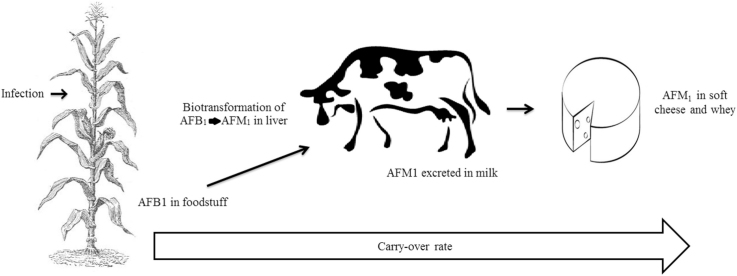

Graphical abstract

Keywords: Aflatoxin B1, Aflatoxin M1, Carry-over, Cheese

Highlights

-

•

The levels of AFM1 in milk produced in Argentina are relatively low.

-

•

Milk production, fiber particle size and AFB1 level affected the carry-over rate.

-

•

The greatest proportion of AFM1 in milk is detected in whey during cheese. production.

Abstract

From January to December 2016, samples of milk and feeds of dairy cattle were monthly collected. The concentration of mycotoxins in all matrices was determined using the enzymatic immunoassay technique. The average concentration of aflatoxin B1 (AFB1), deoxynivalenol (DON) and zearalenone (ZEA) in feed was 3.01, 218.5 and 467 ug/kg, respectively. The average AFB1 carry-over rate was 0.84% with a variation between 0.05 to 5.93%. Particle size of the feed (P = 0.030) and individual milk production (P = 0.001) affected this rate. Mini-soft cheeses were produced using milk naturally contaminated with aflatoxin M1 (AFM1) as raw material to study its distribution both in whey and in cheese. The average level of AFM1 in milk was 0.014 μg/l. None of milk samples exceeded the maximum level accepted for AFB1 by the Southern Common Market (MERCOSUR) legislation (0.5 μg/l) and only 5.5% of samples exceeded the European Union (UE) regulations (0.05 μg/l). After the cheese elaboration, the concentration of AFM1 was determined in whey and in cheese. The greatest proportion (60%) was detected in whey while 40% AFM1 remained in the cheese. However, the concentration of AFM1 was higher in the cheese compared to the original milk.

1. Introduction

Mycotoxins are secondary metabolites produced by specific fungi that are natural contaminants of foods [1]. At appropriate ambient temperature and humidity conditions, mycotoxins can be found at any stage of the production chain. However, the fungi presence does not imply mycotoxin formation [2].

Upon ingestion by ruminants, aflatoxin B1 (AFB1) is partially destroyed in the rumen, whereas the absorbed AFB1 rapidly undergoes metabolic processes in the liver to various secondary metabolites [3,4]. Aflatoxin M1 (AFM1) is major oxidation metabolite derivate of AFB1, and excreted primarily in the urine and secondarily in the milk [5,2]. Even though it is not as mutagenic and genotoxic as AFB1, AFM1 exhibits a high genotoxic activity and it has been classified by IARC as a class 2B human carcinogen [6].

AFM1 is relatively stable in raw milk and milk products and it is not destroyed by heat [7]. Infants and children are the most susceptible population due to the high level of milk consumed and to the fact that their biochemical detoxification mechanisms are not fully operative yet, what constitutes a high risk for the public health [8,5].

Argentina, information on AFM1 levels in dairy products and by-products and carry-over rates through the milk chain is lacking. The objective of this study was to quantify the aflatoxin carry-over rate from feed to milk and its distribution during processing soft cheese.

2. Materials and methods

The level of AFB1 contained in the feeds consumed by the cows, the level of AFM1 in the milk produced by these cows and the concentration of AFM1 in the cheeses made with these milks and the whey derived, were monitored for a year. Monthly, feed and milk samples were collected simultaneously in a semi-intensive voluntary milking system (VMS, DeLaval Group, Tumba, Sweden) where cows have access to pasture and supplements all year round (characteristic of Argentina average milk production system).

2.1. Feeds

2.1.1. Sampling

A total of 32 dairy cattle feedstuffs were sampled: 8 grass samples (in the winter, for four months the cows did not have access to the grass), 12 concentrate samples and 12 Total Mixed Ration (TMR) samples composed of corn and wheat silages, cottonseed, alfalfa hay and by-products (soybean expeller and sunflower pellet). The amount of each ingredient in the diet is detailed in Table S1. The samples were taken following a sampling procedure [9]. Then, feed samples were dried at 65 °C for 48 h in a forced-air oven, and then ground to pass through a 0.9 mm mesh sieve using a high-speed grinder and stored at −20 °C until analysis of aflatoxin.

Additionally, the particle size of TMR was measured by the Penn State Particle Separator (PSPS) [10]. A sample of 500 g of TMR was placed on the upper tray and shaken. Then the materials of the respective trays are weighed and the proportions in each one are calculated.

2.1.2. Aflatoxin detection in feeds

The procedure for AFB1 determination in feed samples was based on an Enzyme-Linked Immunoassay (ELISA) using the RIDASCREEN test kit (R-Biopharm, Darmstadt, Germany). The limit of detection (LOD) was <1.7 μg/kg and solutions 0, 5, 10, 20, 50 μg AFB1/l were used for quantification. Sample preparation and test procedure was performed according to manufacturer’s instructions. The general prevalence was calculated as the number of samples with aflatoxin concentration greater that the LOD divided by the total number of samples.

