Abstract

The present study aimed to reformulate chicken nuggets with reduced sodium content, replacing the NaCl with CaCl2 and assessing the physicochemical and sensory properties of the obtained products. Four treatments of chicken nuggets were processed: Control formulation (1.5 g NaCl/100 g) and three treatments containing CaCl2 substituting 25, 50 and 75% of the NaCl, considering an ionic strength equivalent to 1.5% NaCl. The four different chicken nuggets were similar (p > 0.05) for the variables oil absorption, lipid, protein and moisture contents, water activity, cooking yield, pick-up and texture profile analysis. However, a decrease in ash content (2.21–1.75 g/100 g) was observed. The replacement of 75% NaCl could reduce 34% sodium in chicken nuggets with a concomitant increase in the calcium content (10–130 mg/100 g). For objective colour, the brightness (L*) increased from 74.43 to 78.28 as CaCl2 contents increased in the chicken nuggets, but the a* and b*parameters did not show differences (p > 0.05) among all treatments. Sensory acceptance (texture, flavour and overall quality attributes) did not differ between Control and the 75% sodium reduction treatments (all values around 7.5 in the 9-point hedonic scale), despite the decrease in the salty taste observed in the just about right scale test. Thus, the maximum tested replacement of 75% NaCl by CaCl2 produced healthier chicken nuggets, for having provided a reduction in sodium content and increase in calcium content, besides maintaining sensory quality and most of the technological characteristics.

Keywords: Consumer study, Healthiness, Ionic strength, Meat product, Salt substitute, Physicochemical analysis

Highlights

Nuggets were reformulated by replacing NaCl with CaCl2 with equal ionic strength.

Replacement of NaCl by CaCl2 did not affect the physicochemical characteristics.

75% NaCl replacement lead to 34% sodium reduction in the meat product.

Calcium content (per portion) increased to 16.9% of the recommended daily intake.

The presence of calcium chloride did not affect nuggets sensory acceptance.

Introduction

The development of value added meat products, such as chicken nuggets, has been identified as the best way to increase poultry meat consumption (Yogesh et al. 2013). Nowadays, it has been observed an increase in the consumption of chicken nuggets, mainly due to its convenience (easy-to-prepare, ready for consumption) and to be consumed by all ages and income ranges. Furthermore, chicken nuggets can be a good source of proteins. According to Devatkal et al. (2011) the protein content of chicken nuggets in traditional formulations (control) was 20.29 g/100 g and Barros et al. (2018) found 34.66 (dry basis) g/100 g.

However, according to the Scientific Advisory Committee on Nutrition (SACN2003) and the Food Safety Authority of Ireland (FSAI 2016), meat and meat products provide 21.0 and 27.4% of the sodium in the diet, respectively. For the processing of poultry meat products 1.0–1.6 g/100 g sodium chloride (NaCl) is typically used (Petracci et al. 2013). In traditional formulations of chicken nuggets, the NaCl content can range from 2 g/100 g (Verma et al. 2012a) up to 2.5 g/100 g (Yogesh et al. 2013).

Hereditary predisposition to arterial hypertension is influenced by obesity and excessive sodium ingestion from food (Jiménez-Colmenero et al. 2001). The joint World Health Organisation and Food Agricultural Organisation of the United Nations (WHO/FAO 2003) recommend NaCl (salt) consumption should be below 5 g/day, which is equivalent to a maximum sodium intake of 2 g/day. However, in Europe, the salt intake ranges from 8 to 11 g/day (European Food Safety Authority [EFSA] 2005) and 11.38 g/day in Brazil (Brazilian Association of Food Industries [ABIA] 2013).

Several studies aimed to reduce the sodium content in meat products, by partial replacement of NaCl with chloride salts of calcium, potassium and magnesium (Dos Santos et al. 2015a; Horita et al. 2011). However, the reformulation of meat products with reduced sodium content is not a simple task, as salt reduction not only affects the salty taste but the product intensity regarding the characteristic flavour (Ruusunen and Puolanne 2005). According to Lawless et al. (2003), the calcium chloride is known primarily for contributing a bitter taste and resulting metallic, astringent and irritative sensations. Furthermore, the reduction of NaCl in the meat batter requires other ionic compounds to restore the meat functionality, that is, lost with the salt reduction, such as the water-holding, protein-binding and fat-binding capacities (Doyle and Glass 2010).

One of the alternatives to reduce the undesirable effects of the NaCl substitution in meat products is the use of salt substitutes at concentrations which maintain the same ionic strength (IS) (Zanardi et al. 2010). Horita et al. (2014), evaluated reduced-sodium frankfurter sausages produced with blends of chloride salts (sodium, potassium and calcium chloride) with ionic strength equivalent to 2% NaCl and containing high levels of mechanically deboned poultry meat. They found that the partial substitution of NaCl by mixtures of potassium and calcium chloride represented a viable strategy in reducing the sodium content.

In an approach to substitute NaCl in chicken nuggets, some studies have added mixtures containing potassium chloride (KCl), citric acid, tartaric acid and sucrose (Verma et al. 2012a, b). However, no studies of chicken nuggets with NaCl substitutes, particularly calcium chloride (CaCl2), have yet been published. Thus, the present study reformulated chicken nuggets, by using CaCl2 as NaCl replacer, with IS equivalent to 1.5% NaCl, and assessed the physicochemical and sensory attributes of the obtained products.

