 797, and 781; 1H NMR (CDCl3, 400 MHz) δH 5.20 (d, J = 6.2 Hz, 1H), 4.41 (m, 1H), 3.73 (s, 3H), 2.17–1.94 (br m, 2H), 1.43 (s, 9H), 1.41 (d, J = 21.5 Hz, 6H); 13C NMR (CDCl3, 100 MHz), δC 173.1, 155.3, 95.0 (d, J = 166 Hz), 80.0, 52.4, 50.8, 42.6 (d, J = 22 Hz), 28.3, 27.1 (d, J = 25 Hz), 26.5 (d, J = 25 Hz); 19F{1H} NMR (CDCl3, 377 MHz) δF −136.6 (s); HRMS (ES) m/z: [M + Na]+ calcd for C12H22FNO4Na 286.1425; found 286.1427.

Methyl (2R)-2-{[(tert-Butoxy)carbonyl]amino}-4-fluoro-4-methylpentanoate ent-25

Synthesis was achieved by general procedure C using ent-16 (0.124 g, 0.51 mmol), Fe2(ox)3·6H2O (15 wt % solution) (3.330 g, 1.03 mmol), Selectfluor (0.379 g, 1.07 mmol), and NaBH4 (0.058 g, 1.54 mmol; 0.064 g, 1.69 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave ent-25 as a colorless oil, which solidified on standing (0.118 g, 0.45 mmol, 88%); mp 38–40 °C; [α]D24 +3.1 (c 1.31, CHCl3).

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-5-fluoro-5-methylhexanoate 26

Synthesis was achieved by general procedure C using 17 (0.130 g, 0.51 mmol), Fe2(ox)3·6H2O (15 wt % solution) (3.109 g, 0.96 mmol), Selectfluor (0.368 g, 1.04 mmol), and NaBH4 (0.064 g, 1.70 mmol; 0.061 g, 1.60 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 26 as a colorless oil (0.104 g, 0.38 mmol, 75%); [α]D24 +14.0 (c 1.07, CHCl3); νmax(ATR)/cm–1 3358, 3004, 2980, 2933, 1743, 1712, 1512, 1454, 1438, 1389, 1366, 1276, 1260, 1210, 1160, 1053, 1027, and 875; 1H NMR (CDCl3, 400 MHz) δH 5.08 (d, J = 8.0 Hz, 1H), 4.30 (m, 1H), 3.75 (s, 3H), 2.00–1.91 (br m, 1H), 1.78–1.59 (br m, 3H), 1.43 (s, 9H), 1.34 (d, J = 21.3 Hz, 6H); 13C NMR (CDCl3, 100 MHz), δC 173.1, 155.4, 94.9 (d, J = 166 Hz), 79.9, 53.3, 52.3, 36.78 (d, J = 23 Hz), 28.3, 27.14 (d, J = 5 Hz), 26.7 (d, J = 24 Hz), 26.5 (d, J = 24 Hz); 19F{1H} NMR (CDCl3, 377 MHz) δF −139.5 (s); HRMS (ES) m/z: [M + H]+ calcd for C13H24FNO4 278.1768; found 278.1756.

Synthesis of 26 was also achieved by general procedure C using 21 (0.133 g, 0.52 mmol), Fe2(ox)3·6H2O (15 wt % solution) (3.285 g, 1.02 mmol), Selectfluor (0.358 g, 1.01 mmol), and NaBH4 (0.067 g, 1.77 mmol; 0.067 g, 1.77 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 26 as a colorless oil (0.090 g, 0.32 mmol, 62%), identical to that isolated above.

Methyl (2S,4RS)-2-{[(tert-Butoxy)carbonyl]amino}-4-fluoro-4-methylhexanoate 27

Synthesis was achieved by general procedure C using (E/Z)-18 (7:1, E/Z) (0.132 g, 0.51 mmol), Fe2(ox)3·6H2O (15 wt % solution) (3.460 g, 1.07 mmol), Selectfluor (0.358 g, 1.01 mmol), and NaBH4 (0.062 g, 1.64 mmol; 0.061 g, 1.61 mmol). Purification by flash column chromatography (8% EtOAc in petroleum ether (40–60), over silica) gave 27 as a colorless oil as a mixture of diastereomers (0.114 g, 0.41 mmol, 80%); νmax(thin film, NaCl plates)/cm–1 3371, 2979, 2937, 2889, 1750, 1716, 1513, 1456, 1438, 1386, 1367, 1280, 1249, 1208, 1167, 1056, 1026, 865, and 781; 1H NMR (CDCl3, 400 MHz) δH 5.19 (m, 1H), 4.40 (m, 1H), 3.73 (s, 3H), 2.01 (m, 2H), 1.66 (m, 2H), 1.43 (s, 9H), 1.36 (d, J = 21.9 Hz, 3H), 0.93 (td, J = 7.5 Hz, 1.4 Hz, 3H); 13C NMR (CDCl3, 100 MHz), δC 173.2, 155.3, 97.2 (d, J = 168 Hz), 97.1 (d, J = 168 Hz), 79.9, 52.4, 50.6 (d, J = 24 Hz), 40.8 (d, J = 22 Hz), 40.3 (d, J = 22 Hz), 33.1 (d, J = 23 Hz), 32.3 (d, J = 23 Hz), 28.3, 23.7 (d, J = 25 Hz), 23.2 (d, J = 25 Hz), 8.0 (d, J = 7 Hz), 7.8 (d, J = 7 Hz); 19F{1H} NMR (CDCl3, 377 MHz) δF −144.3 (s), −144.6 (s); HRMS (ES) m/z: [M + Na]+ calcd for C13H24FNO4Na 300.1582; found 300.1586.

