Abstract

Flint corn processing method [coarse ground corn (CGC; 3.2 mm average particle size) or steam-flaked corn (SFC; 0.360 kg/L flake density)] was evaluated in conjunction with 4 levels of NDF from sugarcane bagasse (SCB) as roughage source (RNDF; 4%, 7%, 10%, and 13%; DM basis) to determine impact on growth performance, carcass characteristics, starch utilization, feeding behavior, and rumen morphometrics of Bos indicus beef cattle. Two hundred and forty Nellore bulls were blocked by initial BW (350 ± 37 kg), assigned to 32 feedlot pens and pens within weight block were randomly assigned, in a 2 × 4 factorial arrangement (2 corn processing and 4 levels of RNDF) to treatments. Effects of corn grain processing × RNDF level were not detected (P ≥ 0.14) for growth performance, dietary net energy concentration, carcass traits, rumen morphometrics, and feeding behavior, except for time spent ruminating and time spent resting (P ≤ 0.04), and a tendency for papillae width (P ≤ 0.09). Bulls fed SFC-based diets consumed 7% less (P = 0.001), had 10.6% greater carcass-adjusted ADG (P < 0.001) and 19% greater carcass-adjusted feed efficiency (P < 0.001) compared with bulls fed CGC-based diets. Observed net energy for maintenance and gain values were 14.9% and 19.4% greater (P < 0.001), respectively, for SFC than for CGC-based diets. Fecal starch concentration was less (P < 0.001) for bulls fed SFC compared with those fed CGC. No grain processing effects were detected (P = 0.51) for rumenitis score; however, cattle fed SFC presented smaller ruminal absorptive surface area (P = 0.03). Dry matter intake increased linearly (P = 0.02) and carcass-adjusted feed efficiency tended (P = 0.06) to decrease linearly as RNDF increased. Dietary RNDF concentration did not affect carcass characteristics (P ≥ 0.19), except for dressing percentage, which tended to decrease linearly (P = 0.06) as RNDF in finishing diets increased. Increasing RNDF in finishing diets had no effect (P = 0.26) on time spent eating, but time spent ruminating and resting increased linearly (min/d; P < 0.001) with increased dietary RNDF. Steam flaking markedly increased flint corn energy value, net energy of diets, and animal growth performance, and led to improvements on feed efficiency when compared with grinding, regardless of RNDF content of diets. Increasing dietary RNDF compromised feedlot cattle feed efficiency and carcass dressing.

Keywords: beef cattle, feedlot, ground corn, NDF levels, Nellore, steam-flaked corn

INTRODUCTION

Corn grain produced in South America, especially in Brazil, is primarily flint corn that contains a greater proportion of vitreous endosperm and lower starch availability compared with dent corn (Correa et al., 2002). Extensive methods of grain processing, such as steam flaking, markedly improved NE content of flint corn grain and cattle growth performance (Gouvêa et al., 2016; Marques et al., 2016), and these responses exceeded those typically observed with dent corn grain (Zinn et al., 2011; Owens and Basalan, 2013). Steam flaking and high-moisture ensiling increases starch degradation in the rumen (Owens and Basalan, 2013), potentially leading to accumulation of organic acids in the rumen and low ruminal pH, which could impair development of ruminal papillae (Owens et al., 1998; Wang et al., 2009) and adversely affect animal growth performance (Nagaraja and Titgemeyer, 2007). Greater amounts of effective fiber may be required in these diets compared with dry processed corn diets (NASEM, 2016).

According to several studies in which Bos Taurus cattle were fed yellow dent corn, sorghum, or wheat grain, interactions between grain processing and roughage levels were observed, and more roughage or more effective fiber appears to be required in diets containing high-moisture or steam-flaked grains compared with whole or dry processed grains (Gill et al., 1981; Stock et al., 1990; Milton et al., 1994; Gorocica-Buenfil and Loerch, 2005; Loerch and Gorocica-Buenfil, 2006; Pritchard, 2006).

Caetano et al. (2015) reported that the amount of NDF from sugarcane silage (SCS) needed to maximize intake in finishing Bos indicus cattle differed between diets containing either ground flint corn (GC; 1.3 mm mean particle size; 11.3% NDF from SCS, DM basis) or high-moisture flint corn (13.7% NDF from SCS; DM basis); however, no interactions between NDF levels from SCS and corn grain processing methods were observed for growth performance or carcass traits. According to Santos et al. (2017), finishing Nellore bulls fed high-concentrate diets (whole cottonseed, soybean hulls, and ground corn) containing 4%, 7%, 10%, or 13% NDF from low-quality tropical grass hay (Panicum maximum, cv. BRS Tamani) presented quadratic improvements in DMI, ADG, and HCW, but a linear decrease in feed efficiency (G:F). Intake of DM, ADG, HCW, and G:F was maximized with 12.11%, 10.27%, 8.75%, and 4% grass hay NDF, respectively. This is in agreement with Brown et al. (2006), who suggested that lower levels of forage inclusion in finishing diets can improve feed efficiency.

Sugarcane bagasse (SCB), which is a byproduct generated by ethanol plants, is one of the most used roughage sources in Brazilian finishing cattle diets (Oliveira and Millen, 2014). Nevertheless, little information is available about the optimal level of inclusion of SCB in finishing diets to maximize growth performance of finishing B. indicus cattle (Leme et al., 2003).

We hypothesized that roughage NDF levels from SCB (RNDF) interact with flint corn grain processing and higher levels of RNDF are necessary in SFC-based diets to improve growth performance of finishing Nellore bulls. To test this hypothesis, effects of flint corn processing methods [coarse ground corn (CGC; 3.2 mm average particle size) or steam-flaked corn (SFC; 0.360 kg/L)] were evaluated at 4 levels of RNDF (4%, 7%, 10%, and 13% of diet DM) to determine impact on feedlot growth performance, carcass characteristics, starch utilization, diet energy content, feeding behavior, and rumen morphometrics of finishing Nellore bulls.

MATERIALS AND METHODS

This study was conducted at the experimental feedlot cattle facilities of the Animal Science Department of the “Luiz de Queiroz” College of Agriculture (ESALQ), University of São Paulo (USP), in Piracicaba, State of São Paulo, Brazil. All procedures using animals followed guidelines recommended by the Animal Care and Use Committee of ESALQ/USP, protocol number # 2014–16.

Animals, Housing, and Feeding

Two hundred forty Nellore bulls (initial BW = 350 ± 37 kg) were vaccinated against clostridia (3 mL s.c.; Sintoxan Polivalent T, Merial Saúde Animal Ltda, Paulínia, Brazil), dewormed with 5 mL of 3.15% ivermectin (Ivomec Gold, Merial Saúde Animal Ltda), and received an injection of vitamins A, D, and E (5 mL s.c.; Valléevita ADE, Vallée S/A Produtos Veterinários, Montes Claros, Brazil) at the beginning of the experiment (day 0). The trial was preceded by a 21-d adaptation period. During the adaptation period, dietary concentration of the SCB was reduced each week from 30 to 20 to 15% of the diets (DM basis) and replaced with ground corn accordingly. A randomized complete block design was used with a 2 × 4 factorial arrangement of treatments (4 replications/treatment), in which cattle were blocked by initial BW (day 0; 2 BW blocks) and allocated into 1 of 32 partially covered feedlot pens with concrete floors [24 pens with 6 bulls/pen (5.3 m2/bull) and 8 pens with 12 bulls/pen (7 m2/bull)].

Treatments were randomly assigned to pens within each weight block (4 pens/treatment: 3 pens with 6 bulls + 1 pen with 12 bulls), and consisted of diets containing either CGC corn (3.2 mm average particle size) or SFC (0.360 kg/L density) combined with 1 of 4 levels of RNDF (4%, 7%, 10%, and 13%; DM basis) from SCB. The minimum number of replicates per treatment required to detect a 20% difference in feed efficiency (P < 0.05; 1 − β = 0.95) was determined by using error variance from results published by Gouvêa et al. (2016).

All diets were formulated to meet or exceed requirements of finishing Nellore bulls for 1.5 kg ADG as specified by NRC (1996; Tables 1 and 2). All corn grain used in this trial was flint corn, as is regularly used in Brazil. In order to obtain SFC, grains were processed to a flake density of 0.360 kg/L at a commercial feedyard (Fazenda Conforto, Nova Crixás, Brazil), air dried to approximately 86% DM, and delivered to the research feedlot twice monthly. The CGC was processed through a hammer mill (DPM-4; Nogueira S/A Máquinas Agricolas, São João da Boa Vista, Brazil) for a mean particle size of 3.2 mm (Table 3). Sugarcane bagasse is the fibrous portion remaining after sugarcane stalks are crushed and juices extracted (Marques et al., 2016). Throughout the experimental period, using SCB had an average particle size of approximately 8.2 mm, with particle size distribution using the Penn State Particle Separator of 5.0%, 39.8%, 12.9%, and 42.3% for the screens 19.0, 8.0, 3.5, and pan, respectively (Heinrichs, 1999; Kononoff et al., 2003).

Table 1.

Chemical composition (% of DM) of steam-flaked corn (SFC), coarse ground corn (CGC), soybean meal (SBM), and sugarcane bagasse (SCB) used in experimental diets1

| Item | SFC | CGC | SBM | SCB2 |

|---|---|---|---|---|

| DM | 86.1 | 89.2 | 88.2 | 49.6 |

| Crude protein | 7.52 | 8.43 | 47.2 | 2.30 |

| Extract ether | 3.15 | 5.30 | 1.50 | 0.430 |

| Neutral detergent fiber | 8.70 | 14.7 | 28.1 | 85.9 |

| Acid detergent fiber | 2.51 | 3.64 | 10.0 | 58.2 |

| Lignin | 0.62 | 0.38 | 0.51 | 12.2 |

| Ash | 1.10 | 1.54 | 6.00 | 5.01 |

| Total digestible nutrients3 | 90.5 | 86.3 | 76.6 | 39.5 |

| Starch | 70.4 | 71.2 | – | – |

1All corn grain used was flint corn as is regularly used in Brazil. To form SFC, it was processed to a flake density of 0.360 kg/L at a commercial feed mill (Fazenda Conforto, Nova Crixás, Brazil), air dried, and delivered to the research feedlot twice monthly. Ground corn was processed through a hammer mill (DPM-4; Nogueira S/A Máquinas Agricolas, São João da Boa Vista, Brazil) to achieve a mean particles size of 3.2 mm.

2A byproduct from the ethanol industry; it is the fibrous portion remaining after sugarcane stalks are crushed and juices extracted (Marques et al., 2016).

3The total digestible nutrient content was calculated according to the equations described by Weiss et al. (1992), and using the processing adjusted factors (0.95 and 1.04 for ground corn and SFC, respectively; NRC, 2001).

Table 2.

