Abstract

Objective

This study evaluated the effects of adding titanium oxide (TiO2) nanofillers on the tear strength, tensile strength, elongation percentage, and hardness of room-temperature-vulcanized (RTV) VST50F and high-temperature-vulcanized (HTV) Cosmesil M511 maxillofacial silicone elastomers.

Methods

Two types of maxillofacial elastomers, VST50F RTV and Cosmesil M511 HTV, were used. Nano-TiO2 powder was applied as a nanofiller. A total of 120 specimens were fabricated, 60 each of VST50F and Cosmesil M511. The specimens of each type of elastomer were divided into three equal groups on which tests were conducted for tear strength, tensile strength, and hardness i.e., 20 specimens were used for each test. Each group of 20 specimens was further divided into two equal subgroups: (A) control i.e., silicone without nano-TiO2, and (B) experimental i.e., VST50F and Cosmesil M511 silicone incorporated with 0.25 wt% and 0.2 wt% nano-TiO2, respectively. Each subgroup thus had 10 specimens. The specimens were evaluated, and data were studied using descriptive statistical analysis and two-way analysis of variance (ANOVA).

Results

The addition of 0.25 wt% and 0.2 wt% TiO2 nanofiller into VST50F and Cosmesil M511 elastomers, respectively, resulted in a statistically significant increase in the mean values (p < 0.01) of tear strength, tensile strength, elongation percentage, and hardness of the materials.

Conclusion

The mechanical properties of the VST50F and Cosmesil M511 maxillofacial silicone materials improved with the addition of select concentrations of nano-TiO2.

Keywords: Cosmesil M511, Maxillofacial silicone elastomer, Mechanical properties, Nano-TiO2, VST50F

الملخص

أهداف البحث

قيّمت هذه الدراسة الآثار المترتبة على إضافة أكسيد التيتانيوم كـ ’ نانوفيلر’ على التمزق وقوة الشد، ونسبة الاستطالة، وصلابة اللدائن السيليكونية المبركنة للفك في درجة حرارة الغرفة “في إس تي ٥٠ إف” واللدائن السيليكونية المبركنة للفك في درجة الحرارة العالية “ كوزميسيل إم ٥١١”.

طرق البحث

تم استخدام نوعين من اللدائن الفكية “في إس تي ٥٠ إف” و “ كوزميسيل إم ٥١١”. واستُخدم مسحوق أكسيد التيتانيوم كـ “ نانوفيلر”. وتم إعداد ما مجموعه ١٢٠ عينة: ٦٠ عينة للدائن بدرجة حرارة الغرفة و٦٠ عينة للدائن بدرجة الحرارة العالية. وتم تقسيم العينات من كل نوع من اللدائن إلى ثلاث مجموعات وفقا للاختبارات التي أجريت: اختبار قوة التمزق، واختبار قوة الشد، واختبار الصلابة. أستخدمت عشرون عينة لكل اختبار. وقُسمت كل مجموعة إلى مجموعتين فرعيتين: (أ) مجموعة التحكم، سيليكون بدون نانو- أكسيد التيتانيوم و (ب) مجموعة التجربة، سيليكون مضاف إليه نانو- أكسيد التيتانيوم بنسبة ٠.٢٥٪ من الوزن و٠.٢٪ من الوزن بالنسبة لـ “في إس تي ٥٠ إف” و “ كوزميسيل إم ٥١١” على التوالي. شملت كل مجموعة فرعية عشرة عينات. وتم بعدها تقييم العينات، كما تم تحليل البيانات باستخدام تحليل إحصائي وصفي واختبار “أنوفا” في الاتجاهين.

النتائج

أدت إضافة ٠.٢٥٪ بالوزن و٠.٢٪ بالوزن من أكسيد التيتانيوم كـ ’ نانوفيلر’ إلى كل من “في إس تي ٥٠ إف” و “ كوزميسيل إم ٥١١” على التوالي إلى زيادة ذات دلالة إحصائية في القيم المتوسطة لقوة التمزق وقوة الشد ونسبة الاستطالة والصلابة.

الاستنتاجات

إن إضافة تراكيز مختارة من نانو-أكسيد التيتانيوم إلى كل من “في إس تي ٥٠ إف” و “ كوزميسيل إم ٥١١” من مواد سيليكون الفكين أدت إلى تحسن الخواص الميكانيكية لكل منهما.

الكلمات المفتاحية: كوزميسيل إم ٥١١, لدائن سيليكون الفكين, الخواص الميكانيكية, نانو-أكسيد التيتانيوم, في إس تي ٥٠ إف

Introduction

Surgical reconstruction may be impossible owing to the size or location of facial disfigurement resulting from congenital anomaly, trauma, or surgery for tumors. The patient's medical condition or personal desires may also preclude reconstructive surgery. In such cases, prosthetic rehabilitation is indicated.1

A maxillofacial prosthesis is aimed at restoring the disfigurement to normalcy in appearance and function; it is used to transform congenital, developmental, and acquired head and neck defects through reproduction of the natural aspects of the lost structures.2

Various materials including wax, ivory, metal, wood, and new polymers such as silicone elastomers, polyurethane elastomers, and acrylic resins, have been employed to fabricate maxillofacial prostheses.3

