Abstract

Potato protein is recognized as one of the most valuable nonanimal proteins due to the high content of essential amino acids. So far, it has not been used in human nutrition on a large scale due to technological limitations regarding its acquisition. In this study, the protein fraction of potato juice was concentrated with the use of membrane separation. The obtained potato juice protein concentrate (PJPC) was characterized in terms of nutritional value and biological activity, and the amino acid composition, mineral content, and antioxidant properties were determined. Moreover, in vitro cytotoxic activity against cancer cells of the gastrointestinal tract was investigated. The results of the present study indicate that PJPC is an excellent source of lysine and threonine, while leucine is its limiting amino acid, with an amino acid score (AAS) of 65%. Moreover, PJPC contains substantial amounts of Fe, Mn, K, and Cu. As demonstrated experimentally, PJPC is also characterized by higher antioxidant potential than potato itself. Biological activity, however, is not limited to antioxidant activity alone. Cytotoxicity studies using a gastric cancer cell line (Hs 746T), a colon cancer cell line (HT-29), and human colon normal cells (CCD 841 CoN) proved that PJPC is characterized by selective activity against cancer cells. It can thus be concluded that the developed method of producing protein concentrate from potato juice affords a product with moderate nutritional value and interesting biological activity.

Keywords: potato juice, cancer cells, cytotoxicity, antioxidant activity, protein nutritional value, chemical score, protein composition

1. Introduction

Potato juice, the liquid fraction of potato tubers, is available in large quantities as a side stream of the starch industry. Optimal management of this raw material is still an unresolved technological problem. The most common approach utilizes thermal coagulation of potato protein in acidic conditions. The coagulated mass is then separated, dried, and used for fodder purposes [1]. This procedure is not optimal as only ca. 50% of potato protein undergoes coagulation and often the remaining half is simply discarded with wastewater [2]. Moreover, not only proteins are lost but also many different compounds with proven biological activity [3,4,5]. Solanum tuberosum reveals vast biodiversity; approximately 5000 varieties of potato are known [6]. The content of the individual chemical components is determined by both the variety of the cultivated plant and the technological treatment of mature tubers [7,8,9]. The dry matter content varies between 20 and 50 g/kg, of which the weight of protein amounts to about one-third. Three main groups of proteins can be distinguished in potato: the major potato tuber protein patatin, with a molecular weight of approx. 39–45 kDa; protease inhibitors (4–25 kDa); and other proteins of higher molecular weight [10,11]. Moreover, except for the easily soluble protein fraction, potato juice also contains carbohydrates, lipids, organic acids, polyphenols, minerals, fiber, and glycoalkaloids.

Investigations into the nutritional value of potato proteins have resulted in a number of patent descriptions of new technologies for the production of food-grade potato protein [12,13,14,15], as well as scientific reports that concern its functional properties [16,17,18,19]. However, commercial applications of these results remain unsatisfactory. It should be emphasized that the value of potato juice as an industrial raw material is based not only on its nutritional value but also on its biological activity. In European folk medicine, the interest in freshly squeezed potato juice and its use for the treatment of gastrointestinal complaints can be traced back to the first decade of the 19th century [20,21]. Because of its documented anti-inflammatory activity within the gastrointestinal tract [22], potato juice can be used as an additive in the production of health-promoting foods given to patients suffering from inflammatory bowel diseases [23,24,25,26]. It is widely believed that the anti-inflammatory properties of potato are associated with proteins that manifest protease inhibitor activity. Published data indicate that potato proteins have the ability to relieve perirectal inflammation in patients with gastrointestinal resections, as well as in infants [27]. They may also be responsible for regulating the activity of endogenous proteases and performing protective functions against infections by pathogenic microorganisms or insects [28]. Furthermore, they have been shown to inhibit the activities of trypsin, chymotrypsin, cathepsin D, carbopeptidase A and B, and microbial proteases [29,30,31,32].

Potato protein intended for consumption must be subjected to thermal treatment, which may affect its biological activity or nutritional value. In vivo studies on the anti-inflammatory activity of spray-dried potato juice proved, however, that thermal treatment does not impact the biological activity [22]. Therefore, the aim of this study was to investigate the antioxidant activity, cytotoxicity, and nutritional composition of potato juice protein concentrate preserved by spray-drying. In addition, nutritional properties of protein and amino acid scoring were investigated with respect to FAO recommendations.

2. Materials and Methods

2.1. Experimental Material and Production of Protein Concentrate

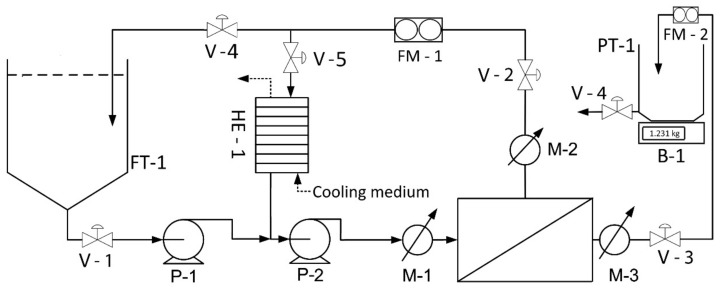

Fresh potato juice (FPJ) was collected during starch production season at “TRZEMESZNO” Sp. z o.o. Potato Industry Company (Trzemeszno, Poland). In starch processing, about 25 varieties of potato, with white and yellow flesh, were used, mainly: Albatros, Skawa, Dominanta, Harpun, and Jubilat. The material was subjected to concentration by means of cross-flow ultrafiltration (UF). A diagram of the setup used for this is presented in Figure 1. A polyethersulfone spiral-wound UF membrane (type 3838, Koch Membrane Systems, Inc., Wilmington, MA, USA) with a molecular weight cut-off of 5 kDa and an area of 3.5 m2 was used to separate proteins from the potato-processing wastewater. The experiments were carried out in an open system where the permeate was drained into a separate container (concentration mode). Concentration was performed at a transmembrane pressure (TMP) of 400 ± 15 kPa, cross-flow velocity inside the membrane of 0.5 ms-1, and temperature of 20 °C. The obtained retentate (potato juice protein concentrate, PJPC) was further subjected to spray-drying to ensure long-term storage stability.

Figure 1.

Schematic diagram of the applied membrane separation system for ultrafiltration. FT-1: feed tank; V-1–5: manual diaphragm valves; P-1, 2: centrifugal pumps; HE-1: shell and tube heat exchanger; M-1–3: pressure sensors; PT-1: permeate tank; FM-1, 2: electromagnetic flowmeters; B-1: electronic balance.

Spray-drying was carried out in a Mobile Minor™ 2000 spray dryer (GEA Co., Søborg, Denmark) using the following conditions: 170 °C at the inlet to the drying chamber and 95 °C at the outlet.