Materials and methods

Reformulation and processing

The present study was performed at the College of Animal Science and Food Engineering of University of São Paulo (FZEA/USP), Brazil. Four treatments of chicken nuggets were processed: a control formulation (1.5 g/100 g NaCl) and three treatments containing CaCl2 by NaCl substitution (25, 50 and 75% NaCl), with IS equivalent to 1.5% NaCl (described in Table 1). The ISs of the different salt concentrations were calculated according to Segel (1976):

| 1 |

where IS = ionic strength, Ci = molarity of the ion (M, mol/L), and Zi= the net charge of the ion.

Table 1.

Various CaCl2 concentrations in chicken nuggets with ionic strength equivalent to 1.5% NaCl

| Treatments | NaCl | CaCl2 | ||

|---|---|---|---|---|

| g/100 g | IS† | g/100 g | IS† | |

| Control | 1.5 | 0.256 | – | – |

| NaCl 25% | 1.125 | 0.192 | 0.237 | 0.064 |

| NaCl 50% | 0.75 | 0.128 | 0.474 | 0.128 |

| NaCl 75% | 0.375 | 0.064 | 0.712 | 0.192 |

†IS = ionic strength

The salts, NaCl (Umari Salineira, Macau, Brazil) and CaCl2 (Asher Produtos Químicos, Ribeirão Preto, Brazil), used in the processing of the chicken nuggets were food grade. The other ingredients and proportions used in all treatments were: 77.7 g/100 g chicken breast fillet, 20 g/100 g chicken skin, 0.05 g/100 g sodium erythorbate (Cori Ingredientes, Rio Claro, Brazil), 0.25 g/100 g sodium tripolyphosphate (Cori Ingredientes), 0.30 g/100 g onion powder (New Max, Americana, Brazil), 0.15 g/100 g garlic powder (New Max) and 0.05 g/100 g white pepper (New Max). The chicken breast fillet and skin were obtained from local market in the city.

The processing of the chicken nuggets followed the one described by Barros et al. (2018). Summarizing, the chicken breast and skin were ground (8 and 4 mm diameter disc, respectively) and homogenised together with the different percentages of salts (Table 1) and other ingredients and shaped in a chicken nuggets format. The chicken nuggets were coated in a three steps system as follows: (1) Pre-dust (type PDA 66-TC; Kerry Company [Campinas, Brazil]): the formatted chicken nuggets were passed in a fine flour whose function is adhere the batter coating, (2) Batter coating (adhesion type BMA91-TC; Kerry Company): the meat products were immersed in a solution prepared in a 1:2 ratio (powder:water), aiming an improvement in the adhesion of the breading flour and (3) Breading (dressing type SA F05; Kerry Company): is a flour (bread crumb) with larger particle size, that has as characteristic to provide the crispness of the chicken nuggets.

After pre-dusting, battering and breading, the chicken nuggets were fried in an industrial electric fryer with two vats, and with capacity of 2.5 L each. In this stage the chicken nuggets were fried in palm fat (type 370F, Agropalma, Belém, Brazil) at 180 °C until an internal temperature of 72 °C, being that for the verification of the internal temperature of the chicken nuggets a digital thermometer type skewer was used. The amount of palm fat added in the fryer was about 2 kg in each vat (enough to completely cover the chicken nuggets). A total of 12 chicken nuggets were fried at a time in each vat. The fat exchange was performed between each different treatment. The chicken nuggets were packed in polyethylene plastic, frozen and stored at − 18 °C. All analyses of the chicken nuggets were undertaken after the frying (product ready for consumption), and the experiment (processing) was repeated twice (n = 2). A total of 5 kg of meat mix were processed, resulting in about 200 chicken nuggets in each treatment and each repetition.

Physicochemical analysis

In order simulate the real conditions that the product is marketed and consumed by consumers in Brazil, the preparation of the chicken nuggets samples for physicochemical analysis were performed according to Barros et al. (2018), that is, before performing all physicochemical analyzes, the fried and frozen chicken nuggets were thawed overnight at 2 °C.

Proximate composition and oil absorption

The proximate composition was evaluated according to the Association of Official Analytical Chemists (AOAC 1998) methods, for determination of protein (981.10), moisture (950.46) and ash (920.153) contents. The lipid contents were determined by the Bligh and Dyer method (1959). The oil absorption was calculated as the difference between the lipid content of the samples before and after frying. All analyses were conducted in triplicate.

Mineral analysis: sodium and calcium contents

The sodium content was determined by following the AOAC 956.01 method (1996), using a flame spectrophotometer (Micronal, B462, Brazil). The calcium content was established by inductively coupled plasma atomic emission spectrometry (Sindirações 2013). In order to carry out these analyzes, 5 grams of each treatment were incinerated in muffle 550 °C until obtaining white ash. The ash obtained was added 20 ml of 50% HCl. After standing for 20 min, the volume was transferred to a 100 ml volumetric flask and the volume adjusted with distilled water. All analyzes of minerals were carried out in aliquots of this solution. The analysis was performed in duplicate, and the results were expressed in mg/100 g.

Objective colour

The thawed samples of chicken nuggets were cut in half for instrumental colour assessment in the internal part of the meat products, i.e., only the pre-cooked meat mix of each different treatment was evaluated, not the enrobing (breading) material. A portable colorimeter (HunterLab®, MiniScan XE model, USA) was used to record the L* (brightness), a* (greenness/redness) and b* (blueness/yellowness) parameters of the CIELAB system, with the D65illuminant, 10° viewing angle and 30 mm cell aperture. The instrument was calibrated using a black and white reference standard. Readings were carried out in the two halves of each sample, in four different chicken nuggets, totalling eight readings in each treatment.