2.2. Milk

2.2.1. Sampling

A total of 36 cows were sampling according to lactation stage: a) <90 days of lactation (high milk production); b) between 90 and 150 days (medium milk production) and c) >150 days of lactation (low milk production). From the total raw milk collected per cow, one portion (1 l) was used immediately for cheese manufacture and other (250 ml) for AFM1 analysis.

2.2.2. Aflatoxin detection in milk

A total of 36 milk samples were analyzed for AFM1 using the RIDASCREEN test kit (R-Biopharm, Darmstadt, Germany) following manufacturer’s instructions. The LOD was 0.005 μg/l, and solutions 0, 5, 10, 20, 40, 80 μg AFM1/l were used for quantification.

2.2.3. Carry-over rate calculation

The carry-over rate of AFB1 to AFM1 in milk was calculated as percentage of consumed AFB1 that was excreted as AFM1 in milk. AFB1 concentration in feed was calculated as the sum of AFB1 concentration in each ingredient (in μg/kg) divided by the total amount of consumed feed (in kg). The total amount of AFM1 excreted in milk was calculated considering AFM1 concentration in milk (in μg/l milk) multiplied by total amount of produced milk (in l).

The carry-over rate was calculated from the feeds consumed by the cows on the day of sampling. The amount of concentrate consumed for cows (in Kg) and the amount of produced milk for cows (in l) were obtained by the VMS management software (Delpro, DeLaval). Regarding fresh grass and TMR, the amount consumed was calculated as the subtraction between the offered feed (Table S1) and consumed by the measurement of remaining feed.

2.2.4. Milk characterization

Milk physico-chemical and sanitary quality parameters were determined: fat and protein were measured by infrared spectroscopy (MilkoScan FT 120, Foss System, Hillerød, Denmark). pH was measured by potentiometric method, using the Titroline Alpha Plus automated autoanalyzer (Schott Instruments, Mainz, Germany). The acidity was determined by manual titration, with acidimeter [11]. The somatic cell count (SCC) and total bacterial counts (TBC) were automatically determined by Fossomatic and Bactoscan [12], respectively [13].

2.3. Cheese and whey

2.3.1. Cheese-making

A total of 36 mini-soft cheeses were manufactured from 1 l of milk according to the standard process for Cremoso Argentino Cheese [14]. Whey samples (250 ml) were collected after mixing the whey from the vat and from the cheese draining. Cheeses were brined for 3 min in saturated brine at 4 °C and ripened at 4 °C for 20 days. Next, the cheeses were weighed and vacuum packed using Cryovac BB2800CB bags (permeability to O2 30 cm3 m−2 24 h−1 bar−1; CO2 150 cm3 m−2 24 h−1 bar−1; water vapor 20 g 24 h−1 m−2; Sealed Air Co., Buenos Aires, Argentina).

2.3.2. Cheese chemical composition

Cheese total protein and fat were assessed in cheese according to International Dairy Federation (IDF) standards [[15], [16], [17]] and results were expressed as percentage of dry matter. The pH was determined as described by Bradley et al. [18] by immersing the electrode (Schott Instrument, Mainz, Germany) in a homogenate (1:1) of grated cheese.

2.3.3. Aflatoxin detection in cheese and whey

Mini-soft cheese samples (n = 36) and whey samples (n = 36) were analyzed for AFM1 using the RIDASCREEN test kit (R-Biopharm, Darmstadt, Germany) following manufacturer’s instructions. The LOD was 0.05 μg/l for both, and solutions 0, 5, 10, 20, 40, 80 μg AFM1/l were used for quantification.

2.3.4. Statistical analysis

The effect of season, lactation stage, milk production, health status (measured as somatic cell counts), particle size, and AFB1 level in different feedstuff (considered as independent variables) on AFM1 concentration in milk and on AFB1 carry-over rate (both outcome variables) was evaluated by Generalized Linear Models with Gamma distribution as a link function. This statistical model was performed because the outcome variables were not normally distributed. Statistical analyses were performed using the InfoStat software (Universidad Nacional de Córdoba, Córdoba, Argentina) [19].

3. Results

3.1. Feeds

The levels of aflatoxin AFB1 in feed samples are shown in Table 1. The general prevalence was 81.3%. AFB1 concentration in feed was not influenced by the season (P = 0.106). AFB1 prevalence was particularly high in TMR, although the highest concentrations were observed in fresh grass.

Table 1.

Occurrence of aflatoxin B1 in feedstuffs, expressed in μg/kg.

| Mycotoxins | Ingredients | Positive a(n) % | Range | Average b | Exceed Legal Limitc |

|---|---|---|---|---|---|

| AFB1 | Fresh grass (n = 8) | (7) 87 | 2.7-8.1 | 5 ± 2.3 | 0% (MERCOSUR) 19% (EU) |

| Concentrate (n = 12) | (8) 67 | 1.9-5.7 | 3.2 ± 1.3 | ||

| TMR (n = 12) | (11) 92 | 1.9-5.3 | 3.4 ± 1.04 | ||

| TOTAL = (26) 81 - 3.8 ± 1.7 | |||||

References: AFB1 = aflatoxin B1. TMR = Total Mixed Ration.

Samples > Limit of Detection (LOD).

Mean of positive samples ± standard deviation.

Maximum levels are 20 μg/kg for MERCOSUR and 5 μg/kg for EU.

The European Union (EU) [20] and MERCOSUR [21], establish maximum levels of 5 and 20 μg AFB1/kg feed, respectively. In this study, approximately 19% feed analyzed exceeded the value stablished by the EU but none exceeded the value established by MERCOSUR (Table 1).