2.2. Chemical Analysis

Total nitrogen content was determined using the Kjeldahl method according to ISO 1871 [33] and protein content was calculated by multiplying the result by the conversion factor of 6.25. Ash content was determined according to ISO 763 [34]. The α-chaconine and α-solanine concentrations were analyzed using high-performance liquid chromatography (HPLC; Waters, Milford, MA, USA) with an XBridge C18 column (3.5 μm, 3.0 x 100 mm) (Waters, Milford, MA, USA) with the temperature controlled at 70 °C. The injection volume was 10 µL. Isocratic separation was carried out at a flow rate of 1.0 mL/min. The mobile phase was a mixture of acetonitrile and 0.1 M KH2PO4 (20:80 v/v). Detection was carried out at a wavelength of 200 nm with a Waters 2998 detector (DAD) (Waters, Milford, MA, USA) [35].

2.3. Analysis of Amino Acid Composition and Nutritional Profile

2.3.1. Amino Acid Composition

Amino acid composition, including histidine (His), isoleucine (Ile), leucine (Leu), lysine (Lys), methionine (Met), phenylalanine (Phe), threonine (Thr), valine (Val), cysteine (Cys), tyrosine (Tyr), glycine (Gly), arginine (Arg), proline (Pro), aspartic acid (Asp), glutamic acid (Glu), alanine (Ala), and serine (Ser), was determined with ultraperformance liquid chromatography (UPLC; Shimadzu Nexera 2.0, Kyoto, Japan) equipped with a PDA and FL detector (Kyoto, Japan) after acidic hydrolysis (110 °C, 23 h) according to the method described by Tomczak et al., 2018 [36], while sulfuric amino acids were prepared by oxidation (4 °C, 16 h) followed by acidic hydrolysis (110 °C, 2.5 h) [37]. The PDA detector was set at 260 nm with a sampling rate of 20 points/s. Tryptophan (Trp) content was determined after 20 h of alkaline hydrolysis and determined by reversed-phase UPLC/FD (excitation and emission at 280 and 356 nm, respectively) [38]. Amino acid content was expressed in g/16 g N (which is equivalent to g/100 g of protein).

2.3.2. Protein Efficiency Ratio (PER)

The PER was calculated from the amino acid composition of PJPC based on the following three equations in accordance with the method described by Alsmeyer et al. [39]:

2.3.3. Scoring of Amino Acids

The amino acid score (AAS) was calculated for adults using the standard method recommended by the FAO [40]:

2.3.4. Digestibility of PJPC

The digestibility of the provided preparations was determined in vitro by a method simulating multienzymatic two-stage (gastric and intestinal) digestion [41]. The digestive phase in the oral cavity was omitted as it has no effect on the digestibility of protein preparations. The large intestine stage (where the release of amino acids is the result of microflora activity) was also not taken into account.

A sample was introduced into distilled water containing pepsin (60,000 U) (Sigma) and the pH of the mixture was lowered to 2.0 with 1 M HCl. Gastric digestion was carried out for 2 h at 37 °C. Then, the pH of the solution was adjusted to 7.4 and a solution containing pancreatic–intestine extract (0.005 g, Sigma) and bile salts (0.03 g, Sigma) in 5 mL 0.1 M NaHCO3 was added. The digestion was again performed at 37 °C for 2 h. The obtained solution was centrifuged and the undigested protein was precipitated with trichloroacetic acid. Protein nitrogen was determined using the Kjeldahl [33] method. A ratio of the result and the total amount of protein nitrogen introduced was used to calculate the digestibility.

2.4. Determination of Mineral Content

The concentrations of minerals Ca, Cu, Fe, K, Mg, Mn, Na, and Zn were determined using flame atomic absorption spectroscopy (F-AAS) (SpectrAA-800, Varian, Palo Alto, CA, USA) preceded by mineralization with nitric acid [42]. The percent of population reference intake (PRI) and adequate intake (AI) was calculated according to the latest EFSA recommendations [43]. Contents of minerals were expressed in g/100 g of the sample.

2.5. Antioxidant Activity and Total Phenolic Compound Content

2.5.1. PJPC Ethanolic Extract Preparation

The extracts were prepared according to Król et al. [44]. PJPC (0.025 g) was diluted in 1.5 mL of 70% ethanol in an Eppendorf-type tube and sonicated for 45 min at 50 °C. Subsequently, the samples were centrifuged at 14,000 rpm for 10 min. Supernatants were used for further analysis. The extracts were prepared in six replicates.

2.5.2. Determination of Antioxidant Activity

The antioxidant activity was assessed using the Trolox equivalent antioxidant capacity (TEAC) method against the ABTS radical (2,2′-azinobis-(3-ethylbenzothiazoline-6-sulfonic acid) [45]. Ferric-reducing antioxidant power (FRAP) was analyzed according to the procedure described by Benzie and Strain, 1996 [46]. Activity of PJPC was expressed as TEAC (in mmol Trolox g-1 of product) and FRAP (mmol of Fe2+ g-1) values.

2.5.3. Determination of Total Phenolic Compounds (TPCs)

The TPC content was determined by the Folin–Ciocalteu colorimetric method [47]. For this, 0.02 mL of the sample was mixed with 0.05 mL of the Folin–Ciocalteu reagent. After 3 min, 0.15 mL of 20% sodium carbonate and 0.78 mL of demineralized water were added and the solution was mixed. The mixture was incubated in the dark at room temperature for 2 h. After 2 h, samples were centrifuged for 5 min at 14,000 rpm to obtain a clear solution. Absorbance was measured at 765 nm. The total content of phenolics was expressed in milligrams of gallic acid per gram of product.

2.5.4. Determination of Total Flavonoid Compounds (TFCs)

The concentration of TFCs was determined according to Karadeniz et al. [48] (±)‑catechin was used as the standard. 0.12 mL of each sample was mixed with 0.60 mL of demineralized water and 0.036 mL of 5% NaNO2. After 5 min, 0.072 mL of 10% AlCl3 and 0.24 mL of 1 M NaOH were added. Following another 5 min incubation, 0.132 mL of demineralized water was added and the solution was mixed. Absorbance was measured at 510 nm. The total content of flavonoids was expressed in milligrams of (±)‑catechin per gram of product.

2.6. Cell Cultures

The human colorectal adenocarcinoma cell line HT-29 (Cat. no: 85061109) was obtained from the European Collection of Authenticated Cell Cultures (ECACC) and supplied by Sigma–Aldrich (Poznań, Poland). The human gastric carcinoma Hs 746T cell line (ATCC® HTB-135™) and human normal colon CCD 841 CoN (ATCC® CRL-1790™) cell line were obtained from the American Type Culture Collection (ATCC) and supplied by LGC Standards (Łomianki, Poland).

The HT-29 and Hs 746T cells were cultured in Dulbecco’s Modified Eagle’s Medium (DMEM; Sigma–Aldrich) supplemented with heat-inactivated fetal bovine serum (FBS; Gibco BRL, Grand Island, NY, USA) to a final concentration of 10% and 1% nonessential amino acids 100X (Sigma–Aldrich, Poznań, Poland). The base medium for CCD 841 CoN cells was ATCC-formulated Eagle’s Minimum Essential Medium with 10% FBS addition.