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-3-(1-fluorocyclobutyl)propanoate 28

Synthesis was achieved by general procedure C using 19 (0.135 g, 0.53 mmol), Fe2(ox)3·6H2O (15 wt % solution) (3.289 g, 1.02 mmol), Selectfluor (0.378 g, 1.07 mmol), and NaBH4 (0.068 g, 1.80 mmol; 0.066 g, 1.74 mmol). Purification by flash column chromatography (8% EtOAc in petroleum ether (40–60), over silica) gave 28 as a colorless oil, which solidifies on standing (0.118 g, 0.43 mmol, 81%); mp 52–54 °C; [α]D25 +7.6 (c 1.19, CHCl3); νmax(ATR)/cm–1 3362, 2982, 2941, 1755, 1686, 1510, 1457, 1440, 1393, 1365, 1291, 1250, 1219, 1158, 1124, 1093, 1048, 1021, 980, 949, 909, 862, 874, 790, 777, and 758; 1H NMR (CDCl3, 400 MHz) δH 5.22 (d, J = 7.0 Hz, 1H), 4.43 (m, 1H), 3.73 (s, 3H), 2.39–2.13 (m, 6H), 1.91–1.82 (m, 1H), 1.60–1.52 (m, 1H), 1.43 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 173.0, 155.2, 96.8 (d, J = 210 Hz), 79.9, 52.4, 50.5, 38.7 (d, J = 22 Hz), 33.9 (d, J = 22 Hz), 33.7 (d, J = 22 Hz), 28.3, 12.1 (d, J = 12 Hz); 19F{1H} NMR (CDCl3, 377 MHz) δF −132.3 (s); HRMS (ES) m/z: [M + Na]+ calcd for C13H22FNO4Na 298.1425; found 298.1425.

Methyl (2S,5RS)-2-{[(tert-Butoxy)carbonyl]amino}-5-fluorohexanoate 29

Synthesis was achieved by general procedure C using 20 (0.123 g, 0.51 mmol), Fe2(ox)3·6H2O (15 wt % solution) (3.253 g, 1.01 mmol), Selectfluor (0.363 g, 1.02 mmol), and NaBH4 (0.064 g, 1.69 mmol; 0.061 g, 1.61 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 29 as a colorless oil as a mixture of diastereomers (0.097 g, 0.37 mmol, 73%); [α]D24 +10.0 (c 1.75, CHCl3); νmax(ATR)/cm–1 3346, 2978, 2933, 1743, 1705, 1508, 1451, 1391, 1366, 1296, 1247, 1214, 1159, 1049, 1020, 923, 838, and 780; 1H NMR (CDCl3, 400 MHz) δH 5.09 (d, J = 6.6 Hz, 1H), 4.76–4.54 (br m, 1H), 4.32 (m, 1H), 3.74 (s, 3H), 2.07–1.51 (br, m, 4H), 1.44 (s, 9H), 1.32 (dd, J = 23.9 Hz, 6.2 Hz, 3H); 13C NMR (CDCl3, 100 MHz), δC 173.1, 155.4, 90.0 (d, J = 165 Hz), 90.3 (d, J = 166 Hz), 79.9, 53.2, 52.9, 52.33, 52.31, 32.7 (d, J = 21 Hz), 32.6 (d, J = 21 Hz), 28.4 (d, J = 4 Hz) 28.3, 21.0 (d, J = 23 Hz), 20.9 (d, J = 23 Hz); 19F{1H} NMR (CDCl3, 377 MHz) δF −173.7 (s), −174.1 (s); HRMS (ES) m/z: [M + H]+ calcd for C12H23FNO4 264.1611; found 264.1621.

1,9-Dimethyl (2S,8S)-2,8-Bis({[(tert-butoxy)carbonyl]amino})-5-fluoro-5-methylnonane-dioate 30

Synthesis was achieved by general procedure C using 22 (0.251 g, 0.55 mmol), Fe2(ox)3·6H2O (15 wt % solution) (3.231 g, 1.00 mmol), Selectfluor (0.361 g, 1.02 mmol), and NaBH4 (0.065 g, 1.72 mmol; 0.064 g, 1.69 mmol). Purification by flash column chromatography (20% EtOAc in petroleum ether (40–60), over silica) gave 30 as a colorless oil (0.237 g, 0.50 mmol, 91%); [α]D25 +17.8 (c 1.01, CHCl3); νmax(ATR)/cm–1 3358, 2978, 2937, 2159, 2031, 1978, 1740, 1694, 1514, 1454, 1438, 1392, 1365, 1276, 1255, 1211, 1158, 1049, 1024, 881, and 856; 1H NMR (CDCl3, 400 MHz) δH 5.10 (d, J = 8.1 Hz, 2H), 4.29 (m, 2H), 3.74 (s, 6H), 1.91 (br m, 2H), 1.63 (br m, 6H), 1.44 (s, 18H), 1.27 (d, J = 21.6 Hz, 3H); 13C NMR (CDCl3, 100 MHz), δC 173.0, 155.4, 95.9 (d, J = 170 Hz), 80.0, 53.3, 52.4, 35.2 (d, J = 23 Hz), 35.0 (d, J = 23 Hz), 28.3, 26.82 (d, J = 6 Hz), 26.76 (d, J = 6 Hz), 23.9 (d, J = 25 Hz); 19F{1H} NMR (CDCl3, 377 MHz) δF −147.1 (s); HRMS (ES) m/z: [M + H]+ calcd for C22H40FN2O8 479.2769; found 479.2774.

