Abstract

Iodine-catalyzed selective C-3 benzylation of indoles with benzylic alcohols is developed. The reaction proceeds with molecular iodine as the catalyst under ligand-, metal-, and base-free conditions and tolerates wide functionalities. The experimental observations account for the halogen-bond activation mechanistic pathway for the molecular iodine catalysis.

Introduction

Heterocyclic compounds are the core building units for the design and synthesis of new molecular entities for drug discovery. Among the myriad of bioactive molecules, a large number of molecules encompass indole derivatives.1 Substituted indoles are of immense interest as they found applications as pharmaceuticals, drugs, agrochemicals, and in materials science.2 Most of the biologically relevant indole alkaloids are C-3-substituted, for example, natural amino acid tryptophan and the neurotransmitter serotonin.3

Traditionally, C-3 benzylation of indoles was achieved mainly via Friedel–Crafts reactions or SN2 reaction of benzyl halides with indoles.4 However, the use of a stoichiometric amount of Lewis acids and formation of unwanted by-products reduce the effectiveness of these methodologies.5 Therefore, the demand for mild, efficient, and economic methods for the direct alkylation of indoles remains an area of active research.6

Benzylic alcohols are gaining interest as green alkylating agents as the only by-product generated is water, thereby producing an environmentally benign and clean process7 compared to the use of corresponding halides, esters, carboxylates, or related compounds for this purpose.8

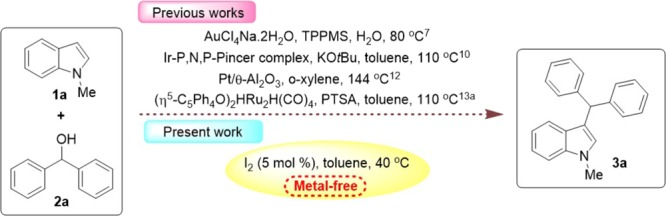

In the past few years, many studies have reported the C-3 benzylation reactions by using expensive transition metal complex based catalytic systems with Fe,9 Ir,10 Au,7 In,8 Pd,11 Pt,12 and Ru,13 which are moisture- and air-sensitive,8,9 and their preparation process needed complex handling10,12 and harsh conditions,8,10,12 which limit their practical utility in a large scale. Some methods required the addition of oxidants, ligands,7,10 bases,9,10 or other additives13 to maximize the catalyst activity and complete their catalytic pathway. Metal-free processes are always favorable in the pharmaceutical industry due to the additional difficulties associated with the metal impurities.14

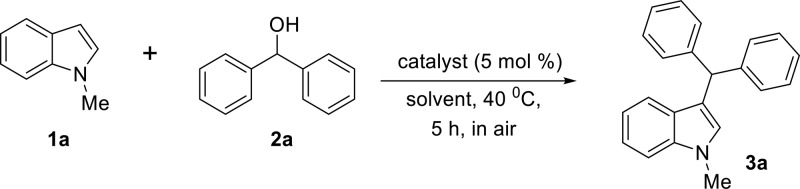

Therefore, there is rising demand for the development of metal-free catalytic systems for C-3 benzylation, which has been less explored to date and will be a beneficial alternative to transition-metal catalysis. Yus and co-workers have reported noncatalytic C-3 alkylation by alcohols through a hydrogen-autotransfer strategy with a stoichiometric amount of base.15 There are reports of C-3 benzylation catalyzed by Br2,16 N-heterocyclic carbene,17 high-temperature water,18 and some Lewis19 and Brønsted acids.20 In recent times, molecular iodine has emerged as a green and environmentally benign reagent and has been successfully employed as a catalyst in different organic transformations forming new C–C, C–N, C–O, and C–S bonds in organic compounds.21 It is naturally abundant, inexpensive, nontoxic, environmentally friendly, and active even in very small amounts.22 Inspired by its catalytic activeness and economic viability,23 we herein report a green, efficient, and economical strategy for C-3 selective benzylation of indoles employing molecular iodine as a catalyst under ligand-, metal-, and base-free conditions (Scheme 1).

Scheme 1. C-3 Benzylation of 1-Methylindole (1a).

Results and Discussion

The studies were initiated with 1-methylindole and diphenylmethanol as substrates to establish the best reaction conditions. It was found that 1-methylindole and diphenylmethanol when treated with molecular iodine (5 mol %) in toluene at 40 °C produced the C-3 benzylated product in 85% yield in 5 h (Table 1, entry 1).

Table 1. Screening of the Effect of Catalysts and Solventsa.

| entry | catalyst | solvent | time (h) | yield (%) |

|---|---|---|---|---|

| 1 | I2 | toluene | 5 | 85 |

| 2 | toluene | 12 | nr | |

| 3b | I2 | toluene | 7 | 83 |

| 4c | I2 | toluene | 7 | 70 |

| 5d | I2 | toluene | 7 | 85 |

| 6e | I2 | toluene | 7 | 65 |

| 7f | I2 | toluene | 7 | 85 |

| 8 | KI | toluene | 12 | nr |

| 9 | I2 | DCM | 7 | 67 |

| 10 | I2 | MeCN | 7 | 72 |

| 11 | I2 | 1,4-dioxane | 7 | 78 |

| 12 | I2 | DMSO | 10 | nr |

| 13 | I2 | DMF | 10 | nr |

| 14 | I2 | H2O | 7 | nr |

| 15 | I2 | MeOH | 7 | nr |

| 16 | I2 | EtOH | 7 | nr |

Reaction conditions: 1a (1.2 equiv), 2a (1 equiv), catalyst (5 mol %), solvent (2 mL), temp (40 °C), time (5 h), in air.

Temp (60 °C).

Catalyst (2 mol %).

Catalyst (10 mol %).

Room temperature.

N2 atmosphere.