3.2. Milk

AFM1 levels in milk samples ranged from 0.003 μg/l to 0.064 μg/l with a mean value of 0.014 μg/l (Table 2). Considering the amount of daily milk produced, the average AFM1 level in individual cow milk was 0.413 μg.

Table 2.

Values (expressed as mean ± standard deviation) of aflatoxin intake, milk data and carry-over for stage of lactation.

| Milk production | AFB1 intake (μg/day) |

Milk yield (kg/day) |

AFM1 concentration in milk (μg/kg) |

AFM1 excretion in milk (μg/day) | Carry-over1 % (range) |

|---|---|---|---|---|---|

| High (n = 12) | 66.08 ± 27.5 | 34.12 ± 9.7 | 0.016 ± 0.02 | 0.484 ± 0.43 | 0.88a (0.06 – 1.99) |

| Medium (n = 12) | 66.92 ± 26.0 | 30.54 ± 5.5 | 0.016 ± 0.02 | 0.514 ± 0.63 | 1.09a (0.07 – 5.93) |

| Low (n = 12) | 67.50 ± 25.6 | 20.15 ± 5.7 | 0.011 ± 0.01 | 0.239 ± 0.22 | 0.56a (0.05 – 3.22) |

|

Means (range) |

66.8 (15 – 108) |

28.27 (13 – 49) |

0.014 (0.003 - 0.064) |

0.413 (0.039 – 2.405) |

0.84 (0.05 – 5.93) |

References: 1Values in the same column with different superscript differ significantly.

Twenty-eight of the 36 milk samples (77.8%) had detectable levels of AFM1, where 5.5% of the samples showed higher levels than the value stablished by the European regulations (0.05 μg/l) [22]. However, all samples were within the maximum level accepted by MERCOSUR regulation (0.5 μg/l) [21].

The presence and concentration of AFM1 in milk were not influenced by season (P = 0.325) nor by lactation stage (P = 0.130). Similarly, the milk yield (P = 0.514) as well as to the health status of the mammary gland (measured as somatic cell count) (P = 0.896) were not associated with the concentration of this mycotoxin. Regarding the feeds used in milk farm, fresh grass (P = 0.118), concentrate (P = 0.758) and TMR (P = 0.285), was not associated with AFM1 concentration in milk.

The particle size of TMR retained on the top screen (greater than or equal to 19.0 mm) was associated with the concentration of AFM1 in milk (P = 0.010). The current recommendations indicate that the amount of TMR retained on the top screen of the PSPS is 8 percent; this value indicates that the animal has enough effective fiber in the diet and of an adequate size for the correct functioning of the rumen [23]. Diets in which the particle size retained on the top screen exceeded 8% presented a higher concentration of AFM1 (mean concentration=0.0164 μg/l) than in the TMR in which sample size was ideal (AFM1 mean concentration=0.0075 μg/l).

3.3. The AFB1 carry-over from feed to the milk

The average AFB1 carry-over rate was 0.84% with a variation between 0.05%–5.93%, and did not present significant differences (P > 0.05) among means (Table 2). The average carry-over rate was not affected by lactation stage (P = 0.298). However, when the milk yield was considered, regardless of the lactation stage, it affected the carry-over rate (P = 0.001). The average carry-over rate was 1.21% (range 0.23–5.93 %) in high-yield cows (more than 28.5 l/day) while low-yield cows (less than 28.5 l/day) presented an average carry-over rate of 0.48% (range 0.05–2.12 %).

The AFB1 level in the fresh grass (P = 0.070), concentrate (P = 0.001) and TMR (P = 0.001) was associated with the carry-over rate. Also, particle size retained on the top screen (P = 0.030) affected the carry-over rate from AFB1 to AFM1 in milk. Diets in which the particle size exceeded 8% presented a higher carry-over rate (0.61%) than diets in which sample size was ideal (0.34%).

Finally, the somatic cell count in milk (P = 0.435) and season (P = 0.405) were not correlated with the carry-over rate of AFB1 to AFM1 in milk.

3.4. Cheese and whey

The characteristics of the milk utilized in the cheese making processes are reported in Table 3 and did not present significant differences (P > 0.05) among means. These values are within the requirements stablished by the EU [24] and by the reference milk system of Argentina [25]. Mini-soft cheese yield ranged from 7.72% to 14.20%, and values (mean ± SD) of pH, moisture, fat and total protein were 5.40 ± 0.05, 48.99% ± 1.15%, 51.23% ± 2.91%, and 37.60% ± 6.01%, respectively. Taking into account these ranges, according to the Argentine Food Code, the cheeses obtained are classified as fatty, high moisture or soft paste.

Table 3.

Composition of milk used for cheese-making.

| Items | High milk production1 (n = 12) |

Medium milk production1 (n = 12) |

Low milk production1 (n = 12) |

|---|---|---|---|

| Fat (%)1 | 3.19 ± 0.20a | 3.71 ± 0.23a | 3.65 ± 0.23a |

| Protein (%)1 | 3.21 ± 0.09a | 3.46 ± 0.09b | 3.59 ± 0.09c |

| pH1 | 6.73 ± 0.06a | 6.72 ± 0.05a | 6.73 ± 0.06a |

| Acidity (°D)1 | 17.33 ± 0.36a | 17.08 ± 0.36a | 16.58 ± 0.35a |

| Somatic cell count (x1000 cells/ml)1 | 80.91 ± 139a | 101 ± 105a | 107 ± 94a |

| Total bacterial count (Log cfu/ml)1 | 4.62 ± 0.29a | 4.63 ± 0.29 a | 4.27 ± 0.27 a |

Reference: 1 Values in the same column with different superscript differ significantly.