Determination of water activity (aw)

The aw was as evaluated using AquaLab equipment (Decagon Devices, Pullman, WA, USA). Triplicates were evaluated per treatment.

Cooking yield and percentage of weight gain by coating (pick-up)

The cooking yield was calculated from the weight relationship between the fried and raw chicken nuggets (with coating) multiplied by 100 (Devatkal et al. 2011). The chicken nuggets were weighed before and after the three-step coating system (pre-dust, batter and breading), and the pick-up was calculated by:

| 2 |

In total, 24 samples of chicken nuggets per treatment were used for each analysis.

Texture profile analysis (TPA)

The TPA was carried out in a texturometer (TA-XT2i Stable Micro Systems, Godalming, UK) and evaluated for hardness, cohesiveness, chewiness and springiness, using an aluminium probe with 30 mm diameter, operating at a velocity of 0.3 mm/s. Six chicken nuggets were measured per treatment. The coating system of the chicken nuggets was removed to obtain results without the interference of the coating system, and the samples were cut into 2 × 2 cm pieces.

Consumer study

The research was approved by the Research Ethics Committee of the FZEA/USP (Process 49161415.3.0000.5422). Sensory tests were performed in the sensory laboratory of the FZEA/USP in only one session and during the morning and afternoon periods. A total of 115 consumers (aged from 17 to 52 years) that had interest, availability and a habit of consuming chicken nuggets participated in the analysis. The consumers evaluated the chicken nuggets with various sodium contents, by the acceptance test. A nine-point hedonic scale, ranging from “1 = disliked very much” to “9 = liked very much” was used for texture, flavour and overall quality attributes. The fried and frozen chicken nuggets were reheated in an electric oven at 200 °C and kept at 60 °C in an electric greenhouse (used to maintain food temperature), until the analysis. For sensory analysis, approximately 60 chicken nuggets per treatment were used, being that, one unit of chicken nuggets served two consumers. All samples were coded with three-digit random numbers and served monadically to the consumers, in a randomised complete block design.

Together with the acceptance test, the chicken nuggets were evaluated for the salty taste, using a just-about-right (JAR) scale ranging from “1 = taste extremely less salty than the ideal” to “9 = taste extremely saltier than the ideal”. Consumers also assessed the chicken nuggets by the check-all-that-apply (CATA) questionnaire containing 29 sensory descriptors (described in Table 2). The descriptive terms used in the CATA test were based on the study about sensory descriptors of low-sodium meat products (Galvão et al. 2014).

Table 2.

List of 29 sensory descriptors used for check-all-that-apply (CATA) questionnaire

| Appearance | Odour | Texture | Flavour |

|---|---|---|---|

| Bright internal appearance | Weak chicken odour | Dry | Weak chicken meat flavour |

| Dark internal appearance | Strong chicken odour | Juiciness | Strong chicken meat flavour |

| Low fatty | Nugget odour | Soft texture | Without seasonings |

| Fatty | Hard texture | Weak seasonings | |

| Crispy | Ideal seasonings | ||

| Little crispy | Strong seasonings | ||

| Tasty | |||

| Without flavour | |||

| Strong flavour | |||

| Weak flavour | |||

| Bad flavour | |||

| Strange flavour | |||

| Bitter flavour | |||

| Metallic flavour | |||

| Rancid | |||

| Little rancid |

Statistical analysis

All the physicochemical and acceptance test results were evaluated by analysis of variance (ANOVA), using Sisvar® program, version 5.6 (Ferreira 2011), and the means were compared by Tukey’s test, at 5% significance. The JAR results for the salty taste were analysed by penalty analysis (Dos Santos et al. 2015b). The correspondence analysis was used to interpret data from the CATA terms, considering the Chi square distance (Vidal et al. 2015). Both analyses were evaluated using XLSTAT® software (version 2016, Addinsoft, Paris, France).

Results and discussion

Table 3 presents the physicochemical data for the chicken nuggets formulated using CaCl2 as NaCl substitute. The different treatments of chicken nuggets were similar (p > 0.05) for the variables oil absorption, lipid, protein and moisture contents. The same outcomes were observed in the work by Horita et al. (2011), who found that the replacement of 50–75% NaCl by salt blends (NaCl, KCl and CaCl2) did not cause differences in the moisture, lipid and protein levels of reduced-fat mortadella. In the present study, the reformulated chicken nuggets would expect to yield comparable results to the control for these evaluated parameters, given the same proportions of raw meat materials (chicken breast and skin) were used. However, there was a decrease in ash content (p < 0.05) with the increase in replacement level of NaCl by CaCl2. This trend could be explained because CaCl2 is a divalent salt and to maintain the same IS (0.256), less CaCl2 addition than NaCl removal was required in the substitution.

Table 3.