Ingredients and chemical composition of experimental diets (DM basis)

| Coarse ground corn | Steam-flaked corn | |||||||

|---|---|---|---|---|---|---|---|---|

| Neutral detergent fiber levels from sugarcane bagasse | ||||||||

| Item | 4 | 7 | 10 | 13 | 4 | 7 | 10 | 13 |

| Ingredient, % of DM | ||||||||

| Sugarcane bagasse1 | 4.70 | 8.10 | 11.6 | 15.1 | 4.70 | 8.10 | 11.6 | 15.1 |

| Coarse ground corn2 | 86.7 | 83.2 | 79.6 | 76.0 | – | – | – | – |

| SFC2 | – | – | – | – | 86.7 | 83.2 | 79.6 | 76.0 |

| Soybean meal | 5.00 | 5.00 | 5.00 | 5.00 | 5.00 | 5.00 | 5.00 | 5.00 |

| Urea | 1.10 | 1.20 | 1.30 | 1.40 | 1.10 | 1.20 | 1.30 | 1.40 |

| Mineral supplement3 | 2.50 | 2.50 | 2.50 | 2.50 | 2.50 | 2.50 | 2.50 | 2.50 |

| Analyzed composition4 | ||||||||

| DM, % | 87.7 | 86.4 | 84.9 | 83.6 | 85.0 | 83.8 | 82.5 | 81.2 |

| Crude protein, % | 13.0 | 13.1 | 13.0 | 13.0 | 12.2 | 12.3 | 12.2 | 12.3 |

| Neutral detergent fiber, % | 18.2 | 20.6 | 23.1 | 25.5 | 13.0 | 15.6 | 18.3 | 21.0 |

| Total digestible nutrients, % | 80.5 | 78.8 | 77.1 | 75.4 | 84.2 | 82.3 | 80.5 | 78.6 |

| NEm,5 Mcal/kg | 2.01 | 1.96 | 1.91 | 1.86 | 2.12 | 2.07 | 2.01 | 1.95 |

| NEg,5 Mcal/kg | 1.36 | 1.31 | 1.27 | 1.22 | 1.45 | 1.41 | 1.36 | 1.31 |

1A byproduct from the ethanol industry; it is the fibrous portion remaining after sugarcane stalks are crushed and juices extracted (Marques et al., 2016).

2SFC = steam-flaked corn. All corn grain used was flint corn as is regularly used in Brazil. To form SFC, it was processed to a flake density of 0.360 kg/L at a commercial feed mill (Fazenda Conforto, Nova Crixás, Brazil), air dried, and delivered to the research feedlot twice monthly. Ground corn was processed through a hammer mill (DPM-4; Nogueira S/A Máquinas Agricolas, São João da Boa Vista, Brazil) to achieve a mean particles size of 3.2 mm.

3Custom blend manufactured by Agroceres Multimix, Piracicaba, Brazil, containing (DM basis) 260 g/kg Ca, 20 g/kg P, 50 g/kg Na, 10 g/kg Mg, 20 g/kg S, 1,000 mg/kg of Mn, 1,800 mg/kg of Zn, 350 mg/kg of Cu, 35 mg/kg of Co, 30 mg/kg of I, 12 mg/kg of Se, 1,100 mg/kg of monensin, 160,000 IU/kg of vitamin A, 120,000 IU/kg of vitamin D3, and 1,500 IU/kg of vitamin E.

4Based on chemical analysis of ingredients collected weekly throughout the experiment (n = 17 samples). At the end of the trial, feed samples were thawed, composited by week, dried in a forced-air oven at 55 °C for 72 h, and ground using a Wiley-type mill for analysis.

5Net energy for maintenance (NEm) and gain (NEg) were estimated according the equations proposed by NASEM (2016; solution type = empirical level) with the addition of monensin as feed additive, and based on the sum of total digestible nutrient values from each ingredient calculated according to the equations described by Weiss et al. (1992) using assumed processing adjustment factors of 0.95 and 1.04 for ground corn and steam-flaked flint corn, respectively.

Table 3.

Impacts of grain processing method (coarse ground corn [CGC] or steam-flaked corn [SFC]) on characteristics of corn grains

| Item | CGC | SFC |

|---|---|---|

| Corn particle size distribution,1 % of total | ||

| >6 mm | 7.10 | 70.6 |

| ≤6 and >3.5 mm | 28.7 | 16.1 |

| ≤3.5 and >2.0 mm | 36.0 | 7.50 |

| ≤2.0 and >1.25 mm | 15.6 | 2.60 |

| ≤1.25 mm | 12.6 | 3.20 |

| Mean particle size | 3.20 | 9.40 |

| Vitreousness,2 % of total endosperm | 70.8 | 67.9 |

1Duplicates samples of each processed grain (CGC and SFC; weight = 100 g) were placed on the top screen (6-mm openings) of a testing sieve (Produtest T Model; Telastem Peneiras para Análises Ltda., São Paulo, SP, Brazil) and vigorously agitated with approximately 60 shakes/min for 5 min. Sieves with 6.0-, 3.5-, 2.0-, and 1.25-mm pores were used to calculate the grain particle size as described by Yu et al. (1998).

2Determined by manual dissection of 50 randomly selected whole kernels from each non-processed CGC and SFC samples as described previously by Gouvêa et al. (2016).

Bulls were fed fresh mixed diets once daily at 0700 h throughout the experiment and had free-choice access to feed and fresh water. Feed ingredients, except for the SCB that was weighed into the feed wagon, were individually weighted using a fixed scale (Weightech WT1000, Weightech Equipamentos de Pesagem, Florianópolis, SC, Brazil). Total mixed ration was prepared using a feed-mix wagon (Totalmix 25, Casale Equipamantos, São Carlos, Brazil) and mixing time was set according manufacture’s recommendation. The amount of fresh feed offered to each pen was adjusted daily based on the DMI of the previous day, and the amount of orts should not exceed 3%. Orts were collected weekly, weighed, sampled and dried in a forced-air oven at 55 °C for 72 h to estimate DMI for each pen.

Sample Collection and Analyses

Before the beginning (day 0) and at the end of the experimental period, individual BW was recorded after a 16-h period of feed and water withdrawal, and these data were used to calculate ADG. The G:F was calculated by dividing ADG by DMI for each pen.

For diet adjustments and diet DM determination, samples of SCB, CGC, SFC, and soybean meal (SBM) were collected weekly throughout the experiment and dried at 105 °C for 12 h.

Samples of SCB, CGC, SFC, and SBM were also collected weekly and stored at −20 °C. At the end of the trial, feed samples were thawed, composited by week, dried in a forced-air oven at 55 °C for 72 h, and ground using a Wiley-type mill (MA-680 Marconi Ltda, Piracicaba, SP, Brazil) through a 1-mm screen. All samples were analyzed for DM at 105° C (method 930.15; AOAC, 2000), ash (method 942.05; AOAC, 2000), ash-corrected NDF (Van Soest et al., 1991, modified for Ankom 200 fiber analyzer, Ankom Technology Corp.) using sodium sulfite for all the samples and heat-stable α-amylase for CGC and SFC, acid detergent fiber (Goering and Van Soest, 1970), ether extract (method 920.85; AOAC, 1986), and total nitrogen (Leco FP-528, Leco Corp., St. Joseph, MI).

Corn grain vitreousness (Table 3) was determined by manual dissection of 50 randomly selected whole kernels from each non-processed CGC and SFC samples as described previously by Gouvêa et al. (2016). Duplicate samples of each processed grain (CGC and SFC; 100 g) were placed on the top screen (6-mm openings) of a testing sieve (Produtest T Model; Telastem Peneiras para Análises Ltda., São Paulo, SP, Brazil) and vigorously agitated with approximately 60 shakes/min for 5 min. Sieves with 6.0-, 3.5-, 2.0-, and 1.25-mm pores were used to calculate grain particle size as described by Yu et al. (1998; Table 3).

Feeding behavior was visually evaluated by 8 trained individuals (4 pens for each person, who were blinded to dietary treatments) on day 60 using a procedure adapted from Robles et al. (2007). Behavior data were recorded every 10 min during a 24-h period from 2 randomly selected bulls per pen as follows: minutes spent eating, ruminating, and resting (if they were not eating or ruminating) (Robles et al., 2007; Pereira et al., 2016). Activities per unit of DMI and NDF intake were also calculated by dividing total minutes by the mean of each parameter measured.

On day 70, three bulls per pen were randomly selected and approximately 300 g of fresh fecal samples were collected before feeding dietary treatments. Samples were dried at 55 °C for 72 h, ground through a 1-mm screen using a Wiley-type mill (MA-680 Marconi Ltda, Piracicaba, SP, Brazil), and analyzed for DM (method 930.15; AOAC, 1986). Fecal starch (FS) concentration was determined according to procedures described by Bach Knudsen (1997). Fecal starch values were used to calculate total tract starch digestion (TSD) and NE content of corn as described previously by Zinn et al. (2007).

Calculations for observed net energy of maintenance (NEm) and gain (NEg) of each dietary treatment were based on the equation proposed by Zinn and Shen (1998) taking into account average values from growth performance data of bulls in each pen. These calculated NE concentrations were compared to those predicted by equations from NASEM (2016; solution type = empirical) with addition of monensin (2.3% increase in diet ME content), and based on the numeric sum of TDN (Weiss et al., 1992) for feed ingredients assuming processing adjustment factors of 0.95 and 1.04 for CGC and SFC, respectively (NRC, 2001).

At the end of the feeding trial, animals were withheld from feed and water for 16 h, weighed, and shipped 10.3 km (approximately 20 min) using 12 commercial beef trucks (20 bulls/truck) to a commercial packing plant (Frigorifico Angelleli S/A, Piracicaba, Brazil), where they were slaughtered on the following day. Bulls from block 1 (heavy) and 2 (light) were assigned to slaugther on 2 separate dates, 28 d apart (n = 96 bulls after 95 d on feed [DOF]; n = 144 bulls after 123 DOF). Slaughter dates were established based on estimated mature weight of 497 kg for Nellore bulls (Costa e Silva et al., 2012). The HCW was obtained at the time of slaughter after evisceration and removal of kidney, pelvic, and heart fat. Dressing percentage was calculated as the ratio of HCW to final shrunk BW. Average dressing percent (55.12%) was used to estimate carcass-adjusted final BW from HCW and so, carcass-adjusted ADG and feed efficiency were also calculated. These carcass-adjusted data were used in the discussion section. Subcutaneous fat thickness and loin muscle area were measured over the 12th rib after a 24-h carcass chill at 4 °C using a digital caliper and a numbered grid, respectively.

Livers were scored for abscess incidence and severity using a 4-point numeric scale (1 = no visible abscess and 4 = severe with more than 4 small abscesses or one or more abscess greater than 2.5 cm in diameter; Brown et al., 1975). After cattle evisceration, rumens were washed and scored for presence of lesions (rumenitis) and abnormalities (e.g., papillae clumped) using a 10-point scale (0 = no lesions and abnormalities and 10 = severe ulcerative lesions; Bigham and McManus, 1975; Pereira et al., 2016). Two bulls per pen were randomly selected and a 1-cm2 fragment of ruminal epithelium was collected from cranial sac (atrium ruminis) and placed into a PBS solution for subsequent macroscopic morphometric evaluation as described by Pereira et al. (2016). From the ventral sac of the rumen, a 1-cm2 fragment was collected for microscopic morphometric evaluation of ruminal-papilae, such as height, width, surface area, and keratinized layer thickness (Pereira et al., 2016).