Cell cultures were incubated at 37 °C in a humidified atmosphere (5% CO2, 95% air).

2.7. In Vitro Cytotoxicity Assay

Cells were grown in 96-well plates at an initial density of 2.5 × 104 cells/cm2. The 24 h cultures were treated with spray-dried potato juice at concentrations ranging from 0.5 to 20 mg/mL and incubated for 48 h under standard culture conditions. Cell viability and metabolic activity were determined using the 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT) colorimetric assay [49] as described previously by Olejnik et al., 2016 [50]. The first cytotoxic dose (IC10), median effective concentration (IC50), and lethal dose (IC90) of the spray-dried potato juice protein concentrate were calculated on the basis of the MTT results. Cell response to PJPC treatment was evaluated concerning control cells not treated with PJPC.

2.8. Statistical Analysis

All measurements were repeated in triplicate, unless otherwise stated. One-way analysis of variance (ANOVA) was carried out independently for each dependent variable. A post hoc Tukey’s HSD multiple comparison test was used to identify statistically homogeneous subsets at α = 0.05. Statistical analysis was performed with Statistica 13 software (Dell Software Inc., Round Rock, TX, USA).

3. Results and Discussion

3.1. Nutritional Value of PJPC

The proximate compositions of FPJ and PJPC are presented in Table 1. Table 2 presents the determined amino acid score of the analyzed concentrate. Research has shown that potato proteins are of moderate nutritional value due to their amino acid composition. The chemical score of potato protein is up to 70, which makes it comparable to egg white [51,52,53]. PJPC can be used to enrich products in the limiting amino acids. Potato proteins are an excellent source of lysine and can thus be a good supplement to cereal products that contain low quantities of this amino acid [54,55]. The prepared PJPC (Table 2) had an AAS of 65, which is comparable to that of potato, but more importantly, only two of the essential amino acids were in amounts that did not provide the required supply. Leucine was the limiting amino acid of PJPC. The histidine content amounted to 86% of the egg standard value. The threonine content was much higher compared with the egg standard, which may exert a positive effect on the nitrogen balance in the body [56].

Table 1.

Proximate composition.

| Parameter | FPJ | PJPC |

|---|---|---|

| Moisture (%) | 94.49 ± 3.21 a | 4.79 ± 0.32 b |

| Protein (g/100 g dm) | 2.37 ± 0.07 b | 63.40 ± 0.82 a |

| Ash (g/100 g dm) | 0.91 ± 0.03 b | 7.54 ± 0.27 a |

| α-chaconine (µg/100 g dm) | 990.06 ± 17.11 a | 837.81 ± 15.36 b |

| α-solanine (µg/100 g dm) | 601.24 ± 19.37 a | 438.40 ± 18.49 b |

Mean values denoted by different letters (a, b) showed statistically significant difference (p < 0.05). FPJ—fresh potato juice; PJPC—potato juice protein concentrate.

Table 2.

Amino acid profile and amino acid score (AAS) for adults according to standards reported by the FAO/WHO [40].

| Amino Acid | FAO/WHO Standard (mg/g) | PJPC (g/16 g N) | AAS |

|---|---|---|---|

| Essential amino acids | |||

| Histidine | 16 | 1.95 ± 0.07 | 86.3 |

| Isoleucine | 30 | 4.31 ± 0.09 | 102.0 |

| Leucine | 61 | 9.06 ± 0.11 | 64.6 |

| Lysine | 48 | 8.33 ± 0.20 | 123.1 |

| Methionine + Cystine | 23 | 3.85 ± 0.18 | 118.7 |

| Phenylalanine + Tyrosine | 41 | 10.44 ± 0.27 | 161.1 |

| Threonine | 25 | 6.24 ± 0.17 | 177.2 |

| Tryptophan | 6.6 | 1.11 ± 0.09 | 120.3 |

| Valine | 40 | 5.64 ± 0.21 | 100.0 |

| Dispensable amino acids | |||

| Alanine | - | 5.10 ± 0.30 | - |

| Arginine | - | 4.69 ± 0.11 | - |

| Aspartic acid | - | 12.74 ± 0.52 | - |

| Glutamic acid | - | 11.22 ± 0.55 | - |

| Glycine | - | 5.20 ± 0.11 | - |

| Proline | - | 5.05 ± 0.19 | - |

| Serine | - | 5.06 ± 0.21 | - |

The nutritional value of a protein may be estimated by calculating the PER. This calculation is based on the concentration of either leucine and proline (PER1); leucine and tyrosine (PER2); or methionine, leucine, histidine, and tyrosine (PER3). Usually, PER values higher than 2 indicate the high quality of a protein. PER values calculated for PJPC indicated good quality of the protein (Table 3) that was higher than those of cowpea and peanut proteins (1.21 and 1.45–1.76, respectively) [57].

Table 3.

Calculated protein efficiency ratio (PER) values of PJPC.

| Parameter | PJPC |

|---|---|

| PER1 | 3.21 ± 0.02 |

| PER2 | 3.13 ± 0.05 |

| PER3 | 1.87 ± 0.02 |

Currently, the nutritional value of a protein is also evaluated by a multienzyme digestion model. For the PJPC, a two-stage model was chosen, because the preparation is free of starches and the effect of salivary enzymes does not influence the final results of the experiment. The determined digestibility of PJPC was unexpectedly low (18.3%), significantly lower compared with reference data [58]. This was probably a result of the preparation method. Even in the case of valuable alimentary goods, such as almond protein, or popular food products, such as corn-based breakfast cereals, digestibility may be limited [59,60]. Increased temperature is known to decrease protein digestibility even though thermal denaturation by itself improves it. Thermal treatment was found to promote lysine modification, which significantly restricts its availability to trypsin [61]. Another disadvantage of spray-drying is its possible direct negative impact on the content of lysine [62]. To improve digestibility, it may be desirable to treat PJPC using proteases with low substrate specificity, such as bromelain, papain, or commercial preparations (e.g., Alcalase® or Savinase®). It should, however, be taken into account that phenolic compounds are known inhibitors of proteases. A high concentration of these antioxidants may have had a strong effect on the digestibility of PJPC [63]. Noteworthy, in our previous investigations, potato juice and products of its processing were found to be rich in polyphenols and other antioxidants [35].

The contents and percentages of PRI and AI realization for minerals are shown in Table 4. The PRI and AI values were: 950 mg for Ca, 3500 mg for K, 300 mg for Mg, 1 mg for Cu, 16 mg for Fe, 3 mg for Mn, and 10 mg* for Zn (* the averaged value) [43].

Table 4.