Physicochemical data for the NaCl-reduced chicken nuggets

| Analysis | Treatments | SEM† | p value | |||

|---|---|---|---|---|---|---|

| Control | NaCl 25% | NaCl 50% | NaCl 75% | |||

| Oil absorption (g/100 g) | 6.12 | 5.59 | 6.18 | 6.06 | 0.52 | 0.8467 |

| Proximate composition (g/100 g) | ||||||

| Lipids | 13.68 | 12.91 | 13.56 | 13.21 | 0.35 | 0.5070 |

| Proteins | 18.21 | 17.32 | 17.72 | 17.46 | 0.34 | 0.3989 |

| Moisture | 52.60 | 52.77 | 51.86 | 51.74 | 0.26 | 0.1457 |

| Ash | 2.21a | 2.06ab | 1.89bc | 1.75c | 0.03 | 0.0035 |

| Mineral analysis (mg/100 g) | ||||||

| Sodium content | 530a | 460ab | 400bc | 350c | 0.01 | 0.0083 |

| Calcium content | 10c | 50bc | 90ab | 130a | 0.01 | 0.0108 |

| Objective colour | ||||||

| L* | 74.43b | 76.44ab | 76.65ab | 78.28a | 0.55 | 0.0573 |

| a* | 1.99 | 1.75 | 1.84 | 1.97 | 0.09 | 0.3756 |

| b* | 17.97 | 17.79 | 17.79 | 17.75 | 0.12 | 0.6222 |

| aw | 0.957 | 0.965 | 0.962 | 0.965 | 0.00 | 0.6244 |

| Cooking yield (%) | 94.02 | 94.57 | 91.80 | 92.22 | 1.17 | 0.4110 |

| Pick-up (%) | 29.66 | 30.49 | 31.46 | 31.92 | 0.56 | 0.1829 |

| Texture profile analysis (TPA) | ||||||

| Hardness (kg) | 3.33 | 3.48 | 3.99 | 4.07 | 0.19 | 0.1526 |

| Cohesiveness | 0.67 | 0.63 | 0.65 | 0.63 | 0.02 | 0.4453 |

| Chewiness (kg.mm) | 1.61 | 1.47 | 1.73 | 1.77 | 0.10 | 0.3221 |

| Springiness (mm) | 0.70 | 0.66 | 0.67 | 0.68 | 0.02 | 0.4385 |

Control: 1.5 g/100 g NaCl; NaCl 25%: 1.125 g/100 g NaCl + 0.237 g/100 g CaCl2; NaCl 50%: 0.75 g/100 g NaCl + 0.474 g/100 g CaCl2, and NaCl 75%: 0.375 g/100 g NaCl + 0.712 g/100 g CaCl2

†SEM standard error of mean

Means with different letters in a row are significantly different (p < 0.05)

It was verified that the substitution of NaCl by CaCl2, at an ionic strength (IS) equivalent to 1.5% NaCl, decreased (p < 0.05) the sodium content (Table 3). A reduction of up to 75% NaCl was only able to reduce 34% sodium in chicken nuggets. Although the same proportions of sodium tripolyphosphate and erythorbate have been used in all formulations, the use of these additives and other sources of sodium, such as the meat raw material and the coating system, may have contributed to the non-proportional reduction of the sodium content, i.e., reductions not corresponding to the sodium chloride reduction percentages (25, 50 and 75%) in the different treatments. Similarly, Horita et al. (2014) observed that a 50% reduction in NaCl in frankfurter sausages was responsible for reducing only 35% sodium. Although these authors have used the same proportions of sodium erythorbate, tripolyphosphate and nitrite and meat raw material in all formulations, they reported that the presence of these ingredients contributed to the sodium content in the formulations. According to Maurer (1983), sodium tripolyphosphate and sodium erythorbate contribute to 31.24 and 11.61% of the increased sodium in meat products, respectively.

The commitment term signed by government agencies and food industries (Brasil 2013) aimed to reduce the sodium content in processed foods to a maximum 650 mg/100 g for breaded meat products, in 2017. In the present study, all chicken nuggets agree with this recommendation, with sodium contents between 350 (NaCl75%) and 530 mg/100 g (control). Moreover, the Brazilian (Brasil 2012) legislation state that if a product presents 25% or more of sodium reduction, like the NaCl 50% and 75% formulations in the current study, it can be labelled as “reduced sodium content”.

For the calcium content, an increase (from 10 to 130 mg/100 g; p < 0.05) was observed, as a function of the added CaCl2 in the chicken nuggets formulation. It is verified that the consumption of one portion (130 g; established by Brazilian legislation [Brasil 2003]) of chicken nuggets with the maximum addition of CaCl2 (NaCl 75% treatment) could provide 169 mg calcium/130 g. This calcium content corresponds to 16.9% of the recommended daily intake for adults in Brazil, which is equivalent to 1000 mg/day (Brasil 2005). Thus, the replacement of NaCl by CaCl2 in chicken nuggets is an alternative to increasing calcium intake. Furthermore, as specified by Brazilian legislation (Brasil 2012), the NaCl 75% chicken nuggets could present the claim “source of calcium”.

Along with the increase in the calcium content, a tendency in increase in the brightness parameter (L*; p = 0.0573) of the meat products was observed, but the parameters a* and b* were comparable (p > 0.05), among the treatments (Table 3). These results corroborated the colour variables in sodium-reduced frankfurter sausages, investigated by Horita et al. (2014). In that study, the authors hypothesised that the presence of calcium tends to increase the brightness parameter.

As expected, the variable aw (Table 3), was similar (p > 0.05) irrespective of the nugget formulations. Zanardi et al. (2010), studying Cacciatore salami (typical Italian dry fermented sausage) with partial NaCl replacement by KCl, CaCl2 and MgCl2 (with the same IS), also did not find differences in the aw relative to the control formulation (2.7 g/100 g pure NaCl).