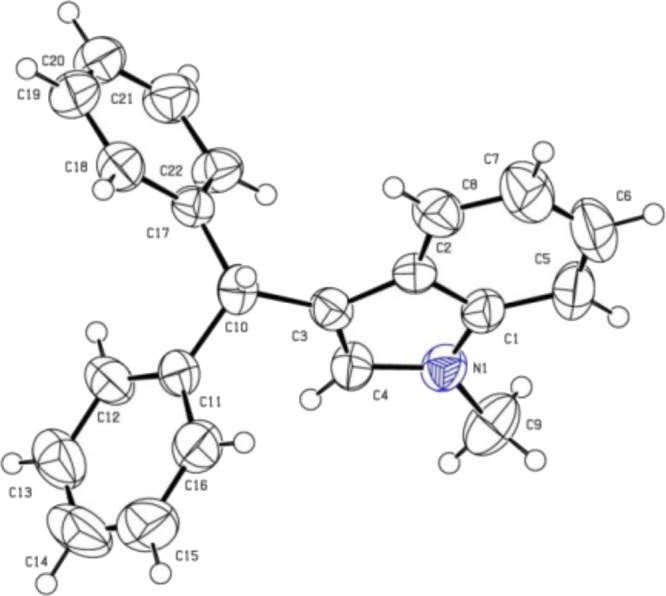

C-3-substituted product formation is confirmed by the presence of characteristic peaks at δ 118.3 (for C-3) and 127.4 (for C-2) in 13C{1H} NMR (100 MHz, CDCl3).7 The single-crystal structure of 3a further confirms the C-3 selectivity of the reaction. The crystal structure is solved and refined in the orthorhombic space group Pna21, with one symmetry independent molecule in the lattice ORTEP with 50% probability ellipsoids displayed in Figure 1. Details of the single-crystal X-ray data collection method, crystal data parameter table, CIF, and Check CIF report are available in the Supporting Information.

Figure 1.

Single-crystal structure of 3a.

No desired product was observed in the absence of the I2 catalyst even after 12 h (Table 1, entry 2). Hence in order to study the activity of iodine as a catalyst, reactions were performed by varying the amount of catalyst. Use of 2 mol % catalyst gave lower yield (Table 1, entry 4), and an increased amount of 10 mol % catalyst gave no significant improvement in the yield (Table 1, entry 5). The highest activity was observed using 5 mol % catalyst (Table 1, entry 1). In order to study the effect of temperature, the reactions were performed by varying the conditions at rt, 40 °C, and 60 °C, and the best result was observed at 40 °C (Table 1, entries 1, 3, and 6). Performing under a N2 atmosphere produced similar results indicating no role of oxygen in the reaction (Table 1, entry 7). The effects of other iodine-containing additives were investigated at 40 °C, and no reaction was observed with 5 mol % KI (Table 1, entry 8), which proved the effectiveness of I2 as a catalyst for the current protocol. Most of the aprotic solvents such as toluene, DCM, MeCN, and 1,4-dioxane resulted in acceptable yields (Table 1, entries 1, and 9–11) except for DMSO and DMF where no product formation was observed even after extended reaction times (Table 1, entries 12 and 13). In contrast, no reaction proceeded at all in protic solvents such as H2O, MeOH, and EtOH (Table 1, entries 14–16). From the study of the influence of the solvent on the reaction, some important conclusions on the mode of iodine catalysis can be drawn. In the presence of protic solvents, iodine is known to decompose slowly to form Brønsted acid HI, which is responsible for further reaction catalysis.21 However, from the observations of Table 1, no reaction proceeded at all in protic solvents such as H2O, MeOH, and EtOH (Table 1, entries 14–16), which clearly rules out the contribution of Brønsted acid mode of catalysis by molecular iodine. On the other hand, iodine in most aprotic solvents gave acceptable yields (Table 1, entries 1 and 9–11), which accounts for the halogen-bond activation mechanism of molecular iodine.21 It also explains why no product formation was observed in DMSO and DMF despite being aprotic solvents as they are expected to form strong halogen bonds with molecular iodine resulting in deactivation of the catalyst for further reaction.21 The reaction did not require any external base or additives.