Mineral composition of PJPC.

| Mineral | Content (mg/100 g) | % PRI/AI |

|---|---|---|

| Fe | 30.5 ± 4.2 | 191 |

| Mn | 3.79 ± 0.17 | 126 |

| K | 4341 ± 271 | 124 |

| Cu | 1.14 ± 0.07 | 114 |

| Mg | 241 ± 9 | 80 |

| Ca | 118 ± 8 | 12 |

| Zn | 6.04 ± 0.11 | 60 |

| Na | 84.5 ± 4.9 | - |

PJPC was found to be a valuable source of the most of analyzed macro- and microelements, excluding Ca. Its 100 g portion realized 60–80% of daily requirements for Mg and Zn. PJPC was particularly rich in Fe, Mn, K, and Cu (approximately 190%, 130%, 120%, and 110% of PRI/AI, respectively). In terms of the content of minerals, PJPC was comparable to dietary supplements. As shown in our previous studies, potato juice in different forms is sensorially compatible with various food products [23,24]. Therefore, it may become a valuable ingredient for the enrichment of food. Furthermore, the gluten-free nature of PJPC makes it suitable for the enrichment of gluten-free food targeted at patients with gluten-related disorders. For example, the nutritional value of gluten-free bread is usually lower than that of bread made from conventional raw materials. Its production is often based mainly on pure starch. In addition, in order to ensure the right consistency and structure, large amounts of fat and sugar are added [64,65]. This significantly reduces the protein content. Moreover, gluten-free foods often contain an insufficient content of mineral compounds. Published data indicate that the gluten-free diet is deficient in Fe, Mg, and Zn [66,67]. The use of PJPC as an additive in the production of gluten-free bread could increase its protein content and help supply the deficient minerals. In this way, it could significantly improve the nutritional value of the product.

Caution must be paid to the content of toxic and antinutritional constituents of potential food additives of natural origin. In the case of potato and the products of its processing, two glycoalkaloids—α-solanine and α-chaconine—can pose a threat to potential consumers. In the case of the analyzed product, the content of any of these compounds was lower than 1 mg per 100 g of the product (Table 1). According to the available toxicological data, such concentrations should not create a significant risk [68,69], provided that PJPC is used as an additive in a limited quantity.

3.2. Antioxidant Activity of PJPC

Plant raw materials, such as fruits and vegetables, are well-recognized sources of antioxidant compounds [70,71,72]. Among antioxidant substances, phenols are characterized by the highest antioxidant activity [73,74,75]. Literature data indicate the anti-inflammatory effect of potatoes and attribute it to the presence of antioxidants, including phenolic acids, carotenoids, or anthocyanins. Human cohort studies have confirmed the systemic anti-inflammatory effect of potato and correlated it with the concentration of certain potato antioxidants in the blood serum [76,77,78]. The results of the analysis of antioxidant properties with respect to the content of dry matter (Table 5) showed that PJPC was characterized by a higher antioxidant potential than selected vegetables [79] or whole potato [80,81]. Moreover, its antioxidant activity was also approximately 10 times higher than fresh potato juice [35]. The content of polyphenolic compounds in PJPC was even two times higher than in flesh-colored potatoes that are rich in anthocyanin pigments and polyphenols [55]. Because of their capabilities to inhibit lipid oxidation, inactivate reactive oxygen species, or chelate prooxidant transition metals, proteins can be used as antioxidant additives in the production of food [82]. PJPC may thus not only be applied as an additive to increase the nutritional value of a product but also to introduce antioxidant properties to it.

Table 5.

Antioxidant activity expressed as the ferric-reducing antioxidant power (FRAP), Trolox equivalent antioxidant capacity (TEAC), total phenolic compounds (TPCs), and total flavonoid compounds (TFCs).

| Parameter | PJPC |

|---|---|

| FRAP (mmol g−1) | 1.41 ± 0.07 |

| TEAC (mmol g−1) | 1.53 ± 0.12 |

| TPC (mg g−1) | 5.82 ± 0.16 |

| TFC (mg g−1) | 2.10 ± 0.11 |

3.3. In Vitro Cytotoxic Activity

The biological activity of potato juice is usually associated with the proteins present in it. Kujawska et al. [22] proved that potato juice inhibits the inflammatory response in experiments on activated macrophages in vitro and in vivo in the gastric mucosa with induced lesions in rats. Additionally, studies indicate that protease inhibitors present in the potato protein inhibit the fecal proteolytic activity almost completely. Therefore, the use of potato proteins can be a new approach in the prevention of protease-induced perianal dermatitis [27].

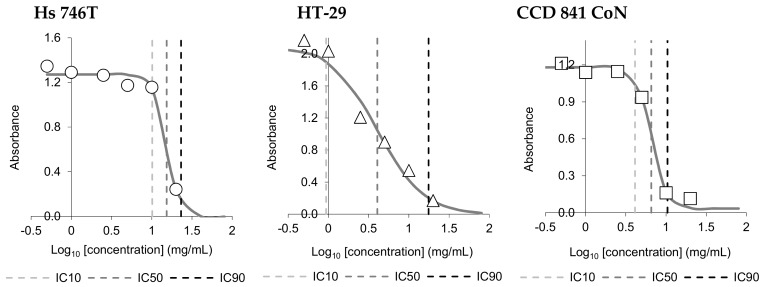

The cytotoxicity of PJPC was determined using a gastric cancer cell line (Hs 746T), a colon cancer cell line (HT-29), and human colon normal cells (CCD 841 CoN). The IC10, IC50, and IC90 cytotoxic doses of PJPC are presented in Table 6. The effects on cell proliferation and viability in model tumor and nontumor cultures are shown in Figure 2. The results indicate differences in the cytotoxic activity of PJPC against cancer (HT-29) and normal (CCD 841 CoN) colon cells. This may be a fact of therapeutic significance, as commonly used anticancer drugs inhibit the proliferation of both cancerous and normal cells, which may lead to additional weakening of the body [83]. In the case of stomach tumor cells of the Hs476T line, the cytotoxic dose IC50 was relatively high. Direct comparison such as the one above was impossible, however, as normal cells from the human stomach were not available. Published data indicate cytotoxic activity of potato proteins towards various tumor lines [18,84]. The antiproliferative effects of potato could also be associated with the presence of glycoalkaloids (solanine and chaconine), which may inhibit the growth of human cancer cell lines, including human colon and stomach cancer cells [85,86,87]. Table 1 presents the content of glycoalkaloids in both fresh juice and PJPC. The developed method of obtaining PJPC caused a decrease in the content of glycoalkaloids compared with the raw material. Nonetheless, high cytotoxic activity, comparable to the published data for fresh potato juice, was maintained even after the treatment [35].

Table 6.

Cytotoxic doses of PJPC [mg/mL].

| Cell Line | IC10 | IC50 | IC90 |

|---|---|---|---|

| Hs 746T | 9.11 ± 0.96 a | 14.69 ± 0.57 a | 23.76 ± 0.65 a |

| HT-29 | 0.80 ± 0.14 c | 3.89 ± 0.21 c | 19.38 ± 2.24 b |

| CCD 841 CoN | 4.71 ± 0.57 b | 6.50 ± 0.20 b | 9.06 ± 1.19 c |

Mean values denoted by different letters (a–c) differ statistically significantly (p < 0.05).