All the chicken nuggets showed analogous cooking yields to each other (p > 0.05; Table 3). Hamm (1986) noted that divalent cations, such as Mg2+ and Ca2+,could decrease the water-holding capacity of meat because the binding of cations reduces electrostatic repulsion between amino acids with negatively charged groups; therefore, the protein structure is tightened, and shrinkage occurs, adversely affecting the cooking yield of meat products. However, this behaviour was not observed in the current study, probably because the lower amount of CaCl2 needed to replace NaCl (to maintain an equivalent IS) was insufficient to affect yield. These results indicate that the substitution of NaCl by divalent salts, such as CaCl2, with the same IS, is an alternative in reducing sodium content and maintaining the product yield, which is an important parameter for the food industry. Contrary to our results, Horita et al. (2011) noticed the cooking yield of reduced-fat mortadella decreased, due to the presence of CaCl2 in blends containing KCl as a partial NaCl replacer.

As expected regarding the pick-up (weight gain by coating), no differences were observed (p > 0.05; Table 3) among the treatments because the changes were only performed in the proportions of salts (NaCl and CaCl2) added to the meat mix and not the coating system. It can also be seen in Table 3 that the substitution of NaCl by CaCl2 did not affect the TPA (p > 0.05) parameters. Similar behaviour was demonstrated by Dos Santos et al. (2015b), who did not observe significant differences in the texture parameters of dry fermented sausage with 50% NaCl replacement by CaCl2 when compared with the control formulation (NaCl only). It is known that the use of high calcium concentrations can increase the hardness of the products (Cáceres et al. 2006). However, in the current study, the addition of calcium chloride did not affect the texture of the chicken nuggets. This may have occurred due to the same ionic strength (0.256) used in all formulations, that is, to replace 75% of NaCl, a lower amount of CaCl2 was used to maintain the same ionic strength equivalent to 1.5% NaCl.

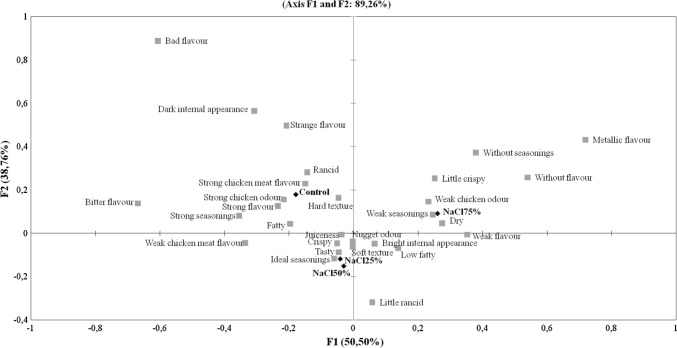

Figure 1 presents the results of the correspondence analysis used to evaluate the CATA questionnaire of the chicken nuggets having a reduced NaCl content (25, 50 and 75%) with IS equivalent to 1.5% NaCl. The results explained 89.26% of the total variance, with 50.50 and 38.76% in the first (F1) and second (F2) dimensions, respectively. Figure 1 suggests that the different formulations of chicken nuggets could be separated into three groups. The first group, composed by the control treatment, was characterised by the sensory attributes, bad flavour, dark internal appearance, strange flavour, rancid, strong chicken meat flavour, bitter flavour, strong chicken odour, hard texture, strong flavour, strong seasonings and fatty. In the second group, NaCl 75% treatment was associated with a metallic flavour, without seasonings, without flavour, little crispy, weak chicken odour, weak seasonings and dry, probably due to the greatest NaCl reduction in this treatment. Both the NaCl 25% and NaCl 50% treatments formed the third group and were identified as possessing positive sensory attributes, being assigned the terms, juiciness, crispy, tasty, ideal seasonings, weak chicken meat flavour, nuggets odour and soft texture by the consumers. Based on these results, it can be stated that the substitution of up to 50% NaCl by CaCl2 (IS = 0.256) did not negatively affect the sensory quality of chicken nuggets. In contrast, Dos Santos et al. (2015a) found that consumers considered reformulated dry fermented sausages containing CaCl2 as a NaCl substitute as having low sensory quality. In that study, the sausages formulated with 50% CaCl2 were linked to the terms, bitter taste and fattiness, and the sausages comprising a blend of 25% KCl and 25% CaCl2 were described as possessing an acid taste and fattiness.

Fig. 1.

Representation of the sample and terms in the first and second dimensions of the correspondence analysis performed on the check-all-that-apply (CATA) questionnaire on the NaCl-reduced chicken nuggets. Control: 1.5 g/100 g NaCl; NaCl 25%: 1.125 g/100 g NaCl + 0.237 g/100 g CaCl2; NaCl 50%: 0.75 g/100 g NaCl + 0.474 g/100 g CaCl2, and NaCl 75%: 0.375 g/100 g NaCl + 0.712 g/100 g CaCl2

