Abstract

Lignin is an abundant biopolymer with a high carbon content and high aromaticity. Despite its potential as a raw material for the fuel and chemical industries, lignin remains the most poorly utilised of the lignocellulosic biopolymers. Effective valorisation of lignin requires careful fine‐tuning of multiple “upstream” (i.e., lignin bioengineering, lignin isolation and “early‐stage catalytic conversion of lignin”) and “downstream” (i.e., lignin depolymerisation and upgrading) process stages, demanding input and understanding from a broad array of scientific disciplines. This review provides a “beginning‐to‐end” analysis of the recent advances reported in lignin valorisation. Particular emphasis is placed on the improved understanding of lignin's biosynthesis and structure, differences in structure and chemical bonding between native and technical lignins, emerging catalytic valorisation strategies, and the relationships between lignin structure and catalyst performance.

Keywords: bioengineering, biorefining, catalysis, lignin, lignocellulose

1. Introduction

Lignocellulosic biomass, an intricate and complex architecture of three classes of biopolymer—cellulose, hemicelluloses and lignin—is an abundant and renewable resource. The separation, isolation, and subsequent chemical transformation of the three constituent polymer groups can afford a broad and multifunctional array of bio‐derived value‐added fuels, chemicals and materials. If these products are obtained by an integrated system of (catalytic) reaction pathways, i.e., in a so‐called biorefinery operation, the optimal potential of each component and thus the maximum value of the biomass feed as a whole can be achieved.

Lignin, a complex and water‐insoluble aromatic polymer, is derived primarily from methoxylated hydroxycinnamyl alcohol building blocks, the prototypical monolignols. Unlike cellulose, with a well‐defined sequence of monomeric units that are linked by regular β‐1,4‐glycosidic bonds, lignin is characterised by a variety of distinct and chemically different bonding motifs, each demanding different conditions for cleavage when selective depolymerisation is targeted. Although structurally more complex, the higher carbon‐content and lower oxygen content of lignin, relative to the polysaccharide or holocellulose fraction, render it an attractive feedstock for the production of biofuels and chemicals. Notably, the highly‐functionalised and aromatic nature of lignin presents the potential for the direct preparation of aromatic specialty and fine chemicals, circumventing the requirement for full defunctionalisation to “BTX” (benzene, toluene and xylenes) and subsequent refunctionalisation to desired platform chemicals. Nonetheless, owing to challenges associated with effective separation of oxygenated aromatics via distillation or other means, full defunctionalisation to arenes and alkanes will also be of importance for the production of chemicals and fuel components from lignin and its products. Such opportunities for valorisation together with its abundance have, amongst other reasons, motivated significant research activity into the catalytic valorisation of lignin.

An understanding of (and control over) the coupled and interdependent processing steps, for conversion of the initial biomass feedstock to the intended lignin‐derived product, requires a collaborative approach encompassing a variety of scientific disciplines (e.g., genetic engineering to increase the homogeneity of the polymer or the proportion of easily‐cleavable linkages, the development of effective analytical techniques for lignin structural determination, reactor engineering and improved catalytic systems for the depolymerisation of lignin and downstream processing, and related processes for product separation), as outlined in several review articles (Table 1).

Table 1.

Selected lignin review articles published since 2010, highlighting different focal topics, ordered from primarily concerned with upstream (e.g., lignin biosynthesis, structure) to downstream (e.g., catalytic transformations) process steps.

| Focal topic(s) | Ref. |

|---|---|

| Lignin biosynthesis & structure | 1, 2, 3, 4, 5, 6, 7, 8, 9 |

| Bioengineering of lignins | 8, 9, 10, 11, 12, 13 |

| Biotic/abiotic stress and effects on lignification | 6, 7, 8, 9, 10, 11 |

| Lignin depolymerisation | 14 |

| Catalytic (deoxygenative) valorisation to fuel and chemicals | 15, 16, 17, 18 |

| Pyrolysis, hydrodeoxygenation, catalytic upgrading | 19, 20, 21 |

| Oxidative valorisation of lignin | 22, 23, 24 |

| Lignin for polymers and composites | 25, 26, 27, 28, 29, 30 |

| Lignin analytics | 31, 32, 33, 34, 35, 36, 37 |

| Biodegradation of lignin | 38, 39, 40 |

The available review papers of lignin typically cover limited or specific aspects, or focus only on one or few stages of the lignin valorisation pathway. Here we aim to offer a “start‐to‐finish” analysis of the progress achieved in lignin valorisation, with a particular focus on the past five years, considering all of the interconnected stages of catalytic lignin biorefinering. On this basis, biosynthesis/genetic engineering of the lignin phenylpropanoid pathway, early‐stage catalytic conversion of lignin (ECCL) beginning with lignocellulosic biomass, and the catalytic valorisation of isolated technical lignins to products are each discussed in sequence, where possible drawing connections between separate stages of processing. Particular emphasis is placed on the characteristics of the interunit bonding in the lignins, and the profound impact of various “upstream” biorefining processes on the abundance of different labile (e.g., C−O) and recalcitrant (e.g., C−C) linkages (and thus also on the downstream processing of technical lignins). This review also aims to demystify or update several of the general statements and some of the misapprehensions often encountered in the current literature, thereby fostering a better understanding of the relationships between lignin molecular properties and the performance of catalytic systems.

This review is broadly subdivided into “upstream” and “downstream” sections—defined as the processes leading up to the separation and isolation of lignin (from the polysaccharide fraction), and subsequent depolymerisation and chemical modification of the isolated lignins to yield valorised products, respectively. Whilst this arbitrary division is imperfect (e.g., ECCL can be regarded as a combination of upstream and downstream elements), it is useful from a conceptual point of view as it mirrors the activities of the petrochemical industry.

The upstream section introduces the biosynthetic “phenylpropanoid pathway” with the genes and enzymes involved in the biosynthesis of lignins’ monomeric units. Phenylpropanoid genetic engineering strategies to give altered lignins are compared and contrasted. Subsequently, the chemical structure and bonding properties of native or protolignin (i.e., the lignins occurring in the plant cell wall) in addition to those of some technical isolated lignins (e.g., Kraft and Organosolv lignins) are reviewed, showing the relationship between the severity of a depolymerisation method and the prevalence of specific bonding motifs in the isolated technical lignins. Lastly, another emerging frontier of research, the catalytic upstream refining methods based on early‐stage conversion of lignin, is presented and discussed.

The downstream processing section covers the catalytic valorisation of isolated lignin streams into commodity chemicals, fuels and, discussed to a far lesser extent in this review, materials. Firstly, some relevant market and economic considerations that underpin lignin valorisation are detailed. Subsequently, an array of “mild” (oxidative, reductive, redox‐neutral) and “harsh” lignin depolymerisation strategies are described and compared.

The final section summarises the progress made in this field of research and proposes future directions for catalytic lignin valorisation research. An exhaustive coverage of all topics or contributions relevant to catalytic lignin valorisation is, indeed, impossible owing to the breadth of lignin research. Therefore, analytical methods for the characterisation of lignins and lignin products are discussed only succinctly. Furthermore, a detailed discussion of enzymatic and biological downstream processes is largely omitted.

2. Upstream Processing

2.1. Bioengineering of Lignins

To improve the economic feasibility of a biorefinery, biomass must be comprehensively converted into value‐added products; this includes the lignin stream. The intricate connectivity (not only by physical arrangement but also via actual covalent bonding) between cellulose, hemicelluloses, and lignin poses a challenge for the direct enzymatic saccharification of cellulose into glucose or, for example, to improve the digestibility of forage crops for animal feed.41 This difficulty has motivated plant biologists to modify the phenylpropanoid biosynthesis—a multi‐step, multi‐enzyme biosynthetic pathway for the preparation of nine‐carbon propenylated p‐hydroxyphenyl derivatives originating from the amino acid phenylalanine (or tyrosine)—in order to modify the molecular structure of lignin and/or the proportion incorporated into the plant cell wall.11 Modifications to the phenylpropanoid pathway may exert changes to plant fitness because the branch‐points of the pathway feed into a variety of other metabolic systems essential to plant growth and development. For a comprehensive discussion, the reader is referred to a recent review article.11

The majority of phenylpropanoid genetic strategies have been directed towards a decrease in lignin content across plant species, with research relating to biomass conversion being targeted at hardwoods,42, 43, 44 softwoods,45 monocots (grasses),46, 47, 48, 49, 50, 51, 52, 53 and dicots (including Arabidopsis and alfalfa/truncatula).43, 54, 55, 56, 57, 58, 59, 60, 61, 62, 63, 64, 65, 66, 67, 68, 69, 70, 71, 72, 73, 74 However, an increase in saccharification yield will not boost the economics of a biorefinery operation if the lignin fraction, at 15–30 wt % of dry biomass, becomes a more recalcitrant material.