General Procedure D, NHBoc Deprotection

The Boc-protected amino acid was dissolved in CH2Cl2 (3 mL), TFA (3 mL) was added, and the solution was stirred overnight. The mixture was concentrated under reduced pressure and the residue redissolved in 1:1 toluene/MeOH (6 mL), which was removed under reduced pressure; this process was repeated twice more to afford the product as the TFA salt without further purification.

Methyl (2S,4RS)-2-Ammonium-4-fluoro-4-methylhexanoate Trifluoroacetate 31

Synthesis was achieved by general procedure D using 27 (0.030 g, 0.11 mmol), CH2Cl2/TFA (1:1, 6 mL) and isolated without further purification gave 31 as a colorless oil as a mixture of diastereomers (0.031 g, 0.11 mmol, >99%); νmax(thin film, NaCl plates)/cm–1 3445, 2962, 2666, 1751, 1675, 1631, 1533, 1441, 1384, 1240, 1203, 1138, 1034, 927, 838, and 800; 1H NMR (CDCl3, 400 MHz) δH 8.42 (br s, 3H), 4.78–4.58 (br m, 1H), 4.07–4.00 (br m, 1H), 3.82 (s, 3H), 2.19–1.68 (br m, 4H), 1.34 (dd, J = 24.0 Hz, 5.6 Hz, 3H); 13C NMR (CDCl3, 100 MHz), δC 169.9, 162.3 (q, J = 36.8 Hz), 90.2 (d, J = 165.6 Hz), 89.9 (d, J = 165.7 Hz), 53.3, 52.9, 52.7, 32.0 (d, J = 21.3 Hz), 31.6 (d, J = 21.1 Hz), 26.4 (d, J = 3.8 Hz), 26.1 (d, J = 3.8 Hz), 20.6 (d, J = 22.4 Hz), 20.5 (d, J = 22.4 Hz); 19F{1H} NMR (CDCl3, 377 MHz) δF −76.0 (s, 3 F), −174.6 (s, 0.46 F), −175.0 (s, 0.49 F); 19F NMR (CDCl3, 377 MHz) δF −76.0 (s, 3 F), −174.7 (m, 0.98 F); HRMS (ES) m/z: [M + H]+ calcd for C7H15FNO2 164.1081; found 164.1081.

Methyl (2S,5RS)-2-Ammonium-5-fluorohexanoate Trifluoroacetate 32

Synthesis was achieved by general procedure D using 29 (0.019 g, 0.07 mmol), CH2Cl2/TFA (1:1, 6 mL) and isolated without further purification gave 32 as a colorless oil as a mixture of diastereomers (0.020 g, 0.07 mmol, 96%); νmax(thin film, NaCl plates)/cm–1 3423, 2980, 1754, 1678, 1533, 1442, 1385, 1299, 1237, 1204, 1137, 1055, 997, 949, 886, 838, and 801; 1H NMR (CDCl3, 400 MHz) δH 7.39 (br m, 3H), 4.26 (m, 1H), 3.81 (s, 3H), 2.44–2.14 (m, 2H), 1.84–1.59 (m, 2H), 1.42 (d, J = 22.0 Hz, 3H), 0.96 (t, J = 7.4 Hz, 3H); 13C NMR (CDCl3, 100 MHz), δC 169.9, 169.7, 97.9 (d, J = 166.6 Hz), 97.6 (d, J = 166.8 Hz), 53.5, 53.4, 50.0, 49.8, 38.9 (d, J = 20.8 Hz), 38.8 (d, J = 20.5 Hz), 33.2 (d, J = 23.0 Hz), 31.6 (d, J = 23.4 Hz), 23.6 (d, J = 24.2 Hz), 22.5 (d, J = 24.8 Hz), 7.8 (d, J = 7.9 Hz), 7.6 (d, J = 7.3 Hz); 19F{1H} NMR (CDCl3, 377 MHz) δF −75.8 (s, 3 F), −146.0 (s, 0.5 F), −147.4 (s, 0.48 F); 19F NMR (CDCl3, 377 MHz) δF −75.8 (s, 3 F), −146.1 (m, 0.49 F), −147.4 (m, 0.47 F); HRMS (ES) m/z: [M + H]+ calcd for C8H16FNO2 178.1238; found 178.1240.

General Procedure E, Radical Hydroazidation

The protected unsaturated amino acid was dissolved in MeCN (20 mL), and the solution was cooled to 0 °C. Fe2(ox)3·6H2O (15 wt % solution) was added followed by deionized water (18 mL), NaN3 was then added followed by NaBH4, which was added in eight portions with ≈2 min between each addition. The reaction was stirred for 45 min at 0 °C. Conc. NH4OH solution (30 mL) was added. The reaction mixture was stirred for 1 min. The aqueous phase was extracted with CH2Cl2 (3 × 50 mL), the combined organic layers were dried with Na2SO4, filtered, and the solvent removed under reduced pressure. The product was purified by flash column chromatography (EtOAc in petroleum ether (40–60) mixtures over silica).