Silicone elastomer is the most preferred material for fabrication of maxillofacial prostheses because of its chemical inertness, durability, ease of manipulation, and biocompatibility.4

The most common reasons for re-fabrication are the expected half-life and degradation of color and mechanical properties of silicone maxillofacial prostheses.5 Silicone elastomers exhibit several unwanted properties such as low tear and tensile strength, inadequate elasticity, and degradation of physical properties and color; these are considered to be the most critical properties of materials used to fabricate maxillofacial prostheses.6

Many factors affect the mechanical properties of silicone elastomers. Among these are the molecular weights of polymer chains, cross-link density, and incorporation of fillers.7 In the last 15 years, the growth of the chemical industry has prompted research into the development of new industrial processes whereby nanoparticles (NPs) are incorporated into the polymer matrix to provide a new class of polymer materials with enhanced flexibility resulting from the strength of the nano-oxides.8, 9

Several studies have been conducted to address the mechanical deficiencies of materials by adding reinforcing agents. In one such study, nano-TiO2, ZnO, and CeO2 incorporated into silicone elastomer A-2186 in concentrations of 2.0% and 2.5% improved its overall mechanical properties (tear strength, tensile strength, and elongation percentage).10

An evaluation of the effects of reinforcing HTV MDX 4-4515 silicone maxillofacial materials with functional polyhedral oligomeric silsesquioxane (POSS) NPs at 0.0, 0.5, 1.0, 2.0, and 5.0 wt% (mass/mass) loading revealed that functional NPs can be used to improve properties (tear strength and tensile strength) without compromising on clinical handling.11

The effects of the incorporation of NPs (ZnO, BaSO4, and TiO2 at concentrations of 1% and 2%) on the tear strength, hardness, and permanent deformation of a facial silicone were evaluated; the study recommended the use of ZnO NPs as they do not negatively affect the properties of the silicone material (V(Silastic MDX4-4210; Dow Corning Corp Medical Products)) evaluated.12

Incorporation of nano-TiO2 can improve the optical and mechanical properties of polymers due to strong interfacial interaction between the organic polymers and the inorganic NPs. NPs are characterized by their small size, large specific area, and ability to produce quantum effects.13

In the present study, TiO2 nanofiller was incorporated into two types of maxillofacial silicone elastomers, VST50F RTV and Cosmesil M511 HTV, to improve their mechanical properties.

Materials and Methods

The maxillofacial silicone elastomers, VST50F RTV and Cosmesil M511 HTV, were procured from Factor II, Inc., Lakeside, AZ, USA. Nano-TiO2 powder (SkySpring Nanomaterials, Inc., Houston, TX, USA) was incorporated into each elastomer in specific concentrations determined from a pilot study. A total of 120 specimens were prepared, 60 each for the RTV and HTV silicone elastomers. The 60 specimens of each type of elastomer were divided into three equal groups according to the tests conducted on them. Each group of 20 specimens was further subdivided into two equal subgroups: (A) control i.e., silicone without nano-TiO2, and (B) experimental i.e., silicone incorporated with nano-TiO2. Each subgroup was composed of 10 specimens.

Pilot study

A pilot study was conducted to determine the most suitable concentration of nano-TiO2 for use by evaluating its effect on the tear strength and hardness of the elastomers. The most suitable nano-TiO2 concentrations for the RTV and HTV silicone elastomers were found to be 0.25 wt% and 0.2 wt%, respectively.

Mold making

The dimensions of the specimen were designed using AutoCAD 2013 (Autodesk Inc., San Rafael, CA, USA) and processed using a computer numerical control machine (Tengzhou Jianda CNC Machine Co., Ltd., China) to form the matrix part of the mold into which the material was poured.14

Mixing of the silicone base (part A) with nano-TiO2

For the experimental groups, nano-TiO2 powder was first added into a mixing container with a clean spatula and weighed by a digital electronic weight balance (0.000 digits; China). Next, the pre-weighed silicone base (part A) was added gradually. Nano-TiO2 powder was first hand mixed with the base for 1 min ± 1 s with a clean, stiff, flat-ended spatula, and then in a mixer container for 2 min ± 1 s by a mechanical mixer (customized vacuum mixer system; Figure 1) without vacuum to prevent suction of the nanopowder.15 The powder was again mixed for 7 min ± 1 s using a mechanical mixer with vacuum to prevent the formation of air bubbles.16 The vacuum pressure was 28 in Hg, as recommended by the manufacturer.17 Prior to the addition of the cross-linking agent (part B), the mixture was left to stand for 2 min because the rotation of the mixer generated heat, which reduced the working time of the material.18

Figure 1.

Customized vacuum mixer system.

Addition of the cross-linking agent (part B)

In accordance with the manufacturer's instructions, the base (part A) was mixed with the catalyst (cross-linking agent, Part B) in the proportion of 10:1 for VST50F, while the base (part A) was mixed with (cross-linking agent, part B) in the same ratio of 10:1 for Cosmesil M511. The mixtures of both the silicone elastomers were prepared at a relative humidity (RH) of 50 ± 10% and the temperature was controlled at 23 ± 2 °C. Parts A and B were mixed using a mechanical mixer with vacuum for 5 min ± 5 s to remove all the air bubbles entrapped during the previous rounds of mixing. Subsequently, the mixture was poured into a 6-mL disposable plastic syringe for injection into the molds.