In this section, recent and relevant genetic modifications of the lignin biosynthetic pathway are discussed, providing an overview of the impact of up‐ and down‐regulation of an array of genes for enzymes involved in the biosynthesis of lignin building blocks on the lignin structure. A survey of current literature related to structural modifications of lignin demonstrates an almost limitless potential for improved utilisation of both the carbohydrate and lignin fractions of lignocellulosic biomass, via catalytic processing.2 An ideal combination of genetic modifications would yield a plant with identical or improved growth compared to the wild‐type. The lignin fraction does not necessarily have to be increased or reduced in quantity, but should be constructed in such a way as to facilitate chemical (or enzymatic) deconstruction under milder conditions than currently required, e.g., by incorporating a restricted subset of linkages or precursor units.1 Bioengineering of lignin, therefore, may aim at enhancing the saccharification yield from biomass whilst simultaneously allowing for the improved valorisation of lignin via subsequent catalytic treatment.1 Optimal conditions for any bioengineering strategy will be determined, at least in part, by the targeted products, and whether these target species evolve from the carbohydrate stream or the lignin stream.

2.2. The Phenylpropanoid Pathway

Scheme 1 summarises the complete phenylpropanoid pathway, outlining enzymes directly involved in the biosynthesis of the prototypical lignin monomers. These monolignols, p‐coumaryl alcohol, coniferyl alcohol, and sinapyl alcohol, are involved in lignification, the polymerisation process that creates the lignin polymer, affording the so‐called “H”, “G” and “S” units, respectively. The phenylpropanoid pathway starts with phenylalanine (Phe), but tyrosine (Tyr) may also be consumed in monocots.75 Phenylalanine is first deaminated to cinnamate (by the enzyme phenylalanine ammonia‐lyase, PAL), and cinnamate is then hydroxylated to p‐coumarate (by cinnamate 4‐hydroxylase, C4H). If tyrosine is used instead as the starting point, this two‐stage enzymatic process is circumvented and Tyr is directly converted into p‐coumarate via deamination (by tyrosine ammonia‐lyase, TAL, but also by PAL which is not absolutely specific for Phe).76

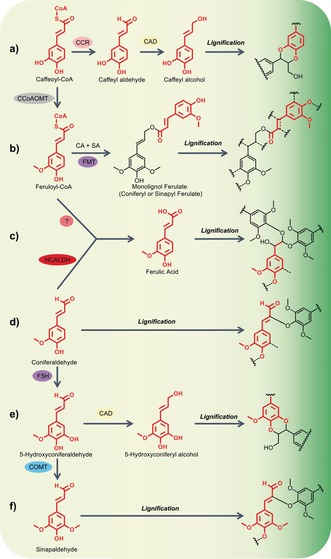

Scheme 1.

Summary of the phenylpropanoid pathway focusing on the formation of native lignin monomer precursors.11, 66 Asterisks (*) represent points at which the intermediate itself may be introduced as a monomer or used to create a new monomer that is used by the plant in its lignification following genetic modification (see Scheme 2). Enzymes are abbreviated as follows: phenylalanine ammonia‐lyase (PAL); cinnamate 4‐hydroxylase (C4H); tyrosine ammonia‐lyase (TAL); 4‐coumarate: CoA ligase (4CL); p‐coumarate 3‐hydroxylase (C3H); shikimate/quinate hydroxycinnamoyltransferase (HCT); cinnamoyl‐CoA reductase (CCR); cinnamyl alcohol dehydrogenase (CAD); caffeoyl shikimate esterase (CSE); caffeic acid O‐methyltransferase (COMT); caffeoyl‐CoA O‐methyltransferase (CCoAOMT); ferulate 5‐hydroxylase (F5H); hydroxycinnamaldehyde dehydrogenase (HCALDH). These enzymes were often named according to the assumed substrates at the time of discovery. They therefore do not necessarily reflect the true preferred substrate. For example, the preferred substrate for F5H is actually coniferaldehyde;95, 96 some have suggested renaming it CAld5H, but the name has not been well adopted. Similarly, the preferred substrates for COMT are 5‐hydroxyconiferaldehyde or 5‐hydroxyconiferyl alcohol;95, 97 AldOMT has been suggested as an alternative name,98 although COMT persists as the preferred name among lignin researchers.

At p‐coumarate, the sequence of enzymatic reactions may diverge to afford either p‐coumaroyl‐CoA (by 4‐coumarate: CoA ligase, 4CL) or caffeate via a second hydroxylation of the aromatic ring (C3H or C4H). In the normal monolignol biosynthetic pathway, the p‐coumaroyl‐CoA is then converted into p‐coumaroyl shikimic/quinic acid (by hydroxycinnamoyltransferase, HCT), or via reduction (cinnamoyl‐CoA reductase, CCR) to p‐coumaraldehyde, which may subsequently be reduced to p‐coumaryl alcohol (cinnamyl alcohol dehydrogenase, CAD); p‐coumaryl alcohol is incorporated into lignin to produce H units, which are usually found in low abundance.

Caffeate can also be converted into ferulate by methylation of the 3‐hydroxy group of the ring (caffeic acid O‐methyltransferase, COMT) to produce ferulic acid and then feruloyl‐CoA (by 4CL), which is more normally considered to arise directly from methylation of caffeoyl‐CoA by CCoAOMT (Scheme 1). Feruloyl‐CoA is then subsequently reduced to coniferaldehyde (by CCR). Coniferaldehyde represents the branching point between the formation of the predominant G (coniferyl‐alcohol‐derived) and S (sinapyl‐alcohol‐derived) units. The hydroxylation of coniferaldehyde (by F5H) and subsequent methylation of the product (by COMT) constitutes the major pathway toward sinapaldehyde. The final stage for the formation of both G and S units is the CAD‐catalysed reduction of the aldehyde moiety to yield the corresponding primary alcohol. Coniferaldehyde may be recycled back into the phenylpropanoid pathway via oxidation of the aldehyde to yield ferulic acid (by hydroxycinnamaldehyde dehydrogenase, HCALDH).

Although, in non‐specialised literature, it is generalised that just the three monolignols are the building blocks of lignins, a number of alternative monomers may be naturally introduced into the lignin structure in normal wild‐type plants or through their genetic modification—the latter, in which products of incomplete monolignol biosynthesis are incorporated into the lignin (and can often also be found at low levels in wild‐type plants), is discussed in Section 2.3.

Natural alternative monomers can also include a number of structures that remain underappreciated for their contributions to lignins in some plants. Of particular note are the acylated monolignols, monolignol acetates, p‐hydroxybenzoates, and p‐coumarates.1 Confusion has arisen with these last two products that are often incorrectly quantified as H‐lignin components. H‐lignin units, by definition, result from the monolignol p‐coumaryl alcohol. The monolignol conjugates, in contrast, are monolignol (usually coniferyl and sinapyl alcohol) ester conjugates of p‐hydroxybenzoic and p‐coumaric acids. Although p‐coumarate esters, in particular, derive from p‐coumaroyl‐CoA on the pathway, p‐coumarate cannot be considered to be a monolignol, nor is it a lignin monomer. In all cases, the monolignol moiety of the conjugate has been found to couple into lignin in the usual manner, whereas the p‐hydroxybenzoate and p‐coumarate moieties do not, as they remain as free‐phenolic pendant “decorations” on the γ‐OH groups of the C3‐sidechain of lignin's various units. The reason has been deduced to be the more facile radical transfer (to more stable G and S radicals) than radical coupling.1, 77, 78 Notably, as pendant esters can occur at significant levels, and indeed may be some of the easiest and more valuable products to “clip off” from various lignin streams, they must be seen as, and are, part of the lignin. In spite of this, they must not be confused with the monomers that enter the radical coupling reactions that typify lignification and create the polymer backbone itself.

The radical coupling products from monolignol conjugates are structurally analogous to those from the monolignols themselves except in the case of their β‐β coupling or their cross‐coupling with a monolignol. In each case, novel tetrahydrofuran (THF) structures result in the lignin instead of the normal resinols; it is these structures that provide the evidence that acylated lignins derive from pre‐acylated monolignols.79, 80, 81 THF structures are present to the almost complete exclusion of the resinol moieties in maize, where essentially all of the β‐β coupling appears to be from sinapyl p‐coumarate dimerisation. Similarly, THF structures are dominant in particularly highly naturally acetylated lignins (such as in curauá) where the monomers are almost exclusively monolignol acetates.80, 82 A gene required for monolignol p‐coumaroylation has been characterised,83, 84, 85, 86 but the genes for analogous p‐hydroxybenzoylation and acetylation remain unknown.

Among other important natural monomers, as reviewed,11, 87, 88, 89 are: dihydroconiferyl alcohol in softwoods that, under the oxidative conditions of lignification, can also produce guaiacylpropan‐1,3‐diols;90, 91, 92 tricin, a flavone from another pathway entirely, only recently identified in grasses.80, 93 In addition, as reviewed,1, 94 ferulates on arabinoxylans, and the dehydrodimers (and higher oligomers) that result from them, must also be considered lignin monomers in the broadest sense, as should the tyramine ferulates that are found incorporated into various of the Solanaceae species (e.g., tobacco, tomato).