Figure 2.

Changes in cell proliferation and viability upon treatment of the stomach cancer cells (Hs 746T line), colon cancer cells (HT-29 line), and colon normal cells (CCD 841 CoN line) with PJPC at concentrations ranging from 0.5 to 20 mg/mL.

4. Conclusions

Potato juice, a low-value side-product of potato starch processing, is a valuable source of functional compounds with therapeutic potential. Valorization of this material is possible provided that sufficient knowledge of its properties is obtained through scientific and technological research. In its raw state, potato juice is unstable and must be processed in order to allow the necessary storage stability. PJPC, a product obtained from fresh potato juice by means of ultrafiltration which is stabilized by spray-drying, was the subject of the research presented herein. Analyses of the amino acid composition proved that it is a rich source of some essential amino acids, especially threonine. The determined AAS of PJPC was 65, with leucine as the limiting AA. Also interesting were the results on the mineral composition of PJPC. A 100 g portion of this material would supply Mn, K, and Cu in amounts surpassing the PRI/AI recommendation by approximately 20%, and its Fe content was especially high, with a 100 g portion supplying almost twice the recommended intake. The nutritional value of the product makes it a potential additive for the production of gluten-free bread, where it could be used to introduce both protein and minerals that are often deficient in the gluten-free diet. Besides chemical analyses, in vitro studies with the use of cancerous and normal cells from the human gastrointestinal tract were performed. These revealed differences in the potency of cytotoxicity of PJPC against normal (CCD 841 CoN) and cancerous (HT-29) colon cells that could potentially be exploited in therapeutic applications.

Author Contributions

Conceptualization, P.L.K. and G.L.; Investigation, P.L.K., A.O., W.B., I.R., M.Z.-D., A.S., and P.K.; Methodology, P.L.K., A.O., W.B., and G.L.; Supervision, G.L.; Writing—Original draft, P.L.K., I.R., M.Z.-D., P.K., and G.L.

Funding

The work was financially supported by the grant of Ministry of Science and Higher Education No. MNiSW/2017/DiR/42/II+ “Innovation Incubator+” implemented within the EU Smart Growth Operational Programme 2014-2020 (Priority Axis 4.4).

Conflicts of Interest

The authors declare no conflict of interest.

References

- 1.Tuśnio A., Pastuszewska B., Święch E., Taciak M. Response of young pigs to feeding potato protein and potato fibre—Nutritional, physiological and biochemical parameters. J. Anim. Feed Sci. 2011;20:361–378. doi: 10.22358/jafs/66192/2011. [DOI] [Google Scholar]

- 2.Lasik M., Nowak J., Kent C., Czarnecki Z. Assessment of Metabolic activity of single and mixed microorganism population assigned for potato wastewater biodegradation. Pol. J. Environ. Stud. 2002;11:719–725. [Google Scholar]

- 3.Ralet M.-C., Guéguen J. Fractionation of Potato Proteins: Solubility, Thermal Coagulation and Emulsifying Properties. LWT-Food Sci. Technol. 2000;33:380–387. doi: 10.1006/fstl.2000.0672. [DOI] [Google Scholar]

- 4.Van Koningsveld G.A., Gruppen H., de Jongh H.H.J., Wijngaards G., van Boekel M.A.J.S., Walstra P., Voragen A.G.J. Effects of pH and Heat Treatments on the Structure and Solubility of Potato Proteins in Different Preparations. J. Agric. Food Chem. 2001;49:4889–4897. doi: 10.1021/jf010340j. [DOI] [PubMed] [Google Scholar]

- 5.Pastuszewska B., Tuśnio A., Taciak M., Mazurczyk W. Variability in the composition of potato protein concentrate produced in different starch factories—A preliminary survey. Anim. Feed Sci. Technol. 2009;154:260–264. doi: 10.1016/j.anifeedsci.2009.09.001. [DOI] [Google Scholar]

- 6.Burlingame B., Mouillé B., Charrondière R. Nutrients, bioactive non-nutrients and anti-nutrients in potatoes. J. Food Compos. Anal. 2009;22:494–502. doi: 10.1016/j.jfca.2009.09.001. [DOI] [Google Scholar]

- 7.Singh J., Colussi R., McCarthy O.J., Kaur L. Advances in Potato Chemistry and Technology. Elsevier; Amsterdam, The Netherlands: 2016. Potato Starch and Its Modification; pp. 195–247. [Google Scholar]

- 8.Yang L., Xia Y., Junejo S.A., Zhou Y. Composition, structure and physicochemical properties of three coloured potato starches. Int. J. Food Sci. Technol. 2018;53:2325–2334. doi: 10.1111/ijfs.13824. [DOI] [Google Scholar]

- 9.Guo L., Cui B. The relationship between entanglement concentration and physicochemical properties of potato and sweet potato starch dispersions. Int. J. Food Sci. Technol. 2018;53:337–346. doi: 10.1111/ijfs.13590. [DOI] [Google Scholar]

- 10.Jørgensen M., Bauw G., Welinder K.G. Molecular Properties and Activities of Tuber Proteins from Starch Potato cv. Kuras. J. Agric. Food Chem. 2006;54:9389–9397. doi: 10.1021/jf0623945. [DOI] [PubMed] [Google Scholar]

- 11.Park Y., Choi B.H., Kwak J.-S., Kang C.-W., Lim H.-T., Cheong H.-S., Hahm K.-S. Kunitz-Type Serine Protease Inhibitor from Potato (Solanum tuberosum L. cv. Jopung) J. Agric. Food Chem. 2005;53:6491–6496. doi: 10.1021/jf0505123. [DOI] [PubMed] [Google Scholar]

- 12.Białas W., Kowalczewski P., Lewandowicz G., Olejnik A., Siger A., Dwiecki K. Method for Obtaining a Pro-Healthy Protein Preparation. Aplication No. P.426837. Polish Patent. 2018 Aug 28;

- 13.Edens L., Van Der Lee J.A.B., Plijter J.J. Novel Food Compositions. No. WO1997042834A1. Patent. 1997 Nov 10;

- 14.Giuseppin M.L.F., van der Sluis C., Laus Marc C. Native Potato Protein Isolates. No. EP 1920662. European Patent. 2008 May 14;

- 15.Marchal J.L.M., Nijssen H.M.J., Knott E.R., Krol F.A.R. Method for Improving a Protein. USA No. 7972647. US Patent. 2011 Jul 5;

- 16.Dabestani S., Arcot J., Chen V. Protein recovery from potato processing water: Pre-treatment and membrane fouling minimization. J. Food Eng. 2017;195:85–96. doi: 10.1016/j.jfoodeng.2016.09.013. [DOI] [Google Scholar]