Pouring of mixture into the molds

The matrix, bottom parts, and cover of the mold for the RTV silicone elastomers were previously coated with a separating medium (alginate solution). The matrix and the bottom parts were securely attached and placed on a dental laboratory vibrator (XH-B VORTEX, China) operating at a low speed. Next, the material was injected from the syringe into the mold in excess. When all the air bubbles disappeared, the vibrator was switched off. The cover of the mold, previously coated with a separating medium, was placed over the matrix starting from one side. At first, only the bottom edge of the cover rested on the matrix while the top edge was held aloft. The cover was then placed slowly and carefully on to the matrix to remove excess material and air from the mold. A constant load of 1 kg (CLW-A; Rex Gauge Company, Inc., Buffalo, NY, USA) was applied over the acrylic mold to ensure that all the bubbles were eliminated (Figure 2). The load was then removed. The molds were secured tightly with nuts and G-clamps (China), and left to cure for 2–4 h, as recommended by the manufacturer.

Figure 2.

Pouring the room-temperature-vulcanized silicone elastomer material into the mold with a constant load (1 kg) placed over the acrylic mold.

To prepare the HTV silicone material, the glass slabs (bottom and cover) and the metal mold were first brushed with a separating medium and left to dry.17 Next, the metallic matrix was placed over the bottom glass slab and secured with screws. The silicone was then injected in excess into the metal mold and left for 1 min to ensure that all the air bubbles were removed from the mold (Figure 3). The glass slab (cover), which was previously coated with separating medium, was placed over the metal mold by the same procedure that was followed for the RTV silicone material. The difference was that the slab was transferred to an oven, preheated to 100 °C, and cured for 1 h, in accordance with the manufacturer's instructions.

Figure 3.

Pouring the high-temperature-vulcanized silicone elastomer material into the mold.

The material was poured at standard conditions with the temperature controlled at 23 ± 2 °C and RH at 50 ± 10%, as suggested by the manufacturer.19, 20

Demolding and storage of samples

According to the product description, the RTV silicone elastomer material sets in approximately 2–4 h, and the HTV silicone elastomer material sets in a hot, dry oven in 1 h. Subsequently, the specimens were removed carefully from the mold.21 Specimens with visible defects, as observed by the same operator, were discarded before the tests.22 The specimens were stored in a customized lightproof box in an air-conditioned room with temperature in the range 10–30 °C and RH ≤ 80%.23

Conditioning of samples

The specimens were conditioned for 24 h prior to testing.24 They were conditioned at a standard laboratory temperature of 23 ± 2 °C for a minimum of 3 h after flash removal.25 The flash was removed with a scalpel and a sharp #11 surgical blade.16

Mechanical testing procedures

-

1.

Tear strength test

In accordance with ASTM D624, specimen testing was conducted using a computer-controlled universal testing machine (WDW-20, Laryee Technology Co., Ltd., Beijing, China).20 Type C specimens were used to measure the tear initiation strength (Figure 4). The following equation was used to determine the tear strength:

where f is the maximum force required to break the sample (kN), and d is the median thickness of each sample (m).20

-

2.

Hardness test

Figure 4.

Type C tear strength test sample, dimensions in mm (adopted from ASTM D624, 2013).

In accordance with ASTM D2240, the test was performed on square specimens with dimensions of 25 × 25 × 6 mm3 using a Type A Shore hardness digital tester (HT6510 Portable Digital Durometer Shore A) with a blunt indenter, 1.25 mm in diameter.25 The hardness of the specimens was measured at five different points that were at a distance of 6 mm from each other and also from the border; the mean measurement values were considered to be the hardness of the specimens.26

-

3.

Tensile strength test

The specimens were prepared in a dumbbell shape (Type 2, Figure 5) in accordance with the ISO 37 test using a computer-controlled universal testing machine (WDW-20, Laryee Technology Co., Ltd., Beijing, China).27 The ultimate tensile strength was calculated from the measured maximum stretching force at break and the original cross-sectional area of the sample using the following equation:

where F is the force recorded at break (N), and A is the original cross-sectional area of the samples (mm2).27

-

4.

Elongation percentage test

Figure 5.

Tensile strength Type 2 sample, dimensions in mm (adopted from ISO 37, 2010).

In accordance with ISO 37, the elongation before break was measured alongside the tensile strength. The elongation percentage at break was measured from the original length of the tensile specimen and the length of the sample at break using the following equation:

where Lo is the original length (mm), and Lb is the extension at break (mm).27

Statistical analyses

To analyze the data of this study, the Statistical Package for the Social Sciences software (version 23) was used. The following statistical analyses were also performed:

-

(1)

Descriptive statistics: graphical display by bar chart, and

-

(2)

Inferential statistics: two-way ANOVA and multiple comparisons were used as post hoc tests, with significance level set at p < 0.01.