Although a wealth of research has contributed to the collective knowledge of biochemical pathways of lignin and phenol derivatives in plants, the interplay between multiple genes (general and plant‐specific) as well as the effects upon lignin biogenesis have only been partially elucidated.8, 11 In this regard, it is perhaps surprising for a pathway that was long ago considered to be fully described, that new enzymes and new pathway steps continue to emerge, for example, the CSE‐catalysed conversion of caffeoyl shikimic or quinic acid to caffeic acid.66

2.3. Bioengineered Lignins

Following biosynthesis of the lignin building blocks, the lignin monomers are transported to the secondary plant cell walls, whereupon they are incorporated into the lignin macromolecular structure via laccase‐/peroxidase‐induced radical polymerisation reactions, affording several structural motifs (Scheme 1).41 The precise roles of laccases/peroxidases in the final polymerisation of lignin monomers are at present only partially understood.41, 61, 64, 70, 124, 125, 126, 127, 128 Laccases, though capable of inducing the radical reactions for the polymerisation of lignin subunits, are many and varied. They perform several functions in plant development, rendering the identification of lignin‐specific laccases difficult.125 Nevertheless, downregulation of various specific laccases has resulted in significantly altered lignification, implying that they certainly play a role in lignification.61, 129, 130 Further investigation is also required to identify individual (or groups of) peroxidases involved in lignin biosynthesis.8 For example, Peroxidase 4 was recently discovered to be involved in syringyl lignin formation in Arabidopsis thaliana,70 but in a mutant, a decrease in the proportion of syringyl units was seen only under optimum lighting conditions, and was also dependent on the age of the plant. This finding highlights the complexity of the interplay of biotic or abiotic stress, and how genetically engineered plants sometimes do not develop the change expected because of factors not related to genetic improvement.131 In this context, some attempts at determining holistic effects (i.e., encompassing bioengineering and an examination of the effects on other pathways, if not on external, “ambient” factors) have been reported.54, 107, 132

Table 2 summarises contemporary research relating to genetic modifications of the phenylpropanoid pathway and effects on plant structure and saccharification yield.

Table 2.

Summary of reported genetic modifications within the phenylpropanoid pathway and their effects on saccharification yield, total lignin content, lignin composition/structure (and/or the effect on metabolites) and plant phenotype; TG (transgenic), M (mutation), ND (not determined).

| Entry | Species | Gene alteration | Type | Compositional/structural change in lignin or metabolites | Effect on lignin content | Saccharif‐ ication yield[a] | Phenotypic effect | Ref. |

|---|---|---|---|---|---|---|---|---|

| 1 | Arabidopsis thaliana | PAL deficient | M | Phe overaccumulation; S/G↑ flavonol glycosides↓ | ↓ | ND | No change | 54 |

| 2 | Brachypodium distachyon | PAL downregulation | TG | S/G↑; ferulate↓ | ↓ | 2×↑ | Delayed development; root growth↓ | 99 |

| 3 | Capsicum annum, C. chinense and Solanum tuberosum | C4H upregulation | TG | S/G↑ | ↓ | ND | Curled leaves, dwarfism, or no change | 55 |

| 4 | Arabidopsis ref3 | C4H deficient | M | S/G↑; New cinnamoylmalate | ↓ | ND | Dwarfism, male sterility, collapsed vasculature | 56 |

| 5 | Populus alba x grandidentata | C3H downregulation | TG | H ≈100×↑; S/G↓ | 50 %↓ | ND | No change | 100 |

| 6 | Lolium perenne | CCR downregulation | TG | No change | ↓ | ↑ | No change | 101 |

| 7 | Arabidopsis thaliana | CCR deficient | M | Ferulic acid‐coniferyl alcohol ether dimers in metabolites; sinapoyl malate ≈4×↓ | 25‐35 %↓ | ND | Dwarfism, delayed senescence | 102 |

| 8 | Pinus radiata | CCR downregulation | TG | Increase of p‐coumaroyl hexose, caffeic acid hexoside and ferulic acid hexoside; H↓ and G↓ | ca. 50 %↓ | ↑ | ND | 67 |

| 9 | Maize | CCR deficient | M | H‐units strongly decreased; S/G slightly↑ | Slight↓ | ↑ | No change | 103 |

| 10 | Nicotiana tabacum | CCR downregulation | TG | S/G↑; β‐O‐4 units↓; introduction of ferulic acid and sinapic acid | ↓ | ↑ | Orange xylem; Less severe: no change; more severe: dwarfism, collapsed vessels | 104 |

| 11 | Populus tremula x Populus alba | CCR downregulation | TG | Ferulic acid incorporated into lignin | 5‐24 %↓ | 15 %↑ | Orange xylem; Less severe: no change; More severe: dwarfism | 105 |

| 12 | Populus tremula x Populus alba | CCR downregulation | TG | Oligolignols↓ | ↓ | ≈20 %↑ | Orange‐coloured wood | 105, 106, 107 |

| 13 | Medicago truncatula | CAD deficient | M | ≈95 % Sinapaldehyde‐ and conifer‐ aldehyde‐derived | Increase in wall‐bound lignin moieties | ND | None at 22 °C; Dwarfed at 30 °C | 43 |

| 14 | Maize | CAD downregulation | TG | S/G↓ | No change | ↑ | No change | 108 |

| 15 | Triticum sinskajae | CAD downregulation | TG | H↓; S/G↑ | No change | ND | Slight dwarfism | 109 |

| 16 | Brachypodium distachyon | CAD deficient | M | Increase in β‐O‐4‐ and 4‐O‐5‐coupled sinapaldehyde units; increase in free phenolic groups | ↓ | ↑ | No change | 110 |

| 17 | Pinus taeda | CAD deficient | M | Incorporation of coniferaldehyde and dihydroconiferyl alcohol; increase in vanillin, ferulic acid, p‐coumaric acid, coniferaldehyde and p‐hydroxybenz‐ aldehyde | ↑ | ↑ | Dark‐brown wood | 91, 92, 93, 94, 95, 96, 97, 98, 99, 100, 101, 102, 103, 104, 105, 106, 107, 108, 109, 110, 111 |

| 18 | Panicum virgatum | CAD downregulation | TG | Hydroxycinnamaldehydes↑ | Lignin↓ and cutin↓ | ↑ | No change | 112 |

| 19 | Koshihikari x Chugoku 117 rice | CAD deficient | TG, M | ND | ↓ | ↑ | No change | 113 |

| 20 | Arabidopsis thaliana | HCT deficient | M | H↑; S≈0; G≈0 | ↓ | ND | Severe dwarfism | 57 |

| 21 | Populus nigra | HCT downregulation | TG | H 17×↑ | No change | ND | Dwarfism | 114 |

| 22 | Medicago sativa | CCoAOMT deficient | TG | Incorporation of 5OH‐CA producing novel 5OH‐G units as benzodioxanes | ≈20 % decrease | ≈10 % increase in cellulose | No change | 42 |

| 23 | Brown midrib‐3 Maize | COMT deficient | M | S/G↓; incorporation of 5OH‐CA producing benzodioxanes | ↓ | Improved | No change | 115 |

| 24 | Arabidopsis thaliana | COMT deficient | M | S/G↓; trimeric moiety 5OHG‐5OHG‐G; benzodioxane linkages | No change | ND | No change | 58 |

| 25 | Saccharum officinarum cv. CP88‐1762 | COMT deficient | M | S↓; p‐coumarate (on lignin)↓ | 6‐12 %↓ | 28‐32 %↑ | No change | 116 |

| 26 | Arabidopsis thaliana | F5H deficient | M | S 70‐75 %↓; G↑ | No change | ND | Lack of 2° wall structure in inter‐fascicular and xylem fibres | 65 |

| 27 | Arabidopsis thaliana | F5H overexpression | TG | ≈100 % S (i.e., G↓, S↑) | ↓ | No change | Decreased plant stiffness | 117, 118 |

| 28 | Arabidopsis thaliana | F5H deficient | M | ≈100 % G (i.e., G↑, S↓) | No change | Decrease | Decreased plant stiffness | 117 |

| 29 | Brassica napus | COMT, C4H, C3H, F5H | TG | No change | 26‐40 % decrease in the seeds | ND | No change | 102 |

| 30 | Arabidopsis thaliana | F5H upregulation; COMT downregulation | TG | Lignin>70 % 5OH‐CA‐derived; ≈90 % benzodioxane units | ↓ | ND | Dwarfism; male sterility | 60, 119 |

| 31 | Arabidopsis thaliana | CCR and CAD deficient | TG | Increase in interunit bonding; incorporation of coniferaldehyde, sinap‐ aldehyde, ferulic acid | 50 %↓ | ↓ | Dwarfism; male sterility | 62 |

| 32 | Arabidopsis thaliana | CSE deficient | M | H↑ | ↓ | 4×↑ | No change | 66 |

| 33 | Populus alba x grandidentata | FMT introduced | TG | Ester linkages introduced into lignin backbone; S/G↑ | Little change | 78 %↑ | No change | 44 |

| 34 | M. sativa | C3H downregulation | TG | H 65×↑ | 50 %↓ | ND | Dwarfism | 120 |

| 35 | Populus tremula x alba | F5H upregulation | TG | 97.4 % S; (i.e., G↓, S↑) | Little change | Pulp yield higher, pulp brighter | No change | 121, 122 |

[a] Measured at low conversion extent; yields at full conversion will not differ.123

In general, downregulation of the genes associated with enzymes responsible for the early steps of phenylpropanoid biosynthesis, i.e., for enzymes PAL, C4H and 4CL (Scheme 1), results in decreased flux through the pathway, and consequently lowers lignin yields (entries 1, 2 and 4). Although researchers long favoured this approach of producing less of the problematic component, plants require lignin, so adverse agronomic effects can result if the lignin reduction is too severe.133

PAL downregulation results in an over‐accumulation of Phe. However, for Arabidopsis thaliana (entry 1), PAL downregulation had no observable impact on the plant phenotype, despite a significant decrease in lignin content. Incorporation of Tyr, as an alternative starting point into the phenylpropanoid pathway, may explain this result.75

3‐Hydroxylation of p‐coumarate by C3H was originally thought to occur at either the acid or the CoA level, until researchers showed the presence of a new enzyme, HCT, in various plants that produce p‐coumaroyl shikimic or quinic acid conjugates that are the preferred substrates of C3H. Following the hydroxylation, HCT was conjectured to return the product to the CoA level as caffeoyl‐CoA. However, again the pathway appears to be more complex as another enzyme, CSE, is now firmly established in some plants as returning the product of the C3H reaction back down to caffeic acid, upon which 4CL must again act to produce the CoA derivative.