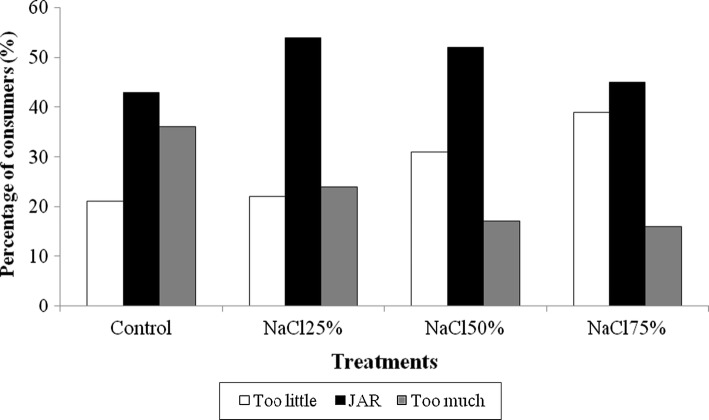

Figure 2 presents the percentage of the frequency of the JAR scale by consumers for the salty taste of the chicken nuggets. As mentioned by Meullenet et al. (2007), for an attribute at its optimum level, a minimum of 70% of the answers should be considered ideal (JAR). Thus, among the evaluated chicken nuggets, none were deemed optimal (JAR) for the salty taste attribute. However, the NaCl 25% and NaCl 50% treatments received higher percentages of JAR score (54 and 52%, respectively) for the salty taste in comparison to the other treatments (control and NaCl 75%). The percentages of JAR score of the control and NaCl 75% treatments were similar. These results imply that the use of CaCl2 as a substitute for NaCl did not interfere in the consumer’s perceptions of the salty taste and a reduction of up to 50% NaCl in chicken nuggets was considered acceptable by consumers for this attribute. Thus, this similarity can be explained by the presence of CaCl2 that contributed to the saltiness. In the sensory study performed by Lawless et al. (2003), where they verified whether NaCl, citric acid and sucrose would mask the bitter taste of CaCl2, an increase in saltiness as a function of concentration of calcium chloride (without addition of NaCl) was observed. Horita et al. (2014) reported that the substitution of 25 and 50% NaCl by CaCl2 indicated an alternative to reduce sodium in frankfurter sausages since they were similar to the control for the flavour parameter. Differently, Dos Santos et al. (2015b) showed that the addition of CaCl2 in dry fermented sausages caused lower responses on the JAR scale for the perception of the salty taste than the control product.

Fig. 2.

Percentages of the frequency of the just-about-right (JAR) scale by consumers for the salty taste of NaCl-reduced chicken nuggets. JAR values are shown as percentages of the frequency of consumers ratings from options: 1–4 = too little, 5 = JAR and 6–9 = too much. Control: 1.5 g/100 g NaCl; NaCl 25%: 1.125 g/100 g NaCl + 0.237 g/100 g CaCl2; NaCl 50%: 0.75 g/100 g NaCl + 0.474 g/100 g CaCl2, and NaCl 75%: 0.375 g/100 g NaCl + 0.712 g/100 g CaCl2

Additionally, for the NaCl 75% treatment, 39% of consumers affirmed that chicken nuggets were less salty than ideal and 36% of the consumers considered the control formulation had a salty taste above the ideal (Fig. 2). As a result, the high and low amounts of salt present in control and NaCl 75% samples, respectively, may adversely affect consumer’s perceptions for salty taste in chicken nuggets.

The sensory acceptance test results (Table 4) identified the texture attribute of the NaCl 50% treatment did not differ (p > 0.05) from the NaCl 25% and NaCl 75% treatments but was better (p < 0.05) accepted than the control formulation. However, it is possible to affirm that all the treatments presented a well-accepted texture, receiving scores of “7 = liked moderately” and “8 = liked much”, which parallel the TPA results, where no differences were found among all treatments. Likewise, Verma et al. (2012a) revealed that replacement of NaCl by mixtures of substitute salts in chicken nuggets did not affect the sensory texture parameter.

Table 4.

Acceptance test results of NaCl-reduced chicken nuggets

| Acceptance test | Treatments | Root MSE† | p value | |||

|---|---|---|---|---|---|---|

| Control | NaCl 25% | NaCl 50% | NaCl 75% | |||

| Texture | 7.48b | 7.80ab | 7.94a | 7.57ab | 1.13 | 0.0078 |

| Flavour | 7.26b | 7.73a | 7.85a | 7.50ab | 1.16 | 0.0007 |

| Overall quality | 7.30b | 7.73a | 7.86a | 7.59ab | 1.05 | 0.0006 |

Control: 1.5 g/100 g NaCl; NaCl 25%: 1.125 g/100 g NaCl + 0.237 g/100 g CaCl2; NaCl 50%: 0.75 g/100 g NaCl + 0.474 g/100 g CaCl2, and NaCl 75%: 0.375 g/100 g NaCl + 0.712 g/100 g CaCl2

†Root MSE root mean square error

Means with different letters in a row are significantly different (p < 0.05) by the acceptance test (nine-point hedonic scale)

For the flavour parameter, the NaCl 25% and NaCl 50% treatments presented higher sensory scores (p < 0.05) than the Control treatment, but neither formulation differed (p > 0.05) from the NaCl 75% treatment. These results indicate that the addition of CaCl2 did not contribute to the bitter taste in chicken nuggets, which could be explained by the lower amount of CaCl2 as a substitute for NaCl, to maintain the same ionic strength (IS = 0.256). In addition, the type of meat product tested, which is breaded (enrobed) and fried, thus presenting strong flavour, may have helped to mask any undesirable sensory parameters of CaCl2. According to Lawless et al. (2003), the bitter and metallic taste of CaCl2 decreased with the presence of NaCl. In support of these findings, Horita et al. (2011) verified that reduced-fat mortadella reformulated with 1% NaCl, 0.5% KCl and 0.5% CaCl2 were considered accepted by consumers for the flavour parameter. Verma et al. (2012b) noticed that replacement of NaCl by mixtures of salt substitutes (KCl, citric acid, tartaric acid and sucrose) in chicken nuggets did not affect flavour.