In 36 samples studied, AFM1 was detected in 19 (52.8%) cheese samples and one whey sample (2.8%). Only one cheese sample exceeded the maximum acceptable level set by European Community countries regulating AFM1 in cheeses (>0, 25 μg/kg).

Table 4 shows the distribution of AFM1 in cheese and whey during cheese production from the naturally contaminated milk. In the whey samples AFM1 levels were between 55% and 58% of the total amount of the toxin present in the naturally contaminated milk, being the percentage remaining in the cheeses. The level of AFM1 in cheese was higher than in the original milk, resulting in a concentration factor, for the Cremoso Argentino cheese, ranging from 5.4 to 5.6.

Table 4.

Distribution of AFM1 in cheese, whey and milk from which they were made, for the Cremoso Argentino Cheese production method.

| Milk production | Samples | Amount (ml or g) | AFM1c |

% of AFM1 mass distribution a | |

|---|---|---|---|---|---|

| (μg/l, kg) | Total mass (μg) | ||||

|

High (n=12) |

Milk | 1000 | 0.01607 | 0.01607 | |

| Whey | 851 | 0.01435 | 0.01225 | 56.9 | |

| Cheese | 107 | 0.08662 | 0.00927 | 43.1 | |

| bConcentration factor in cheese = 5.4 | |||||

| Medium (n=12) | Milk | 1000 | 0.01564 | 0.01564 | |

| Whey | 850 | 0.01501 | 0.1276 | 58.1 | |

| Cheese | 107 | 0.08615 | 0.00922 | 41.9 | |

| Concentration factor in cheese = 5.5 | |||||

|

Low (n=12) |

Milk | 1000 | 0.01094 | 0.01094 | |

| Whey | 848 | 0.01014 | 0.0086 | 56.7 | |

| Cheese | 107 | 0.06130 | 0.00656 | 43.3 | |

| Concentration factor in cheese = 5.6 | |||||

| Means (n=36) | Milk | 1000 | 0.01519 | 0.01519 | |

| Whey | 849 | 0.01317 | 0.01118 | 55.4 | |

| Cheese | 107 | 0.08421 | 0.00900 | 44.6 | |

| Concentration factor in cheese = 5.5 | |||||

[(Total AFM1 mass (μg) in whey or cheese) * 100 / (AFM1 in cheese + whey)].

Concentration of AFM1 in cheese on milk.

Limits for milk established by MERCOSUR: 0.5 μg/l. Limits for milk and cheese established by European Union: 0.05 μg/l and >0.25 μg/kg, respectively.

4. Discussion

The average concentration of AFB1 in the dairy cattle diets in the present study was slightly lower that the reported by Signorini et al. [26] in the same dairy production region in Argentina. This small difference may be explained by the climatic conditions of the year of study, characterized by a high humidity which could encourage the proliferation of fungi.

Seasons, milk yield and the amount of feed consumed were not associated with the level of aflatoxins in milk, results opposite to those reported by Signorini et al. [26]. These results may be due to the system evaluated where the composition of the diet is stable throughout the year, especially in feeds such as silages and products and by-products of the agroindustry (ingredients very susceptible to mycotoxigenic fungi), contrary to the information provided by Signorini et al. [26], where the establishments evaluated had a composition of diet that generally use more of these feeds in autumn-winter due to the deficit of pastures in that season. Seasonal variations in the occurrence and in the average levels of AFM1 were described in other similar studies where show an increasing trend in both AFM1 prevalence during the winter or in the dry season, when cattle are mostly fed with possibly contaminated feedstuffs and silages [27].

Levels of AFM1 in milk detected in this study were slightly lower than those observed in other studies carried out in our country. Previous studies conducted in the similar dairy area [28,29] reported average levels of 0.016 μg/l and Michlig et al. [30] reported levels of AFM1 of 0.037 μg/l in bulk milk. Other authors observed levels of AFM1 of 0.028 μg/l in studies conducted in dairy farms from Villa Maria (Argentina) [31]. This differences may be due to the analytical technique employed (rapid test vs. chromatography) being the last more sensitive, or differences in the productive systems (geographical location, quantity and type of ingredients in the diet).

None of the samples showed AFM1 levels above the safety limit determined by MERCOSUR, while 5.5% of samples exceeded the limit of the EU. A previous study conducted in Argentina’s central dairy region [30], reported that the 19.4% of the milk samples positive to AFM1 had concentrations above the maximum level established by the EU, but all milk samples were within the limit acceptable by MERCOSUR.

In Argentina, the National Plan for Residue Management and Food Safety (CREHA) monitors the AFM1 in raw milk. In 2016, 158 samples of raw milk in dairy industry were analyzed, of which 27 (17.1%) had AFM1 higher values than 0.025 μg/l, but lower than 0.5 μg/l [32]. CREHA Plan’s samples were taken directly from the dairy industry whereas that in the present work, samples individual cow's milk were analyzed, situation which could generate a dilution effect of aflatoxins in milk and, as a consequence present lower concentrations. All this shows that, regardless of geographical areas, methods of analysis and type of sample considered, levels of AFM1 in milk produced in Argentina are relatively low.

The incidence and levels of AFM1 in raw milk was also reported by others countries where the results of this study are comparable, showing high incidence at low levels [[33], [34], [35], [36], [37], [38], [39]].