Methyl (2S)-4-Azido-2-{[(tert-butoxy)carbonyl]amino}-4-methylpentanoate 33

Synthesis was achieved by general procedure E using 16 (0.127 g, 0.52 mmol), Fe2(ox)3·6H2O (15 wt % solution) (7.698 g, 2.39 mmol), NaN3 (0.125 g, 1.92 mmol), and NaBH4 (0.066 g, 1.74 mmol; 0.078 g, 2.06 mmol; 0.067 g, 1.77 mmol; 0.073 g, 1.93 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 33 as a colorless oil (0.133 g, 0.46 mmol, 88%); [α]D24 +11.6 (c 0.86, CHCl3); νmax(thin film, NaCl plates)/cm–1 3364, 2978, 2932, 2851, 2100, 1747, 1716, 1512, 1456, 1438, 1392, 1368, 1252, 1218, 1167, 1051, 1028, 994, 863, and 760; 1H NMR (CDCl3, 400 MHz) δH 5.21 (d, J = 7.7 Hz, 1H), 4.40 (m, 1H), 3.74 (s, 3H), 1.97 (dd, J = 14.5 Hz, 4.4 Hz, 1H), 1.78 (dd, J = 14.5 Hz, 8.4 Hz, 1H), 1.43 (s, 9H), 1.36 (s, 6H); 13C NMR (CDCl3, 100 MHz), δC 173.1, 155.2, 80.1, 60.3, 52.4, 50.9, 43.0, 28.3, 26.3, 26.0; HRMS (ES) m/z: [M + Na]+ calcd for C12H22N4O4Na 309.1533; found 309.1536.

Methyl (2S)-3-(1-Azidocyclopentyl)-2-{[(tert-butoxy)carbonyl]amino}propanoate 34

Synthesis was achieved by general procedure E using 1a (0.141 g, 0.52 mmol), Fe2(ox)3·6H2O (15 wt % solution) (7.371 g, 2.37 mmol), NaN3 (0.109 g, 1.68 mmol), and NaBH4 (0.071 g, 1.77 mmol; 0.065 g, 1.72 mmol; 0.066 g, 1.74 mmol, 0.071 g, 1.88 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 34 as a colorless oil (0.107 g, 0.34 mmol, 65%); [α]D25 +15.1 (c 1.33, CHCl3); νmax(thin film, NaCl plates)/cm–1 3364, 2968, 2919, 2880, 2102, 1748, 1717, 1513, 1451, 1438, 1393, 1367, 1254, 1208, 1166, 1055, 1023, 864, and 779; 1H NMR (CDCl3, 400 MHz) δH 5.21 (d, J = 7.6 Hz, 1H), 4.44 (m, 1H), 3.75 (s, 3H), 2.18 (dd, J = 14.6 Hz, 4.9 Hz, 1H), 1.98 (dd, J = 14.3, J = 7.2 Hz, 1H), 1.92 (m, 2H), 1.82–1.66 (br m, 4H), 1.65–1.54 (br m, 2H), 1.44 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 173.1, 155.1, 80.0, 71.7, 52.5, 51.5, 40.8, 37.3, 37.2, 28.3, 23.4, 23.3; HRMS (ES) m/z: [M + Na]+ calcd for C14H24N4O4Na 335.1690; found 335.1688.

Methyl (2S)-3-(1-Azidocyclohexyl)-2-{[(tert-butoxy)carbonyl]amino}propanoate 35

Synthesis was achieved by general procedure E using 1b (0.142 g, 0.50 mmol), Fe2(ox)3·6H2O (15 wt % solution) (7.371 g, 2.29 mmol), NaN3 (0.145 g, 2.23 mmol), and NaBH4 (0.068 g, 1.80 mmol; 0.059 g, 1.56 mmol; 0.075 g, 1.98 mmol, 0.070 g, 1.85 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 35 as a colorless oil (0.116 g, 0.36 mmol, 72%); [α]D24 +4.4 (c 1.59, CHCl3); νmax(thin film, NaCl plates)/cm–1 3363, 2977, 2934, 2861, 2103, 1747, 1717, 1513, 1450, 1438, 1390, 1367, 1254, 1211, 1164, 1051, 1024, 864, and 779; 1H NMR (CDCl3, 400 MHz) δH 5.18 (d, J = 7.8 Hz, 1H), 4.42 (m, 1H), 3.74 (s, 3H), 2.06 (dd, J = 14.8 Hz, 4.5 Hz, 1H), 1.83 (dd, J = 14.8 Hz, 8.1 Hz, 1H), 1.72 (m, 2H), 1.59–1.24 (br m, 17H); 13C NMR (CDCl3, 100 MHz), δC 173.2, 155.1, 80.0, 62.8, 52.5, 50.2, 41.5, 34.8, 34.3, 28.3, 25.1, 22.0; HRMS (ES) m/z: [M + Na]+ calcd for C15H26N4O4Na 349.1846; found 349.1851.

Methyl (2S)-5-Azido-2-{[(tert-butoxy)carbonyl]amino}-5-methylhexanoate 36

Synthesis was achieved by general procedure E using 21 (0.134 g, 0.52 mmol), Fe2(ox)3·6H2O (15 wt % solution) (7.585 g, 2.35 mmol), NaN3 (0.130 g, 2.00 mmol), and NaBH4 (0.061 g, 1.61 mmol; 0.074 g, 1.96 mmol; 0.066 g, 1.74 mmol; 0.076 g, 2.01 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave the product 36 as a colorless oil (0.108 g, 0.36 mmol, 69%); [α]D24 +17.4 (c 1.09, CHCl3); νmax(thin film, NaCl plates)/cm–1 3359, 2977, 2935, 2098, 1745, 1718, 1512, 1454, 1440, 1392, 1368, 1255, 1209, 1166, 1056, 1029, 867, 853, and 780; 1H NMR (CDCl3, 400 MHz) δH 5.11 (d, J = 7.9 Hz, 1H), 4.29 (m, 1H), 3.74 (s, 3H), 1.91 (br m, 1H), 1.68 (br m, 1H), 1.53 (br m, 2H), 1.43 (s, 9H), 1.25 (s, 6H); 13C NMR (CDCl3, 100 MHz), δC 173.0, 155.3, 79.9, 61.0, 53.3, 52.4, 36.8, 28.3, 27.5, 26.0, 25.8; HRMS (ES) m/z: [M + Na]+ calcd for C13H24N4O4Na 323.1690; found 323.1692.