Regarding the overall quality attribute, the NaCl 25% and NaCl 50% treatments received better scores (p < 0.05) than the Control treatment. However, the NaCl 75% treatment was similar (p > 0.05) to all formulations. Horita et al. (2014) were also unable to identify differences in overall acceptance among the control treatment and the formulations containing 25 and 50% CaCl2 as a NaCl substitute (at an IS equivalent to 2% NaCl) in frankfurter sausages. The current study alludes to one of the possible reasons for the decrease in the overall quality consumer acceptance of the control versus NaCl 25% and NaCl 50% treatments is its higher sodium content (Table 3), which consumers considered above the ideal for salty taste (Fig. 2).

Therefore, in view of the all sensorial results obtained (CATA, JAR and acceptance test), the substitution of 50% NaCl by CaCl2 was considered acceptable by the consumers, obtaining positive sensory parameters and making the chicken nuggets healthy by reducing the sodium content and increasing the calcium content.

Conclusion

The replacement of up to 50% of the NaCl with CaCl2 (with an ionic strength equivalent to 1.5% NaCl) did not affect most of the physicochemical characteristics and sensory acceptance of chicken nuggets. Given the obtained results, one can recommend this level of replacement (reduction of 50% of the sodium chloride) as a good strategy to reduce the sodium content and increase the calcium content in chicken nuggets, producing a healthier meat product.

Acknowledgements

The authors thank the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior –Finance Code 001 (CAPES, Brazil) for the doctoral scholarship granted to the first author (J. C. Barros). Also to the Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP, Brazil) for supporting the research (Process 2015/12429-7), and Kerry, New Max and Cori Ingredientes Company (Brazil) for their donations. The author M. A. Trindade is a member of the MARCARNE network, funded by CYTED (ref. 116RT0503).

Compliance with ethical standards

Conflict of interest

The authors declare that they have no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AOAC (1996) Potassium and/or sodium in plants. Official methods of analysis, 16th edn. Association of Official Analytical Chemists, Washington, DC

- AOAC (1998) In P. Cunniff (ed) Official methods of analysis of the Association of Official Analytical Chemists, 16th edn. AOAC International, Arlington

- Barros JC, Munekata PES, Pires MA, Rodrigues I, Andaloussi OS, Rodrigues CEC, Trindade MA. Omega-3- and fibre-enriched chicken nuggets by replacement of chicken skin with chia (Salvia hispanica L.) flour. LWT Food Sci Technol. 2018;90:283–289. doi: 10.1016/j.lwt.2017.12.041. [DOI] [Google Scholar]

- Bligh EG, Dyer WJ. A rapid method of total lipid extraction and purification. Can J Biochem Phys. 1959;37:911–917. doi: 10.1139/y59-099. [DOI] [PubMed] [Google Scholar]

- Brasil (2003) Agência Nacional de Vigilância Sanitária Resolução RDC No. 359/2003. Regulamento Técnico de Porções de Alimentos Embalados para Fins de Rotulagem Nutricional. Diário Oficial da União; Poder Executivo, Brasília

- Brasil (2005) Agência Nacional de Vigilância Sanitária Resolução RDC No. 269/2005. Regulamento técnico sobre ingestão diária recomendada (IDR) para proteína, vitaminas e minerais

- Brasil (2012) Agência Nacional de Vigilância Sanitária. Resolução da Diretoria Colegiada RDC No. 54/2012. Regulamento técnico MERCOSUL sobre informação nutricional complementar (Declarações de Propriedades Nutricionais)

- ABIA Cenário do consumo de sódio no Brasil (2013). http://www.abia.org.br/sodio/sodio2.pdf. Accessed 17 Dec 2017

- Brasil (2013) Termo de compromisso que firmam entre si a União, por intermédio do Ministério da Saúde, a Associação Brasileira das Indústrias de Alimentos—ABIA, Associação Brasileira das Indústrias de Queijo—ABIQ, Associação Brasileira da Indústria Produtora e Exportadora de Carne Suína—ABIPECS, Sindicato da Indústria de Carne e Derivados no Estado de São Paulo—SINDICARNES e União Brasileira de Avicultura—UBABEF. Estabelecimento de metas nacionais para a redução do teor de sódio em alimentos processados no Brasil. Diário Oficial da União, No. 242, Brasília

- Cáceres E, García ML, Selgas MD. Design of a new cooked meat sausage enriched with calcium. Meat Sci. 2006;73:368–377. doi: 10.1016/j.meatsci.2005.12.016. [DOI] [PubMed] [Google Scholar]

- Devatkal SK, Kadam DM, Naik PK, Sahoo J. Quality characteristics of gluten-free chicken nuggets extended with sorghum flour. J Food Qual. 2011;34:88–92. doi: 10.1111/j.1745-4557.2010.00367.x. [DOI] [Google Scholar]

- Dos Santos BA, Bastianello Campagnol PC, da Cruz AG, Galvão MTEL, Monteiro RA, Wagner R, Pollonio MAR. Check all that apply and free listing to describe the sensory characteristics of low sodium dry fermented sausages: comparison with trained panel. Food Res Int. 2015;76:725–734. doi: 10.1016/j.foodres.2015.06.035. [DOI] [PubMed] [Google Scholar]

- Dos Santos BA, Campagnol PCB, da Cruz AG, Morgano MA, Wagner R, Pollonio MAR. Is there a potential consumer market for low-sodium fermented sausages? J Food Sci. 2015;80:S1093–S1099. doi: 10.1111/1750-3841.12847. [DOI] [PubMed] [Google Scholar]

- Doyle ME, Glass KA. Sodium reduction and its effect on food safety, food quality, and human health. Compr Rev Food Sci Food Saf. 2010;9:44–56. doi: 10.1111/j.1541-4337.2009.00096.x. [DOI] [PubMed] [Google Scholar]