Statistical Analyses

Feedlot growth performance, carcass characteristics, FS excretion, feeding behavior, rumen morphometrics, and diet energy values were analyzed using the PROC MIXED procedure of SAS (SAS Inst., Inc., Cary, NC) as a generalized randomized block design (4 replications/treatment) with a 2 × 4 factorial arrangement of treatments [2 corn grain processing methods (CGC and SFC) and 4 levels of RNDF (4%, 7%, 10%, and 13%; DM basis)]. Bulls were blocked by initial BW (total of 2 blocks; 2 replicates per treatment within each block). Pen was the experimental unit and Satterthwaite approximation was used to determine denominator degrees of freedom for testing fixed effects. All model statements included fixed effects of corn grain processing, RNDF level, and corn grain processing × RNDF level interaction. Pen (corn grain processing × RNDF level × block) and bull (pen) were used as random variables for all variables analyzed, except for DMI and G:F that did not include bull (pen). Trained individuals were also included as random effect for feeding behavior analyses. When no significant interactions were detected, main effects of corn processing and RNDF levels were evaluated. When significant interactions were observed, however, orthogonal polynomial contrasts were used to detect linear and quadratic effects of RNDF inclusion levels within each corn processing methods. The Solution statement was used to estimate regression coefficients. Results are reported as least-squares means. Differences were declared significant P ≤ 0.05 and regarded as tendencies when P > 0.05 and P ≤ 0.10.

RESULTS

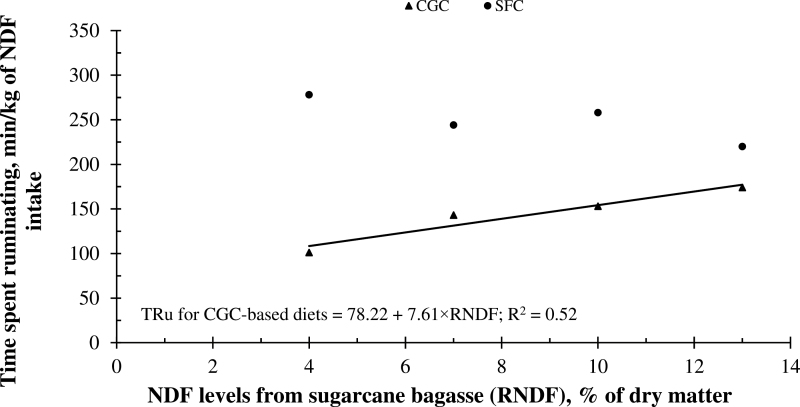

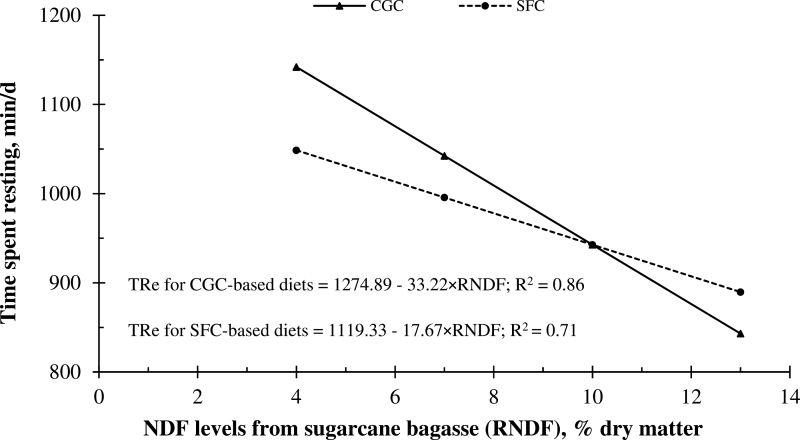

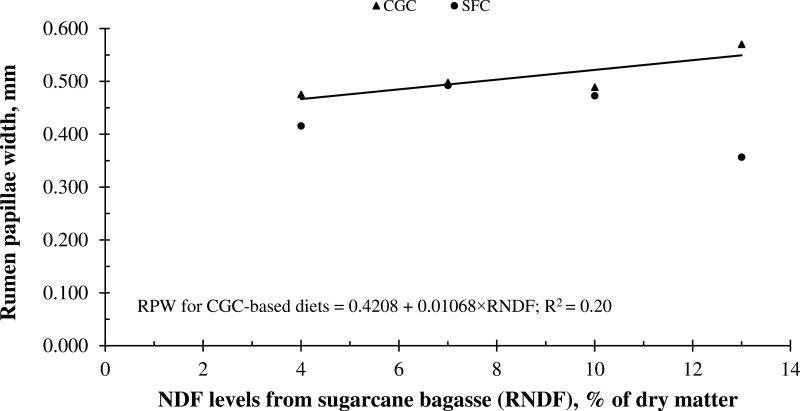

Effects of corn grain processing × RNDF level were not detected (P ≥ 0.14) for any feedlot growth performance, dietary NE concentration, carcass traits, rumen morphometrics, and feeding behavior variables, except for time spent ruminating (as expressed as min/kg NDF; P = 0.01), time spent resting (P = 0.04), and a tendency for papillae width (P = 0.09).

Effects of Corn Processing × Roughage NDF Level

No effect of RNDF levels were observed in time spent ruminating for bulls fed SFC-based diets (P = 0.15) but increasing RNDF levels tended (P = 0.07) to linearly increase the time spent ruminating (expressed as min/kg NDF) in bulls fed CGC-based diets (Fig. 1). At RNDF levels greater than 10% of diet DM, bulls fed SFC-based diets spent more time resting than bulls fed CGC-based diets (Fig. 2). No effects of RNDF levels were observed in papillae width for bulls fed SFC-based diets (P = 0.42), but increasing RNDF levels tended to linearly increase the papillae width in bulls fed CGC-based diets (P = 0.07; Fig. 3).

Figure 1.

Effects of flint corn grain processing method [coarse ground corn (CGC; 3.2 mm) or steam-flaked corn (SFC; 0.360 kg/L)] and neutral detergent fiber (NDF) levels (% of DM) from sugarcane bagasse (RNDF) on feeding behavior of finishing Nellore bulls. Effect of corn grain processing × RNDF level was detected for time spent ruminating expressed as min/kg of NDF intake (TRu; P = 0.01; SEM = 16.5). No effect of RNDF levels on TRu was observed in SFC-based diets (P = 0.15; SEM = 16.3), but a tendency of linear effect of RNDF levels was detected in CGC-based diets (P = 0.07; SEM = 16.6). Animals were visually evaluated by 8 trained individuals (4 pens for each evaluator blinded to dietary treatments) on day 60 of the feeding period using a procedure adapted from Robles et al. (2007). Behavior data were recorded every 10 min during a 24-h period from 2 randomly selected bulls per pen as follows: minutes spent eating, ruminating, and resting (if they were not eating or ruminating) (Robles et al., 2007; Pereira et al., 2016). Activities per unit of DMI and NDF intake were also calculated by dividing total minutes by the mean of each parameter measured.

Figure 2.

Effects of flint corn grain processing method [coarse ground corn (CGC; 3.2 mm) or steam-flaked corn (SFC; 0.360 kg/L)] and neutral detergent fiber (NDF) levels (% of DM) from sugarcane bagasse (RNDF) on feeding behavior of finishing Nellore bulls. Effect of corn grain processing × RNDF level was detected for time spent resting (TRe; P = 0.04; SEM = 26.7). Linear effect of RNDF levels in CGC diets (P < 0.001; SEM = 49.4) and SFC diets (P < 0.001; SEM = 41.9). Animals were visually evaluated by 8 trained individuals (4 pens for each evaluator blinded to dietary treatments) on day 60 of the feeding period using a procedure adapted from Robles et al. (2007). Behavior data were recorded every 10 min during a 24-h period from 2 randomly selected bulls per pen as follows: minutes spent eating, ruminating, and resting (if they were not eating or ruminating) (Robles et al., 2007; Pereira et al., 2016). Activities per unit of DMI and NDF intake were also calculated by dividing total minutes by the mean of each parameter measured.

Figure 3.

Effects of flint corn grain processing method [coarse ground corn (CGC; 3.2 mm) or steam-flaked corn (SFC; 0.360 kg/L)] and neutral detergent fiber (NDF) levels (% of DM) from sugarcane bagasse (RNDF) on rumen tissue morphometrics of finishing Nellore bulls. A tendency for corn grain processing × RNDF level was detected for rumen papillae width, mm (RPW; P = 0.09; SEM = 0.04). No effects of RNDF levels on RPW were observed in SFC diets (P = 0.42; SEM = 0.07), but a tendency for positive linear effect of RNDF levels on RPW was observed in CGC diets (P = 0.07; SEM = 0.04). Bulls from block 1 and 2 were assigned to slaughter on 2 separate dates, 28 d apart (n = 96 bulls after 95 d on feed [DOF]; n = 144 bulls after 123 DOF). Rumen samples were collected from 2 randomly selected bulls in each pen. Approximately a 1-cm2 fragment of rumen was collected from cranial sac (atrium ruminis) and placed into a phosphate-buffered saline solution as described by Pereira et al. (2016).

Effects of corn processing.

As designed, initial BW were similar (P = 0.99) among bulls assigned SFC or CGC-based diets (Table 4). Bulls fed SFC-based diets had 7.0% less DMI (P = 0.001), 10.6% greater carcass-adjusted ADG (P < 0.001) and 19% greater carcass-adjusted G:F (P < 0.001) compared to bulls fed CGC-based diets (Table 4). Corn grain processing method did not affect carcass-adjusted final BW and carcass traits (P ≥ 0.18). Bulls fed SFC-based diets spent less time (P = 0.007) eating (min/d and min/kg of DMI) and tended to increase (P = 0.08; min/d) or increased (P < 0.01; min/kg of DMI) time spent ruminating compared with bulls fed CGC-based diets (Table 5). Dietary NE intakes, which were calculated from growth performance measurements (BW, ADG, and DMI), were greater (P ≤ 0.03) for bulls fed SFC compared with bulls fed CGC (Table 6). Observed NEm and NEg values were respectively 14.9% and 19.4% greater (P < 0.001) for SFC- than for CGC-based diets (Table 6). The observed NE:expected NE ratios were greater (P < 0.001) for SFC- than CGC-based diets (Table 6). Fecal starch concentration was reduced (P < 0.001) for bulls fed SFC vs. CGC-based diets. Consequently, bulls fed SFC-based diets had greater (P < 0.001) TSD compared with CGC-fed cattle (Table 6). Based on FS values and calculations described by Zinn et al. (2007), steam flaking increased (P < 0.001) NEm and NEg of flint corn grain by 8.0% and 10.2%, respectively, compared to grinding (Table 6).

Table 4.