Synthesis of 36 was also achieved by general procedure E using 17 (0.128 g, 0.50 mmol), Fe2(ox)3·6H2O (15 wt % solution) (6.733 g, 2.09 mmol), NaN3 (0.125 g, 1.92 mmol), and NaBH4 (0.066 g, 1.74 mmol; 0.058 g, 1.53 mmol; 0.060 g, 1.59 mmol; 0.066 g, 1.74 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 36 as a colorless oil (0.130 g, 0.43 mmol, 86%), identical to that isolated above.

Methyl (2S,4RS)-4-Azido-2-{[(tert-butoxy)carbonyl]amino}-4-methylhexanoate 37

Synthesis was achieved by general procedure E using (E/Z)-18 (7:1, E/Z) (0.131 g, 0.51 mmol), Fe2(ox)3·6H2O (15 wt % solution) (7.627 g, 2.37 mmol), NaN3 (0.126 g, 1.94 mmol), and NaBH4 (0.060 g, 1.59 mmol; 0.074 g, 1.96 mmol; 0.075 g, 1.98 mmol; 0.078 g, 2.06 mmol). Purification by flash column chromatography (10% EtOAc in petroleum ether (40–60), over silica) gave 37 as a colorless oil, which is a mixture of diastereomers (0.096 g, 0.32 mmol, 63%); νmax(thin film, NaCl plates)/cm–1 3361, 2977, 2935, 2883, 2105, 1748, 1716, 1514, 1458, 1437, 1390, 1367, 1255, 1205, 1166, 1056, 1025, 862, and 779; 1H NMR (CDCl3, 400 MHz) δH 5.20 (d, J = 7.8 Hz, 1H), 4.39 (m, 1H), 3.75 (s, 3H), 1.95 (m, 1H), 1.76 (m, 1H), 1.65 (m, 2H), 1.44 (s, 9H), 1.33 (s, 3H), 0.95 (t, J = 7.4 Hz, 3H); 13C NMR (CDCl3, 100 MHz), δC 173.2, 155.2, 80.1, 63.1, 52.5, 50.7, 50.6, 41.0, 40.5, 32.8, 32.4, 28.3, 22.6, 22.4, 8.4, 8.3; HRMS (ES) m/z: [M + H]+ calcd for C13H25N4O4 301.1870; found 301.1872.

General Procedure F, Azide Reduction

The azido amino acid was dissolved in EtOAc, 10 wt % Pd on carbon was added (≈20 wt %), and the mixture was stirred overnight under an atmosphere of hydrogen. The product was purified by flash column chromatography (EtOAc in petroleum ether (40–60) mixtures over silica).

tert-Butyl N-[(3S)-5,5-Dimethyl-2-oxopyrrolidin-3-yl]carbamate 38

Synthesis was achieved by general procedure F using 33 (0.138 g, 0.48 mmol), EtOAc (4 mL), Pd/C 10 wt % (0.037 g, ≈20 wt %). Purification by flash column chromatography (50% EtOAc in petroleum ether (40–60), over silica) gave 38 as a white solid (0.109 g, 0.48 mmol, >99%); mp 121–123 °C; [α]D25 +27.4 (c 1.09, CHCl3); νmax(thin film, NaCl plates)/cm–1 3284, 2975, 2933, 2883, 1705, 1528, 1455, 1420, 1392, 1368, 1327, 1292, 1247, 1169, 1056, 1028, 1001, 979, 885, 835, and 755; 1H NMR (CDCl3, 400 MHz) δH 7.11 (br s, 1H), 5.24 (br d, J = 4.3 Hz, 1H), 4.35 (br m, 1H), 2.54 (br t, J = 8.3 Hz, 1H), 1.75 (br t, J = 11.1 Hz, 1H), 1.43 (s, 9H), 1.31 (s, 3H), 1.27 (s, 3H); 13C NMR (CDCl3, 100 MHz), δC 174.2, 155.9, 79.8, 53.9, 52.1, 44.2, 29.9, 28.5, 28.3; HRMS (ES) m/z: [M + Na]+ calcd for C11H20N2O3Na 251.1366; found 251.1366.

tert-Butyl N-[(3S)-2-Oxo-1-azaspiro[4.4]nonan-3-yl]carbamate 39

Synthesis was achieved by general procedure F using 34 (0.161 g, 0.52 mmol), EtOAc (4 mL), Pd/C 10 wt % (0.038 g, ≈20 wt %). Purification by flash column chromatography (50% EtOAc in petroleum ether (40–60), over silica) gave 39 as a colorless oil (0.121 g, 0.48 mmol, 92%); [α]D25 +13.9 (c 1.22, CHCl3); νmax(thin film, NaCl plates)/cm–1 3276, 2967, 2874, 1702, 1523, 1454, 1391, 1366, 1323, 1285, 1248, 1168, 1062, 1028, 1007, 839, and 753; 1H NMR (CDCl3, 400 MHz) δH 7.57 (br s, 1H), 5.28 (br s, 1H), 4.29 (m, 1H), 2.61 (br t, J = 9.4 Hz, 1H), 1.86–1.63 (br m, 9H), 1.42 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 174.6, 160.0, 79.7, 64.0, 52.2, 42.8, 39.4, 38.4, 28.3, 23.5, 22.7; HRMS (ES) m/z: [M + Na]+ calcd for C13H22N2O3Na 277.1523; found 277.1525.