The carry-over rate from AFB1 to AFM1 in milk in this study had a wide variation but with low average levels, and it was associated with the milk yield. Cows with a production higher than 28.5 l/day had a higher carry-over rate than those cows with lower production. These data coincide with studies reported in other countries. According to the European Food Safety Authority [40], in ruminants, the carry-over rate is between 1 and 3%. However, for high-producing dairy cows with up to 40 l/day of milk, this rate may reach 6%. Britzi et al. [41] suggested that milk production is the main factor affecting the carry-over rate, with an average carry-over rate of 2.5% for low production cows (<35 l/day) and 5.4% for high production cows (>35 l/day).

The AFB1 level in feeds consumed by dairy cows affected the carry-over rate. Concentrated feeds and ingredients of the TMR such as for example cottonseed and soybean expeller were components highly correlated with the level of aflatoxins in dairy milk [30]. The AFB1 proportion from these two ingredients was, on average, 56.9% of the total diet. For those reason, the conditions of harvest and storage feed should be carefully controlled in order to reduce the exposure of dairy cattle to aflatoxins and subsequently reduce their concentration in milk.

Other variable associated with the carry-over rate in this study was the particle size of the TMR. Rumen has some natural ability to detoxify mycotoxins although that capacity depends on the characteristics of the rumen (pH, time of feed permanence) [42].

When the proportion of material retained on the top screen of the SPSP is greater than 8%, there is an excess of effective fiber in the diet due to lack of homogeneity in the feed, which leads the cows to select smaller particles that pass quickly through the rumen, shortening the permanence time of the feed avoiding that bacteria from degrading mycotoxins [43].

The incorporation of less effective fiber affects the rumen balance due to pH fluctuations, which results in lower growth rates of some bacterial groups identified in the processing and detoxification of mycotoxins [44]. In this study, it was observed that those months in which the particle size was not ideal, cows made a greater selection of feed, preferably of short fiber, causing a shorter stay time of the feed in the rumen. The lower permanence of the feed in the rumen could explain the higher carry-over rate.

The presence of higher levels of AFM1 in cheese than milk, have been described by several research [[45], [46], [47], [48], [49]], supporting the findings in the present study. Different types of cheese produced with milk artificially contaminated with AFM1 have been reported to have concentrations 1.8–4.4 fold higher than in milk [50,48,51]. Parmesan and Mozzarella found AFM1 levels of 5.8 and 7.1 fold higher than in milk [52].

The affinity of AFM1 for the casein could be mentioned as a reason to increase the concentration of AFM1 in cheese, besides, this toxin is chemically a water-soluble component, therefore its high concentration in the cheeses may be due also to the affinity with the hydrophilic portion of the casein [53].

Several studies [7] have reported a wide range of AFM1 distribution between cheese and whey, which is fundamentally affected by the manufacturing process. In this study, levels of AFM1 in the whey and cheese samples were between 55.4% and 44.6% of the total amount of aflatoxin present in milk, respectively. This is in coincidence with Lopez [54], who evaluated the AFM1 distribution in fresh cheese produced in Argentina using milk artificially contaminated with AFM1 (at levels of 1.7–2.0 ng AFM1 /ml), finding values of 60% of the AFM1 in whey and 40% in cheese. Also, Battacone et al. [55] observed a similar distribution of AFM1 between whey and cheese during the elaboration of cheese using sheep milk. In cheese made in Minas (Brazil) using artificially contaminated milk (0.250 and 0.500 ng AFM1/ml), the AFM1 transfer from milk to cheese was 30.64% and 34.91%, respectively [56]. Fremy et al. [57] evaluated Camembert cheese produced with milk artificially contaminated with AFM1 (at levels as high as 0.3–7.5 ng AFM1/ml) and observed transfers of 35.6% and 57.7% of AFM1 to cheese, respectively.

Research carried out by Cavallarin et al. [49] following three Italian traditional cheese production methods, found that those cheeses in which the pH after syneresis was around 4.50, showed a lower AFM1 partitioning percentage to whey than those which had a pH of 6. In previous studies [58], it was found that the combined action of heat and low pH is able to denature whey proteins to a point where they lost the AFM1 binding capacity, showing a lower concentration of the mycotoxin in the whey. In the elaboration of Cremoso Argentino Miniature Cheese, the whey pH, after syneresis, was on average 6.6. Therefore, soluble proteins did not lose their affinity for AFM1, explaining the higher AFM1 partitioning percentage to whey.

Whey is an important by-product of the cheese-making industry [59]. Whey proteins have a number of useful nutritional and functional properties, which are used in a wide range of commercial products, as food additives [60]. These products may contribute to the intake of AFM1 and their effect on the consumers’ health should be evaluated.

From these data, it would be important to evaluate the human exposure to AFM1 through the consumption of milk in the diet and at the same time evaluate the potential risk through different scenarios of risk assessment [62].

5. Conclusions

Although animal diets contain significant levels of aflatoxins, the prevalence and the levels of AFM1 in milk produced and commercialized in Argentina are relatively low. However, factors such as characteristics of diet (appropriate particle size) affect the carry-over rate of AFM1. The implementation of good management practices are required to minimize this rate and ensure adequate cattle health.