The advantage of discovering all of the genes associated with the expression of the enzymes in the biosynthesis of lignin building blocks is that there are now more ways to perturb the system. In general, however, the main result of downregulating HCT, C3H, or CSE is a relative increase in the H‐unit level. Downregulation or deficiency of HCT (Scheme 1, Table 2, entries 20 and 21) leads to a significant decrease in growth, a reduction in the lignin quantity, over‐accumulation of flavonoids, and a predictable rise in the relative level of H‐units. The c3h mutant of Arabidopsis, called ref8, is a particularly stunted plant that does not produce seed but has H‐only lignin. Intriguingly, however, the agronomic issues do not arise from the change to H‐lignin per se—co‐downregulating a pair of mediator genes results in recovery of seed production as well as much of the dwarfing yet retains the novel high‐H lignin characteristics.134

To proceed toward the monolignols, p‐coumaroyl‐CoA, feruloyl‐CoA, and/or sinapoyl‐CoA are first reduced to the corresponding aldehydes (via CCR). CCR‐downregulation has attracted considerable interest (entries 6–12), particularly in Europe, as Arabidopsis and then poplar plants proved to be significantly more readily saccharifiable, and strikingly so even in the absence of a pretreatment.105 Plants show a small growth penalty and have lower lignin levels, but the most intriguing characteristic was that ferulic acid, as a monomer, was shown to be incorporated (at low levels) into the lignins.106, 107 As the incorporation produced novel acetal branch‐points in the polymer, and as acetals are readily cleaved with acid, the analysis of CCR‐deficient plants have produced another strategy for engineering lignins that are easier to chemically degrade.

The enzymatic conversion of coniferaldehyde is an important branching point in the lignin biosynthetic pathway, leading to G‐units (CAD), to S‐units (F5H, COMT and CAD), or back to ferulic acid (HCALDH). The overexpression of F5H with a powerful lignin promoter (entry 27) leads to a lignin almost exclusively composed of S‐units, whereas downregulation or deficiencies in F5H (entry 28) results in a predominance of G‐units.117 However, in both cases in Arabidopsis, a decrease in plant stiffness, caused by the lack of secondary plant wall structure in the interfascicular and xylem fibres, was observed.65 For lignins composed primarily of G‐units, no change in overall lignin content was observed, yet the saccharification yield of the biomass decreased, indicating the formation of a more recalcitrant biomass.117

Two classes of O‐methyltransferases, the so‐called CCoAOMT and COMT enzymes (Scheme 1), are involved in producing the 3‐ and 5‐methoxyl groups on G and S monomers. 5‐Hydroxyconiferaldehyde, when 5‐O‐methylation is deficient, reduces to 5‐hydroxyconiferyl alcohol that is then integrally incorporated into lignins in COMT‐deficient plants (entries 23 and 24). The resulting 5‐hydroxyguaiacyl units react by typical 4‐O‐β‐coupling with any of the hydroxycinnamyl alcohol monomers (the prototypical monolignols or further 5‐hydroxyconiferyl alcohol), but the internal trapping of the intermediate quinone methide product by the novel 5‐OH results in the formation of benzodioxane structures in the polymer.11, 92, 135, 136, 137, 138, 139 Benzodioxane levels can be amplified through a combination of F5H upregulation and COMT downregulation. In Arabidopsis, the resulting plants may incorporate up to ca. 70 % 5‐hydroxyconiferyl alcohol monomer and produce benzodioxane levels of as high as 90 % in the polymer (entry 30). However, the phenotypic outcome at this extreme level was abnormal plant growth.60, 119 CCoAOMT, invoked earlier in the pathway, has a similar effect on guaiacyl units and results in the incorporation of caffeyl alcohol into lignin, but only in softwoods (that do not make S‐lignin);140 attempts to even downregulate both OMTs (and various genes) in hardwoods, or dicots in general, have not produced any authentic evidence for caffeyl alcohol incorporation. Furthermore, other OMTs (or other genes besides those currently targeted) appear to be implicated as even strong downregulation of CCoAOMT and/or COMT results in the production of the normal G and S monolignols, albeit at a lower level.141

The downregulation of CAD, producing the CAD enzyme that is involved in the final step of production of all conventional lignin monomers, often results in the introduction of hydroxycinnamaldehydes into lignification, resulting in various types of atypical unit in the lignin structure (entries 17 and 18). Both coniferaldehyde and sinapaldehyde may be introduced into the lignin structure as monomers in their own right.42, 58, 60, 115 Particularly intriguing was the observation that coniferaldehyde will not, in vitro or in vivo, β‐O‐4‐cross‐couple with G units and is therefore poorly integrated into gymnosperm (G‐only) lignins. In contrast, coniferaldehyde readily cross‐couples with S units so it, and sinapaldehyde that readily cross‐couples with both G and S units, are well incorporated into dicot lignins. Recent CAD misregulation examples show just how high the level of non‐canonical monomers can be tolerated in plants that grow more or less normally, at least under some conditions. A CAD‐deficient mutant of Medicago truncatula has reportedly some 95 % of its lignin derived from hydroxycinnamaldehydes.43 In Arabidopsis, manipulation of the G and S monomer synthesis coupled with CAD deficiency has been examined, again producing plants that have essentially none of their lignin derived from the conventional monolignols, and plants that are derived almost solely from either coniferaldehyde or sinapaldehyde.142

Entirely new or non‐traditional monomers can be utilised in lignification, resulting in novel structures in the lignin polymer. To be completely accurate, some of these are also found in normal wild‐type plants at low levels (by sensitive analytical methods). For example, downregulation/suppression of C4H, C3H, CCR, COMT or CCoAOMT resulted in the incorporation of monomers other than the three H, G, or S monolignols into the lignin structure, regardless of the plant species. The nature of the monomers that are alternatively incorporated in the lignin structure vary between species, but include: ferulic acid;67, 102, 104, 105 coniferaldehyde;43, 62, 111 sinapaldehyde;43, 110, 111 5‐hydroxyconiferyl alcohol (5OH‐CA),42, 44, 58, 115 caffeyl alcohol,140, 143 and monolignol ferulates.44 In addition, various new products, or enhanced levels, arise in the extractable low molecular weight metabolites from actively lignifying tissues. Examples include sinapic acid,104 p‐coumaroyl hexose,67 caffeic acid hexoside,67 and various hydroxycinnamate esters.56 The alternative monomers that have been found incorporated into the lignin structure are summarised in Table 3; the monomers and metabolites are summarised in Scheme 2.

Table 3.

Summary of various alternative monomers incorporated into lignin, and the mutation(s) responsible for their incorporation (Scheme 2).

| Entry | Alternative monomer | Effect on lignin structure | Gene responsible |

|---|---|---|---|

| 1 | Ferulic acid | New acetal branch‐points in lignin | CCR 67, 102, 104, 105 |

| 2 | Sinapaldehyde | Sinapaldehyde integrally incorporated into polymer, enhanced unsaturation, and increased free‐phenolics | CAD 43, 110, 111 |

| 3 | Coniferaldehyde | Coniferaldehyde integrated into polymer chain in G/S lignins only, enhanced unsaturation, increased free‐phenolics | CAD/CAD‐CCR 43, 62, 91, 111 |

| 4 | 5‐Hydroxyconiferyl alcohol | Benzodioxane units in polymer; linear polymer if 100 % 5OHCA | COMT, F5H‐COMT 42, 58, 60, 115 |

| 5 | Caffeyl alcohol | Benzodioxane units in polymer; linear polymer if 100 % caffeyl alcohol | CCoAOMT 140, 143 |

| 6 | Monolignol ferulates | Incorporation of ester linkages into the polymer backbone | FMT (Ferulate monolignol transferase) 1, 44 |

Scheme 2.