- 17.Waglay A., Karboune S. A novel enzymatic approach based on the use of multi-enzymatic systems for the recovery of enriched protein extracts from potato pulp. Food Chem. 2017;220:313–323. doi: 10.1016/j.foodchem.2016.09.147. [DOI] [PubMed] [Google Scholar]

- 18.Waglay A., Karboune S., Alli I. Potato protein isolates: Recovery and characterization of their properties. Food Chem. 2014;142:373–382. doi: 10.1016/j.foodchem.2013.07.060. [DOI] [PubMed] [Google Scholar]

- 19.Cheng Y., Xiong Y.L., Chen J. Antioxidant and emulsifying properties of potato protein hydrolysate in soybean oil-in-water emulsions. Food Chem. 2010;120:101–108. doi: 10.1016/j.foodchem.2009.09.077. [DOI] [Google Scholar]

- 20.Vlachojannis J.E., Cameron M., Chrubasik S. Medicinal use of potato-derived products: A systematic review. Phyther. Res. 2010;24:159–162. doi: 10.1002/ptr.2829. [DOI] [PubMed] [Google Scholar]

- 21.Mohamed Saleem T.S., Chetty C.M., Ramkanth S., Alagusundaram M., Gnanaprakash K., Thiruvengada Rajan V.S., Angalaparameswari S. Solanum nigrum Linn—A review. Pharmacogn. Rev. 2009;3:342–345. [Google Scholar]

- 22.Kujawska M., Olejnik A., Lewandowicz G., Kowalczewski P., Forjasz R., Jodynis-Liebert J. Spray-Dried Potato Juice as a Potential Functional Food Component with Gastrointestinal Protective Effects. Nutrients. 2018;10:259. doi: 10.3390/nu10020259. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Kowalczewski P.Ł., Lewandowicz G., Krzywdzińska-Bartkowiak M., Piątek M., Baranowska H.M., Białas W., Jeziorna M., Kubiak P. Finely comminuted frankfurters fortified with potato juice—Quality and structure. J. Food Eng. 2015;167:183–188. doi: 10.1016/j.jfoodeng.2015.05.016. [DOI] [Google Scholar]

- 24.Kowalczewski P., Lewandowicz G., Makowska A., Knoll I., Błaszczak W., Białas W., Kubiak P. Pasta Fortified with Potato Juice: Structure, Quality, and Consumer Acceptance. J. Food Sci. 2015;80:S1377–S1382. doi: 10.1111/1750-3841.12906. [DOI] [PubMed] [Google Scholar]

- 25.Kowalczewski P., Różańska M., Makowska A., Jeżowski P., Kubiak P. Production of wheat bread with spray-dried potato juice: Influence on dough and bread characteristics. Food Sci. Technol. Int. 2019;25:223–232. doi: 10.1177/1082013218814605. [DOI] [PubMed] [Google Scholar]

- 26.Baranowska H.M., Masewicz Ł., Kowalczewski P.Ł., Lewandowicz G., Piątek M., Kubiak P. Water properties in pâtés enriched with potato juice. Eur. Food Res. Technol. 2018;244:387–393. doi: 10.1007/s00217-017-2965-4. [DOI] [Google Scholar]

- 27.Ruseler-van Embden J.G.H., van Lieshout L.M.C., Smits S.A., van Kessel I., Laman J.D. Potato tuber proteins efficiently inhibit human faecal proteolytic activity: Implications for treatment of peri-anal dermatitis. Eur. J. Clin. Investig. 2004;34:303–311. doi: 10.1111/j.1365-2362.2004.01330.x. [DOI] [PubMed] [Google Scholar]

- 28.Ledoigt G., Griffaut B., Debiton E., Vian C., Mustel A., Evray G., Maurizis J.-C., Madelmont J.-C. Analysis of secreted protease inhibitors after water stress in potato tubers. Int. J. Biol. Macromol. 2006;38:268–271. doi: 10.1016/j.ijbiomac.2006.03.016. [DOI] [PubMed] [Google Scholar]

- 29.Kim J.-Y., Park S.-C., Kim M.-H., Lim H.-T., Park Y., Hahm K.-S. Antimicrobial activity studies on a trypsin–chymotrypsin protease inhibitor obtained from potato. Biochem. Biophys. Res. Commun. 2005;330:921–927. doi: 10.1016/j.bbrc.2005.03.057. [DOI] [PubMed] [Google Scholar]

- 30.Fischer M., Kuckenberg M., Kastilan R., Muth J., Gebhardt C. Novel in vitro inhibitory functions of potato tuber proteinaceous inhibitors. Mol. Genet. Genom. 2015;290:387–398. doi: 10.1007/s00438-014-0906-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Pouvreau L., Gruppen H., Piersma S.R., van den Broek L.A.M., van Koningsveld G.A., Voragen A.G.J. Relative Abundance and Inhibitory Distribution of Protease Inhibitors in Potato Juice from cv. Elkana. J. Agric. Food Chem. 2001;49:2864–2874. doi: 10.1021/jf010126v. [DOI] [PubMed] [Google Scholar]

- 32.Kim M.-H., Park S.-C., Kim J.-Y., Lee S.Y., Lim H.-T., Cheong H., Hahm K.-S., Park Y. Purification and characterization of a heat-stable serine protease inhibitor from the tubers of new potato variety “Golden Valley”. Biochem. Biophys. Res. Commun. 2006;346:681–686. doi: 10.1016/j.bbrc.2006.05.186. [DOI] [PubMed] [Google Scholar]

- 33.ISO . ISO 1871:2009 Food and Feed Products—General Guidelines for the Determination of Nitrogen by the Kjeldahl Method. ISO; Geneva, Switzerland: 2009. [Google Scholar]

- 34.ISO . ISO 763:2003 Fruit and Vegetable Products—Determination of Ash Insoluble in Hydrochloric Acid. ISO; Geneva, Switzerland: 2003. [Google Scholar]

- 35.Kowalczewski P.Ł., Olejnik A., Białas W., Kubiak P., Siger A., Nowicki M., Lewandowicz G. Effect of Thermal Processing on Antioxidant Activity and Cytotoxicity of Waste Potato Juice. Open Life Sci. 2019;14:150–157. doi: 10.1515/biol-2019-0017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Tomczak A., Zielińska-Dawidziak M., Piasecka-Kwiatkowska D., Lampart-Szczapa E. Blue lupine seeds protein content and amino acids composition. Plant Soil Environ. 2018;64:147–155. [Google Scholar]

- 37.AOAC . Official Method 994.12 Amino Acids in Feeds. AOAC International; Rockville, MD, USA: 2000. [Google Scholar]

- 38.ISO . ISO 13904:2016 Animal Feeding Stuffs—Determination of Tryptophan Content. ISO; Geneva, Switzerland: 2016. [Google Scholar]