tert-Butyl N-[(3S)-2-Oxo-1-azaspiro[4.5]decan-3-yl]carbamate 40

Synthesis was achieved by general procedure F using 35 (0.106 g, 0.32 mmol), EtOAc (5 mL), Pd/C 10 wt % (0.023 g, ≈20 wt %). Purification by flash column chromatography (40% EtOAc in petroleum ether (40–60), over silica) gave a colorless oil that solidified on standing. Recrystallization from hot Et2O/pentane (1:1) gave compound 40 (0.079 g, 0.29 mmol, 91%); mp 160–163 °C; [α]D24 +24.1 (c 1.14, CHCl3); νmax(thin film, NaCl plates)/cm–1 3231, 3029, 3006, 2978, 2932, 2857, 1702, 1501, 1453, 1391, 1366, 1332, 1293, 1280, 1246, 1170, 1064, 973, 854, and 760; 1H NMR (CDCl3, 400 MHz) δH 7.49 (br s, 1H), 5.24 (br s, 1H), 4.29 (br m, 1H), 2.67 (br t, J = 9.7 Hz, 1H), 1.62–1.49 (br m, 11H), 1.43 (s, 9H); 13C NMR (CDCl3, 100 MHz), δC 174.3, 156.0, 79.8, 56.8, 51.5, 41.7, 39.4, 37.3, 28.3, 25.0, 23.0, 22.7; HRMS (ES) m/z: [M + Na]+ calcd for C14H24N2O3Na 291.1679; found 291.1679.

tert-Butyl N-[(3S)-6,6-Dimethyl-2-oxopiperidin-3-yl]carbamate 41

Synthesis was achieved by general procedure F using 36 (0.180 g, 0.60 mmol), EtOAc (3 mL), Pd/C 10 wt % (0.037 g, ≈20 wt %). Purification by flash column chromatography (50% EtOAc in petroleum ether (40–60), over silica) gave compound 41 as a white solid (0.144 g, 0.59 mmol, 98%); mp 124–127 °C; [α]D25 +47.8 (c 1.36, CHCl3); νmax(thin film, NaCl plates)/cm–1 3285, 3230, 2974, 2935, 1705, 1665, 1490, 1459, 1416, 1367, 1344, 1312, 1249, 1164, 1076, 1054, 1024, 971, 831, and 756; 1H NMR (CDCl3, 400 MHz) δH 5.82 (br s, 1H), 5.46 (br s, 1H), 3.96 (m, 1H), 2.40 (m, 1H), 1.75 (m, 3H), 1.46 (s, 9H), 1.29 (s, 3H), 1.27 (s, 3H); 13C NMR (CDCl3, 100 MHz), δC 170.8, 156.0, 79.4, 53.1, 51.4, 34.4, 31.6, 29.7, 28.3, 25.3; HRMS (ES) m/z: [M + H]+ calcd for C12H23N2O3 243.1705; found 243.1703.

General Procedure G, Radical Hydroxylation

The amino acid was dissolved in MeCN (20 mL), and Fe2(ox)3 (15 wt % solution) and deionized water (18 mL) were added. The mixture was stirred, and a flow of air passed through the solution. NaBH4 was added in eight portions with ≈2 min between each addition. The reaction mixture was then stirred for 45 min. Conc. NH4OH solution (4 mL) was added, and the reaction mixture stirred for 1 min. The aqueous phase was extracted with 5% MeOH in CH2Cl2 (3 × 50 mL). The combined organic phases were dried with Na2SO4, filtered, and concentrated under reduced pressure. The product was purified by flash column chromatography (EtOAc in petroleum ether (40–60) mixtures over silica).

tert-Butyl N-[(3S)-5,5-Dimethyl-2-oxooxolan-3-yl]carbamate 42

Synthesis was achieved by general procedure G using 16 (0.133 g, 0.55 mmol), Fe2(ox)3·6H2O (15 wt % solution) (7.701 g, 2.39 mmol), and NaBH4 (0.027 g, 0.71 mmol; 0.0306 g, 0.81 mmol; 0.0228 g, 0.60 mmol; 0.039 g, 1.03 mmol; 0.031 g, 0.82 mmol; 0.036 g, 0.95 mmol; 0.025 g, 0.66 mmol; 0.037 g, 0.98 mmol). Purification by flash column chromatography (15–30% EtOAc in petroleum ether (40–60), over silica) gave 42 as a white solid (0.055 g, 0.24 mmol, 44%); mp 110–113 °C; [α]D24 +20.0 (c 0.95, CHCl3); νmax(thin film, NaCl plates)/cm–1 3317, 2981, 2937, 1759, 1708, 1531, 1453, 1375, 1368, 1307, 1272, 1249, 1207, 1158, 1109, 1001, 973, 952, 923, 885, and 809; 1H NMR (CDCl3, 400 MHz) δH 5.12 (br s, 1H), 4.57 (br m, 1H), 2.67 (apparent t, J = 10.2 Hz, 1H), 1.97 (apparent t, J = 11.9 Hz, 1H), 1.50 (s, 3H), 1.46 (s, 9H), 1.43 (s, 3H); 13C NMR (CDCl3, 100 MHz), δC 174.6, 155.5, 82.4, 80.5, 51.3, 42.6, 29.0, 28.3, 26.9; HRMS (ES) m/z: [M + Na]+ calcd for C11H19NO4Na 252.1206; found 252.1209.