Results

Tear strength test

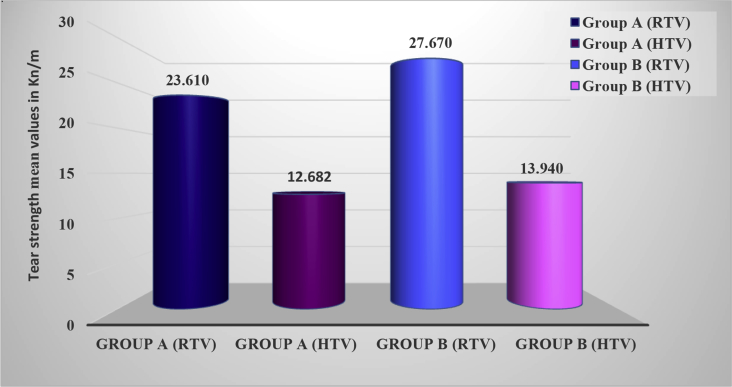

The mean values of the tear strength of the RTV specimens (control = 23.610 and experimental = 27.670) were higher than those of the HTV groups (control = 12.682 and experimental = 13.940; Figure 6). The results of the two-way ANOVA for tear strength showed that the difference was highly statistically significant with p < 0.01 (Table 1).

Figure 6.

Bar chart presenting the mean values of tear strength for all groups in kN/m.

Table 1.

Main effects of the two-way ANOVA on the tear strength test.

| Material | Group | Mean | ±SD | Material | Group | Material*Group | *R2 |

|---|---|---|---|---|---|---|---|

| RTV | A | 23.610 | .341 | F = 8435.360 P-value = 0.00 |

392.360 P-value = 0.000 |

F = 108.924 P-value = 0.000 |

0.996 |

| B | 27.670 | .469 | |||||

| HTV | A | 12.682 | .281 | ||||

| B | 13.940 | .552 |

The post hoc test was used for comparison among the four groups namely, the control and experimental groups of both the materials. A high statistically significant difference (p < 0.01) in the mean values of tear strength was observed between each pair of groups i.e., the control groups of the two materials, the experimental groups of the two materials, and the control and experimental groups of each material (Table 2, Table 3).

Table 2.

Descriptive and statistical tests on the tear strength of materials in each group.

| Group | Statistics | Material |

F | Sig. | |

|---|---|---|---|---|---|

| RTV | HTV | ||||

| A | Mean | 23.610 | 12.682 | 3313.594 | .000 HS |

| SE | .134 | .134 | |||

| B | Mean | 27.670 | 13.940 | 5230.690 | .000 HS |

| SE | .134 | .134 | |||

Table 3.

Descriptive and statistical tests on the tear strength of each group of material.

| Material | Statistics | Group |

F | Sig. | |

|---|---|---|---|---|---|

| A | B | ||||

| RTV | Mean | 23.610 | 27.670 | 457.372 | .000 HS |

| SE | .134 | .134 | |||

| HTV | Mean | 12.682 | 13.940 | 43.912 | .000 HS |

| SE | .134 | .134 | |||

Hardness test

The mean values of hardness of the RTV specimens (control = 27.210 and experimental = 29.270) were higher than those of their HTV counterparts (control = 23.150 and experimental = 24.080; Figure 7). The results of the two-way ANOVA for Shore A hardness showed a high statistically significant difference with p < 0.01 (Table 4).

Figure 7.

Bar chart presenting the mean values of Shore A hardness for all groups.

Table 4.

Main effects of the two-way ANOVA on the Shore A hardness test.

| Material | Group | Mean | ±SD | Material | Group | Material *Group | R2 |

|---|---|---|---|---|---|---|---|

| RTV | A | 27.210 | .288 | F = 1500.804 P-value = 0.00 |

22.397 P-value = 0.000 |

F = 156.813 P-value = 0.000 |

0.977 |

| B | 29.270 | .529 | |||||

| HTV | A | 23.150 | .249 | ||||

| B | 24.080 | .381 |

The post hoc test was used to compare the mean values of the four groups: namely, the control and experimental groups of both the materials. A high statistically significant difference (p < 0.01) was again detected between each pair of groups i.e., the control groups of the two materials, the experimental groups of the two materials, and the control and experimental groups of each material (Table 5, Table 6).

Table 5.

Descriptive and statistical tests on the Shore A hardness of materials in each group.

| Group | Statistics | Material |

F | Sig. | |

|---|---|---|---|---|---|

| RTV | HTV | ||||

| A | Mean | 27.210 | 23.150 | 343.684 | 0.000 HS |

| SE | .119 | .119 | |||

| B | Mean | 29.270 | 24.080 | 1313.933 | 0.000 HS |

| SE | .119 | .119 | |||

Table 6.

Descriptive and statistical tests on the Shore A hardness of each group of material.

| Material | Statistics | Group |

F | Sig. | |

|---|---|---|---|---|---|

| A | B | ||||

| RTV | Mean | 27.210 | 29.270 | 148.869 | 0.000 HS |

| SE | .119 | .119 | |||

| HTV | Mean | 23.150 | 24.080 | 30.341 | 0.000 HS |

| SE | .119 | .119 | |||

Tensile test

The mean values of the tensile strength of the RTV specimens (control = 5.890 and experimental = 6.450) were higher than those of the HTV specimens (control = 3.110 and experimental = 3.360; Figure 8). The two-way ANOVA yielded a highly significant difference with p < 0.01 (Table 7).

Figure 8.