Incorporation of non‐native monomers in the lignification process, via genetic modification to the phenylpropanoid biosynthetic pathway (Scheme 1, see asterisked intermediates that are either the new monomers themselves, or give rise to a new monomer via the subsequent transformations shown here). The incorporation of new monomers (highlighted in red) by the same radical coupling modes gives rise to new structures in the lignin polymer (Table 3), mainly as a result of new opportunities for rearomatisation of the intermediate quinone methides: a) In CCoAOMT‐deficient softwoods, caffeyl alcohol is incorporated into the lignins producing benzodioxane structures. Some plants, such as vanilla, make lignin in their seed coats entirely from caffeyl alcohol, producing a polymer that is almost entirely composed of long chains of benzodioxane units. b) Employing a novel monolignol transferase enzyme, FMT, Feruloyl‐CoA can be conjugated to a monolignol, coniferyl alcohol (CA) or sinapyl alcohol (SA), to produce monolignol ferulate conjugates. Formation of labile ester linkages in the lignin polymer backbone can be achieved via lignification with a proportion of its monomer pool as these monolignol ferulate conjugates. Conjugates of this type are incorporated into the lignin structure in the same manner as conventional monomers.1 c) Ferulic acid itself can be formed either via the action of the enzyme HCALDH or by downregulation of CCR (Scheme 1). During lignification, double‐β‐O‐4‐coupling is undergone, to yield acid‐labile acetal bonds in the lignin. d) The intermediate, coniferaldehyde, accumulates in CAD‐deficient plants and can be incorporated into lignins via β‐O‐4‐coupling (shown) as well as other modes (not shown); the β‐O‐4‐coupling product is unsaturated due to the acidity of the β‐proton in the quinone methide intermediate that allows rearomatisation via H‐abstraction. e) In COMT‐deficient angiosperms, the intermediate 5‐hydroxyconiferaldehyde that accumulates can still be reduced by CAD, producing 5‐hydroxyconiferyl alcohol that, like caffeyl alcohol, produces benzodioxane analogues in the lignin. f) Sinapaldehyde also incorporates into lignins in CAD‐deficient angiosperms.

Inspired by three independent findings regarding lignin structure, namely that 1) ferulates were excellent lignin monomers and were implicated in monocot lignification, 2) monolignol conjugates were being used in lignification in certain natural plants, and 3) monolignol substitution was becoming increasingly evident with the study of transgenics, an attempt was made to “redesign lignin for processing”.1, 44

In preliminary model studies, it was estimated that with ca. 25 % incorporation of monolignol ferulate conjugates, the alkaline pulping temperature could be decreased from 160–170 °C to 100 °C for the same degree of delignification.1 At an incorporation level of ca. 65 % (that is likely unattainable), the pulping process on the model system could operate at just 30 °C whilst maintaining equivalent lignin removal from the biomass.1 The insertion of ester linkages into the lignin backbone may feasibly retain the lignin quantity whilst also maintaining the natural function. In a recent investigation,44 it was estimated that cell wall lignin could be augmented with perhaps 7–20 % of its units derived from monolignol ferulates via a specific transferase enzyme, FMT. The genetically modified biomass exhibited increased delignification and higher fibre yields after mild alkaline pretreatments compared to the control. Coniferyl ferulate and sinapyl ferulate monomer conjugates may be incorporated into the lignin macrostructure analogous to that of a dimer of G, S or H units (Scheme 2 b).

In certain instances, similar phenotypic characteristics may be exhibited by the same genetic mutation for different plant species; with Nicotiana tabacum (Table 2, entry 10)104 and Populus tremula x Populus alba (entry 11)105 severe downregulation of CCR results in dwarfed plants, for example. By contrast, the same genetic mutation can also have a profoundly different result depending on the selected plant type: for CAD‐deficient Pinus taeda (entry 17),111 a slightly higher quantity of lignin is observed compared to the wild‐type, yet for CAD‐deficient Koshihikari x Chugoku 117 rice (entry 19),113 a decrease in lignin content occurred. In some cases in which the plant phenotype was not affected, the saccharification yield increased regardless of the lignin content.

2.4. Practical Challenges of Lignin Bioengineering

Currently, the majority of bioengineering strategies have been directed towards decreasing the lignin content in order to achieve higher saccharification yields/improved fermentability. However, to ensure economic feasibility of a biorefinery, the recalcitrance of the lignin fraction must also be considered.1 In light of this consideration, preparation of lignin with a more chemically labile structure (e.g., by incorporating some ester bonds into the backbone of the polymer rather than dealing with the more recalcitrant ether linkages) is an interesting prospect (Scheme 2 b).

Research on plant improvement towards better lignin processing is a non‐trivial task. One major challenge is the time required for production and growth of the biomass. For most softwoods and hardwoods, this is between 5 and 30 years.131 To alleviate this limitation, the bulk of research on lignin bioengineering has been directed towards angiosperms with a shorter life cycle (e.g., the model dicot, Arabidopsis thaliana and, more recently, the model monocot, Brachypodium distachyon). Arabidopsis and Brachypodium are useful models of longer life‐cycle analogues such as Poplar/Aspen and the commercially produced monocots (grasses), exhibiting many similar biochemical and genetic traits. Model plants are valuable for indicating possible directions for genetic alterations. Nevertheless, the strategies still need to be applied to the actual softwood or hardwood trees, or grasses, at some stage of the development, and it is crucial to not assume trait portability between gymnosperms, dicots, and monocots. Differences in the phenotypic behaviour of any one plant species may even vary according to whether the plants are grown in a greenhouse or in the field.131 Application into readily transformable, moderately rapid growing and commercially important plants, is often via Poplar, Aspen, or Eucalypts (for hardwoods), and corn, barley, and switchgrass (for monocots); Loblolly and Radiata pine (Pinus taeda, Pinus radiata) are among the best for applications to softwoods, but the development remains difficult and slow.

Phenotypic alterations (i.e., changes in the morphology, in development, or behaviour) of a plant are common upon perturbing the phenylpropanoid pathway (although specific explanations for individual phenotypic changes are difficult to pinpoint). Dwarfism is typically accompanied by collapsed xylem vessels and, therefore, decreased water transport.43, 56, 57, 60, 62, 65, 102, 104, 105, 109, 114 However, contrary to prior belief, over‐accumulation of flavonoids is not necessarily associated with a decrease in plant growth.13 The precise cause of dwarfism remains elusive.

The challenges associated with predicting plant physiology and long‐term growth performance upon slight genetic modification has led to the proposal of using high‐throughput multi‐trait genetic modification. In this strategy, large numbers of genetically modified plants are screened for favourable growth traits at multiple stages during their life‐cycle.131 Plants are exposed to both biotic and abiotic stresses. Tolerant plants are carried on into further studies (assessed on the basis of growth, saccharifiability, and/or lignin composition) whilst non‐tolerant plants are discarded. This method of high‐throughput screening allows rapid identification of a plant with a lignin that can be chemically deconstructed. After this plant has been discovered, work may then be undertaken to try to identify the genetic changes responsible for the plant improvement. One high‐throughput strategy for multi‐trait genetic engineering, modified to include lignin screening, is illustrated in Scheme 3.131

Scheme 3.

High‐throughput multi‐gene engineering scheme.131 Final field trial stages are of critical importance to identify potential environmental impacts, (e.g., toxicity to insects, impact on soil chemistry). For a thorough review of environmental risk assessments for genetically‐engineered trees, the reader is directed to other literature.154 Adapted from Plant Sci. 2013, 212, 72–101.

Immunostimulatory activities of different lignins depend on their structure, neutral sugar content, molecular weight, and degree of polymerisation.144 Although research has been conducted on the response of lignin to abiotic stress (e.g., drought, salinity, wounding, low temperature, and UV‐B radiation), these studies typically focused on how lignin quantity was affected and not on structural analysis of lignin, therefore there are several pending questions.41 Abiotic stress directly impacts the formation of lignin via the phenylpropanoid and lignin biosynthetic pathways.5, 41, 99, 145, 146, 147, 148, 149, 150, 151 The response of these pathways to abiotic stresses is crucial for understanding the full biological role of lignin in the plant.5, 145 Effects of abiotic stress can be analysed either by individually introducing stresses, e.g., growing the plant in a medium with high salinity),150, 152 or by monitoring how the plants perform in a greenhouse setting vs. in field trials.153 Recent review literature provides a comparison of the impacts of biotic and abiotic stress on plant fitness when transferring from a controlled greenhouse environment to field trials.131 However, even for non‐transgenic tree varieties, it is hard to predict the behaviour and performance of the mature tree from greenhouse analyses.

To conclude, the rational incorporation of chemically‐labile linkages into the chemical structure of lignin represents a promising area of future investigation. Furthermore, developments in “high‐throughput multi‐gene engineering” will aid in identifying specific effective strategies to reduce the recalcitrance of the native lignin polymer. Notably, the wealth of variables associated with each stage of the valorisation stream (and difficulties associated with assigning the observed phenotypic changes to specific biotic or abiotic influences), in conjunction with the highly multidisciplinary nature of the research (from the initial introduction of the genetic mutation through to eventual chemical processing), render any bioengineering strategy challenging. In order to genetically engineer a more chemically deconstructible lignin whilst maintaining full functionality of the plant species, a combination of different types of expertise is required. To achieve this, long‐term research objectives, funding security, and commitment from multiple complementary research teams are mandatory.

2.5. Structural Features of Native Lignins

Over the past three decades, plant biochemists have made significant progress in the understanding and manipulation of genes associated with the expression of enzymes involved in the phenylpropanoid biosynthetic pathway, enabling modification of the prevalence and nature of lignin's building blocks, thus altering the distribution of structural motifs or linkages as well as the content of lignin in the plant biomass. However, manipulation of the biosynthesis of lignin monomers is just one of many key variables of lignification (i.e., the polymerisation of phenylpropanoid units rendering native protolignins). In fact, the concentrations of monolignols are governed not only by their relative prevalence, following their biosyntheses, but also by the transport and diffusion of monomers to the secondary plant cell wall.31 Moreover, other physical stress conditions (e.g., temperature, pressure, salinity and light) may dramatically affect lignification.131 These variables may partially offset the anticipated benefits from genetic manipulation of the phenylpropanoid biosynthetic pathway.