Cheese has been shown to retain a significant portion of AFM1 contained in milk. The impact on public health derived from the consumption of soft cheese and other products made from whey should be examined.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Transparency document

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Binder E.M. Managing the risk of mycotoxins in modern feed production. Anim. Feed Sci. Technol. 2007;133:149–166. [Google Scholar]

- 2.Van Egmond H.P. Introduction. In: Van Egmond H.P., editor. Mycotoxins in Dairy Products. Elsevier; London: 1989. pp. 1–10. [Google Scholar]

- 3.Kensler T.W., Roebuck B.D., Wogan G.N., Groopman J.D. Aflatoxin: a 50-year odyssey of mechanistic and translational toxicology. Toxicol. Sci. 2010;120:28–48. doi: 10.1093/toxsci/kfq283. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Kuilman M.E.M., Maas R.F.M., Fink-Gremmels J. Cytochrome P450-mediated metabolism and cytotoxicity of aflatoxin B1 in bovine hepatocytes. Toxicol. Vitr. 2000;14:321–327. doi: 10.1016/s0887-2333(00)00025-4. [DOI] [PubMed] [Google Scholar]

- 5.Prandini A., Tansini G., Sigolo S., Filippi L., Laporta M., Piva G. On the occurrence of aflatoxin M1 in milk and dairy products. Food Chem. Toxicol. 2009;47:984–991. doi: 10.1016/j.fct.2007.10.005. [DOI] [PubMed] [Google Scholar]

- 6.IARC (International Agency for Research on Cancer) Vol. 62. IARC Press; Lyon, France: 2002. Aflatoxins; pp. 171–300. (IARC Monographs on the Evaluation of Carcinogenic Risks to Humans). [Google Scholar]

- 7.Galvano F., Galofaro V., Galvano G. Occurrence and stability of aflatoxin M1 in milk and milk products: a worldwide review. J. Food Prot. 1996;59:1076–1090. doi: 10.4315/0362-028X-59.10.1079. [DOI] [PubMed] [Google Scholar]

- 8.Pietry A., Bertuzzi T., Bertuzzi P., Piva G. Aflatoxin M1 occurrence in samples of Grana Padano Cheese. Food Addit. Contam. 1997;14:341–344. doi: 10.1080/02652039709374536. [DOI] [PubMed] [Google Scholar]

- 9.INTA (Instituto Nacional de Tecnología Agropeciaria) 1995. Técnicas de muestreo y parámetros de calidad de los recursos forrajeros, Publicación Técnica N°56.http://rafaela.inta.gov.ar/info/pubtecnicas/inta_rafaela_publicacion_tecnica_056.pdf Available at. [Google Scholar]

- 10.Heinrichs J., Kononoff P. Departmento de Ciencias Animales y Lecheras de la Universidad Estatal de Pennsylvania, Extensión Cooperativa, DAS 02-42; 2002. Evaluando el tamaño de partícula de forrajes y TMR usando el Nuevo Separador de Partículas de Forraje de Penn State; p. 3. [Google Scholar]

- 11.IRAM (Instituto Argentino de Normalización y Certificación) 2006. Milk. Determination of Titratable Acidity, Part 1: Alkalimetric Titration without Sample Dilution.http://web.iram.org.ar Available at. [Google Scholar]

- 12.Foss Electric . Foss Electric; Hillerød, Denmark: 2001. Count Bacteria on Bactoscan FC Technical Specifications, P/N 1025136, Issue 4GB, October. [Google Scholar]

- 13.IDF (International Dairy Federation) 1995. Enumeration of Somatic Cells, FIL-IDF Standard No 148A. Brussels, Belgium. [Google Scholar]

- 14.Costabel L., Audero G.M.L., Cuatrin A., Costamagna D. XVI Congreso de Ciencia y Tecnología de los Alimentos. Mar del Plata, Buenos Aires; 2017. Desarrollo de un protocolo para la elaboración de quesos blandos miniatura. ISBN 978-987-22165-8-0. [Google Scholar]

- 15.IDF (International Dairy Federation) 1993. Milk. Determinations of Nitrogen Content, Nº 20: B. Brussels, Belgium. [Google Scholar]

- 16.IDF (International Dairy Federation) 1997. Milk and Milk Products, Determination of Fat Content (general Guidance on the Use of Butyrometric Methods), Nº 152: a. Brussels, Belgium. [Google Scholar]

- 17.IDF (International Dairy Federation) 1982. Cheese and Processed Cheese, Determination of the Total Solids Content, Nº 4: a. Brussels, Belgium. [Google Scholar]

- 18.Bradley R.L., Arnold E., Barbano D.M., Semerad R.G., Smith D.E., Vines B.K. Chemical and physical methods. In: Marshall R., editor. Standard Methods for the Examination of Dairy Products. American Public Health Association; Washington, DC: 1993. pp. 433–531. [Google Scholar]

- 19.Di Rienzo F., Casanoves M.G., Balzarini L., Gonzalez M., Tablada C.W. FCA. Cordoba National University; Argentina: 2012. InfoStat version InfoStat group. (available at http://www.infostat.com.ar) [Google Scholar]

- 20.European Community . 2002. Directive 2002/32/EC of the European Parliament and of the Council of 7 May 2002 on Undesirable Substances in Animal Feed. [Google Scholar]

- 21.MERCOSUR (Mercado Común del Sur) 2002. Reglamento técnico MERCOSUR sobre límites máximos de aflatoxinas admisibles en leche, maní y maíz, GMC/RES. N° 25/02. [Google Scholar]

- 22.European Community . 2006. Commission Regulation N° 1881/2006 of 19 December 2006, Setting Maximum Levels for Certain Contaminants in Foodstuffs. [Google Scholar]

- 23.Kononoff P. Nebraska University, UNL Extension publications; 2005. Understanding Effective Fiber in Rations for Dairy Cattle, Dairy Feeding and Nutrition; p. G 1587. [Google Scholar]

- 24.European Parliament Regulation (EC) N° 853/2004 of the european parliament and of the council of 29 April 2004. Off. J. Eur. Union. 2004;L 139/55:1–155. [Google Scholar]