Bar chart presenting the mean values of tensile strength for all groups in MPa.

Table 7.

Main effects of the two-way ANOVA on the tensile strength test.

| Material | Group | Mean | ±SD | Material | Group | Material*Group | R2 |

|---|---|---|---|---|---|---|---|

| RTV | A | 5.890 | .285 | F = 1838.246 P-value = 0.00 |

35.002 P-value = 0.000 |

F = 5.127 P-value = 0.030 |

0.980 |

| B | 6.450 | .288 | |||||

| HTV | A | 3.110 | .088 | ||||

| B | 3.360 | .126 |

The post hoc test was used to compare the four groups namely, the control and experimental groups of both the materials. A highly statistically significant difference (p < 0.01) was again observed between the control groups of the two materials, the experimental groups of the two materials, and the control and experimental groups of each material (Table 8, Table 9).

Table 8.

Descriptive and statistical tests on the tensile strength of materials in each group.

| Group | Statistics | Material |

F | Sig. | |

|---|---|---|---|---|---|

| RTV | HTV | ||||

| A | Mean | 5.890 | 3.110 | 824.607 | 0.000 HS |

| SE | .068 | .068 | |||

| B | Mean | 6.450 | 3.360 | 1018.766 | 0.000 HS |

| SE | .068 | .068 | |||

Table 9.

Descriptive and statistical tests on the tensile strength of each group of material.

| Material | Group |

F | Sig. | ||

|---|---|---|---|---|---|

| A | B | ||||

| RTV | Mean | 5.890 | 6.450 | 33.461 | 0.000 HS |

| SE | .068 | .068 | |||

| HTV | Mean | 3.110 | 3.360 | 6.669 | 0.014 HS |

| SE | .068 | .068 | |||

Elongation percentage (%) test

The mean values of the elongation percentage of the RTV specimens (control = 1431.166 and experimental = 1462.707) were higher than those of their HTV counterparts (control = 1040.561 and experimental = 1097.500; Figure 9). The two-way ANOVA for these results showed that the difference was highly statistically significant with p < 0.01 (Table 10).

Figure 9.

Bar chart presenting the mean values of elongation percentage (%) for all groups.

Table 10.

Main effects of the two-way ANOVA on the elongation percentage test.

| Material | Group | Mean | ±SD | Material | Group | Material*Group | R2 |

|---|---|---|---|---|---|---|---|

| RTV | A | 1431.166 | 56.900 | F = 269.526 P-value = .000 |

F = 3.694 P-value = .063 |

F = .304 P-value = .585 |

0.874 |

| B | 1462.707 | 120.003 | |||||

| HTV | A | 1040.561 | 59.120 | ||||

| B | 1097.500 | 7.824 |

The post hoc test was used for comparison between the four groups namely, the control and experimental groups of both the materials. A highly statistically significant difference (p < 0.01) was noted between the control groups of the RTV and HTV materials and also between the experimental groups of the two materials. However, unlike in the previous tests, statistically significant difference was not observed between the control and experimental groups of each of the two materials with p > 0.01 (Table 11, Table 12).

Table 11.

Descriptive and statistical tests on the elongation percentage of materials in each group.

| Group | Statistics | Material |

F | sig. | |

|---|---|---|---|---|---|

| RTV | HTV | ||||

| A | Mean | 1431.166 | 1040.561 | 143.972 | .000 HS |

| SE | 23.019 | 23.019 | |||

| B | Mean | 1462.707 | 1097.500 | 125.858 | .000 HS |

| SE | 23.019 | 23.019 | |||

Table 12.

Descriptive and statistical tests on the elongation percentage of each group of material.

| Material | Statistics | Group |

F | Sig. | |

|---|---|---|---|---|---|

| A | B | ||||

| RTV | Mean | 1431.166 | 1462.707 | .939 | .339 NS |

| SE | 23.019 | 23.019 | |||

| HTV | Mean | 1040.561 | 1097.500 | 3.059 | .089 NS |

| SE | 23.019 | 23.019 | |||

Discussion

In this study, TiO2 NPs (TiO2 anatase, 99%, 10–30 nm) were used as reinforcement materials to enhance the mechanical properties of the maxillofacial elastomers. Titanium oxide NPs, 30–150 nm in size, are considered safe for use in cosmetic products in concentrations of up to approximately 25%.28 Although the TiO2 NPs used in this study were of low concentrations, they were handled with considerable care in accordance with the instructions supplied in the safety data sheet.29

The properties that are considered essential for maxillofacial silicone elastomers are high tear resistance, high tensile strength, good level of elongation at break, adequate hardness, and ideal color stability. Results from various studies indicate that none of the trading materials tested can meet all these criteria. Given the different components used in their formulations, the materials available exhibit several differences in their mechanical and physical properties.4, 30

To achieve the degree of reinforcement requisite for significant improvement in mechanical properties, filler addition is deemed highly necessary. The reinforcement depends to a large extent on the filler loading (amount of filler), filler characteristics (particle size or specific surface area, structure, and surface activity), polymer properties, and processing conditions.31