Effects of flint corn grain processing (PRC) method [coarse ground corn (CGC; 3.2 mm) or steam-flaked corn (SFC; 0.360 kg/L)] and neutral detergent fiber (NDF) levels (% of DM) from sugarcane bagasse (RNDF) on growth performance, feeding behavior, and carcass traits of finishing Nellore bulls

| Corn grainprocessing method | NDF levels from sugarcane bagasse | P-value | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Item | CGC | SFC | 4 | 7 | 10 | 13 | SEM | PRC | RNDF | PRC × RNDF |

| Growth performance | ||||||||||

| Initial BW,1 kg | 360 | 360 | 360 | 360 | 360 | 360 | 19.5 | 0.99 | 0.99 | 0.99 |

| Final BW,1 kg | 492 | 508 | 496 | 506 | 497 | 503 | 13.1 | 0.08 | 0.86 | 0.98 |

| Adj. final BW,2 kg | 494 | 508 | 500 | 507 | 494 | 502 | 14.6 | 0.18 | 0.85 | 0.97 |

| ADG,3 kg | 1.22 | 1.37 | 1.25 | 1.34 | 1.26 | 1.32 | 0.050 | <0.001 | 0.19 | 0.79 |

| Adj. ADG,2 kg | 1.23 | 1.36 | 1.29 | 1.35 | 1.23 | 1.31 | 0.053 | <0.001 | 0.15 | 0.76 |

| DMI,4,5 kg | 9.11 | 8.47 | 8.29 | 9.00 | 8.80 | 9.09 | 0.266 | 0.001 | 0.02 | 0.85 |

| Feed efficiency, g/kg | 136 | 164 | 153 | 153 | 146 | 149 | 5.77 | <0.001 | 0.54 | 0.57 |

| Adj. feed efficiency,5 g/kg | 137 | 163 | 157 | 154 | 142 | 147 | 6.06 | <0.001 | 0.06 | 0.48 |

| Carcass characteristics | ||||||||||

| HCW, kg | 272 | 280 | 276 | 280 | 272 | 277 | 7.96 | 0.18 | 0.84 | 0.96 |

| Dressing percentage5 | 55.3 | 55.0 | 55.6 | 55.2 | 54.8 | 55.0 | 0.289 | 0.19 | 0.06 | 0.61 |

| 12th rib fat thickness, mm | 3.79 | 3.96 | 4.07 | 3.92 | 3.84 | 3.66 | 0.297 | 0.43 | 0.58 | 0.40 |

| Longissimus muscle area, cm2 | 66.3 | 67.3 | 67.1 | 66.9 | 66.2 | 67.1 | 1.76 | 0.40 | 0.94 | 0.87 |

1Initial and final individual BW measured live and after 16 h of feed and water restriction. Bulls from block 1 and 2 were assigned to slaughter on 2 separate dates, 28 d apart (n = 96 bulls after 95 d on feed [DOF]; n = 144 bulls after 123 DOF).

2Carcass-adjusted values. Adjusted (Adj.) final BW was estimated by dividing HCW by the overall average dressing percentage obtained for treatments (55.12%) and so, adjusted ADG and feed efficiency were calculated.

3Calculated using initial and final BW (after 16 h of feed and water restriction).

4Recorded from each pen (4 pens/treatment: 3 pens with 6 bulls + 1 pen with 12 bulls) and divided by the number of animals within each pen, and expressed as kg animal/d.

5Orthogonal contrast: Linear effect of NDF levels from sugarcane bagasse (main effect; P ≤ 0.05).

Table 5.

Effects of flint corn grain processing (PRC) method [coarse ground corn (CGC; 3.2 mm) or steam-flaked corn (SFC; 0.360 kg/L)] and neutral detergent fiber (NDF) levels (% of DM) from sugarcane bagasse (RNDF) on feeding behavior of finishing Nellore bulls

| Corn grainprocessing method | NDF levels from sugarcane bagasse | P-value | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Item1 | CGC | SFC | 4 | 7 | 10 | 13 | SEM | PRC | RNDF | PRC × RNDF |

| Time spent eating | ||||||||||

| min/d | 148 | 107 | 110 | 119 | 136 | 145 | 18.6 | <0.01 | 0.26 | 0.72 |

| min/kg of DMI | 15.7 | 12.3 | 12.9 | 12.7 | 15.1 | 15.4 | 2.12 | 0.03 | 0.44 | 0.71 |

| min/kg of NDFI | 72.1 | 74.4 | 84.4 | 70.1 | 72.4 | 66.2 | 12.3 | 0.80 | 0.50 | 0.55 |

| Time spent ruminating | ||||||||||

| min/d | 300 | 364 | 227 | 311 | 369 | 422 | 29.8 | 0.08 | 0.001 | 0.15 |

| min/kg of DMI2 | 31.9 | 41.9 | 27.3 | 33.7 | 41.3 | 45.2 | 3.14 | <0.001 | <0.001 | 0.12 |

| min/kg of NDFI | 143 | 250 | 190 | 193 | 206 | 197 | 16.5 | <0.001 | 0.78 | 0.01 |

| Time spent resting, min/d | 993 | 970 | 1,104 | 1,011 | 935 | 875 | 26.7 | 0.24 | 0.001 | 0.04 |

1Visually evaluated by 8 trained individuals (4 pens for each evaluator, blinded to dietary treatments) on day 60 using a procedure adapted from Robles et al. (2007). Behavior data were recorded every 10 min during a 24-h period from 2 randomly selected bulls per pen as follows: minutes spent eating, ruminating, and resting (if they were not eating or ruminating) (Robles et al., 2007; Pereira et al., 2016). Activities per unit of DMI and NDF intake (NDFI) were also calculated by dividing total minutes by the mean of each parameter measured.

2Orthogonal contrast: linear effect of NDF levels from sugarcane bagasse (main effect; P ≤ 0.05).

Table 6.

Effects of flint corn grain processing (PRC) method [coarse ground corn (CGC; 3.2 mm) or steam-flaked corn (SFC; 0.360 kg/L)] and neutral detergent fiber (NDF) levels (% of DM) from sugarcane bagasse (RNDF) on dietary net energy (NE) concentrations, fecal starch (FS), total tract starch digestion (TSD), and energy values of flint corn

| Corn grain processing method | NDF levels from sugarcane bagasse | P-value | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Item | CGC | SFC | 4 | 7 | 10 | 13 | SEM | PRC | RNDF | PRC × RNDF |

| NEm intake,1 Mcal/d | 17.1 | 17.7 | 17.3 | 18.1 | 17.4 | 17.0 | 0.690 | 0.03 | 0.42 | 0.91 |

| NEg intake,1 Mcal/d | 11.2 | 12.5 | 11.6 | 12.2 | 11.7 | 12.0 | 0.510 | <0.01 | 0.58 | 0.87 |

| Observed NE2 | ||||||||||

| NEm, Mcal/kg | 1.88 | 2.16 | 2.07 | 2.03 | 1.98 | 1.98 | 0.052 | <0.001 | 0.28 | 0.51 |

| NEg, Mcal/kg | 1.24 | 1.48 | 1.41 | 1.37 | 1.33 | 1.34 | 0.045 | <0.001 | 0.27 | 0.52 |

| Observed NE:expected NE3 | ||||||||||

| NEm | 0.971 | 1.06 | 1.00 | 1.01 | 1.01 | 1.04 | 0.024 | <0.001 | 0.38 | 0.58 |

| NEg | 0.960 | 1.07 | 1.00 | 1.01 | 1.01 | 1.05 | 0.035 | <0.001 | 0.37 | 0.56 |

| Estimated fecal analysis4 | ||||||||||

| Starch, % | 13.7 | 3.76 | 10.3 | 9.00 | 8.08 | 7.63 | 1.70 | <0.001 | 0.46 | 0.59 |

| TSD, % | 92.2 | 98.2 | 94.1 | 95.0 | 95.6 | 95.9 | 1.20 | <0.001 | 0.42 | 0.55 |

| Corn NEm, Mcal/kg | 2.26 | 2.44 | 2.32 | 2.35 | 2.36 | 2.37 | 0.030 | <0.001 | 0.48 | 0.57 |

| Corn NEg, Mcal/kg | 1.57 | 1.73 | 1.62 | 1.65 | 1.66 | 1.67 | 0.030 | <0.001 | 0.49 | 0.51 |

1Calculated using observed NE values based on equation described by Zinn and Shen (1998).

2Calculated using cattle growth performance data based on the equation proposed by Zinn and Shen (1998).

3Expected NE values were estimated with the equations proposed by NASEM (2016; solution type = empirical level) with addition of monensin as feed additive and using the total digestible nutrient values, which had been calculated with the equation proposed by Weiss et al. (1992), and using the processing adjustment factors (0.95 and 1.04 for ground and steam-flaked flint corn, respectively; NRC, 2001).

4Fecal samples were collected on day 70 from 3 bulls per pen, randomly selected (Charles et al., 2011) and starch concentration was determined according to procedures described by Bach Knudsen (1997). Fecal starch values were used to calculate TSD and the net energy for maintenance (NEm) and gain (NEg) of corn as described by Zinn et al. (2007).

Corn grain processing method did not affect (P ≥ 0.45) rumenitis score, papillae area, papillae height, papillae surface area, or keratinized layer thickness (Table 7), whereas bulls fed SFC-based diets had reduced (P ≤ 0.05) number of papillae and absorptive surface area (ASA).

Table 7.

Effects of flint corn grain processing (PRC) method [coarse ground corn (CGC; 3.2 mm) or steam-flaked corn (SFC; 0.360 kg/L)] and neutral detergent fiber (NDF) levels (% of DM) from sugarcane bagasse (RNDF) on rumenitis score and rumen tissue morphometrics of finishing Nellore bulls

| Corn grain processing method | NDF levels from sugarcane bagasse | P-value | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Item | CGC | SFC | 4 | 7 | 10 | 13 | SEM | PRC | RNDF | PRC × RNDF |

| Rumenitis score1 | 2.00 | 1.78 | 2.36 | 1.90 | 2.05 | 1.24 | 0.510 | 0.51 | 0.38 | 0.23 |

| Tissue morphometrics | ||||||||||

| Macroscopic measurements2 | ||||||||||

| Number of papillae, no. | 45.5 | 40.4 | 41.9 | 43.7 | 39.8 | 46.4 | 3.55 | 0.05 | 0.30 | 0.14 |

| Papillae area, cm2 | 0.694 | 0.679 | 0.725 | 0.646 | 0.795 | 0.681 | 0.061 | 0.73 | 0.59 | 0.58 |

| ASA, cm2/cm2 of rumen wall | 32.0 | 27.7 | 30.0 | 29.0 | 28.8 | 31.6 | 2.70 | 0.03 | 0.71 | 0.19 |

| Microscopic measurements3 | ||||||||||

| Papillae height, mm | 3.61 | 3.75 | 3.67 | 3.53 | 3.97 | 3.56 | 0.349 | 0.69 | 0.81 | 0.87 |

| Papillae width, mm | 0.512 | 0.434 | 0.440 | 0.511 | 0.477 | 0.480 | 0.048 | 0.03 | 0.53 | 0.09 |

| Papillae surface area, mm2 | 1.93 | 1.82 | 1.64 | 1.70 | 1.98 | 1.63 | 0.322 | 0.76 | 0.30 | 0.81 |

| Keratinized layer thickness, µm | 17.7 | 18.8 | 18.6 | 18.9 | 15.5 | 18.8 | 1.43 | 0.45 | 0.73 | 0.39 |

1Bulls from block 1 and 2 were assigned to slaughter on 2 separate dates, 28 d apart (n = 96 bulls after 95 d on feed [DOF]; n = 144 bulls after 123 DOF). Rumens were washed and scored for incidence of lesions and abnormalities (e.g., papillae clumped) using a 10-point scale (0 = no lesions and abnormalities and 10 = severe ulcerative lesions; Bigham and McManus, 1975; Pereira et al., 2016).