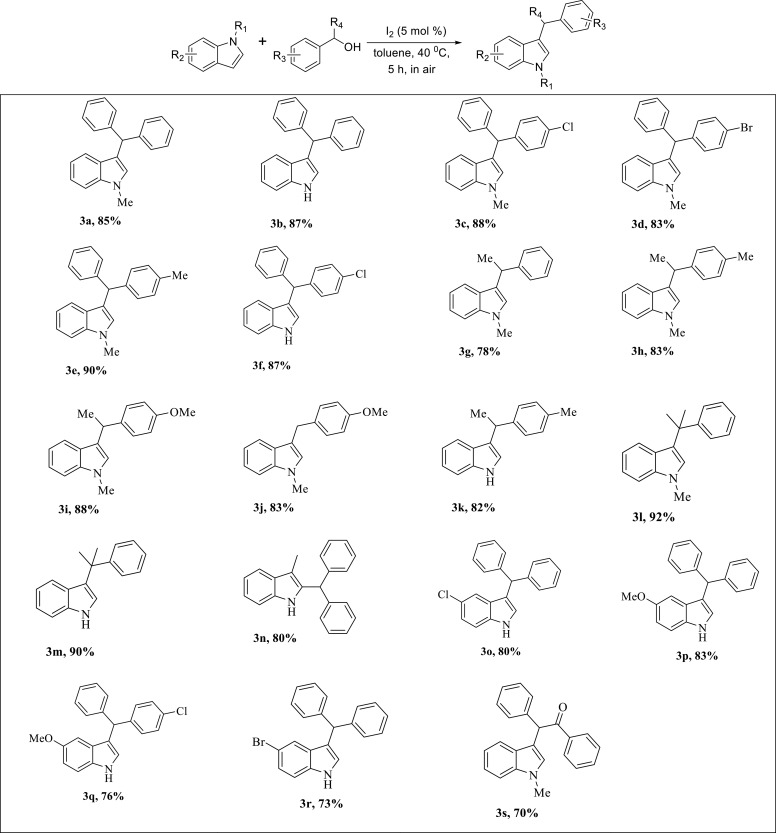

The scope and limitations of the C-3 benzylation of indoles were investigated based on electronically diverse indole and benzyl alcohol derivatives. The results are summarized in Scheme 2. Benzyl alcohols with both electron-donating substituents such as Me and OMe (Scheme 2: 3e, 3h–3k) and electron-withdrawing substituents such as Cl and Br (Scheme 2: 3c, 3d, 3f, 3q) afforded products in good yields (70–92%). Primary benzylic alcohols with electron-donating substituents (OMe) resulted in the desired product in 83% yield (Scheme 2: 3j), whereas electron-poor or unsubstituted primary benzylic alcohols resulted in no reaction. This observation can be explained by the increased stability of intermediate species formed during the process in the presence of electron-rich benzylic systems. In contrast, secondary benzylic alcohols bearing both electron-donating and electron-withdrawing groups afforded the benzylated products in 80–90% yield (Scheme 2: 3a–3i, 3k). Tertiary benzylic alcohols showed highest reactivity and resulted in the desired products in 90–92% yield (Scheme 2: 3l, 3m), which can be attributed to the carbocation stability. Interestingly, if the 3-position of indole is preoccupied, the reaction proceeds at the 2-position (Scheme 2: 3n). Sensitive functionalities such as Br, Cl, carbonyl, and OMe remained unaffected under the reaction conditions. The protocol was also examined for chain alkyl alcohol but produced no significant result.

Scheme 2. C-3 Benzylation of Indole with Benzyl Alcohols.

Reaction conditions: indole (1.2 equiv), alcohol (1 equiv), iodine (5 mol %), toluene (2 mL), temp (40 °C), time (5 h), in air.

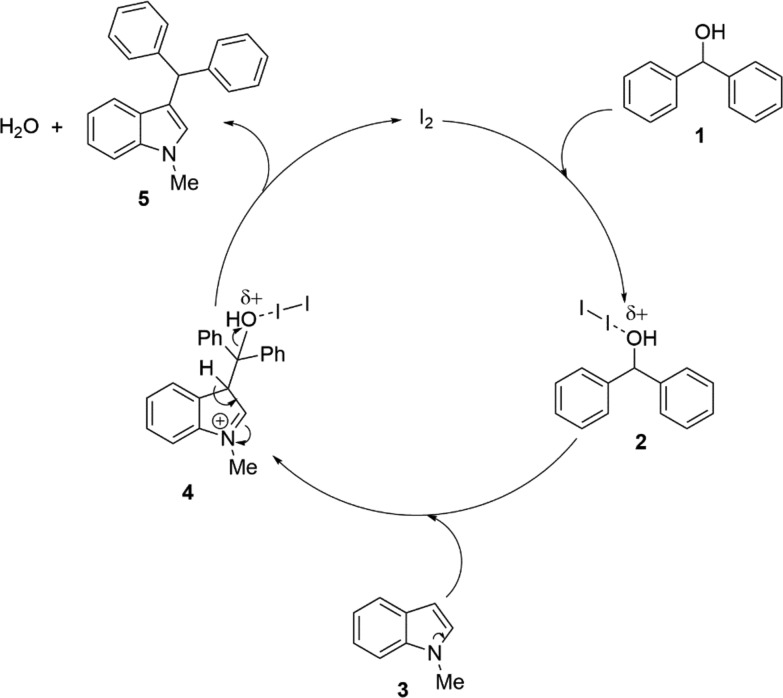

From Table 1, it was observed that no reaction proceeds in protic solvents due to the decomposition of iodine into HI ruling out Brønsted acid mode of catalysis. To experimentally prove the contribution of the halogen-bond activation mechanism of molecular iodine in our catalytic pathway, the following experiments were performed. 1-Methylindole and diphenylmethanol when treated with molecular iodine in toluene at 40 °C produced the C-3 benzylated product in 85% yield in 5 h (Table 2, entry 1). On the other hand, addition of aqueous HI (57 wt %) produced only 26% of the desired product, which supported our earlier observation on solvent effects and excluded the contribution of Brønsted acid mode of catalysis for the reaction pathway (Table 2, entry 5). We analyzed the influence of trace amounts of water (the amount of water present in aqueous HI) in the reaction on the catalytic activity of molecular iodine and observed no comparable change in reactivity (Table 2, entry 2). The catalytic activity of molecular iodine is suppressed by the addition of KI due to the formation of triiodide ions,24 which is evident from the lowered reaction yield (Table 2, entry 3) whereas the activity of HI remains unchanged (Table 2, entry 6). Addition of a molecular sieve (25 mg) resulted in no change in reactivity of molecular iodine (Table 2, entry 4) indicating no moisture sensitivity.

Table 2. Comparative Study of I2 and HI Mode of Catalysisa.

Reaction conditions: 1-methylindole (1.2 equiv), diphenylmethanol (1 equiv), catalyst (5 mol %), solvent (2 mL), temperature (40 °C), time (5 h), in air.

28 mol % water.

1 equiv of KI.

From the experimental observations and literature findings, a plausible mechanism has been proposed as shown in Scheme 3. The first step is expected to be the activation of alcohol by iodine forming a halogen bond between the oxygen of benzyl alcohol 1 and molecular iodine.21a The oxygen atom of the alcohol bears a partial positive charge due to the halogen bonding and forms an intermediate species as shown in 2, which is stabilized by the resonance effect (+R effect) of the phenyl rings attached to the nearby secondary carbon center. In the presence of strong π-nucleophile indole 3, an electrophilic substitution reaction takes place at the C-3 position of the indole ring (the most nucleophilic center on the indole nucleus) to form an intermediate species 4, which undergoes rearomatization to form 3-benzylated indole 5 with elimination of water and regeneration of molecular iodine to complete the catalytic cycle. No generation of any other side products in the reaction was observed. The stability of the intermediate species 2 can be increased by introducing electron-donating substituents to the phenyl rings or using tertiary benzyl alcohols.