The results of the tear strength test indicate that the tear strength exhibited a highly statistically significant increase (p < 0.01) when nano-TiO2 was added to VST50F (RTV) and Cosmesil M511 (HTV). In addition, a highly statistically significant difference (p < 0.01) was observed between the tear strengths of the two materials (Table 1, Table 2, Table 3). The action of the NPs in the continuous phase of the silicone elastomer causes an increase in the formation of cross-linked structures in the silicone material and in the cross-sectional area and force, thereby enhancing the tear strength of the reinforced material. Thus, incorporating TiO2 NPs strengthens the silicone elastomers.32

The increase in tear strength can be explained by the ability of the polymer to dissipate strain energy near the tips of the growing cracks. When tearing propagates, nanofillers dissipate the energy within the polymer matrix, making it highly resistant to tearing; hence, a large load will be required to break the polymer matrix completely.33

A reduction in curing time increases tear strength; thus, when the matrix is slightly undercured, the tear resistance of an elastomer is improved.34 The result of this study is similar to those reported in previous studies that found that incorporation of NPs improved the tear strength of silicone elastomers.10, 11, 18

The results of the hardness test indicate that the RTV silicone was harder than the HTV silicone, the difference being statistically significant (p < 0.01). The increase in Shore A hardness was highly statistically significant (p < 0.01) when 0.25wt% and 0.2wt% of nano-TiO2 was added to the RTV and HTV silicone materials, respectively. This finding indicates that hardness increased but within a limited range (Table 4, Table 5, Table 6).

The mean value of the Shore A hardness of the experimental group was higher than that of the control group for both the materials. This can be attributed to the effects of the NPs on the elastic modulus of the silicone elastomer.35 The elastic modulus of the silicone elastomer is proportional to its Shore A hardness.36 Nanoparticle dispersion in the silicone elastomer increases the cross-link density and hardness.37

The intermolecular or interatomic forces of a material affect its elasticity. The stiffness or rigidity of a material with high elastic modulus can be attributed to potent basic attraction forces.38 These results are supported by the findings of Han et al. (2008), Guiotti et al. (2016), and Tukmachi and Moudhaffer (2017) who found that incorporation of NPs increased the hardness of silicone elastomers.10, 15, 18

The results of the tensile strength and elongation at break tests indicate that the mean value of the RTV silicone was higher than that of the HTV silicone, with a statistically significant difference (p < 0.01). The results also show that tensile strength exhibited a statistically significant increase (p < 0.01) when nano-TiO2 was added in concentrations of 0.25wt% and 0.2wt% to the RTV and HTV silicone materials, respectively. The elongation percentage increased after the addition of nano-TiO2 into both the types of elastomers. Nevertheless, the amount added was not statistically significant (p > 0.01) when compared with unreinforced silicone (Table 7, Table 8, Table 9, Table 10, Table 11, Table 12). This finding can be attributed to the chemical and physical interactions of nano-TiO2 with the polymer chains. The tensile strength and elongation of the cured silicone elastomer depend considerably on the cross-linking system, cross-linking density, and interaction between the fillers and polymer chains.4

The reinforcement mechanism of the nanofiller is that NPs act as multifunctional cross-links by forming strong hydrogen bonds between surface hydroxyl groups and polydimethylsiloxane (PDMS) chains. These multifunctional cross-links increase the overall cross-linking density of the polymer and make it largely stiff and strong. Under tensional forces, these cross-links prevent the PDMS chains from breaking, thus increasing the tensile strength.39

Tensile strength can be considered based on the catastrophic tearing of cracks from voids. A small amount of elastic energy can break the polymer network when the elastomeric network can dissipate input energy into heat. Filler addition is a good source of energy dissipation.40

At a high TiO2 particle loading, the filler–filler interaction results in an agglomerated morphology. Particle agglomeration leads to a reduction in the aspect ratio of the TiO2 particles. Consequently, the contact surface between the polymer matrix and the particles is reduced. The agglomerated TiO2 particles may also act as stress concentration sites in the composites. Thus, when exposed to tensile mode distortion, the particles detach and de-bond from the polymer matrix.41 The findings on tensile strength and elongation at break in this study agree with those of previous studies.10, 11, 18

Conclusion

Within the limits of this study, the incorporation of nano-TiO2 into VST50F (RTV) and Cosmesil M511 (HTV) maxillofacial silicone elastomers improved some of their mechanical properties such as tear strength, tensile strength, and elongation at break. Nano-TiO2 increased the hardness of silicone in direct proportion to the concentration of the nanofiller.

Conflict of interest

The authors have no conflict of interest to declare.

Authors' contributions

FA conceived and designed the study and conducted the research. DS provided the research materials and collected and organized the data. FA and DS analyzed and interpreted the data. FA wrote the initial and final drafts of the article and provided logistic support. All authors have critically reviewed and approved the final draft and are responsible for the content and similarity index of the manuscript.

Ethical approval and statement of declaration of Helsinki

We would like to inform you that our research has not used human or animal studies.

Footnotes

Peer review under responsibility of Taibah University.