- 25.SAGPA (Secretaría de Agricultura, Ganadería y Pesca) 2016. Sistema de Pago de la Leche Cruda, Resolución 229 - E/16.http://www.loa.org.ar/legNormaDetalle.aspx?id=28888 available at. [Google Scholar]

- 26.Signorini M.L., Gaggiotti M., Molineri A., Chiericatti C.A., Zapata de Basílico M.L., Basílico J.C. Exposure assessment of mycotoxins in cow’s milk in Argentina. Food Chem. Toxicol. 2012;50:250–257. doi: 10.1016/j.fct.2011.09.036. [DOI] [PubMed] [Google Scholar]

- 27.Peña-Rodas O., Martinez-Lopez R., Hernandez-Rauda R. Occurrence of Aflatoxin M1 in cow milk in El Salvador: results from a two year survey. Toxicol. Rep. 2018;5:671–678. doi: 10.1016/j.toxrep.2018.06.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.López C., Ramos L., Ramadan S., Rodriguez F., Bulacio L. Estudio de Aflatoxina M1 en leches argentinas. Limit of AFB1 in feed for animals of 10 mg/ml Proceedings of The XIV Congreso Latinoamericano de Microbiología. 1998:73. [Google Scholar]

- 29.López C.E., Ramos L.L., Ramadan S.S., Bulacio L.C. Presence of aflatoxin M1 in milk for human consumption in Argentina. Food Control. 2003;14:31–34. [Google Scholar]

- 30.Michlig N., Signorini M., Gaggiotti M., Chiericatti C., Basílico J.C., Repetti M.R., Beldomenico H.R. Risk factors associated with the presence of aflatoxin M1 in raw bulk milk from Argentina. Food Control. 2016;64:151–156. [Google Scholar]

- 31.Alonso V.A., Monge M.P., Larriestra A., Dalcero A.M., Cavaglieri L.R., Chiacchiera S.M. Naturally occurring aflatoxin M1 in raw bulk milk from farm cooling tanks in Argentina. Food Addit. Contam. Part A. 2010;27:373–379. doi: 10.1080/19440040903403362. [DOI] [PubMed] [Google Scholar]

- 32.CREHA (Residue and Food Hygiene National Control Plan) 2016. Resumen de resultados.http://www.senasa.gob.ar/sites/default/files/arbol_senasa/animal/abejas/prod_primaria/plan_creha/ctrol_res/resumen_resultados_plan_creha_2016.pdf available at. [Google Scholar]

- 33.Diaz G.J., Espitia E. Ocurrence of M1 in retail milk samples from Bogota, Colombia. Food Addit. Contam. 2006;23(8):811–815. doi: 10.1080/02652030600681617. [DOI] [PubMed] [Google Scholar]

- 34.Galvano F., Galofaro V., Ritieni A., Bognanno M., De Angelis A., Galvano G. Survey of the ocurrence of aflatoxin M1 in dairy products marketed in Italy: second year of observation. Food Addit. Contam. 2001;18(7):644–646. doi: 10.1080/02652030118086. [DOI] [PubMed] [Google Scholar]

- 35.Gurbay A., Aydin S., Girgin G., Engin A.B., Sahin G. Assessment of aflatoxin M1 levels in milk in Ankara, Turkey. Food Control. 2006;17(1):1–4. [Google Scholar]

- 36.Kim E.K., Shon D.H., Ryu D., Park J.W., Hwang H.J., Kim Y.B. Ocurrence of aflatoxin M1 in Korean dairy products determined by ELISA and HPLC. Food Addit. Contam. 2000;17(1):59–64. doi: 10.1080/026520300283595. [DOI] [PubMed] [Google Scholar]

- 37.Oveisi M.R., Jannat B., Sadeghi N., Hajimahmoodi M., Nikzad A. Presence of aflatoxin M1 in milk and infant milk products in Tehran, Iran. Food Control. 2007;18(10):1216–1218. [Google Scholar]

- 38.Zinedine A., Gonzalez-Osnaya L., Soriano J.M., Molto J.C., Idrissi L., Manes J. Presence of aflatoxin M1 in pasteurized milk from Morocco. Int. J. Food Microbiol. 2007;114(1):25–29. doi: 10.1016/j.ijfoodmicro.2006.11.001. [DOI] [PubMed] [Google Scholar]

- 39.Jawaid S., Talpur F.N., Nizamani S.M., Afridi H.I. Contamination profile of aflatoxin M1 residues in milk supply chain of Sindh, Pakistan. Toxicol. Rep. 2015;2:1418–1422. doi: 10.1016/j.toxrep.2015.10.011. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.EFSA (European Food Safety Authority) Opinion of the scientific panel on contaminants in the food chain on a request from the commission related to aflatoxin B1 as undesirable substance in animal feed. EFSA J. 2004;39:1–27. [Google Scholar]

- 41.Britzi M., Friedman S., Miron J., Solomon R., Cuneah O., Shimshoni J.A. Carry-over of Aflatoxin B1 to Aflatoxin M1 in high yielding Israeli cows in mid- and late-lactation. Toxins. 2013;5:173–183. doi: 10.3390/toxins5010173. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Diaz D.E., Hagler J.W.M., Blackwelder J.T., Eve J.A., Hopkins B.A., Anderson K.L., Jones F.T., Whitlow L.W. Aflatoxin binders II: reduction of aflatoxin M1 in milk by sequestering agents of cows consuming aflatoxin in feed. Mycopathologia. 2004;157:233–241. doi: 10.1023/b:myco.0000020587.93872.59. [DOI] [PubMed] [Google Scholar]