Methyl (2S)-2-{[(tert-Butoxy)carbonyl]amino}-5-hydroxy-5-methylhexanoate 43

Synthesis was achieved by general procedure G using 17 (0.149 g, 0.58 mmol), Fe2(ox)3·6H2O (15 wt % solution) (7.117 g, 2.21 mmol), and NaBH4 (0.031 g, 0.82 mmol; 0.035 g, 0.93 mmol; 0.031 g, 0.82 mmol; 0.032 g, 0.85 mmol; 0.032 g, 0.85 mmol; 0.039 g, 1.03 mmol; 0.038 g, 1.00 mmol; 0.027 g, 0.71 mmol). Purification by flash column chromatography (30–100% EtOAc in petroleum ether (40–60), over silica) gave 43 as a colorless oil (0.099 g, 0.36 mmol, 62%); [α]D24 +10.1 (c 1.09, CHCl3); νmax(thin film, NaCl plates)/cm–1 3439, 3373, 2975, 2934, 1738, 1712, 1521, 1455, 1437, 1392, 1367, 1273, 1252, 1208, 1165, 1054, 1028, 914, and 858; 1H NMR (CDCl3, 400 MHz) δH 5.20 (br m, 1H), 4.32 (br m, 1H), 3.74 (s, 3H), 1.98–1.67 (br m, 3H), 1.55–1.44 (br m, 11H), 1.21 (s, 6H); 13C NMR (CDCl3, 100 MHz), δC 173.4, 155.4, 79.9, 70.4, 53.6, 52.3, 38.8, 29.4, 29.2, 28.3, 27.6; HRMS (ES) m/z: [M + Na]+ calcd for C13H25NO5Na 298.1625; found 298.1626.

Acknowledgments

We thank Medivir for partial support of a Ph.D. studentship (P.A.P.R.) and Harry Adams and Craig Robertson for carrying out the X-ray crystal structure analyses.

Supporting Information Available

The Supporting Information is available free of charge on the ACS Publications website at DOI: 10.1021/acsomega.9b01509.

Author Present Address

⊥ Research Institutes of Sweden, RISE Bioscience and Materials/Chemistry and Materials, Brinellgatan, SE-504 64 Borås, Sweden (F.W.).

Author Present Address

∥ Swedish Defence Research Agency, FOI, CBRN Defence and Security, Cementvägen 20, 90182 Umeå, Sweden (D.W.).

Author Present Address

§ F-star Biotechnology Limited, Eddeva B920, Babraham Research Campus, Cambridge CB22 3AT, U.K. (U.G.).

The authors declare no competing financial interest.

Supplementary Material

References

- Blaskovich M. A.Handbook on Syntheses of Amino Acids: General Routes for the Syntheses of Amino Acids; Oxford University Press: Oxford, 2010. [Google Scholar]

- a Welch J. T.; Eswarakrishnan S.. Fluorine in Bioorganic Chemistry; John Wiley & Sons: Chichester, 1991. [Google Scholar]; b Salwiczek M.; Nyakatura E. K.; Gerling U. I. M.; Ye S. J.; Koksch B. Fluorinated Amino Acids: Compatibility with Native Protein Structures and Effects on Protein-protein Interactions. Chem. Soc. Rev. 2012, 41, 2135–2171. 10.1039/C1CS15241F. [DOI] [PubMed] [Google Scholar]

- Gauthier J. Y.; Chauret N.; Cromlish W.; Desmarais S.; Duong L. T.; Falgueyret J. P.; Kimmel D. B.; Lamontagne S.; Leger S.; LeRiche T.; Li C. S.; Masse F.; Mckay D. J.; Nicoll-Griffith D. A.; Oballa R. A.; Palmer J. T.; Percival M. D.; Riendeau D.; Robichaud J.; Rodan G. A.; Rodan S. B.; Seto C.; Therien M.; Truong V. L.; Venuti M. C.; Wesolowski G.; Young R. N.; Zamboni R.; Black W. C. The Discovery of Odanacatib (MK-0822), a Selective Inhibitor of Cathepsin K. Bioorg. Med. Chem. Lett. 2008, 18, 923–928. 10.1016/j.bmcl.2007.12.047. [DOI] [PubMed] [Google Scholar]

- Papageorgiou C.; Borer X.; French R. R. Calcineurin Has a Very Tight-Binding Pocket for the Side-Chain of Residue-4 of Cyclosporine. Bioorg. Med. Chem. Lett. 1994, 4, 267–272. 10.1016/S0960-894X(01)80127-X. [DOI] [Google Scholar]

- Truong V. L.; Gauthier J. Y.; Boyd M.; Roy B.; Scheigetz J. Practical and Efficient Route to (S)-gamma-Fluoroleucine. Synlett 2005, 1279–1280. 10.1055/s-2005-868494. [DOI] [Google Scholar]

- Nadeau C.; Gosselin F. S.; O’Shea P. D.; Davies I. W.; Volante R. P. A Concise Synthesis of (S)-gamma-Fluoroleucine Ethyl Ester. Synlett 2006, 291–295. 10.1055/s-2005-923593. [DOI] [Google Scholar]

- Limanto J.; Shafiee A.; Devine P. N.; Upadhyay V.; Desmond R. A.; Foster B. R.; Gauthier D. R.; Reamer R. A.; Volante R. P. An Efficient Chemoenzymatic Approach to (S)-gamma-Fluoroleucine Ethyl Ester. J. Org. Chem. 2005, 70, 2372–2375. 10.1021/jo047918j. [DOI] [PubMed] [Google Scholar]

- a Halperin S. D.; Fan H.; Chang S.; Martin R. E.; Britton R. A Convenient Photocatalytic Fluorination of Unactivated C-H Bonds. Angew. Chem., Int. Ed. 2014, 53, 4690–4693. 10.1002/anie.201400420. [DOI] [PubMed] [Google Scholar]; b Halperin S. D.; Kwon D.; Holmes M.; Regalado E. L.; Campeau L. C.; DiRocco D. A.; Britton R. Development of a Direct Photocatalytic C-H Fluorination for the Preparative Synthesis of Odanacatib. Org. Lett. 2015, 17, 5200–5203. 10.1021/acs.orglett.5b02532. [DOI] [PubMed] [Google Scholar]