2Rumen samples were collected from 2 randomly selected bulls in each pen. Approximately a 1-cm2 fragment of rumen was collected from cranial sac (atrium ruminis) and placed into a phosphate-buffered saline solution as described previously by Pereira et al. (2016). ASA = absorptive surface area.

3Samples were collected from the ventral sac of the rumen (1-cm2 fragment) from 2 randomly selected bulls in each pen as described by Pereira et al. (2016).

Liver abscess incidence was very low in this study. Just 2 bulls presented 1 small abscess each (2-point numeric scale) and for this reason, a statistical analysis was not performed.

Effects of Roughage NDF Level

Dry matter intake increased linearly (P = 0.02) when RNDF levels increased (Table 4) while carcass-adjusted ADG was not affected (P = 0.15), resulting in a tendency (P = 0.06) for a linear decrease in carcass-adjusted feed efficiency. However, such increase in DMI was insufficient (P ≥ 0.19) to affect carcass characteristics variables evaluated, except for dressing percentage, which tended to decrease linearly (P = 0.06) as RNDF levels increased in the finishing diets (Table 4). Increasing RNDF in the finishing diets had no effect (P = 0.26) on time spent eating, whereas as the RNDF levels increased, time spent ruminating (min/d and min/kg of DMI) increased linearly (P < 0.001; Table 5). No differences were noted (P ≥ 0.27) for NE intake, dietary NE concentration, fecal variables, or corn NE as concentration of RNDF increased from 4% to 13% of the fishing diet (Table 6). No effects of RNDF levels were observed (P ≥ 0.30) for rumenitis score or and rumen morphometric variables (Table 7).

DISCUSSION

Effects of Grain Processing

Published research examining methods of processing of yellow dent corn grain is abundant with finishing Bos taurus cattle fed high-concentrate diets (Owens et al., 1997; Zinn et al., 2011; Owens and Basalan, 2013). Less is known, however, about potential impacts of processing of flint corn typically used in feedlot diets for B. indicus cattle (Oliveira and Millen, 2014; Gouvêa et al. 2016; Marques et al. 2016). The lower DMI of bulls fed SFC compared with CGC in this study is consistent with previous reports pertaining to finishing cattle fed high-concentrate diets containing either yellow dent corn (Zinn et al., 2011; Owens and Basalan, 2013) or flint corn (Gouvêa et. al., 2016; Marques et al., 2016). When comparisons were based on only paired trials, Zinn et al. (2011) and Owens and Basalan (2013) reported that cattle fed yellow dent corn processed by steam flaking consumed 3.8% and 4.3% less DM respectively than cattle fed dry rolled corn (DRC). On the other hand, the decrease in DMI appears to be greater when flint corn is steam-flaked. Similar to our findings, Gouvêa et al. (2016) reported 7.9% lower DMI for bulls fed flint SFC compared with GC (1.32 mm mean particle size), while Marques et al. (2016) reported 17% lower DMI for flint corn processed as steam-flaked compared with whole corn. Brazilian flint corn has higher vitreousness and lower starch availability compared with U.S. yellow dent corn when fed as dry processed corn (Correa et al., 2002). Granules of starch in the vitreous endosperm region are densely compacted within a protein matrix, which has negative impact on starch colonization by ruminal bacteria and consequently on starch digestion in flint corn (McAllister and Ribeiro, 2013). Based on the greater relative increase in starch digestion and energy value for dent versus flint corn grain, the response to steam-flaking on DMI appear greater for the flint corn.

Beneficial effects of corn processing on carcass-adjusted ADG and on carcass-adjusted G:F in our study are consistent with observations from previously reported studies with flint corn (Gouvêa et al., 2016; Marques et al., 2016). Gouvêa et al. (2016) reported 12.5% greater ADG and 23.3% greater G:F for cattle fed diet high in flint SFC compared with GC (both diets contained 100% corn and no citrus pulp). Marques et al. (2016) reported no difference in ADG but 20.3% greater G:F for cattle fed diet high in flint corn processed by steam flaking compared with whole corn (both diets contained 6% SCB). Owens and Basalan (2013) summarized comparisons from 17 paired trials with yellow dent corn and reported that SFC increased ADG by 3.9% and G:F by 8.4% compared with DRC.

In contrast to the current experiment, where HCW was not increased by SFC, Owens and Gardner (2000) reported that cattle fed SFC had heavier carcass weights than those fed DRC, high-moisture, or whole grains. It should be expected that compared with grinding, flaking corn would increase the extent of ruminal starch digestion (Theurer, 1986; Drouillard and Reinhardt, 2006), increase the molar proportion of propionate in the rumen (Corona et al., 2006; Gouvêa et al., 2016), and increase intake of NEg (Zinn et al., 2011), thus resulting in a greater carcass production and heavier final BW.

The presented data corroborate findings of other authors where SFC did not alter dressing percentage (LaBrune et al., 2008; Corrigan et al., 2009; Gouvêa et al., 2016; Marques et al., 2016), back fat thickness (Barajas and Zinn, 1998; Corrigan et al., 2009; Gouvêa et al., 2016; Marques et al., 2016), and LM area (Scott et al., 2003; Luebbe et al., 2012; Gouvêa et al., 2016; Marques et al., 2016) when compared with DRC, ground corn, or whole grain. Within breeds and at similar HCW, carcass traits generally are similar.

Steam-flaking of corn disrupts the grain pericarp, breaks down the recalcitrant barriers such as the protein matrix, and increases the surface area available for microbial attachment and colonization, thus leading to greater rate and extent of starch digestion in the rumen (McAllister et al., 2006). Steam flaking also increases starch digestion in the small intestine (Owens and Soderlund, 2007), resulting in reduced FS and increased estimated TSD as observed in this study. The increased starch utilization contributed to increasing energy content of the grain and consequently of the diet, but the incremental improvement in total tract digestibility of starch (98.2% vs. 92.2%) in this study was less than that reported by Owens and Soderlund (2007) for dent corn and it does not explain the difference in growth performance between SFC- and CGC-fed cattle. Based on FS concentration, the estimated grain NEm and NEg were only 8.0% and 10.2% greater for SFC when compared with CGC; however, based on cattle growth performance data (mean BW, ADG, and DMI), observed diet NEm and NEg values increased by 14.9% and 19.4% when bulls were fed SFC compared with those fed CGC-based diets, respectively. Assuming the improvements are attributable solely to processing of corn that constitutes 81.4% of the diet (DM basis; average value for the roughage levels), steam flaking increased the NEm and NEg of corn grain by 18.3% and 23.8%, respectively. These increments with flint corn are greater than the ones reported with dent corn where steam flaking increased NEm by 15% and NEg by 18% compared with cracked or DRC (Zinn et al., 2002), and are explained primarily because flint corn contains higher proportion of vitreous endosperm and lower starch availability compared with dent corn (Correa et al., 2002). In agreement with current data, Gouvêa et al. (2016) and Marques et al. (2016) also reported that the beneficial effect of steam flaking on grain energy content was greater for flint than for dent corn.

Underestimation of the improvement in grain energy content with steam flaking based on FS concentration compared with the increment based on growth performance data may have occurred because the increase in starch digestion is the major but not the only cause for the increase in grain energy value when it is steam-flaked. Owens and Basalan (2013) pointed out the potential importance of increased ruminal propionate production, decreased methane production, increases in digestibility of other feed components, and the site and efficiency of starch digestion as contributing factors. Assuming the starch digestibility values proposed by Owens and Soderlund (2007) for CGC of 63.80%, 58.83%, and 56.32% and for SFC of 84.05%, 92.48%, and 20.47% within the rumen, small intestine, and large intestine, respectively, and the observed total daily starch intake of 5.34 and 4.96 kg for CGC and SFC, respectively, the amounts of starch digested in the rumen, small intestine, and large intestine would be respectively 3.41, 1.13, and 0.45 kg for CGC and 4.17, 0.73, and 0.01 kg for SFC. Based on these calculations, cattle fed SFC would have the advantage of digesting more starch in the total tract with essentially no starch digestion in the large intestine. Energy losses are greater when starch is digested in the large intestine compared with the rumen and small intestine (McLeod et al., 2007).

The general concept is that cattle on high-grain diets (2.7 to 3.3 Mcal of ME/kg of DM) eat to maintain energy intake (Krehbiel et al., 2006), and according to this review, the upper caloric limit for maximizing energy intake and ADG was 3.16, while for maximizing G:F the value was 3.45 Mcal ME/kg of DM (assuming feed ingredients energy values from the NRC, 1996). In this study, diets containing CGC and SFC averaged 2.88 and 3.01 Mcal ME/kg of DM, respectively (expected energy content based on chemical composition of ingredients) and 2.81 and 3.15 Mcal ME/kg of DM (observed energy based on growth performance data). Thus, cattle fed flint SFC were able to consume 11.6% more NEg despite their lower DMI, and gained more weight with greater G:F than cattle fed CGC.

Based on the observed NEg:expected NEg ratios of 0.96 for CGC and 1.07 for SFC diets, and recognizing that corn comprised 76.0% to 86.7% of diet DM, we can speculate that energy values for flint corn grain calculated from chemical composition of ingredients and using Weiss et al. (1992) equations for TDN, were overestimated for CGC and underestimated for SFC. The same was observed by Gouvêa et al. (2016) and by Marques et al. (2016) with flint corn.

As expected, eating time decreased for cattle fed SFC, because of lower DMI. Increasing the energy content of corn by steam flaking typically decreases intake (Zinn et al. 2011) because dietary energy is the primary regulator of DMI for concentrate-based diets (Krehbiel et al., 2006). In addition, the tendency for increasing ruminating time in SFC-based diets may be associated to the larger geometric size of the SFC compared with CGC, which can increase retention time in the rumen, thus leading to increased rumination time (Savari et al., 2018). The lower DMI, lower content of NDF in the diet and the tendency for greater ruminating time (min/d) for cattle fed SFC compared with cattle fed CGC explains the greater time spent ruminating expressed as kg of ingested DM and NDF of cattle fed SFC. One may speculate that the greater time spent ruminating by cattle fed SFC diets, besides stimulated by the greater particle size of SFC, also could be a protective mechanism against rumen acidosis when highly fermentable starch sources are fed.