- ESFA Opinion of the scientific panel on dietetic products, nutrition and allergies on a request from the commission related to the tolerable upper intake level of sodium. EFSA J. 2005;209:1–26. [Google Scholar]

- Ferreira DF. Sisvar: a computer statistical analysis system. Ciênc Agrotec. 2011;35:1039–1042. doi: 10.1590/S1413-70542011000600001. [DOI] [Google Scholar]

- FSAI . Salt and health: Review of the scientific evidence and recommendations for public policy in Ireland. Dublin: Food Safety Authority of Ireland; 2016. [Google Scholar]

- Galvão MTEL, Moura DB, Barretto ACS, Pollonio MAR. Effects of micronized sodium chloride on the sensory profile and consumer acceptance of turkey ham with reduced sodium content. Food Sci Technol (Campinas) 2014;34:189–194. doi: 10.1590/S0101-20612014005000009. [DOI] [Google Scholar]

- Hamm R. Functional properties of the myofibrillar system and their measurements. In: Bechtel PJ, editor. Muscle as food. Orlando: Academic Press; 1986. pp. 135–199. [Google Scholar]

- Horita CN, Morgano MA, Celeghini RMS, Pollonio MAR. Physico-chemical and sensory properties of reduced-fat mortadella prepared with blends of calcium, magnesium and potassium chloride as partial substitutes for sodium chloride. Meat Sci. 2011;89:426–433. doi: 10.1016/j.meatsci.2011.05.010. [DOI] [PubMed] [Google Scholar]

- Horita CN, Messias VC, Morgano MA, Hayakawa FM, Pollonio MAR. Textural, microstructural and sensory properties of reduced sodium frankfurter sausages containing mechanically deboned poultry meat and blends of chloride salts. Food Res Int. 2014;66:29–35. doi: 10.1016/j.foodres.2014.09.002. [DOI] [Google Scholar]

- Jiménez-Colmenero F, Carballo J, Cofrades S. Healthier meat and meat products: their role as functional foods. Meat Sci. 2001;59:5–13. doi: 10.1016/S0309-1740(01)00053-5. [DOI] [PubMed] [Google Scholar]

- Lawless HT, Rapacki F, Horne J, Haye A, Wang G. The taste of calcium chloride in mixtures with NaCl, sucrose and citric acid. Food Qual Prefer. 2003;15:83–89. doi: 10.1016/S0950-3293(03)00099-5. [DOI] [Google Scholar]

- Maurer AJ. Reduced sodium usage in poultry muscle foods. Food Technol. 1983;37:60–65. [Google Scholar]

- Meullenet J-F, Xiong R, Findlay CJ. Multivariate and probabilistic analyses of sensory science problems. New York: IFT Press; 2007. [Google Scholar]

- Petracci M, Rimini S, Mulder RWAW, Cavani C. Quality characteristics of frozen broiler breast meat pretreated with increasing concentrations of sodium chloride. J Poult Sci. 2013;50:396–401. doi: 10.2141/jpsa.0120173. [DOI] [Google Scholar]

- Ruusunen M, Puolanne E. Reducing sodium intake from meat products. Meat Sci. 2005;70:531–541. doi: 10.1016/j.meatsci.2004.07.016. [DOI] [PubMed] [Google Scholar]

- SACN . Salt and health. Norwich: TSO; 2003. [Google Scholar]

- Segel IH. Biochemical calculations: how to solve mathematical problems in general biochemistry. 2. New York: Wiley; 1976. [Google Scholar]

- Sindirações . Compêndio Brasileiro de alimentação animal. 4. São Paulo: Sindirações; 2013. Métodos analíticos—Minerais por espectrometria de emissão atomic por plasma indutivamente acoplado (ICP-OES) pp. 175–180. [Google Scholar]

- Verma AK, Banerjee R, Sharma BD. Quality of low fat chicken nuggets: effect of sodium chloride replacement and added chickpea (Cicerarietinun L.) hull flour. Asian-Aust J Anim Sci. 2012;25:291–298. doi: 10.5713/ajas.2011.11263. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Verma AK, Sharma BD, Banerjee R. Quality characteristics of low-fat chicken nuggets: effect of common salt replacement and added bottle gourd (Lagenariasiceraria L.) J Sci Food Agric. 2012;92:1848–1854. doi: 10.1002/jsfa.5691. [DOI] [PubMed] [Google Scholar]

- Vidal L, Tárrega A, Antúnez L, Ares G, Jaeger SR. Comparison of correspondence analysis based on Hellinger and Chi square distances to obtain sensory spaces from check-all-that-apply (CATA) questions. Food Qual Prefer. 2015;43:106–112. doi: 10.1016/j.foodqual.2015.03.003. [DOI] [Google Scholar]

- WHO/FAO (2003) Diet, nutrition and the prevention of chronic diseases. Report of a Joint WHO/FAO Expert Consultation. WHO Technical Report Series No. 916. World Health Organization, Geneva [PubMed]

- Yogesh K, Ahmad T, Manpreet G, Mangesh K, Das P. Characteristics of chicken nuggets as affected by added fat and variable salt contents. J Food Sci Technol. 2013;50:191–196. doi: 10.1007/s13197-012-0617-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zanardi E, Ghidini S, Conter M, Ianieri A. Mineral composition of Italian salami and effect of NaCl partial replacement on compositional, physico-chemical and sensory parameters. Meat Sci. 2010;86:742–747. doi: 10.1016/j.meatsci.2010.06.015. [DOI] [PubMed] [Google Scholar]