- Padmakshan D.; Bennett S. A.; Otting G.; Easton C. J. Stereocontrolled Synthesis of (S)-gamma-Fluoroleucine. Synlett 2007, 1083–1084. 10.1055/s-2007-977420. [DOI] [Google Scholar]

- Liu W.; Huang X.; Placzek M. S.; Krska S. W.; McQuade P.; Hooker J. M.; Groves J. T. Site-selective 18F Fluorination of Unactivated C–H Bonds Mediated by a Manganese Porphyrin. Chem. Sci. 2018, 9, 1168–1172. 10.1039/C7SC04545J. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wuttke C.; Ford R.; Lilley M.; Grabowska U.; Wiktelius D.; Jackson R. F. W. New Routes to Lipophilic Amino Acids: Synthesis of Alkynyl and Fluoro-Containing Alanine Derivatives. Synlett 2012, 243–246. 10.1055/s-0031-1290123. [DOI] [Google Scholar]

- Ayesa S.; Ersmark K.; Grabowska U.; Hewitt E.; Jönsson D.; Kahnberg P.; Klasson B.; Lind P.; Lundgren S.; Odén L.; Parkes K.; Wiktelius D.. Cysteine Protease Inhibitors. WO2011070539, 2011.

- Barker T. J.; Boger D. L. Fe(III)/NaBH4-Mediated Free Radical Hydrofluorination of Unactivated Alkenes. J. Am. Chem. Soc. 2012, 134, 13588–13591. 10.1021/ja3063716. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fanelli R.; Martinez J.; Cavelier F. Expedient Synthesis of Fmoc-(S)-Fluoroleucine and Late-Stage Fluorination of Peptides. Synlett 2016, 27, 1403–1407. 10.1055/s-0035-1561568. [DOI] [Google Scholar]

- Leggans E. K.; Barker T. J.; Duncan K. K.; Boger D. L. Iron(III)/NaBH4-Mediated Additions to Unactivated Alkenes: Synthesis of Novel 20′-Vinblastine Analogues. Org. Lett. 2012, 14, 1428–1431. 10.1021/ol300173v. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Carrillo-Marquez T.; Caggiano L.; Jackson R. F. W.; Grabowska U.; Rae A.; Tozer M. J. New Routes to beta-Cycloalkylalanine Derivatives using Serine-derived Organozinc Reagents. Org. Biomol. Chem. 2005, 3, 4117–4123. 10.1039/b512784j. [DOI] [PubMed] [Google Scholar]

- Salih N.; Adams H.; Jackson R. F. W. Synthesis of omega-Oxo Amino Acids and trans-5-Substituted Proline Derivatives Using Cross-Metathesis of Unsaturated Amino Acids. J. Org. Chem. 2016, 81, 8386–8393. 10.1021/acs.joc.6b01571. [DOI] [PubMed] [Google Scholar]

- Jackson R. F. W.; Perez-Gonzalez M. Synthesis of N-(tert-Butoxycarbonyl)-β-iodoalanine Methyl Ester: A Useful Building Block in the Synthesis of Nonnatural α-Amino Acids via Palladium Catalyzed Cross Coupling Reactions. Org. Synth. 2005, 81, 77–88. 10.1002/0471264229.os081.08. [DOI] [Google Scholar]

- McMurry J. E.; Scott W. J. A Method for the Regiospecific Synthesis of Enol Triflates by Enolate Trapping. Tetrahedron Lett. 1983, 24, 979–982. 10.1016/S0040-4039(00)81581-6. [DOI] [Google Scholar]

- Jana N.; Nguyen Q.; Driver T. G. Development of a Suzuki Cross-Coupling Reaction between 2-Azidoarylboronic Pinacolate Esters and Vinyl Triflates To Enable the Synthesis of [2,3]-Fused Indole Heterocycles. J. Org. Chem. 2014, 79, 2781–2791. 10.1021/jo500252e. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Allen J. R.; Bourbeau M. P.; Chen N.; Hu E.; Kunz R.; Rumfelt S.. Pyrazine Compounds as Phosphodiesterase Inhibitors. WO2010/057121A1, 2010.

- a Weber J.; Haslinger U.; Brinker U. H. 1-Bromobicyclo[1.1.0]butane as an Easily Obtainable C4-Building Block: A Novel Route to Cyclobutanone. J. Org. Chem. 1999, 64, 6085–6086. 10.1021/jo980190k. [DOI] [Google Scholar]; b Jayathilaka L. P.; Deb M.; Standaert R. F. Asymmetric Synthesis and Translational Competence of l-α-(1-Cyclobutenyl)glycine. Org. Lett. 2004, 6, 3659–3662. 10.1021/ol049026b. [DOI] [PubMed] [Google Scholar]; c Feng J.; Szeimies G. An Efficient Synthesis of Arylcyclobutenes via Cross-Coupling of Aryl Halides with 1-(Tri-n-butylstannyl)cyclobutene. Tetrahedron 2000, 56, 4249–4252. 10.1016/S0040-4020(00)00350-1. [DOI] [Google Scholar]

- Dunn M. J.; Jackson R. F. W.; Pietruszka J.; Turner D. Synthesis of Enantiomerically Pure Unsaturated Alpha-Amino-Acids Using Serine-Derived Zinz/Copper Reagents. J. Org. Chem. 1995, 60, 2210–2215. 10.1021/jo00112a048. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.