The lignification process is induced by the action of peroxidase and laccase enzymes producing the corresponding phenolic radicals that undergo cross‐coupling reactions to incorporate the monomer units into the growing lignin polymer. Certain peroxidases and laccases are believed to oxidise lignin oligomers directly.155 In these instances, the reaction was suggested to involve a one‐electron transport chain from the active site to the enzyme surface.155, 156 Despite the key roles of peroxidases and laccases in initiating the polymerisation, lignification per se is not an enzyme/protein‐controlled process. In fact, lignification is a “solution‐like” chemical process, as evidenced by the lack of optical activity in native lignins.155, 157 This fact implies that lignification neither occurs in the proximity of an enantioselective enzyme cavity nor is affected by the chiral environment of the surrounding polysaccharides.

Although coupling of lignin monomers into the growing polymer is evidenced to take place in a combinatorial and non‐stereospecific manner, i.e., lacking a specific sequence of monomers,158 there is ample evidence for the cell's control of the composition and structure by altering monomer supply. It was long ago revealed that, in dicots, lignification proceeded from H to G to S (in overlapping regimes) with cell maturity.159 More recently, under optimised conditions (pH 9, 488 nm excitation wavelength), fluorescence microscopy images were able to identify lignins at specific regions in Pine and Poplar cell structures that were likely enriched with G or S units, (Figure 1).160 An investigation of 25 Chinese hardwood biomass species demonstrated similar topochemical patterns of lignin whereby, e.g., in diffuse‐porous hardwoods the vessel cell walls incorporated predominantly guaiacyl (G) lignin yet the fibres were primarily composed of syringyl (S) lignin.161 Softwood lignins are predominantly G, although high‐compression‐wood zones are particularly H‐rich.162, 163 There is little question that harsh and unselective delignification processes will dismantle any such arrangement of enriched domains in hardwoods, affording a more uniform distribution of units in the isolated technical lignins through the recombination of lignin fragments dissolved in the extraction liquor. However, the development of soft delignification methods may represent a novel but challenging strategy to explore for the selective extraction of (H‐), G‐ or S‐type units, with potential for reducing the costs associated with product separation in the catalytic downstream processing of lignin streams.

Figure 1.

Topochemical distribution of likely G (magenta) and S (green) enriched lignin domains of lignocellulose feedstocks: monochrome fluorescence images of Pine (A) and Poplar (B) woods, and; the corresponding images coloured according to the fluorescence emissions (C and D, respectively); spectral image of Salix chilensis demonstrating the difference in guaiacyl and syringyl distributions in vessels and middle lamella from fibre walls (E); uniform distribution of lignin units in Acacia melanoxylon (F) and Eucalyptus nitens (G). The scale bars represent 60 μm. Reproduced with permission from IAWA Journal 2013, 34, 3–19, copyright 2013 Brill.160

The advent of multidimensional NMR methods in the 1980s enabled easier characterisation of complex molecules, including lignins. Short‐range 1H‐13C correlation experiments, such as the now popular Heteronuclear Single‐Quantum Coherence (HSQC) experiment, have taken over from the traditional 1D 1H and 13C experiments that suffered from insufficient resolution to distinguish subtle structural details, and are now widely employed for the investigation of lignin composition and structure. The interested reader is referred to thorough recent review articles on the methodology, potential and limitations of NMR spectroscopy for the characterisation of lignin, even without requiring its isolation from the cell wall.33, 34 HSQC experiments have been instrumental in the identification and (approximate) estimation of the relative abundance of bonding motifs of the types A, B, C, D and F (Scheme 5) and other structural elements that may occur both in untreated native lignins (e.g., spirodienone moieties, derived from β‐1 coupling of a monolignol with a preformed β‐ether unit),164 and residual linkages in the depolymerised material.165 Expansive literature, and two book chapters,31, 166 describe its application to deduce the changes in normal units and to elucidate and validate new products in the many transgenics.

Scheme 5.

Diagram highlighting the bonding motifs and potential linkages as targets for depolymerisation (in green), % occurrence values from the literature, and bond dissociation energies for a range of commonly encountered linkages/bonding motifs in native lignins.177, 178, 179, 180, 186, 187 It is important to point out that many of these % occurrence values, although reported in the literature, are unlikely or even untenable: β‐1 moieties likely do not exceed 1–2 % of all structures (substantially lower than the 9 % reported); it is impossible to encounter 19–27 % of 5‐5‐units in any lignin (it is probably restricted to a maximum of approximately 9 % in softwoods), and; the abundance of 4‐O‐5‐linkages in softwoods is almost certainly much lower than the 4–7 % claimed.

Despite the obvious value of 1H‐13C HSQC NMR spectroscopy for lignin characterisation, the information provided should not be over‐interpreted. The difficulty of performing quantitative analysis is indeed an important limitation of HSQC NMR in general. Semi‐quantitative determination of integral ratios is, however, possible when the 1H‐13C pairs are located in similar chemical environments, e.g., Cα‐Hα signals for lignin sidechains or C2‐H2/C6‐H6 aromatic signals, because 1 J CH assumes similar values under this condition.165, 167, 168 The 1 J CH dependence of polarisation transfer was previously an issue, with cross‐peaks having different response factors. However, various adiabatic variants in particular minimise this problem. Indeed, progress has been achieved for quantitative HSQC NMR, using so‐called QQ‐HSQC and HSQC0, with pulse sequences allowing better quantification of the identified functionalities.169, 170, 171 However, these methods still fail for rapidly and differentially relaxing samples. For example, in lignins, correlation peaks from the more mobile endgroups, including the p‐coumarates and p‐hydroxybenzoates that adorn some lignin sidechains, relax much more slowly than those from units in the polymer backbone and are consequently overestimated by often large factors. Methods for overcoming such issues are still actively sought. Regardless, regular HSQC NMR experiments still offer highly valuable semi‐quantitative, relative information on the linkage abundance, allowing for comparison of lignin structures and whole plant cell compositions.167, 168, 172 It should also be noted that 31P NMR provides quantitative data on the nature of the various OH groups in lignin, and is also capable of quantifying various interunit linkage types in lignins.173

The most common structural element in native lignins is the β‐ether (usually indicated by the letter “A” in HSQC NMR studies of lignins, Scheme 5), accounting for 50–80 % or more of the measurable interunit linkage types. The threo (syn) and erythro (anti) forms of the arylglycerol‐β‐aryl ethers are present in amounts that reflect the kinetics of the proton‐assisted rearomatisation of the quinone methide (by water); β‐guaiacyl ethers form in approximately equal proportions, whereas β‐syringyl ethers form with erythro‐isomers predominating by ca. 3:1; in both cases the thermodynamic ratio is close to 50:50, indicating that lignification is not under thermodynamic control.174, 175 As for all the units in lignins, β‐ether units do not possess any optical activity, implying that both the radical coupling itself and the addition of water to the quinone methide intermediate produce fully racemic products. Lignification is therefore concluded, as originally theorised,176 to be simply a chemical reaction, independent of proteinaceous control.155, 158, 168

DFT calculations performed on molecular models have predicted values of bond dissociation energy (BDE) for the β‐O‐4 bond between 54 and 72 kcal mol−1.177, 178, 179, 180 Notably, substituent effects can have a significant impact on the BDE of a β‐O‐4 bond. For example, oxidation of the α‐hydroxy group to a ketone was found to lower the BDE by 15 kcal mol−1.178

A phenylcoumaran unit B has a five‐membered ring that results from internal trapping of the intermediate quinone methide by the phenolic‐OH following the β‐5 coupling (Scheme 5). Again it is racemic, but the ring‐closure is trans‐selective such that there is only a single isomer of the dimeric unit. DFT calculations predict the α‐O‐4 bond of phenylcoumaran molecular models to have a low value of BDE (50–56 kcal mol−1), suggesting that these structural motifs can easily undergo radical cleavage under conditions of high severity.

Resinol structures C that are formed via β‐β coupling can only occur at the monomer stage, i.e., in dimerisation or crossed dimerisation reactions. In fact, sinapyl alcohol produces syringaresinol as its only authenticated dimer in peroxidase‐H2O2‐catalyzed reactions. Structures A and B can also form directly from the coupling of coniferyl alcohol with another monolignol, but most of these structures in lignin arise from the more common monomer‐oligomer cross‐coupling reactions that extend the polymer chain.155 Biphenyl linkages D from 5‐5‐coupling, that almost always result in dibenzodioxocin structures D2 after addition of the next monolignol to the chain, are only obtained from the coupling of two preformed oligomers.155

In 2001, spirodienone bonding motifs (F) were discovered in the structure of native lignins, shedding light on the divergence within the wood chemistry community regarding the occurrence and frequency of the β‐1 linkage.164 These spirodienone structures are particularly prone to undergo ring opening under mildly acidic conditions, leading to the formation of structures containing solely the β‐1 linkage (Scheme 4). The discovery of spirodienone structures through modern 2D NMR methods illustrates how challenging the structural elucidation of native lignins may be, as the native polymer is modified even by mild isolation methods.