Scheme 3. Plausible Mechanism.

Conclusions

In summary, we have developed a protocol for the C-3 selective benzylation of indoles with benzylic alcohols employing molecular iodine as a green catalyst. Our protocol is simple and environmentally benign and proceeds under ligand-, metal-, and base-free conditions. The mild conditions and wide functional group tolerance make the protocol suitable for further applications.

Experimental Section

General Information

All reactions were carried out using Tarsons Spinot digital magnetic stirrers under standard conditions. Analytical thin layer chromatography (TLC) was carried out on Merck silica gel 60F254 plates using short wave (254 nm) UV light. Column chromatography purifications were performed over silica gel (100–200 mesh). 1H and 13C{1H} NMR spectra were recorded on a JEOL JNM ECS NMR spectrometer (400 and 100 MHz, respectively) using CDCl3 as the solvent and TMS as the internal standard. Chemical shifts (δ) are reported in parts per million (ppm) relative to the central peak of the solvent. Multiplicities are indicated as s (singlet), d (doublet), t (triplet), q (quartet), m (multiplet), dd (doublet of doublet), and br (broad). Coupling constants (J values) are given in hertz (Hz). HRMS data were recorded via electrospray ionization with a Q-TOF mass analyzer. Single-crystal X-ray diffraction spectra were collected on a Bruker SMART APEX-II CCD diffractometer using Mo Kα (λ =0.71073 Å) radiation. Melting points were recorded in a digital melting point apparatus and are uncorrected. All chemicals used were purchased commercially and used without further purification. Solvents used for extraction and chromatographic separations were distilled prior use.

General Procedure for C-3 Benzylation of Indoles with Benzylic Alcohols

A round-bottom flask was charged with indole 1 (1 mmol) and alcohol 2 (0.8 mmol) in the presence of 5 mol % (0.05 mmol, 12.6 mg) molecular iodine (I2) in toluene (2 mL) at 40 °C for 5 h. After completion of reaction (confirmed by TLC), the reaction mixture was poured into water and extracted with ethyl acetate. The organic layer was dried over Na2SO4 and concentrated under reduced pressure. The residue was purified by column chromatography (silica gel, hexane/ethyl acetate) to give the desired products 3a–3s.

3-Benzhydryl-1-methyl-1H-indole (3a)

Following the general procedure, 3a was obtained as a white solid, 252 mg, 85% yield; mp 142–144 °C; 1H NMR (400 MHz, CDCl3): δ 7.26–7.18 (m, 13H), 6.97–6.92 (m, 1H), 6.35 (s, 1H), 5.64 (s, 1H), 3.64 (s, 3H); 13C{1H} NMR (100 MHz, CDCl3): δ 144.1, 137.4, 129.0, 128.7, 128.2, 127.4, 126.1, 121.6, 120.0, 118.8, 118.3, 109.1, 48.8, 32.6.

3-Benzhydryl-1H-indole (3b)

Following the general procedure, 3b was obtained as a white solid, 246 mg, 87% yield; mp 121–123 °C; 1H NMR (400 MHz, CDCl3): δ 7.94 (s, 1H), 7.35 (d, J = 8.2 Hz, 1H), 7.30–7.14 (m, 12H), 6.98 (t, J = 7.3 Hz, 1H), 6.57 (s, 1H), 5.67 (s, 1H); 13C{1H} NMR (100 MHz, CDCl3): δ 143.9, 136.7, 135.7, 129.0, 128.3, 127.0, 126.2, 124.0, 122.1, 119.9, 119.4, 111.0, 48.8.

3-[(4-Chlorophenyl)(phenyl)methyl]-1-methyl-1H-indole (3c)

Following the general procedure, 3c was obtained as a colorless liquid, 292 mg, 88% yield; 1H NMR (400 MHz, CDCl3): δ 7.30–7.14 (m, 12H), 6.98 (t, J = 7.3 Hz, 1H), 6.38 (s, 1H), 5.63 (s, 1H), 3.69 (s, 3H); 13C{1H} NMR (100 MHz, CDCl3): δ 143.6, 142.6, 137.4, 131.9, 130.3, 128.9, 128.7, 128.4, 127.1, 126.4, 121.8, 119.8, 118.9, 117.7, 109.2, 48.1, 32.7.

3-[(4-Bromophenyl)(phenyl)methyl]-1-methyl-1H-indole (3d)

Following the general procedure, 3d was obtained as a colorless liquid, 312 mg, 83% yield; 1H NMR (400 MHz, CDCl3): δ 7.38 (d, J = 8.7 Hz, 2H), 7.27–7.25 (m, 3H), 7.20–7.17 (m, 5H), 7.09 (d, J = 8.2 Hz, 2H), 6.97 (t, J = 8.2 Hz, 1H), 6.38 (s, 1H), 5.60 (s, 1H), 3.67 (s, 3H); 13C{1H} NMR (100 MHz, CDCl3): δ 143.5, 143.2, 137.5, 131.3, 130.7, 128.9, 128.7, 128.4, 127.2, 126.4, 121.8, 120.0, 119.8, 118.9, 117.7, 109.2, 48.2, 32.6.

1-Methyl-3-[phenyl(p-tolyl)methyl]-1H-indole (3e)

Following the general procedure, 3e was obtained as a colorless liquid, 280 mg, 90% yield; 1H NMR (400 MHz, CDCl3): δ 7.27–7.15 (m, 8H), 7.09 (q, J = 8.2 Hz, 4H), 6.96 (t, J = 7.8 Hz, 1H), 6.39 (s, 1H), 5.63 (s, 1H), 3.68 (s, 3H), 2.32 (s, 3H); 13C{1H} NMR (100 MHz, CDCl3): δ 144.4, 141.1, 137.5, 135.6, 129.0, 128.9, 128.7, 128.2, 127.4, 126.1, 121.6, 120.0, 118.8, 118.5, 109.1, 48.4, 32.6, 21.0.