According to Perdigão et al. (2016), the adequate development and growth of papillae are closely associated with feeding habits of cattle, such as dietary adaptation protocol, availability and digestibility of feed, and proportion of concentrate in the diet. High-concentrate rations increased the ASA of the rumen by increasing the length and width of rumen papillae compared to animals fed forage-based diets (Zitnan et al., 2003). Melo et al. (2013) reported that ASA of rumen wall was the morphometric variable most correlated to the speed of VFA absorption. According to Costa et al. (2008), propionate is the VFA responsible for promoting the physiological growth of metabolically active papillae. In this study, cattle fed SFC had greater NE intake and theoretically greater rumen degradable starch intake (4.17 vs. 3.40 kg/d; assuming 63.80% vs. 84.05% ruminal starch degradation for CGC and SFC, respectively; Owens and Soderlund, 2007). Bulls fed SFC-based diets had reduced number of papillae, resulting in smaller ASA and papillae width compared with bulls fed CGC-based diets, however. Wang et al. (2009) reported that excessive starch degradation in the rumen resulted in lower ruminal pH, which impaired development of rumen papillae. No differences between SFC and CGC were observed with respect to rumenitis scores in this study, and cattle fed SFC spent more time ruminating and had superior growth performance compared with their counterparts fed CGC. Kern et al. (2016) reported that morphological characteristics of rumen papillae did not affect feed intake or BW gain in finishing cattle.

No effect of RNDF levels was observed in papillae width for bulls fed SFC-based diets, but a tendency for linear effects of RNDF levels was observed in bulls fed CGC-based diets. Greater rumen papillae width was observed when animals were fed diets containing higher physical effective fiber (Wang et al. 2017), but the reasons why RNDF level just increased papillae width in CGC-based diets in this study are unclear.

Effects of Roughage NDF Level

In finishing beef diets, forage is usually included in small amounts to promote better mixing of the diet, to stimulate saliva production and rumination (Armbruster, 2007), and to maintain digestive function and maximize energy intake (Galyean and Hubbert, 2014). In addition, several review articles (Galyean and Defoor, 2003; Pritchard, 2006; Arelovich et al., 2008; Galyean and Hubbert, 2014) have demonstrated that including a small amount of roughage in high-concentrate feedlot diets containing low levels of NDF (<15%), increased intakes of DM and NEg. These increases in DMI could be attributed, at least partially, to an attempt by the animal to maintain a constant energy intake (Krehbiel et al., 2006). In this study, the linear increase in DMI when diet RNDF levels increased is in agreement with the 11 experiments summarized by Galyean and Defoor (2003) with a variety of roughage sources such as corn silage, alfalfa hay, sorghum silage, sudan grass silage, cottonseed hulls, and wheat straw, fed at 0% to 30% of diet DM to supply 0% to 26.5% roughage NDF in the diet. Farran et al. (2006) and Parsons et al. (2007) also reported a linear increase on DMI of cattle fed diets containing wet corn gluten feed and roughage levels varying from 0% to 9.0% (DM basis). On the other hand, Hales et al. (2013), Caetano et al. (2015), Marques et al. (2016), and Santos et al. (2017) fed different roughage sources as alfalfa hay, SCS, SCB, and low-quality grass hay, respectively, and reported a quadratic response in DMI as RNDF level increased in the feedlot diet. The last three authors also used B. indicus cattle, as in this study.

The absence of interaction between grain processing method and RNDF level in this study is in contrast with most of the literature reviewed (Gill et al., 1981; Stock et al., 1990; Milton et al., 1994; Gorocica-Buenfil and Loerch, 2005; Owens, 2005; Loerch and Gorocica-Buenfil, 2006; Pritchard, 2006; Caetano et al., 2015). Gill et al. (1981) reported that 8%, 12%, and 16% roughage (1/3 alfalfa hay + 2/3 corn silage) in the diet DM was required to optimize ADG of cattle fed SFC, SFC:high-moisture corn (HMC) mixture and HMC diets respectively. Caetano et al. (2015) reported that the level of NDF from SCS to maximize DMI in finishing cattle differed between animals fed diets containing either ground corn or HMC (11.3% vs. 13.7% NDF from roughage, respectively; DM basis). These outcomes could be attributed to the higher ruminal degradation rate of starch from HMC compared with starch from dry processed or SFC (Owens and Soderlund, 2007). In this study, greater ruminating time of cattle fed SFC diets may have counterbalanced its greater starch degradability in the rumen and its greater potential for causing acidosis compared with CGC.

Despite the linear increase in DMI as RNDF levels from SCB increased, observed diet NE content, NE intake and consequently cattle carcass-adjusted ADG were not altered. It is possible that more than 7% RNDF levels from SCB have caused some filling effect limiting a significant increase in DMI (Allen, 1997). Based on data from 8 reviewed experiments, inclusion of roughage in the diet caused a linear increase in intakes of DM and NEg in 4 experiments (Defoor et al., 2002; Farran et al., 2006; Parsons et al., 2007) and a quadratic increase in the other 4 experiments (Hales et al., 2013; Caetano et al., 2015; Marques et al., 2016; Santos et al., 2017). Therefore, we can speculate that the type of response, linear or quadratic, may be affected by several factors such as the NDF content of the roughage source, the effectiveness of the fiber source, the level of roughage inclusion in the diet and also, by the level and degradability of starch in the diet. Since carcass-adjusted ADG was not different, we did not expect to observe effects of RNDF level on HCW, back fat thickness, or LM area, but carcass dressing percent tended to decrease linearly as RNDF level was increased in the diets. Santos et al. (2017) reported a linear decrease in carcass dressing percent in B. indicus cattle as grass hay NDF was increased in the diet from 4% to 13% probably due to the filling effect of greater roughage inclusion in the diet.

The tendency for the linear decrease in carcass-adjusted G:F as RNDF level from SCB was included in the diet was caused by the linear increase in DMI, with no alteration in carcass-adjusted ADG. The effects of RNDF levels on cattle G:F are not consistent in the literature and may be dictated by level and source of roughage and grain source and processing methods. Stock et al. (1990) reported that adding roughage (0%, 4%, 8%, and 12% of diet DM) to HMC or dry rolled grain sorghum diets decreased G:F in one trial, but in a second trial, in comparison with no roughage diets (0%) adding 10% of roughage decreased G:F of cattle fed DRC diets but had no effect on G:F of cattle fed dry rolled wheat. In most recent studies with corn grain, the inclusion of roughage decreased G:F in 9 studies (Calderon-Cortes and Zinn, 1996; Farran et al., 2006; Turgeon et al., 2010; Carareto, 2011; May et al., 2011; Hales et al., 2013; Shreck et al., 2015; Santos et al., 2017) and had no effect on G:F in other 7 studies (Leme et al., 2003; Parsons et al., 2007; Sindt et al., 2002; Depenbusch et al., 2009; Benton et al., 2015; Caetano et al., 2015; Marques et al., 2016).

Diet NEg estimated from chemical composition of ingredients was expected to decrease (1.35, 1.31, 1.27, and 1.24 Mcal/kg DM) as RNDF level increased in the diets. When calculated from growth performance data, however, NEg was not decreased by addition of RNDF to the diets. The same response was observed by Marques et al. (2016) who hypothesized that the inclusion of roughage in the diet should increase chewing or rumination time and saliva flow and consequently, ruminal pH, passage rate and rumen fermentation, counterbalancing the lower energy value of roughage compared to corn grain. In this study, time spent ruminating increased linearly as RNDF level increased in the diet, however, greater ruminating time did not increase starch digestion form either CGC or SFC.

Changes in ruminal papillae surface could be related to differences in dietary NDF supplied by roughage (Allen, 1997), but according to Galyean and Defoor (2003), it is still unknown whether roughage source or level in feedlot finishing diets affect ruminal surface area for absorption. In this study, RNDF levels did not impact neither rumenitis score nor rumen morphometrics. Nevertheless, research is still warranted to fully elucidate the impacts of RNDF levels and corn processing on rumen morphometrics.

In summary, steam flaking markedly increased flint corn energy value, NE of diets, animal growth performance, and feed efficiency compared with coarse grinding, independently of the dietary roughage level. Benefits of steam flaking on energy value for flint corn were considerably greater than what has been previously reported in the literature for yellow dent corn. Varying the level of NDF from SCB from 4% to 13% increased DMI, had no effect on observed NE content of the diet, NE intake, rumen morphometrics and cattle carcass-adjusted ADG, but decreased carcass-adjusted feed efficiency and carcass dressing. Varying estimated NE content of the diets through steam flaking flint corn is a powerful and more effective strategy to increase NE intake and growth performance of B. indicus cattle than varying the level of NDF from SCB in the diet.

Footnotes

This study and the scholarship of the first author were supported by São Paulo Research Foundation (FAPESP, Brazil, process number 2011/22332-0 and 2011/22623-4, respectively).

LITERATURE CITED

- Allen M. S. 1997. Relationship between fermentation acid production in the rumen and the requirement for physically effective fiber. J. Dairy Sci. 80:1447–1462. doi: 10.3168/jds.S0022-0302(97)76074-0 [DOI] [PubMed] [Google Scholar]

- AOAC 1986. Official methods of analysis. 14th ed. Assoc. Off. Anal. Chem, Arlington, VA. [Google Scholar]

- AOAC 2000. Official methods of analysis. 17th ed. Assoc. Off. Anal. Chem; Gaithersburg, MD. [Google Scholar]

- Arelovich H. M., Abney C. S., Vizcarra J. A., and Galyean M. L.. 2008. Effects of dietary neutral detergent fiber on intakes of dry matter and net energy by dairy and beef cattle: Analysis of published data. Prof. Anim. Scientist 24:5375–383. doi: 10.15232/S1080-7446(15)30882-2 [DOI] [Google Scholar]

- Armbruster S. 2007. Steam flaking grains for feedlot cattle: A consultants’s perspective. Proc. Cattle Grain Process. Symp., Tulsa, OK: http//beefextension.com/proceedings/cattle_ grains06/06-17.pdf (Accessed 13 March 2014). 46–55. [Google Scholar]

- Bach Knudsen K. E. 1997. Carbohydrate and lignin contents of plant materials used in animal feeding. Anim. Feed Sci. Technol. 67:319–338. doi: 10.1016/S0377-8401(97)00009-6 [DOI] [Google Scholar]

- Barajas R., and Zinn R. A.. 1998. The feeding value of dry-rolled and steam-flaked corn in finishing diets for feedlot cattle: influence of protein supplementation. J. Anim. Sci. 76:1744–1752. doi: 10.2527/1998.7671744x [DOI] [PubMed] [Google Scholar]

- Beauchemin K. A., and Buchanan-Smith J. G.. 1989. Effects of dietary neutral detergent fiber concentration and supplementary long hay on chewing activities and milk production of dairy cows. J. Dairy Sci. 72:2288–2300. doi: 10.3168/JDS.S0022-0302(89)79360-7 [DOI] [PubMed] [Google Scholar]