- 39.Alsmeyer R.H., Cunningham A.E., Happich M.L. Equations predicting PER from amino acid analysis. Food Technol. 1974;28:34–40. [Google Scholar]

- 40.FAO . Dietary Protein Quality Evaluation in Human Nutrition. FAO; Rome, Italy: 2013. Report of an FAO Expert Consultation. FAO Food and Nutrition Paper 92. [PubMed] [Google Scholar]

- 41.Butts C.A., Monro J.A., Moughan P.J. In vitro determination of dietary protein and amino acid digestibility for humans. Br. J. Nutr. 2012;108:S282–S287. doi: 10.1017/S0007114512002310. [DOI] [PubMed] [Google Scholar]

- 42.Rybicka I., Gliszczyńska-Świgło A. Minerals in grain gluten-free products. The content of calcium, potassium, magnesium, sodium, copper, iron, manganese, and zinc. J. Food Compos. Anal. 2017;59:61–67. doi: 10.1016/j.jfca.2017.02.006. [DOI] [Google Scholar]

- 43.European Food Safety Authority Dietary Reference Values for nutrients Summary report. EFSA Support. Publ. 2017;14:e15121 [Google Scholar]

- 44.Król A., Amarowicz R., Weidner S. Content of Phenolic Compounds and Antioxidant Properties in Seeds of Sweet and Bitter Cultivars of Lupine (Lupinus angustifolius L.) Nat. Prod. Commun. 2018;13:1235–1418. [Google Scholar]

- 45.Re R., Pellegrini N., Proteggente A., Pannala A., Yang M., Rice-Evans C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999;26:1231–1237. doi: 10.1016/S0891-5849(98)00315-3. [DOI] [PubMed] [Google Scholar]

- 46.Benzie I.F.F., Strain J.J. The Ferric Reducing Ability of Plasma (FRAP) as a Measure of “Antioxidant Power”: The FRAP Assay. Anal. Biochem. 1996;239:70–76. doi: 10.1006/abio.1996.0292. [DOI] [PubMed] [Google Scholar]

- 47.Singleton V.L., Orthofer R., Lamuela-Raventós R.M. Methods in Enzymology. Volume 299. Academic Press; Cambridge, MA, USA: 1999. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent; pp. 152–178. [Google Scholar]

- 48.Karadeniz F., Burdurlu H.S., Koca N., Soyer Y. Antioxidant activity of selected fruits and vegetables grown in Turkey. Turk. J. Agric. For. 2005;29:297–303. [Google Scholar]

- 49.Mosmann T. Rapid colorimetric assay for cellular growth and survival: Application to proliferation and cytotoxicity assays. J. Immunol. Methods. 1983;65:55–63. doi: 10.1016/0022-1759(83)90303-4. [DOI] [PubMed] [Google Scholar]

- 50.Olejnik A., Rychlik J., Kidoń M., Czapski J., Kowalska K., Juzwa W., Olkowicz M., Dembczyński R., Moyer M.P. Antioxidant effects of gastrointestinal digested purple carrot extract on the human cells of colonic mucosa. Food Chem. 2016;190:1069–1077. doi: 10.1016/j.foodchem.2015.06.080. [DOI] [PubMed] [Google Scholar]

- 51.Barta J., Curn V. Potato (Solanum tuberosum L.) Tuber Proteins—Classification, Characterization, Importance. Chem. Listy. 2004;98:373–378. [Google Scholar]

- 52.Galdón B.R., Mesa D.R., Rodríguez E.M.R., Romero C.D. Amino acid content in traditional potato cultivars from the Canary Islands. J. Food Compos. Anal. 2010;23:148–153. doi: 10.1016/j.jfca.2009.08.009. [DOI] [Google Scholar]

- 53.Friedman M. Nutritional Value of Proteins from Different Food Sources. A Review. J. Agric. Food Chem. 1996;44:6–29. doi: 10.1021/jf9400167. [DOI] [Google Scholar]

- 54.Miedzianka J., Pęksa A., Aniołowska M. Properties of acetylated potato protein preparations. Food Chem. 2012;133:1283–1291. doi: 10.1016/j.foodchem.2011.08.080. [DOI] [Google Scholar]

- 55.Pęksa A., Miedzianka J., Nemś A. Amino acid composition of flesh-coloured potatoes as affected by storage conditions. Food Chem. 2018;266:335–342. doi: 10.1016/j.foodchem.2018.06.026. [DOI] [PubMed] [Google Scholar]

- 56.Sibian M.S., Saxena D.C., Riar C.S. Effect of germination on chemical, functional and nutritional characteristics of wheat, brown rice and triticale: A comparative study. J. Sci. Food Agric. 2017;97:4643–4651. doi: 10.1002/jsfa.8336. [DOI] [PubMed] [Google Scholar]

- 57.Mir N.A., Riar C.S., Singh S. Effect of pH and holding time on the characteristics of protein isolates from Chenopodium seeds and study of their amino acid profile and scoring. Food Chem. 2019;272:165–173. doi: 10.1016/j.foodchem.2018.08.048. [DOI] [PubMed] [Google Scholar]

- 58.Boye J., Wijesinha-Bettoni R., Burlingame B. Protein quality evaluation twenty years after the introduction of the protein digestibility corrected amino acid score method. Br. J. Nutr. 2012;108:S183–S211. doi: 10.1017/S0007114512002309. [DOI] [PubMed] [Google Scholar]

- 59.Rutherfurd S.M., Fanning A.C., Miller B.J., Moughan P.J. Protein Digestibility-Corrected Amino Acid Scores and Digestible Indispensable Amino Acid Scores Differentially Describe Protein Quality in Growing Male Rats. J. Nutr. 2015;145:372–379. doi: 10.3945/jn.114.195438. [DOI] [PubMed] [Google Scholar]

- 60.Aletor O. Protein quality evaluation and in vitro multi-enzyme digestibility of some plant protein isolates and concentrates. Archiva Zootechnica. 2012;15:5–16. [Google Scholar]

- 61.Pęksa A., Rytel E., Kita A., Lisińska G., Tajner-Czopek A. Food. Volume 3. Global Science Books; Tokyo, Japan: 2009. The properties of potato protein; pp. 79–87. [Google Scholar]

- 62.Schmitz-Schug I., Foerst P., Kulozik U. Impact of the spray drying conditions and residence time distribution on lysine loss in spray dried infant formula. Dairy Sci. Technol. 2013;93:443–462. doi: 10.1007/s13594-013-0115-8. [DOI] [Google Scholar]

- 63.Cirkovic Velickovic T.D., Stanic-Vucinic D.J. The Role of Dietary Phenolic Compounds in Protein Digestion and Processing Technologies to Improve Their Antinutritive Properties. Compr. Rev. Food Sci. Food Saf. 2018;17:82–103. doi: 10.1111/1541-4337.12320. [DOI] [PubMed] [Google Scholar]