3-[(4-Chlorophenyl)(phenyl)methyl]-1H-indole (3f)

Following the general procedure, 3f was obtained as a colorless liquid, 276 mg, 87% yield; 1H NMR (400 MHz, CDCl3): δ 7.96 (br s, 1H), 7.34 (d, J = 8.2 Hz, 1H), 7.29–7.13 (m, 11H), 6.98 (t, J = 7.8 Hz, 1H), 6.54 (s, 1H), 5.62 (s, 1H); 13C{1H} NMR (100 MHz, CDCl3): δ 143.4, 142.4, 136.7, 132.0, 130.3, 128.9, 128.4, 126.8, 126.4, 124.0, 122.2, 119.8, 119.5, 119.4, 111.1, 48.2.

1-Methyl-3-(1-phenylethyl)-1H-indole (3g)

Following the general procedure, 3g was obtained as a colorless liquid, 183 mg, 78% yield; 1H NMR (400 MHz, CDCl3): δ 7.36 (d, J = 7.8 Hz, 1H), 7.30–7.24 (m, 5H), 7.21–7.14 (m, 2H), 6.99 (t, J = 7.8 Hz, 1H), 6.82 (s, 1H), 4.36 (q, J = 6.9 Hz, 1H), 3.73 (s, 3H), 1.69 (d, J = 7.3 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3): δ 146.9, 137.3, 128.3, 127.4, 127.2, 125.9, 125.8, 121.5, 120.0, 119.7, 118.6, 109.1, 36.9, 32.6, 22.5.

1-Methyl-3-[1-(p-tolyl)ethyl]-1H-indole (3h)

Following the general procedure, 3h was obtained as a colorless liquid, 206 mg, 83% yield; 1H NMR (400 MHz, CDCl3): δ 7.38 (d, J = 7.8 Hz, 1H), 7.25 (t, J = 8.2 Hz, 1H), 7.17 (t, J = 7.8 Hz, 3H), 7.07 (d, J = 7.8 Hz, 2H), 6.99 (t, J = 7.3 Hz, 1H), 6.82 (s, 1H), 4.33 (q, J = 6.9 Hz, 1H), 3.73 (s, 3H), 2.30 (s, 3H), 1.67 (d, J = 6.9 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3): δ 143.9, 137.3, 135.2, 129.0, 127.3, 127.2, 125.8, 121.4, 120.1, 119.7, 118.5, 109.0, 36.4, 32.6, 22.6, 21.0.

3-[1-(4-Methoxyphenyl)ethyl]-1-methyl-1H-indole (3i)

Following the general procedure, 3i was obtained as a colorless liquid, 233 mg, 88% yield; 1H NMR (400 MHz, CDCl3): δ 7.36 (d, J = 8.2 Hz, 1H), 7.26–7.14 (m, 4H), 6.99 (t, J = 7.3 Hz, 1H), 6.82–6.79 (m, 3H), 4.32 (q, J = 6.9 Hz, 1H), 3.76 (s, 3H), 3.73 (s, 3H), 1.66 (d, J = 7.3 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3): δ 157.7, 139.1, 137.3, 128.3, 127.2, 125.8, 121.4, 120.3, 119.8, 118.5, 113.6, 109.0, 55.2, 36.0, 32.6, 22.6.

3-(4-Methoxybenzyl)-1-methyl-1H-indole (3j)

Following the general procedure, 3j was obtained as a colorless liquid, 208 mg, 83% yield; 1H NMR (400 MHz, CDCl3): δ 7.51 (d, J = 7.8 Hz, 1H), 7.27 (d, J = 8.2 Hz, 1H), 7.23–7.18 (m, 3H), 7.06 (t, J = 7.3 Hz, 1H), 6.82 (d, J = 8.2 Hz, 2H), 6.72 (s, 1H), 4.04 (s, 2H), 3.78 (s, 3H), 3.71 (s, 3H); 13C{1H} NMR (100 MHz, CDCl3): δ 157.7, 137.1, 133.5, 129.5, 127.8, 127.0, 121.5, 119.2, 118.7, 114.7, 113.7, 109.1, 55.2, 32.5, 30.6.

3-[1-(p-Tolyl)ethyl]-1H-indole (3k)

Following the general procedure, 3k was obtained as a colorless liquid, 193 mg, 82% yield; 1H NMR (400 MHz, CDCl3): δ 7.88 (br s, 1H), 7.37 (d, J = 7.8 Hz, 1H), 7.31 (d, J = 8.2 Hz, 1H), 7.18–7.15 (m, 2H), 7.12 (d, J = 7.3 Hz, 1H), 7.07 (d, J = 7.8 Hz, 2H), 6.99 (t, J = 7.3 Hz, 2H), 4.33 (q, J = 7.3 Hz, 1H), 2.29 (s, 3H), 1.68 (d, J = 7.3 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3): δ 143.8, 136.6, 135.3, 129.0, 127.3, 126.9, 121.9, 121.7, 121.0, 119.7, 119.1, 111.0, 36.5, 22.5, 21.0.

1-Methyl-3-(2-phenylpropan-2-yl)-1H-indole (3l)

Following the general procedure, 3l was obtained as a colorless liquid, 229 mg, 92% yield; 1H NMR (400 MHz, CDCl3): δ 7.35 (d, J = 7.3 Hz, 2H), 7.25 (q, J = 8.2 Hz, 3H), 7.14 (q, J = 7.3 Hz, 2H), 7.04 (d, J = 8.2 Hz, 1H), 6.94 (s, 1H), 6.86 (t, J = 7.3 Hz, 1H), 3.77 (s, 3H), 1.76 (s, 6H); 13C{1H} NMR (100 MHz, CDCl3): δ 150.0, 137.7, 127.9, 126.4, 125.49, 125.46, 124.5, 121.3, 121.1, 118.3, 109.1, 38.9, 32.6, 30.7.