References

- 1.Maller U.S., Karthik K.S., Maller S.V. Maxillofacial prosthetic materials - past and present trends. J Indian Acad Dent Spec. 2010;1(2):42–44. [Google Scholar]

- 2.Roberts A.C. Facial reconstruction by prosthetic means. Br J Oral Surg. 1967;4(3):157–182. doi: 10.1016/s0007-117x(66)80032-x. [DOI] [PubMed] [Google Scholar]

- 3.Andres C.J., Haug S.P., Munoz C.A., Bernal G. Effects of environmental factors on maxillofacial elastomers: Part I-Literature review. J Prosthet Dent. 1992;68(2):327–330. doi: 10.1016/0022-3913(92)90339-c. [DOI] [PubMed] [Google Scholar]

- 4.Aziz T., Waters M., Jagger R. Analysis of the properties of silicone rubber maxillofacial prosthetic materials. J Dent. 2003;31(1):67–74. doi: 10.1016/s0300-5712(02)00084-2. [DOI] [PubMed] [Google Scholar]

- 5.Haug S.P., Andres C.J., Moore B.K. Color stability and colorant effect on maxillofacial elastomers. Part III: weathering effect on color. J Prosthet Dent. 1999;81(4):431–438. doi: 10.1016/s0022-3913(99)80010-9. [DOI] [PubMed] [Google Scholar]

- 6.Aziz T., Waters M., Jagger R. Development of a new poly (dimethylsiloxane) maxillofacial prosthetic material. J Biomed Mater Res Part B. 2003;65:252–261. doi: 10.1002/jbm.b.10559. [DOI] [PubMed] [Google Scholar]

- 7.Bellamy K., Limbert G., Waters M., Middleton J. An elastomeric material for facial prostheses: synthesis, experimental and numerical testing aspects. Biomaterials. 2003;24(27):5061–5066. doi: 10.1016/s0142-9612(03)00412-5. [DOI] [PubMed] [Google Scholar]

- 8.Hayashi S., Fujikiand K., Tsubokawa N. Grafting of hyperbranched polymers onto ultrafine silica: postgraft polymerization of vinyl monomers initiated by pendant initiating groups of polymer chains grafted onto the surface. React Funct Polym. 2000;46(2):193–201. [Google Scholar]

- 9.Khanand A., Alam M. Synthesis, characterization and analytical applications of a new and novel ‘organic–inorganic’ composite material as a cation exchanger and Cd (II) ion-selective membrane electrode: polyaniline Sn(IV) tungstoarsenate. React Funct Polym. 2003;55(3):277–290. [Google Scholar]

- 10.Han Y., Kiat-amnuay S., Powers J.M., Zhao Y. Effect of nanooxide concentration on the mechanical properties of a maxillofacial silicone elastomer. J Prosthet Dent. 2008;100(6):465–473. doi: 10.1016/S0022-3913(08)60266-8. [DOI] [PubMed] [Google Scholar]

- 11.Mohammad S.A., Wee A.G., Rumsey D.J., Schricker S.R. Maxillofacial materials reinforced with various concentrations of polyhedral silsesquioxanes. J Dent Biomech. 2010;1:701845–701851. doi: 10.4061/2010/701845. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Noberga A.S., Andreotti A.M., Moreno Amalia, Sinhoreti Mario A.C., Dos santos Daniela M., Goiato Macelo C. Influence of adding nanoparticles on the hardness, tear strength and permanent deformation of facial silicone subjected to accelerated aging. Prosthet Dent. J. 2016;116(4):623–629. doi: 10.1016/j.prosdent.2016.03.004. [DOI] [PubMed] [Google Scholar]

- 13.Han Y., Zhao Y., Xie C., Powers J.M., Kiat-Amnuay S. Color stability of pigmented maxillofacial silicone elastomer: effects of nano-oxides as opacifiers. J Dent. 2010;2(38 Suppl):e100–e105. doi: 10.1016/j.jdent.2010.05.009. [DOI] [PubMed] [Google Scholar]

- 14.Chi Y.H. Indiana University School of Dentistry; Indianapolis (MI): 2014. Effect of silica filler on the mechanical properties of silicone maxillofacial prothesis [dissertation] [Google Scholar]

- 15.Guiotti A.M., Goiato M.C., Dos Santos D.M., Vechiato-Filho A.J. Comparison of conventional and plant-extract disinfectant solution on the hardness and color stability of a maxillofacial elastomer after artificial weathering. J Prosthet Dent. 2016;115(4):501–508. doi: 10.1016/j.prosdent.2015.09.009. [DOI] [PubMed] [Google Scholar]

- 16.Zayed S., Alshimy A., Fahmy A. Effect of surface treated silicon dioxide nanoparticles on some mechanical properties of maxillofacial silicone elastomer. Int J Biomater. 2014;2014(2014):750398–750405. doi: 10.1155/2014/750398. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Abudullah H.A. College of Dentistry (Baghdad): University of Baghdad; 2016. Evaluation of some mechanical properties of a new silicone material for maxillofacial prostheses after addition of intrinsic pigments [dissertation] [Google Scholar]

- 18.Tukmachi M.S., Moudhaffer M.A. Effect of nano silicone dioxide addition on some properties of heat vulcanized maxillofacial silicone elastomer. IOSR - JPBS. 2017;12(3):37–43. [Google Scholar]

- 19.ISO 23529 . 2010. Rubber – general procedures for prearing and conditioning test pieces for physical test methods. [Google Scholar]

- 20.ASTM D624-00 . ASTM International; West Conshohocken, PA, USA: 2013. Standard test method for tear strength of conventional vulcanized rubber and thermoplastic elastomers. [Google Scholar]