- 43.Moschini M., Masoero F., Diaz D.E., Gallo A., Pietri A., Piva G. Plasma aflatoxin concentrations over time in bolus fed lactating dairy cows. J. Anim. Sci. 2006;84(1):74. [Google Scholar]

- 44.Jouany J.P., Diaz D.E. Effects of mycotoxins in ruminants. In: Diaz D.E., editor. The Mycotoxin Blue Book. Nottingham University Press; Nottingham: 2005. pp. 295–321. [Google Scholar]

- 45.Bakirci I. A study on the occurrence of aflatoxin M1 in milk and milk products produced in Van province of Turkey. Food Control. 2001;12(1):47–51. [Google Scholar]

- 46.Elgerbi A.M., Aidoo K.E., Candlish A.A.G., Tester R.F. Occurrence of aflatoxin M1 in randomly selected North African milk and cheese samples. Food Addit. Contam. 2004;21:592–597. doi: 10.1080/02652030410001687690. [DOI] [PubMed] [Google Scholar]

- 47.Manetta A.C., Giammarco M., Di Giuseppe L., Fusaro I., Gramenzi A., Formigoni A. Distribution of aflatoxin M1 during Grana Padano cheese production from naturally contaminated milk. Food Chem. 2009;113:595–599. [Google Scholar]

- 48.Oruc H.H., Cibik R., Yilmaz E., Kalkanli O. Distribution and stability of Aflatoxin M1 during processing and ripening of traditional white pickled cheese. Food Addit. Contam. 2006;23:190–195. doi: 10.1080/02652030500389048. [DOI] [PubMed] [Google Scholar]

- 49.Cavallarin L., Antoniazzi S., Giaccone D., Tabacco E., Borreani G. Transfer of aflatoxin M1 from milk to ripened cheese in three Italian traditional production methods. Food Control. 2014;38:174–177. [Google Scholar]

- 50.Govaris A., Roussi V., Koidis P.A., Botsoglou N.A. Distribution and stability of aflatoxin M1 during processing, ripening and storage of Telemes cheese. Food Addit. Contam. 2001;18:437–443. doi: 10.1080/02652030120550. [DOI] [PubMed] [Google Scholar]

- 51.Kamkar A., Karim G., Aliabadi F.S., Khaksar R. Fate of aflatoxin M1 in Iranian white cheese processing. Food Chem. Toxicol. 2008;46(6):2236–2238. doi: 10.1016/j.fct.2008.02.028. [DOI] [PubMed] [Google Scholar]

- 52.Brackett R.E., Marth E.H. Association of aflatoxin M1 with casein. Zeitschrift fur Lebensmittel-Untersuchung und Forschung. 1982;174:439–441. doi: 10.1007/BF01042721. [DOI] [PubMed] [Google Scholar]

- 53.Dosako S., Kaminogawa S., Taneya S., Yamauchi K. Hydrophobic surface areas and net charges of αs1-, κ-casein and αs1-casein: κ-casein complex. J. Dairy Res. 1980;47(1):123–129. [Google Scholar]

- 54.López C.E., Ramos L.L., Ramadan S.S., Bulacio L.C., Perez J. Distribution of aflatoxin M1 in cheese obtained from milk artificially contaminated. Int. J. Food Microbiol. 2001;64:211–215. doi: 10.1016/s0168-1605(00)00444-x. [DOI] [PubMed] [Google Scholar]

- 55.Battacone G., Nudda A., Palomba M., Pascale M., Nicolussi P., Pulina G. Transfer of aflatoxin B1 from feed to milk and from milk to curd and whey in dairy sheep fed artificially contaminated concentrates. J. Dairy Sci. 2005;88:3063–3069. doi: 10.3168/jds.S0022-0302(05)72987-8. [DOI] [PubMed] [Google Scholar]

- 56.Fernandes A.M., Corrêa B., Rosim R.E., Kobashigawa E., Oliveira C.A.F. Distribution and stability of aflatoxin M1 during processing and storage of Minas Frescal cheese. Food Control. 2012;24:104–108. [Google Scholar]

- 57.Fremy J.M., Roiland J.C., Gaymard A. Behavior of 14C aflatoxin M1 during Camembert cheese making. J. Environ. Pathol. Toxicol. Oncol. 1990;10:95–98. [PubMed] [Google Scholar]

- 58.Barbiroli A., Bonomi F., Benedetti F., Mannino S., Monti L., Cattaneo T., Iametti S. Binding of aflatoxin M1 to different protein fractions in ovine and caprine mil. J. Dairy Sci. 2007;90:532–540. doi: 10.3168/jds.S0022-0302(07)71536-9. [DOI] [PubMed] [Google Scholar]

- 59.Terán J.C., Paez R., Pirola M.B., Schmidt E. 2014. Características generales sobre el uso del suero de queso en la Provincia de Santa Fe.http://www.ecosuero.com.ar/userfiles/image/2267Publicacion%20_%20Gestion%20del%20Suero%20-%20INTA%20-%20INTI.pdf available at. [Google Scholar]

- 60.Silva H.E., Verdalet G.I. Alimentos e ingredientes funcionales. Archivos Latinoamericanos de Nutrición. 2003;53(4):333–347. [PubMed] [Google Scholar]

- 62.Tsakiris I.N., Tzatzarakis M.N., Alegakis A.K., Vlachou M.I., Renieri E.A., Tsatsakis A.M. Risk assessment scenarios of children’s exposure to aflatoxin M1 residues indifferent milk types from the Greek market. Int. J. Food Microbiol. 2013;56:261–265. doi: 10.1016/j.fct.2013.02.024. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.