3-(2-Phenylpropan-2-yl)-1H-indole (3m)

Following the general procedure, 3m was obtained as a colorless liquid, 211 mg, 90% yield; 1H NMR (400 MHz, CDCl3): δ 7.83 (br s, 1H), 7.35–7.29 (m, 3H), 7.25–7.20 (m, 2H), 7.16–7.03 (m, 4H), 6.86 (t, J = 7.8 Hz, 1H), 1.76 (s, 6H); 13C{1H} NMR (100 MHz, CDCl3): δ 149.9, 137.1, 128.0, 126.4, 126.1, 126.0, 125.5, 121.6, 121.3, 120.5, 118.8, 111.0, 38.9, 30.6.

2-Benzhydryl-3-methyl-1H-indole (3n)

Following the general procedure, 3n was obtained as a colorless liquid, 237 mg, 80% yield; 1H NMR (400 MHz, CDCl3): δ 7.54 (d, J = 8.7 Hz, 1H), 7.46 (s, 1H), 7.33–7.09 (m, 14H), 5.77 (s, 1H), 2.17 (s, 3H); 13C{1H} NMR (100 MHz, CDCl3): δ 142.1, 135.2, 135.1, 129.4, 129.0, 128.7, 126.8, 121.3, 119.2, 118.4, 110.6, 108.2, 48.5, 8.6.

3-Benzhydryl-5-chloro-1H-indole (3o)

Following the general procedure, 3o was obtained as a colorless liquid, 254 mg, 80% yield; 1H NMR (400 MHz, CDCl3): δ 7.97 (br s, 1H), 7.30–7.19 (m, 12H), 7.11 (dd, J = 8.2, 1.4 Hz, 1H), 6.58 (s, 1H), 5.60 (s, 1H); 13C{1H} NMR (100 MHz, CDCl3): δ 143.5, 135.0, 128.9, 128.4, 128.1, 126.4, 125.4, 125.1, 122.5, 119.7, 119.2, 112.0, 48.5. HRMS (ESI/Q-TOF) m/z: [M – H]+ calcd for C21H15ClN 316.0893; found 316.0936.

3-Benzhydryl-5-methoxy-1H-indole (3p)

Following the general procedure, 3p was obtained as a colorless liquid, 260 mg, 83% yield; 1H NMR (400 MHz, CDCl3): δ 7.85 (br s, 1H), 7.30–7.20 (m, 11H), 6.82 (dd, J = 8.7, 2.3 Hz, 1H), 6.62 (d, J = 2.3 Hz, 1H), 6.55 (d, J = 1.4 Hz, 1H), 5.61 (s, 1H), 3.65 (s, 3H); 13C{1H} NMR (100 MHz, CDCl3): δ 153.7, 143.8, 131.8, 129.0, 128.3, 127.4, 126.2, 124.8, 119.6, 112.1, 111.7, 101.9, 55.8, 48.8. HRMS (ESI/Q-TOF) m/z: [M + H]+ calcd for C22H20NO 314.1545; found 314.1538.

3-[(4-Chlorophenyl)(phenyl)methyl]-5-methoxy-1H-indole (3q)

Following the general procedure, 3q was obtained as a colorless liquid, 264 mg, 76% yield; 1H NMR (400 MHz, CDCl3): δ 8.07 (br s, 1H), 7.35–7.11 (m, 11H), 6.86 (dd, J = 8.7, 2.3 Hz, 1H), 6.49 (s, 1H), 5.81 (s, 1H), 3.85 (s, 3H); 13C{1H} NMR (100 MHz, CDCl3): δ 154.2, 143.4, 142.2, 133.3, 130.9, 130.3, 128.9, 128.63, 128.58, 128.4, 127.9, 126.5, 124.8, 112.3, 111.7, 102.3, 55.8, 48.2. HRMS (ESI/Q-TOF) m/z: [M + H]+ calcd for C22H19ClNO 348.1155; found 348.1098.

3-Benzhydryl-5-bromo-1H-indole (3r)

Following the general procedure, 3r was obtained as a colorless liquid, 264 mg, 73% yield; 1H NMR (400 MHz, CDCl3): δ 7.96 (br s, 1H), 7.35 (s, 1H), 7.30–7.19 (m, 12H), 6.57 (s, 1H), 5.60 (s, 1H); 13C{1H} NMR (100 MHz, CDCl3): δ 143.5, 135.3, 128.9, 128.7, 128.4, 126.4, 125.2, 125.0, 122.3, 119.6, 112.7, 112.5, 48.5.

2-(1-Methyl-1H-indol-3-yl)-1,2-diphenylethan-1-one (3s)

Following the general procedure, 3s was obtained as an orange liquid, 227 mg, 70% yield; 1H NMR (400 MHz, CDCl3): δ 8.05 (d, J = 7.3 Hz, 2H), 7.49 (t, J = 7.3 Hz, 2H), 7.38 (t, J = 8.2 Hz, 4H), 7.29 (t, J = 7.3 Hz, 3H), 7.21 (t, J = 6.4 Hz, 2H), 7.07 (t, J = 7.3 Hz, 1H), 6.88 (s, 1H), 6.27 (s, 1H), 3.68 (s, 3H); 13C{1H} NMR (100 MHz, CDCl3): δ 198.4, 139.1, 137.2, 136.9, 132.9, 129.0, 128.8, 128.6, 128.5, 128.4, 127.0, 121.9, 119.3, 118.8, 112.7, 109.4, 50.5, 32.8. HRMS (ESI/Q-TOF) m/z: [M + H]+ calcd for C23H20NO 326.1545; found 326.1525.