- Benedeti P. D. B., Silva B. C., Pacheco M. V. C., Serão N. V. L., Carvalho Filho I., Lopes M. M., Marcondes M. I., Mantovani H. C., Valadares Filho S. C., Detmann E., and Duarte M. S.. 2018. Effects of grain processing methods on the expression of genes involved in volatile fatty acid transport and pH regulation, and keratinization in rumen epithelium of beef cattle. PLoS One. 13:1–14. doi: 10.1371/journal.pone.0198963 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Benton J. R., Watson A. K., Erickson G. E., Klopfenstein T. J., Pol K. J., Meyer N. F., and Greenquist M. A.. 2015. Effects of roughage source and inclusion in beef finishing diets containing corn wet distillers’ grains plus solubles. J. Anim. Sci. 93:4358–4367. doi: 10.2527/jas.2015-9211 [DOI] [PubMed] [Google Scholar]

- Bigham M. L., and McManus W. R.. 1975. Whole wheat grain feeding of lambs. V. Effects of roughage and wheat grain mixtures. Aust. J. Agric. Res. 26:1053–1062. doi: 10.1071/ar9751053 [DOI] [Google Scholar]

- Brown H., Bing R. F., Grueter H. P., McAskill J. W., Cooley C. O., and Rathmacher R. P.. 1975. Tylosin and chloretetracycline for the prevention of liver abscesses, improved weight gains and feed efficiency in feedlot cattle. J. Anim. Sci. 40:207–213. doi: 10.2527/jas1975.402207x [DOI] [PubMed] [Google Scholar]

- Brown M. S., Ponce C. H., and Pulikanti R.. 2006. Adaptation of beef cattle to high-concentrate diets: performance and ruminal metabolism. J. Anim. Sci. 84(Suppl.):E25–E33. doi: 10.2527/2006.8413_supple25x [DOI] [PubMed] [Google Scholar]

- Caetano M., Goulart R. S., Silva S. L., Drouillard J. S., Leme P. R., and Lanna D. P.. 2015. Effect of flint corn processing method and roughage level on finishing performance of Nellore-based cattle. J. Anim. Sci. 93:4023–4033. doi: 10.2527/jas.2015-9051 [DOI] [PubMed] [Google Scholar]

- Calderon-Cortes J. F., and Zinn R. A.. 1996. Influence of dietary forage level and forage coarseness of grind on growth performance and digestive function in feedlot steers. J. Anim. Sci. 74:2310–2316. doi: 10.2527/1996.74102310x [DOI] [PubMed] [Google Scholar]

- Carareto R., Santos F. A. P., Mourao G. B., Pedroso A. M., Sitta C., Soares M. P., Paula M. R., Marques R. S., and Soares M. C.. 2011. Corn grain processing methods and forage levels on diets for finishing Nellore bulls. J. Anim. Sci. 89(Suppl. 1):115 (Abstr.). [Google Scholar]

- Corona L., Owens F. N., and Zinn R. A.. 2006. Impact of corn vitreousness and processing on site and extent of digestion by feedlot cattle. J. Anim. Sci. 84:3020–3031. doi: 10.2527/jas.2005-603 [DOI] [PubMed] [Google Scholar]

- Correa C. E. S., Shaver R. D., Pereira M. N., Lauer J. G., and Kohn K.. 2002. Relationship between corn vitreousness and ruminal in situ starch degradability. J. Dairy Sci. 85:3008–3012. doi: 10.3168/jds.S0022-0302(02)74386-5 [DOI] [PubMed] [Google Scholar]

- Corrigan M. E., Erickson G. E., Klopfenstein T. J., Luebbe M. K., Vander Pol K. J., Meyer N. F., Buckner C. D., Vanness S. J., and Hanford K. J.. 2009. Effect of corn processing method and corn wet distillers grains plus solubles inclusion level in finishing steers. J. Anim. Sci. 87:3351–3362. doi: 10.2527/jas.2009-1836 [DOI] [PubMed] [Google Scholar]

- Costa S. F., Pereira M. N., Melo L. Q., Resende Júnior J. C., and Chaves M. L.. 2008. Lactate, propionate and, butyrate induced morphological alterations on calf ruminal mucosa and epidermis – I Histologycals aspects. Arq. Bras. Med. Vet. Zootec. 60:1–9.5. doi: 10.1590/S0102-09352008000100001 [DOI] [Google Scholar]

- Costa e Silva L. F., Valadres Filho S. C., Detman E., Rotta P. P., Zanetti D., Villadiego F. A. C., Pellizzoni S. G. and Pereira R. M. G.. 2012. Performance, growth, and maturity of Nellore bulls. Trop. Anim. Health. Prod. 45:795–803. doi: 10.1007/s11250-012-0291-1 [DOI] [PubMed] [Google Scholar]

- Defoor P. J., Galyean M. L., Salyer G. B., Nunnery G. A., and Parsons C. H.. 2002. Effects of roughage source and concentration on intake and performance by finishing heifers. J. Anim. Sci. 80:1395–1404. doi: 10.2527/2002.8061395x [DOI] [PubMed] [Google Scholar]

- Depenbusch B. E., Loe E. R., Sindt J. J., Cole N. A., Higgins J. J., and Drouillard J. S.. 2009. Optimizing use of distiller’s grains in finishing diets containing steam-flaked corn. J. Anim. Sci. 86:2644–2652. doi: 10.2527/jas.2008-1358 [DOI] [PubMed] [Google Scholar]

- Drouillard J. S., and Reinhardt C.. 2006. Flaked grain variables: Control points and evaluation of flaked grains. In Cattle Grain Processing Symposium, Oklahoma State University, Stillwater, OK: http://beefextension.com/files/Proceedings%20final.pdf (Accessed 19 February 2019). [Google Scholar]

- Farran T. B., Erickson G. E., Klopfenstein T. J., Macken C. N., and Lindquist R. U.. 2006. Wet corn gluten feed and alfalfa hay levels in dry-rolled corn finishing diets: effects on finishing performance and feedlot nitrogen mass balance. J. Anim. Sci. 84:1205–1214. doi: 10.2527/2006.8451205x [DOI] [PubMed] [Google Scholar]

- Galyean M. L., and Defoor P. J.. 2003. Effects of roughage source and level on intake by feedlot cattle. J. Anim Sci. 81:E8–16. doi: 10.2527/2003.8114_suppl_2E8x [DOI] [Google Scholar]

- Galyean M. L., and Hubbert M. E.. 2014. Traditional and alternative sources of fiber – Roughage values, effectiveness, and levels in starting and finishing diets. Prof. Anim. Sci. 30:571–584. doi: 10.15232/pas.2014-01329 [DOI] [Google Scholar]

- Gill D., Owens F., Martin J., Williams D., Zinn R., and Hillier R.. 1981. Roughage levels in feedlot rations. Anim. Sci. Res. Rep. 141–146. https://pdfs.semanticscholar.org/fcab/fc14ec213f66d5400c3c726db8d744faad54.pdf (Accessed 19 February 2019). [Google Scholar]

- Goering H. K., and Van Soest P. J.. 1970. Forage fiber analyses (apparatus, reagents, procedures, and some applications). Agric. Handbook, 379. ARS-USDA, Washington, DC. [Google Scholar]

- Gorocica-Buenfil M. A., and Loerch S. C.. 2005. Effect of cattle age, forage level, and corn processing on diet digestibility and feedlot performance. J. Anim. Sci. 83:705–714. doi: 10.2527/2005.833705x [DOI] [PubMed] [Google Scholar]

- Gouvêa V. N., Batistel F., Souza J., Chagas L. J., Sitta C., Campanili P. R., Galvani D. B., Pires A. V., Owens F. N., and Santos F. A.. 2016. Flint corn grain processing and citrus pulp level in finishing diets for feedlot cattle. J. Anim. Sci. 94:665–677. doi: 10.2527/jas.2015-9459 [DOI] [PubMed] [Google Scholar]

- Hales K. E., Freetly H. C., Shackelford S. D., and King D. A.. 2013. Effects of roughage concentration in dry-rolled corn-based diets containing wet distillers grains with solubles on performance and carcass characteristics of finishing beef steers. J. Anim. Sci. 91:3315–3321. doi: 10.2527/jas.2012-5942 [DOI] [PubMed] [Google Scholar]

- Heinrichs A. J., Buckmaster D. R., and Lammers B. P.. 1999. Processing, mixing, and particle size reduction of forages for dairy cattle. J. Anim. Sci. 77:180–186. doi: 10.2527/1999.771180x [DOI] [PubMed] [Google Scholar]

- Kern R. J., Lindholm-Perry A. K., Freetly H. C., Kuehn L. A., Rule D. C., and Ludden P. A.. 2016. Rumen papillae morphology of beef steers relative to gain and feed intake and the association of volatile fatty acids with kallikrein gene expression. Livest. Sci. 187:24–30. doi: 10.1016/j.livsci.2016.02.007 [DOI] [Google Scholar]

- Kononoff P. J., Heinrichs A. J., and Lehman H. A.. 2003. The effect of corn silage particle size on eating behavior, chewing activities, and rumen fermentation in lactating dairy cows. J. Dairy Sci. 86:3343–3353. doi: 10.3168/jds.S0022-0302(03)73937-X [DOI] [PubMed] [Google Scholar]

- Krehbiel C. R., Cranston J. J., and McCurdy M. P.. 2006. An upper limit for caloric density of finishing diets. J. Anim. Sci. 84(Suppl.):E34–E49. doi: 10.2527/2006.8413_supple34x [DOI] [PubMed] [Google Scholar]

- LaBrune H. J., Reinhardt C. D., Dikeman M. E., and Drouillard J. S.. 2008. Effects of grain processing and dietary lipid source on performance, carcass characteristics, plasma fatty acids, and sensory properties of steaks from finishing cattle. J. Anim. Sci. 86:167–172. doi: 10.2527/jas.2007-0011 [DOI] [PubMed] [Google Scholar]

- Leme P. R., Silva S. L., Pereira A. S. C., Putrino S. M., Lanna D. P. D., Nogueira Filho J. C. M.. 2003. Levels of sugarcane bagasse in diets with high concentrate for Nellore steers in feedlot. Braz. J. Anim. Sci., 32:1786–1791. [Google Scholar]

- Loerch S. C., and Gorocica-Buenfil M.. 2006. Advantages and disadvantages of feeding whole shelled corn. In Cattle Grain Processing Symposium, Oklahoma State University, Stillwater, OK: http://beefextension.com/files/Proceedings%20final.pdf (Accessed 19 November 2015). [Google Scholar]

- Luebbe M. K., Patterson J. M., Jenkins K. H., Buttrey E. K., Davis T. C., Clark B. E., McCollum F. T. 3rd, Cole N. A., and MacDonald J. C.. 2012. Wet distillers grains plus solubles concentration in steam-flaked-corn-based diets: Effects on feedlot cattle performance, carcass characteristics, nutrient digestibility, and ruminal fermentation characteristics. J. Anim. Sci. 90:1589–1602. doi: 10.2527/jas.2011-4567 [DOI] [PubMed] [Google Scholar]