- 21.Pinheiro J.B., Reis A.C., Pisani M.X., Leite V.M.F., Souza R.F., Paranhos H.F.O. Microstructural characterization and evaluation of the properties of polymeric materials for maxillofacial prosthetics. J Med Eng Technol. 2014;38(2):67–75. doi: 10.3109/03091902.2013.864715. [DOI] [PubMed] [Google Scholar]

- 22.Al-Harbi F.A., Ayad N.M., Saber M.A., ArRejaie A.S., Morgano S.M. Mechanical behavior and color change of facial prosthetic elastomers after outdoor weathering in a hot and humid climate. J Prosthet Dent. 2014;113(2015):146–151. doi: 10.1016/j.prosdent.2014.09.008. [DOI] [PubMed] [Google Scholar]

- 23.Brown R. 4th ed. Springer Science & Business Media; 2006. Physical testing of rubber. [Google Scholar]

- 24.ASTM D1349 . ASTM International; West Conshohocken, PA, USA: 2014. Standard temperature for testing. [Google Scholar]

- 25.ASTM D2240-05 . ASTM International; West Conshohocken, PA, USA: 2010. Standard test method for rubber property durometer hardness. [Google Scholar]

- 26.Hatamleh M.M., Watts D.C. Mechanical properties and bonding of maxillofacial silicone elastomers. Dent Mater J. 2010;26(2):185–191. doi: 10.1016/j.dental.2009.10.001. [DOI] [PubMed] [Google Scholar]

- 27.ISO 37 . 2011. Rubber, vulcanized or thermoplastic - determination of tensile stress-strain properties. [Google Scholar]

- 28.Schilling K., Bradford B., Castelli D., Dufour E., Nash J.F., Pape W. Human safety review of "nano" titanium dioxide and zinc oxide. Photochem Photobiol Sci. 2010;9(4):495–509. doi: 10.1039/b9pp00180h. [DOI] [PubMed] [Google Scholar]

- 29.US Research Nanomaterials, Inc . 2016. Safty data sheet.www.us-nano.com Revised 2016. [Google Scholar]

- 30.Lewis D.H., Castleberry D.J. An assessment of recent advances in external maxillofacial materials. J Prosthet Dent. 1980;43(4):426–432. doi: 10.1016/0022-3913(80)90215-2. [DOI] [PubMed] [Google Scholar]

- 31.Mahrholz T., Stängle J., Sinapius M. Quantitation of the reinforcement effect of silica nanoparticles in epoxy resins used in liquid composite moulding processes. J Comp Part A: App Sci Manu. 2009;40(3):235–243. [Google Scholar]

- 32.Li Q., Xia Y.Y., Tang J.C., Wang R.Y., Bei C.Y., Zeng Y. In vitro and in vivo biocompatibility investigation of diamond-like carbon coated nickel-titanium shape memory alloy. Artif Cell Blood Substit Biotechnol. 2011;39(3):137–142. doi: 10.3109/10731199.2010.502880. [DOI] [PubMed] [Google Scholar]

- 33.Sun L., Gibson R., Gordaninejad F., Suhr J. Energy absorption capability of nanocomposites: a review. Compos Sci Technol. 2009;69(14):2392–2409. [Google Scholar]

- 34.Sreeja T. Cochin University of Science and Technology; Cochin: 2012. Studies on short nylon fiber-reclaimed rubber/elastomer composites [dissertation] [Google Scholar]

- 35.Xia L., Xu Z., Sun L., Gaveney P.M., Zhang M.J. Nano-fillers to tune Young's modulus of silicone matrix. J Nanoparticle Res. 2013;15(4):1570. [Google Scholar]

- 36.Meththananda I.M., Parker S., Patel M.P., Braden M. The relationship between shore hardness of elastomeric dental materials and Young's modulus. Dent Mater. 2009;25(8):956–959. doi: 10.1016/j.dental.2009.02.001. [DOI] [PubMed] [Google Scholar]

- 37.Stoyanov H., Brochu P., Niu X., Della G.E., Pei Q.B. Dielectric elastomer transducers with enhanced force output and work density. Appl Phys Lett. 2012;100(26):262902–262910. [Google Scholar]

- 38.Sakaguchi R.L., Powers J.M. 13th ed. Elsevier Health Sciences; 2012. Craig's restorative dental materials-E-Book. [Google Scholar]

- 39.Andreopoulos A.G., Evangelatou M. Evaluation of various reinforcements for maxillofacial silicone elastomers. J Biomater Appl. 1994;8(4):344–360. doi: 10.1177/088532829400800403. [DOI] [PubMed] [Google Scholar]

- 40.Rajkumar K., Ranjan P., Thavamani P., Jeyanthi P., Jeyanthi P. Dispersion studies of nanosilica in nbr based polymer nanocomposite. Rasayan J Chem. 2013;6(2):122–133. [Google Scholar]

- 41.Mirabedini S.M., Mohseni M., PazokiFard S., Esfandeh M. Effect of TiO2 on the mechanical and adhesion properties of RTV silicone elastomer coatings. Colloids Surf A: Physicochem Eng Aspect. 2008;317(1–3):80–86. [Google Scholar]