Scheme 4.

Degradation of (native) spirodienone (F) structures under mildly acidic conditions.164

It was recently suggested that the thermodynamics of the radical reactions leading to lignification may govern the selectivity to the formation of different bonding motifs in the native lignins (Figure 2). Dimerisation of lignols was explored by DFT calculations at the M06‐2X/6‐311++G(d,p) level of theory.181 The formation of the β‐O‐4 linkage was predicted to be the most exothermic coupling reaction (for an H‐H or G‐G dimer, approximately 15 kcal mol−1 more favourable than the corresponding 4‐O‐5 linkage). This thermodynamic data concurs with the β‐O‐4 linkage being more abundant than 4‐O‐5 motifs. However, this prediction should not be taken as evidence that lignification is a thermodynamically controlled process. It is also important to bear in mind that 4‐O‐5 units are formed by coupling of oligomers, whereas lignification is mostly the result of sequential addition of monomers to the chain; the formation of β‐ether units would therefore prevail over 4‐O‐5 counterparts, regardless of the thermodynamics. Most importantly, there is convincing evidence that the processes leading to the formation of lignin linkages are instead kinetically controlled, as previously noted.

Figure 2.

Calculated ΔH r ranges for homo‐coupling and cross‐coupling reactions, yielding a variety of lignin linkages and bonding motifs (M06‐2X/6‐311++G(d,p) level of theory). Adapted with permission from J. Phys. Chem. B 2012, 116, 4760–4768.181 Copyright 2012 American Chemical Society.

From the DFT predictions, the enthalpy values for self‐/cross‐coupling reactions of lignols become gradually less exothermic values in the order: β‐O‐4> β‐β> β‐5≫ 5‐5> β‐1> 4‐O‐5.181 Not surprisingly, this ranking contradicts that originated from BDE values (Scheme 5), giving the false impression that β‐O‐4 linkages would be the most stable against homolytic cleavage of the C−O bond. Notably, one should consider that the initial and final states for the studies on BDE and heat of dimerisation of lignols are not identical. Accordingly, these sets of theoretical predictions cannot directly be compared.

The absence, or at least extremely low abundance, of non‐cyclic α‐O‐4 linkages, in addition to the discovery of eight‐membered ring structures D2, constitutes an important update to the classical models of lignin proposed by Nimz (1974)182 and Adler (1977).31, 183 These dibenzodioxocin motifs became recognised as crucial branching points in native lignins.184 However, various researchers have so far found evidence only for structures of type D2 in which the added monolignol unit remains free‐phenolic (to form a “U” type branch).185 Although D2 units could also implicate the joining of three chains, there is currently no evidence that D2 units forms a true “Y” branch. The same can be said for 5‐O‐4‐units in lignins. If this is the case, then native lignins must be thought of as essentially linear, and not branched to any significant degree. Indeed, although lignins are referred to as “polymer networks”, the quantity of condensed structures (i.e., aromatic units linked to others via their 3 or 5 ring positions in ways that form Y‐type structures) occurring in native lignins is now understood to be very low,184, 185 which at least in part explains the ease of depolymerising native lignins. This observation is in strong contrast with technical lignins, for which prior upstream treatment often results in a highly condensed structure (as discussed in further detail later in this review).

The progress made in the identification of native substructures of lignin, elucidated largely by NMR methods and validated using synthetic model compound data, allows for accurate identification of specific linkages/bonding motifs occurring in native lignins. It has been noted that 2D NMR is capable of pinpointing only a fraction of all the linkages because detection by HSQC is limited to C−H fragments a priori, with the technique being blind to other linkage patterns containing non‐protonated tertiary or quaternary carbons, such as in 5‐5 (biaryl) and 4‐O‐5 (biaryl ether) structures.168 However, this is not actually true. Essentially all of the 5‐5‐linked units in native lignins are in the form of dibenzodioxocins D2 that are easily seen, well dispersed and, in principle, quantified. Even the 4‐O‐5 structures leave signatures, because their C2–H2 and C6–H6 correlations are unique (at least in the G‐only softwoods).

Finally, it is important to note that as polymer growth occurs, the likelihood of observing two identical lignin macromolecules becomes vanishingly small.88, 158 On this basis, the sequencing of lignin building blocks in a similar manner as performed for amino acid residues (in “proteomics”) is impossible and, in any case, of limited value for the design of catalytic lignin conversion processes. Strategies for lignin conversion ought to be designed bearing in mind the occurrence of linkage/bonding motifs rather than a specific macromolecular structure. Due to lignin's racemic nature, its complexity, and its largely unknown associations with other cell wall polymers, many macromolecular aspects of the structure remain elusive.

2.6. Structural Features of Technical Lignins

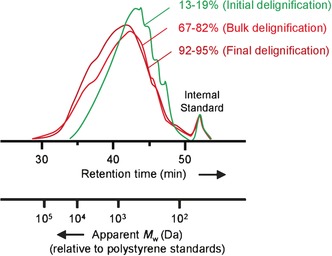

Native lignins undergo extensive chemical transformation as a result of pulping or pretreatment processes. The extent of structural modification hinges upon the process “severity” (i.e., temperature and duration of cooking and concentration of pulping.188, 189, 190, 191, 192, 193 The abundances of different C−O and C−C linkages in technical lignins, therefore, are likely to differ substantially from those determined for the native lignin,190, 194 a realisation that greatly impacts any choices made for further depolymerisation. An example of the impact of pretreatment severity on the nature of the lignin isolated is shown in Figure 3, in which mild acetolysis produces a lignin high in β‐ethers, whereas almost no native lignin identity remains following the harshest pretreatment.

Figure 3.

Influence of pretreatment severity on the nature of a processed lignin as revealed by HSQC NMR spectroscopy. Knowing the method by which a lignin sample is prepared does not yield sufficient information about structural properties—it must be characterised. Here, a comparison is drawn between A) a maize Enzyme Lignin (EL), isolated in the lab, with B–D) lignins that are precipitated from an acetosolv process,195 in which acetic acid is the organic solvent. As can be seen by examining especially the β‐ether A correlations (cyan) but also the general nature of the aromatics, the mild process in (B) produces a rather native‐like lignin, with β‐ethers largely intact, and only a little “distortion” of the aromatics; the “lignin” does however contain significant levels of polysaccharide‐derived material (as seen by the additional grey peaks). With the medium‐severity treatment (C), which uses added mineral acid and a lower level of AcOH, β‐syringyl ethers have disappeared, the β‐ether level in general is lower, more tricin has detached from the polymer, and the aromatics are decidedly more complex. Under the highest severity conditions, in (D), no recognizable structural features (other than methoxyl and general aromatic signals) are evident—it has no β‐ethers. Any or all of these could be marketed as “acetosolv” lignin yet, clearly, those processes that rely on β‐ether cleavage may be wholly effective with the low‐severity material but would be completely worthless against the high‐severity material; material D is not valueless, nevertheless the method for valorisation will be highly different from material B. At some point, when effective processes for lignin utilisation evolve, techno‐economic analysis must be used to optimise the production of not just the sugars or pulp, but also the best lignin component, to fully optimise the profitability of the biorefinery. L:W=liquor to wood ratio. Contours in the NMR spectra, where they are sufficiently well resolved, are color‐coded to match the structures below; overlapping peaks are simply colored gray along with peaks from polysaccharides or other unidentified materials.

Structural characterisation (via 2D NMR and/or chemical degradation methods, e.g., acidolysis, thioacidolysis, etc.) of the technical lignins before catalytic treatment, and any remaining technical lignin after catalytic treatment, must become common practice in this field. The effectiveness of a catalyst either for performing a particular chemical transformation or for the cleavage of a specific linkage can then be better assessed.194 Such a strategy circumvents the difficulties associated with the limitations of simple model compounds. Indeed, these often offer a poor representation of the actual lignin structure (reactions on model compounds are discussed in greater detail later in this review), and such results can thus typically only with difficulty be extrapolated to “real” lignins. Model compounds of high structural fidelity can nonetheless provide valuable insight and aid in the elucidation of changes in the lignin structure upon catalytic processing. For instance, in the oxidation of Kraft lignin with DDQ, the characteristic resinol (from β‐β‐coupling) signal was found to disappear. The reaction performed on a model compound of appropriate complexity allowed for the identification of an unexpected pyron‐4‐one product.196 It is also worth noting that model compounds can be particularly useful for screening for the best reactions and conditions. Thus, although there is no guarantee that a reaction that works well on a model compound will also perform well on an actual lignin sample, the converse is almost always upheld, i.e., it is almost universally true that little is to be expected of a reaction on lignin if that reaction does not perform well on a lignin model compound of sufficient fidelity.