- Marques R. S., Chagas L. J., Owens F. N., and Santos F. A. P.. 2016. Effects of various roughage levels with whole flint corn grain on performance of finishing cattle. J. Anim. Sci. 94:339–348. doi: 10.2527/jas.2015-9758 [DOI] [PubMed] [Google Scholar]

- May M. L., Quinn M. J., DiLorenzo N., Smith D. R., and Galyean M. L.. 2011. Effects of roughage concentration in steamflaked corn-based diets containing wet distillers grains with solubles on feedlot cattle performance, carcass characteristics, and in vitro fermentation. J. Anim. Sci. 89:549–559. doi: 10.2527/jas.2010-3049 [DOI] [PubMed] [Google Scholar]

- Mcallister T. A., Gibb D. J., Beauchemin K. A., and Wang Y.. 2006. Starch type, structure and ruminal digestion. Proc. Cattle Grain Process. Symp Tulsa, Oklahoma: http// beefextension.com/proceedings/cattle_grains06/06-5.pdf (Accessed 13 March 2014). 30–41. [Google Scholar]

- Mcallister T. A., and Ribeiro G.. 2013. Microbial strategies in the ruminal digestion of starch. Proc. 50th Annu. Meet. Braz. Soc. Anim. Sci., Campinas, Brazil: 140–151. [Google Scholar]

- McLeod K. R., Baldwin VI R. L., Solomon M. B., and Baumann R. G.. 2007. Influence of ruminal and postruminal carbohydrate infusion on visceral organ mass and adipose tissue accretion in growing beef steers. J. Anim. Sci. 85:2256–2270. [DOI] [PubMed] [Google Scholar]

- Melo L. Q., Costa S. F., Lopes F., Guerreiro M. C., Armentano L. E., and Pereira M. N.. 2013. Rumen morphometrics and the effect of digesta pH and volume on volatile fatty acid absorption. J. Anim. Sci. 91:1775–1783. doi: 10.2527/jas.2011-4999 [DOI] [PubMed] [Google Scholar]

- Milton C. T., Brandt R. T. Jr., and Shuey S. A.. 1994. Roughage levels and comparison of mixed rations vs. self-feeders in whole shelled corn finishing programs. In: Kansas Agricultural Experiment Station Research Reports. Cattlemen’s Association, Kansas State University, Manhattan, KS: p. 21–23. [Google Scholar]

- Nagaraja T. G., and Titgemeyer E. C.. 2007. Ruminal acidosis in beef cattle: the current microbiological and nutritional outlook. J. Dairy Sci. 90(Suppl. 1):E17–E38. doi: 10.3168/jds.2006-478 [DOI] [PubMed] [Google Scholar]

- National Academies of Sciences, Engineering, and Medicine (NASEM) 2016. Nutrient requirements of beef cattle. 8th rev. ed. The National Academies Press, Washington, DC. doi: 10.17226/19014 [DOI] [Google Scholar]

- NRC 2001. Nutrient requirements of dairy cattle. 7th rev. ed. National Academies Press, Washington, DC. [PubMed] [Google Scholar]

- Oliveira C. A., and Millen D. D.. 2014. Survey of the nutritional recommendations and management practices adopted by feedlot cattle nutritionists in Brazil. Anim. Feed Sci. Technol. 197:64–75. doi: 10.1016/j.anifeedsci.2014.08.010 [DOI] [Google Scholar]

- Owens F. N., and Basalan M.. 2013. Grain processing: Gain and efficiency responses b feedlot cattle. Proc. Plains Nutr. Counc., Amarillo, TX: http//amarillo.tamu.edu/files/2010/10/2013-proceedings.pdf (Accessed 10 November 2014). 76–100. [Google Scholar]

- Owens F. N., and Gardner B. A.. 2000. A review of the impact of feedlot management and nutrition on carcass measurements of feedlot cattle. J. Anim. Sci. 77:1–18. doi: 10.2527/jas2000.00218812007700ES0034x [DOI] [Google Scholar]

- Owens F. N., Secrist D. S., Hill W. J., and Gill D. R.. 1997. The effect of grain source and grain processing on performance of feedlot cattle: a review. J. Anim. Sci. 75:868–879. doi: 10.2527/1997.753868x [DOI] [PubMed] [Google Scholar]

- Owens F. N., Secrist D. S., Hill W. J., and Gill D. R.. 1998. Acidosis in cattle: a review. J. Anim. Sci. 76:275–286. doi: 10.2527/1998.761275x [DOI] [PubMed] [Google Scholar]

- Owens F. N., and Soderlund S.. 2007. Ruminal and post ruminal starch digestion by cattle. In: Proc. Cattle Grain Process. Symp., Tulsa, OK; p. 116–128. http://beefextension.com/proceedings/cattle_grains06/06-17.pdf. (Accessed 13 March 2014.) [Google Scholar]

- Parsons C. H., Vasconcelos J. T., Swingle R. S., Defoor P. J., Nunnery G. A., Salyer G. B., and Galyean M. L.. 2007. Effects of wet corn gluten feed and roughage levels on performance, carcass characteristics, and feeding behavior of feedlot cattle. J. Anim. Sci. 85:3079–3089. doi: 10.2527/jas.2007-0149 [DOI] [PubMed] [Google Scholar]

- Perdigão A., Millen D. D., Brichi A. L. C., Vicari D. V. F., Franzói M. C. S., Barducci R. S., Martins C. L., Estevam D. D., Cesar M. T., and Arrigoni M. D. B.. 2016. Effects of restricted vs. step up dietary adaptation for 6 or 9 days on feedlot performance, feeding behaviour, ruminal and blood variables of Nellore cattle. J. Anim. Physiol. Anim. Nutr. (Berl). 102:224–234. doi: 10.1111/jpn.12681 [DOI] [PubMed] [Google Scholar]

- Pereira M. C., Cruz G. D., Arrigoni M. D., Rigueiro A. L., Silva J., Carrara T. V., Santos P. C., Cursino L. L., and Millen D. D.. 2016. Relationships of feedlot performance, feeding behavior, rumen morphometrics, and carcass characteristics of Nellore cattle differing in phenotypic residual feed intake. J. Anim. Sci. 94:4287–4296. doi: 10.2527/jas.2016-0579 [DOI] [PubMed] [Google Scholar]

- Pritchard R. H. 2006. Processing effects on management: Type, form, and level of roughage. In Cattle Grain Processing Symposium, Oklahoma State University, Stillwater, OK: http://beefextension.com/files/Proceedings%20final.pdf (Accessed 19 February 2019). [Google Scholar]

- Resende-Junior J. C. de, Alonso L. da S., Pereira M. N., Magallanes M. G. R., Duboc M. V., de Oliveira E. C., and de Melo L. Q.. 2006. Efeito do padrão alimentar sobre a morfologia da parede ruminal de vacas e carneiros. Brazilian J. Vet. Res. Anim. Sci. 43:526–536. doi: 10.11606/issn.1678-4456.bjvras.2006.26469 [DOI] [Google Scholar]

- Robles V., González L. A., Ferret A., Manteca X., and Calsamiglia S.. 2007. Effects of feeding frequency on intake, ruminal fermentation, and feeding behavior in heifers fed high-concentrate diets. J. Anim. Sci. 85:2538–2547. doi: 10.2527/jas.2006-739 [DOI] [PubMed] [Google Scholar]

- Santos F. A. P., Fernandes J. J. R., Drouillard J. S., Oliveira L. G., and Leite L. S.. 2017. Varying levels of low quality grass hay NDF in finishing diets for Nellore cattle. J. Anim. Sci. 95:299 (Abstr). [Google Scholar]

- Savari M., Khorvash M., Amanlou H., Ghorbani G. R., Ghasemi E., and Mirzaei M.. 2018. Effects of rumen-degradable protein:rumen-undegradable protein ratio and corn processing on production performance, nitrogen efficiency, and feeding behavior of Holstein dairy cows. J. Dairy Sci. 101:1111–1122. doi: 10.3168/jds.2017-12776 [DOI] [PubMed] [Google Scholar]

- Scott T. L., Milton C. T., Erickson G. E., Klopfenstein T. J., and Stock R. A.. 2003. Corn processing method in finishing diets containing wet corn gluten feed. J. Anim. Sci. 81:3182–3190. doi: 10.2527/2003.81123182x [DOI] [PubMed] [Google Scholar]

- Shreck A. L., Nuttelman B. L., Harding J. L., Griffin W. A., Erickson G. E., Klopfenstein T. J., and Cecava M. J.. 2015. Digestibility and performance of steers fed low quality crop residues treated with calcium oxide to partially replace corn in distillers grains finishing diets. J. Anim. Sci. 93:661–671. doi: 10.2527/jas2013-7194 [DOI] [PubMed] [Google Scholar]

- Sindt J. J., Drouillard J. S., Thippareddi H., Phebus R. K., Lambert D. L., Montgomery S. P., Farran T. B., LaBrune H. J., Higgins J. J., and Ethington R. T.. 2002. Evaluation of finishing performance, carcass characteristics, acid-resistant E. coli and total coliforms from steers fed combinations of wet corn gluten feed and steam-flaked corn. J. Anim. Sci. 80:3328–3335. doi: 10.2527/2002.80123328x [DOI] [PubMed] [Google Scholar]

- Stock R. A., Sindt M. H., Parrott J. C., and Goedeken F. K.. 1990. Effects of grain type, roughage level and monensin level on finishing cattle performance. J. Anim. Sci. 68:3441–3455. doi: 10.2527/1990.68103441x [DOI] [PubMed] [Google Scholar]

- Theurer C. B. 1986. Grain processing effects on starch utilization by ruminants. J. Anim. Sci. 63:1649–1662. doi: 10.2527/jas1986.6351649x [DOI] [PubMed] [Google Scholar]

- Turgeon O. A., Szasz J. I., Koers W. C., Davis M. S., and Vander Pol K. J.. 2010. Manipulating grain processing method and roughage level to improve feed efficiency in feedlot cattle. J. Anim. Sci. 88:284–295. doi: 10.2527/jas.2009-1859 [DOI] [PubMed] [Google Scholar]

- Utley P. R., and McCormick W. C.. 1980. Evaluation of protein sources in whole shelled corn-based steer finishing diets. J. Anim. Sci. 50:323–328. doi: 10.2527/jas1980.502323x [DOI] [Google Scholar]

- Van Soest P. J., Robertson J. B., and Lewis B. A.. 1991. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 74:3583–3597. doi: 10.3168/jds.S0022-0302(91)78551-2 [DOI] [PubMed] [Google Scholar]

- Wang B., Wang D., Wu X., Cali J., Liu M., Huang X., Wu J., Liu J. and Guan L.. 2017. Effects of dietary physical or nutritional factors on morphology of rumen papillae and transcriptome changes in lactating dairy cows based on three different forage-based diets. BMC Genomics, 18:353. doi: 10.1186/s12864-017-3726-2 [DOI] [PMC free article] [PubMed] [Google Scholar]