Acknowledgments

Financial support from the Department of Science and Technology, New Delhi is acknowledged (No. EMR/2016/005944). Authors are also grateful to Dr. Bipul Sarma and Mr. Biraj Jyoti Borah, Department of Chemical Sciences, Tezpur University, for studies on the single-crystal structure.

Supporting Information Available

The Supporting Information is available free of charge on the ACS Publications website at DOI: 10.1021/acsomega.9b01481.

Accession Codes

CCDC 1893717 contains the supplementary crystallographic data for this paper. These data can be obtained free of charge via www.ccdc.cam.ac.uk/data_request/cif, or by emailing data_request@ccdc.cam.ac.uk, or by contacting The Cambridge Crystallographic Data Centre, 12 Union Road, Cambridge CB2 1EZ, UK; fax: +44 1223 336033.

The authors declare no competing financial interest.

Supplementary Material

References

- a Chen M.; Shao C.-L.; Fu X.-M.; Xu R.-F.; Zheng J.-J.; Zhao D.-L.; She Z.-G.; Wang C.-Y. Bioactive Indole Alkaloids and Phenyl Ether Derivatives from a Marine-Derived Aspergillus sp. Fungus. J. Nat. Prod. 2013, 76, 547–553. 10.1021/np300707x. [DOI] [PubMed] [Google Scholar]; b Sashidhara K. V.; Kumar M.; Sonkar R.; Singh B. S.; Khanna A. K.; Bhatia G. Indole-based fibrates as potential hypolipidemic and antiobesity agents. J. Med. Chem. 2012, 55, 2769–2779. 10.1021/jm201697v. [DOI] [PubMed] [Google Scholar]

- Shiri M. Indoles in Multicomponent Processes (MCPs). Chem. Rev. 2012, 112, 3508–3549. 10.1021/cr2003954. [DOI] [PubMed] [Google Scholar]

- Homer J. A.; Sperry J. Mushroom-derived indole alkaloids. J. Nat. Prod. 2017, 80, 2178–2187. 10.1021/acs.jnatprod.7b00390. [DOI] [PubMed] [Google Scholar]

- a Rueping M.; Nachtsheim B. J. A review of new developments in the Friedel–Crafts alkylation – From green chemistry to asymmetric catalysis. Beilstein J. Org. Chem. 2010, 6, 6. 10.3762/bjoc.6.6. [DOI] [PMC free article] [PubMed] [Google Scholar]; b Herrera R. P.; Sgarzani V.; Bernardi L.; Ricci A. Catalytic enantioselective Friedel–Crafts alkylation of indoles with nitroalkenes by using a simple thiourea organocatalyst. Angew. Chem. 2005, 117, 6734–6737. 10.1002/ange.200500227. [DOI] [PubMed] [Google Scholar]

- Bandini M.; Umani-Ronchi A. Eds.; Catalytic Asymmetric Friedel-Crafts Alkylations; Wiley-VCH: Weinheim, 2009. [Google Scholar]

- Westermaier M.; Mayr H. Electrophilic allylations and benzylations of indoles in neutral aqueous or alcoholic solutions. Org. Lett. 2006, 8, 4791–4794. 10.1021/ol0618555. [DOI] [PubMed] [Google Scholar]

- Hikawa H.; Suzuki H.; Azumaya I. Au(III)/TPPMS-catalyzed benzylation of indoles with benzylic alcohols in water. J. Org. Chem. 2013, 78, 12128–12135. 10.1021/jo402151g. [DOI] [PubMed] [Google Scholar]

- Wu L.; Jiang R.; Yang J. M.; Wang S. Y.; Ji S. J. In(OTf)3 catalyzed C3-benzylation of indoles with benzyl alcohols in water. RSC Adv. 2013, 3, 5459–5464. 10.1039/c3ra40251g. [DOI] [Google Scholar]

- a Di Gregorio G.; Mari M.; Bartoccini F.; Piersanti G. Iron-Catalyzed Direct C3-Benzylation of Indoles with Benzyl Alcohols through Borrowing Hydrogen. J. Org. Chem. 2017, 82, 8769–8775. 10.1021/acs.joc.7b01603. [DOI] [PubMed] [Google Scholar]; b Jana U.; Maiti S.; Biswas S. An FeCl3-catalyzed highly C3-selective Friedel–Crafts alkylation of indoles with alcohols. Tetrahedron Lett. 2007, 48, 7160–7163. 10.1016/j.tetlet.2007.07.208. [DOI] [Google Scholar]

- Koller S.; Blazejak M.; Hintermann L. Catalytic C-Alkylation of Pyrroles with Primary Alcohols: Hans Fischer’s Alkali and a New Method with Iridium P, N, P-Pincer Complexes. Eur. J. Org. Chem. 2018, 1624–1633. 10.1002/ejoc.201800146. [DOI] [Google Scholar]

- Das D.; Roy S. Palladium (II)-Catalyzed Efficient C-3 Functionalization of Indoles with Benzylic and Allylic Alcohols under Co-Catalyst, Acid, Base, Additive and External Ligand-Free Conditions. Adv. Synth. Catal. 2013, 355, 1308–1314. 10.1002/adsc.201300048. [DOI] [Google Scholar]

- Siddiki S. M. A. H.; Kon K.; Shimizu K. General and Selective C-3 Alkylation of Indoles with Primary Alcohols by a Reusable Pt Nanocluster Catalyst. Chem. – Eur. J. 2013, 19, 14416–14419. 10.1002/chem.201302464. [DOI] [PubMed] [Google Scholar]

- a Bähn S.; Imm S.; Mevius K.; Neubert L.; Tillack A.; Williams J. M. J.; Beller M. Selective Ruthenium-Catalyzed N-Alkylation of Indoles by Using Alcohols. Chem. – Eur. J. 2010, 16, 3590–3593. 10.1002/chem.200903144. [DOI] [PubMed] [Google Scholar]; b Ye L.; Cai S. H.; Wang D. X.; Wang Y. Q.; Lai L. J.; Feng C.; Loh T. P. Photoredox Catalysis Induced Bisindolylation of Ethers/Alcohols via Sequential C–H and C–O Bond Cleavage. Org. Lett. 2017, 19, 6164–6167. 10.1021/acs.orglett.7b03073. [DOI] [PubMed] [Google Scholar]