The distinct bonding features of technical lignins are described in the following subsections, describing the predominant structural modifications brought about by Kraft and Organosolv processing and their implications for catalysis. Herein, emphasis is placed on these two specific pulping processes for two main reasons. Firstly, Kraft pulping is operated on a large scale commercially, producing the largest volumes of lignin‐containing streams.197 In addition, the chemistry of Organosolv pulping underpins the novel class of valorisation processes referred to here as “Early‐stage Catalytic Conversion of Lignins” (ECCL)198 or the “Lignin‐first” strategy.277

2.6.1. Kraft Pulping Process

Globally, the Kraft process is the dominant technology of the pulp and paper industry. Approximately 130 million tons of Kraft pulp are generated annually.197 Surprisingly, this technology is one of the few persistent examples of a chemical organic process, performed at a million‐ton‐scale, that is stoichiometric and not catalytic. The Kraft process originated in 1879 in Danzig, Prussia (nowadays Gdańsk in Poland). It is so‐named after the German word for “strength”, because of the superior resilience of the pulps vs. those obtained from the earlier soda and sulfite processes. The long‐term success of the Kraft process lies in the recyclability of the inorganic pulping agents (Na2S/NaOH) and, more recently, in the efficient generation of electricity by the Kraft recovery boiler.197 In the boiler, the black liquor obtained from the pulping step (which contains the lignin fraction) is incinerated and Na2S is regenerated (Na2SO4+2 C→Na2S+2 CO2), i.e., the lignin's carbon is employed as a reducing agent. The boiler produces high‐pressure steam that powers turbo‐generators.197 Modern Kraft mills generate a considerable electricity surplus, which is often sold back to the local electrical grid.199 Considering the global scale of the process (incineration of lignin generates ca. 700 million tons of high‐pressure steam per year),200 Kraft lignin actually constitutes one of the world's most important biofuels.199 Notably, Kraft lignin black liquor represents the largest share of renewable biofuel in the Finnish and Swedish energy matrices.199

Although Kraft lignins currently constitute the largest lignin stream by volume, they are not available commercially in isolated form in the same abundance. This is because the black lignin liquor plays a key role as an internal energy supply and to recover the inorganic chemicals used in the pulping process. Nonetheless, the diversion of a fraction of Kraft lignin away from fuel use and towards the production of bulk, specialty or fine chemicals may be economically viable if the price of a lignin‐derived product exceeds the price of electricity, once all further downstream costs (i.e., for lignin isolation from the alkaline liquor, neutralisation, chemical transformation, product separation and purification) are accounted for. Despite recent advances, there are currently no widespread catalytic processes for the valorisation of Kraft lignins into bulk or fine chemicals. This fact can at least partly be attributed to the highly complex and condensed nature of the Kraft lignin, with a prevalence of highly recalcitrant linkages/bonding motifs in addition to a considerable sulfur content, an established catalyst poison. These properties of Kraft lignins render them challenging feedstocks for downstream catalytic valorisation.

Delignification of wood fibres can be regarded as a heterogeneous process in which lignin is “peeled” away from the residual lignocellulosic matrix via lignin depolymerisation.201 In the Kraft process, the wood fibres are treated with “white liquor” (a 1 mol l −1 NaOH and 0.25–0.70 mol l −1 Na2S aqueous solution) at temperatures of 165–175 °C. The process is maintained at this maximum temperature for 1–2 h, depending on the type of wood feedstock, the desired extent of delignification, and the exact digestion temperature.202 Throughout the pulping process, it is essential to ensure a liquor pH value >10, to avoid re‐deposition of lignin residues onto the remaining cellulosic fibres.203 The degradation and dissolution of lignin fragments from Spruce wood into the cooking liquor, as a function of time and programmed temperature, is displayed in Figure 4 a.188 The quantification of β‐ether units (as inferred from analytical acidolysis) of Kraft lignin from Pinewood, both isolated from the liquor and residual in the pulp (functions of time and programmed temperature), are displayed in Figure 4 b.190

Figure 4.

Reaction profiles for Kraft delignification of two native softwood biomass feedstocks: a) evolution of Spruce wood lignin into the liquor (green) as a function of cooking time and temperature, and; b) the quantification of β‐ethers in Pine wood lignin (quantified via analytical acidolysis), isolated from the liquor (light red) and residual lignin in the pulp (dark red), as a function of cooking time and temperature. For each graph, the programmed temperature (blue) increases steadily up to a fixed maximum of 170 °C.188, 190

The evolution of lignin into the liquor can be categorised into three approximate stages: initial (0–15 %), bulk (15–60 %) and final (60–90 %) delignification (shown for Spruce Kraft lignin in Figure 4 a).188 Analysis of the evolution of β‐ether content in Kraft lignins provides valuable insight into the design of future catalytic valorisation technologies. During initial delignification, the lignin dissolved in the liquor still has significant quantities of β‐ether units (approximately half of that estimated for the residual lignin in the pulp).193 On this basis, it is a reasonable assumption that the lignins following initial treatment will still exhibit good reactivity under mild conditions, as the subunits are linked largely via these relatively weak ether linkages. However, during the bulk delignification stage, the content of β‐ethers drastically decreases for both the liquor‐phase (Kraft) and solid‐residue lignins.190, 203, 204 At the final delignification point, both lignins exhibit approximately one seventh the content of β‐ethers present in the initial native lignin, as inferred from analytical acidolysis data.190 Recent HSQC NMR characterisation has confirmed that some β‐O‐4 and other bonding motifs (e.g., phenylcoumaran (β‐5) and resinol (β‐β) structures) are still present in a Kraft lignin, albeit indeed with very low abundance.196

β‐Ether units predominate in native lignins. Therefore, a substantial level of research has been devoted to understanding the fundamental aspects of β‐ether cleavage under the Kraft processing conditions. Detailed information regarding the mechanisms involved is contained in several recent book chapters.203, 204 Represented in Scheme 6 is a network of reactions underpinning the formation of recalcitrant, highly‐condensed and cross‐linked (C‐C) Kraft lignin from native feedstocks rich in β‐ether (C‐O) linkages.

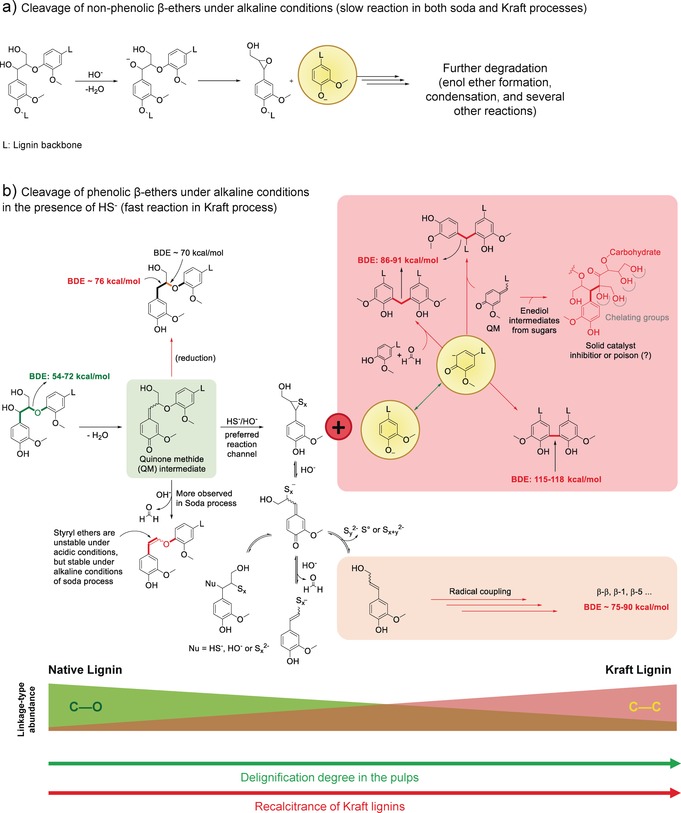

Scheme 6.

Reaction pathways for the conversion of β‐O‐4‐rich native lignins to recalcitrant and highly‐condensed/cross‐linked Kraft lignins via a quinone methide (QM) intermediate (shaded green). The Kraft lignins are characterised by C‐C linkages with high bond dissociation energies (86–118 kcal mol−1, shaded red).203 For clarity, the Scheme depicts only G‐units.

Kraft pulping shares one of its major depolymerising reactions with that of soda pulping, the cleavage of internal, non‐phenolic β‐ethers occurring in native lignins via an epoxide mechanism (Scheme 6 a). The second major depolymerising reaction, which is exclusive to the Kraft process, involves the trapping of quinone methide (QM) intermediates in an essential step in the cleavage of free‐phenolic β‐aryl ethers, including those that get produced by these non‐phenolic β‐ether cleavage reactions (Scheme 6 b).203, 205 Under the conditions of the Kraft process (HS−/OH−), the QM undergoes addition of nucleophilic HS−, followed by the elimination of a phenolate species via anchimeric assistance and formation of a thioepoxide.203 This is the particular reaction that explains the improvement seen upon introduction of sulfide (and the HS− produced during the process) to the earlier soda (NaOH‐only) process. In soda pulping, the retro‐aldol elimination of γ‐CH2OH as formaldehyde from the QM occurs more frequently. Such a transformation leads to styryl ether (sometimes called by the less specific term, vinyl ether) structures that are quite stable under alkaline conditions (but are prone to hydrolysis under acidic conditions).203 More importantly, the formaldehyde released in the soda process can react with any free‐phenolic guaiacyl unit (at its 5‐position) where subsequent o‐QM formation and condensation at C5 with another phenolic unit can result in additional condensation producing diphenylmethane structures (Scheme 6 b, shaded in red).206