- 64.Pruska-Kędzior A., Kędzior Z., Gorący M., Pietrowska K., Przybylska A., Spychalska K. Comparison of rheological, fermentative and baking properties of gluten-free dough formulations. Eur. Food Res. Technol. 2008;227:1523–1536. doi: 10.1007/s00217-008-0875-1. [DOI] [Google Scholar]

- 65.Pellegrini N., Agostoni C. Nutritional aspects of gluten-free products. J. Sci. Food Agric. 2015;95:2380–2385. doi: 10.1002/jsfa.7101. [DOI] [PubMed] [Google Scholar]

- 66.Rybicka I., Doba K., Bińczak O. Improving the sensory and nutritional value of gluten-free bread. Int. J. Food Sci. Technol. 2019 doi: 10.1111/ijfs.14190. [DOI] [Google Scholar]

- 67.Rybicka I. The Handbook of Minerals on a Gluten-Free Diet. Nutrients. 2018;10:1683. doi: 10.3390/nu10111683. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 68.Barceloux D.G. Potatoes, Tomatoes, and Solanine Toxicity (Solanum tuberosum L., Solanum lycopersicum L.) Dis. Mon. 2009;55:391–402. doi: 10.1016/j.disamonth.2009.03.009. [DOI] [PubMed] [Google Scholar]

- 69.Slanina P. Solanine (glycoalkaloids) in potatoes: Toxicological evaluation. Food Chem. Toxicol. 1990;28:759–761. doi: 10.1016/0278-6915(90)90074-W. [DOI] [PubMed] [Google Scholar]

- 70.Mustafa A., Turner C. Pressurized liquid extraction as a green approach in food and herbal plants extraction: A review. Anal. Chim. Acta. 2011;703:8–18. doi: 10.1016/j.aca.2011.07.018. [DOI] [PubMed] [Google Scholar]

- 71.Li H.-B., Wong C.-C., Cheng K.-W., Chen F. Antioxidant properties in vitro and total phenolic contents in methanol extracts from medicinal plants. LWT-Food Sci. Technol. 2008;41:385–390. doi: 10.1016/j.lwt.2007.03.011. [DOI] [Google Scholar]

- 72.Kumari B., Tiwari B.K., Hossain M.B., Rai D.K., Brunton N.P. Ultrasound-assisted extraction of polyphenols from potato peels: Profiling and kinetic modelling. Int. J. Food Sci. Technol. 2017;52:1432–1439. doi: 10.1111/ijfs.13404. [DOI] [Google Scholar]

- 73.Balasundram N., Sundram K., Samman S. Phenolic compounds in plants and agri-industrial by-products: Antioxidant activity, occurrence, and potential uses. Food Chem. 2006;99:191–203. doi: 10.1016/j.foodchem.2005.07.042. [DOI] [Google Scholar]

- 74.Wojdylo A., Oszmianski J., Czemerys R. Antioxidant activity and phenolic compounds in 32 selected herbs. Food Chem. 2007;105:940–949. doi: 10.1016/j.foodchem.2007.04.038. [DOI] [Google Scholar]

- 75.Cai Y., Luo Q., Sun M., Corke H. Antioxidant activity and phenolic compounds of 112 traditional Chinese medicinal plants associated with anticancer. Life Sci. 2004;74:2157–2184. doi: 10.1016/j.lfs.2003.09.047. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 76.Camire M.E., Kubow S., Donnelly D.J. Potatoes and Human Health. Crit. Rev. Food Sci. Nutr. 2009;49:823–840. doi: 10.1080/10408390903041996. [DOI] [PubMed] [Google Scholar]

- 77.Kaspar K.L., Park J.S., Brown C.R., Mathison B.D., Navarre D.A., Chew B.P. Pigmented Potato Consumption Alters Oxidative Stress and Inflammatory Damage in Men. J. Nutr. 2011;141:108–111. doi: 10.3945/jn.110.128074. [DOI] [PubMed] [Google Scholar]

- 78.Lipsky L.M., Cheon K., Nansel T.R., Albert P.S. Candidate measures of whole plant food intake are related to biomarkers of nutrition and health in the US population (National Health and Nutrition Examination Survey 1999–2002) Nutr. Res. 2012;32:251–259. doi: 10.1016/j.nutres.2012.03.005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 79.Ismail A., Marjan Z., Foong C. Total antioxidant activity and phenolic content in selected vegetables. Food Chem. 2004;87:581–586. doi: 10.1016/j.foodchem.2004.01.010. [DOI] [Google Scholar]

- 80.Liu Y.-W., Han C.-H., Lee M.-H., Hsu F.-L., Hou W.-C. Patatin, the Tuber Storage Protein of Potato (Solanum tuberosum L.), Exhibits Antioxidant Activity In Vitro. J. Agric. Food Chem. 2003;51:4389–4393. doi: 10.1021/jf030016j. [DOI] [PubMed] [Google Scholar]

- 81.Pihlanto A., Akkanen S., Korhonen H.J. ACE-inhibitory and antioxidant properties of potato (Solanum tuberosum) Food Chem. 2008;109:104–112. doi: 10.1016/j.foodchem.2007.12.023. [DOI] [PubMed] [Google Scholar]

- 82.Elias R.J., Kellerby S.S., Decker E.A. Antioxidant Activity of Proteins and Peptides. Crit. Rev. Food Sci. Nutr. 2008;48:430–441. doi: 10.1080/10408390701425615. [DOI] [PubMed] [Google Scholar]

- 83.Galluzzi L., Buqué A., Kepp O., Zitvogel L., Kroemer G. Immunological Effects of Conventional Chemotherapy and Targeted Anticancer Agents. Cancer Cell. 2015;28:690–714. doi: 10.1016/j.ccell.2015.10.012. [DOI] [PubMed] [Google Scholar]

- 84.Zhang M., Mu T.-H., Sun M.-J. Purification and identification of antioxidant peptides from sweet potato protein hydrolysates by Alcalase. J. Funct. Foods. 2014;7:191–200. doi: 10.1016/j.jff.2014.02.012. [DOI] [Google Scholar]

- 85.Ji Y., Gao S. Antihepatocarcinoma Effect of Solanine and Its Mechanisms. Chin. Herb. Med. 2012;4:126–135. [Google Scholar]

- 86.Ji Y.B., Gao S.Y., Ji C.F., Zou X. Induction of apoptosis in HepG2 cells by solanine and Bcl-2 protein. J. Ethnopharmacol. 2008;115:194–202. doi: 10.1016/j.jep.2007.09.023. [DOI] [PubMed] [Google Scholar]

- 87.Mandimika T., Baykus H., Poortman J., Garza C., Kuiper H., Peijnenburg A. Induction of the cholesterol biosynthesis pathway in differentiated Caco-2 cells by the potato glycoalkaloid α-chaconine. Food Chem. Toxicol. 2007;45:1918–1927. doi: 10.1016/j.fct.2007.04.009. [DOI] [PubMed] [Google Scholar]