- Kloss F.; Neuwirth T.; Haensch V. G.; Hertweck C. Metal-Free Synthesis of Pharmaceutically Important Biaryls by Photosplicing. Angew. Chem., Int. Ed. 2018, 57, 14476–14481. 10.1002/anie.201805961. [DOI] [PubMed] [Google Scholar]

- Cano R.; Yus M.; Ramón D. J. Environmentally friendly and regioselective C3-alkylation of indoles with alcohols through a hydrogen autotransfer strategy. Tetrahedron Lett. 2013, 54, 3394–3397. 10.1016/j.tetlet.2013.04.062. [DOI] [Google Scholar]

- Liang D.; Li X.; Li Y.; Yang Y.; Gao S.; Cheng P. Br2-Catalyzed regioselective dehydrative coupling of indoles with acyloins: direct synthesis of α-(3-indolyl) ketones. RSC Adv. 2016, 6, 29020–29025. 10.1039/C6RA03321K. [DOI] [Google Scholar]

- Zhu Y. F.; Lu G. P.; Cai C. A highly regioselective C-3 benzylation reaction of indoles with alcohols catalysed by an N-heterocyclic carbene. J. Chem. Res. 2015, 39, 438–441. 10.3184/174751915X14376593652711. [DOI] [Google Scholar]

- Hirashita T.; Kuwahara S.; Okochi S.; Tsuji M.; Araki S. Direct benzylation and allylic alkylation in high-temperature water without added catalysts. Tetrahedron Lett. 2010, 51, 1847–1851. 10.1016/j.tetlet.2010.01.112. [DOI] [Google Scholar]

- a Baeza A.; Nájera C. Recent advances in the direct nucleophilic substitution of allylic alcohols through SN1-type reactions. Synthesis 2014, 46, 25–34. 10.1055/s-0033-1340316. [DOI] [Google Scholar]; b McCubbin J. A.; Krokhin O. V. Organocatalyzed Friedel–Crafts arylation of benzylic alcohols. Tetrahedron Lett. 2010, 51, 2447–2449. 10.1016/j.tetlet.2010.02.151. [DOI] [Google Scholar]

- a Sanz R.; Miguel D.; Álvarez-Gutiérrez J. M.; Rodríguez F. Brønsted acid catalyzed C3-selective propargylation and benzylation of indoles with tertiary alcohols. Synlett 2008, 2008, 975–978. 10.1055/s-2008-1072584. [DOI] [Google Scholar]; b Motokura K.; Nakagiri N.; Mizugaki T.; Ebitani K.; Kaneda K. Nucleophilic substitution reactions of alcohols with use of montmorillonite catalysts as solid Brønsted acids. J. Org. Chem. 2007, 72, 6006–6015. 10.1021/jo070416w. [DOI] [PubMed] [Google Scholar]; c Ortiz R.; Herrera R. Direct substitution of alcohols in pure water by brønsted acid catalysis. Molecules 2017, 22, 574. 10.3390/molecules22040574. [DOI] [PMC free article] [PubMed] [Google Scholar]

- a von der Heiden D.; Bozkus S.; Klussmann M.; Breugst M. Reaction mechanism of iodine-catalyzed michael additions. J. Org. Chem. 2017, 82, 4037–4043. 10.1021/acs.joc.7b00445. [DOI] [PubMed] [Google Scholar]; b Breugst M.; von der Heiden D. Mechanisms in Iodine Catalysis. Chem. Eur. J. 2018, 24, 9187–9199. 10.1002/chem.201706136. [DOI] [PubMed] [Google Scholar]; c Xiao F.; Chen H.; Xie H.; Chen S.; Yang L.; Deng G.-J. Iodine-catalyzed regioselective 2-sulfonylation of indoles with sodium sulfinates. Org. Lett. 2014, 16, 50–53. 10.1021/ol402987u. [DOI] [PubMed] [Google Scholar]; d Yi S.; Li M.; Mo W.; Hu X.; Hu B.; Sun N.; Jin L.; Shen Z. Metal-free, iodine-catalyzed regioselective sulfenylation of indoles with thiols. Tetrahedron Lett. 2016, 57, 1912–1916. 10.1016/j.tetlet.2016.03.073. [DOI] [Google Scholar]; e Srihari P.; Bhunia D.; Sreedhar P.; Yadav J. Iodine-catalyzed nucleophilic substitution reactions of benzylic alcohols. Synlett 2008, 1045–1049. 10.1055/s-2008-1072652. [DOI] [Google Scholar]; f Čebular K.; Stavber S. Molecular iodine as a mild catalyst for cross-coupling of alkenes and alcohols. Pure Appl. Chem. 2018, 90, 377–386. 10.1515/pac-2017-0414. [DOI] [Google Scholar]

- Yusubov M. S.; Zhdankin V. V. Iodine catalysis: A green alternative to transition metals in organic chemistry and technology. Resour.-Effic. Technol. 2015, 1, 49–67. 10.1016/j.reffit.2015.06.001. [DOI] [Google Scholar]

- Hao W. J.; Wang S. Y.; Ji S. J. Iodine-catalyzed cascade formal [3+ 3] cycloaddition reaction of indolyl alcohol derivatives with enaminones: constructions of functionalized spirodihydrocarbolines. ACS Catal. 2013, 3, 2501–2504. 10.1021/cs400703u. [DOI] [Google Scholar]

- Popov A. I.Polyhalogen Complex Ions. In Halogen Chemistry; Gutmann V., Ed.; Academic Press: London, 1967; Vol. 1, pp 225–264. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.